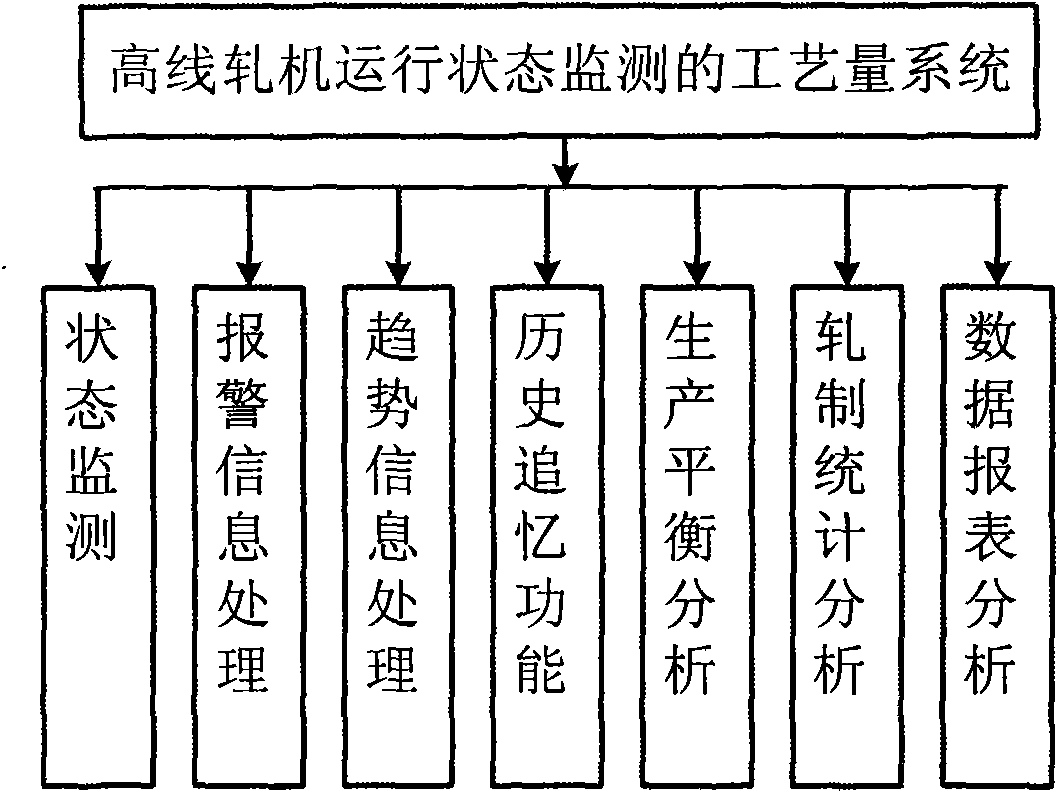

Equipment operating and process quality state monitoring system for high-speed rolling mill

A condition monitoring system and equipment operation technology, applied in metal processing equipment, length measuring devices, metal rolling, etc., can solve the problems of steel mills lack of production process monitoring and management means, incompatibility of installed capacity, etc. The effect of laying quality, increasing process analysis and management tools, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

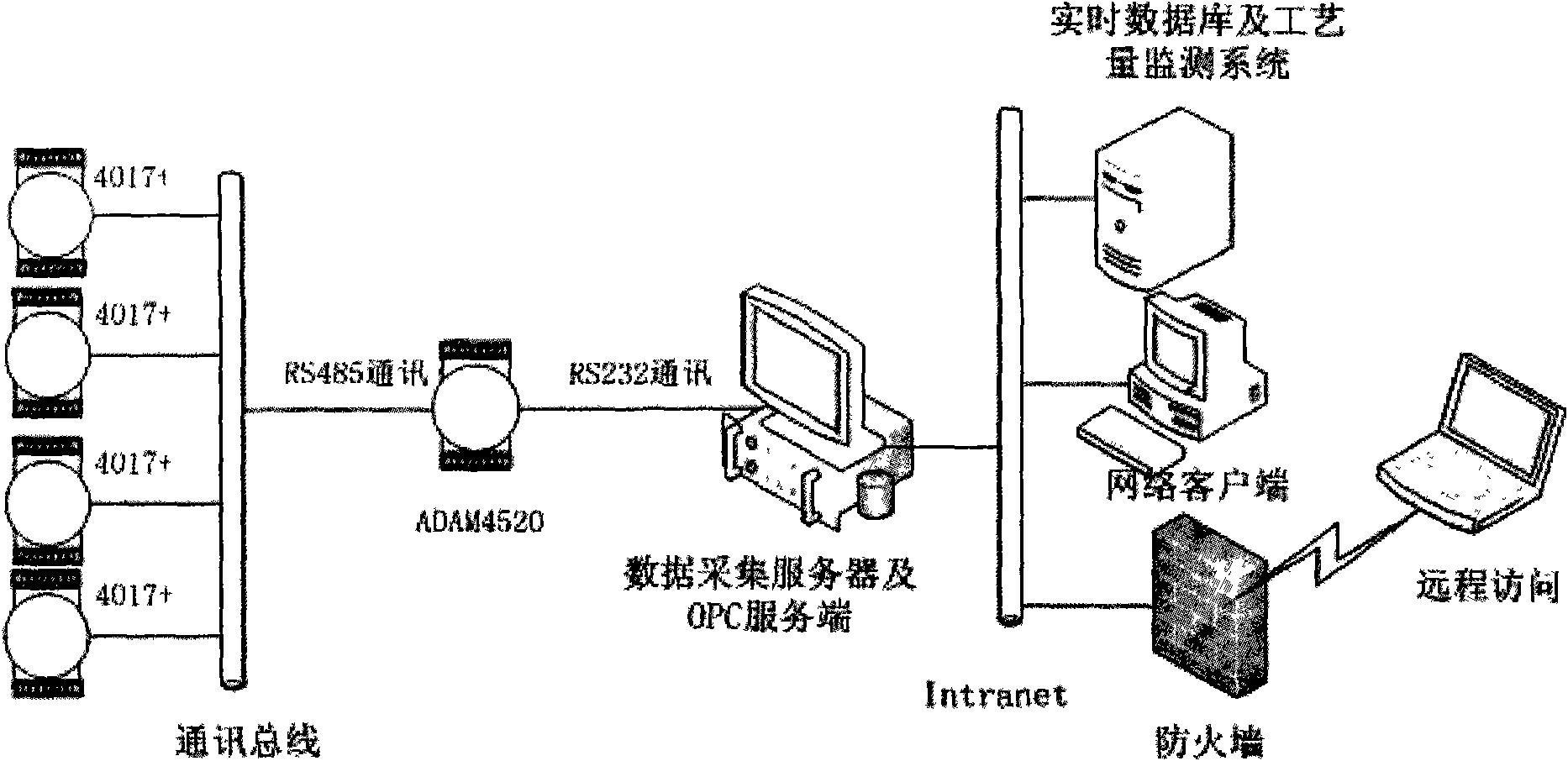

[0027] Such as figure 1 As shown, the invention includes hardware and software. The hardware includes current and speed sensors, 4017+ intelligent modules, ADAM4520 isolation converters, OPC standardized interfaces, and industrial control computers.

[0028] The acquisition of the current and rotational speed signals is completed through the 4017+ intelligent module. The 4017+ module is connected to 8 input signal terminals, namely Vin0~Vin7, and two data output signal terminals. The output of this port is a set of 8 The current value collected by the measuring point, Vs is the power port, the ADAM-4520 converter does not need to make any modifications to the PC hardware and software, and can realize the effective combination of the on-site DCS system industrial bus and the traditional serial communication. The OPC is Standardized interface for industrial equipment server...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com