Method for preparing silicon-nitride ceramic substrate through silicon-powder tape casting

A technology for silicon nitride ceramics and silicon powder is applied in the field of silicon powder casting to prepare silicon nitride ceramic substrates. superior effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

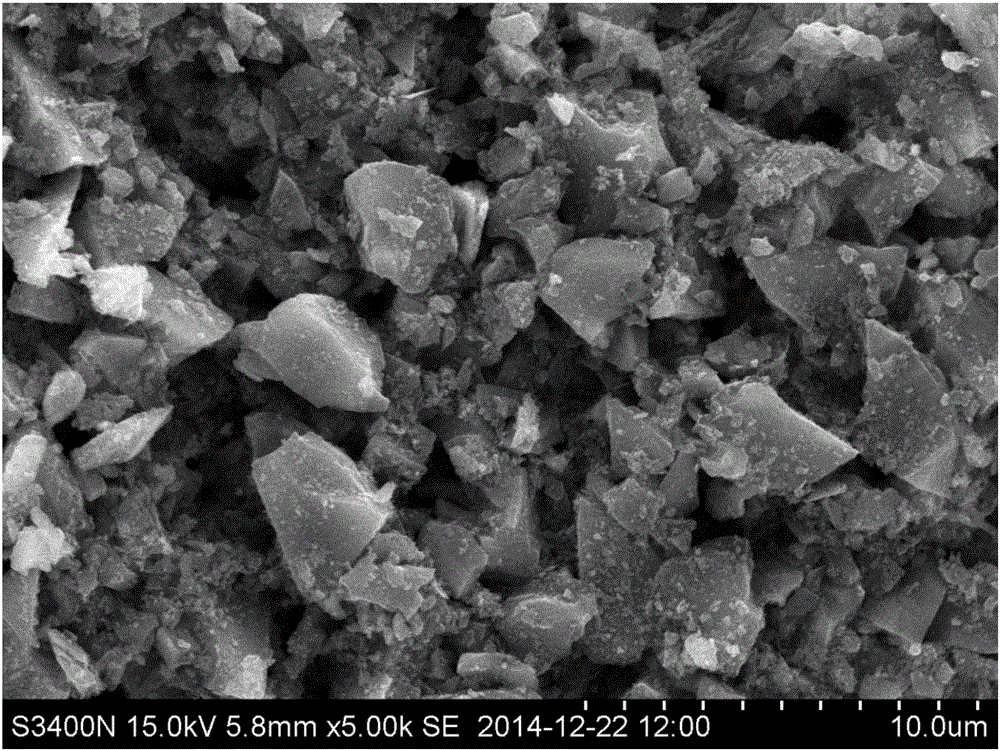

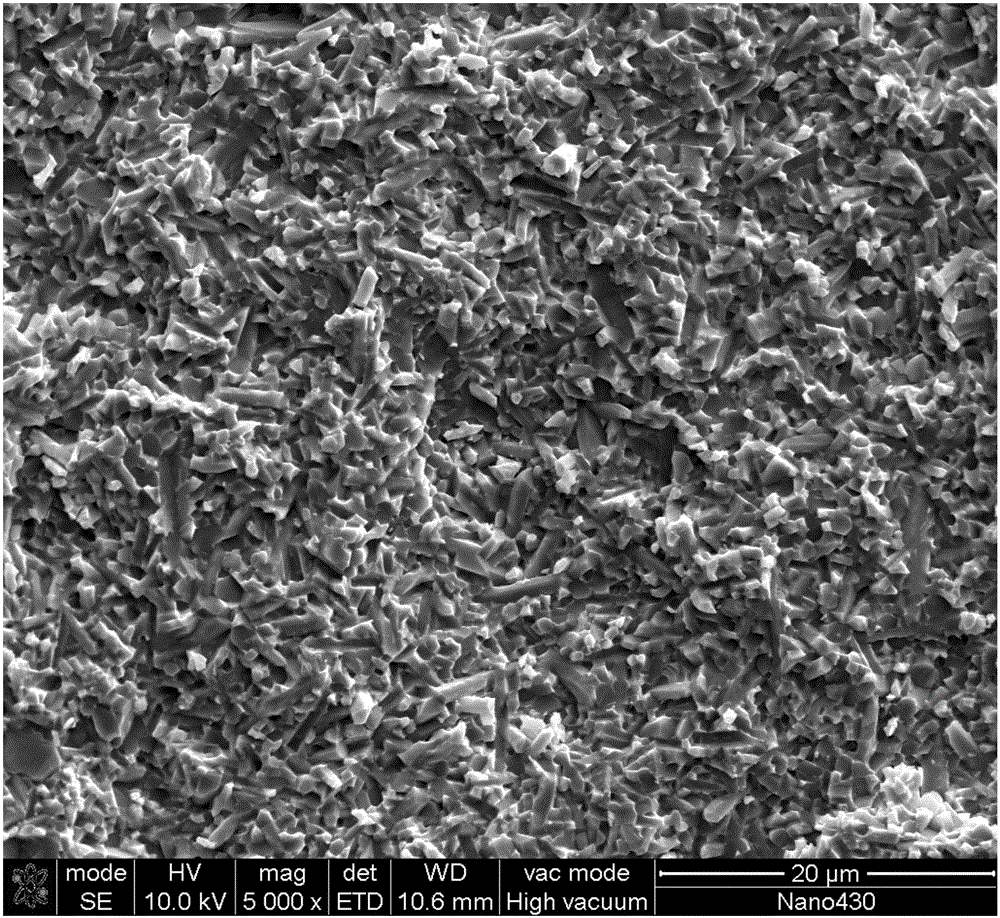

[0030] (1) Preparation of cast slurry: ①Weigh silicon powder (d50=4μm), inorganic sintering aid and dispersant according to the ratio; wherein, the inorganic sintering aid is MgO, Lu 2 o 3 and ZrO 2 The mixture (MgO:Lu 2 o 3 :ZrO 2 =2:8:3), the ratio of inorganic sintering aid powder to silicon powder is 1:9; the dispersant is castor oil, and the ratio of dispersant to silicon powder is 1:50; the added weight is inorganic matter (silicon powder , inorganic sintering aids and dispersants) 1.2 times the absolute ethanol-butanone azeotrope, with silicon nitride balls as the ball milling medium, mixed ball milling for 20 hours; Type plasticizer; Wherein, plasticizer is triethylene glycol diisocaprylate, and the ratio of plasticizer to silicon powder is 1:8; Adhesive is polyvinyl butyral, and the ratio of adhesive to silicon powder 1:8; mixed ball milling again for 24 hours; ③ the slurry obtained after ball milling was defoamed under the condition of vacuum degree of 0.1Pa to ...

Embodiment 2

[0033] (1) Preparation of cast slurry: ①Weigh silicon powder (d50=4μm), inorganic sintering aid and dispersant according to the ratio; wherein, the inorganic sintering aid is MgO, Lu 2 o 3 and ZrO 2 The mixture (MgO:Lu 2 o 3 :ZrO 2 =2:8:3), the ratio of inorganic sintering aid powder to silicon powder is 1:9; the dispersant is castor oil, and the ratio of dispersant to silicon powder is 1:50; the added weight is inorganic matter (silicon powder , inorganic sintering aids and dispersants) 1.2 times the absolute ethanol-butanone azeotrope, with silicon nitride balls as the ball milling medium, mixed ball milling for 20 hours; Type plasticizer; Wherein, plasticizer is triethylene glycol diisocaprylate, and the ratio of plasticizer to silicon powder is 1:8; Adhesive is polyvinyl butyral, and the ratio of adhesive to silicon powder 1:8; mixed again and ball milled for 24 hours; ③The slurry obtained after ball milling was defoamed under the condition of vacuum degree of 0.1 Pa ...

Embodiment 3

[0037] (1) Preparation of cast slurry: ①Weigh silicon powder (d50=8μm), inorganic sintering aid and dispersant according to the proportion. Among them, the inorganic sintering aids are MgO, Gd 2 o 3 and ZrO 2 The mixture (MgO:Lu 2 o 3 :ZrO 2 =2:8:3), the ratio of inorganic sintering aid powder to silicon powder is 1:9; the dispersant is castor oil, and the ratio of dispersant to silicon powder is 1:50. Add anhydrous ethanol-butanone azeotrope whose weight is 1.5 times of inorganic matter (silicon powder, inorganic sintering aid and dispersant), use silicon nitride balls as ball milling medium, and mix ball milling for 20 hours; Adhesive and environment-friendly plasticizer are added to the material; among them, the plasticizer is triethylene glycol di-n-heptanoate, and the ratio of plasticizer to silicon powder is 1:10; the adhesive is polyvinyl butyral, The ratio of adhesive to silicon powder is 1:10; mix and ball mill again for 24 hours; ③ defoam the slurry obtained af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com