Patents

Literature

181results about How to "Improve spinning quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

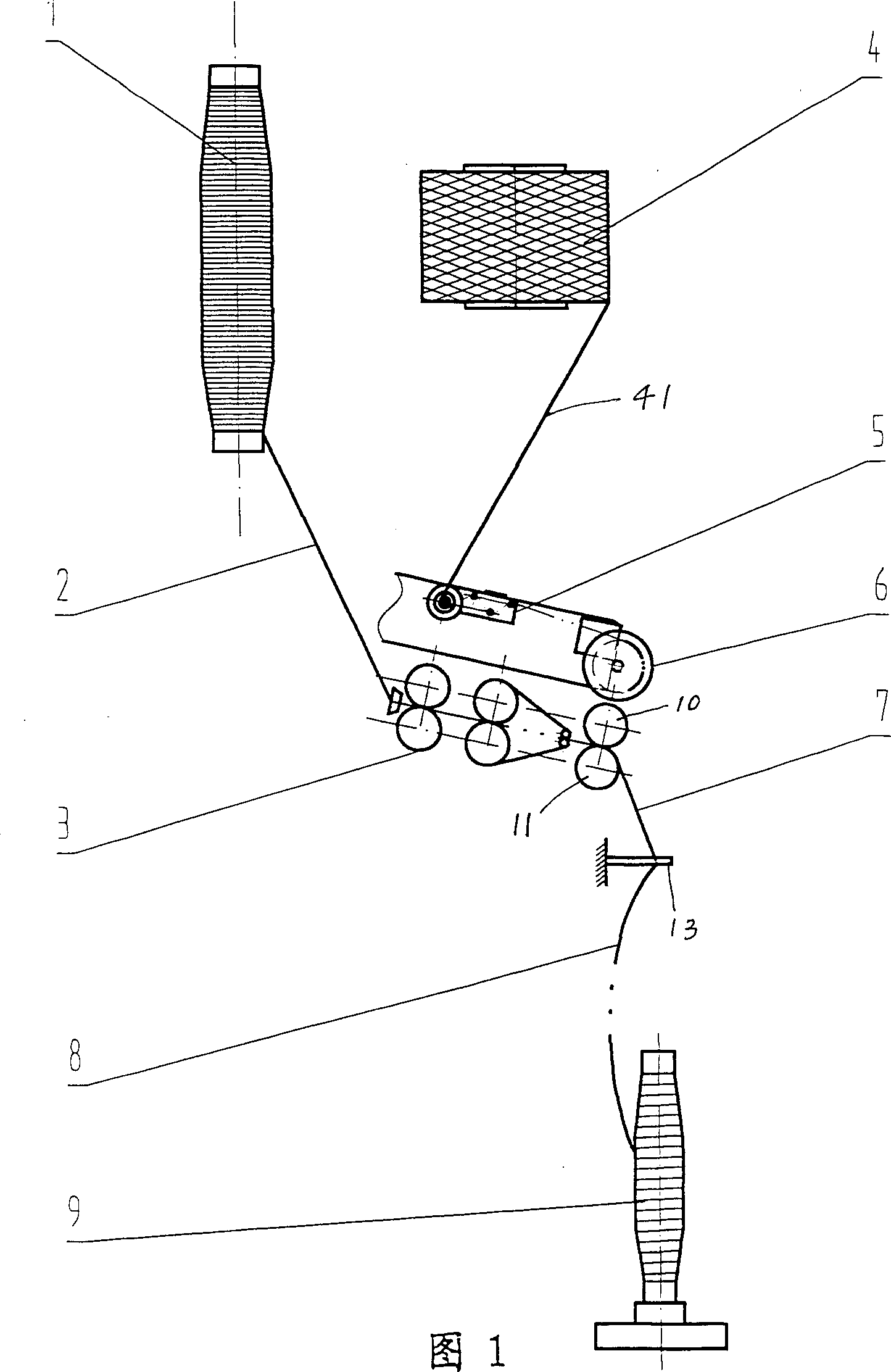

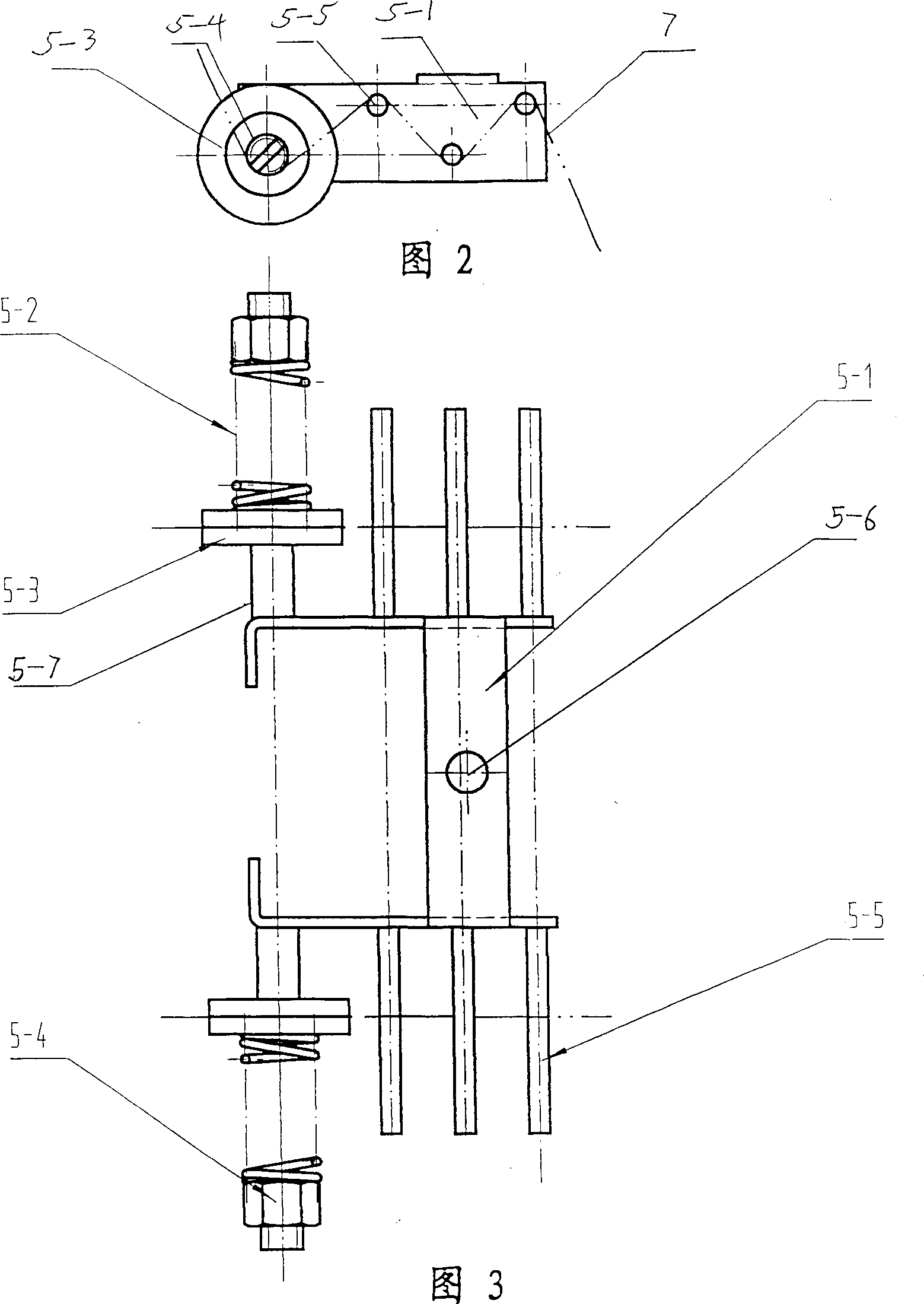

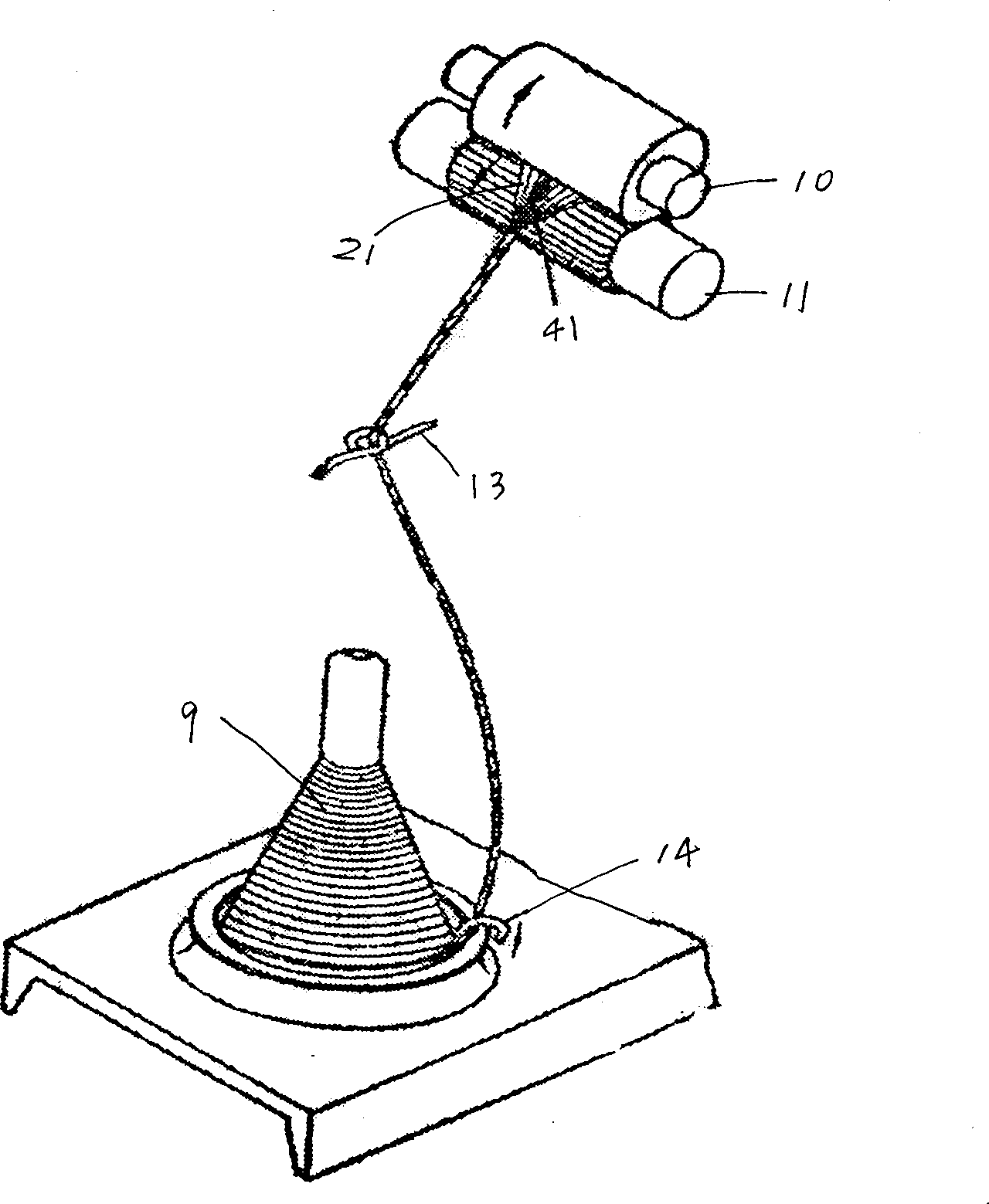

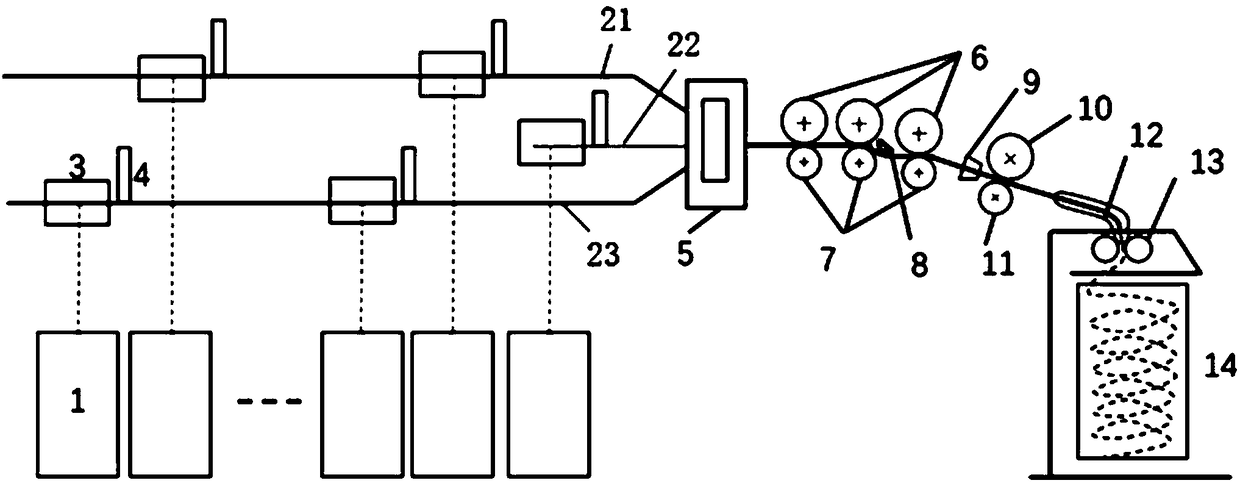

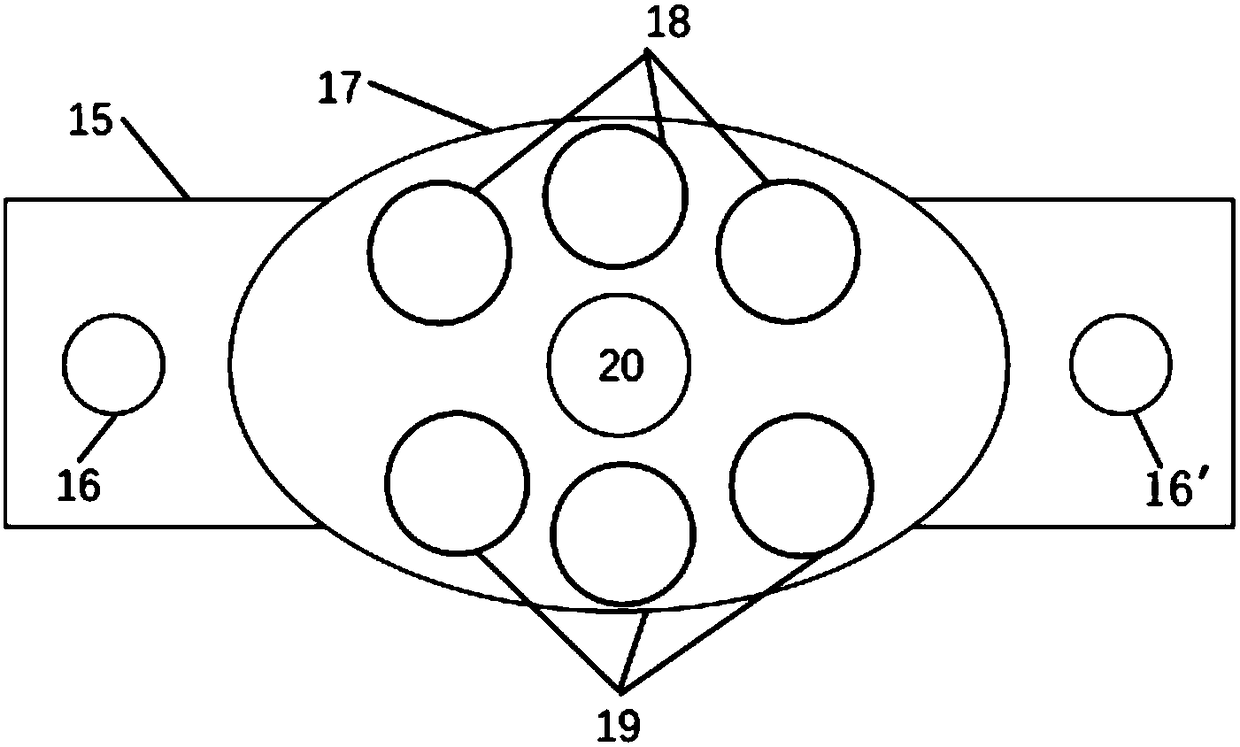

Method and apparatus for making core-spun yarn of steple-fibre covered filament

The present invention is characterized by that on the spinning machine it utilizes addition of a yarn tension control device and simple renovation of guide wheel to spin the invented core-spun composition yarn whose yarn is covered with staple fiber, and its covering rate is high. Said composite core-covered yarn not only has the appearance style, hand property, fluffy property and other advantages of staple fibre, but also possesses the strength and elongation, conformal property and drapping property, etc. of yarn.

Owner:薛元

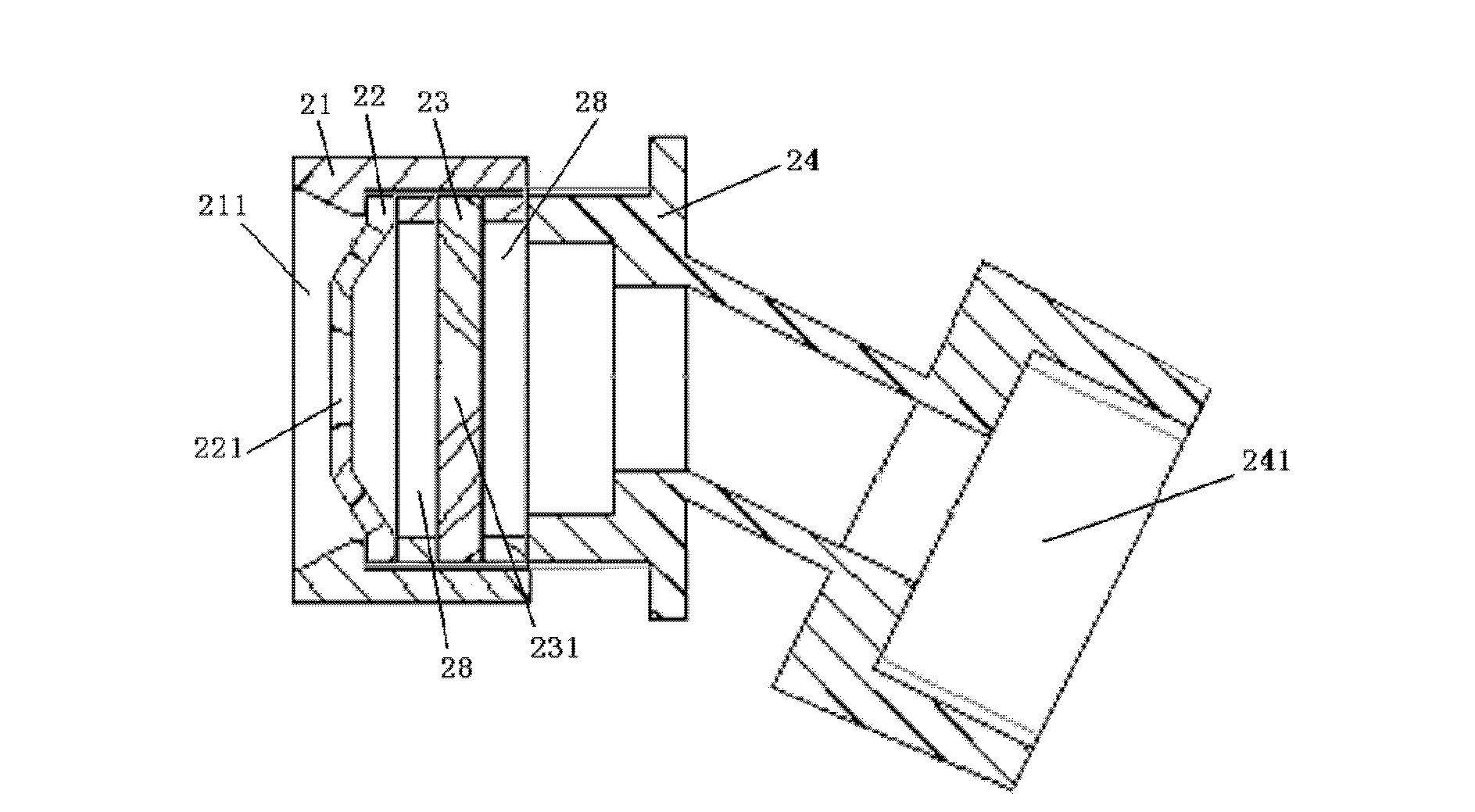

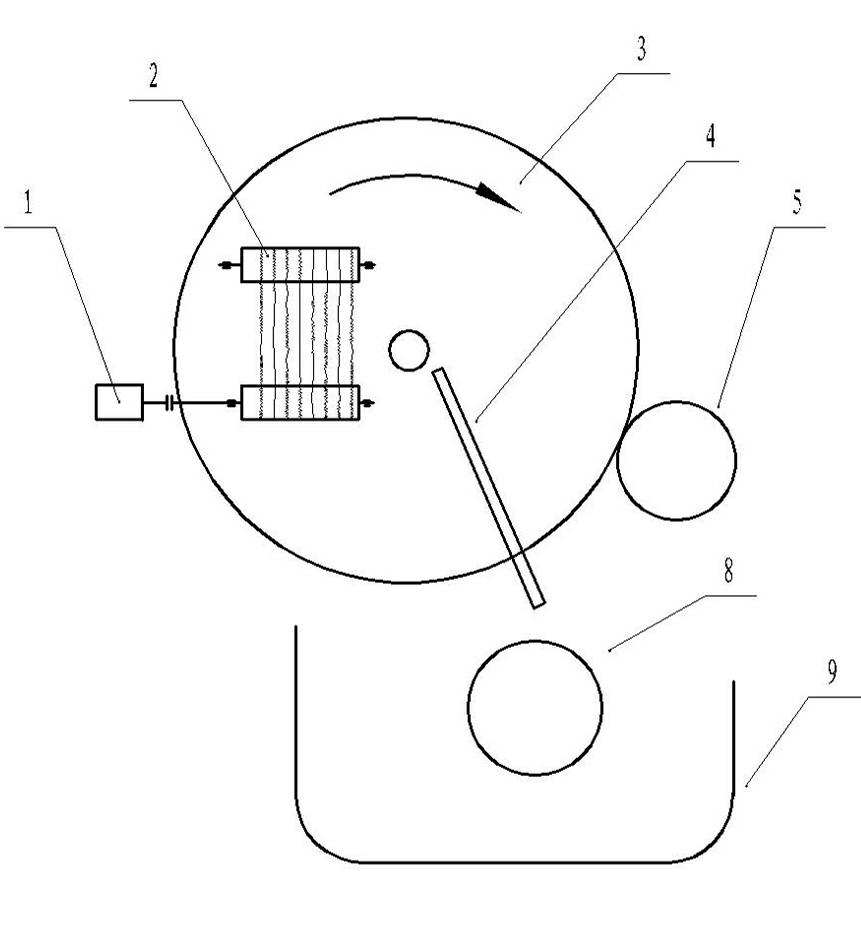

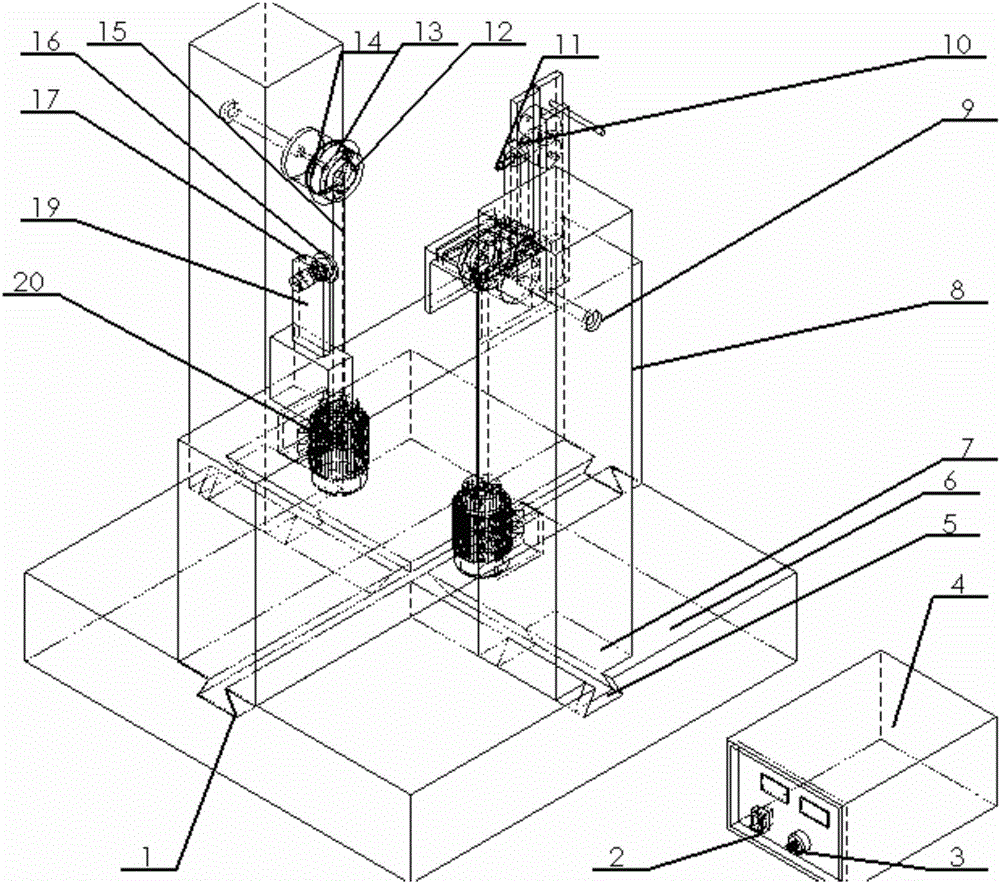

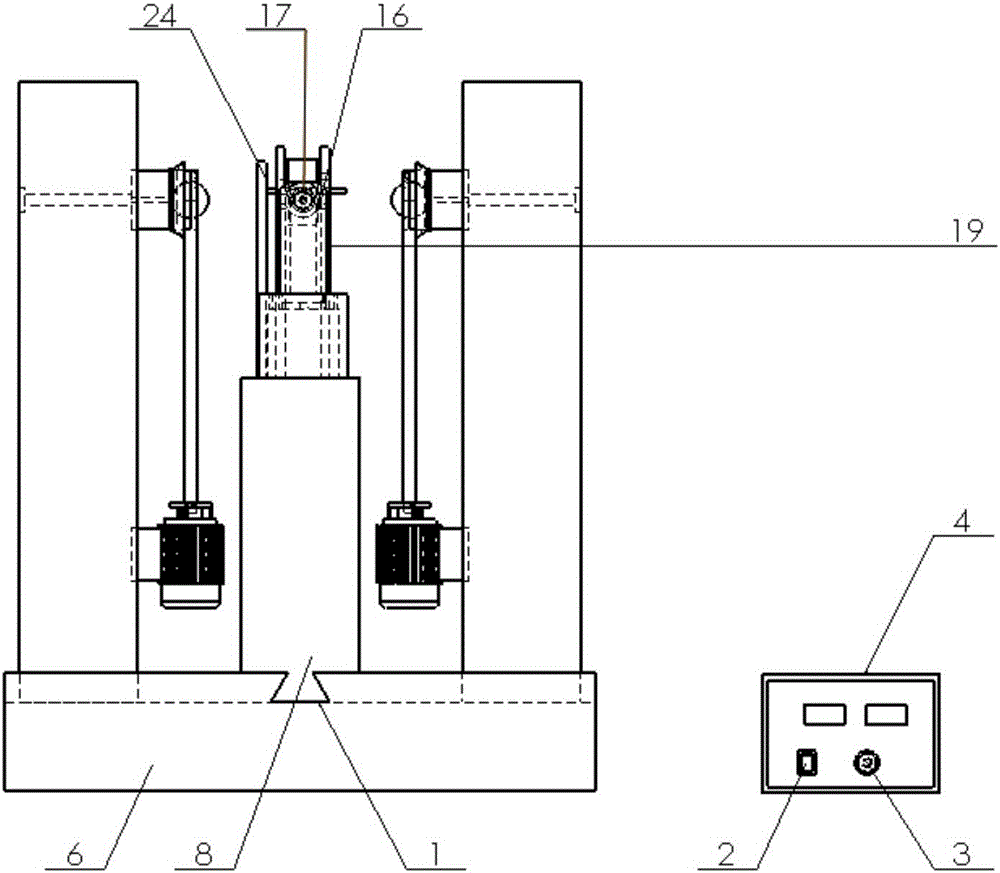

High-speed centrifugal spinning device for producing nanofiber yarn in one-step shaping and production method of nanofiber yarn

InactiveCN105887223AImprove mechanical propertiesIncrease productionArtificial thread manufacturing machinesFilament/thread formingYarnFiber

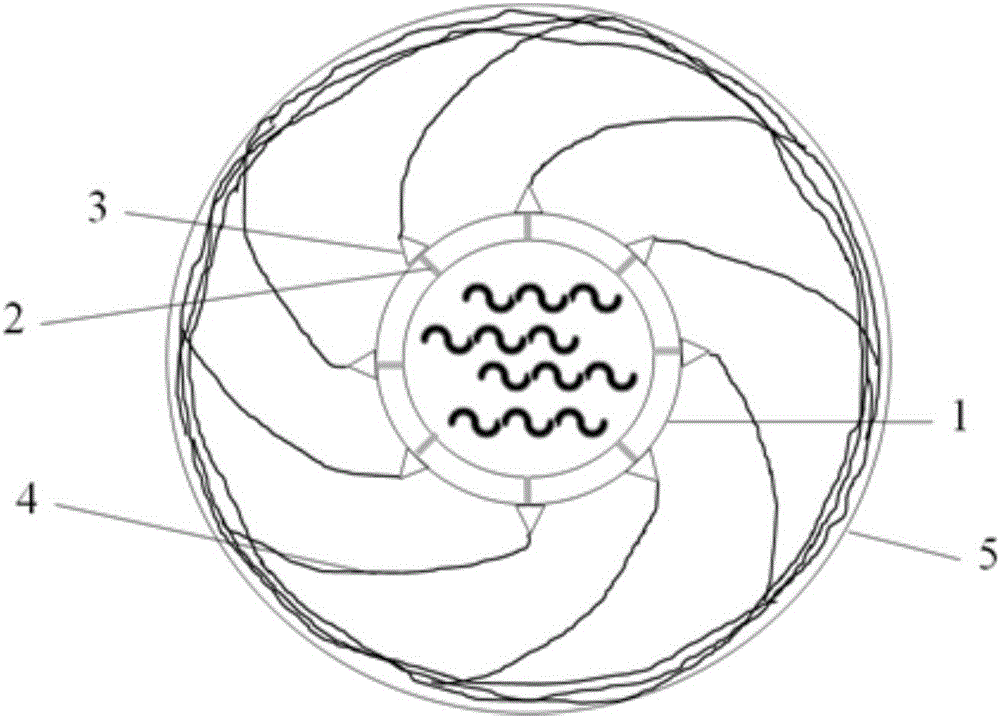

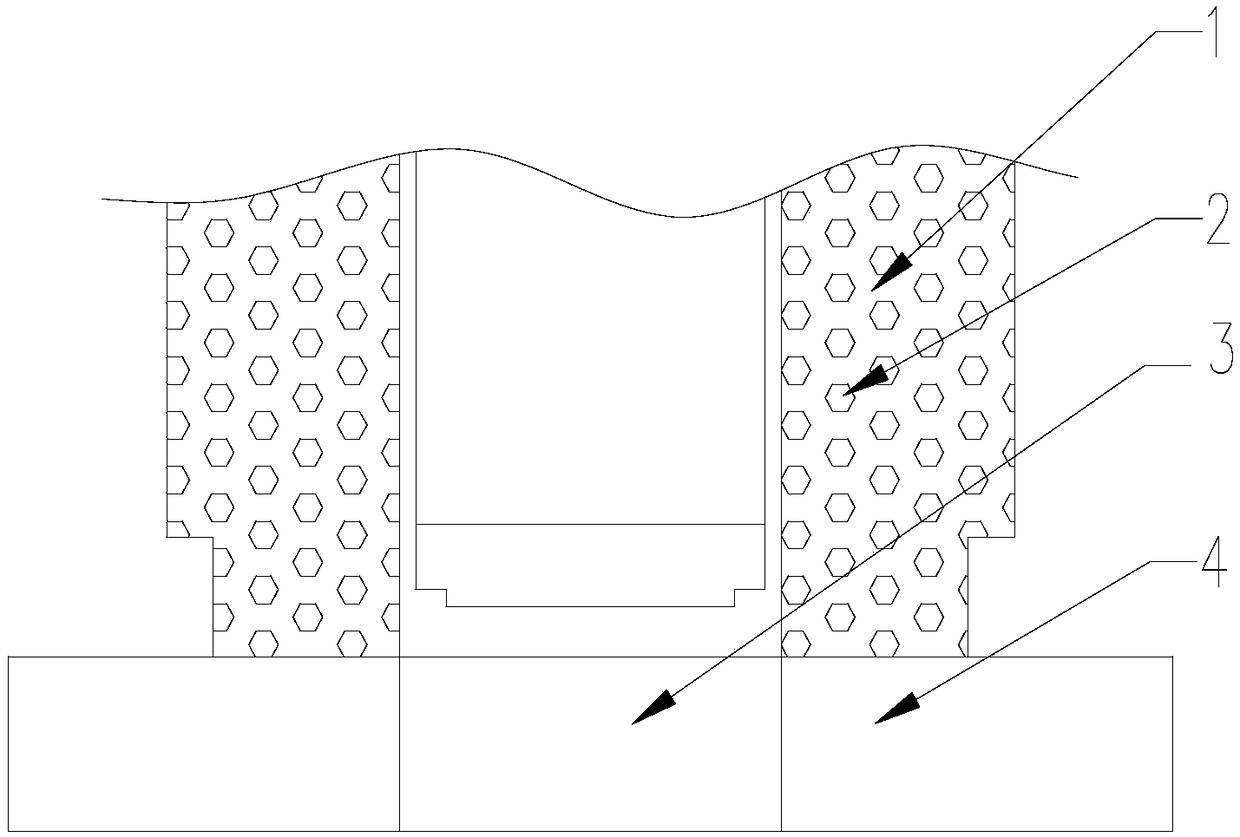

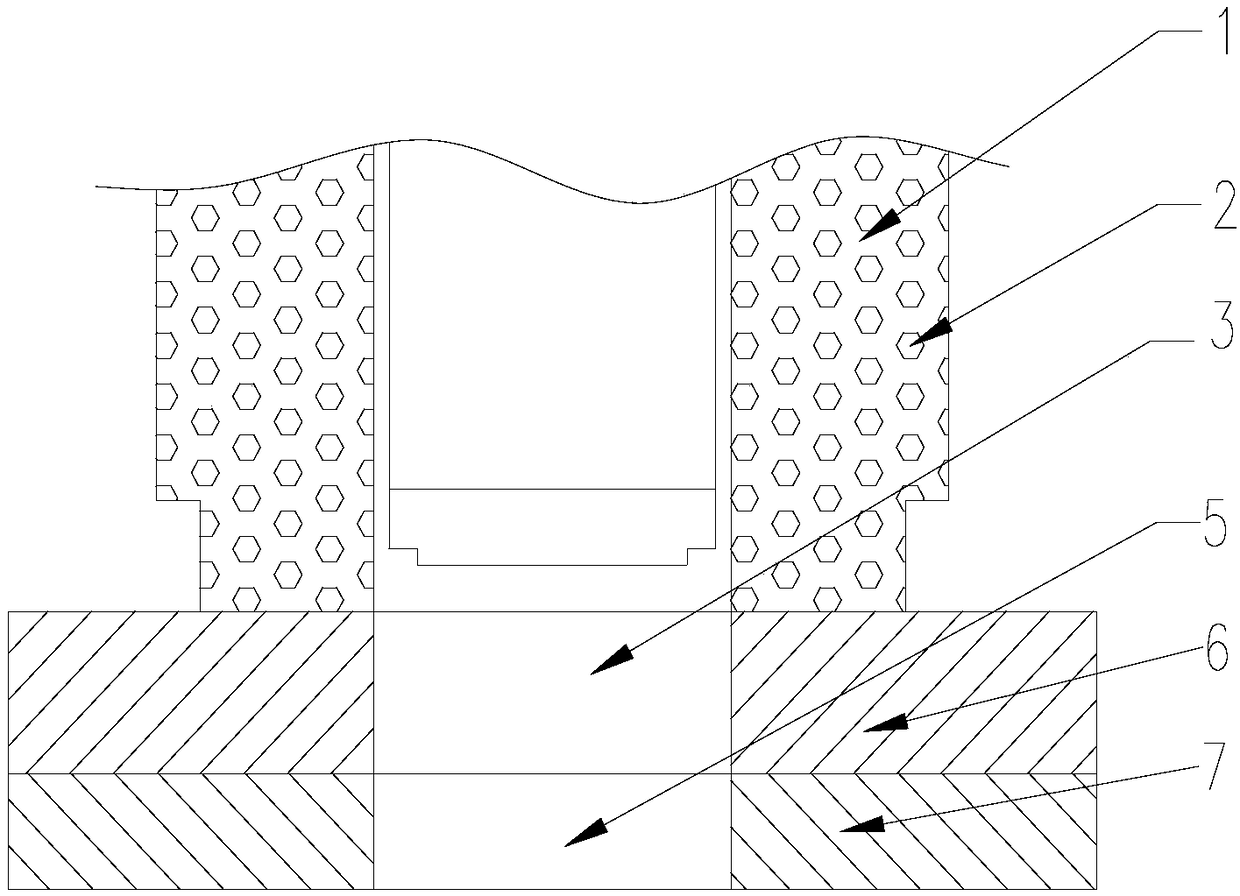

The invention discloses a high-speed centrifugal spinning device for producing nanofiber yarn. The high-speed centrifugal spinning device is characterized by comprising a hollow rotating centrifugal column, a rotating cylinder collector, a roller, a winding unit and a transmission gear; a plurality of spray nozzles are arranged in the outer wall of the rotating centrifugal column, and the spray nozzles are communicated with a central cavity of the rotating centrifugal column through radial channels in the rotating centrifugal column; the rotating cylinder collector is located on the outer periphery of the rotating centrifugal column; the roller is located on the upper side of the rotating cylinder collector; the winding unit is located at the rear end of the roller, and the transmission gear drives the winding unit to rotate. The invention further discloses a production method of the nanofiber yarn. According to the advantages of the high-speed centrifugal spinning device in producing the nanofiber yarn, and spinning of the collector is combined technically, the nanofiber yarn which is controllable and highly oriented is obtained; the yield is greatly increased as compared with that of the nanofiber yarn obtained by other production methods, spinning quality is greatly improved, mechanical property of the nanofiber yarn is enhanced, machining reproducibility is good, and good industrial production prospect is achieved.

Owner:JIANGNAN UNIV

Equipment operating and process quality state monitoring system for high-speed rolling mill

ActiveCN102059256AState of economic productionImprove spinning qualityMeasuring devicesMetal rolling arrangementsProcess qualityData acquisition

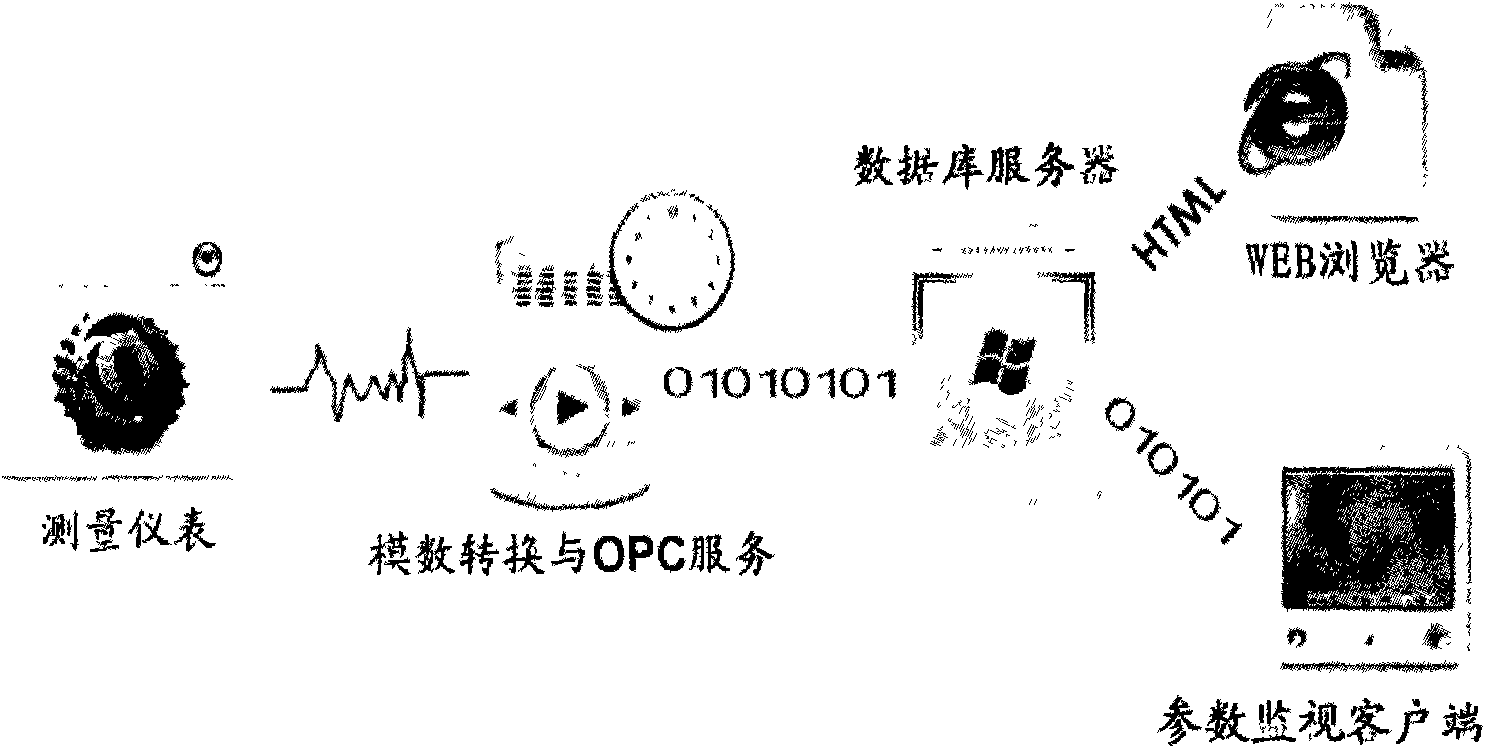

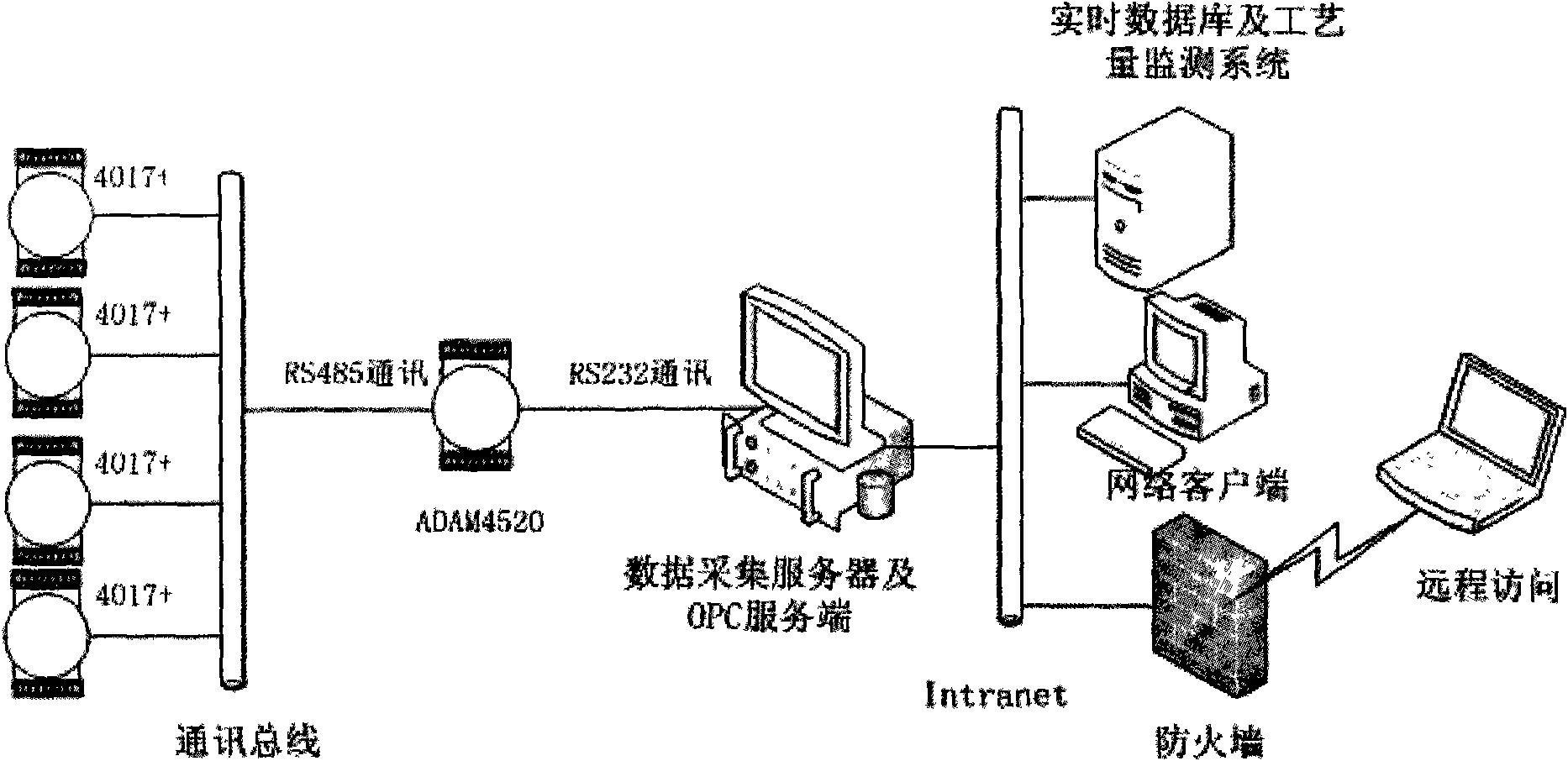

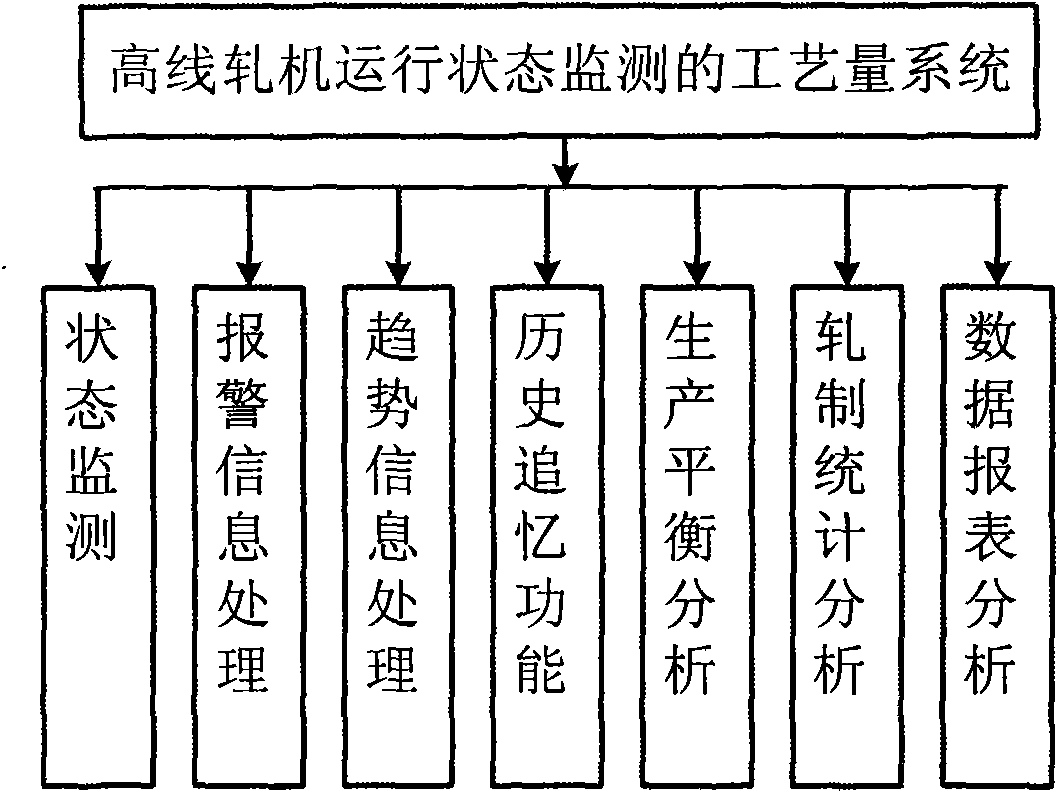

The invention discloses an equipment operating and process quality state monitoring system for a high-speed rolling mill, belonging to the technical field of high-speed wire rolling. Hardware comprises sensors for electric quantity, rotation speed and the like, a 4017+ intelligent data acquisition module, an RS485-RS232 communication conversion module and an industrial control computer. A rolling current signal, a rolling rotation speed signal and other signals are measured by the sensors, then subjected to A / D (Analog to Digital) conversion by the data acquisition module and then stored into the industrial control computer through the RS485-RS232 communication conversion module, the acquired data are issued to a network by utilizing an OPC (OLE (Object Linking and Embedding) for Process Control) protocol, and a user extracts the recorded information from an IE browser or a client side through the network for observing and analyzing. Software comprises an OPC communication module, an operation state real-time monitoring module, an alarm information recording and analyzing module, a trend information analyzing and processing module, a historical recall functional module and an industrial signal logic analysis module. The equipment operating and process quality state monitoring system has the advantages of improving the reliability for equipment operation, prolonging the service life and effectively lowering the cost.

Owner:SHOUGANG CORPORATION

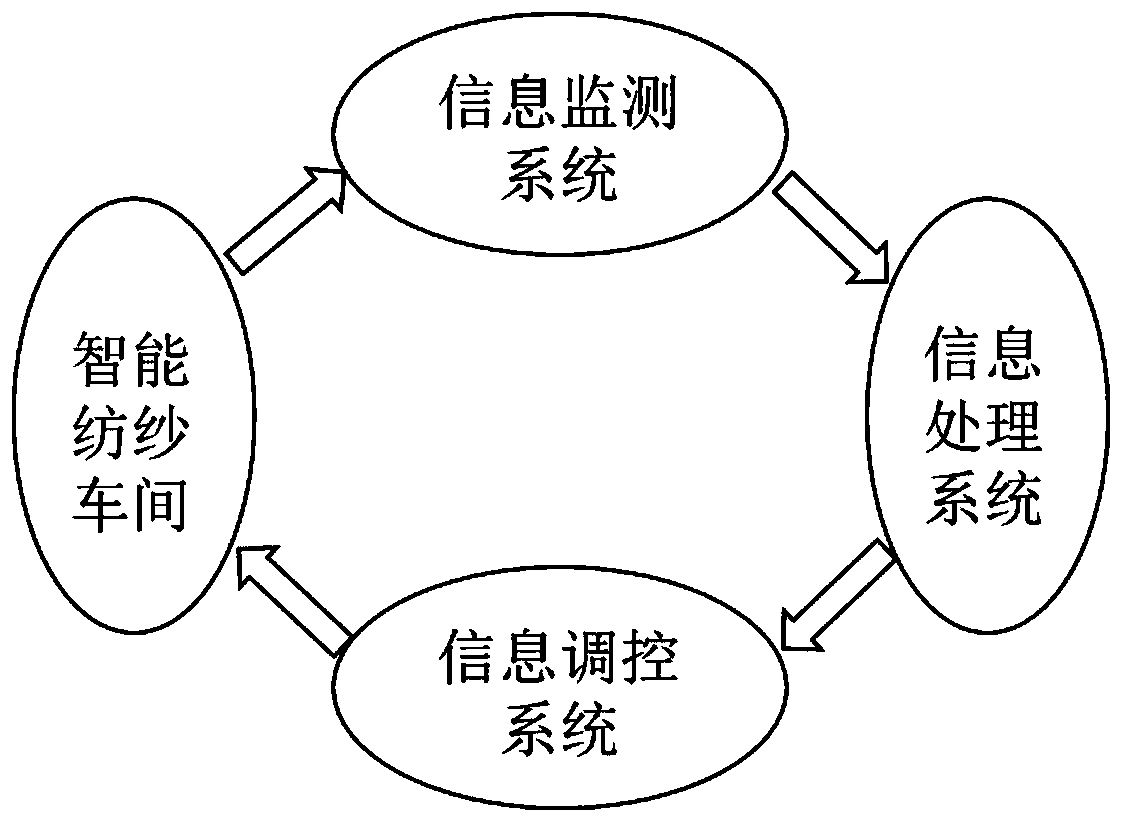

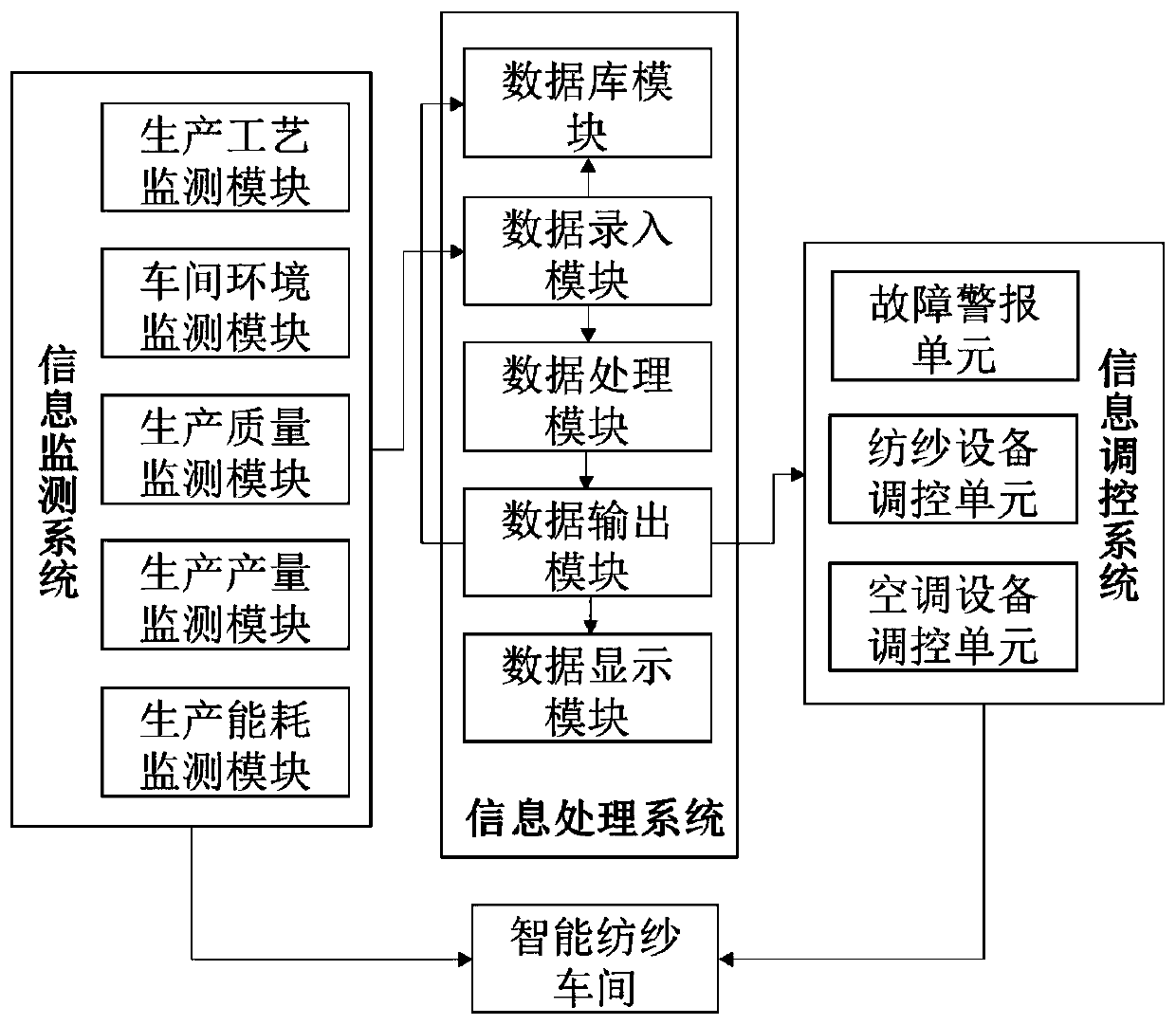

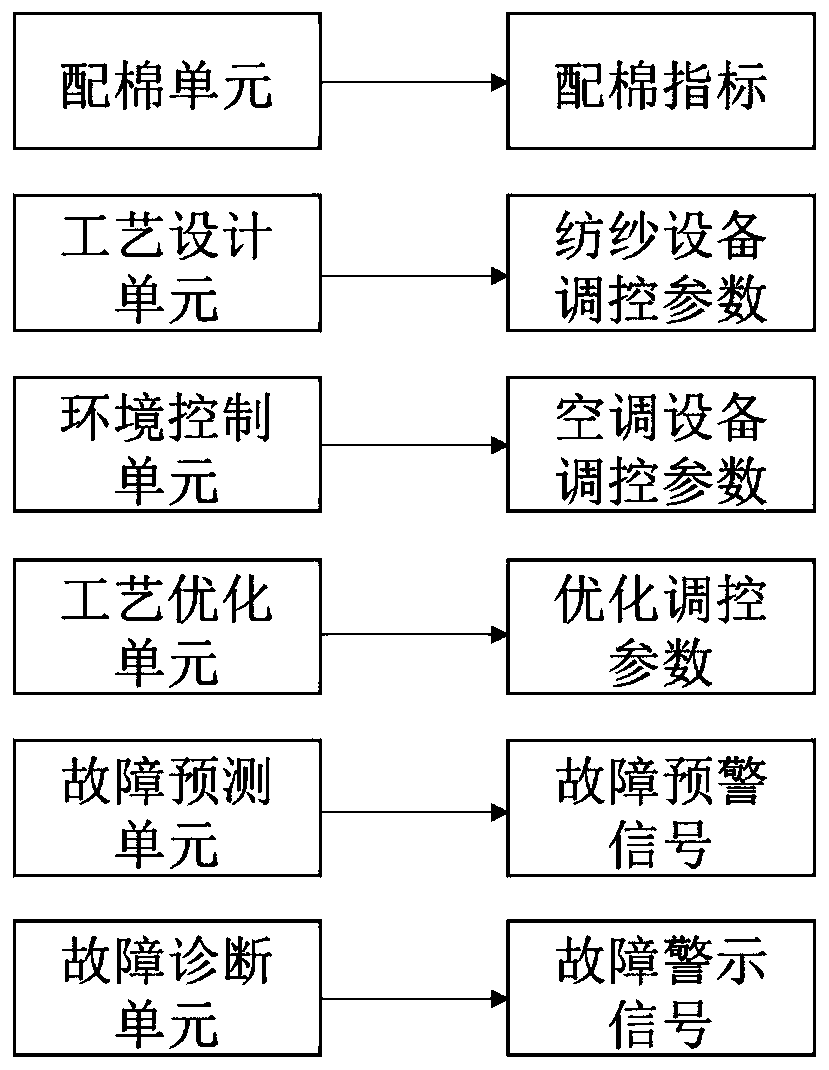

Intelligent management system for intelligent spinning workshop

ActiveCN110427004AIncrease production capacityEasy to controlTotal factory controlProgramme total factory controlInformation processingInformatization

The invention discloses an intelligent management system for an intelligent spinning workshop. The intelligent management system comprises an information monitoring system, an information processing system and an information regulation system. Data of the whole spinning workshop is monitored by the information monitoring system in real time, then data in the spinning workshop is processed by the information processing system to obtain regulation parameters of the intelligent spinning workshop, and finally, running of equipment in the intelligent spinning workshop is regulated by the information regulation system. The intelligent management system for the intelligent spinning workshop achieves automatic production and transportation control from raw materials to finished products and onlinemonitoring and control over the quality and yield of the products through an informatization network technology, a fusion sensor technology, frequency-conversion speed regulation and the like, the product quality and the production efficiency are significantly improved, the production cost is reduced, and the intelligent management system has the advantages of modernization, scientification and standardization.

Owner:武汉裕大华纺织有限公司

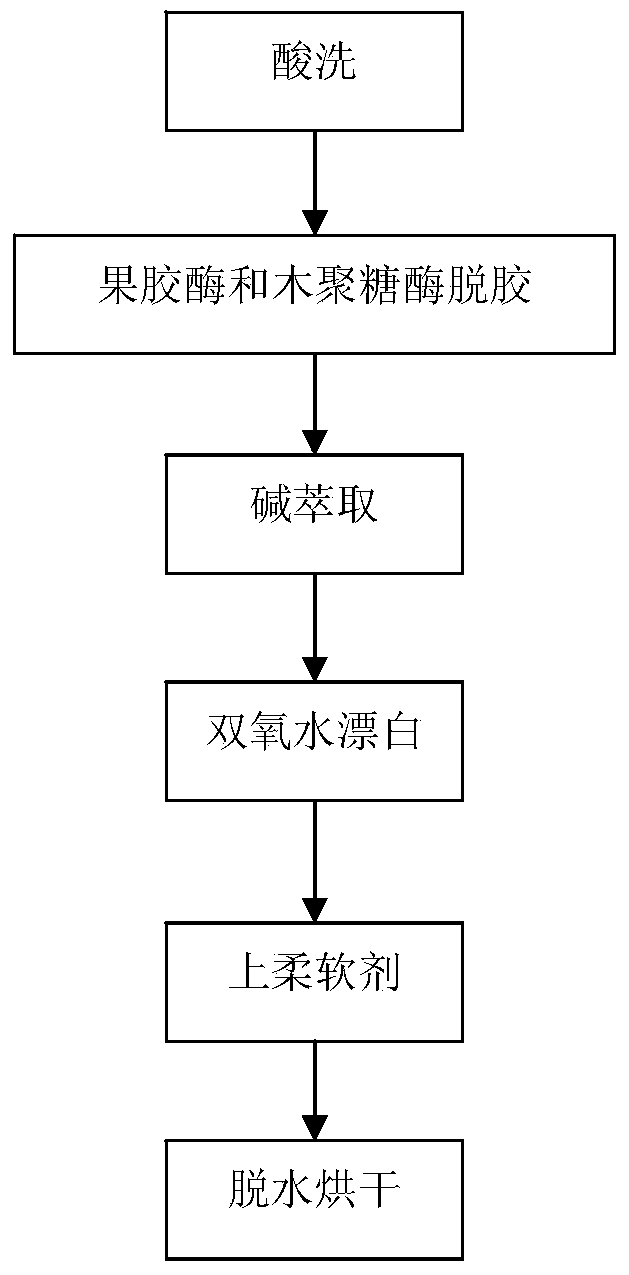

Flax fiber degumming method

ActiveCN103436970ANo damageIncrease the number of splitsFibre treatment to obtain bast fibrePectinaseXylanase

The invention provides a flax fiber degumming method. The method comprises the following steps: (1) pickling by using sulfuric acid; (2) degumming by using pectinase and xylanase, wherein the pectinase accounts for 1-2% of the flax fiber in mass fraction, and the xylanase accounts for 0.5-2% of the flax fiber in mass fraction; (3) extracting by using caustic soda and calcined soda; (4) bleaching by using hydrogen peroxide. According to the flax fiber degumming method provided by the invention, the pectinase and the xylanase which are free of damage to the flax fiber, free of pollution to the environment and strong in specificity are adopted for sufficiently degumming the flax fiber, so that the division index of the flax fiber can be effectively increased, the uniformity of the flax fiber can be effectively improved; then, commensals of the flax fiber are sufficiently removed through extracting and bleaching, so that the spinning count is increased, the spinning quality is improved, the production cost is reduced, the production difficulty is lowered, and meanwhile, the pollutant discharge is reduced.

Owner:TONGXIANG SIYUAN TEXTILE

Preparation method of bio-based 2,5-FDCA (furandicarboxylic acid)-based copolyester

The invention relates to a preparation method of a bio-based 2,5-FDCA (furandicarboxylic acid)-based copolyester. Dibasic acid, aliphatic diol I, a primer and a Ti-Si-Co composite catalyst are uniformly mixed and sequentially subjected to an esterification reaction, a pre-condensation polymerization reaction and a final condensation polymerization reaction, and the bio-based 2,5-FDCA-based copolyester is prepared; the primer is ester produced through a reaction of bio-based 2,5-FDCA and aliphatic diol II, the molar ratio of dibasic acid to aliphatic diol I is 1:(1.05-1.10), the Ti-Si-Co composite catalyst is formed by compositing a Ti-Si composite catalyst and a Co catalyst, the Ti-Si composite catalyst is obtained through supporting of a Ti catalyst on a Si catalyst, and the aliphatic diol I and the aliphatic diol II are the same or different. The preparation method has few side reactions and high reaction rate, and the prepared product has concentrated molecular weight distribution,high viscosity, good quality and great application prospects.

Owner:DONGHUA UNIV

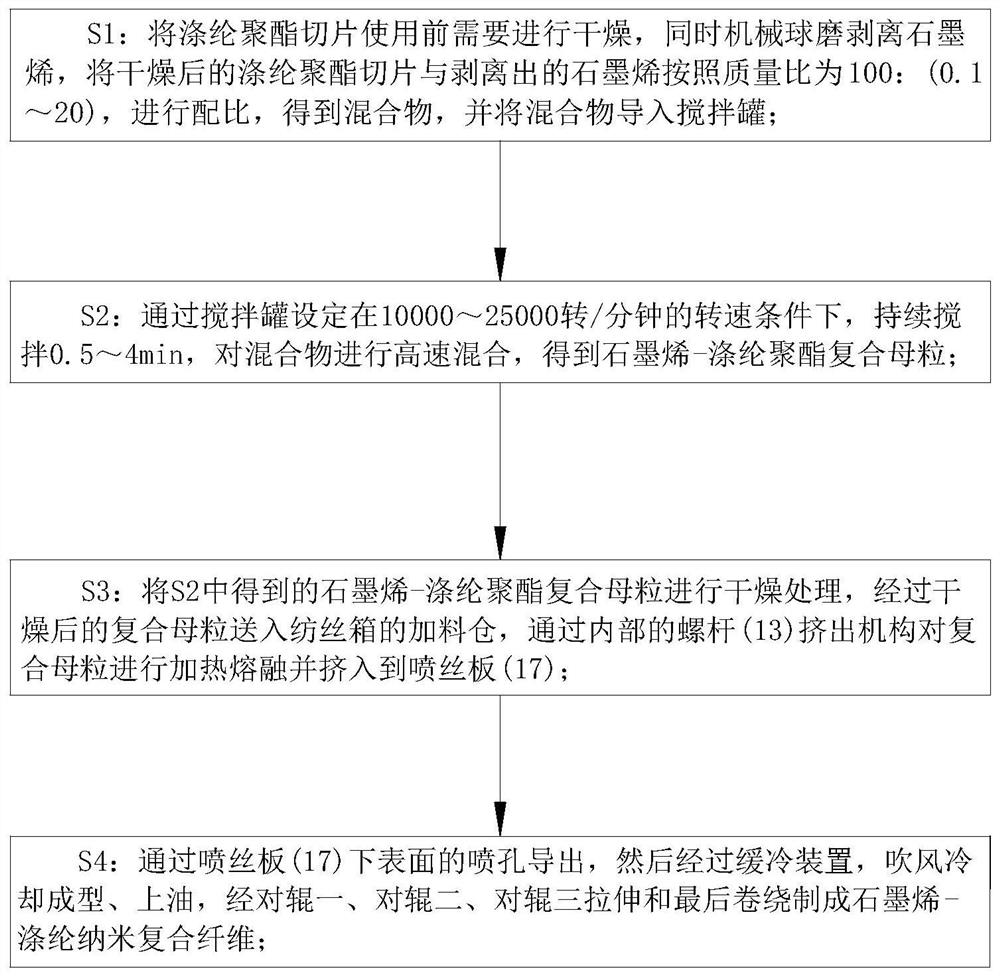

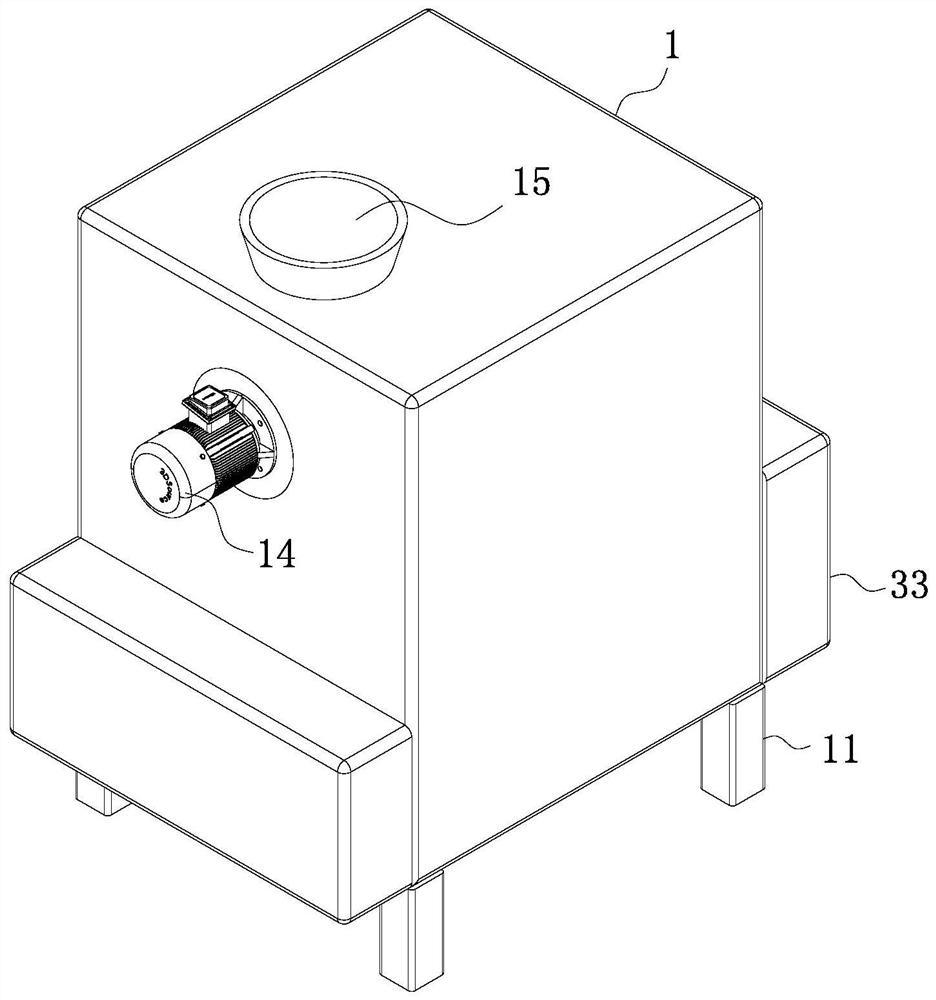

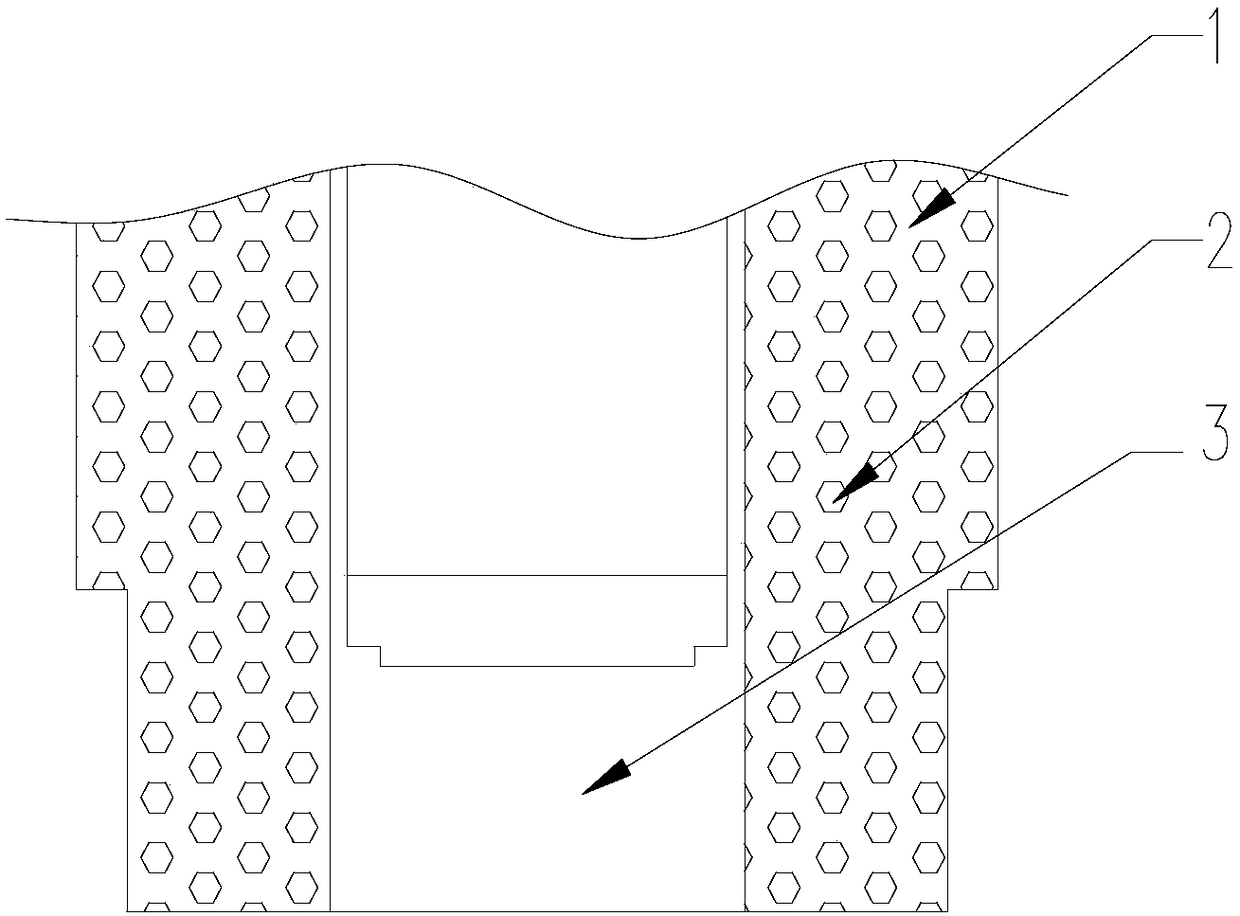

Preparation method of graphene-polyester nanometer composite fiber

InactiveCN111690994AAchieving Parallel Airflow CoolingUniform cooling effectSpinnerette packsMelt spinning methodsPolyesterFiber

The invention belongs to the technical field of composite fibers and specifically relates to a preparation method of a graphene-polyester nanometer composite fiber. A spinning box used in the preparation method of the graphene-polyester nanometer composite fiber is provided with a box body, a rotating disc and an air guide rod; a spinneret plate is arranged in a position, close to the upper surface of the box body, in the box body; a conduit is fixedly connected to the lower surface of the spinneret plate; a cold plate is fixedly connected to the position, close to the lower end surface of theconduit, in the box body; the air guide rod is connected to the interior of the cold plate to slide from left to right; and the rotating disc is rotationally connected to the interior of the conduit.Through adoption of the preparation method of the graphene-polyester nanometer composite fiber, parallel airflow cooling of spun fibers is effectively realized, the wind direction and the fibers areprevented from being in a vertical state, uneven air speed is very easy to cause air turbulence to cause a filament drifting problem, and meanwhile, the cooling effect on the spun fibers is more uniform so that the cooling time of the spun fibers and the drawing ratio are kept consistent with each other; and therefore, the qualities of the prepared spun silks are higher.

Owner:孟伟东

Nanometer far infrared ceramic fiber woven fabric and production method of nanometer far infrared ceramic fiber woven fabric

ActiveCN104593931AImprove heat insulation and flame retardant effectImprove wear resistanceConjugated cellulose/protein artificial filamentsWoven fabricsMethacrylateEpoxy

The invention discloses nanometer far infrared ceramic fiber woven fabric. The nanometer far infrared ceramic fiber woven fabric is formed by warp yarns and weft yarns in a woven mode through an air jet loom, and is characterized in that raw materials of the warp yarns and raw materials of the weft yarns comprise, by weight, 27 parts to 33 parts of syndiotactic polypropylene, 10 parts to 14 parts of linear low-density polyethylene, 8 parts to 10 parts of polyurethane films, 16 parts to 22 parts of epoxy resin, 0.4 part to 0.7 part of zinc nitrate, 0.6 part to 0.9 part of magnesium hydrate, 1 part to 3 parts of water glass, 20 parts to 25 parts of nylon yarns, 23 parts to 26 parts of colored cotton fibers, 18 parts to 23 parts of nanometer far infrared ceramic fibers, 21 parts to 24 parts of cellulose acetate fibers, 7 parts to 10 parts of isobutyl methacrylate, 5 parts to 9 parts of peach gum, 1 part to 3 parts of radix bupleuri, 2 parts to 5 parts of fossil fragments, 80 parts to 90 parts of 1-butyl-3-methylimidazolium acetate, 90 parts to 100 parts of 1-allyl-3-methylimidazolium chlorine salt, a proper amount of water and 4 parts to 8 parts of assistants. By means of the nanometer far infrared ceramic fiber woven fabric, the spinnability of plant fibers and the spinning quality are improved, the warmth keeping performance, the wearing resistance, the pilling resistance and the washing resistance of the woven fabric are further improved, and the market prospects are good.

Owner:JIXI YUANDAO AGRI IND TECH

Woven fabric with sound insulation and warm keeping properties and manufacturing method thereof

InactiveCN104652017AImprove spinnabilityImprove spinning qualityConjugated cellulose/protein artificial filamentsWoven fabricsFiberLophatherum

The invention discloses a woven fabric with sound insulation and warm keeping properties. The woven fabric is formed by weaving warp yarns and weft yarns through an air jet loom; the warp yarns and the weft yarns are prepared from the following raw materials in parts by weight: 30-34 parts of isotatic polypropylene, 1-3 parts of hargil, 3-7 parts of rock wool, 20-25 parts of modal fibers, 22-26 parts of fireproof fiber cotton, 25-28 parts of waste down feather fibers, 16-19 parts of bambusa texlitis pulp, 0.6-0.9 part of sodium hexametaphosphate, 8-10 parts of methyl methacrylate, 2-4 parts of eucalyptus oil, 12-15 parts of butyl glycidyl ether, 1-3 parts of jasmine, 2-5 parts of herba cepbalanoplosis segeti, 3-4 parts of lophatherum gracile, 85-95 parts of 1-butyl-3-methyl imidazole acetate, 95-110 parts of 1-allyl-3-methyl imidazole chlorine salt, proper amount of water and 5-8 parts of an auxiliary agent. The woven fabric has the sound insulation and warm keeping properties, and antibacterial and mould-proof, and inflaming retarding properties, is applied to automotive trims, and has the properties of low cost, high cost performance and good shape keeping performance and the like; the prospect is wide.

Owner:章云

Polyester DTY fiber and preparation method thereof

ActiveCN108385195AIncrease the cross-sectional areaReduce the temperatureFilament/thread formingArtificial filament heat treatmentThermal insulationDiol

The invention relates to polyester DTY fiber and a preparation method thereof. The preparation method comprises: metering a modified polyester melt, extruding, cooling, oiling, winding to prepare polyester POY fiber, and carrying out fiber conduction pipe, network, heating drawing, false twisting, heat setting and winding molding on the polyester POY fiber to obtain the polyester DTY fiber. According to the present invention, during the cooling, the longitudinal height is maintained, and the cross section area of the slow cooling chamber is increased while the plate surface temperature of thespinning plate is maintained by using the thermal insulation method; the material of the polyester POY fiber is the modified polyester with the molecular chain including a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the structure formula of the diol chain segment having the branched chain is defined in the specification, R1and R2 are respectively and independently selected from straight chain alkylidene with a carbon atom number of 1-3, R3 is selected from alkyl with a carbon atom number of 1-5, and R4 is selected fromalkyl with a carbon atom number of 2-5; and the preparation method is simple, and the chromatic aberration [delta]E of the prepared fiber is less than 0.200.

Owner:JIANGSU HENGLI CHEM FIBER

Catechinic acid fiber blended deodorization flame-retardant woven fabric and manufacturing method thereof

ActiveCN104726994AVersatileImprove technical indicatorsFlame-proof filament manufactureMelt spinning methodsFiberPolyethylene glycol

The invention discloses catechinic acid fiber blended deodorization flame-retardant woven fabric. Raw materials of needed warp and needed weft for weaving comprise, by weight, 29 to 35 parts of syndiotactic polypropylene, 18 to 23 parts of polylactic acid, 8 to 12 parts of polyhydroxybutyrate, 3 to 5 parts of montmorillonoid, 0.02 to 0.05 part of canthaxanthin, 0.4 to 0.8 part of diprophylline, 0.5 to 0.9 part of calcium chloride, 23 to 28 parts of catechinic acid fibers, 25 to 30 parts of reed fibers, 18 to 24 parts of flame-retardant fibers, 17 to 23 parts of Lenzing modal fibers, 19 to 27 parts of zein fibers, 7 to 9 parts of oleic acid polyethylene glycol ester, 10 to 14 parts of ethylene glycol monoethyl ether acetate, 3 to 4 parts of peppermint, 2 to 5 parts of isatis roots, 1 to 3 parts of rheum officinale, 85 to 100 parts of 1-butyl-3-methylimidazolium acetate, 95 to 105 parts of 1-allyl-3-methylimidazolium chloride, 4 to 6 parts of auxiliaries and a proper amount of water. The fabric has the advantages of being resistant to odor, flames and abrasion, capable of absorbing sound and isolating heat and the like.

Owner:JIXI YUANDAO AGRI IND TECH

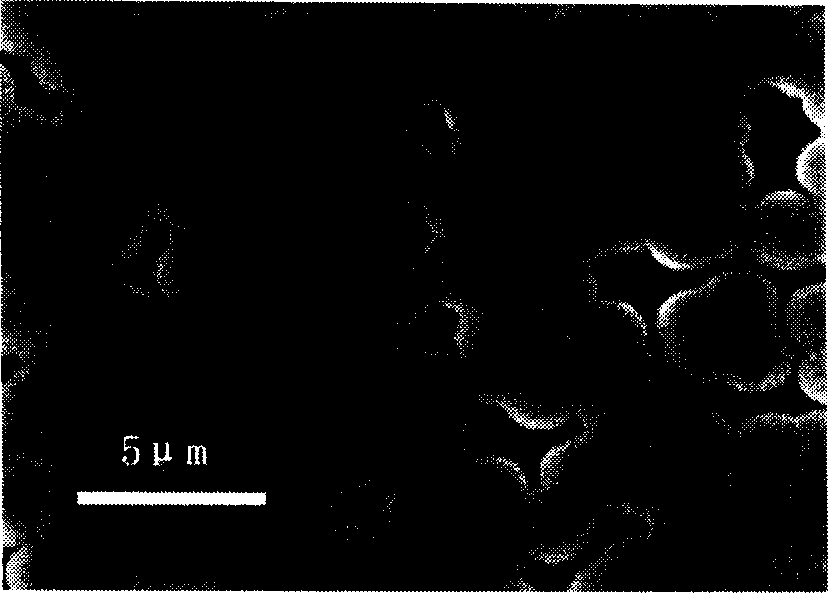

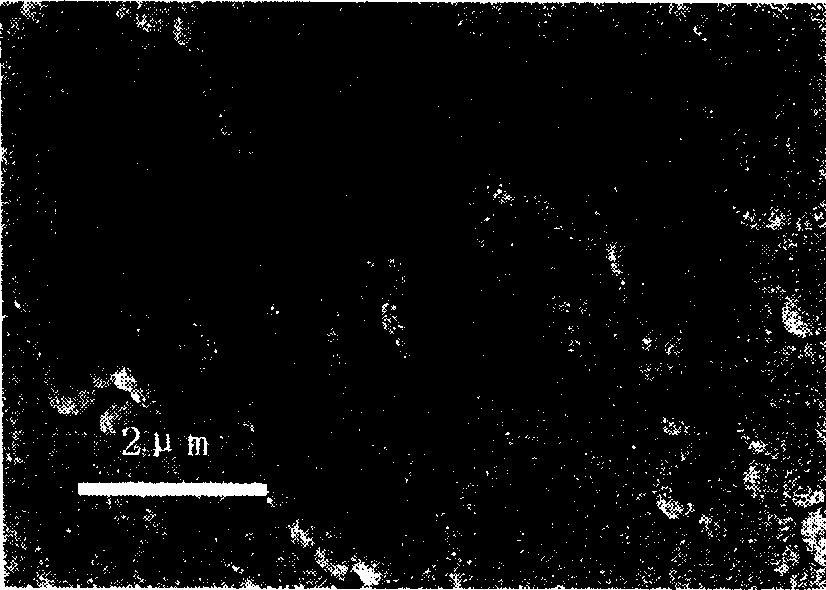

Diamond thin-film reinforcement on tantalum spinning head surface by chemical gas phase deposition

InactiveCN1896303AImprove spinnabilityExtended service lifeSpinnerette packsChemical vapor deposition coatingGas phaseHead surface

A strengthening process of diamond film on Tantalum spinneret surface prepared by chemical vapor deposition process includes the following steps: a. ultrasonic grinding of the Tantalum spinneret in the alcohol suspension containing diamond fine powder and ultrasonic cleaning of the spinneret surface in acetone and alcohol, as the pretreatment process; b. deposition of the diamond film by CVD process. In the deposition process, the concentration of carbon source is 1-4%, the substrate temperature is 600-900DEG C, the pressure is 0.5 -5kpa and the deposition time is controlled from 0.5 to 2h. This process can be used on the spinneret surfaces of different shapes, increases the hardness and the resistance to alkaline of spinneret surfaces significantly, and controls the local heat stress due to the temperature difference. The spinning quality and service life of the spinneret are also increased by film deposition.

Owner:SHANGHAI JIAO TONG UNIV

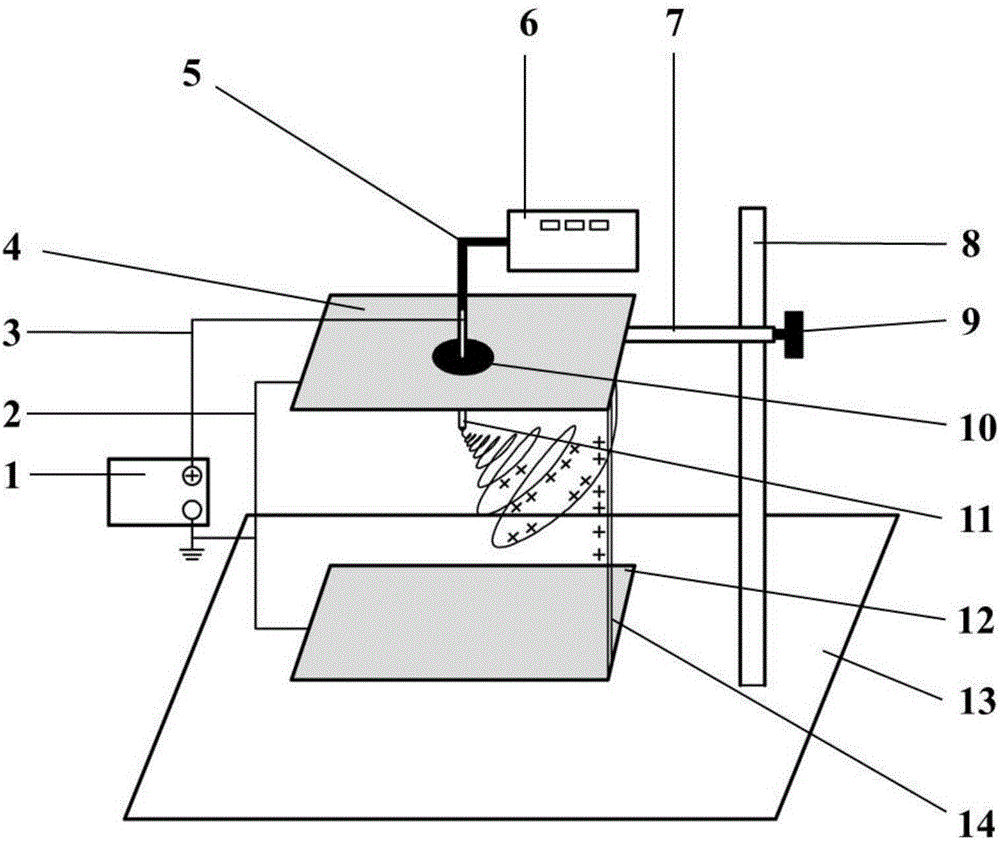

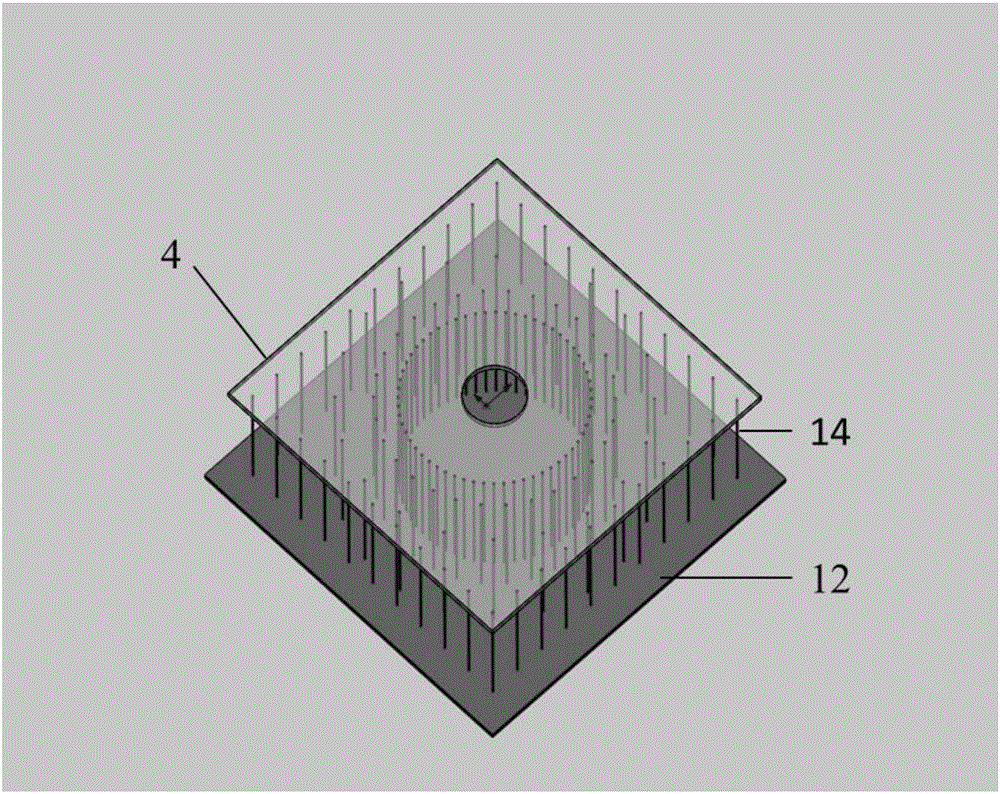

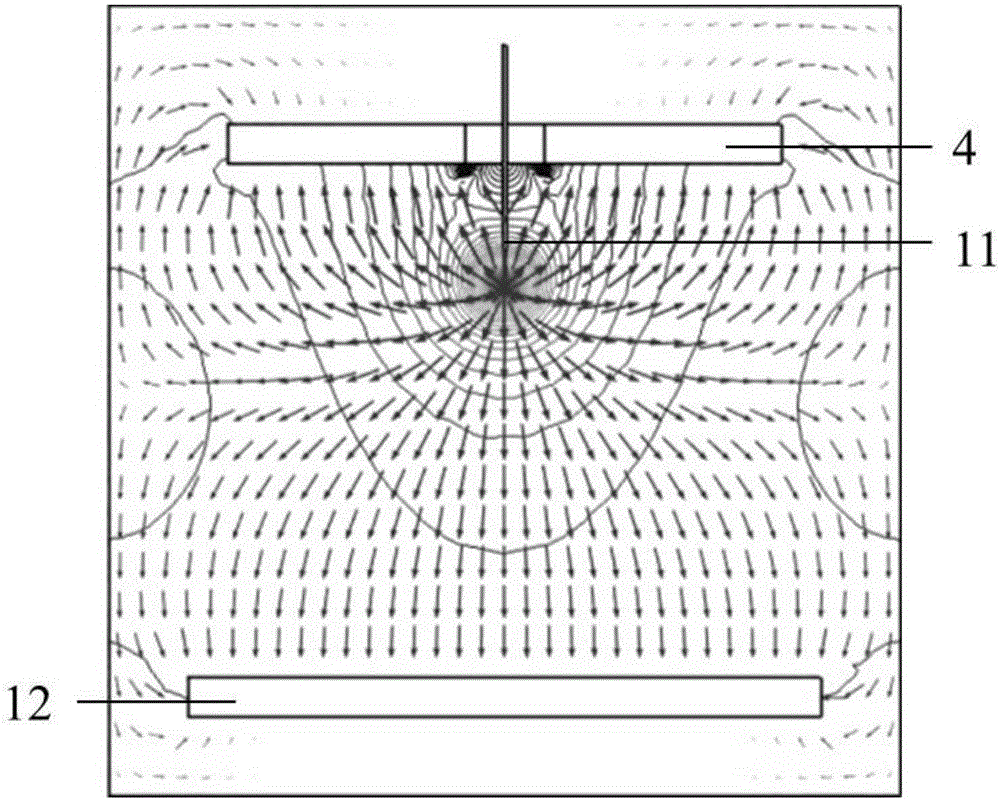

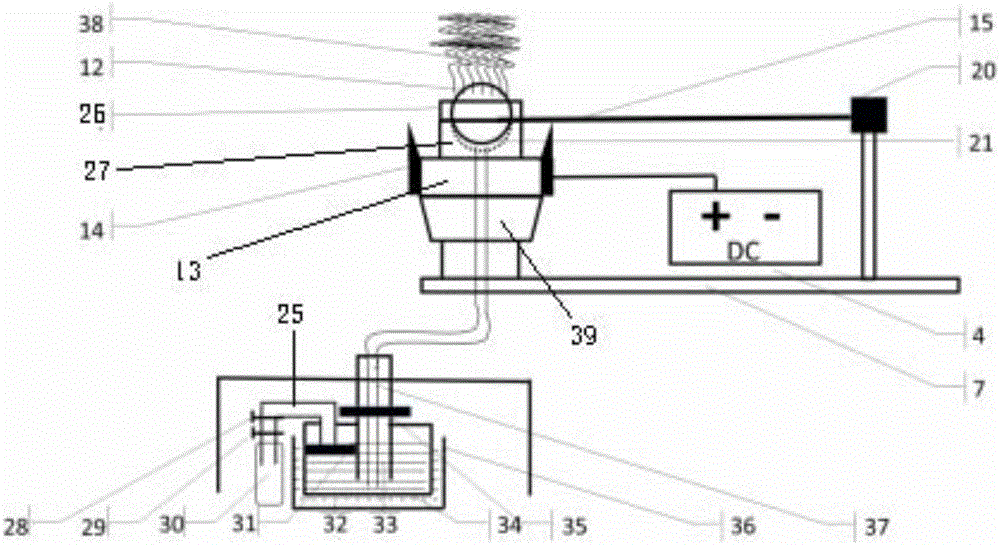

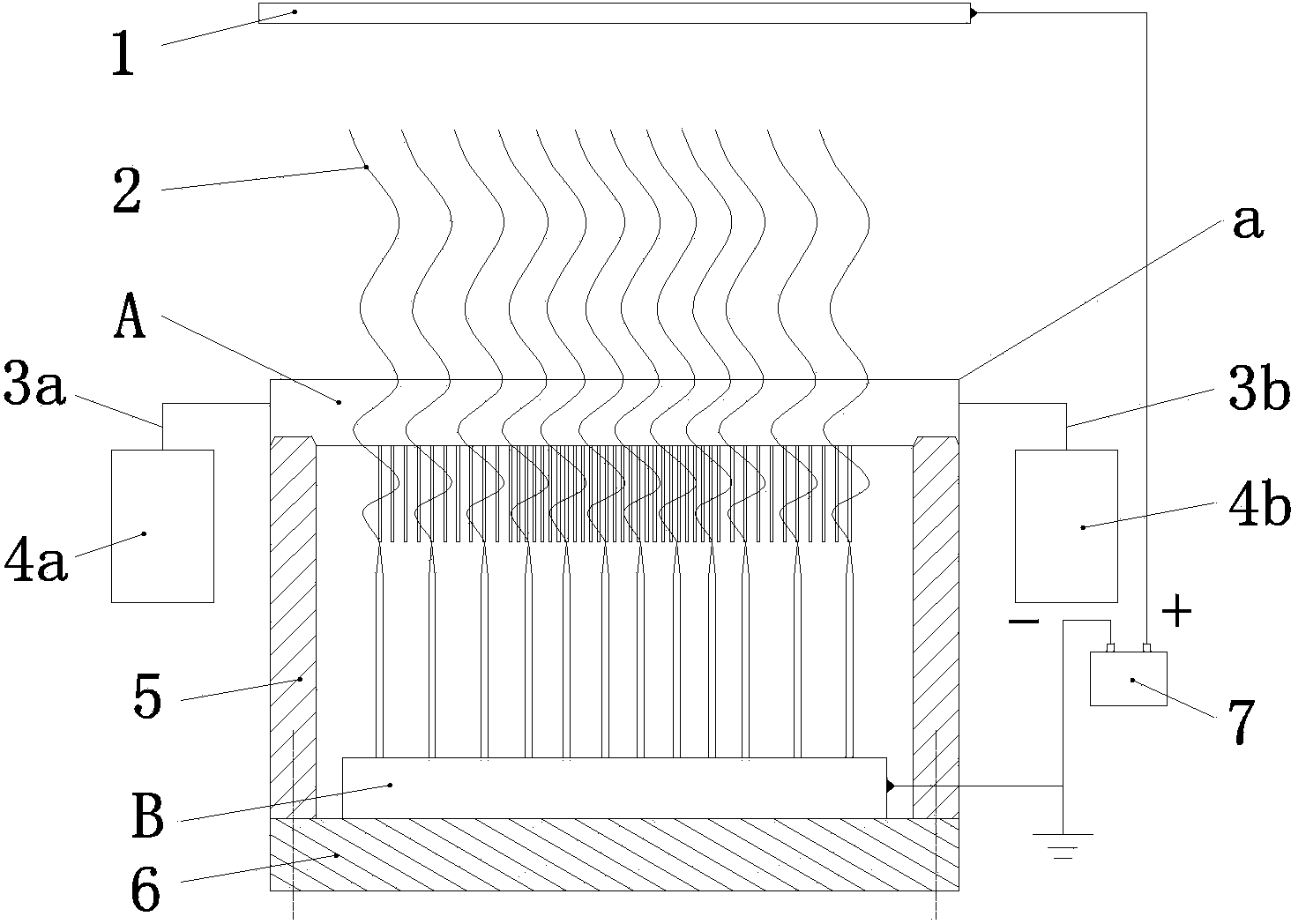

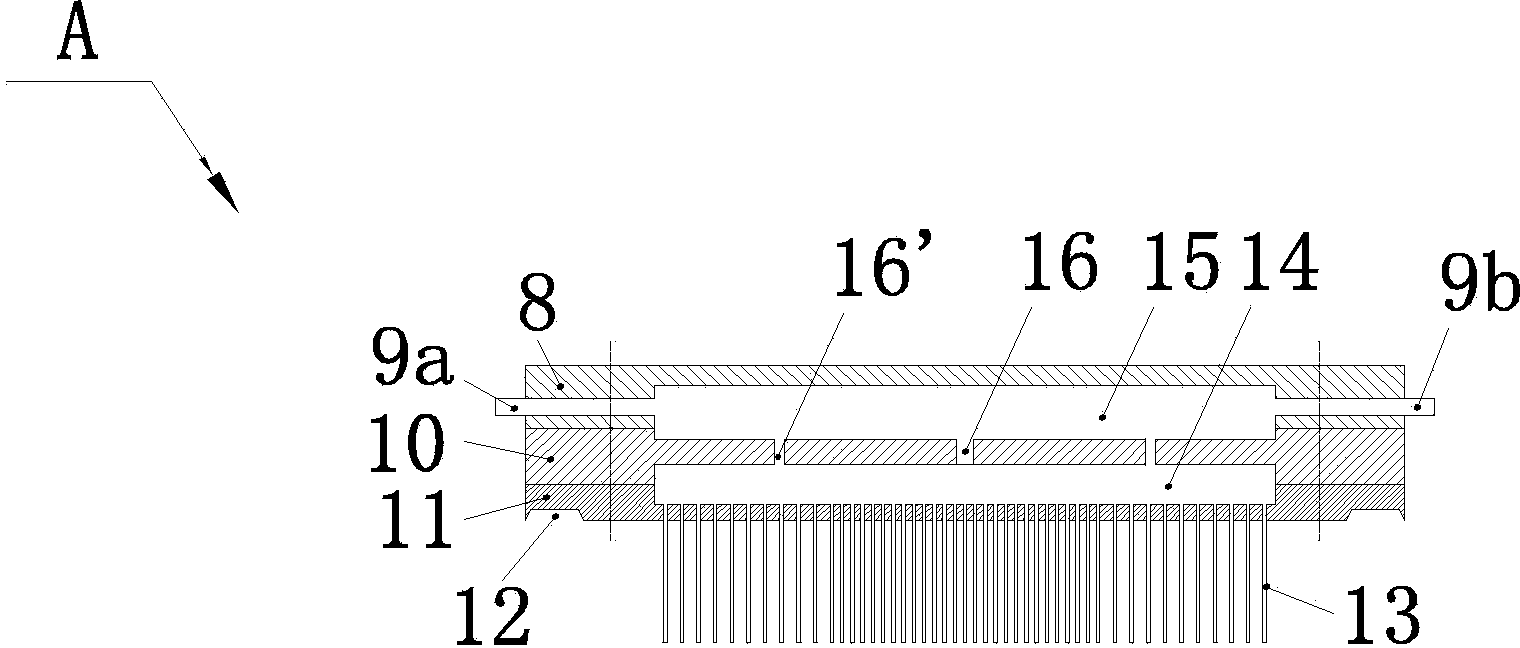

Multi-nozzle static spinning device

InactiveCN104060336AEffective isolationBalanced working electric fieldFilament/thread formingFiberAir pump

The application discloses a multi-nozzle static spinning device which comprises a plurality of spinning nozzles, a collecting device and high voltage power supplies, wherein a spinning solution flow passage is formed in each spinning nozzle in the axial direction; warm air flow passages are formed in the periphery of each spinning solution flow passage; the warm air flow passages are communicated with an air pump; a heating device is arranged between the air pump and the warm air flow passages. According to the invention, the warm air flow passages are formed in the periphery of each spinning solution flow passage, through the stretching function of the warm air flow passage, the diameter of the fiber can be further reduced, the unstability of the static spinning process can be improved, the landing direction of fibers can be guided, and the efficiency of the static spinning technology can be improved; through the utilization of the combined action of airflow stretching and electrostatic force stretching, the controllability and yield of nanofiber preparation can be improved, and the yield is improved by times to dozens of times as compared with the standard electrospinning technology.

Owner:张家港市宏盛贸易有限公司

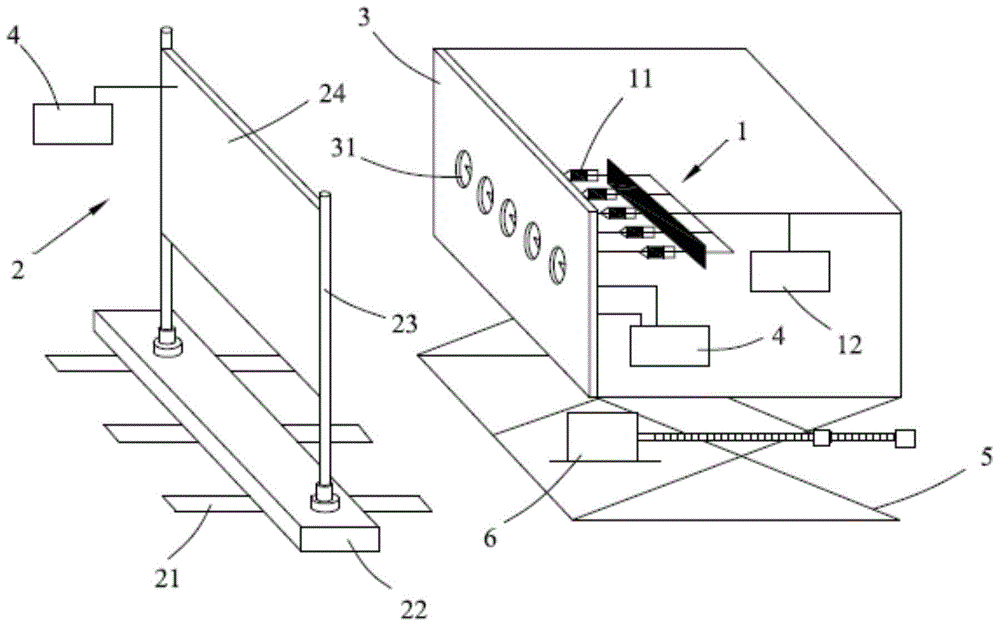

Drying machine with sprinkler

ActiveCN102997620AIncrease moisture contentStable moisture contentDrying solid materials without heatPolyesterPulp and paper industry

The invention discloses a drying machine with a sprinkler. The top of the drying machine is provided with the sprinkler; the sprinkler comprises a nozzle body; one side of the nozzle body is provided with a water inlet, and the other side of the nozzle body is provided with a nozzle; the nozzle is connected with an atomizing disc; the atomizing disc is connected with a nozzle cap; the nozzle cap is provided with a water orifice; and the nozzle cap is positioned above a conveyor of the drying machine. By the drying machine, the water content of polyester chips is proper and stable and can be adjusted according to actual requirements, and the drying machine can be matched with a centrifugal dryer to be widely applied to the production process of polyester chips.

Owner:JIANGSU SHENJIU CHEM FIBER CO LTD

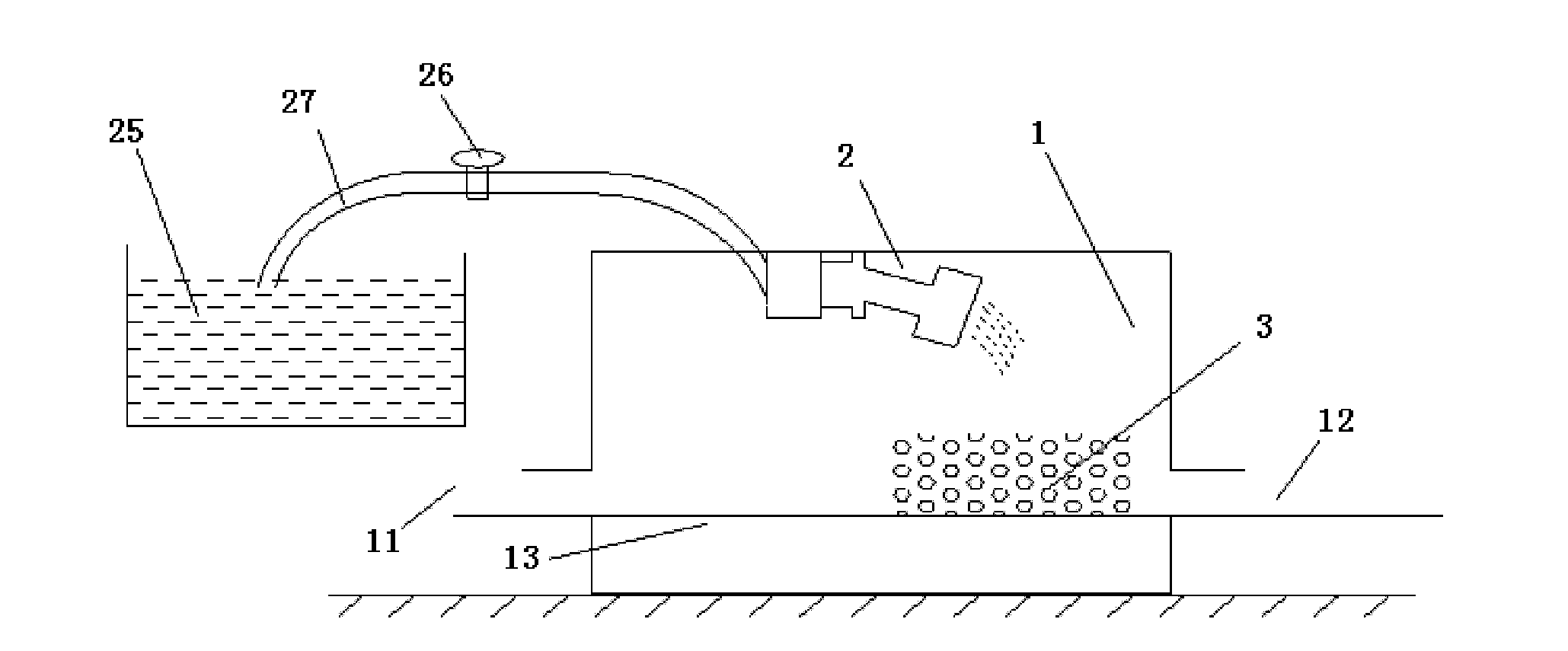

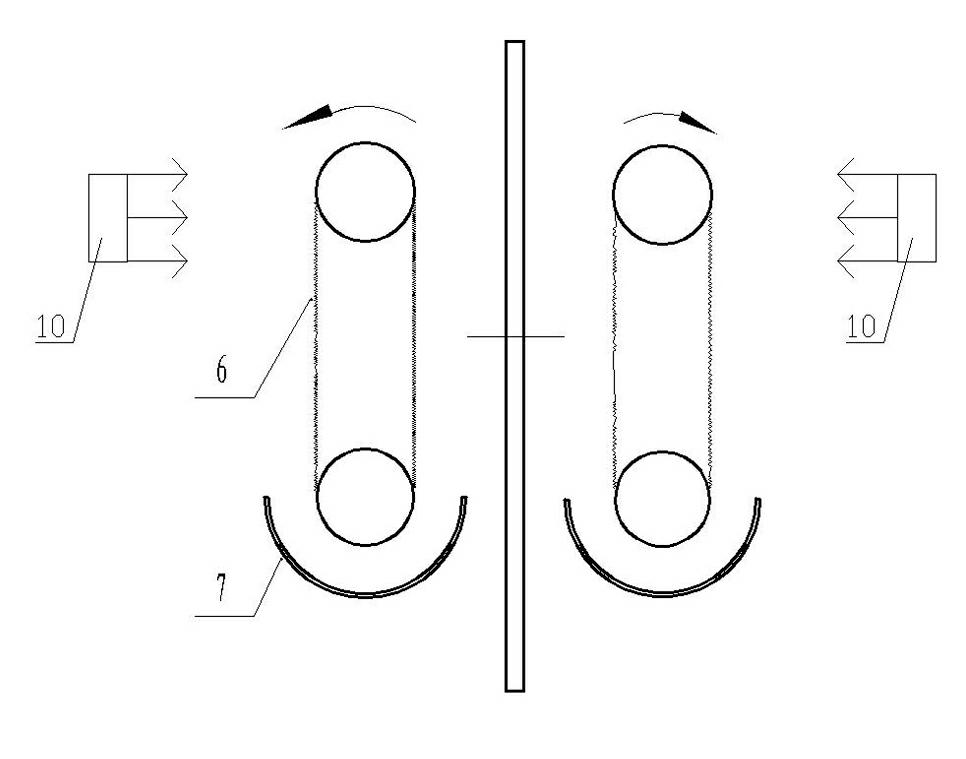

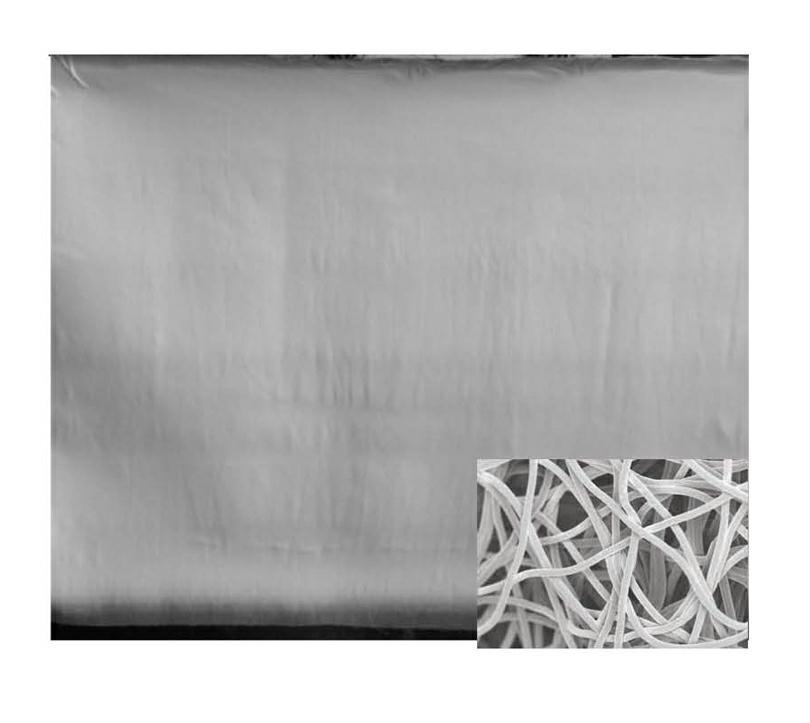

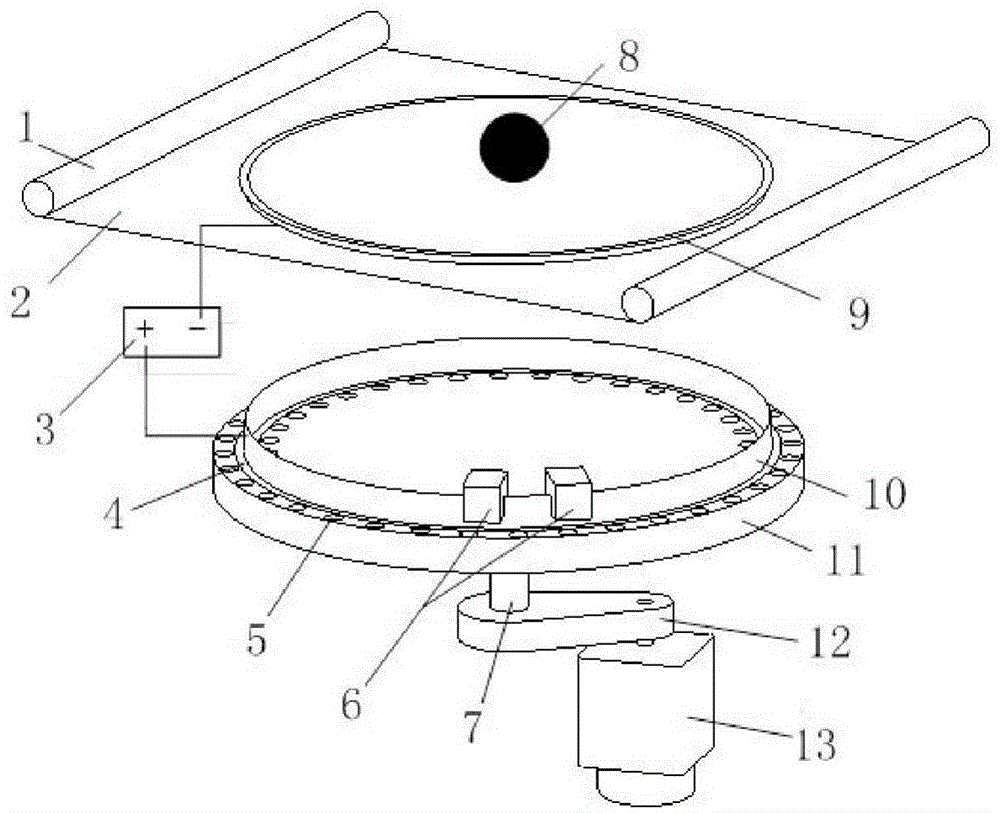

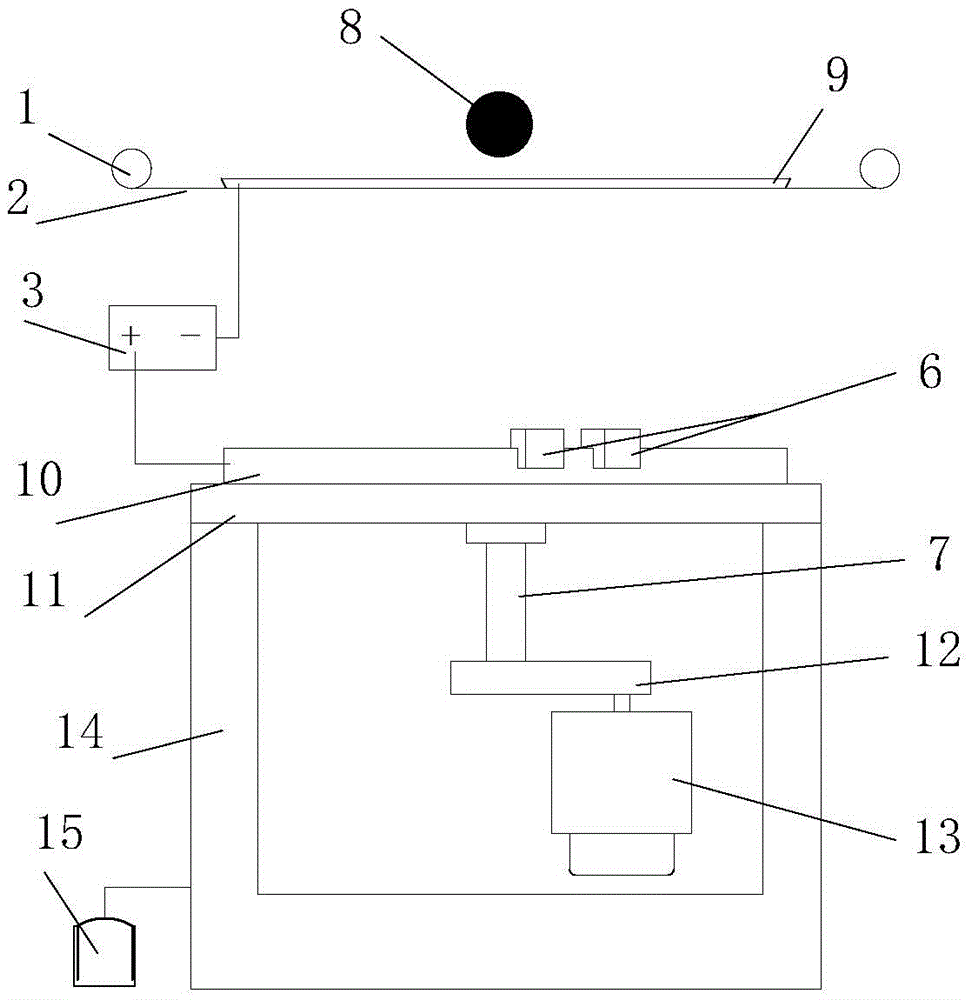

Electrostatic spinning device for efficiently preparing nano-fiber fabrics

InactiveCN102108603AImprove spinning efficiencyImprove spinning qualityFilament/thread formingNon-woven fabricsFiberElectrospinning

The invention discloses an electrostatic spinning device for efficiently preparing nano-fiber fabrics, which comprises a frame, a collector, and at least one group of jet generating device, wherein the at least one group of jet generating device comprises two rotatable electrode rollers; the two electrode rollers are arranged vertically and have charges in the same direction; a plurality of spring-shaped wire electrodes are wound between the two electrode rollers; the lower electrode roller in the two electrode rollers is soaked in a trough filled with spinning solution; the collector comprises an electrode disc parallel to the spring-shaped wire electrodes; the electrode disc is provided with a guide plate connected with a take-up roller; the electrode disc is connected with a drag wheel; and the electrode disc and the drag wheel are connected with a drag motor. The efficiency of the electrostatic spinning device for producing the nano-fiber fabrics can be doubled; and unique nano-fiber fabrics can be prepared. The formed nano-fiber fabrics have good properties such as flexibility and the like; and compared with the prior art, the preparation method is simple, so that the cost is greatly reduced. Therefore, the electrostatic spinning device has good market prospect.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Electrostatic spinning method for preparing directional nanofiber

ActiveCN106498514AImprove spinning efficiencyImprove spinning qualityFilament/thread formingFiberElectrospinning

The invention discloses an electrostatic spinning method for preparing an aligned nanofiber, belongs to the technical field of nanofiber preparation, and relates to the electrostatic spinning method for preparing the aligned nanofiber. According to the electrostatic spinning method for preparing the aligned nanofiber, an auxiliary pole plate mutually parallel to a fixed receiving plate is adopted, and control over motion direction of a spinning solution jet flow is conducted to make the nanofiber form a space directional alignment between the fixed receiving plate and the auxiliary pole plate. The electrostatic spinning method for preparing the aligned nanofiber comprises the steps that firstly an electrostatic spinning device is installed, a spinning solution is prepared, a micro pump pushes the spinning solution to a spinning jet at a constant speed through a solution delivery tube, the nanofiber is drawn out at the position of the spinning jet, and fiber arrays with different cross directional nanofiber knitting angles are obtained by utilizing an additional collecting plate to change different angles. The electrostatic spinning method for preparing the aligned nanofiber has the advantages that fiber directional property is good, length is adjustable and space directional arranged fiber arrays can be obtained and the like, and spinning efficiency and spinning quality of the directional nanofiber are improved.

Owner:DALIAN UNIV OF TECH

High-modulus low-shrinkage stiff cord and preparation method thereof

ActiveCN108385418AIncrease the cross-sectional areaReduce the temperatureFibre typesFilament/thread formingYarnSlow cooling

The invention relates to a high-modulus low-shrinkage stiff cord and a preparation method thereof. The preparation method comprises the following steps: performing solid-phase polycondensation-viscosity enhancement, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding to obtain high-modulus and low-shrinkage polyester industrial yarns; twisting to obtain a cord; making the cord into a high-modulus low-shrinkage stiff cord by a two-bath impregnation method, wherein during cooling, the longitudinal height is kept constant and the cross-sectional area of a slow cooling chamber is increased; meanwhile, the surface temperature of a spinneret plate is kept in a heat preserving way in the slow cooling chamber; an oiling agent contains 67.30 to 85.58 percent by weight of crown ether; during use of the oiling agent, 14 to 18 percent by weight emulsion is prepared with water. The preparation method disclosed by the invention is simple; the prepared high-modulus low-shrinkage stiff cord is made from modified polyester of which the molecular chain includes a terephthalic acid chain segment, an ethylene glycol chain segment and a dihydric alcohol chain segment with a branched chain, is greater than or equal to 80N in breaking strength, and is greater than or equal to 37KN / m in cord bonding strength.

Owner:JIANGSU HENGLI CHEM FIBER

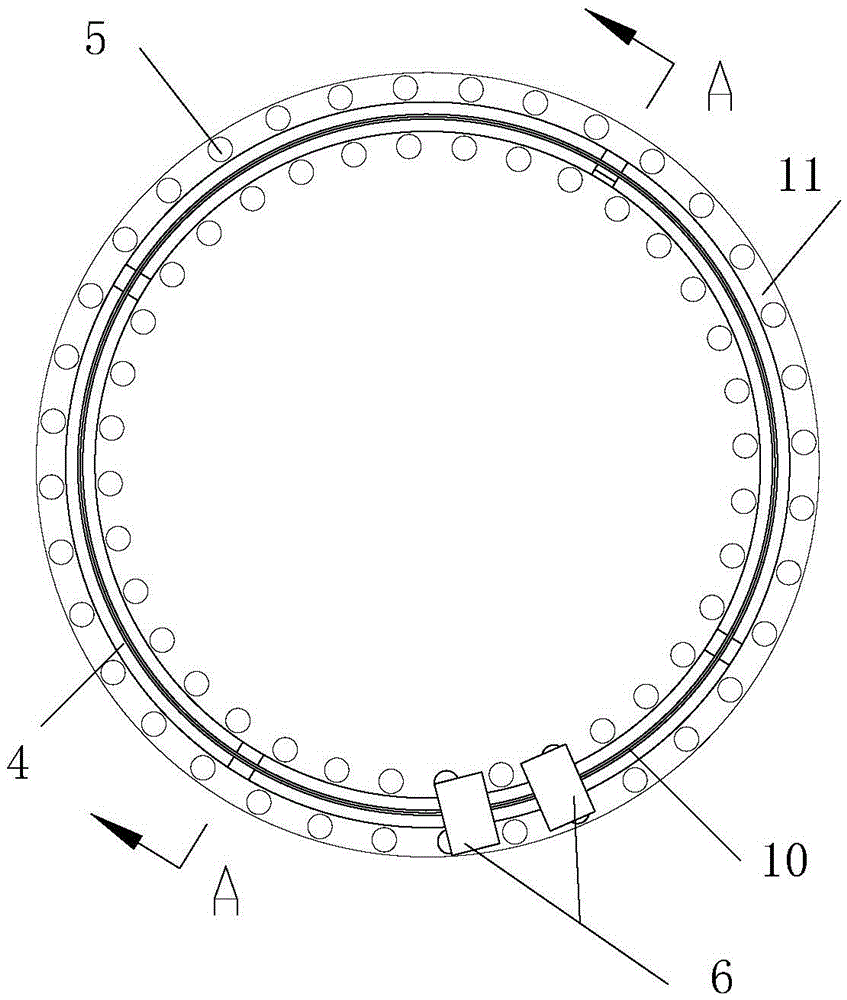

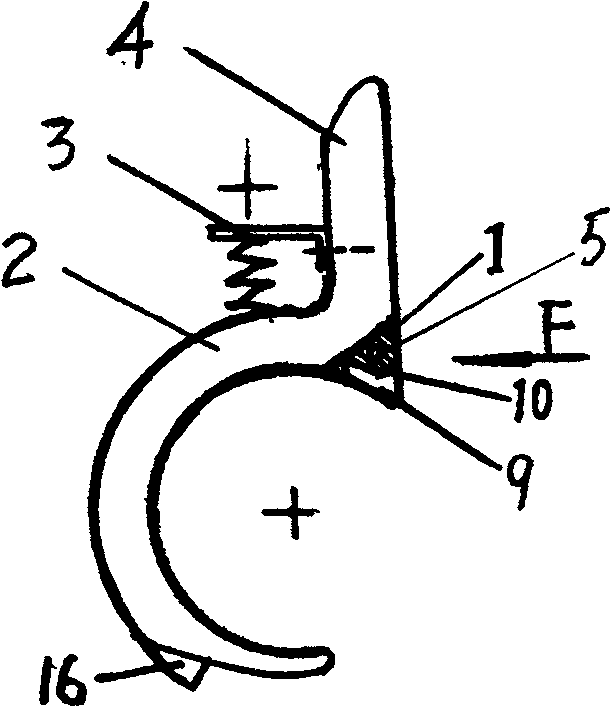

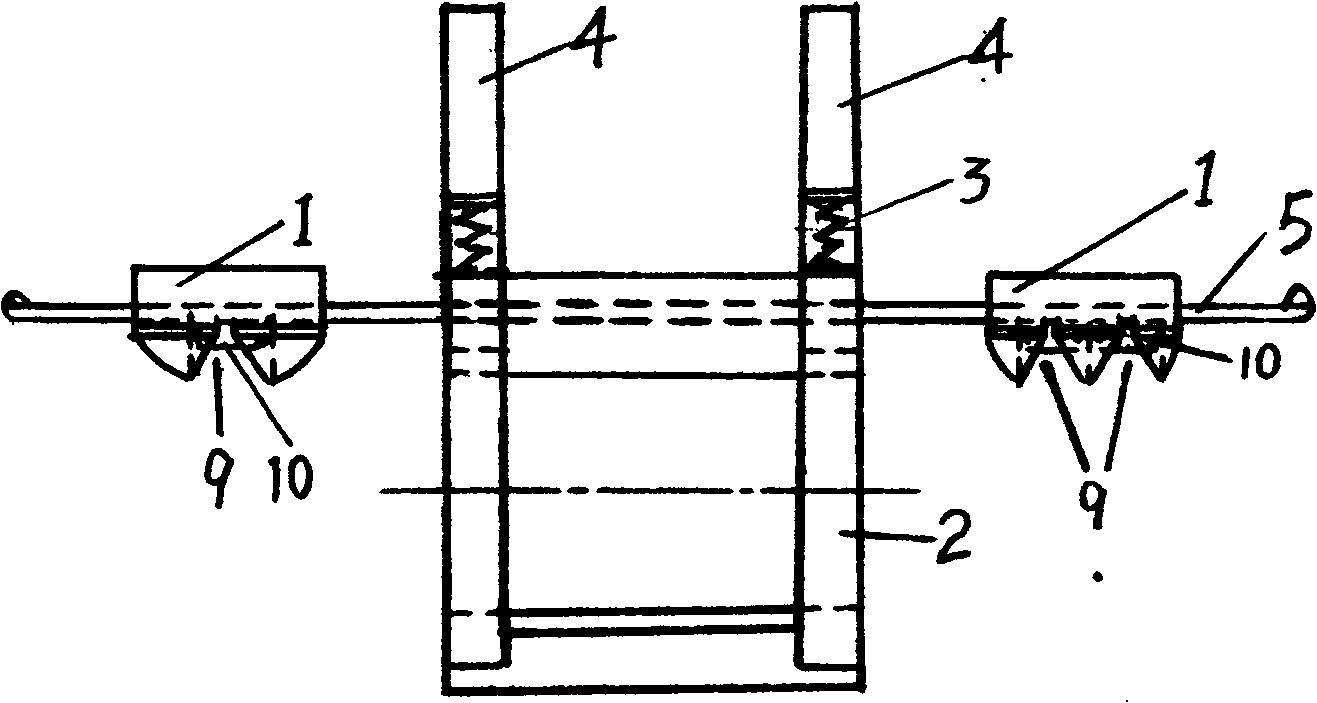

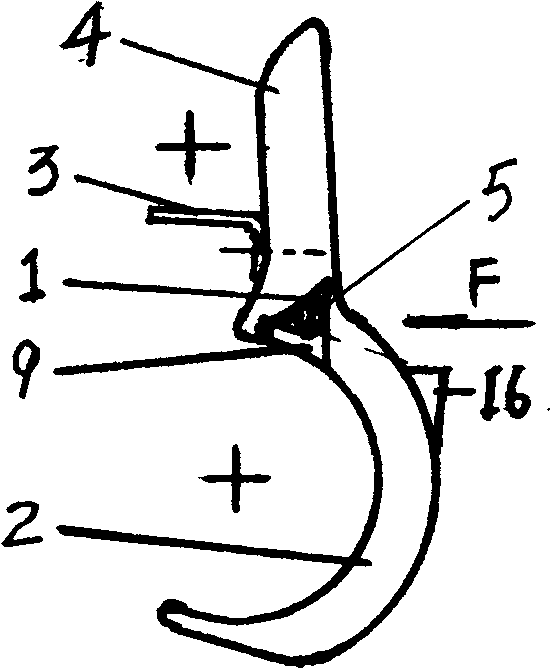

Annular flake-shaped electrode electrostatic spinning device

ActiveCN105624808AReasonable fixed installationAchieve continuous cleanlinessFilament/thread formingNanofiberEngineering

The invention discloses an annular flake-shaped electrode electrostatic spinning device. The annular flake-shaped electrode electrostatic spinning device comprises a spinning system, a power system, a coating mechanism, a liquid supply system, a cleaning mechanism, a collecting system and a high-voltage power supply, wherein the collecting system is positioned above the spinning system; the spinning system comprises a spinning electrode and a base; the spinning electrode is fixed to the base; the power system drives the base and the spinning electrode to rotate in a single direction; the coating mechanism and the cleaning mechanism are arranged on the spinning electrode and are fixed; the cleaning mechanism is positioned in front of the coating mechanism in the direction of motion of the spinning electrode; the collecting system comprises a collecting electrode; the spinning electrode is an annular flake; the emitting end of the annular flake is of a tip structure. According to the annular flake-shaped electrode electrostatic spinning device, the yield and the quality of nano-fibres can be improved; batch preparation of the nano-fibres is realized; the mechanisms are simple; the operation is simple and convenient; industrialized application is easy to realize.

Owner:FOSHAN QINGZI PRECISION MEASUREMENT & CONTROL TECH

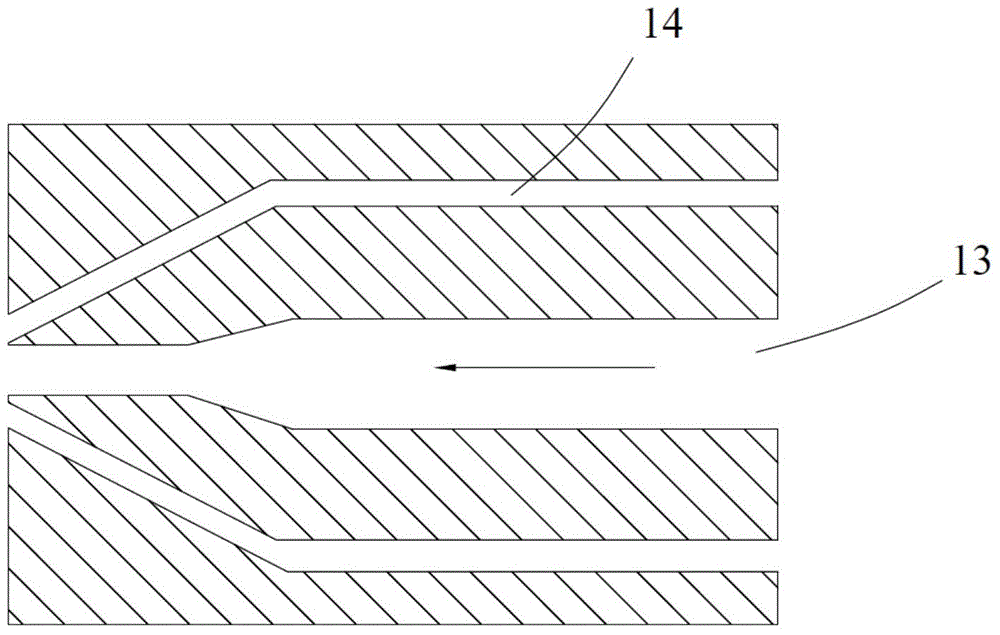

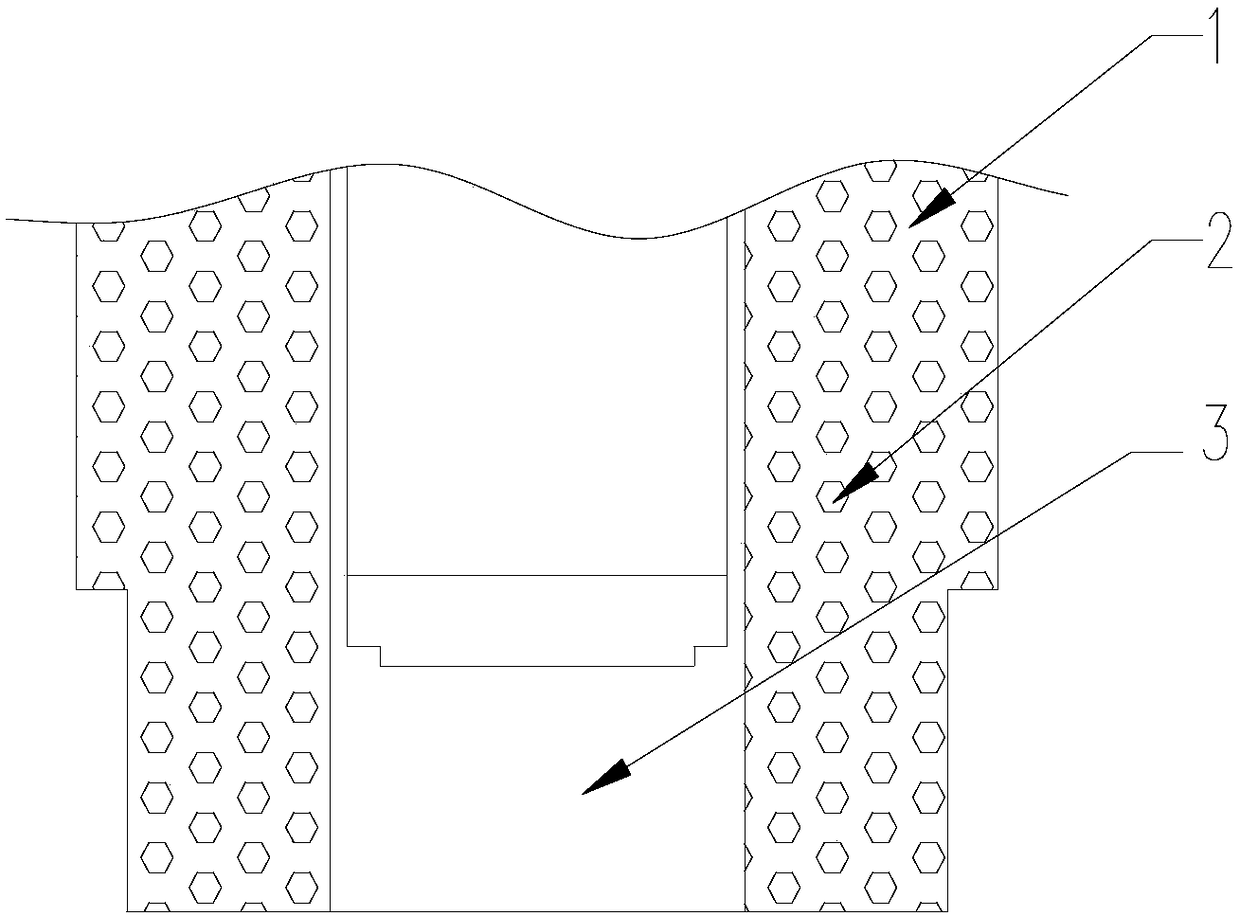

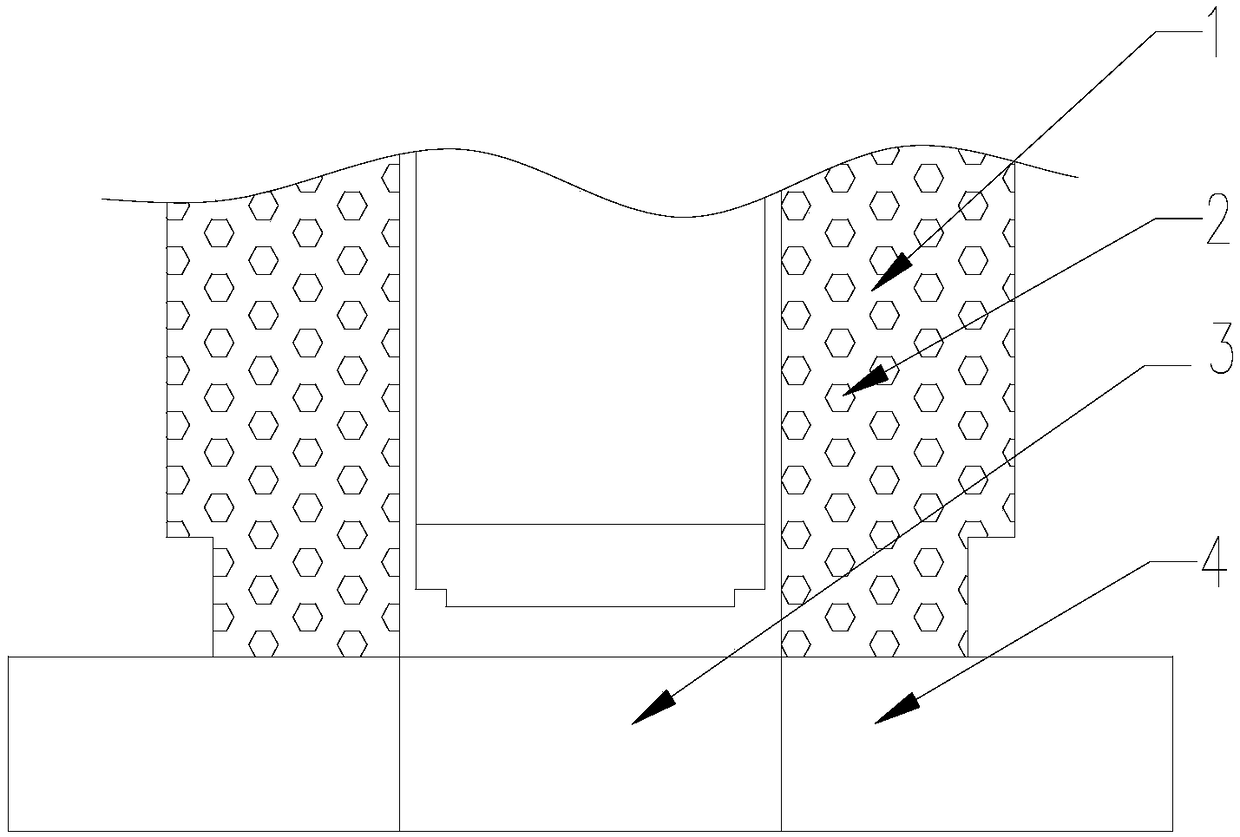

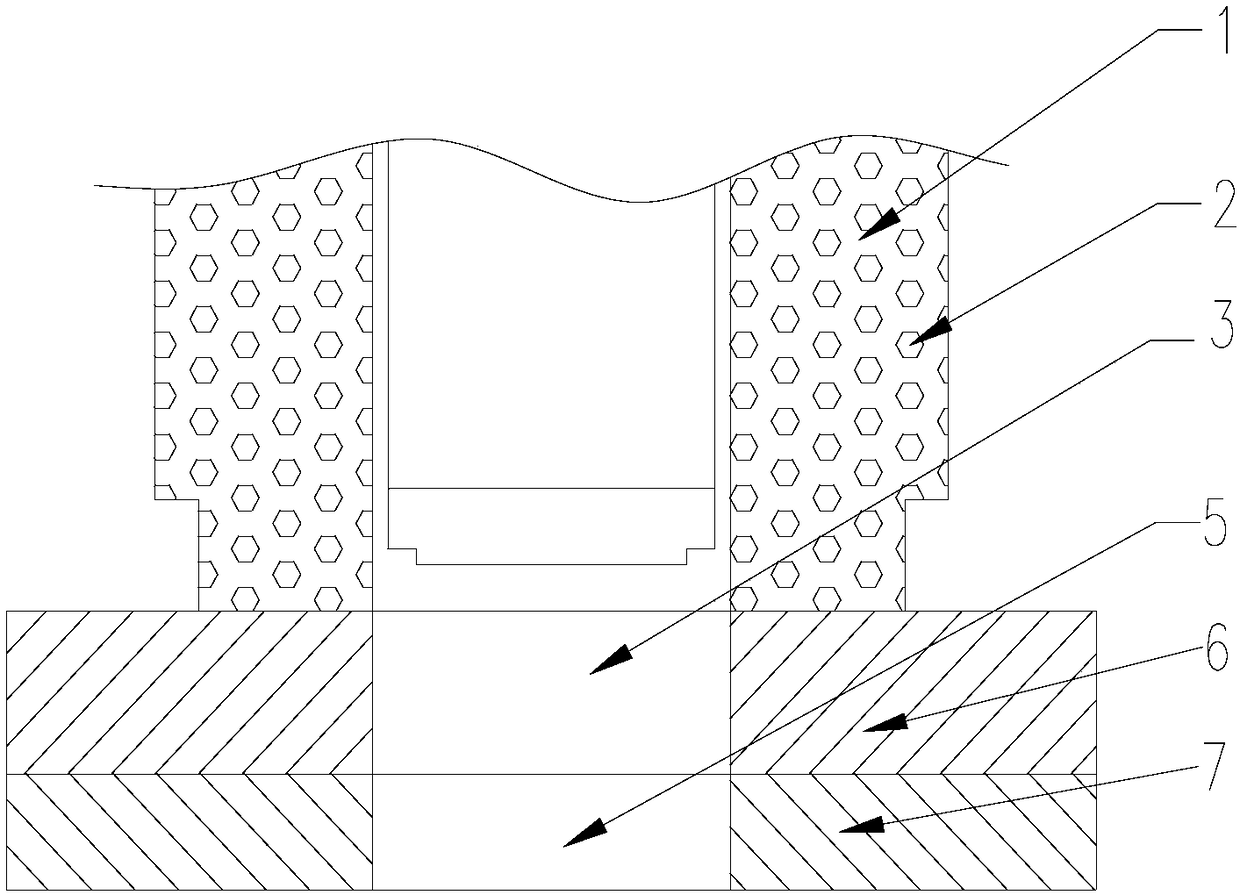

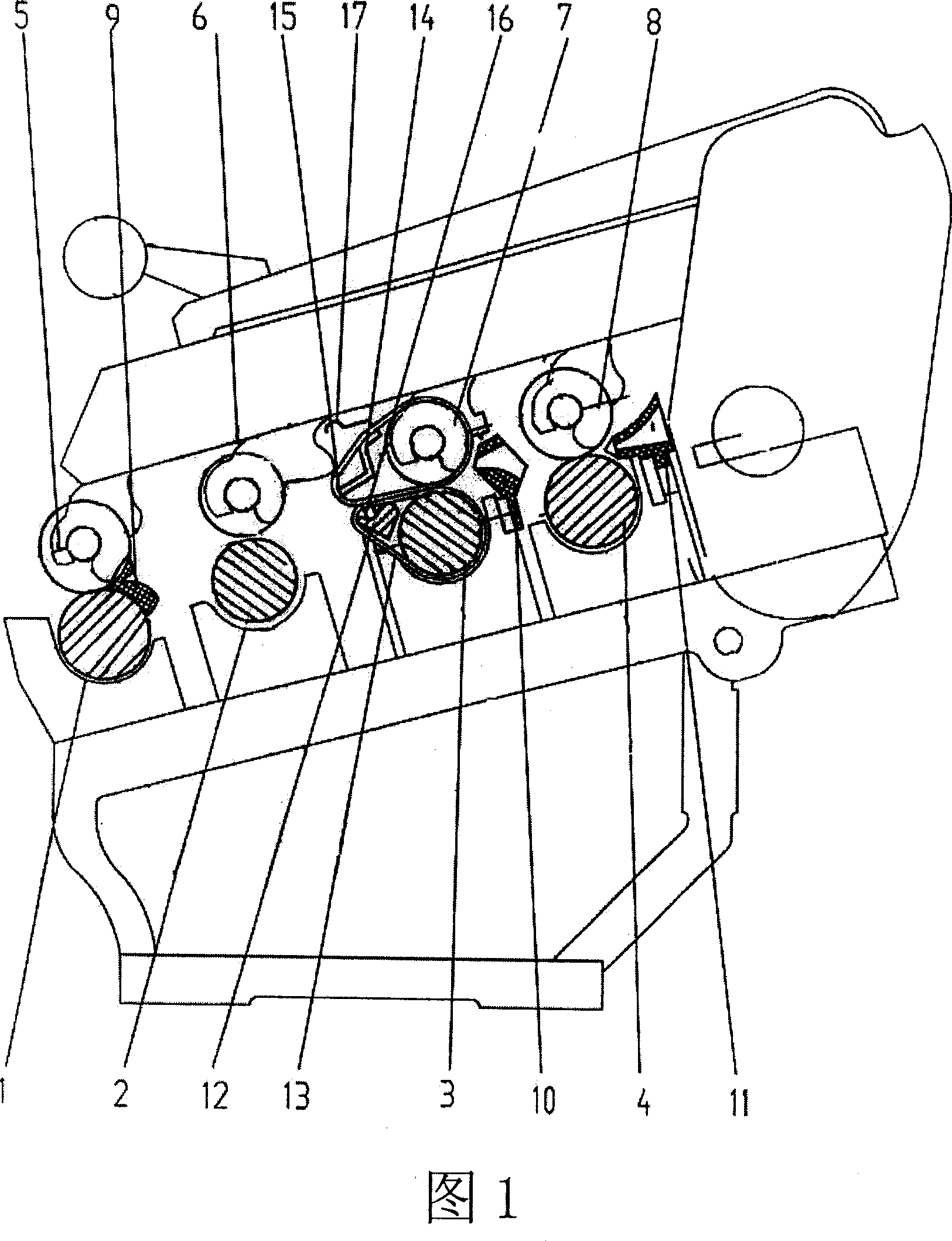

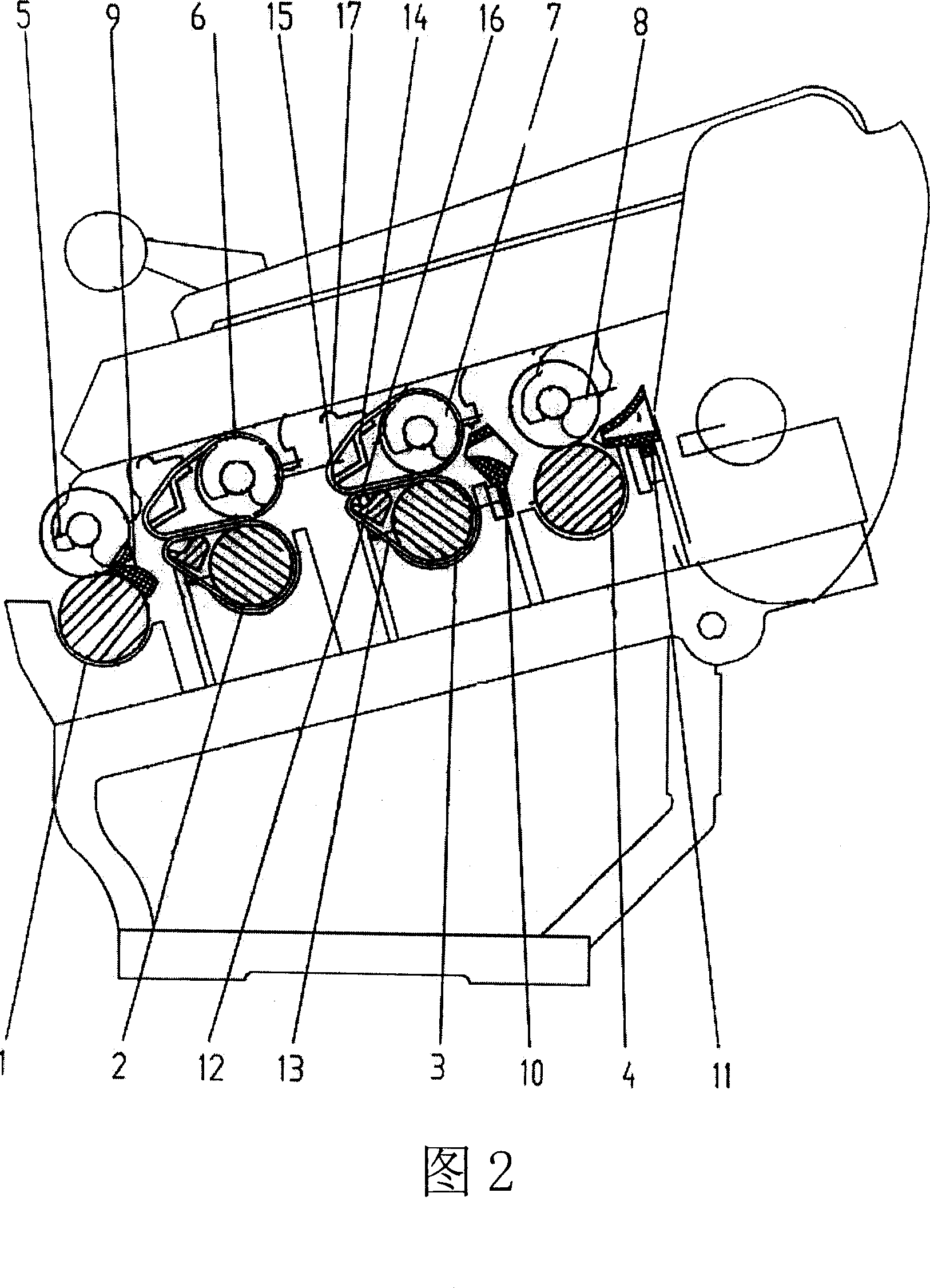

Traversing compact spinning apparatus

The invention relates to a cotton and wool weaving mechanical component, in particular to a transverse type compact spinning and transverse type compact Siro-spinning device for a spinning machine, which is applicable to equipment of cotton and wool spinning machines. The device comprises a tightener, a positioner, a gag lever post, a slide rod, etc. The tightener is arranged in a floating zone behind a front jaw consisting of a front roller and a front roller roller or a twisting triangular zone in front of the front jaw; the slender slide rod is transversely sleeved and fixed on the positioner; the slide rod and the front roller are arranged in a parallel mode in the floating zone or the twisting triangular zone; the tightener is sleeved on the slide rod and can move transversely; a fiber channel of the tightener is provided with splayed smooth crown faces on two sides with large inlets and small outlets; fiber strand becomes compact through the fiber channel of the tightener; and the quality level in fluff, strength, evenness, thick places, thin places, neps and the like for final yarn is remarkably improved after twisting forming. The transverse type compact spinning and transverse type compact Siro-spinning device is the transverse type compact spinning device which is low in investment and can comprehensively improve the spinning quality.

Owner:刘志祥

Preparation method of heat-sensitive copolyester fiber

ActiveCN108660537AReduce consumptionReduce self-condensation side reactionsMonocomponent polyetheresters artificial filamentMonocomponent copolyesters artificial filamentFiberPolymer science

The invention relates to a preparation method of a heat-sensitive copolyester fiber. The preparation method comprises the following steps: mixing terephthalic acid, aliphatic diol I, a guide and a titanium-silicon-cobalt composite catalyst uniformly, then subjecting the mixture to an esterification reaction, a pre-polycondensation reaction and a final polycondensation in sequence to obtain heat-sensitive copolyester, and then preparing the heat-sensitive copolyester fiber by melt direct spinning; the aliphatic diol I is propylene glycol or butylene glycol; the guide is an ester compound generated by a reaction between dibasic acid and aliphatic diol II; the molar ratio of the terephthalic acid to the aliphatic diol I is 1:(1.05-1.10); the titanium-silicon-cobalt composite catalyst is formed by compounding a titanium-silicon composite catalyst and a cobalt catalyst; the titanium-silicon composite catalyst is obtained by loading a titanium-based catalyst with a silicon-based catalyst; and polysiloxane and a copolymerization component are added during the final polycondensation reaction. The preparation method provide by the invention is few in side reactions and high in reaction rate; an obtained product is concentrated in molecular weight distribution and good in quality; and the fiber is prepared with the melt direct spinning.

Owner:DONGHUA UNIV

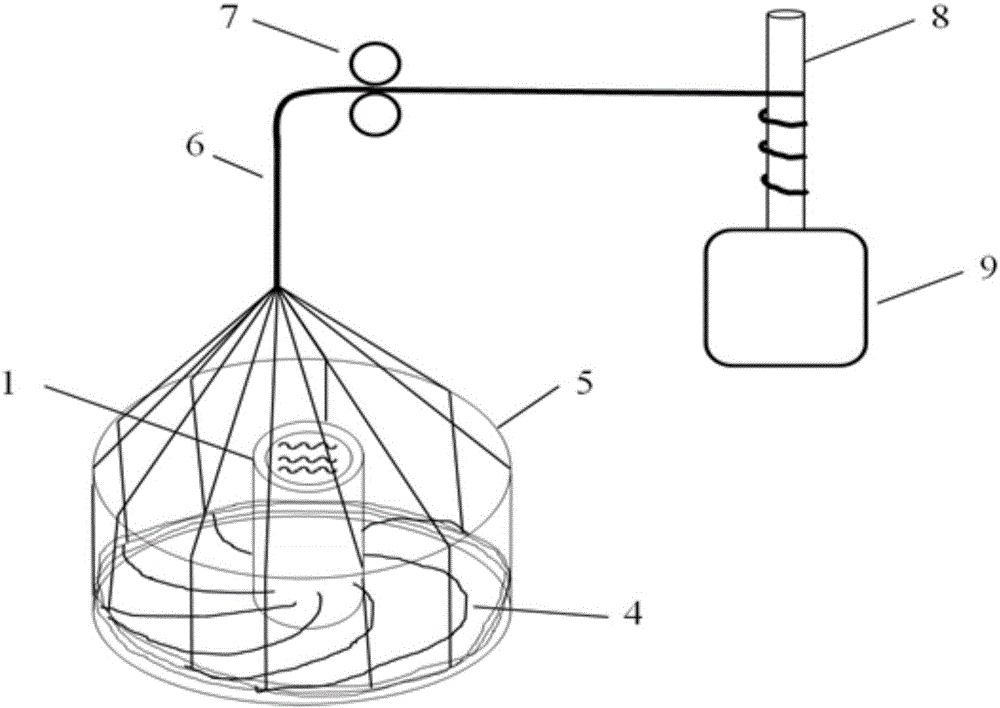

Spherical opposite-spraying type batched nanofiber yarn processing device and using method thereof

ActiveCN106811845ARealize automatic supplyEasy to operateSpinnerette packsNew-spun product collectionYarnFiber

The invention relates to a spherical opposite-spraying type batched nanofiber yarn processing device and a using method thereof. The device comprises a body and a base. Crossed wedge grooves are formed in the middle of the base. The body is symmetrically arranged on the second wedge groove along the first wedge groove. The body comprises a liquid supply system, a separation electric field control system, a spherical brush type spinneret system, a nanofiber yarn forming system and a nanofiber yarn collecting system. The liquid supply system comprises an air cylinder, a spinning solution storage bottle, an oil bath groove and a liquid guiding pipe. The spinning solution storage bottle is arranged inside the oil bath groove. The spinning solution storage bottle, the liquid guiding pipe and a liquid brushing groove form a communicating vessel structure. The spinning solution storage bottle is connected with the air cylinder through an air pipe. A main valve and a pressure reduction valve are sequentially arranged at the portion, close to the air cylinder, of the air pipe. Due to the liquid supply system adopting the air pressure communicating vessel, automatic supply of a high polymer solution can be achieved, and the device is simple and easy to use, and convenient to operate.

Owner:DONGHUA UNIV

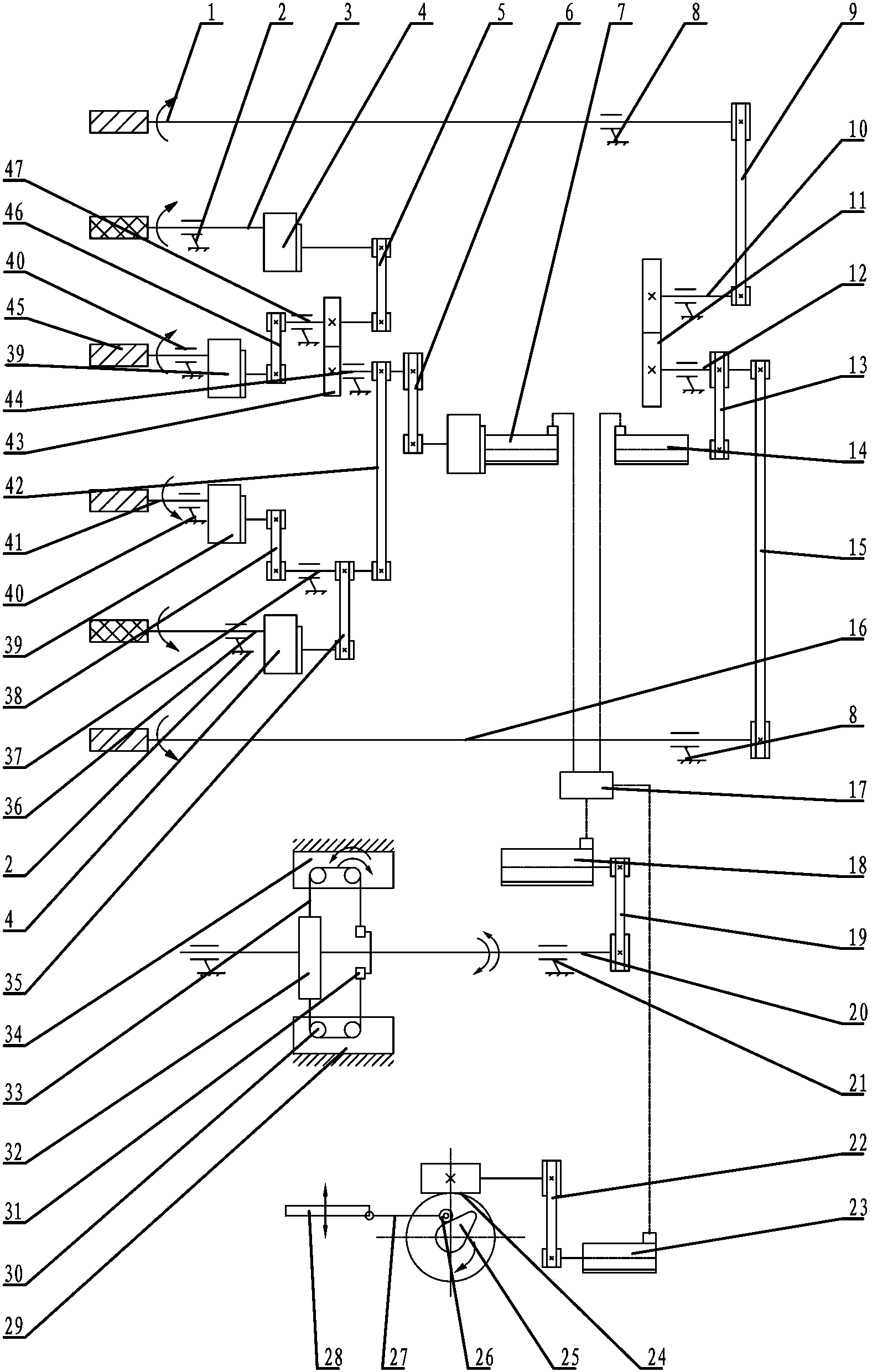

Driving device for wool spinning machine

ActiveCN102704059BReduce labor intensityReasonable structureContinuous wound-up machinesGear driveGear wheel

The invention relates to a driving device for a wool spinning machine. After a front roller motor decelerates, one path of front roller motor subjected to deceleration is connected with a front-right roller through the driving of a first belt; the other path of front roller motor subjected to deceleration is connected with a front-left roller through driving of a first intermediate gear pair and a second belt; after a rear-middle roller motor decelerates, one path of rear-middle roller motor subjected to deceleration is connected with an intermediate roller gearbox through driving of a third belt and a fourth belt; the other path of rear-middle roller motor subjected to deceleration is connected with the intermediate roller gearbox through driving of a second intermediate gear pair and a fifth belt; left and right intermediate rollers are connected with the intermediate roller gearbox; the third belt drives to be connected with a rear roller gearbox through the driving of a sixth belt; the second intermediate gear pair is connected with a rear roller gearbox through driving of a seventh belt; left and right rear rollers are connected with the rear roller gearbox; after a main motor decelerates, the main motor subjected to deceleration is connected with a spindle through a spindle belt via a main shaft and a rolling disk; and a lifting motor subjected to deceleration is connected with a ring rail through a worm gear and worm transmission pair, a stroke cam, a cam roller and a swing rod. The driving device disclosed by the invention has the advantages of simple structure, reduced amount of driving mechanisms and reduction of production cost.

Owner:常州市同和纺织机械制造有限公司

Degumming method of linen yarn

InactiveCN105401413AImprove spinning qualityReduce manufacturing costBiochemical treatment with enzymes/microorganismsVegetal fibresYarnPectinase

The invention relates to a degumming method of linen yarn. The degumming method comprises following steps: (1) linen yarn is delivered into a yarn cage for 60 to 90min of immersing; (2) linen yarn is treated with an acetic acid solution with a concentration of 2.1ml / l for two times, and then is washed with cold water for one time; (3) linen yarn is subjected to degumming with pectinase; (4) linen yarn is heated to 100 to 120 DEG C rapidly, and then is subjected to acid washing with the acetic acid solution; (5) after acid washing, linen yarn is delivered into a soaping device for 30 to 50min of soaping with a soaping agent, and then water is discharged; (6) at normal temperature, linen yarn is subjected to degumming with xylitol enzyme; (7) linen yarn is washed with water for two times; (8) linen yarn is delivered into a centrifugal dehydrator for 3 to 5min of dehydration; and (9) the obtained linen yarn is dried for 60 to 90min. No damage on linen yarn is caused by the degumming method; no environment pollution is caused; and pectinase and xylitol enzyme with high selectivity are used for fabric degumming, so that spinning quality of linen yarn is improved, production cost is reduced, and pollutant discharge is reduced.

Owner:ZHANGJIAGANG ZHENXIN PRINTING & DYEING

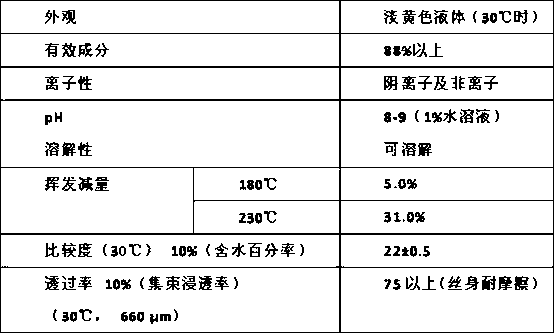

Polyester long-fiber FDY (fully drawn yarn) oil solution

The invention provides a polyester long-fiber FDY (fully drawn yarn) oil solution. On the basis of the total weight of the polyester long-fiber FDY oil solution, the polyester long-fiber FDY oil solution comprises 12-14% of POE (polyoxyethylene) (5) octadeyl alcohol ether, 5-8% of POE (5) lauryl ether phosphate potassium salt, 4-7% of POE (30) castor oil, 4-8% of PEG (polyethylene glycol) (400) dilaurate, 4-6% of sodium dodecylsulfate, 13-15% of random polyether, 8-10% of POE (7) benzylphenyl phenolic ether, 8-12% of dioctyl sebacate, 22-25% of trimethylolpropane didecanoate, 4-5% of capryl alcohol and 3-4% of butyl cellosolve. The oil solution provided by the invention has excellent heat resistance, smoothness and antistatic property, can not bring about impediment in the drafting spinning and false twisting process, reduces the possibility of yarn breaking and fluffing, fills up the blank of high quality oil solutions in China, and has wide application prospects.

Owner:SUZHOU SHENGDEZHU TECH DEV

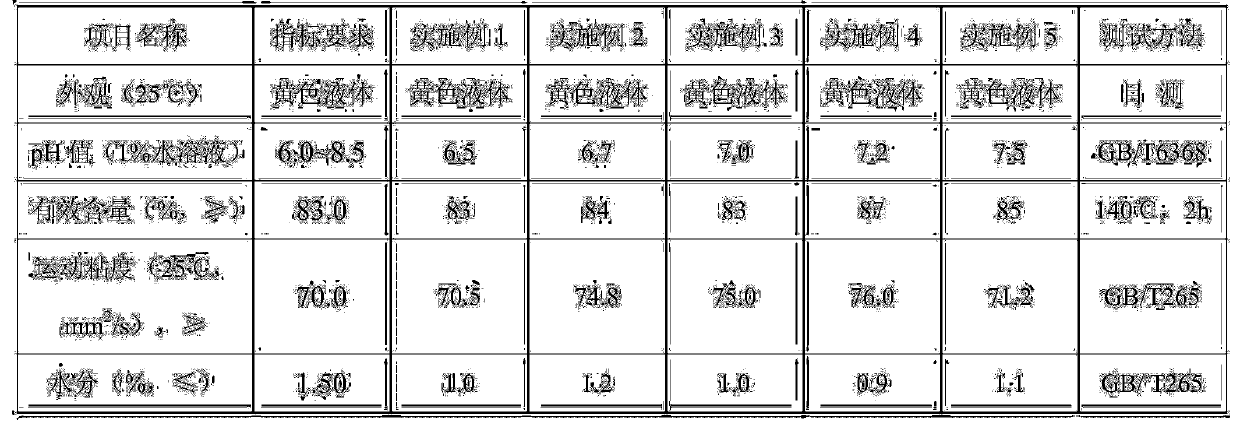

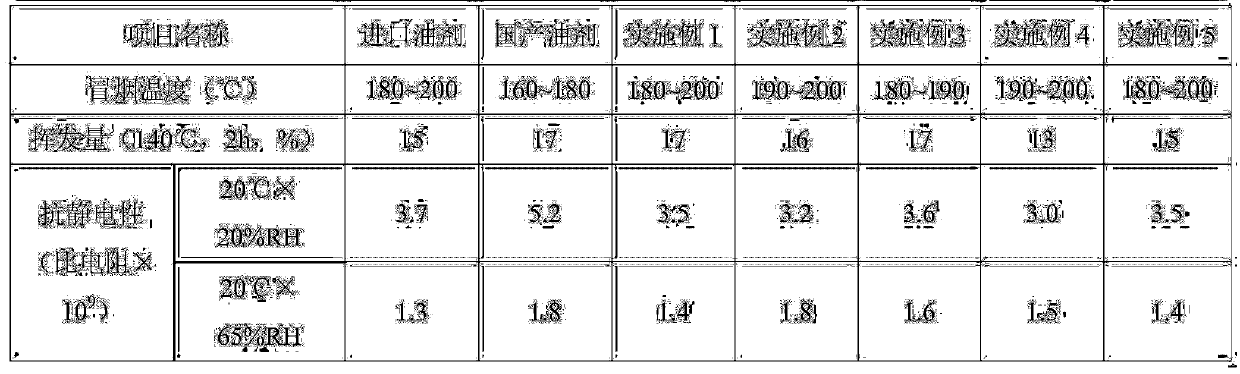

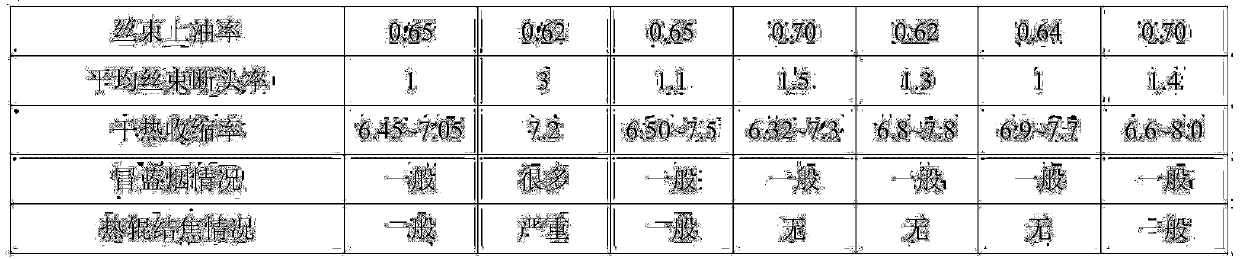

High-temperature oil agent for polyester industrial yarns, and preparation method thereof

The invention provides a high-temperature oil agent for polyester industrial yarns, and a preparation method thereof, and in particular relates to the technical field of textiles of polyester industrial yarns. The high-temperature oil agent in the invention is composed of the following components in mass percentage: 45-65% of a smoothing agent, 8-18% of an emulsifying agent, 2-8% of a collecting agent, 5-10% of an anti-static agent, 2-5% of a dispersing agent, 1-3% of a humectant, 8-18% of a diluent solvent, 0.1-1.5% of an antioxygen, 0.1-0.5% of a pH adjusting stabilizer, and 0.5-1% of water,wherein the smoothing agent is a synthetic ester smoothing agent. Various components are compounded and modulated into the high-temperature oil agent according to the ratio. The high-temperature oilagent in the invention has good lubricating property, and can effectively inhibit electrostatic generation; and simultaneously, the igh-temperature oil agent in the invention is good in high-temperature resistance, low in tarring degree on a hot roller, little in blue smoke generation, uniform to oil, low in oiling rate, and good in tow spinnability.

Owner:金浦新材料股份有限公司

Processing method of drawing frame and core spun yarn

The invention discloses a processing method of a drawing frame and a core spun yarn. The drawing frame includes a feeding cylinder, a guide bar roller, a guide bar frame, a fiber bar positioning plate, a feeding device and a rubber roller. The guide bar frame is arranged on one side of the fiber bar positioning plate. The feeding device is arranged on the side of the rubber roller. The guide bar frame includes an upper guide bar frame, a middle guide bar frame and a lower guide bar frame. The feeding device includes a fixed plate, a positioning plate arranged on the fixed plate. The positioning plate is provided with an upper covered yarn positioning hole, a core yarn positioning hole and a lower covered yarn positioning hole. When being processed, corn yarns pass through the middle guidebar frame and the core yarn positioning hole, and covered yarns completely cover the core yarns after respectively passing through the upper and lower guide bar frame and the upper and lower coveringyarn positioning hole. The core spun yarn made according to the processing method of the drawing frame and the core spun yarns have the advantages of being high in coverage rate, strong in yarn cohesion, difficult in peeling, soft in feeling of the core spun yarns and good in appearance.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

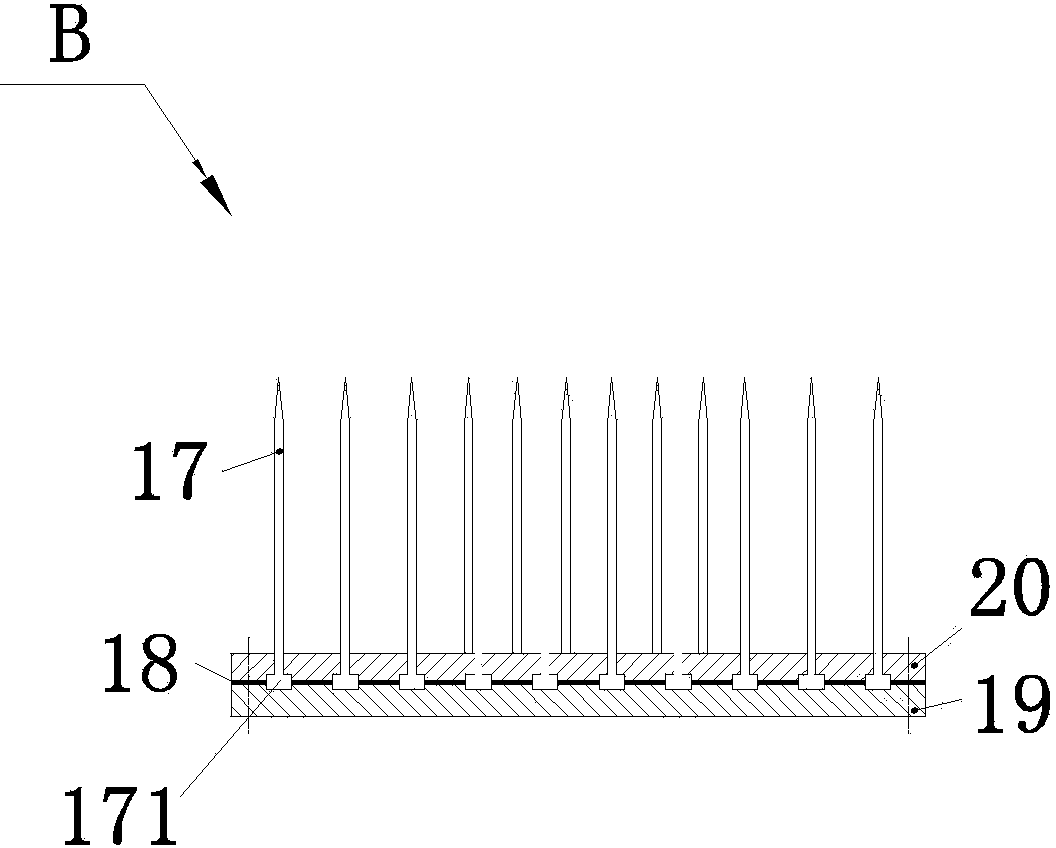

Evenly-liquid-spraying batch electrostatic spinning device

ActiveCN104164706AImprove spinning qualityTimely replacementSpinnerette packsFilament/thread formingElectrospinningBiomedical engineering

The invention relates to the technical field of electrostatic spinning, in particular to an evenly-liquid-spraying batch electrostatic spinning device. The evenly-liquid-spraying batch electrostatic spinning device comprises a base plate, a liquid even-distribution device, at least one liquid supply device, at least one needle point array device, a collecting plate and a high-voltage power source. The two sides of the base plate are provided with guide rails respectively. Capillary tubes for liquid to flow out are distributed on the bottom face of the liquid even-distribution device. The liquid supply device is used for supplying the required liquid to the liquid even-distribution device. The needle point array device is arranged on the base plate, a nozzle is formed in the needle point array device, and the outlet direction of the nozzle faces the bottom face of the liquid even-distribution device. The collection plate is arranged above the liquid even-distribution device and the needle point array device. The anode of the high-voltage power source is electrically connected with the collecting plate. The cathode of the high-voltage power source is electrically connected with the needle point array device and earthed. The device can achieve evenly-liquid-spraying batch electrostatic spinning.

Owner:XIAMEN UNIV

Drafting device and control method of flyer frame

InactiveCN101092766AIncrease draft ratioImprove spinning qualityDrafting machinesKnurlingStructural engineering

This invention relates to a drafting system and a control method for roving machines, in which the drafting system includes a four roller drafting pattern, a four roller double-zone double apron drafting pattern, the four lines of lower rollers contain the following from the front to back: the first includes a metal groove roller, the second includes a metal knurling roller, the third is metal knurling roller and the fourth includes a metal groove roller, the four lines of upper rollers are: the first one is a roller cladding spring materials, the second is a metal apron roller or an apron upper roller cladding spring materials, the third one is a metal apron upper roller or an apron upper roller cladding spring materials and the fourth one is a belt roller cladding spring materials. The control method includes: double -apron low times of drafting is done for the front region, 2.5-10 times of double-apron middle times of drafting for the middle region and 1.1-2 times of low drafting for the back region.

Owner:TIANJIN HONGDA TEXTILE MACHINERY

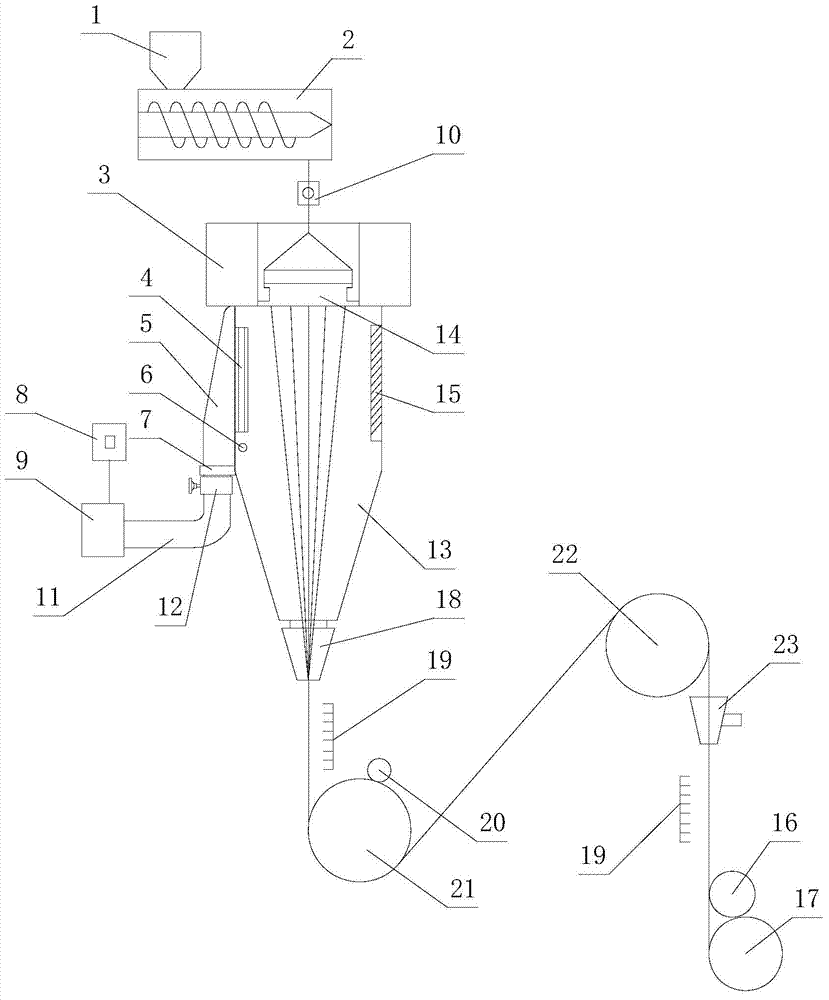

Continuous spinning set of polyester filament yarns

InactiveCN104846450AImprove spinning qualitySimple structureArtificial thread manufacturing machinesFilament/thread formingEngineeringFiber strength

The invention discloses a continuous spinning set of polyester filament yarns, comprising a screw extruder. A hopper is connected to the top of the screw extruder. A spinning component is disposed below the screw extruder. A yarn chamber used for yarn cooling is disposed below the spinning component. Below the yarn chamber along a spinning path, provided in order are a first collector, a first hot roller, a second hot roller, a second collector and a winding roller, and a friction roller is disposed on the outer periphery of the winding roller. The continuous spinning set is simple in structure, reasonable in design and convenient to operate; under mutual cooperation of the screw extruder, the spinning component, the yarn chamber, the first collector, the first hot roller, the second collector and the winding roller, the process of from raw materials to spinning is achieved; operating is simple, the cost is low, and fiber strength is high; meanwhile, the yarn chamber is provided with a side blower, and spinning quality of polyester filament yarns can be improved.

Owner:ZHANGJIAGANG XINYANG CHEM FIBER

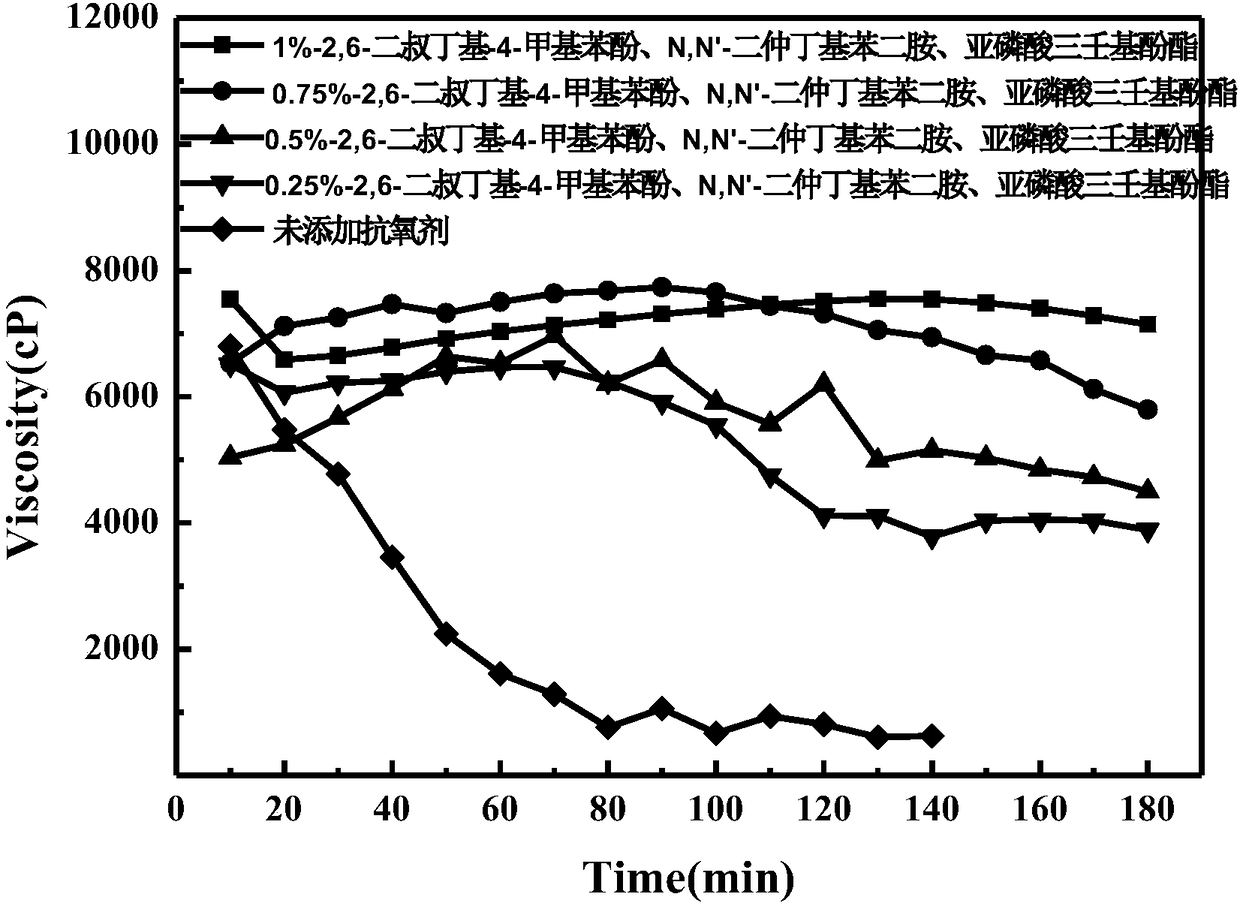

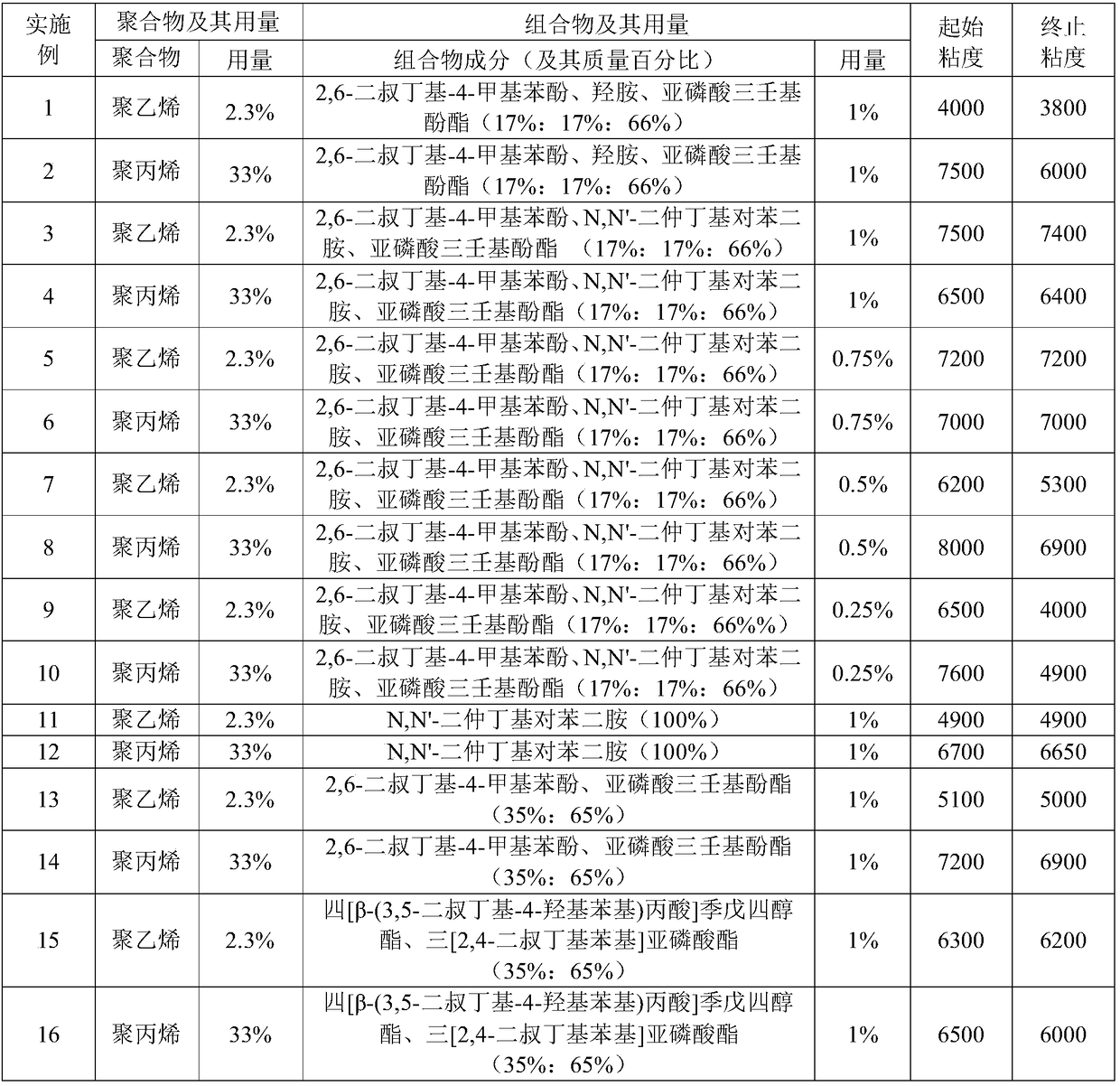

Composition providing polymer with inoxidizability and application thereof

ActiveCN108570173AHas antioxidant propertiesSolve Oxidation ProblemsMonocomponent polyolefin artificial filamentArtifical filament manufactureOxidation resistantLiquid composition

The invention provides a liquid composition providing a polymer with inoxidizability and application thereof. The composition comprises the following components: (1) hindered phenol and / or (2) phosphite or thioester, and (3) an amine antioxidant. The composition has antioxidant properties, is in a liquid state at a temperature of 30 to -10 DEG C, and is added into a polymer to be provided with inoxidizability in the liquid state. The liquid composition can be used as an antioxidant, especially as an antioxidant in polymer resin. The invention also provides a polymer mixture system having oxidation resistance. In the system, the antioxidant composition for providing the polymer with inoxidizability is added into the mixture system, and the integral system is a homogeneous solution. Throughintroduction of the antioxidant in such a manner, the problem of oxidation of polymers during processing is overcome, and an excess amount of the antioxidant composition does not crystallize during the spinning of polymers, which allows the spinning quality of the polymers to be significantly improved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com