Polylactic acid-polyethylene glycol coated florfenicol nanofiber and preparation method thereof

A polyethylene glycol and florfenicol-coated technology, which is applied to medical preparations with no active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, can solve the problems of rapid release and poor water solubility, and achieve fiber-shaped Good appearance, solution to drug burst release, simple and quick preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

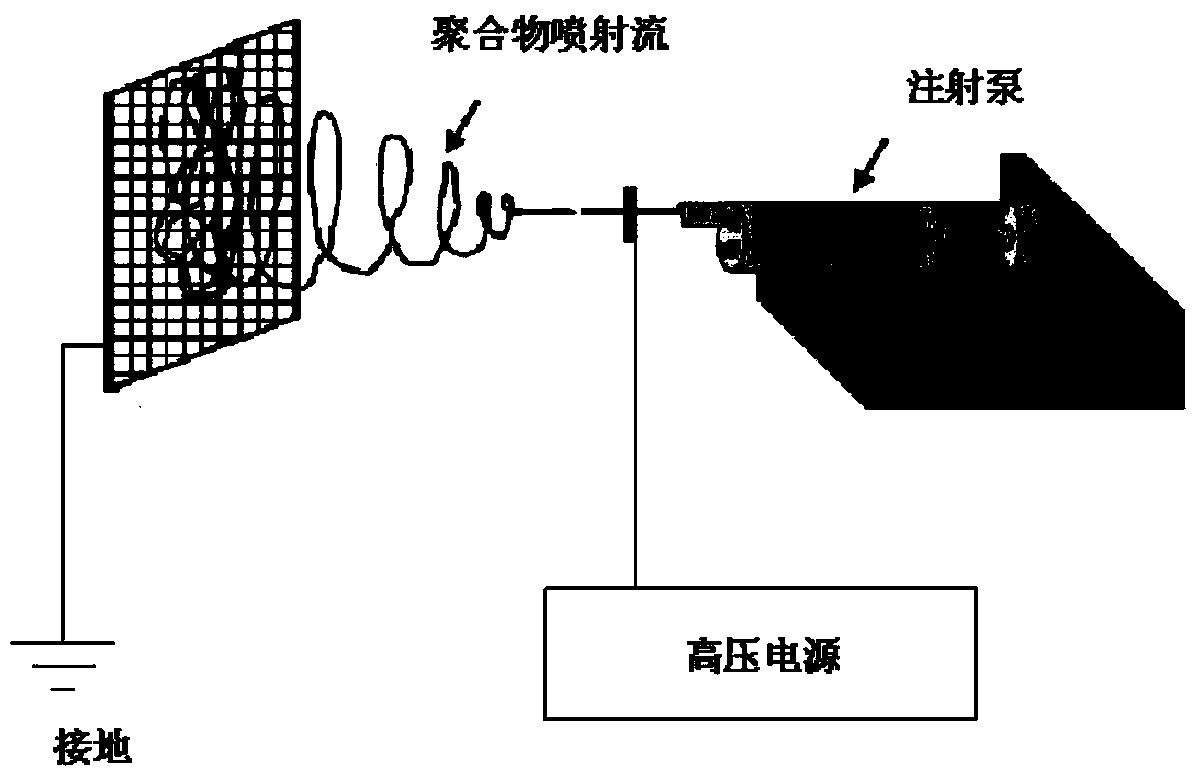

Method used

Image

Examples

Embodiment 1

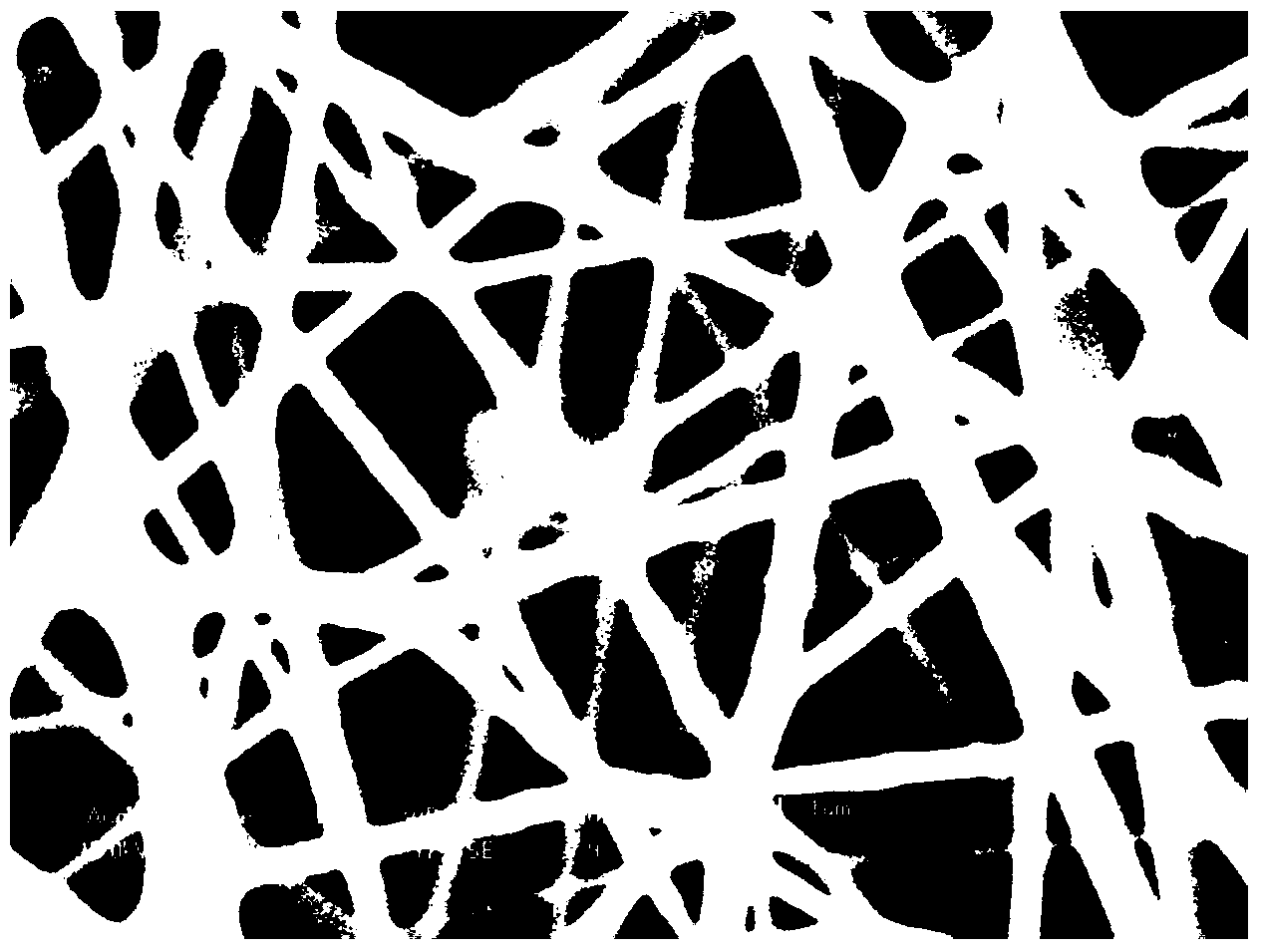

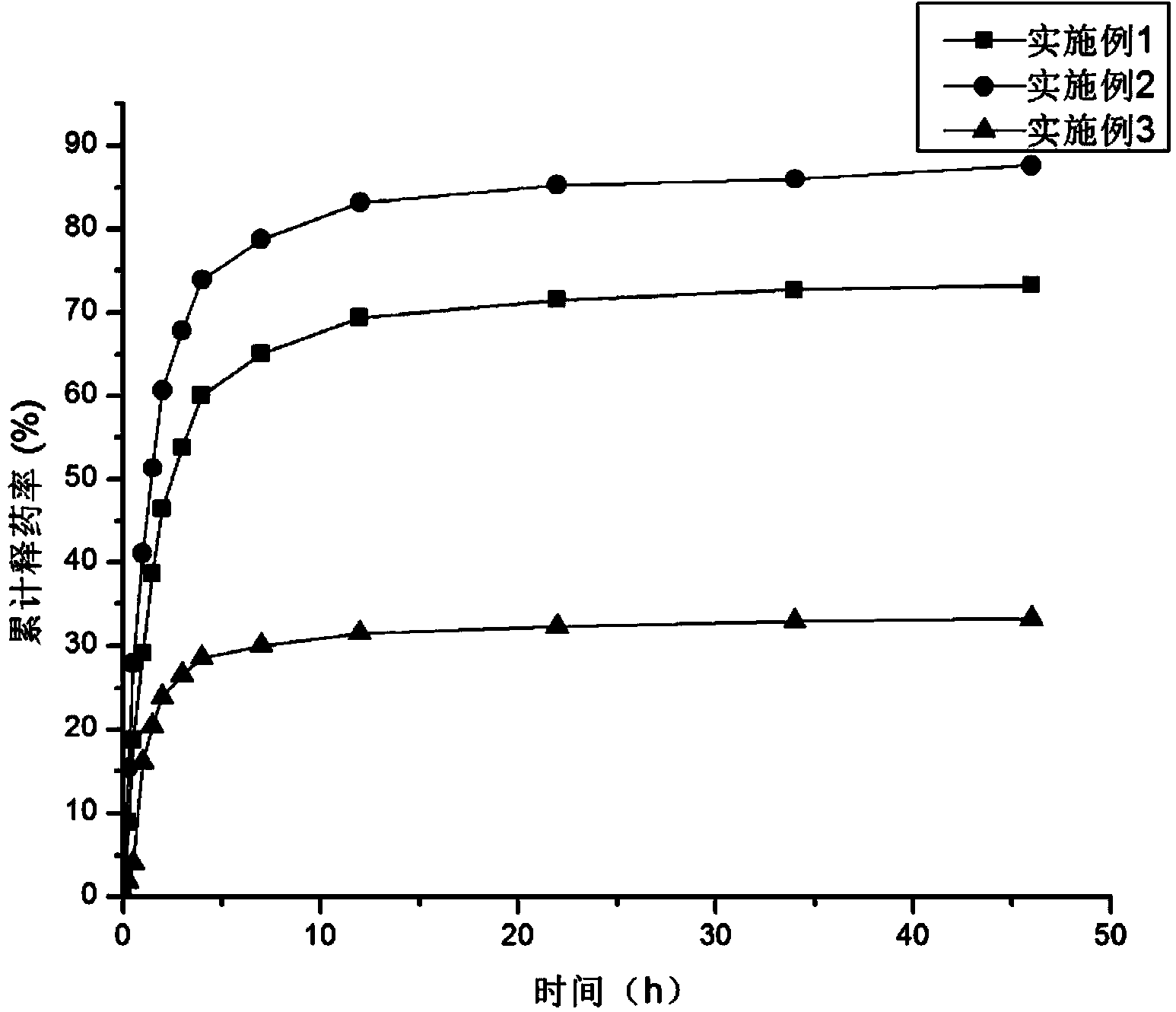

[0027] Take 0.653g of block copolymer with a molecular weight of 60000-20000-60000 and 0.085g of florfenicol, and dissolve it in 7.46g of dimethylformamide (DMF) and chloroform (CHCl) under magnetic stirring at a temperature of 40°C. 3 ) (volume ratio 1 / 2) mixed with an organic solvent to obtain a spinning solution. Then, the prepared spinning solution was subjected to electrospinning, the control voltage was 18kv, the flow rate was 2mL / h, and the distance from the receiving table to the spinneret was 12-20cm. Obtained nanofiber film product observes its morphology under SEM as figure 2 As shown, it has a network structure, and the fiber diameter is 230-390nm. The sustained release experiment in vitro shows that the cumulative drug release rate within 46 hours is 73.26%.

Embodiment 2

[0029] Take 0.796g of block copolymer with a molecular weight of 60000-20000-60000 and 0.082g of Florfenicol, and dissolve them in 7.695g of DMF and CHCl with magnetic stirring at a temperature of 40°C 3 (volume ratio 1 / 2) mixed with an organic solvent to obtain a spinning solution. Then, the prepared spinning solution was subjected to electrospinning, the control voltage was 18kv, the flow rate was 2mL / h, and the distance from the receiving table to the spinneret was 12-20cm. The obtained nanofiber film product is observed under SEM to have a network structure, and the fiber diameter is 210-400nm. In vitro sustained release experiments show that the cumulative drug release rate within 46 hours is 87.597%.

Embodiment 3

[0031] Take 0.822g of block copolymer with a molecular weight of 60000-20000-60000 and 0.088g of Florfenicol, and dissolve them in 7.688g of DMF and CHCl with magnetic stirring at a temperature of 40°C 3 (volume ratio 1 / 2) mixed with an organic solvent to obtain a spinning solution. Then, the prepared spinning solution was subjected to electrospinning, the control voltage was 18kv, the flow rate was 2mL / h, and the distance from the receiving table to the spinneret was 12-20cm. The obtained nanofiber film product has a network structure under SEM observation, and the fiber diameter is 680-1470nm. The sustained release experiment in vitro shows that the cumulative drug release rate within 46 hours is 33.235%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com