Electrostatic spinning device for efficiently preparing nano-fiber fabrics

A nanofiber, electrospinning technology, applied in fiber processing, non-woven fabrics, textiles and papermaking, etc., can solve the problems of uneven spinning solution, affect fabric strength, insufficient improvement, etc., to improve spinning quality, The effect of improving spinning efficiency and spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

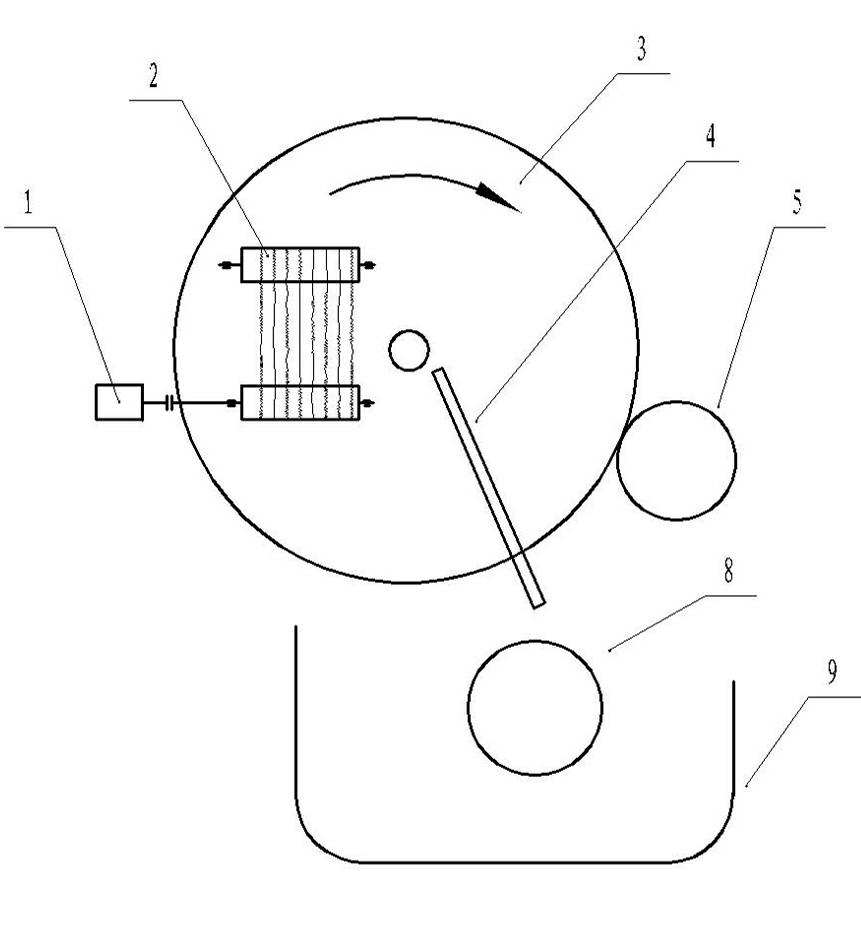

[0026] Such as figure 1 As shown, an electrospinning device for efficiently preparing nanofiber fabrics, the device includes a frame, a collection device and at least one group of jet generation devices, and the group of jet generation devices includes two rotatable electrode rollers 2, both A number of spring-like electrode wires 6 are wound between them, and the lower electrode roller 2 of the two electrode rollers 2 is soaked in the trough 7 containing the spinning solution, which has a positive charge; the collecting device includes a The electrode disk 3 is arranged in parallel with the spring electrode wire 6, the electrode disk 3 is provided with a guide plate 4, the guide plate 4 is connected to a winding roller 8; the electrode disk 3 is connected to the drag wheel 5, and the electrode disk 3 is connected to the The drag wheels 5 are all connected with the drag motor 1.

[0027] There is an opposite voltage between the spinning solution and the electrode disk 3, and ...

Embodiment 2

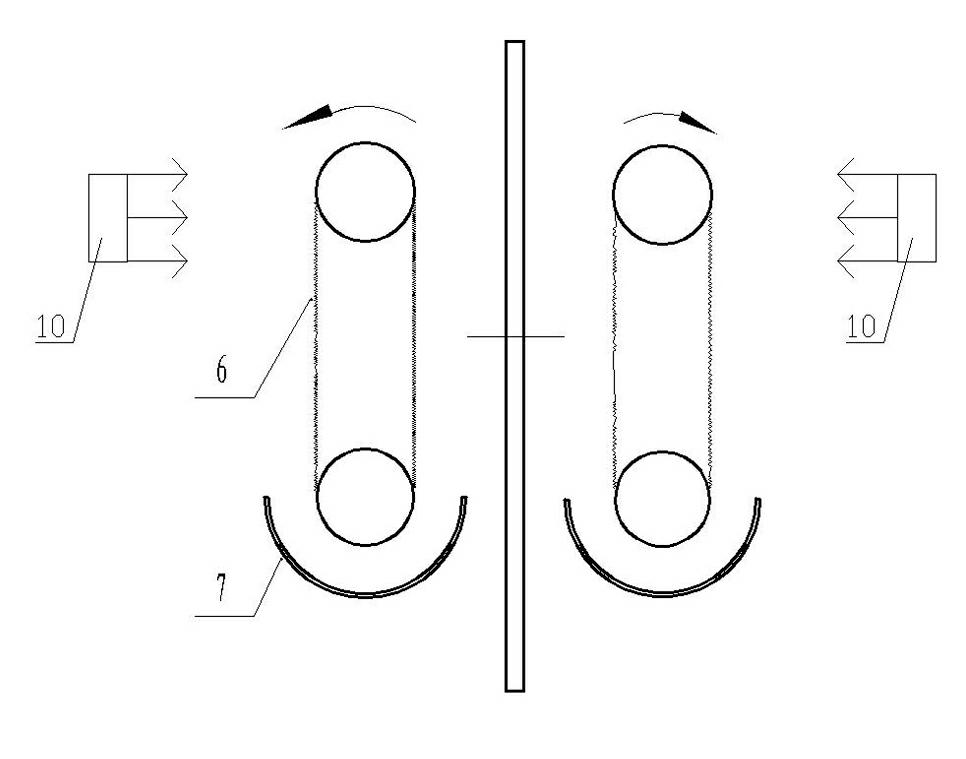

[0030] Such as figure 2 As shown, the spinning solution is connected to a positive voltage (can also be a negative voltage), and the electrode disk 3 is grounded, and the voltage difference between the two is 30kV. There are two groups of jet generating devices, which are located on both sides of the electrode disc and are oppositely arranged.

[0031] The electrode disc 3 rotates clockwise under the drive of the drag wheel 5 at a rotation speed of 3 r / min. The two electrode rollers 2 rotate in the same direction to drive the spring-shaped electrode wire 6 to move in the direction of rotation, and the rotation speed is 3r / min. The spring-like electrode wire 6 is a spring-like helical structure with a pitch of 3 mm. The distance between the electrode roller 2 and the electrode disc 3 is 5 cm.

[0032] It also includes a one-way air blowing device 10 arranged on one side of the jet generating device to blow air to the electrode disc.

[0033]The spinning solution is: dissol...

Embodiment 3

[0036] Such as figure 1 As shown, an electrospinning device for efficiently preparing nanofiber fabrics, the device includes a frame, a collection device and at least one group of jet generation devices, and the group of jet generation devices includes two rotatable electrode rollers 2, two electrodes The rollers have positive charges in the same direction, and a number of spring-shaped electrode wires 6 are wound between the two. The electrode roller 2 located below the two electrode rollers 2 is soaked in the trough 7 containing the spinning solution. The liquid has a positive charge; the collection device includes an electrode disk 3, which is arranged in parallel with the spring-shaped electrode wire 6, and the electrode disk 3 is provided with a guide plate 4, and the guide plate 4 is connected to a winding roller 8; the electrode disk 3 The drag wheel 5 is connected, and both the electrode disc 3 and the drag wheel 5 are connected with the drag motor 1 .

[0037] There ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com