Patents

Literature

37results about How to "Good fiber shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biocompatible nano-conductive fiber and preparation method thereof

InactiveCN101805938AReasonable formReasonable morphology is better, the distribution of carbon nanotubes in the fiberElectroconductive/antistatic filament manufactureFilament/thread formingCarbon nanotubeBiocompatibility Testing

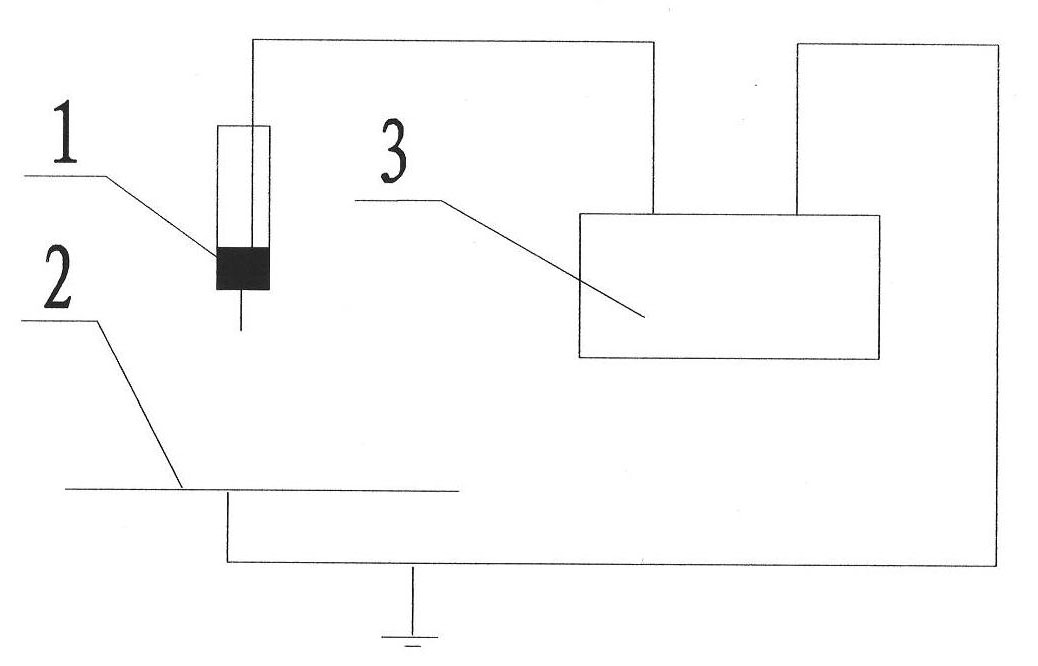

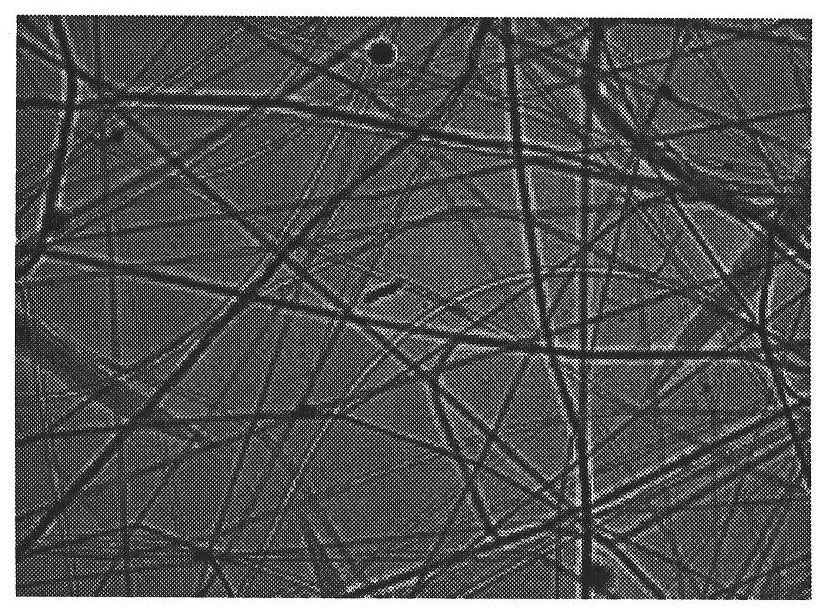

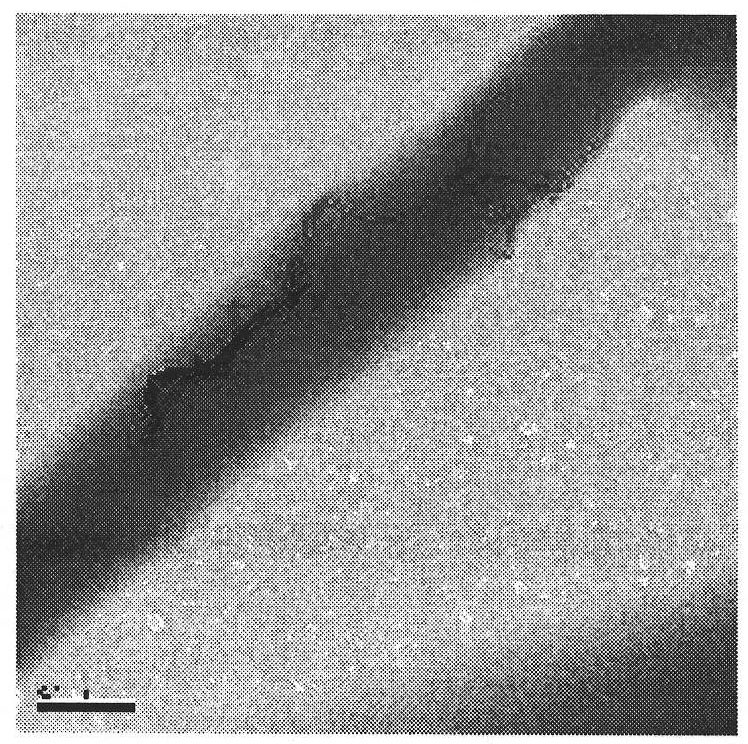

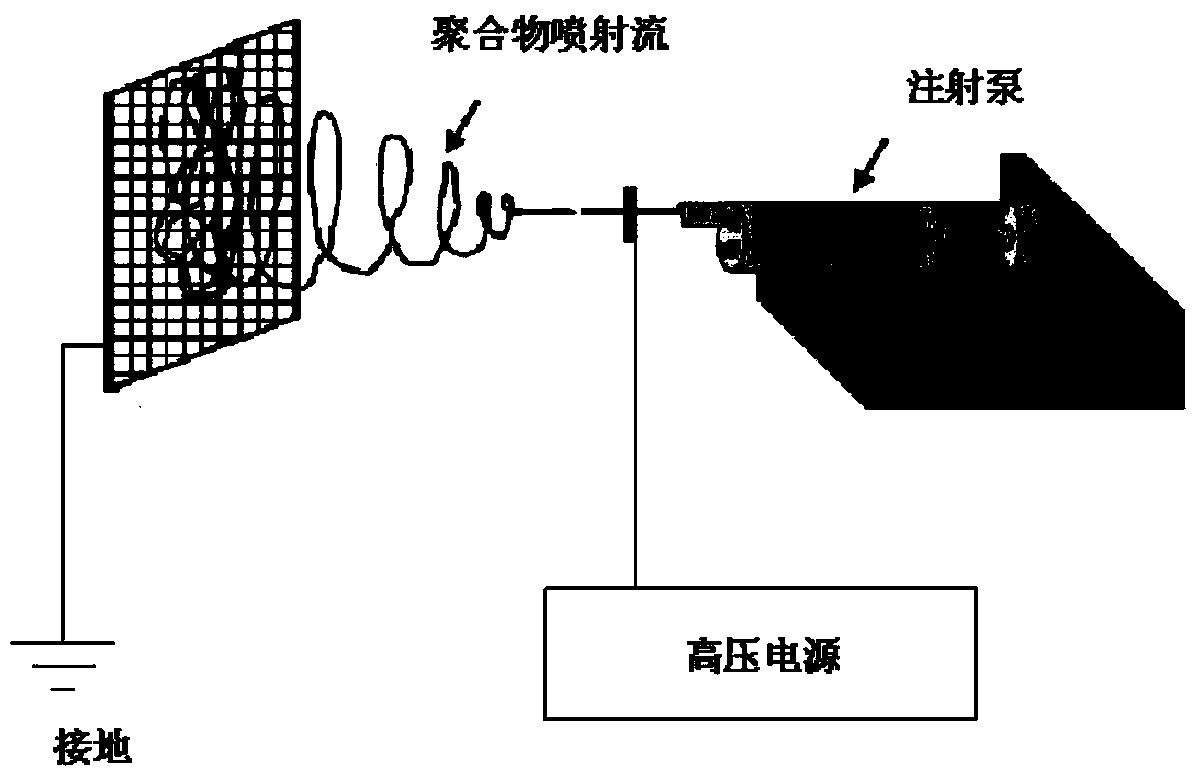

The invention discloses a biocompatible nano-conductive fiber and a preparation method thereof. The biocompatible nano-conductive fiber comprises the following three components in part by mass: 100 parts of polylactic acid, 5 to 10 parts of carbon nano tubes and 1 part of sodium dodecyl sulfate. The three components are prepared into spinning solution by utilizing compound solvents, i.e. chloroform and dimethyl sulfoxide, and an electrostatic spinning device is used to spray to prepare the biocompatible nano-conductive fiber, wherein the fiber diameter is between 200 and 500nm; the carbon nano tubes are coated uniformly with the polylactic acid and are orderly arrayed in the fiber; the surfaces of the carbon nano tubes are subjected to hydroxylation; the mass percentage of hydroxy is 3.06 weight percent; the diameter of the carbon nano tubes is between 10 and 20nm; the length of the carbon nano tubes is 30mum; the purity of the carbon nano tubes is over 95 weight percent; and the specific surface area of the carbon nano tubes is over 200m<2> / g. The invention has advanced and simple process and reasonable formula. The prepared nano-conductive fiber has good biocompatibility and has wide application prospect.

Owner:YANGZHOU UNIV

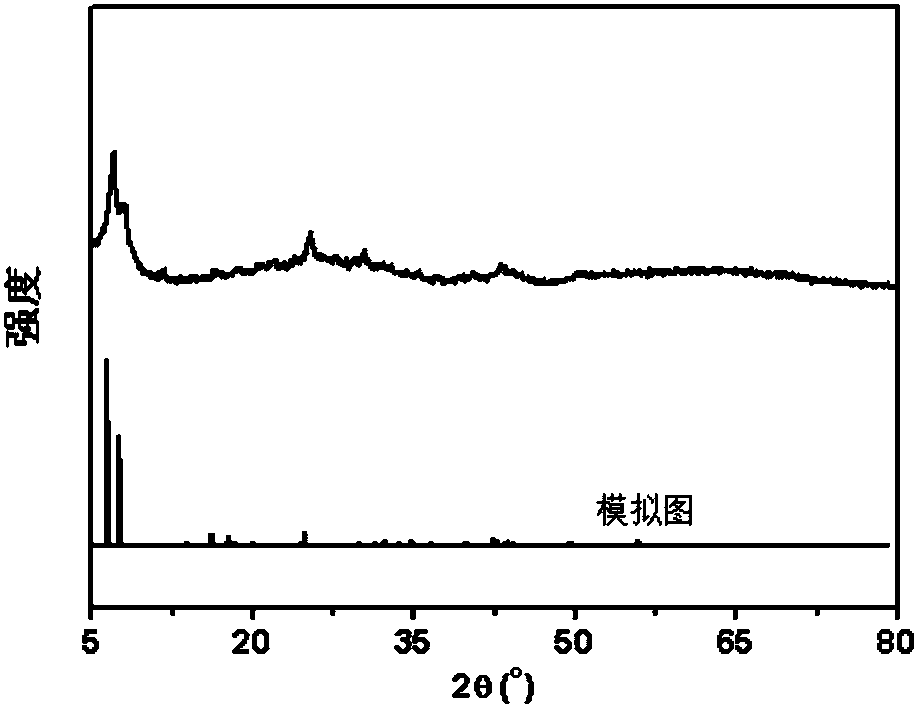

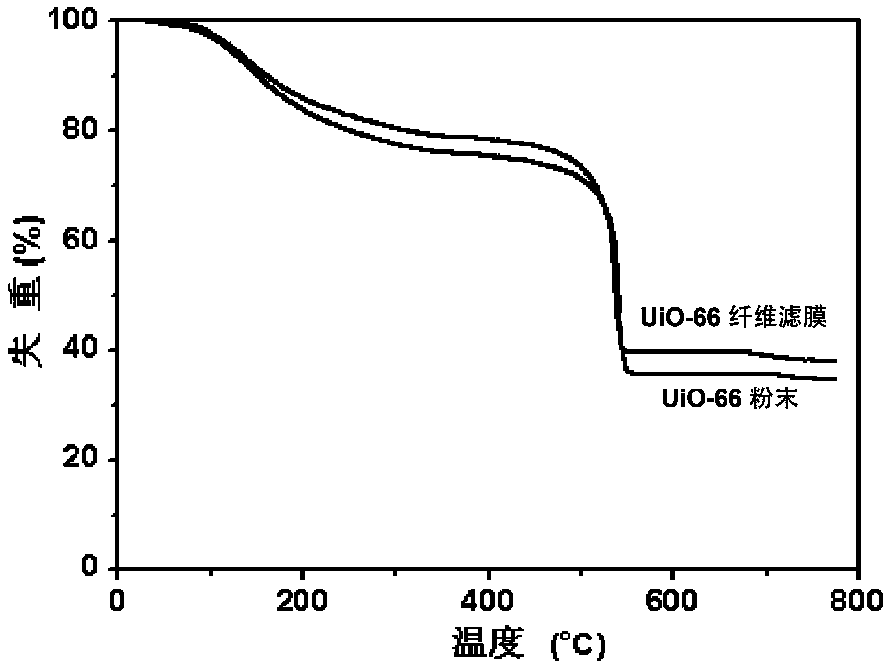

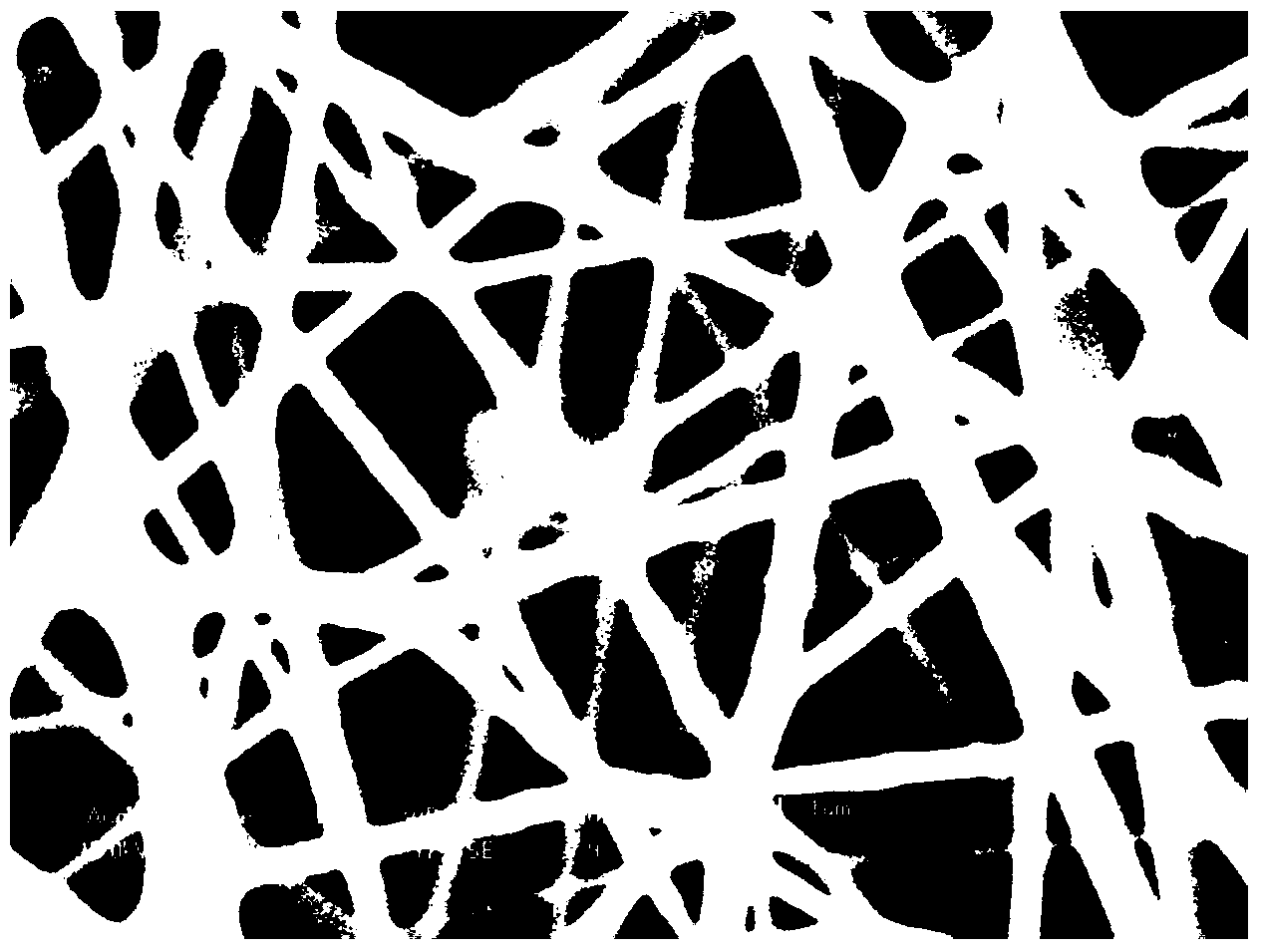

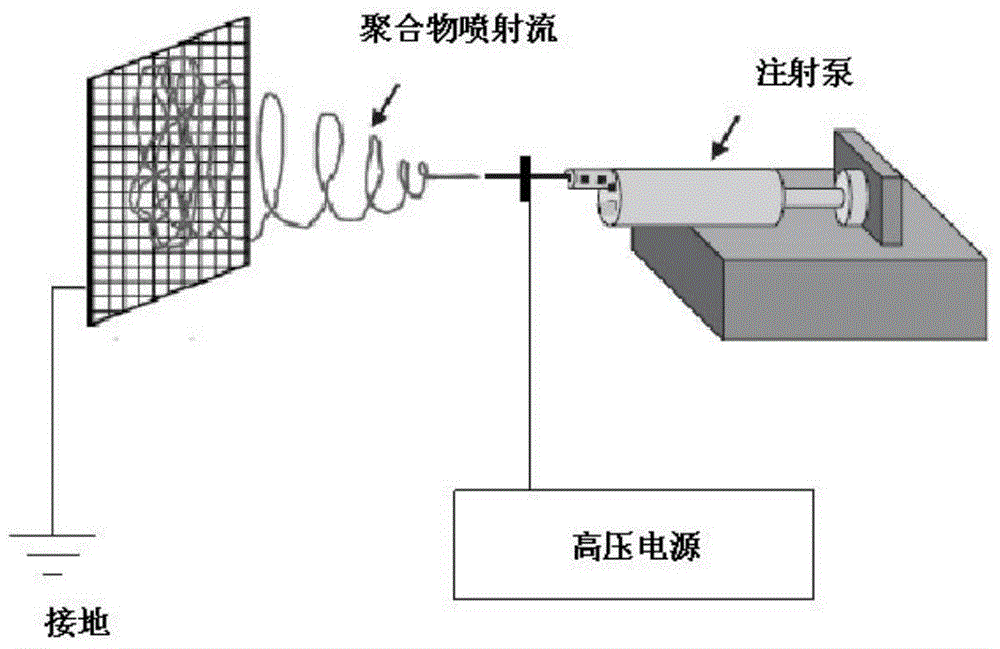

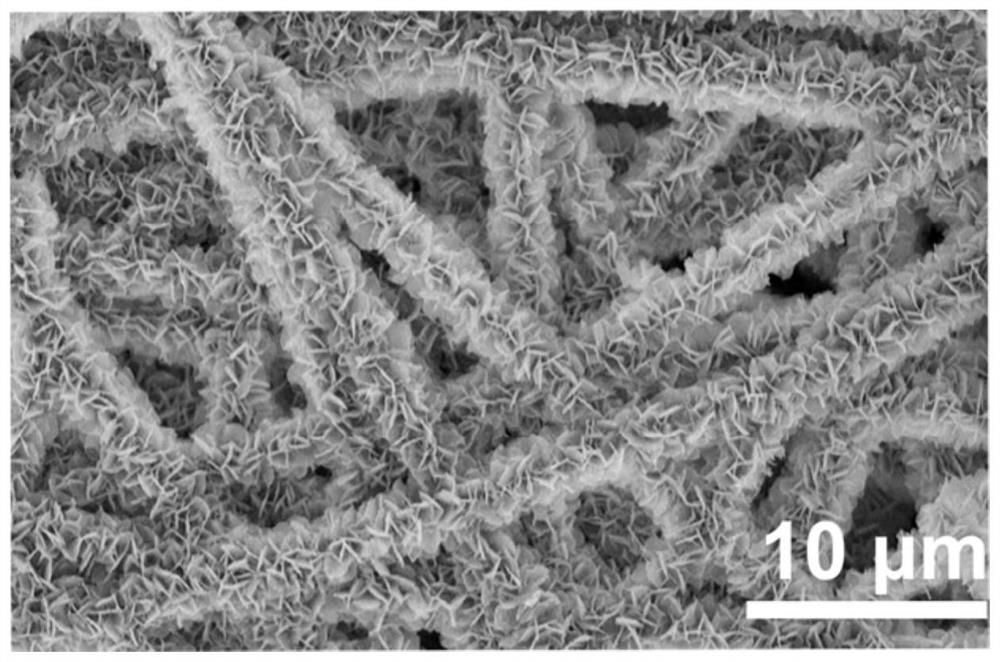

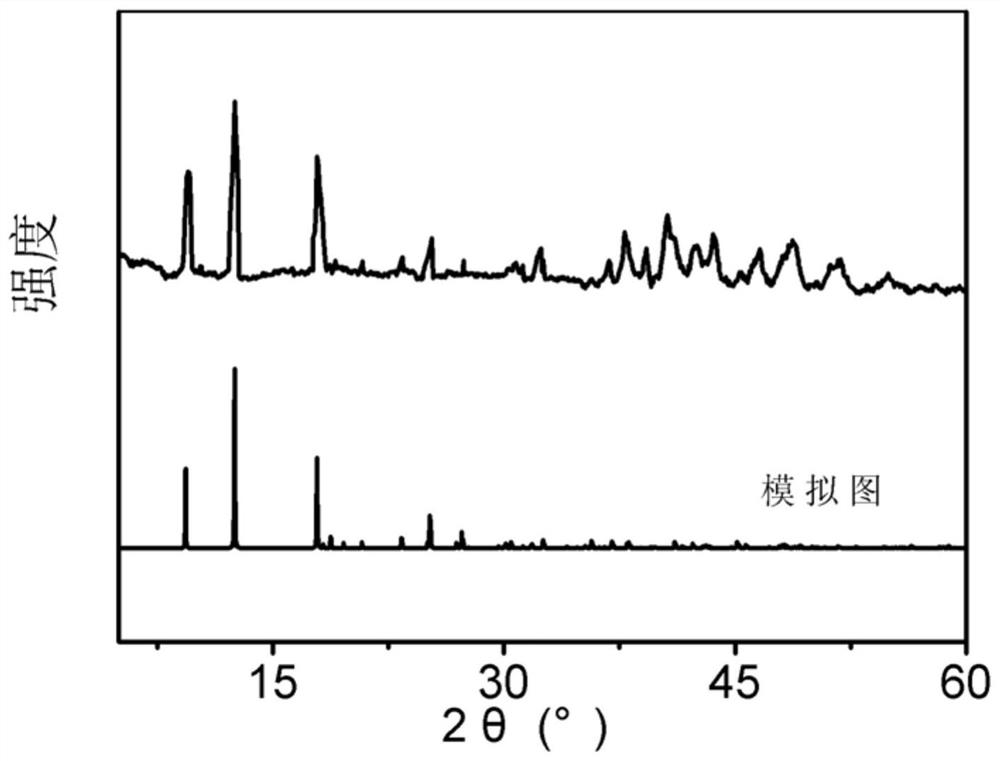

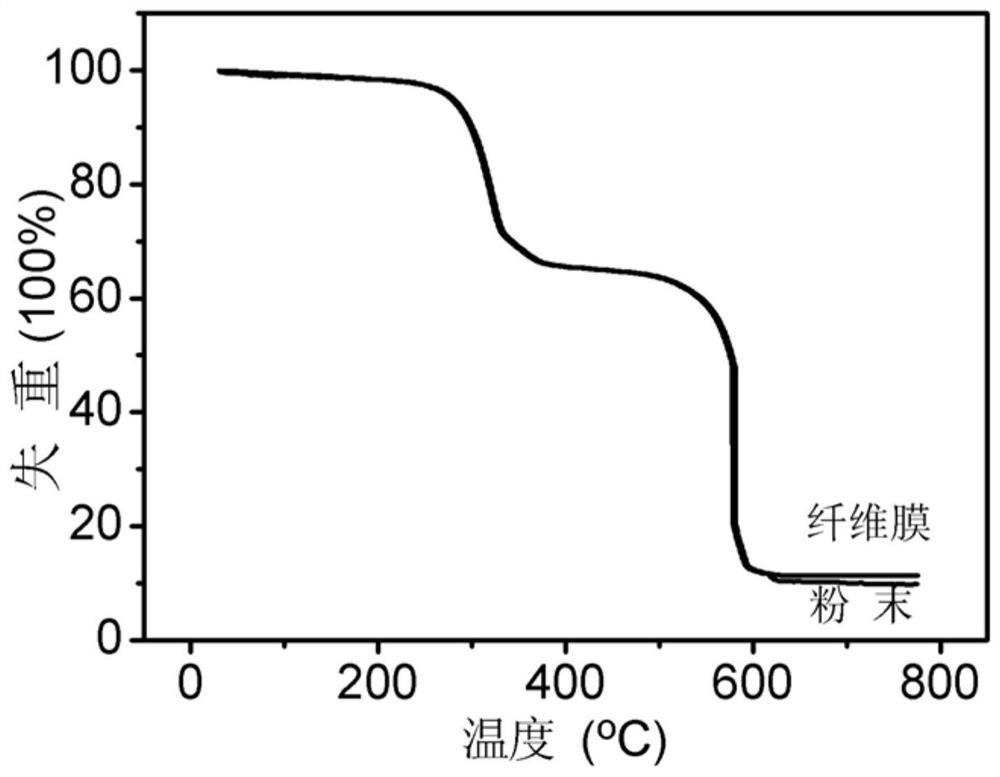

Chemical warfare agent self-disinfection MOF (metal organic framework) fiber filtering membrane and preparation method thereof

PendingCN108310982ALarge specific surface areaImprove adsorption capacitySemi-permeable membranesFiberHalf-life

The invention provides a chemical warfare agent self-disinfection MOF (metal organic framework) fiber filtering membrane and a preparation method thereof. The preparation method comprises the following steps of performing electrostatic spinning calcining to prepare a zirconium oxide fiber film; mixing with a corresponding organic ligand and an activated acid solution, and performing hydrothermal reaction, so as to obtain the self-disinfection MOF fiber filtering membrane. The prepared self-disinfection MOF fiber filtering membrane has the advantages that the additional support material is notneeded, the self ultra-large specific surface area of MOFs is maintained, and the adsorption capacity and catalytic property are excellent; by adopting the micro-nano multi-stage structure, the reaction matter is favorably transmitted, the catalytic sites are exposed, and the agglomeration of the catalyst is avoided; the excellent self-disinfection property is realized; the degrading conversion rate of a simulating matter of a chemical warfare agent is high, the half-life period is short, and the stability in cyclic use is good; by adopting the thin film form, the self-disinfection MOF fiber filtering membrane can be directly applied into the actual filtering protection device.

Owner:SHANDONG UNIV

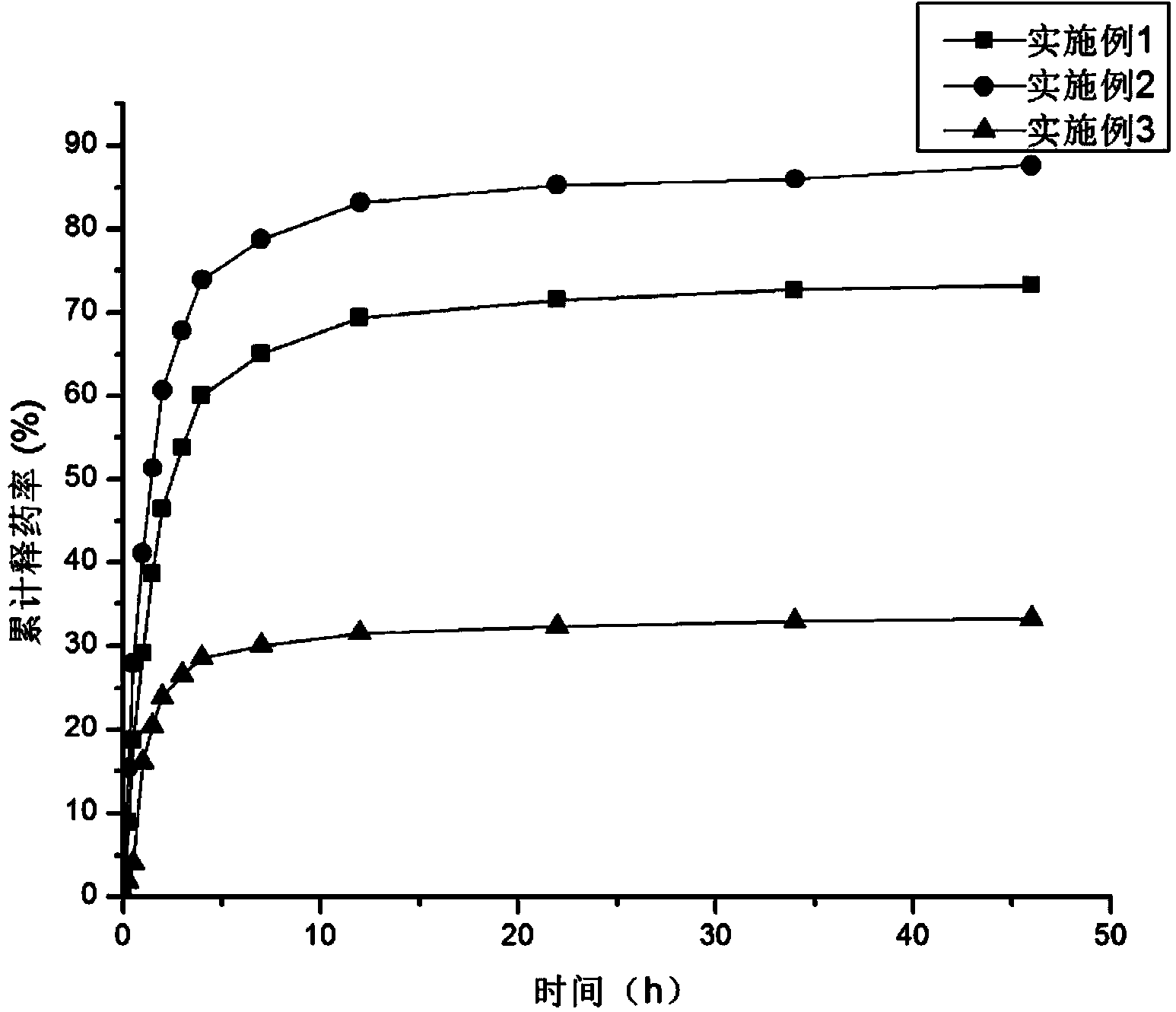

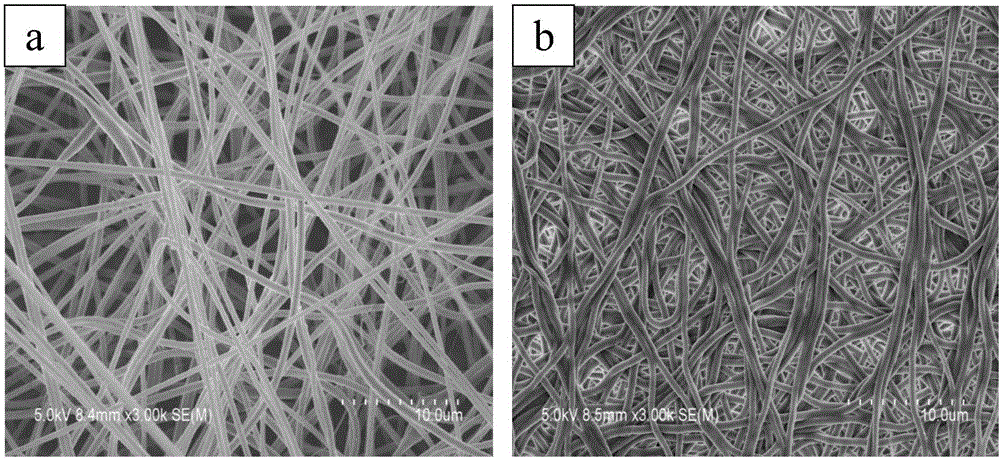

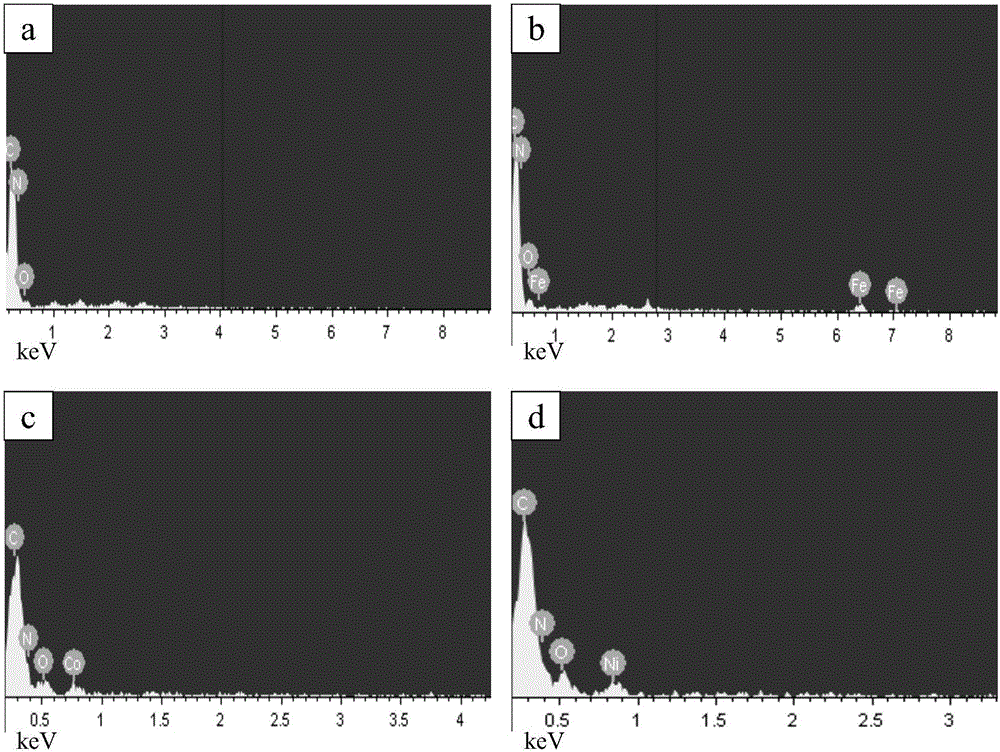

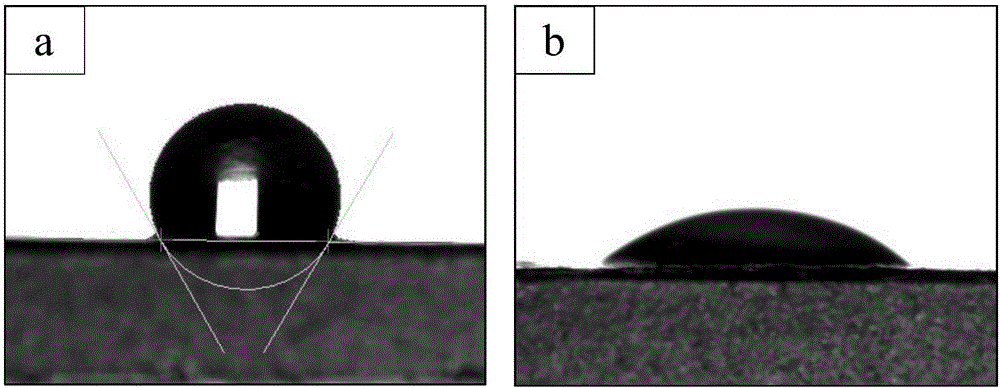

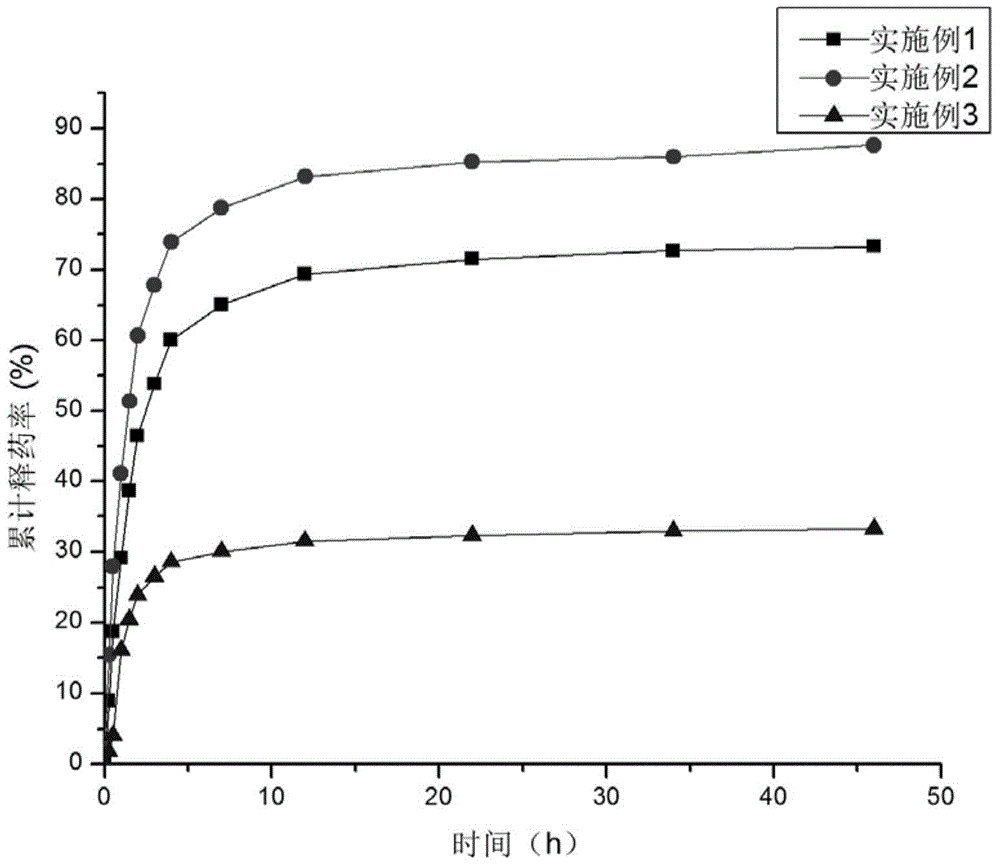

Polylactic acid-polyethylene glycol coated florfenicol nanofiber and preparation method thereof

InactiveCN103705932APromote degradationGood biocompatibilityAntibacterial agentsOrganic active ingredientsSolubilityPolyethylene glycol

The invention relates to polylactic acid-polyethylene glycol coated florfenicol nanofiber and a preparation method thereof, belonging to the technical fields of veterinary drugs and preparation thereof. The polylactic acid-polyethylene glycol is segmented copolymer D, L-polylactic acid-polyethylene glycol-D, L-polylactic acid; and florfenicol is filled in a reticular structure of polylactic acid-polyethylene glycol, and mass ratio of the florfenicol to the polylactic acid-polyethylene glycol is 1: (3.5-10). The preparation method comprises the steps of adding the polylactic acid-polyethylene glycol and the florfenicol into an organic solvent, stirring and dissolving to obtain a spinning solution; and then carrying out electrostatic spinning to obtain a polylactic acid-polyethylene glycol coated florfenicol nanofiber membrane. The preparation method provided by the invention realizes drug loading while carrying out electrostatic spinning on the polylactic acid-polyethylene glycol, and solves the problems such as sudden release of drugs, short action time and poor water solubility; and the adopted raw materials cannot cause the problem of environmental protection after degradation, the cost is low, the preparation process is simple and quick, and the polylactic acid-polyethylene glycol coated florfenicol nanofiber and the preparation method are applicable to mass production.

Owner:JILIN UNIV

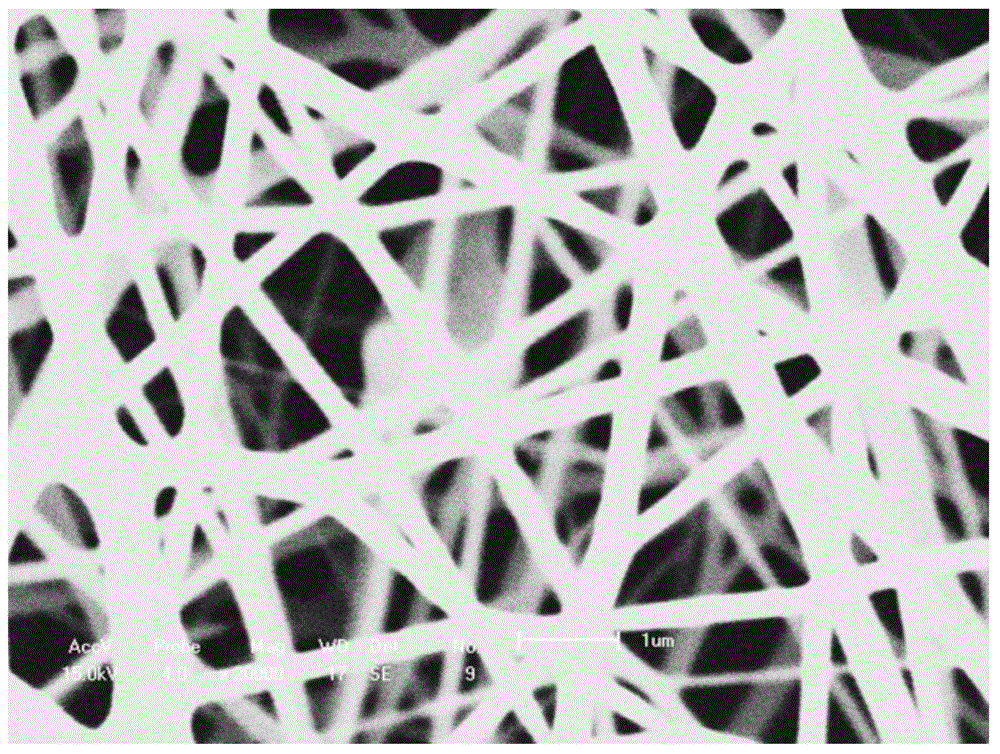

Preparation method of functional PU-AOPAN (polyurethane-amidoximepolyacrylonitrile) composite nanofiber membrane

InactiveCN106480710AImprove hydrophilicityFunction increaseFibre typesElectro-spinningComposite nanofibersOrganic solvent

The invention discloses a preparation method of a functional PU-AOPAN (polyurethane-amidoximepolyacrylonitrile) composite nanofiber membrane, comprising the steps of first, dissolving PU and PAN in an electrostatic spinning polar organic solvent, preparing electrostatic spinning solution with PU and PAN accounting for 8-12% by weight of total weight, and preparing a PU-PAN composite nanofiber membrane by electrostatic spinning process; second, subjecting the PU-PAN composite nanofiber membrane to amidoximation modification to obtain the PU-AOPAN composite nanofiber membrane. The defects are improved that PAN and PU are poor in hydrophilic performance and have few surface functional groups; the PU ingredient is introduced to functional nanofiber, the mechanical properties of amidoximepolyacrylonitrile are greatly improved, and the practical applicability of amidoximepolyacrylonitrile can be greatly enhanced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

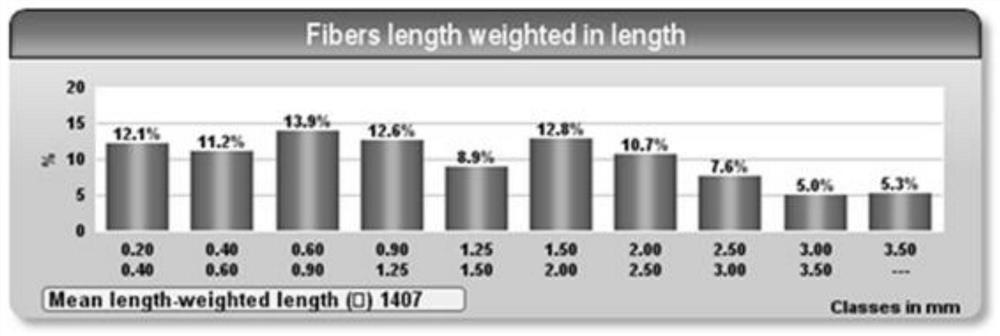

Wood and bamboo fiber mercerizing pulp and preparation method thereof

InactiveCN102121205AImprove breathabilityGood flexibilityNatural cellulose pulp/paperCellulose material pulpingFiberFree state

The invention relates to a wood and bamboo fiber mercerizing pulp and a preparation method thereof. The fiber mercerizing pulp is prepared through the following steps: swelling, mercerizing, neutralizing, washing, concentrating, drying a wood pulp or bamboo pulp which is utilized as a raw material in a free state of the fiber without a pressing or clamping state, wherein the obtained mercerized fiber is natural in flexibility. The mercerizing pulp obtained in the invention is good in air permeability, good in intensity, large in fiber length, high in yield and low in cost; and the cotton fiber is saved.

Owner:张金

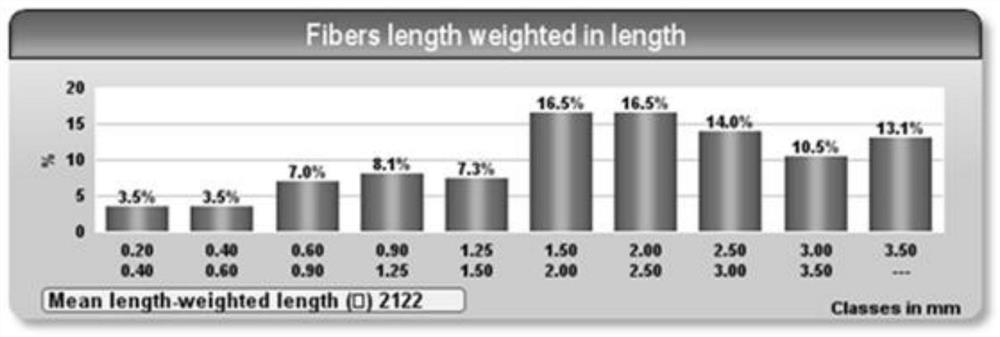

Preparation method for pulp fiber-reinforced starch plastic

The invention discloses a preparation method for a pulp fiber-reinforced fully-degradable starch plastic. According to the invention, a broad-leaved wood or coniferous wood pulp fiberboard for the paper-making industry is mainly used and two-step pretreatment is carried out so as to obtain pulp fiber of a certain scale; the pulp fiber is further mixed with starch and a degradable plasticizer, and then the pulp fiber-reinforced starch plastic is prepared through plasticizing by a double screw extruder. The prepared pulp fiber-reinforced starch plastic has the advantages of obviously improved mechanical properties, complete degradation, low cost, a simple preparation process and the like and can be extensively used for preparation of a variety of fully-degradable starch plastic products.

Owner:河南省南街村(集团)有限公司

A kind of eucalyptus engraving and milling fiberboard and its manufacturing method

ActiveCN105479580BSolve the problem of high production costImprove use valueFlat articlesDomestic articlesParaffin waxFiber

Owner:GUANGXI UNIV

Preparation method of acrylic board surface lining protective body paper

ActiveCN109706780AReduce dosageReduce manufacturing costNon-fibrous pulp additionPaper/cardboardSpecific gravityXylanase

The invention discloses a preparation method of acrylic board surface lining protective body paper. The preparation method comprises following steps: by weight, 3 to 10 parts of cellulase, 1 to 8 parts of pectase, 3 to 10 parts of xylanase, 0.1 to 0.8 part of an alkylolamide, 0.1 to 0.6 part of Span-60, and 75.7 to 88.8 parts of water are combined to prepare a composite bio-enzyme preparation; byweight, 1 to 5 parts of a mixed pulpboard is introduced into a pulper, 95 to 99 parts of water is added, the composite bio-enzyme preparation is added, and defibering is carried out for 5 to 30min soas to obtain a mixed slurry, wherein the adding amount of the composite bio-enzyme preparation accounts for 100 to 300ppm of the weight amount of absolutely dry paper pulp; the mixed slurry is introduced into a pulping machine for pulp refining, pulping concentration ranges from 1 to 4%, and pulp refining is carried out until beating degree is 20 to 45 DEG SR; obtained paper pulp is subjected to dilution, screen moulding, squeezing, drying, and curling processing so as to obtain a finished product. According to the preparation method, the composite bio-enzyme preparation at an optimal ratio isadded in body paper pulp refining process, so that paper pulp beating degree is increased, pulp refining time is shortened, energy consumption is reduced, pollution is reduced, the ratio of fiber morphological substances in paper pulp is improved, and body paper object amount index is increased obviously.

Owner:浙江蓝宇新材料有限公司

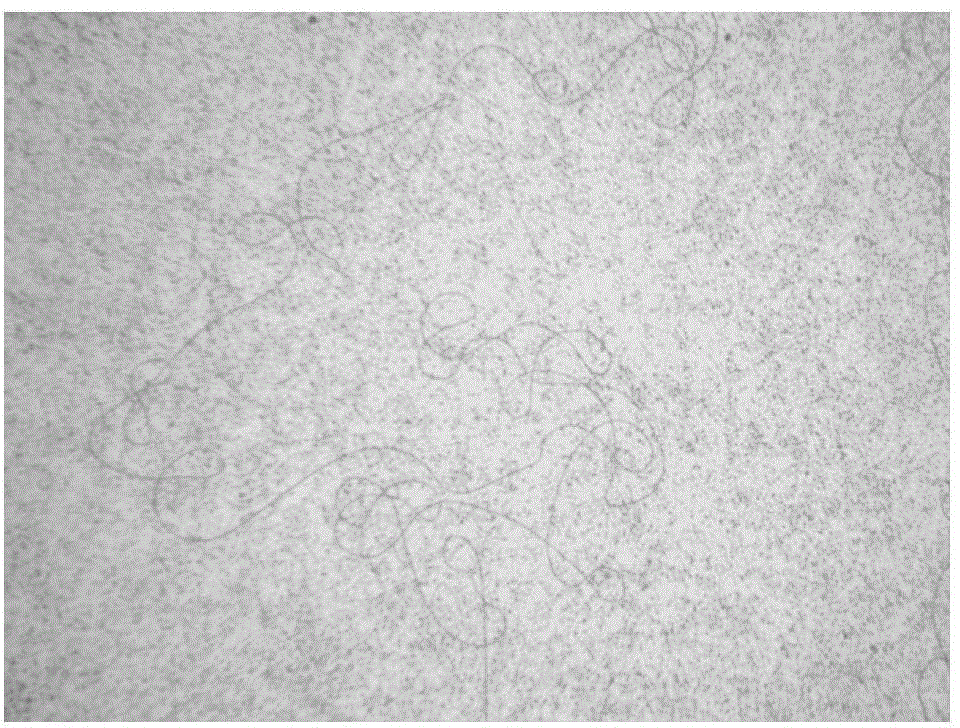

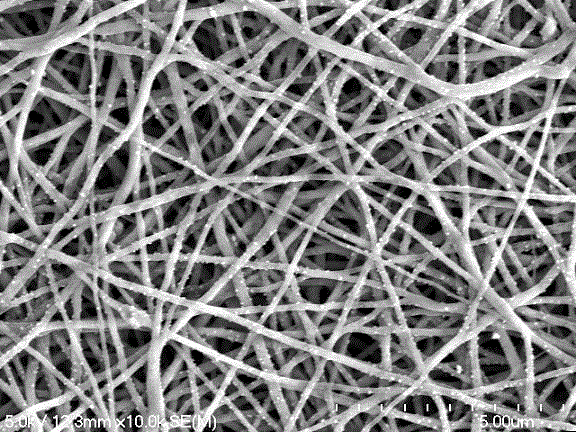

Chitosan-human recombinant collagen electrostatic spinning nanofiber scaffold and preparation method

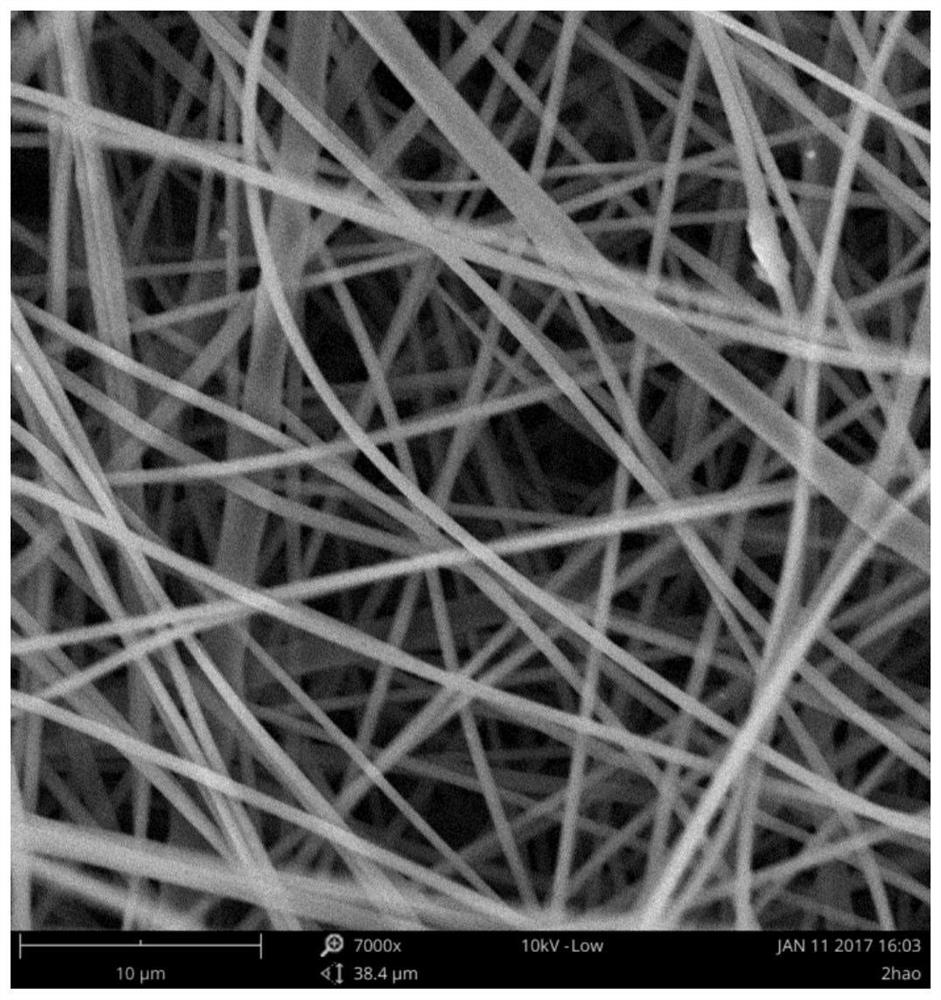

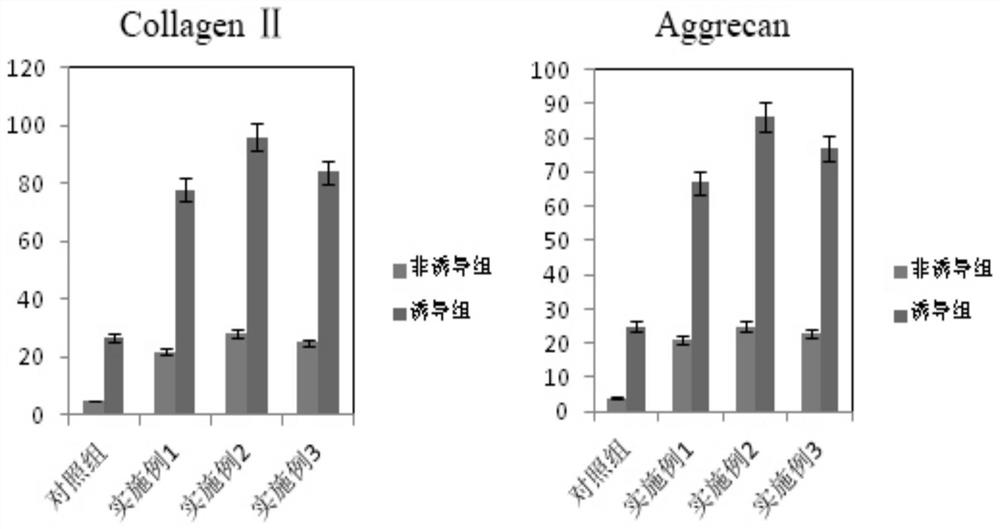

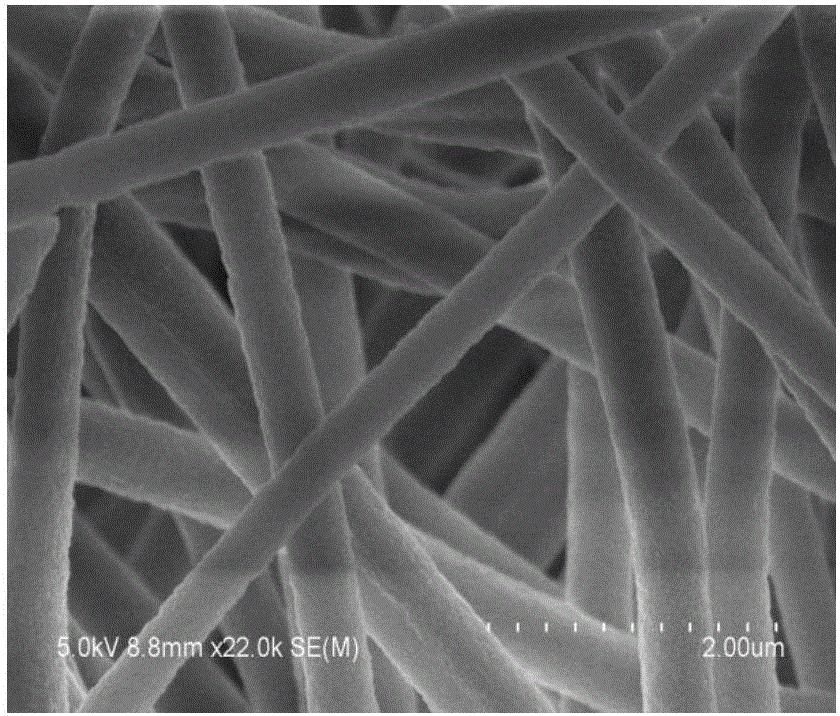

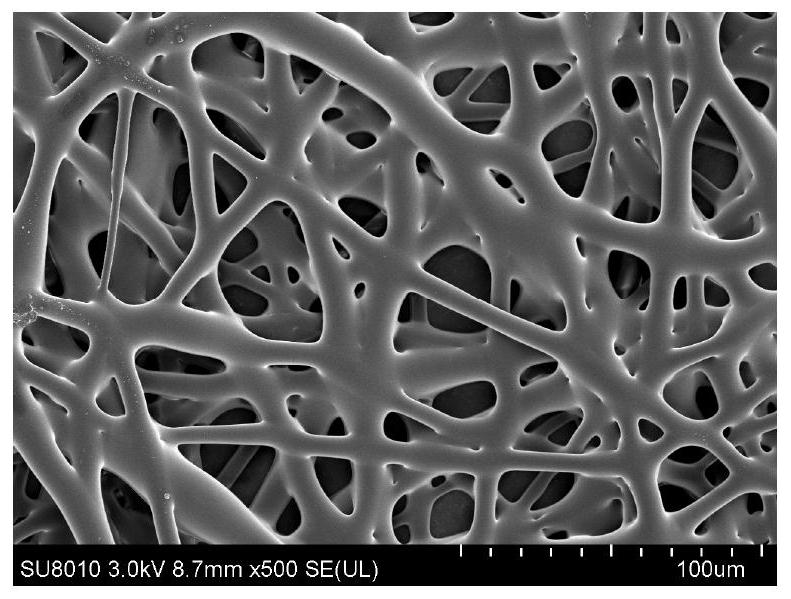

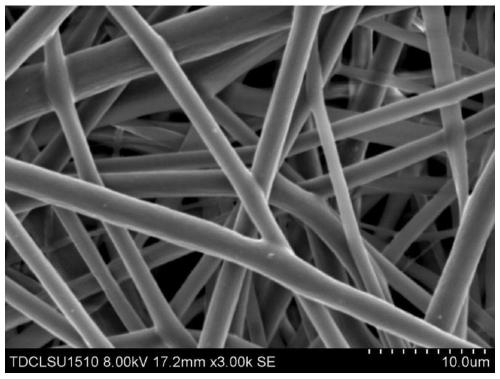

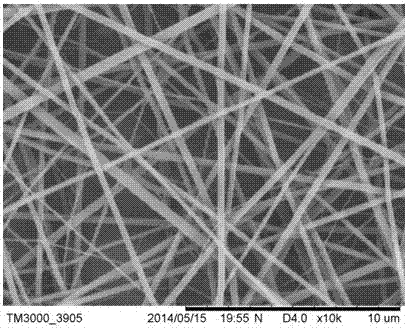

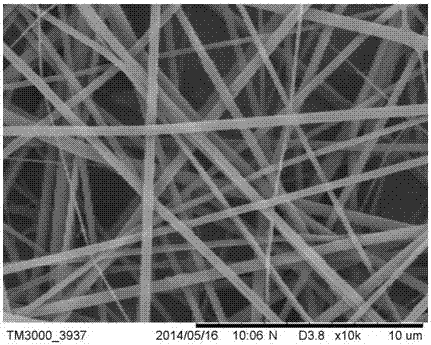

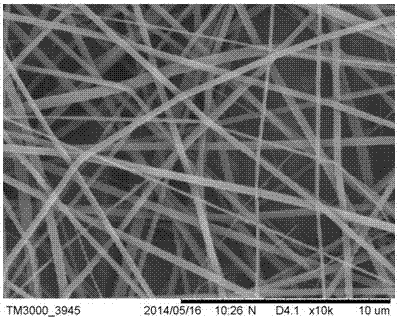

InactiveCN111821515AGood fiber shapeGood biocompatibilityFibre typesPharmaceutical delivery mechanismFiberSpinning

The invention relates to the technical field of tissue engineering and biological manufacturing, in particular to a chitosan-human recombinant collagen electrostatic spinning nanofiber scaffold and apreparation method. The specific preparation method comprises the following steps: preparing a hexafluoroisopropanol spinning solution with a certain concentration from three components, namely humanrecombinant collagen, chitosan and polycaprolactone according to a certain ratio; and preparing chitosan, humanized recombinant collagen and polycaprolactone electrostatic spinning nanofiber scaffoldsfrom the prepared solution through an electrostatic spinning technology, then cross-linking the nanofiber scaffolds through a cross-linking agent, and applying the cross-linked scaffolds to cartilagetissue regeneration. The chitosan-human recombinant collagen electrostatic spinning nanofiber scaffold prepared by the invention has high fiber morphology, high biocompatibility and biodegradability,has the capability of guiding cartilage regeneration, is remarkable in effect, and can be used for repairing cartilage tissue defects.

Owner:青海创铭医疗器械有限公司

Preparing method and application of functional AOPAN-AA nanofiber membrane

ActiveCN106544861ALow priceWide variety of sourcesSemi-permeable membranesWater contaminantsPorosityFiltration

The invention discloses a preparing method and application of a functional AOPAN-AA nanofiber membrane. The preparing method includes the following steps that A, electrostatic spinning PAN nanofiber is processed in an amidoxime mode to prepare AOPAN nanofiber containing an amidoxime active group; B, the functional AOPAN-AA nanofiber membrane is prepared from the AOPAN nanofiber prepared in the step A through atom transfer radical polymerization grafted acrylate. The obtained AOPAN-AA nanofiber membrane is stable in form, high in porosity and large in specific area, and a great number of carboxylic groups are grafted to the surface so that the material can be applied to the fields of macromolecule filtration, enzyme immobilization and metal ion adsorption and has remarkable functionality.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

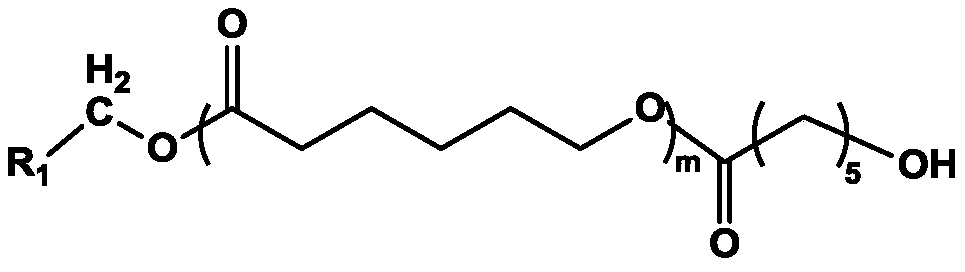

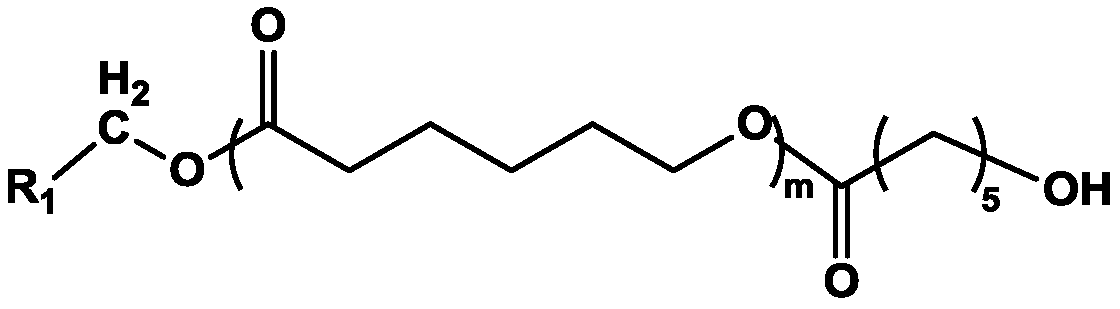

Nanofiber coated with polylactic acid-polyethylene glycol and preparation method thereof

InactiveCN103705932BPromote degradationGood biocompatibilityAntibacterial agentsOrganic active ingredientsSolubilityPolyethylene glycol

The invention relates to polylactic acid-polyethylene glycol coated florfenicol nanofiber and a preparation method thereof, belonging to the technical fields of veterinary drugs and preparation thereof. The polylactic acid-polyethylene glycol is segmented copolymer D, L-polylactic acid-polyethylene glycol-D, L-polylactic acid; and florfenicol is filled in a reticular structure of polylactic acid-polyethylene glycol, and mass ratio of the florfenicol to the polylactic acid-polyethylene glycol is 1: (3.5-10). The preparation method comprises the steps of adding the polylactic acid-polyethylene glycol and the florfenicol into an organic solvent, stirring and dissolving to obtain a spinning solution; and then carrying out electrostatic spinning to obtain a polylactic acid-polyethylene glycol coated florfenicol nanofiber membrane. The preparation method provided by the invention realizes drug loading while carrying out electrostatic spinning on the polylactic acid-polyethylene glycol, and solves the problems such as sudden release of drugs, short action time and poor water solubility; and the adopted raw materials cannot cause the problem of environmental protection after degradation, the cost is low, the preparation process is simple and quick, and the polylactic acid-polyethylene glycol coated florfenicol nanofiber and the preparation method are applicable to mass production.

Owner:JILIN UNIV

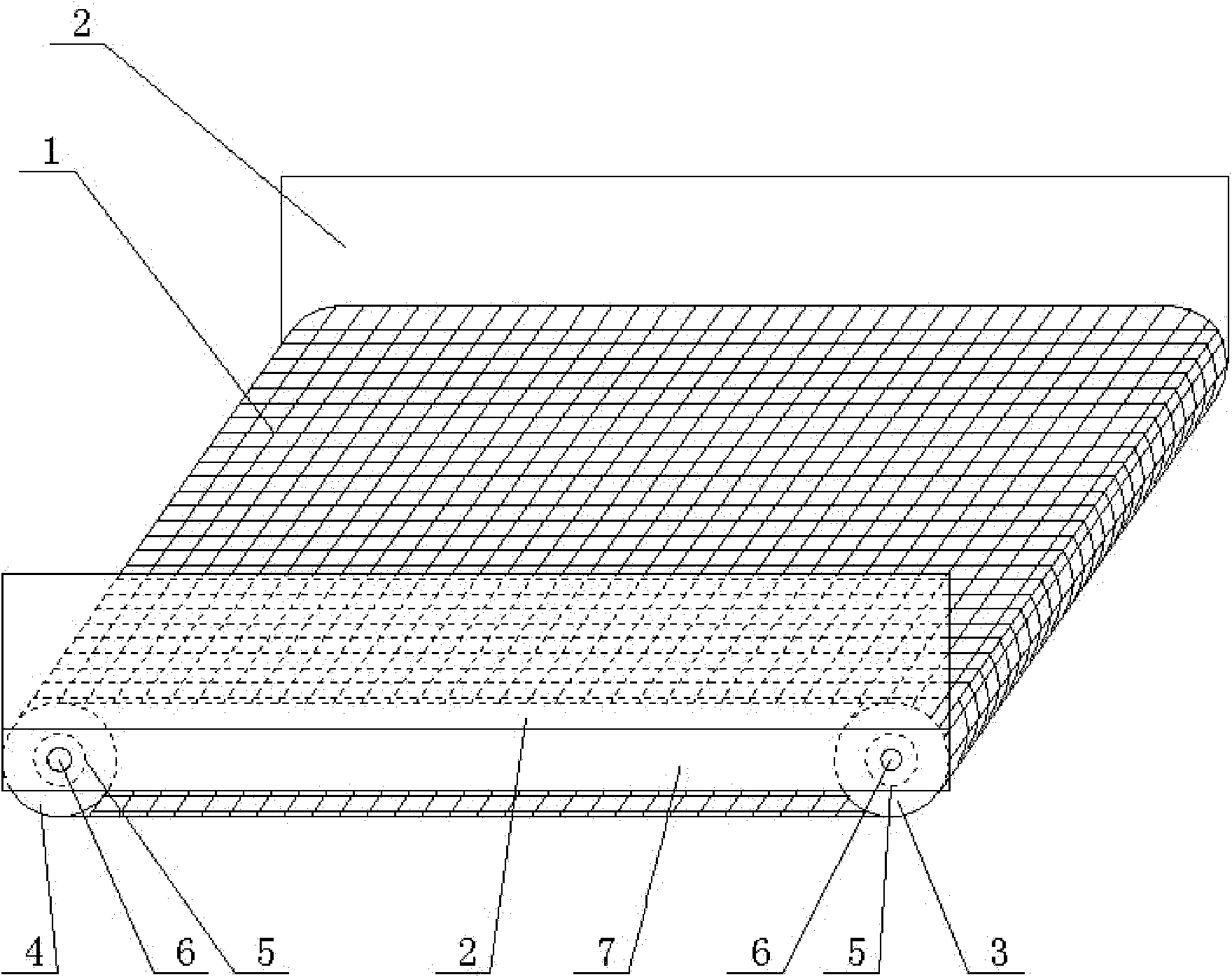

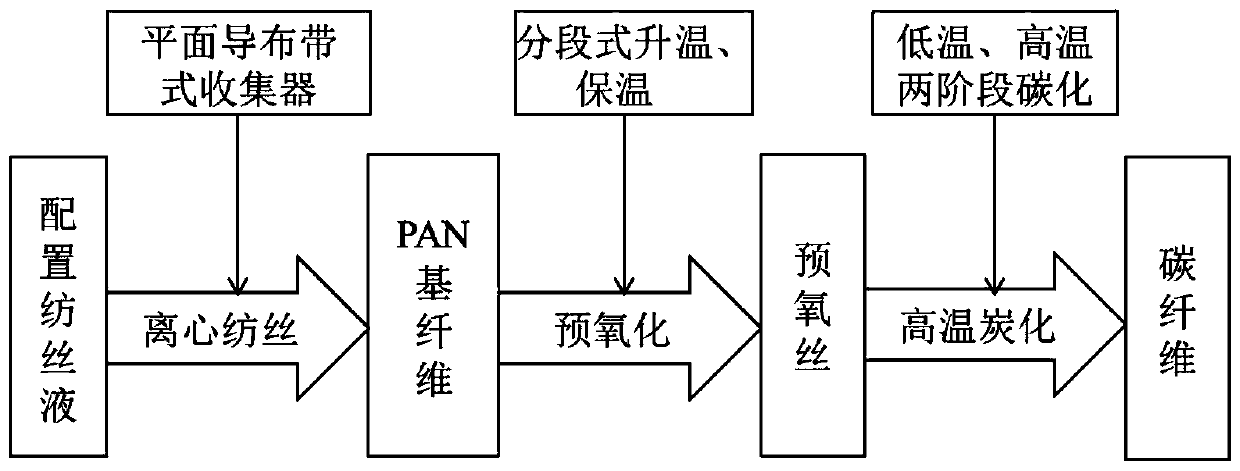

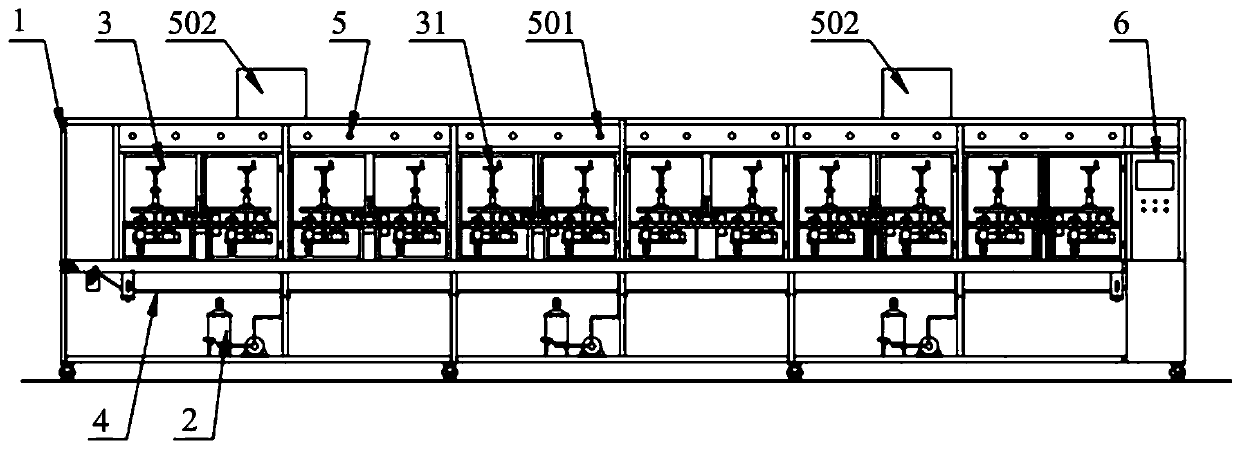

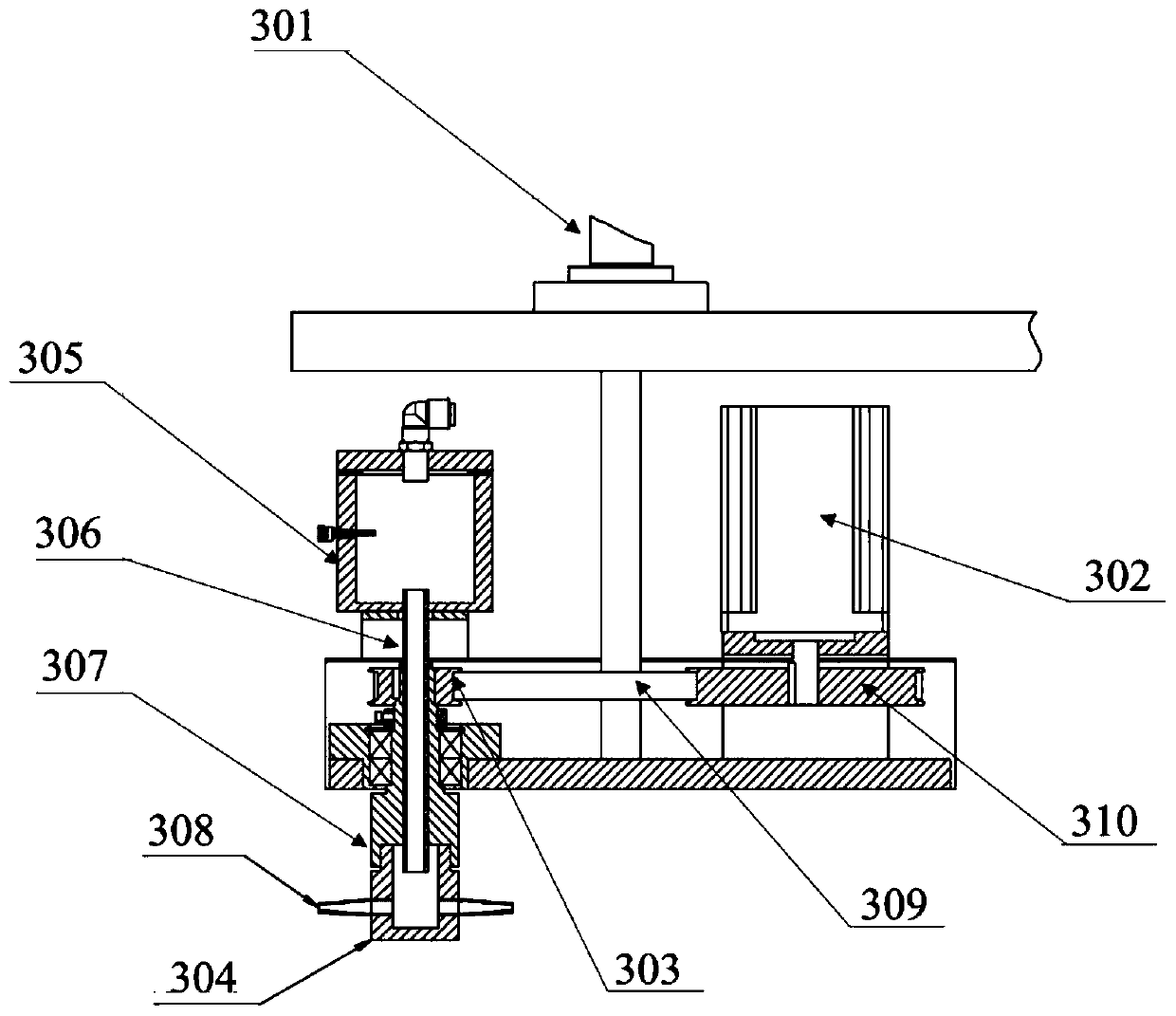

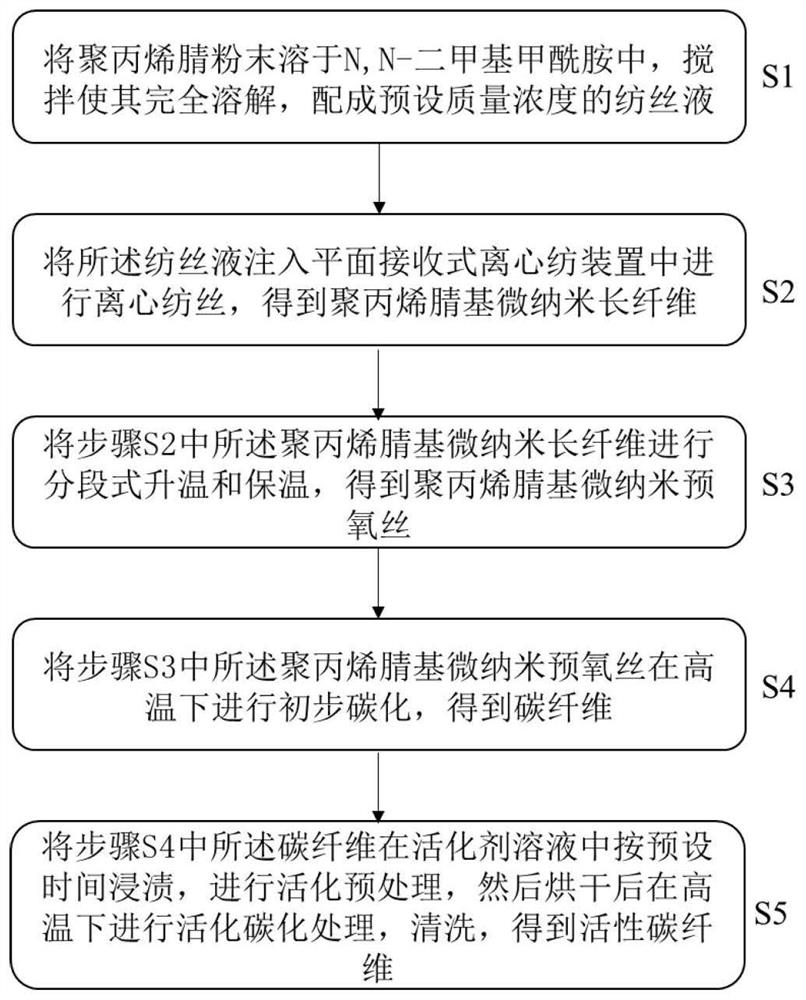

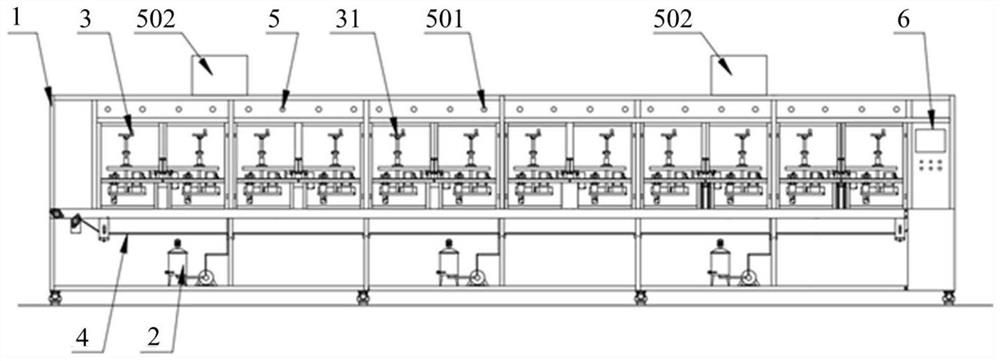

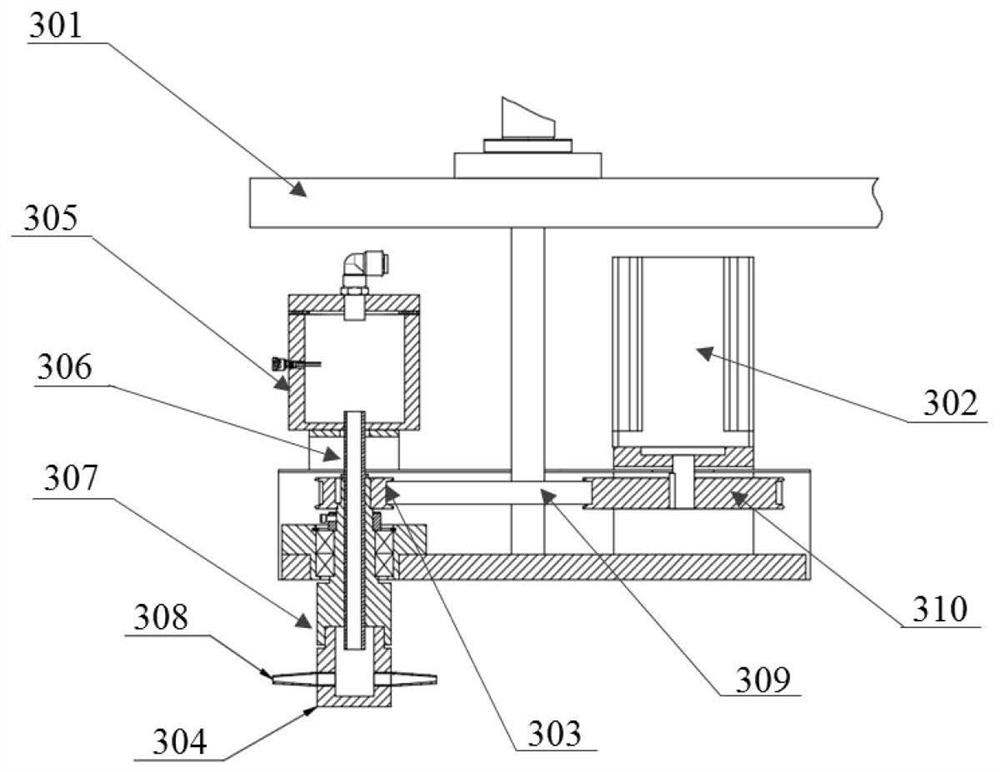

Centrifugal spinning preparation method of polyacrylonitrile-based pre-pre-oxidized fibers and carbon fibers

ActiveCN110499550ASpinning efficiency and quality improvementGood heat resistance and fiber shape retentionSpinning head liquid feederFilament/thread formingPolyvinyl butyralCarbonization

The invention provides a centrifugal spinning preparation method of polyacrylonitrile-based pre-pre-oxidized fibers and carbon fibers. A prepared polyacrylonitrile-based N,N-dimethylformamide spinningsolution is injected into a plane receiving type centrifugal spinning device and jetted from a spinneret hole to a plane collecting belt under the action of centrifugal force to prepare polyacrylonitrile-based precursor fibers with relatively small diameter and uniform size distribution, then pre-oxidation is conducted through sectional heating and heat preservation, and the prepared polyacrylonitrile-based pre-oxidized fibers are high in heat resistance, good in fiber morphology and free of the adhesion phenomenon; high-temperature carbonization is carried out to obtain the polyacrylonitrile-based carbon fibers with uniform diameter distribution and good heat resistance. According to the method, polyvinyl butyral is added, so that the polyacrylonitrile-based carbon fibers of a porous structure are prepared.

Owner:WUHAN TEXTILE UNIV

Glaze and preparation method of high-temperature-resistant metal coating

The invention belongs to the field of glazes, in particular to glaze and a preparation method of a high-temperature-resistant metal coating. When the surface glaze coating is prepared, the adopted glaze material comprises base glaze, a grinding additive and inorganic fibers, and for every 100 parts of base glaze, the grinding additive comprises the following components in parts by mass: 5 parts ofclay, 0.2-0.6 part of sodium nitrite, 0.2-0.6 part of borax, 2-25 parts of refractory aggregate and 2-20 parts of inorganic fibers. According to the invention, the fibers are added into the metal coating, the fiber having one-dimensional structure; after a short-time enamel sintering process, the fibers are not melted; therefore, the strength of the enamel material can be remarkably improved by the coating at 600 DEG C; the liquid phase flowing property and the melting property of the enamel are reduced, good fiber morphology can be kept in a metal coating; the invention can be applied in thehigh-temperature-resistant high-strength metal composite material, the use temperature of the metal coating can be remarkably increased, and the use temperature can be increased to 750 DEG C in the highest period of time.

Owner:SHANGHAI FINEWAY ENERGY ENG

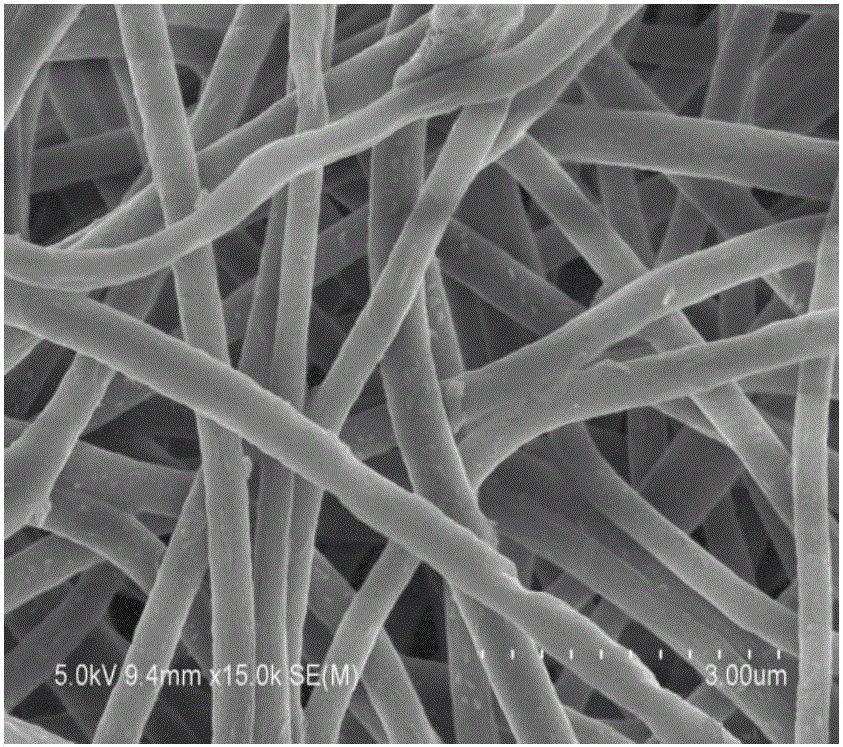

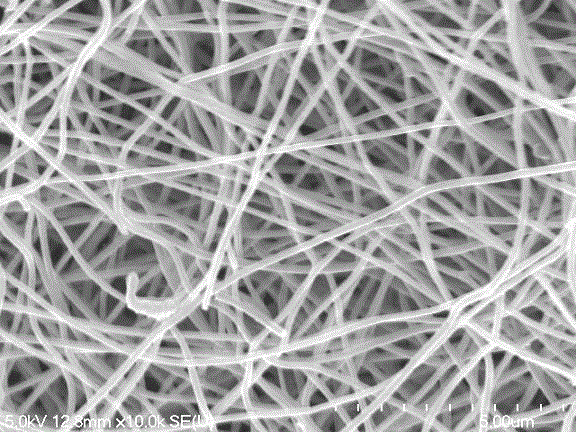

Preparation method of nanofiber dermal scaffold

InactiveCN111330088AGood fiber shapePromote healingPharmaceutical delivery mechanismProsthesisFiberSpinning

The invention belongs to the technical field of bioengineering, and particularly relates to a preparation method of a nanofiber dermal scaffold. The method includes the following steps: (1) dissolving, by weight, 20-25% of human-derived recombinant collagen and 0-5% of auxiliary materials in a solvent so as to prepare a spinning solution; (2) preparing a nanofiber membrane through electrostatic spinning; (3) cross-linking the nanofiber membrane by using a crosslinking agent; and (4) loading the crosslinked nanofiber membrane on a silica gel membrane so as to obtain the nanofiber dermal scaffold. The prepared scaffold has good fiber morphology and high mechanical strength, needs of medical dressings can be met, and the scaffold can be fitted into damaged tissue parts, and is capable of effectively helping regeneration of dermal tissue, accelerating healing of wounds, maintaining the wound surface moist and reducing risks of scar formation.

Owner:江苏创铭医疗器械有限公司

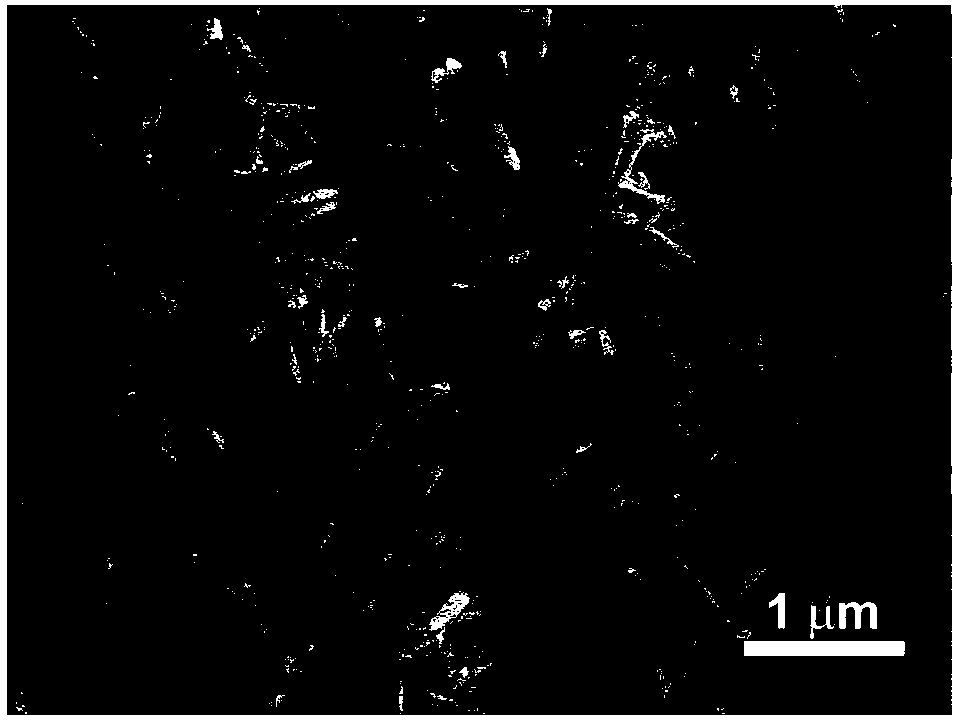

A metal-organic framework fiber membrane for filtering tobacco smoke particles and its application

ActiveCN107551831BGood effectLarge specific surface areaSemi-permeable membranesDispersed particle filtrationFiberMetal-organic framework

The invention relates to a metal-organic framework fiber membrane for filtering tobacco smoke particles and its application. The metal-organic framework fiber membrane is obtained by completely converting an oxide fiber membrane directly with an organic ligand, and has a super high ratio surface area. The metal-organic framework fiber membrane for filtering tobacco smoke particles of the present invention has excellent filtering performance for tobacco smoke particles, and has excellent filtration performance for PM 10 and PM 2.5 The filtration rates are above 91% and 89% respectively.

Owner:SHANDONG UNIV

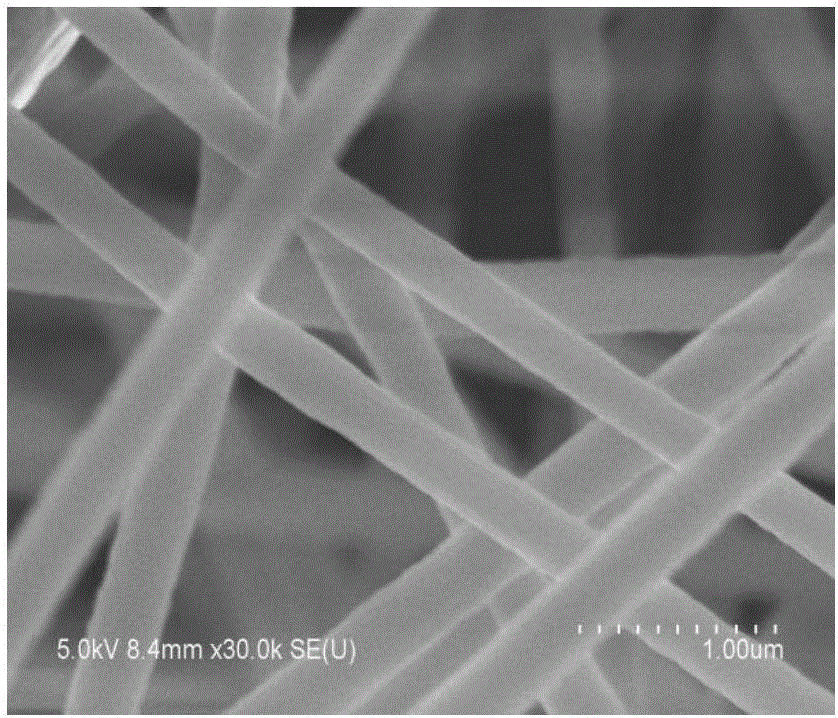

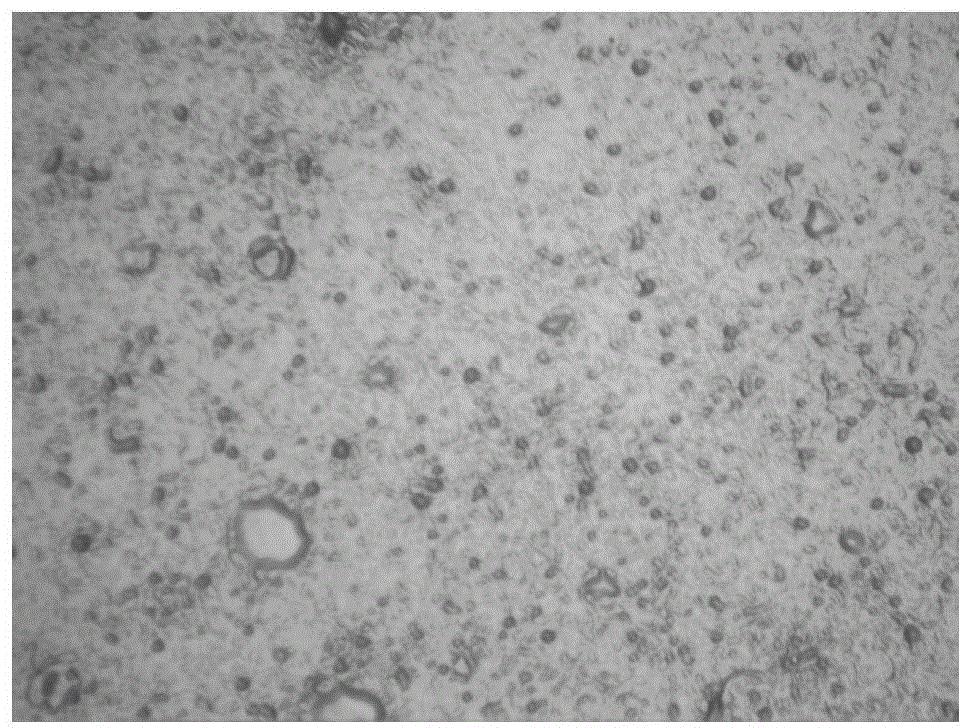

A kind of pelcl/polycaprolactone-redv electrospun fiber membrane and preparation method

InactiveCN106729976BGood fiber shapeLow viscosityNon-woven fabricsProsthesisPolymer scienceVascular endothelium

The invention relates to a polyethylene glycol-b-poly(L-lactide-co-epsilon-caprolactone) / poly (epsilon-caprolactone)-REDV blended superfine electrospun fiber film and a preparation method thereof. Poly (epsilon-caprolactone) with low molecular weight is coupled with REDV small peptides, poly (epsilon-caprolactone)-g-REDV is prepared, poly (epsilon-caprolactone)-g-REDV and polyethylene glycol-b-poly(L-lactide-co-epsilon-caprolactone) with high molecular weight are together dissolved in a mixed solvent of chloroform and N,N-dimethyl formamide, and an electrostatic spinning method is used for preparation in order to obtain the superfine fiber film. The electrospun fiber film comprises superfine fiber whose diameter is 400-1000nm, and thickness is 50-200[mu]m. The electrospun fiber film contains REDV small peptides on the surface, in order to promote adhesion and growth functions of vascular endothelial cells; at the same time, the superfine fiber film is used for wrapping and loading nucleic acid, protein, medicament and other bioactive substances, and has capability for controlled release of bioactive substances. The product is used for biomedical materials.

Owner:TIANJIN UNIV

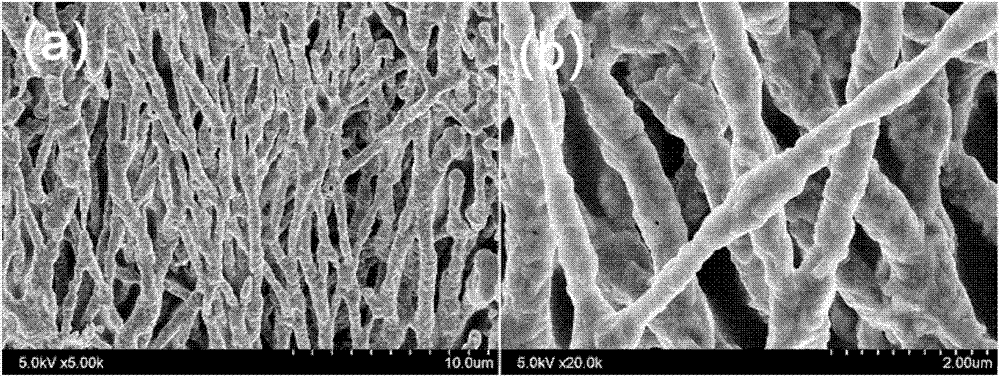

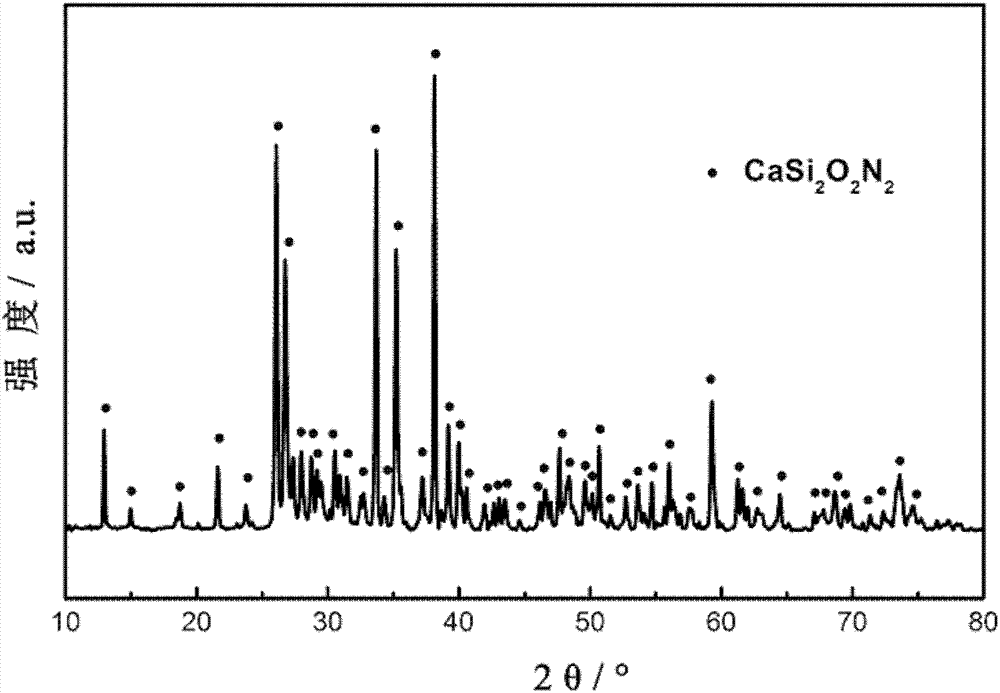

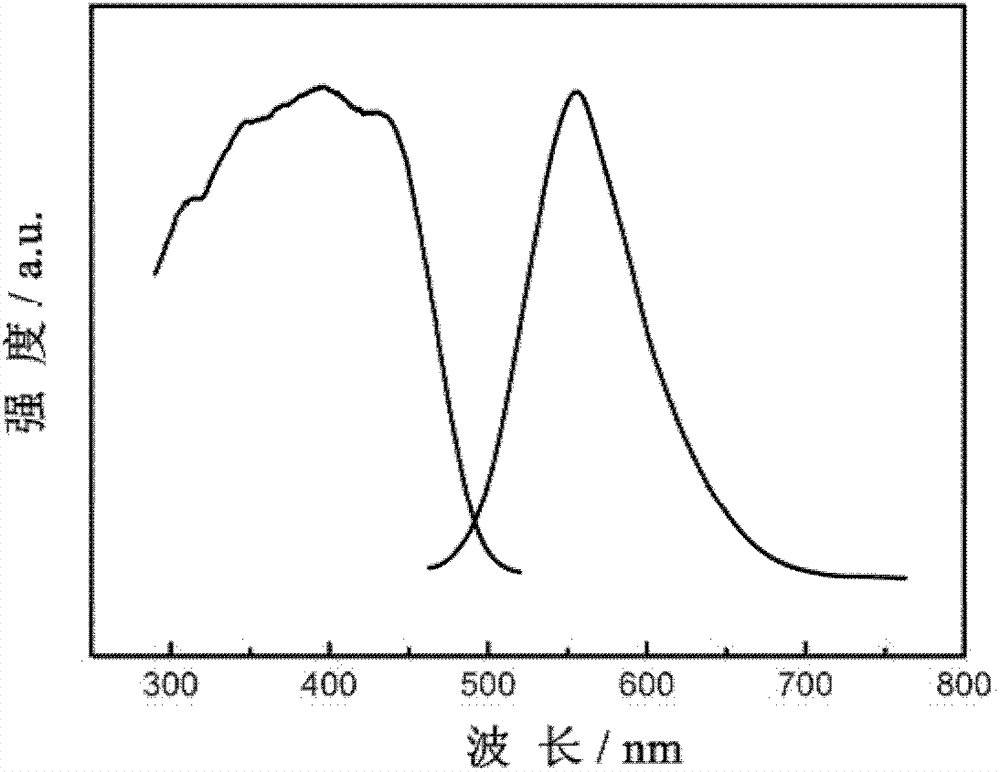

Preparation method for CaSi2O2N2:Eu<2+> fluorescence nano-fiber

InactiveCN102358963BGood fiber shapeSimple methodFilament/thread formingArtificial filament heat treatmentFluorescenceSolvent

The present invention relates to a preparation method for CaSi2O2N2:Eu<2+> fluorescence nano-fiber. The method comprises the following steps: (1) dissolving calcium nitrate and europium nitrate in a mixed solvent comprising alcohol and water; adding tetraethyl orthosilicate while stirring; adding polyvinylpyrrolidone after stirring; continuously stirring to obtain a spinning liquid; (2) pouring the spinning liquid into a syringe, carrying out electrostatic spinning to collect a layer of uniform white fiber on receiving aluminum foil; (3) placing the white fiber into a high-temperature tubularatmosphere furnace to carry out a heat treatment; finally carrying out cooling along with the furnace to obtain the CaSi2O2N2:Eu<2+> fluorescence nano-fiber. The method of the present invention has characteristics of simpleness, low nitridation temperature and short time. The prepared CaSi2O2N2:Eu<2+> phosphor has good fiber morphology so as to contribute to improvement of the luminescent property and the later package in the LED, and has a good application prospect.

Owner:DONGHUA UNIV

Method for preparing polyvinyl alcohol BiVO4 composite fiber by electrostatic spinning method

ActiveCN103088457BGood fiber shapeEvenly dispersedFilament/thread formingMonocomponent synthetic polymer artificial filamentFiberAmmonium metavanadate

The invention provides a method for preparing polyvinyl alcohol BiVO4 composite fiber by an electrostatic spinning method. The method comprises the following steps of: firstly adding Bi(NO3)3.5H2O and citric acid monohydrate in deionized water and stirring evenly, and then adding ethanolamine and continuously stirring to be clear so as to obtain a solution A; then adding ammonium metavanadate and the citric acid monohydrate in the deionized water to obtain orange mixed liquid, stirring at the constant temperature of 70 DEG C to enable the color of the mixed liquid to turn into dark blue without precipitation, and obtaining a solution B; mixing the solution B and the solution A, and stirring to obtain a precursor solution; then evenly mixing the precursor solution and a polyvinyl alcohol solution binding agent to prepare an electrostatic spinning solution; and finally putting the electrostatic spinning solution into a syringe to start spinning, and collecting the prepared polyvinyl alcohol BiVO4 composite fiber by a receiver. The preparation method provided by the invention is simple and convenient, low in energy consumption and cost, and environmentally-friendly, the prepared polyvinyl alcohol BiVO4 composite fiber has good dispersibility, and nanofiber with good appearance can be obtained in a high-voltage electric field.

Owner:SHAANXI UNIV OF SCI & TECH

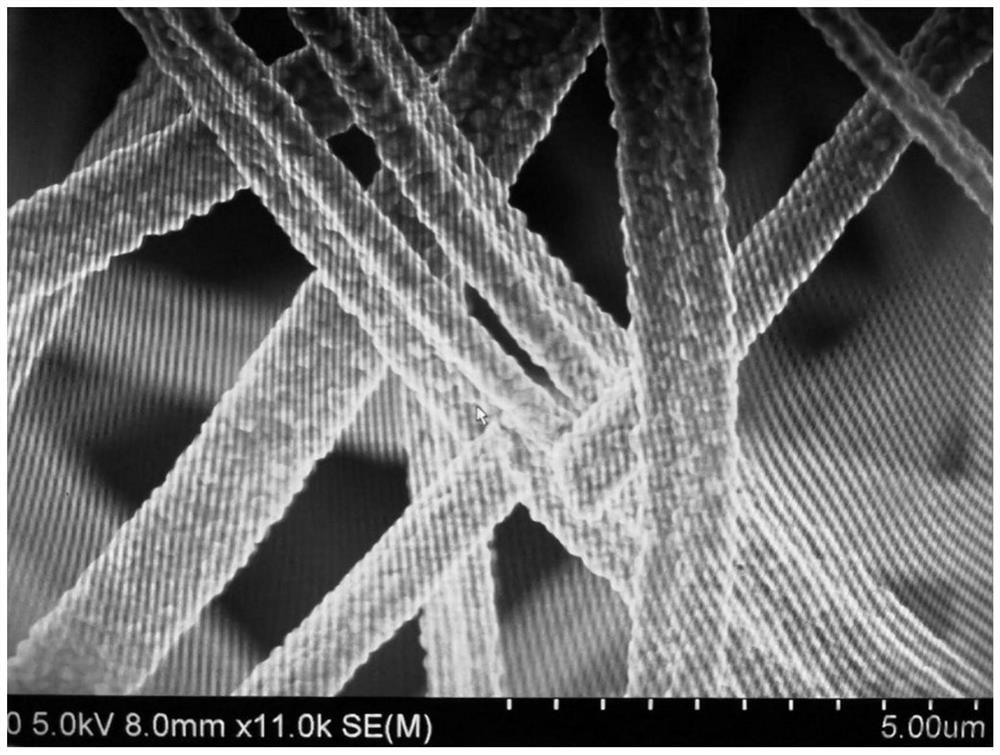

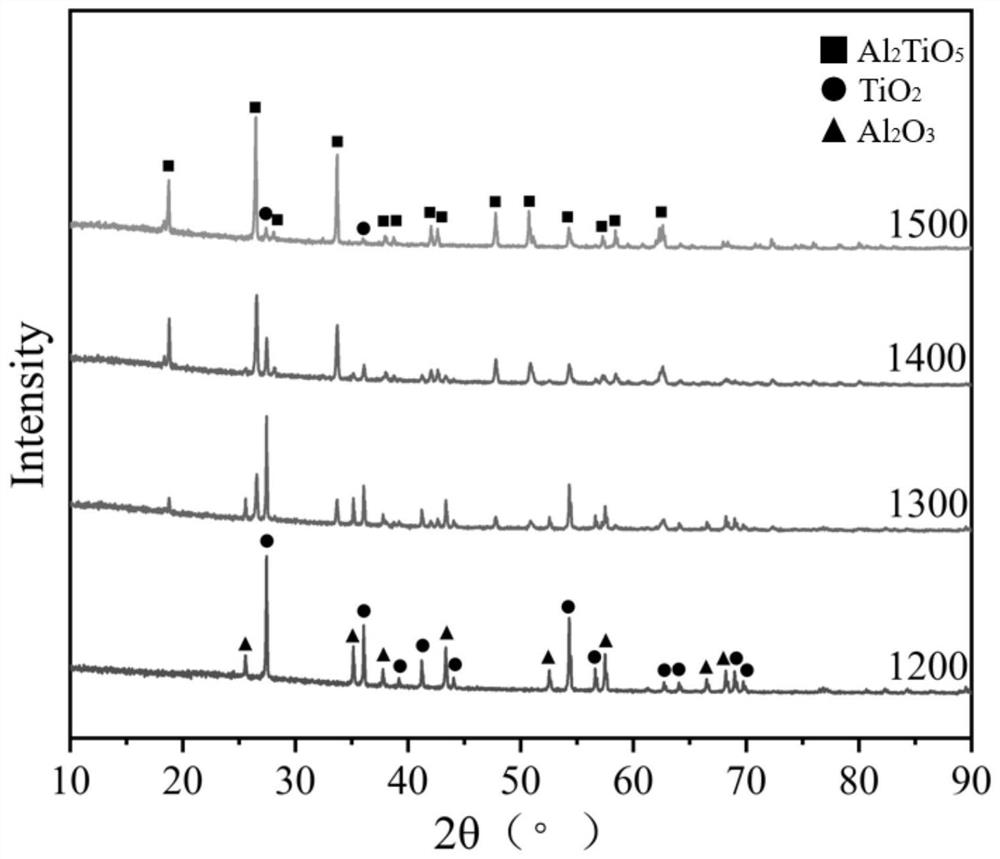

A kind of method that titanium-aluminum polymer precursor prepares aluminum titanate ceramic fiber

ActiveCN111995393BImprove high temperature resistanceGood fiber shapeFibre chemical featuresFiberThermal dilatation

The invention relates to a method for preparing aluminum titanate ceramic fibers from a titanium-aluminum polymer precursor. The method is to obtain the titanium-aluminum polymer precursor on the basis of metal coordination chemistry, add spinning aids to the titanium-aluminum polymer precursor sol, and obtain the sol-spinning solution. Under high temperature conditions, the solvent volatilizes, and the solute solidifies into titanium-aluminum polymer precursor fibers. The prepared aluminum titanate ceramic fibers not only have good high temperature resistance, but also maintain good fiber morphology under high temperature conditions up to 1400 ° C, and have Low thermal expansion coefficient and good thermal shock resistance.

Owner:SHANDONG UNIV

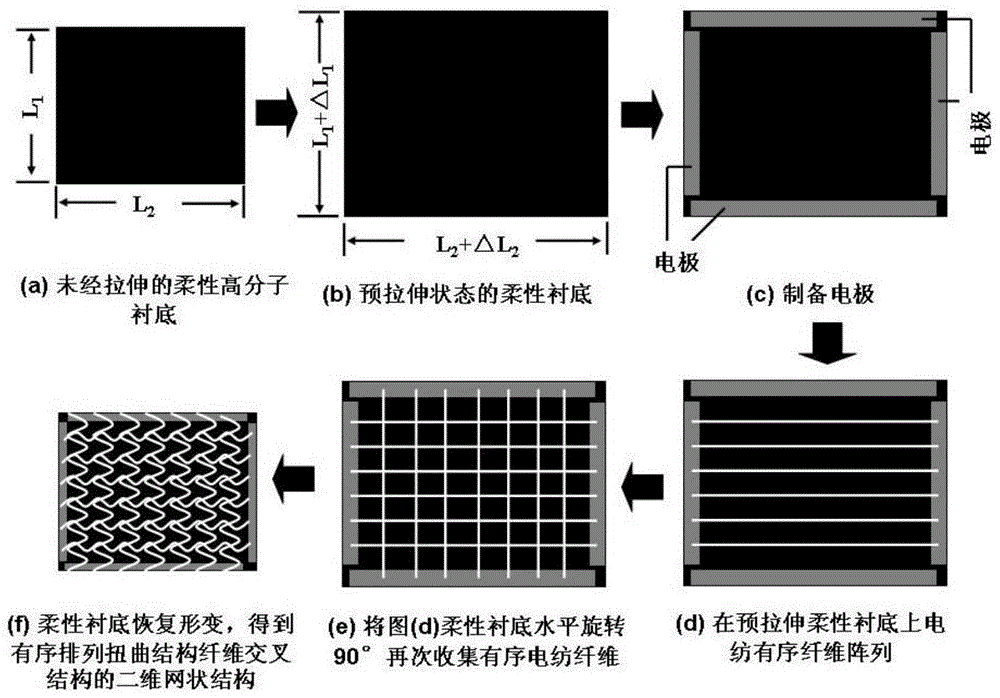

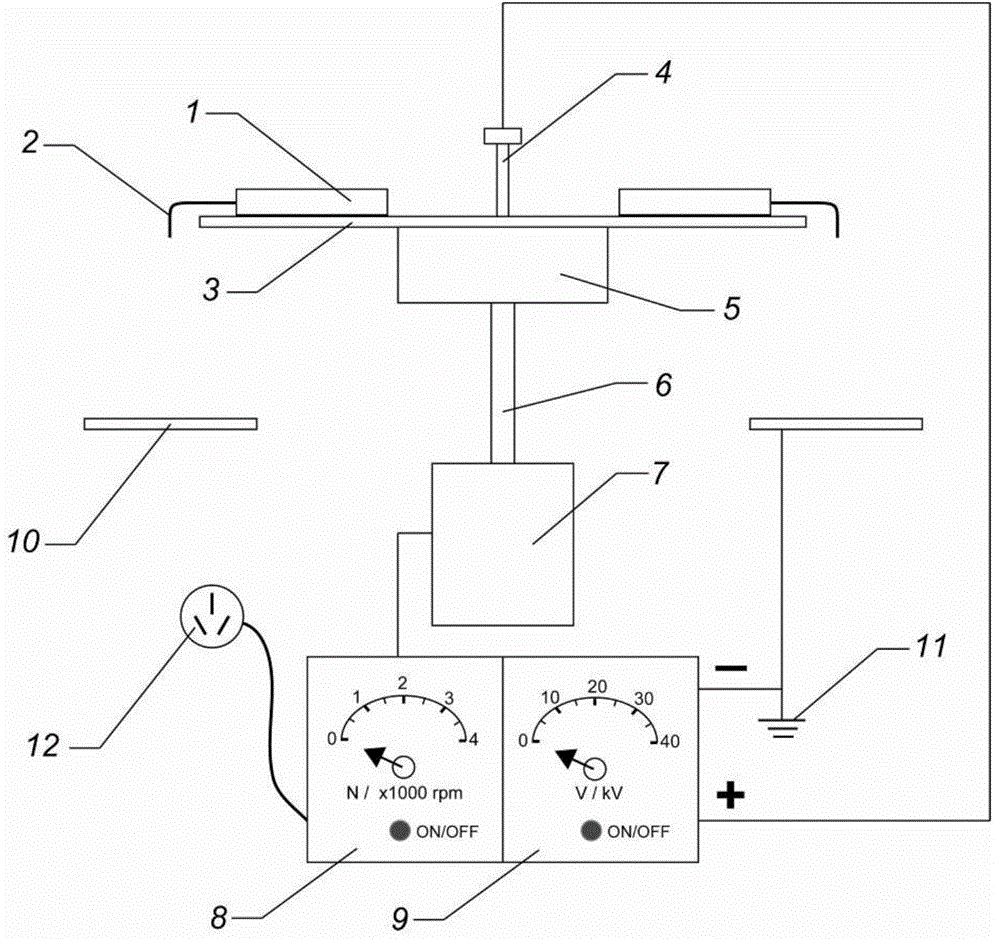

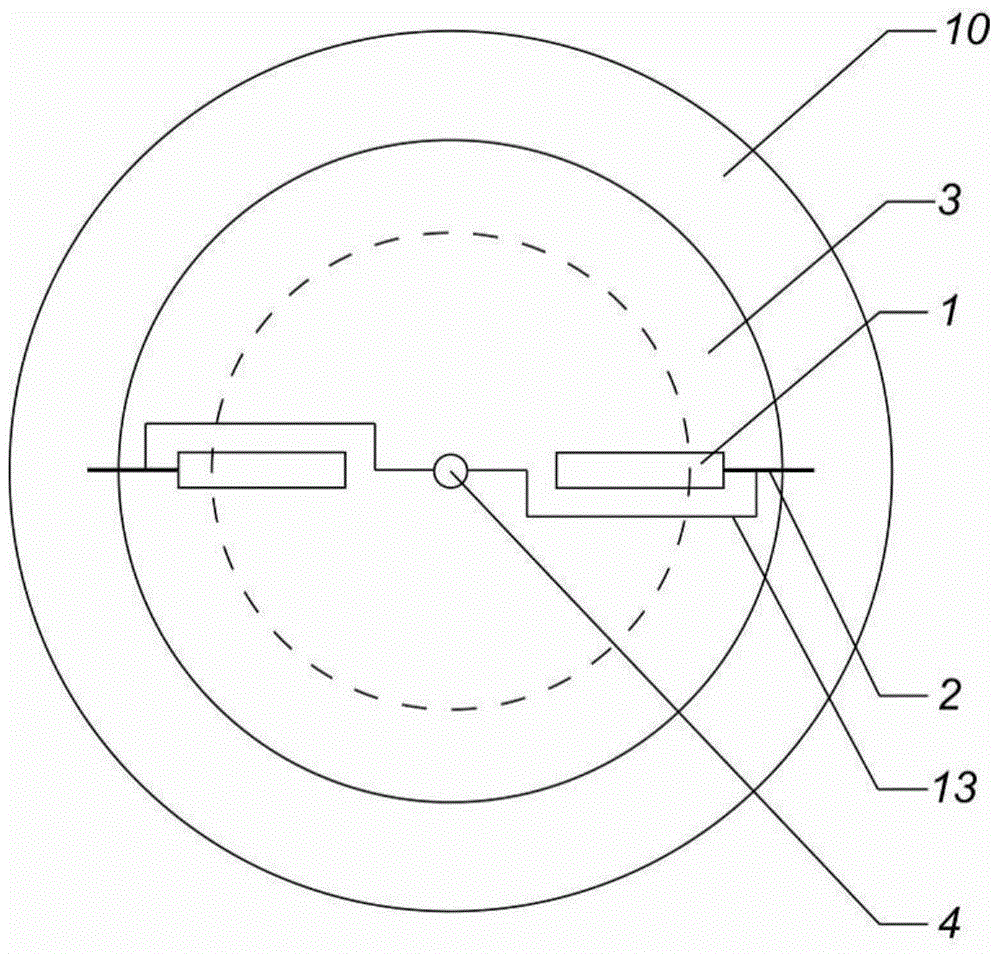

A Fabrication Method of Flexible and Stretchable Devices Based on Ordered Arrangement and Twisted Structures

InactiveCN104153128BAccurate realization of pre-strain controlAchieve pre-strain controlNew-spun product collectionFilament/thread formingPre strainElectrospinning

Owner:QINGDAO UNIV

Lithium ferrous phosphate/iron phosphide/carbon composite nanofiber and its preparation method and application

The invention provides a lithium iron phosphate / iron phosphide / carbon composite nanofiber including the following components by mass percent: 50-99% of lithium iron phosphate, 0.5-30% of iron phosphide and 1-20% carbon. The average diameter of the lithium iron phosphate / iron phosphide / carbon composite nanofiber is 50-500nm and spherical particles of iron phosphide exist in the composite nanofiber. The lithium iron phosphate / iron phosphide / carbon composite nanofiber has good fiber morphology and conductivity and is high in discharge capacity when being used as a positive material of a lithium-ion battery.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

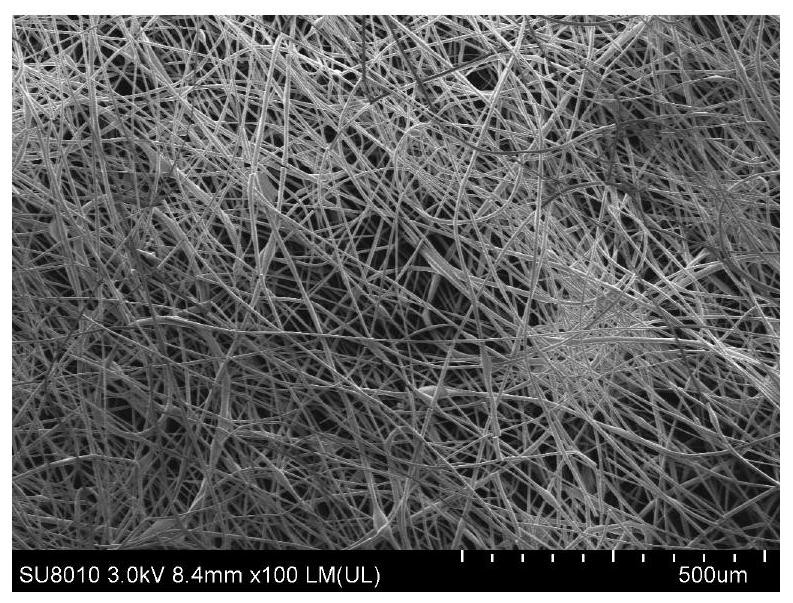

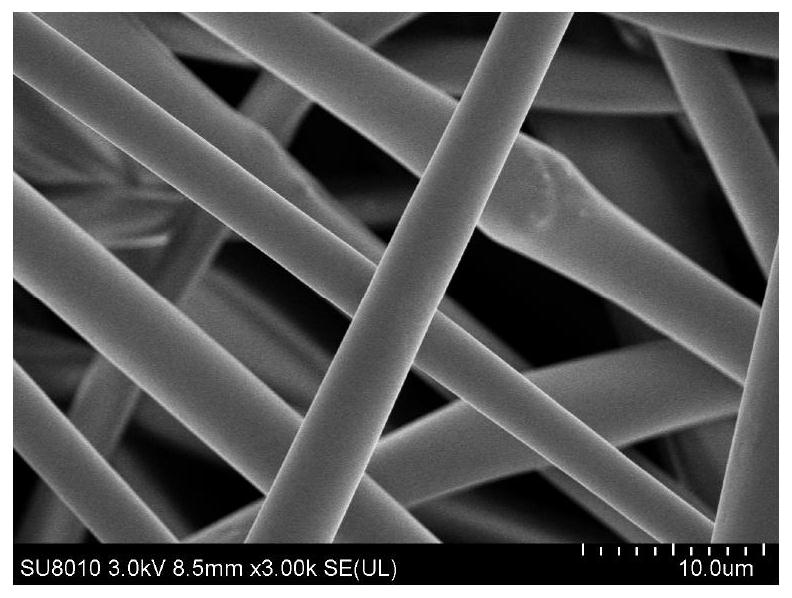

Preparation method of agar nanofibers

PendingCN113493933ASmall fiber diameterGood fiber shapeArtificial filament washing/dryingFibre chemical featuresNanofiberPolymer science

The invention provides a preparation method of agar nanofibers. Fibers are prepared through a jet spinning method, the fibers obtained through the jet spinning method are relatively small in diameter, good in fiber appearance and smooth in surface, cavities cannot be generated, and the mechanical property of the fibers can meet application requirements.

Owner:苏州合祥纺织科技有限公司

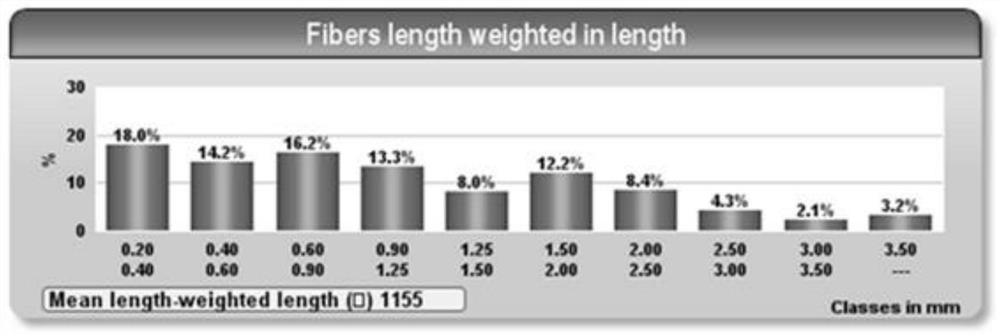

A method for preparing activated carbon fibers based on centrifugal spinning method

ActiveCN110485001BEnabling wide-format nonwovens productionFacilitate mass adoptionFilament/thread formingArtificial filament chemical after-treatmentPolymer scienceCarbon fibers

The invention discloses a method for preparing activated carbon fibers based on a centrifugal spinning method. The configured polyacrylonitrile-based N,N-dimethylformamide spinning solution is injected into a plane receiving type centrifugal spinning device to prepare a fiber with a finer diameter. And polyacrylonitrile-based micro-nano long fibers with uniform size distribution; then pre-oxidized by segmental heating and heat preservation to obtain polyacrylonitrile-based micro-nano pre-oxidized filaments; then pre-oxidized filaments are initially carbonized at high temperatures, It can not only improve the adsorption rate of the activator during the pre-activation treatment, but also overcome the defect that the micropores collapse due to the severe carbonization process when the pre-oxidized wire is directly activated and carbonized at high temperature; High-temperature carbonization makes the activation process mild, and the micropore diameter and porosity are easy to control. The activated carbon fiber prepared by the invention has the advantages of high specific surface area, high porosity and small pore diameter, and is suitable for large-scale mass production.

Owner:WUHAN TEXTILE UNIV

A kind of preparation method of acrylic plate veneer protection base paper

ActiveCN109706780BImprove beating degreeReduce the degree of beatingNon-fibrous pulp additionPaper/cardboardPectinaseFiber

Owner:浙江蓝宇新材料有限公司

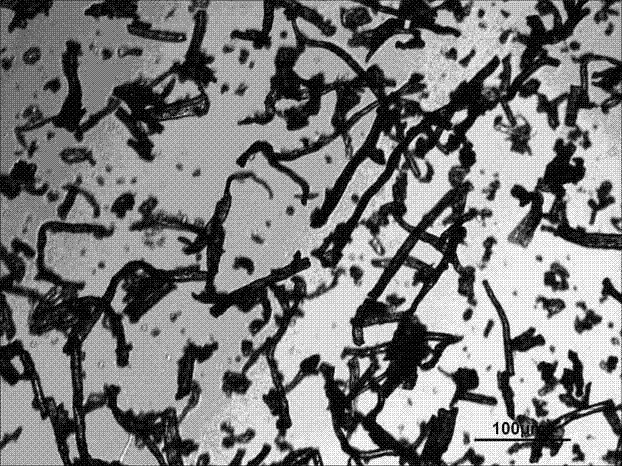

Method for preparing para-aramid pulp by ultrasonic induction

InactiveCN103724615BNo pollutionSimple processWet spinning methodsSpinning solutions preparationFiltrationSlurry

The invention discloses a method for preparing PPTA-pulp by ultrasonic induction, and belongs to the field of chemical fiber preparation. The method comprises the following steps: completely dissolving p-phenylenediamine powder into a calcium chloride-contained solvent; then, adding paraphthaloyl chloride at twice, wherein the mass ratio of the paraphthaloyl chloride at twice is (1:9) to (9:1), and the time interval is 2-5 minutes, and starting an ultrasonic device after the paraphthaloyl chloride is added at the second time to obtain a faint yellow PPTA slurry liquid, wherein the ultrasonic frequency is 28-120 kHz, and the condensation polymerization is 0.2-2 hours; diluting the prepared faint yellow PPTA slurry liquid by using N-methyl pyrrolidone, adding the diluted faint yellow PPTA slurry liquid into a solidification liquid composed of the N-methyl pyrrolidone and water with a volume ratio of (2:1) to (4:1), chopping at high speed to form a chopped fiber-shaped pulp fiber, washing and drying after suction filtration to obtain the PPTA-pulp. The prepared PPTA-pulp has good fiber morphology, and high specific surface area; the feather-shaped structure feature of the pulp is obvious; meanwhile, excellent high temperature resistance is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Graphene/polysiloxane spun fiber membrane and preparation method thereof

ActiveCN113529281AGood compatibilityGood dispersionElectro-spinningConjugated synthetic polymer artificial filamentsPolymer scienceSpinning

The invention provides a graphene / polysiloxane spun fiber membrane and a preparation method thereof. The preparation method comprises the following steps of dispersing graphene in a silane dilute solution, and performing a stirring reaction to obtain a graphene suspension; uniformly mixing graphene turbid liquid with a multifunctional silane monomer, adding a catalyst, performing a hydrolysis pre-polycondensation reaction, and removing small molecules under reduced pressure to prepare a prepolymer; dissolving the prepolymer in an organic solvent to prepare a polymer spinning solution; and carrying out electrostatic spinning. According to the preparation method, the polycondensation degree, the crosslinking degree and the structure of the polysiloxane prepolymer for spinning are regulated and controlled, a polysiloxane sol-gel chemical process in a short time of electrostatic spinning is accurately controlled, and graphene is supplemented for supporting and enhancing the fiber performance, so that the graphene / polysiloxane spun fiber membrane is prepared, and the technical difficulty of curing forming of polysiloxane spun fiber is overcome. The prepared fiber membrane has important application prospects in the fields of electrochemistry, catalysis, sensors, adsorption and separation, flexible electronic elements and medical engineering.

Owner:SHANDONG UNIV

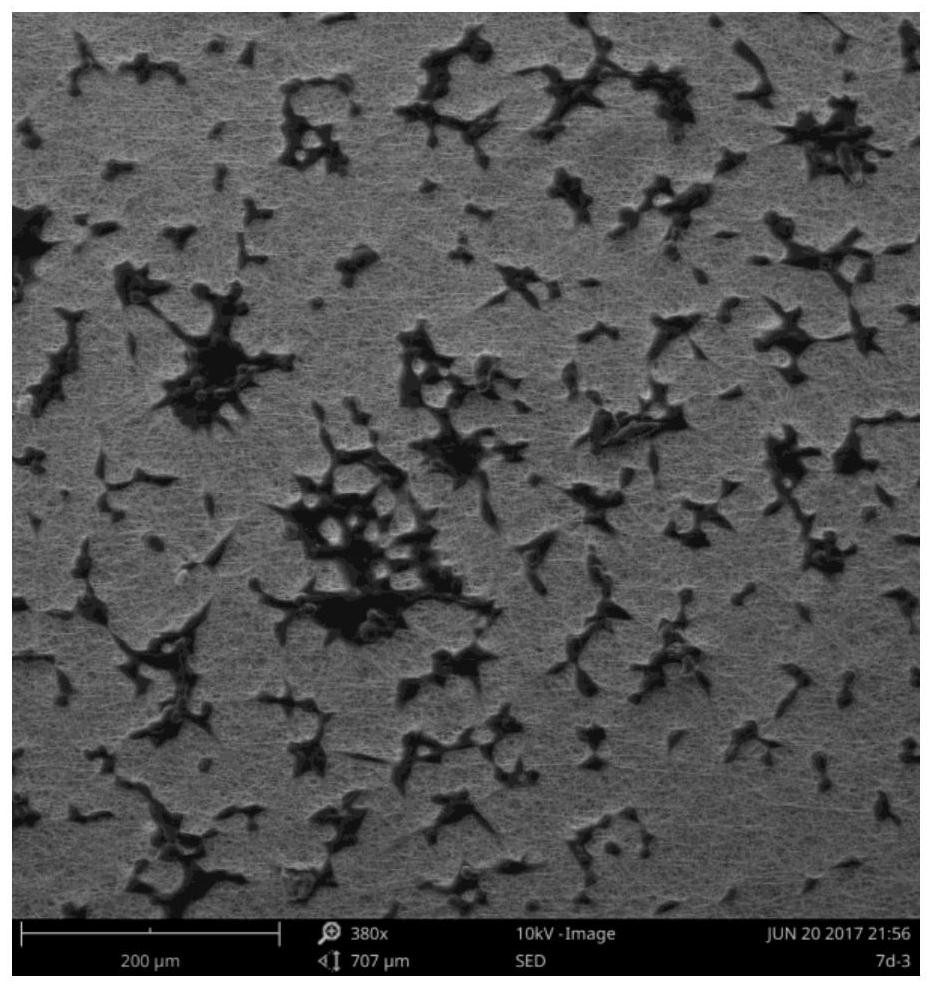

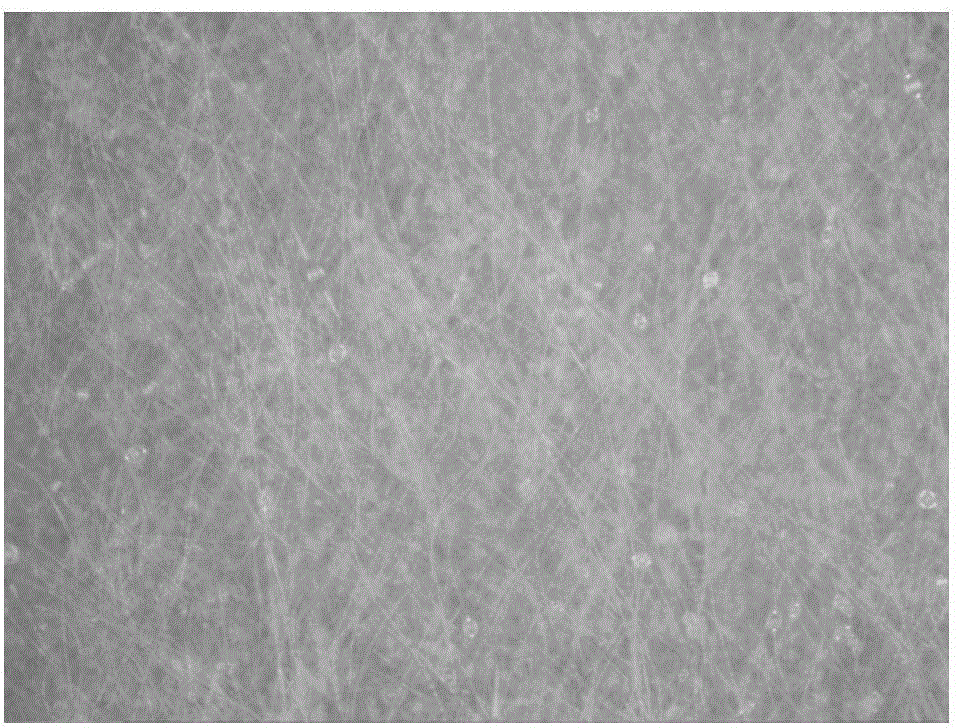

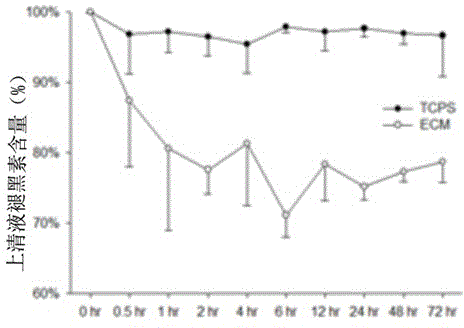

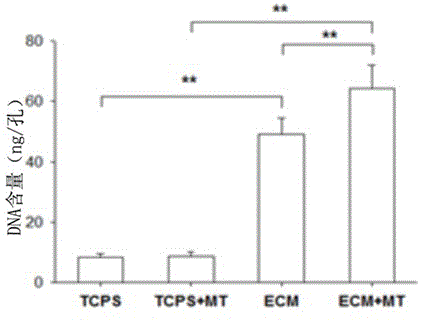

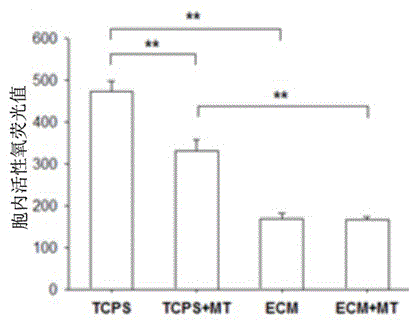

Application of melatonin in synergy with extracellular matrix biomaterials in the preparation of drugs to promote osteogenic differentiation of mesenchymal stem cells

InactiveCN103736150BGood fiber shapeFacilitate depositionSkeletal/connective tissue cellsProsthesisOsseous DifferentiationDisease

Owner:SUN YAT SEN UNIV

Lasting mutually promoting and win-win developing implementation scheme for wood plastic production, resource exploitation and environment protection

InactiveCN102241888AImprove textureIncrease the lengthWood working apparatusPulping with inorganic basesFiberEcological environment

The invention relates to a lasting mutually promoting and win-win developing implementation scheme for wood plastic production, resource exploitation and environment protection. The scheme is characterized in that: osier is planted in low-lying areas which are easy to be flooded, and sword iris is planted in saline-alkali lands; osier powder and sword iris fiber are used for replacing wood powder, such that the lasting mutually promotion and win-win development of wood plastic production, low-lying flooded area treatment, saline-alkali land treatment and ecological environment protection can be realized. With the scheme, wood plastic production is changed from a dependant industry into a leading industry; the dependence of wood plastic base material on wood is solved; a problem of insufficient biomass base material is solved; a history that wood products are dependant on deforestation is ended; the performance of wood plastic material is improved; wood plastic composite material with light weight and high toughness is produced; and ecological environment is obviously improved. With the scheme, an integral production system of osier powder, sword iris fiber and wood plastic composite material is established; and problems in each link can be coordinated and solved scientifically and quickly. Therefore, a lasting mutually promotion and win-win development of wood plastic production, resource exploitation and environment protection can be ensured.

Owner:翟云升

A kind of pelcl/polycaprolactone-g-polyethylene glycol-redv electrospun fiber membrane and preparation method

InactiveCN106581751BGood fiber shapeLow viscosityPharmaceutical delivery mechanismNon-woven fabricsFiberVascular endothelium

Owner:TIANJIN UNIV

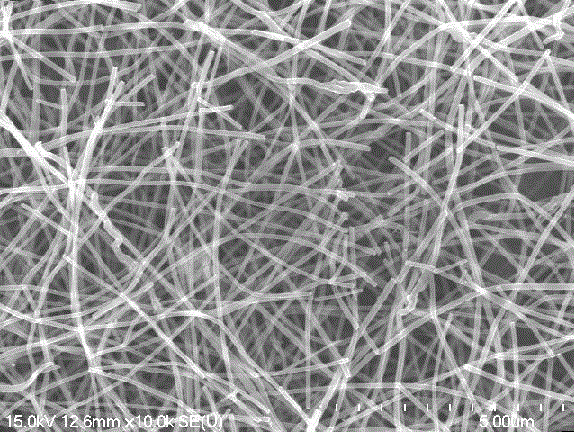

A kind of preparation method of composite micro-nano fiber film for biological dressing

The invention discloses a method for preparing a biological dressing composite micro-nano fiber membrane. The method can solve the main problems in electrostatic spinning of collagen and chitosan. According to the method, a mixed solution of hexafluoroisopropanol and acetic acid, and an acetic acid water solution serve as a spinning solvent of a high molecular weight I-type collagen and a spinning solvent of the chitosan respectively, and then the toxicity and the cost of the solvent are reduced; a cross-linking agent genipin with excellent biocompatibility is directly added into a spinning solution to allow electrostatic spinning and chemical crosslinking to effectively combine together, so that the secondary biological toxicity due to the conventional crosslinking manner can be avoided; and the prepared collagen / chitosan / polyoxyethylene composite micro-nano fiber membrane is excellent in fiber morphology and biocompatibility, can serve as a biological dressing material, and has the functions of hemostasis, antibiosis, and wound healing.

Owner:ZHEJIANG TEXTILE GARMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com