Drafting device and control method of flyer frame

A technology of drafting device and roving frame, which is applied in spinning frame, drafting equipment, textile and paper making, etc. Yarn quality, the effect of extending the draft ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

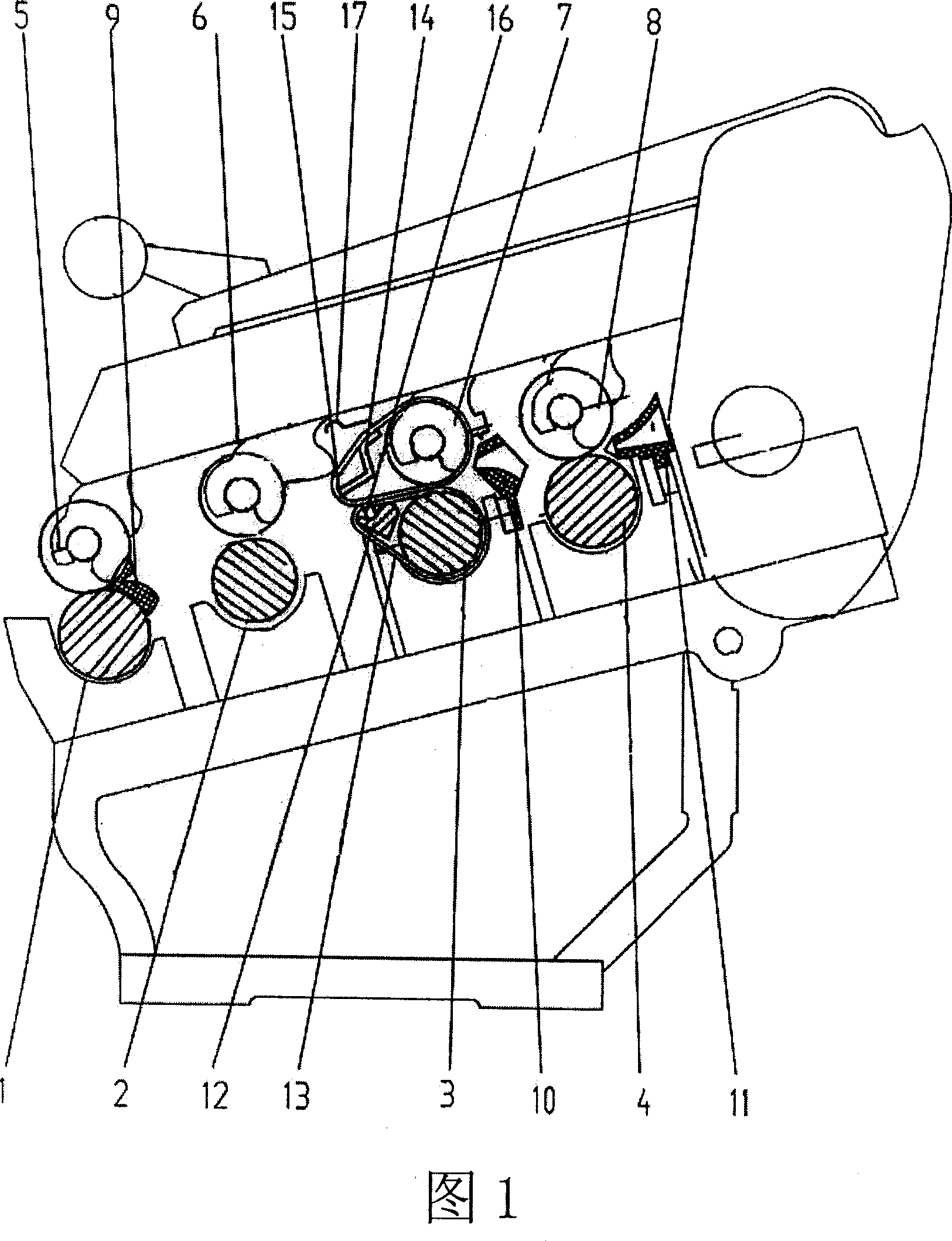

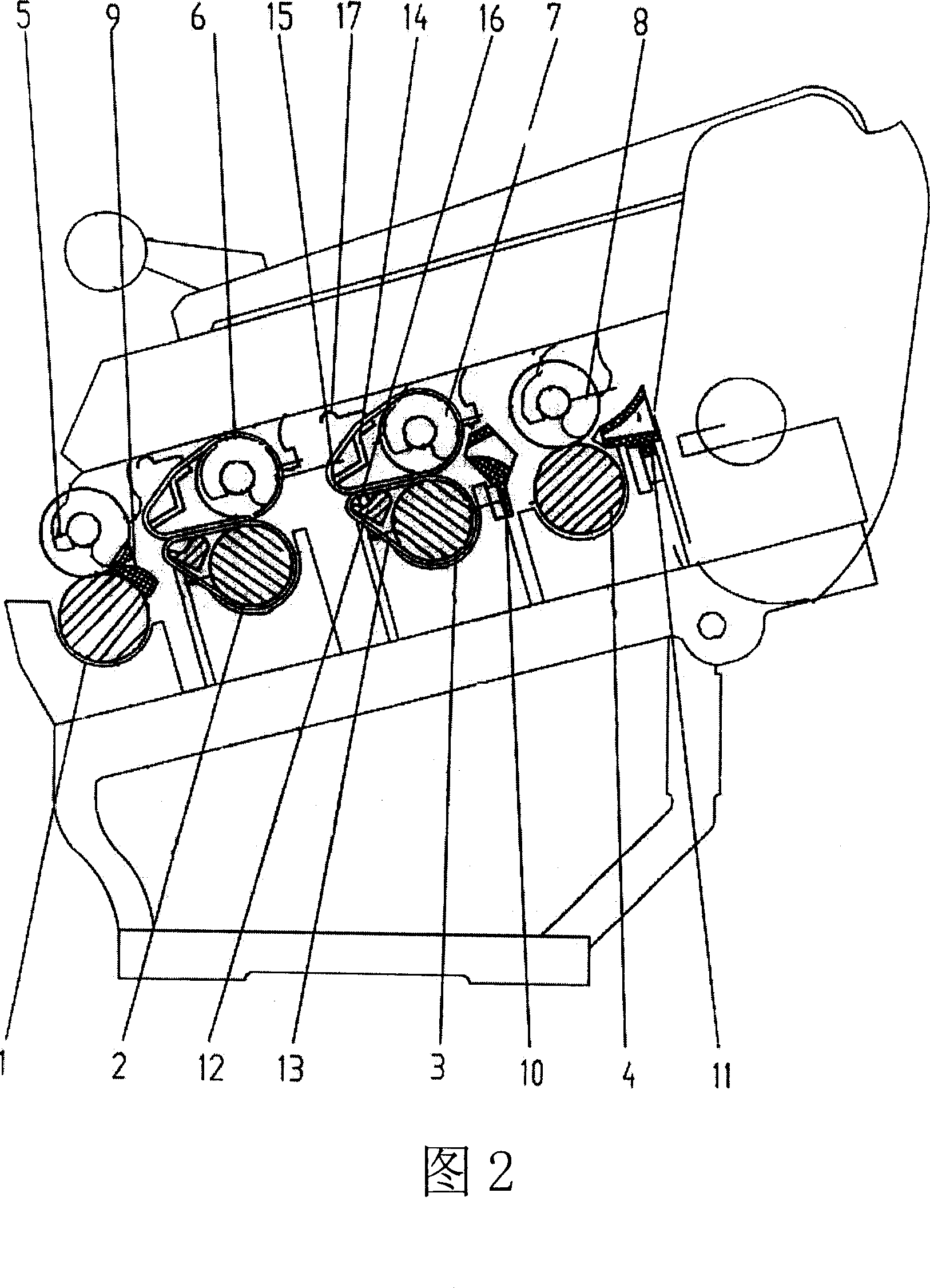

[0012] The invention is a new drafting device and a control method for a roving frame. As shown in Figure 2, in the drafting roller configuration of the present invention, there are still four rows of metal material bottom rollers 1 to 4, and four rows of top rollers 5 to 8, wherein the second metal material bottom roller is a cover ring, and the diameter is changed from the original The 28mm metal material groove roller of the drafting type is changed to a metal knurling roller with a diameter of 25 to 30mm. The diameter of the bottom roller in this embodiment is the groove roller of Φ28mm and the knurled roller of Φ25mm from front to back. , Φ25mm knurled rollers, Φ28mm groove rollers; the second top roller is a cover ring, the diameter of which is changed from the 28mm covered elastic top roller of the original drafting type to the metal material with a diameter of 25 to 28mm Smooth apron top rollers or smooth surface rollers covered with elastic materials, the diameters of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com