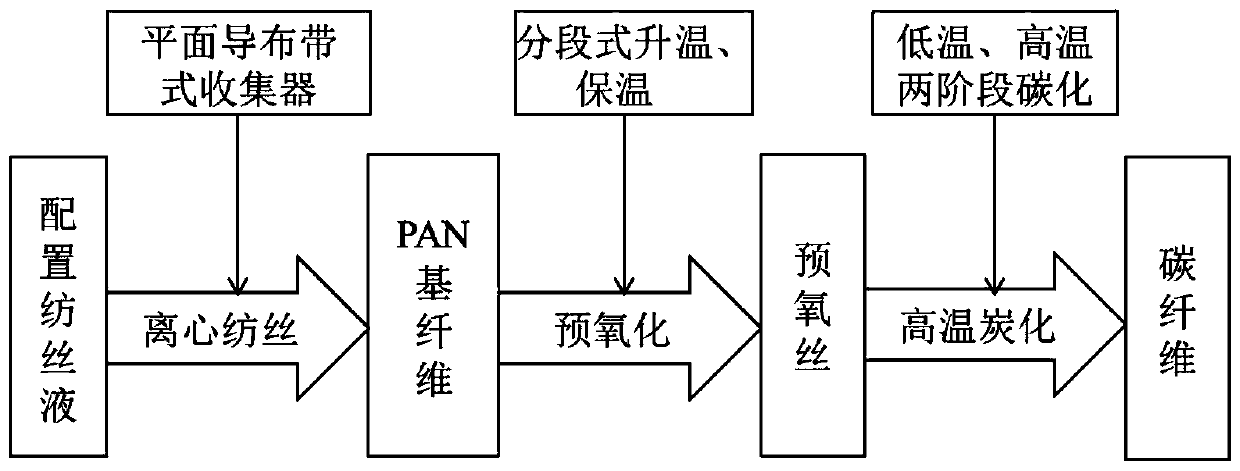

Centrifugal spinning preparation method of polyacrylonitrile-based pre-pre-oxidized fibers and carbon fibers

A polyacrylonitrile-based pre-oxidized yarn, polyacrylonitrile-based long technology, applied in fiber processing, fiber chemical characteristics, filament/thread forming, etc., can solve the limitations of large-scale application of centrifugal spinning, poor performance of carbon fiber, fiber Discontinuity and other problems, to achieve the effect of improved spinning efficiency and quality, good heat resistance and stability, and uniform diameter distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A preparation method for centrifugal spinning of polyacrylonitrile-based pre-oxidized yarn, comprising the following steps:

[0056] S1. Preparation of spinning solution: dissolve the dried polyacrylonitrile powder in N,N-dimethylformamide, stir for 4 hours to dissolve completely, and then let it stand in a vacuum drying oven for 1 hour to prepare the mass concentration Be the spinning solution of 22wt%;

[0057] S2. Centrifugal spinning: The spinning solution prepared in step S1 is centrifugally spun at 60° C., the spinneret aperture is 0.16 mm, the receiving distance is 5 cm, and the spinning speed is 7000 r / min to obtain polyacrylonitrile-based long fiber;

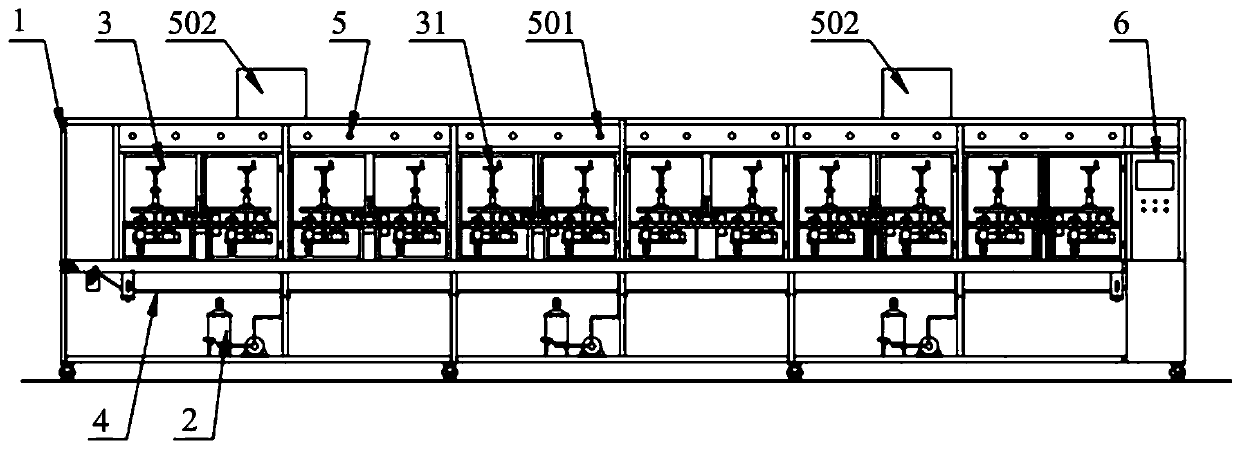

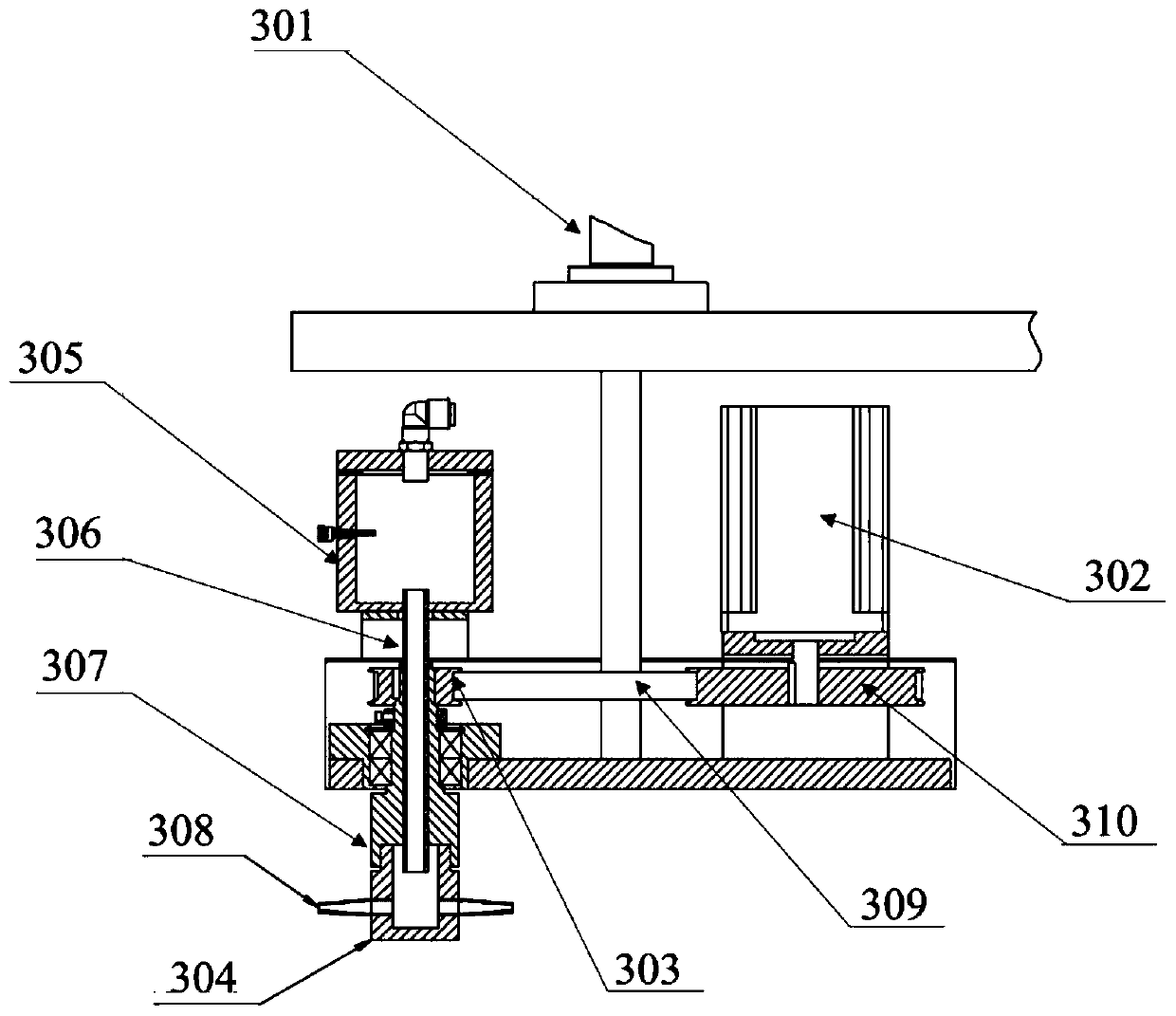

[0058] The fiber collector of the centrifugal spinning device used in the centrifugal spinning is a flat cloth guide belt collector, and the cloth guide belt is transported and collected by guide rollers; in the spinning process, the jet is solidified into continuous filaments by heat radiation , the continuous...

Embodiment 2-7

[0066] Compared with Example 1, the centrifugal spinning preparation method of polyacrylonitrile-based pre-oxidized yarn provided by Examples 2-7 differs in that the content of PAN powder in the spinning solution is as shown in Table 1, and the others are basically the same as those in Example 1. Same, no more details here.

[0067] Table 1 embodiment 2-7 spinning solution composition

[0068] Example DMF(g) PAN(g) 2 85 15 3 82 18 4 80 20 5 79 21 6 77 23 7 75 25

[0069] Figure 5 Among them, 5-1 to 5-4 are scanning electron micrographs of the polyacrylonitrile-based long fibers prepared by centrifugal spinning in Example 1 and Example 4-6 respectively. It can be seen that with the increase of polyacrylonitrile in the spinning solution, When the concentration increases, the fiber diameter and uniformity first increase and then decrease, when the concentration is 22wt% ( Figure 5-3 ), the fiber diameter distribution is t...

Embodiment 8-13

[0071] Compared with Example 1, the centrifugal spinning preparation method of the polyacrylonitrile-based pre-oxidized yarn provided by Examples 8-13 differs in that polyvinyl butyral is added in the spinning solution, and the spinning solution composition is as follows: As shown in Table 2, the others are basically the same as in Embodiment 1, and will not be repeated here.

[0072] Table 2 embodiment 8-13 spinning solution composition

[0073] Example DMF(g) PAN(g) PVB(g) 8 77 9.2 13.8 9 77 6.9 16.1 10 77 8.05 14.95 11 75 10 15 12 80 9 11 13 85 6 9

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com