Anti-haze screen window and preparing method thereof

A technology for preventing smog and screen windows, which is applied in the fields of insect prevention, textile and paper making, filament/thread forming, etc., to achieve the effect of easy to obtain raw materials, easy large-scale production, and block invasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) The mass percent content of configuring thermoplastic polyurethane is 15-22wt%, and the organic solvent is a mixed solution of dimethylformamide and acetone, wherein the mass percent of dimethylformamide and acetone is 1:1, with a magnetic stirrer Stir the solution for 2h, then add 1wt% titanium dioxide nanoparticles and continue stirring for 2h to obtain a uniform electrospinning precursor solution;

[0030] (2) Place the prepared electrospinning precursor solution in the liquid storage mechanism of the electrospinning device, place the screen window on the collection mechanism of the electrospinning device, and the vertical distance between the nozzle and the collection mechanism is 10-18cm , the spinning voltage is 22kV, and the electrospinning method is used to deposit nanofibers on the screen window of the collection mechanism, and finally deposited as a thin layer of fiber film, that is, the anti-fog screen window is obtained.

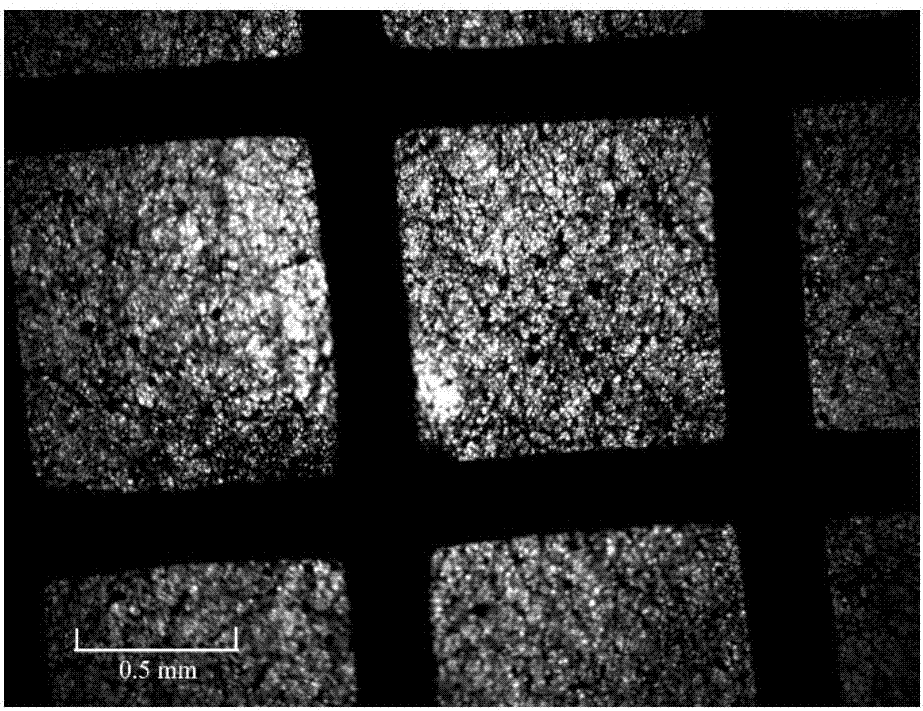

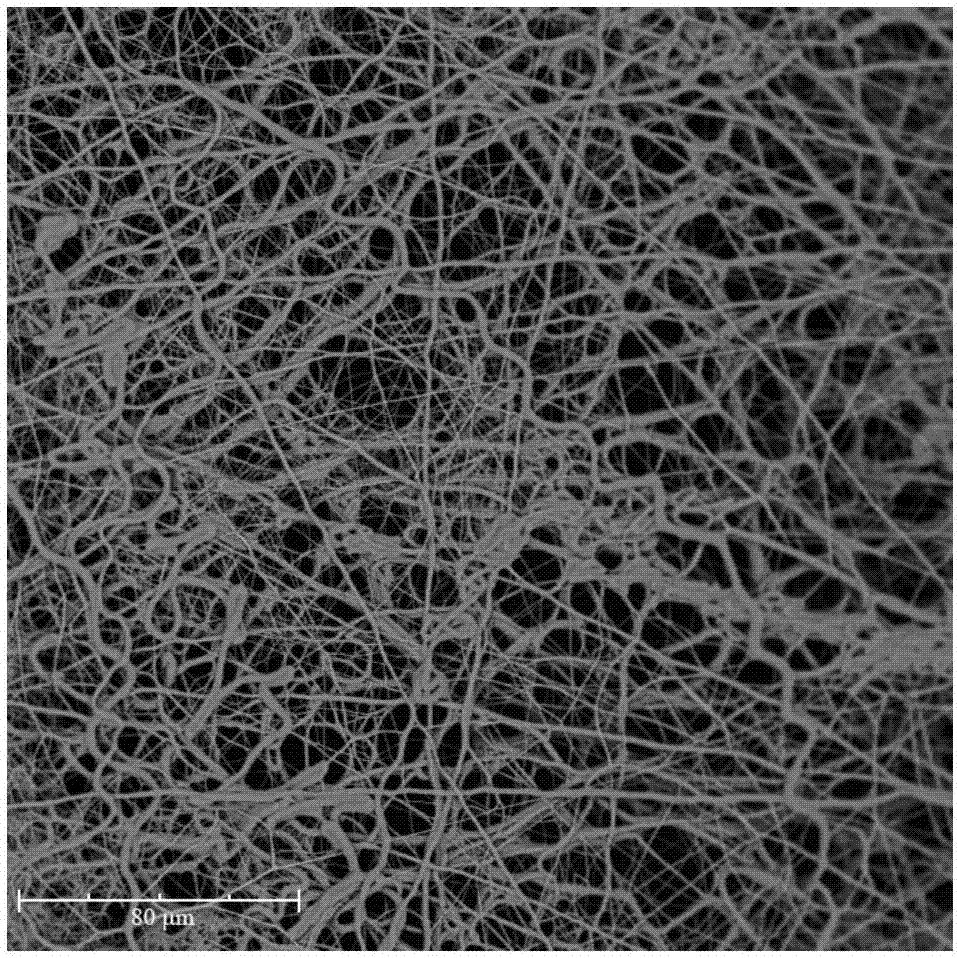

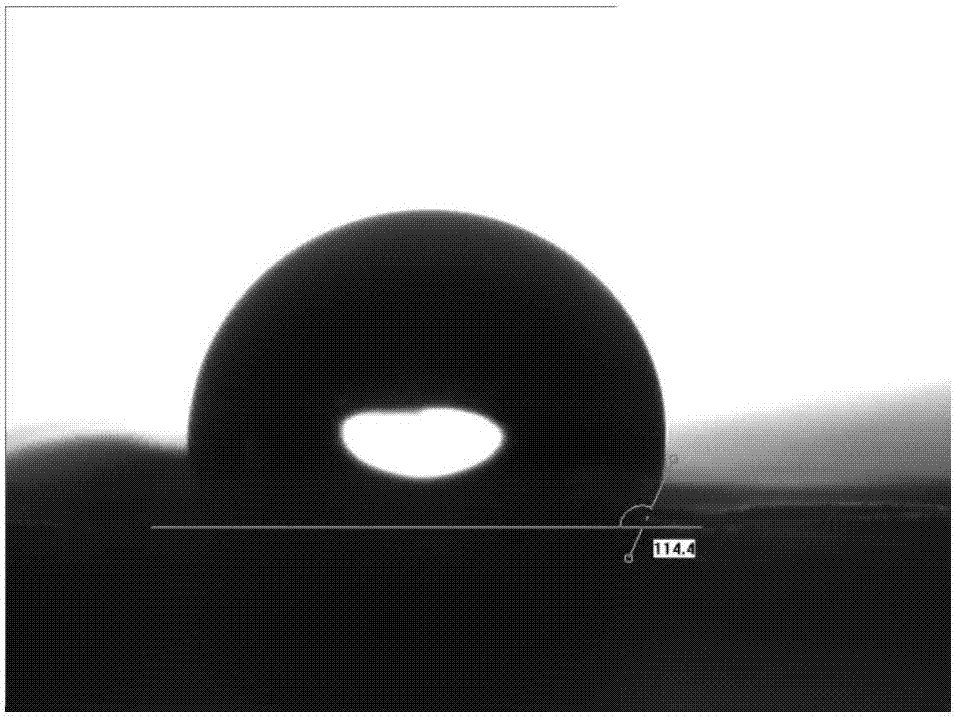

[0031] figure 1 The low-magnif...

Embodiment 2

[0033] (1) Configure the mass percent content of polyvinylidene fluoride to be 10-18wt%, the organic solvent is a mixed solution of dimethylformamide and acetone, the mass percent of dimethylformamide and acetone is 1:1, stir with a magnetic force Stir the solution for 2 hours, then add 1wt% titanium dioxide nanoparticles and continue stirring for 2 hours to obtain a uniform electrospinning precursor solution;

[0034] (2) Place the prepared electrospinning precursor solution in the liquid storage mechanism of the electrospinning device, place the screen window on the collection mechanism of the electrospinning device, and the vertical distance between the nozzle and the collection mechanism is 10-15cm , the spinning voltage is 17kV, and the electrospinning method is used to deposit nanofibers on the screen window of the collection mechanism, and finally deposited as a thin layer of fiber film, that is, the anti-fog screen window is obtained.

Embodiment 3

[0036] (1) The mass percent content of configuration polyacrylonitrile is 10-16wt%, and organic solvent is dimethylformamide, and solution is stirred 2h with magnetic stirrer, then adds 1wt% titanium dioxide nanoparticles and continues to stir 2h, obtains uniform electrostatic Spinning precursor solution;

[0037] (2) Place the prepared electrospinning precursor solution in the liquid storage mechanism of the electrospinning device, place the screen window on the collection mechanism of the electrospinning device, and the vertical distance between the nozzle and the collection mechanism is 11-15cm , the spinning voltage is 18kV, and the nanofibers are deposited on the screen window of the collection mechanism by electrospinning, and finally deposited as a thin layer of fiber film, that is, the anti-fog screen window is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com