High-adhesion polysulfide sealant

A polysulfide sealant and high-adhesion technology, applied in the field of sealants, can solve problems such as increasing the adhesion performance of polysulfide sealants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

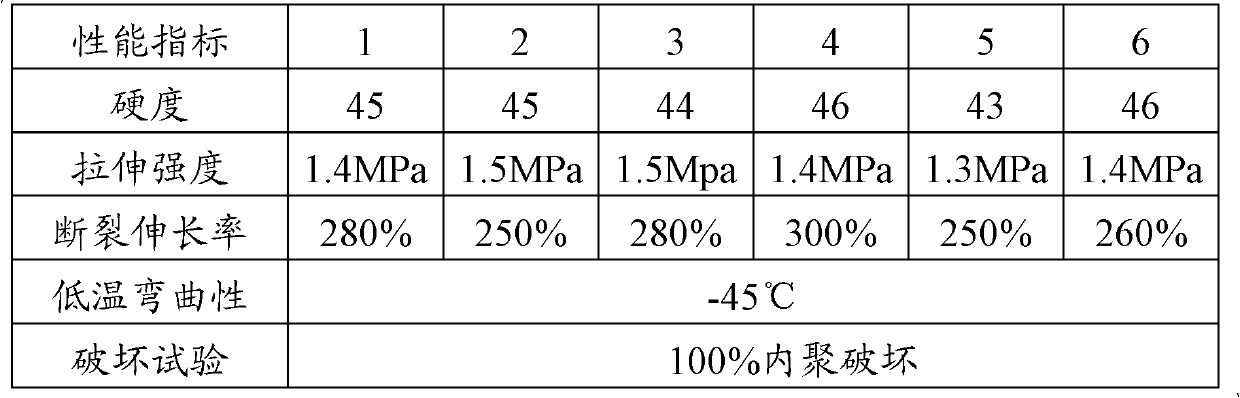

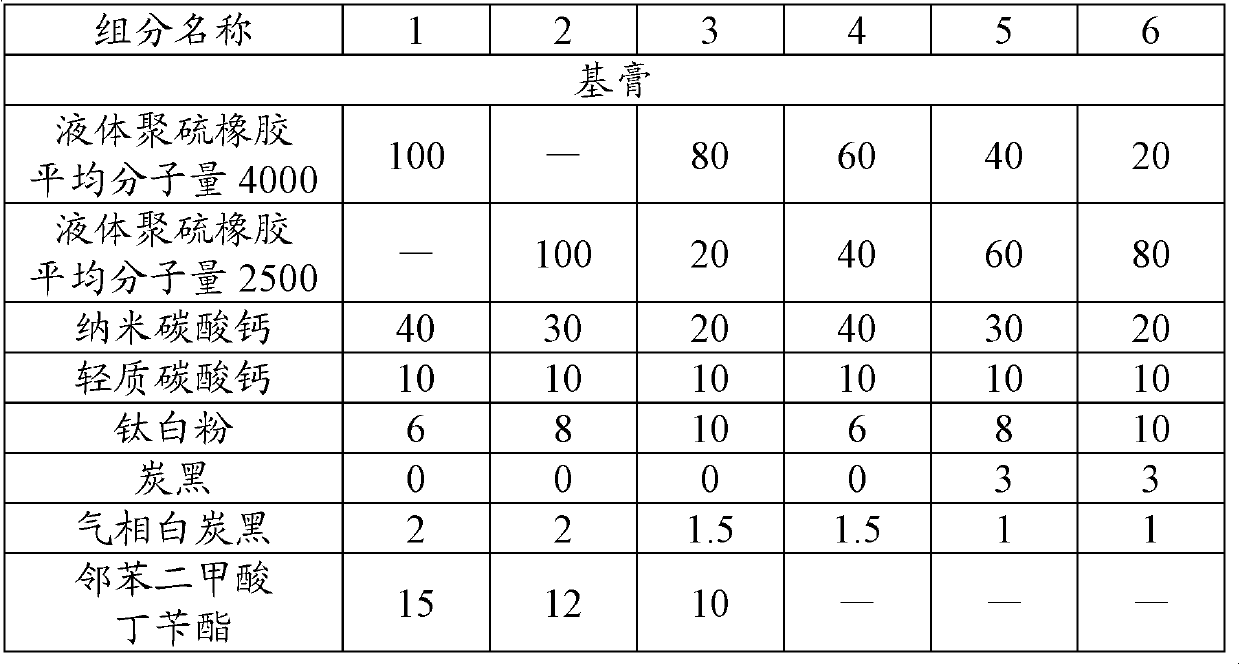

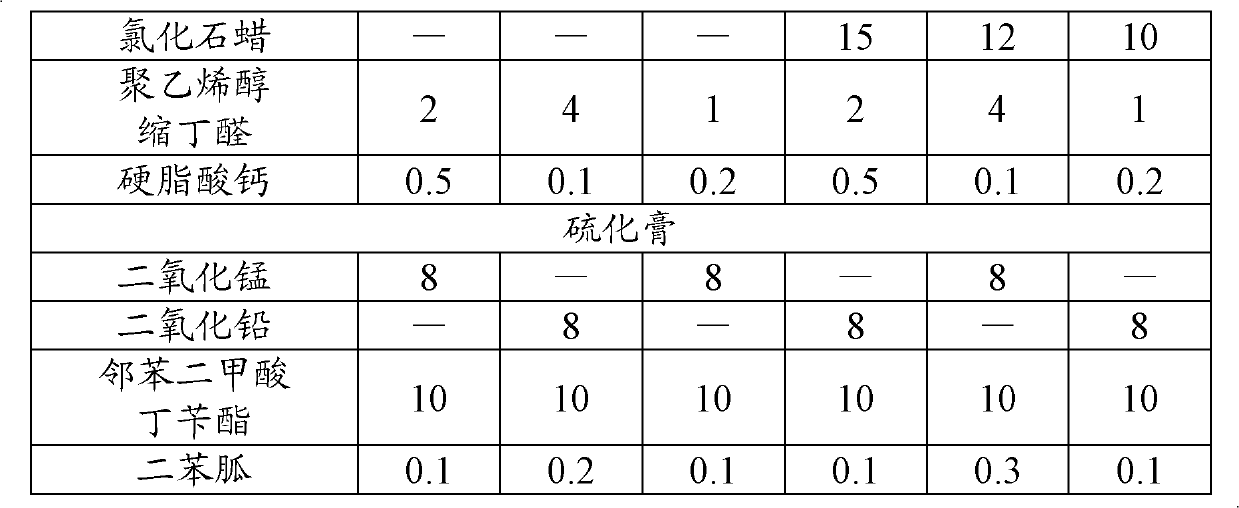

[0033] Six formulations in Table 1 were used to prepare polysulfide adhesives.

[0034] The base paste (A component) and vulcanized paste (B component) are prepared and kneaded separately.

[0035] When weighing the base paste raw materials, first weigh solid materials such as nano-calcium carbonate, light calcium carbonate, titanium dioxide, carbon black, and fumed silica, and then weigh liquid materials such as liquid polysulfide rubber; after mixing the above liquid materials evenly, , and then mix them with the previously weighed solid materials in order, and fully wet them.

[0036] When preparing vulcanized paste, first weigh manganese dioxide and plasticizer and mix them evenly; then weigh other components, mix them and fully wet them.

[0037] The amount of diphenylguanidine should be adjusted according to different use environments. When the temperature is low, the amount should be increased appropriately, and the curing cycle should be adjusted to about 7 days.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com