Flax fiber degumming method

A technology of flax fiber and degumming method, which is applied in the direction of producing bast fiber by chemical method, which can solve the problems of difficulty, pollution, and high requirements, and achieve the effects of reducing production cost and difficulty, reducing pollution emissions, and increasing spinning count

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

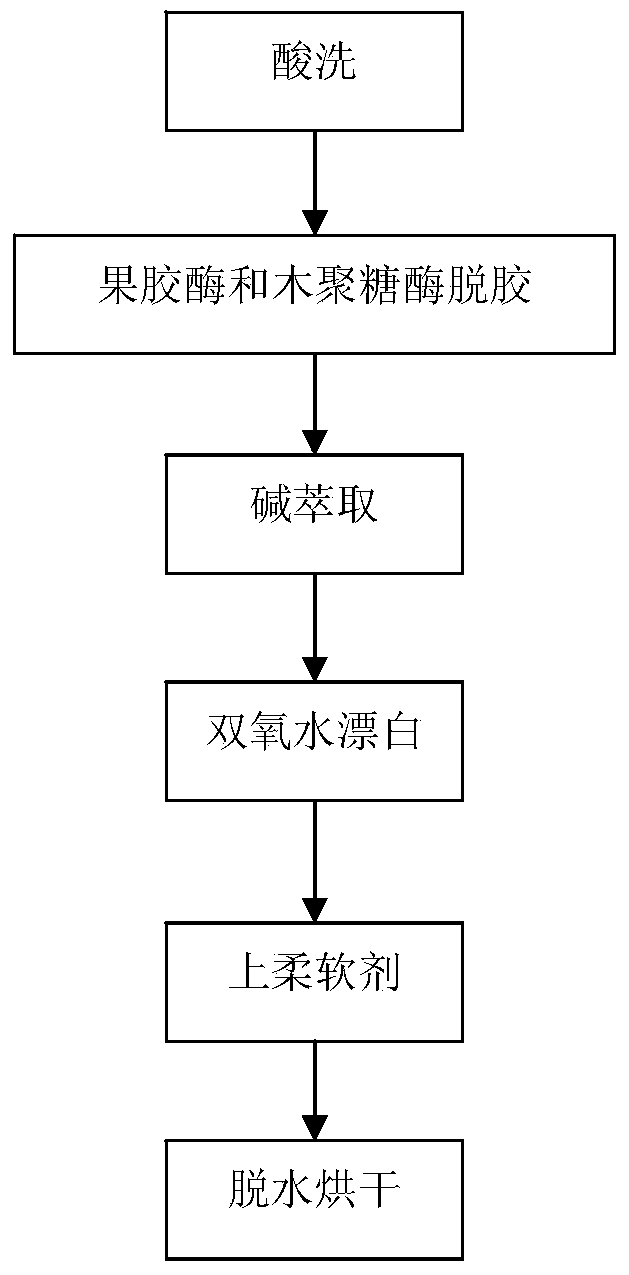

Method used

Image

Examples

Embodiment 1

[0039] Taking the degumming process of 200kg flax fiber as an example, first put the flax fiber into a cage with a bath ratio of 1:12, and then use the following steps for processing:

[0040] (1) Pickling: use H 2 SO 4 6kg, treated at 40°C for 30 minutes;

[0041] (2) Biological enzyme degumming: Use 2kg of pectinase and 2kg of xylanase, adjust the pH value to 7-8 with soda ash, soak at 40°C-50°C for 150 minutes;

[0042] (3) Alkali extraction: use caustic soda 6kg, soda ash 2kg, Na 2 SO 3 4kg, chelating dispersant CBI 2kg, treated at 98°C-100°C for 70min;

[0043] (4) Hydrogen peroxide bleaching: Use 22kg of 27.5% hydrogen peroxide, 2kg of soaking soda, 952kg of refining agent H, use caustic soda to adjust the pH value to 11, and treat at 98°C-100°C for 60 minutes;

[0044] (5) Apply softener: use 40kg of softener and treat it at 40°C for 30 minutes;

[0045] (6) Dehydration and drying

Embodiment 2

[0047] Taking the degumming process of 200kg flax fiber as an example, first put the flax fiber into a cage with a bath ratio of 1:12, and then use the following steps for processing:

[0048] (1) Pickling: use H 2 SO 4 10kg, treated at 60°C for 30 minutes;

[0049] (2) Biological enzyme degumming: Use 4kg of pectinase and 1kg of xylanase, adjust the pH value to 7-8 with soda ash, soak at 60°C-70°C for 90 minutes;

[0050] (3) Alkali extraction: use caustic soda 7kg, soda ash 6kg, Na 2 SO 3 3kg, 1kg of chelating dispersant CBI, treated at 90°C-92°C for 90min;

[0051] (4) Hydrogen peroxide bleaching: Use 36kg of 27.5% hydrogen peroxide, 4kg of soaking soda, 953kg of refining agent H, use caustic soda to adjust the pH value to 11, and treat at 95°C-98°C for 90min;

[0052] (5) Apply softener: Use 20kg of softener and treat at 30°C for 50 minutes;

[0053] (6) Dehydration and drying

Embodiment 3

[0055] Taking the degumming process of 200kg flax fiber as an example, first put the flax fiber into a cage with a bath ratio of 1:12, and then use the following steps for processing:

[0056] (1) Pickling: use H 2 SO 4 8kg, treated at 30°C for 60 minutes;

[0057] (2) Biological enzyme degumming: Use 3kg of pectinase and 4kg of xylanase, adjust the pH value to 7-8 with soda ash, soak at 50°C-60°C for 120 minutes;

[0058] (3) Alkali extraction: use caustic soda 8kg, soda ash 4kg, Na 2 SO 3 2kg, 4kg of chelating dispersant CBI, treated at 95°C-98°C for 80min;

[0059] (4) Hydrogen peroxide bleaching: Use 30kg of 27.5% hydrogen peroxide, 3kg of soaking soda, 954kg of refining agent H, use caustic soda to adjust the pH value to 10, and treat it at 98°C-100°C for 70min;

[0060] (5) Apply softener: Use 80kg of softener and treat it at 35°C for 20 minutes;

[0061] (6) Dehydration and drying

[0062] The present invention fully degummes the flax fiber by pectinase and xylan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com