Four-roller three-thick-yarn feeding full compact spinning device, spinning method thereof and color yarn

A technology of four rollers, three rovings and three rovings is applied in the directions of spinning machines, textiles, papermaking, and yarns, which can solve the problems of not meeting the new requirements for the development of textile raw materials, so as to improve the spinning efficiency and increase the added value of yarns. , Improve the effect of color style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

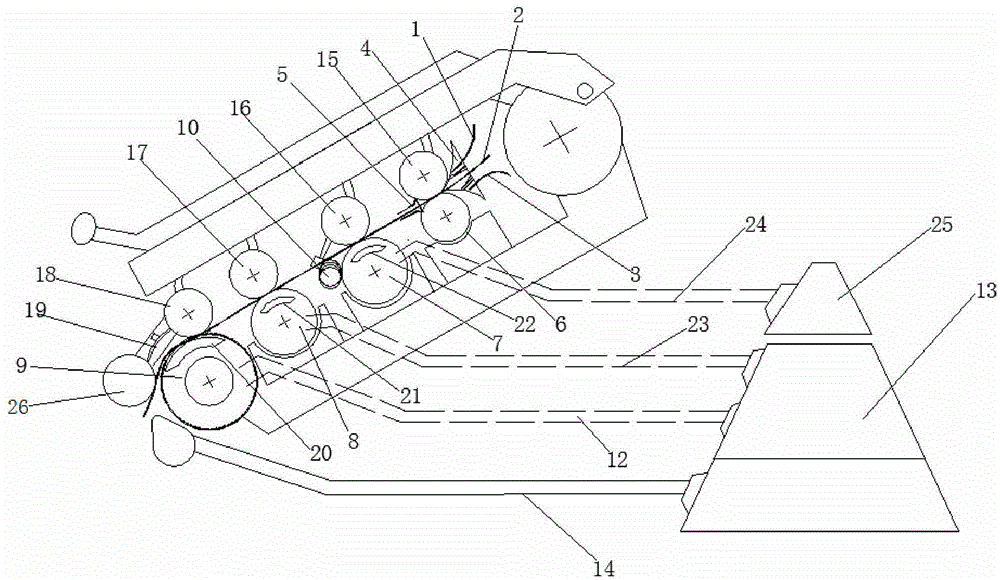

Method used

Image

Examples

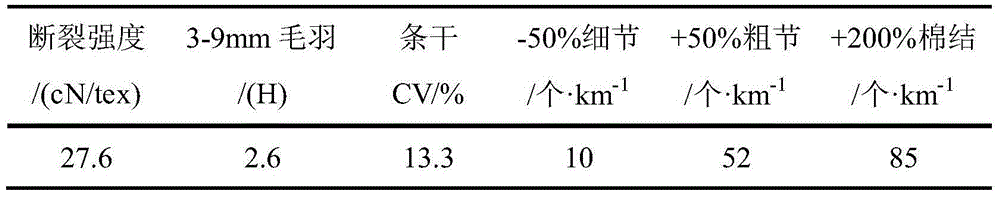

Embodiment 1

[0038] Embodiment 1: to produce 6.47tex (90 S ) colorful yarn as an example. Raw cotton: Xinjiang long-staple cotton with a fineness of 1.44dtex, a main body length of 38.2mm, a short staple rate of less than 20mm of 4.4%, a breaking strength of 24.4cN / tex, a breaking elongation of 7.7%, a micronaire value of 3.4, and a uniformity of 78.1%.

[0039] The specific process steps are as follows:

[0040] (1) Pretreatment

[0041] For the A roving, dye the long-staple cotton fiber yellow and let it stand for 20 hours; for the C roving, dye the long-staple cotton fiber green and let it stand for 20 hours.

[0042] (2) Open and clean cotton

[0043] For A roving, the speed of the beater is 780r / min, the distance of the beater blade extending from the rib is 2.5mm, and the annular sawtooth form of the beater is adopted, which is densely distributed on the outside and thin on the inside; The interval is 11mm, the distance between the dust bar and the beater is 8mm at the entrance, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com