Core yarn neatening entwisting parallel spinning device

A technology of parallel spinning and yarn guiding device, which is applied in the direction of yarn, textile and paper making, and can solve problems such as the limitation of spinning variety and yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

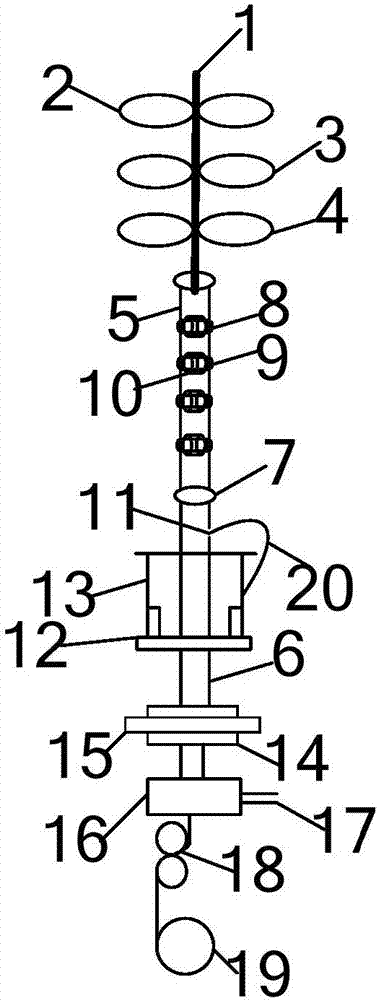

[0010] Such as figure 1 As shown, a core yarn finishing twisted parallel spinning device includes a drafting device, which includes a rear roller pair 2, a middle roller pair 3 and a front roller pair 4, and an upper hollow spindle is arranged at the lower part of the drafting device 5. The top of the upper hollow spindle is open, and a yarn guide device 8 is installed inside the upper hollow spindle. The number of yarn guide devices is between 3-10. The yarn guide device includes an intermediate shaft 9, which is cylindrical. The two ends of the shaft are respectively fixed on the inner side of the upper hollow spindle, and a yarn guide wheel 10 is installed on the intermediate shaft, and the yarn guide wheel can rotate freely along the intermediate shaft, and a lower hollow spindle 6 is arranged at the bottom of the upper hollow spindle. The hollow spindle is hollow cylindrical, and the bottom end of the upper hollow spindle is interconnected with the top end of the upper ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com