Evenly-liquid-spraying batch electrostatic spinning device

A liquid-equalizing device and electrospinning technology, applied in textiles and papermaking, spinneret assembly, filament/thread forming, etc., can solve the problems of different fiber thickness, falling into the solution tank, solution splashing, etc. To achieve the effect of improving spinning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

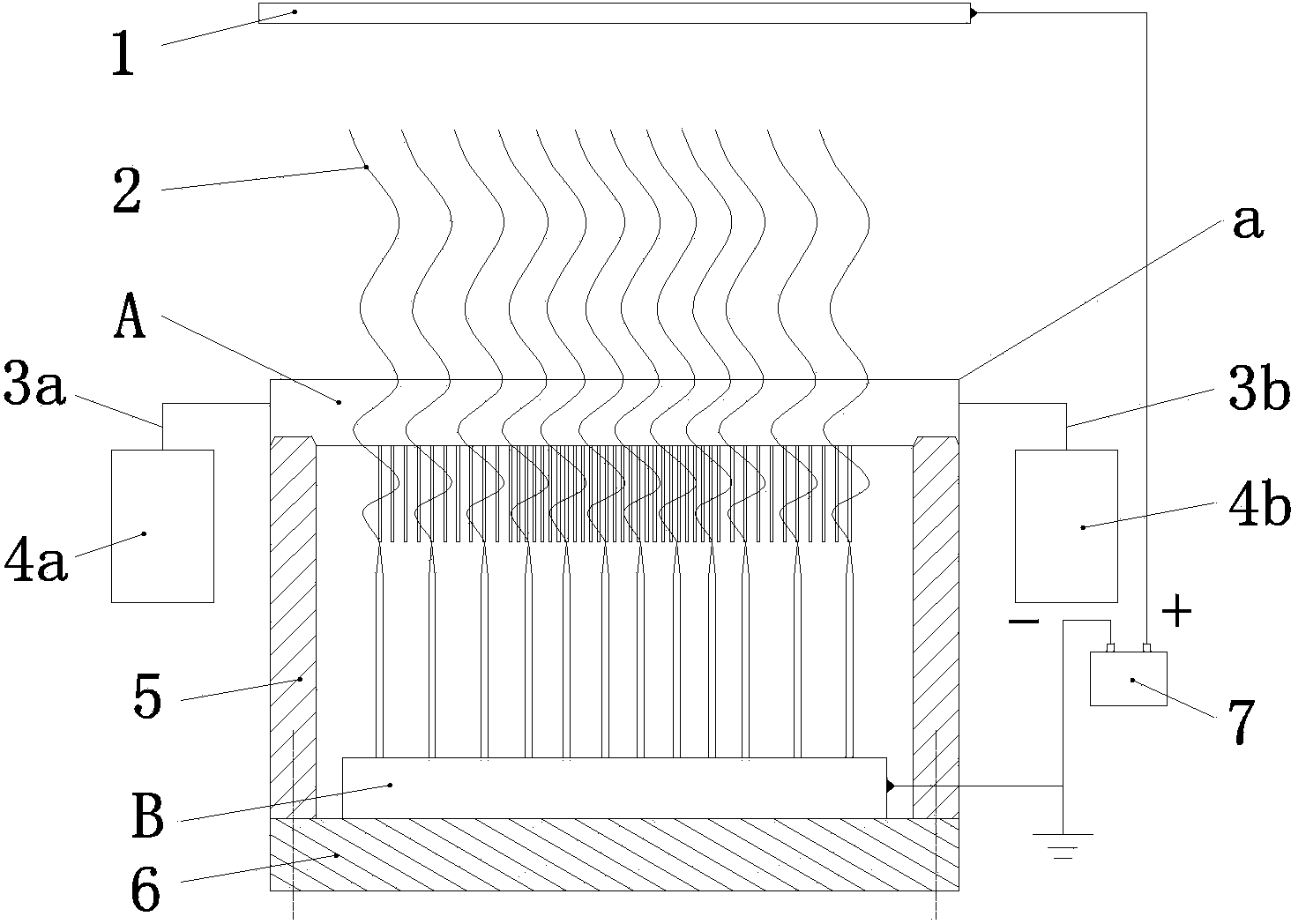

[0034] As a specific example, such as Figure 1 to Figure 4 Shown, a kind of batch electrospinning device of a kind of uniform coating liquid of the present invention comprises:

[0035] A base plate 6, the two sides of the base plate 6 are respectively provided with guide rails 5,

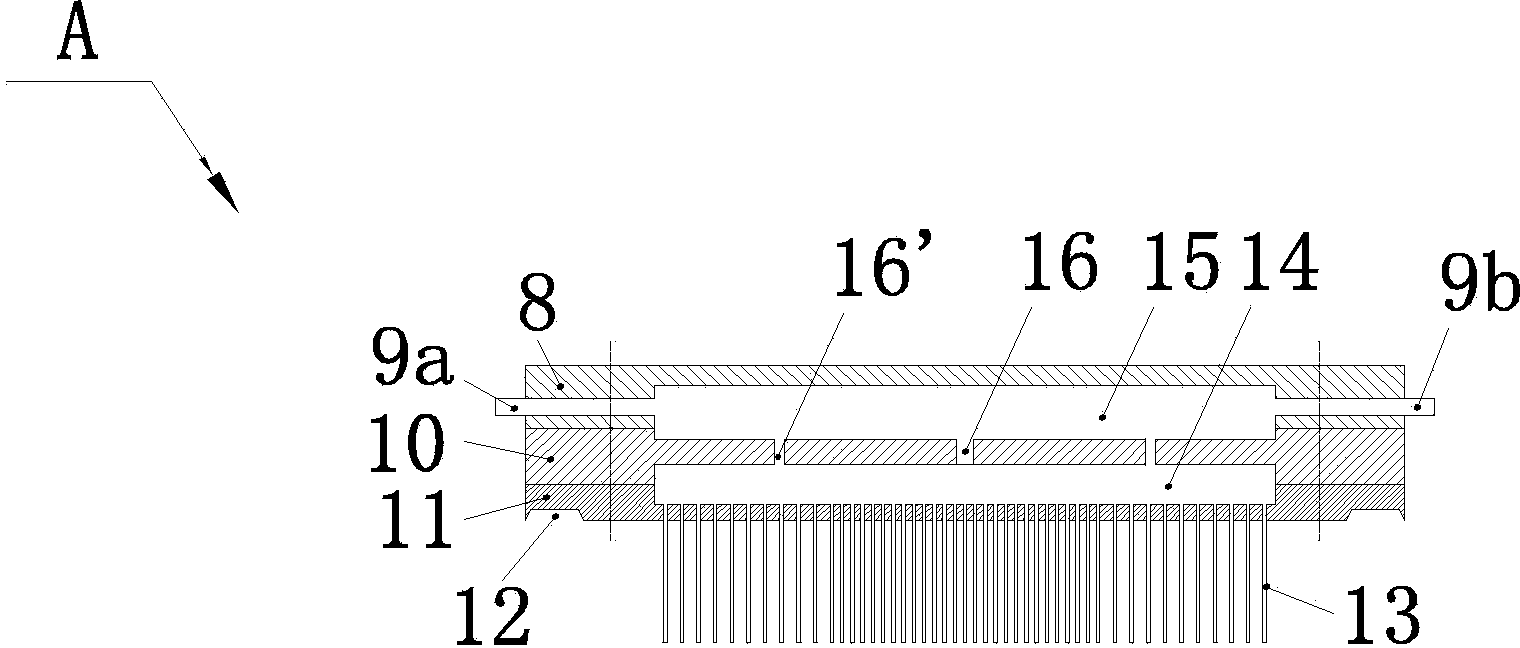

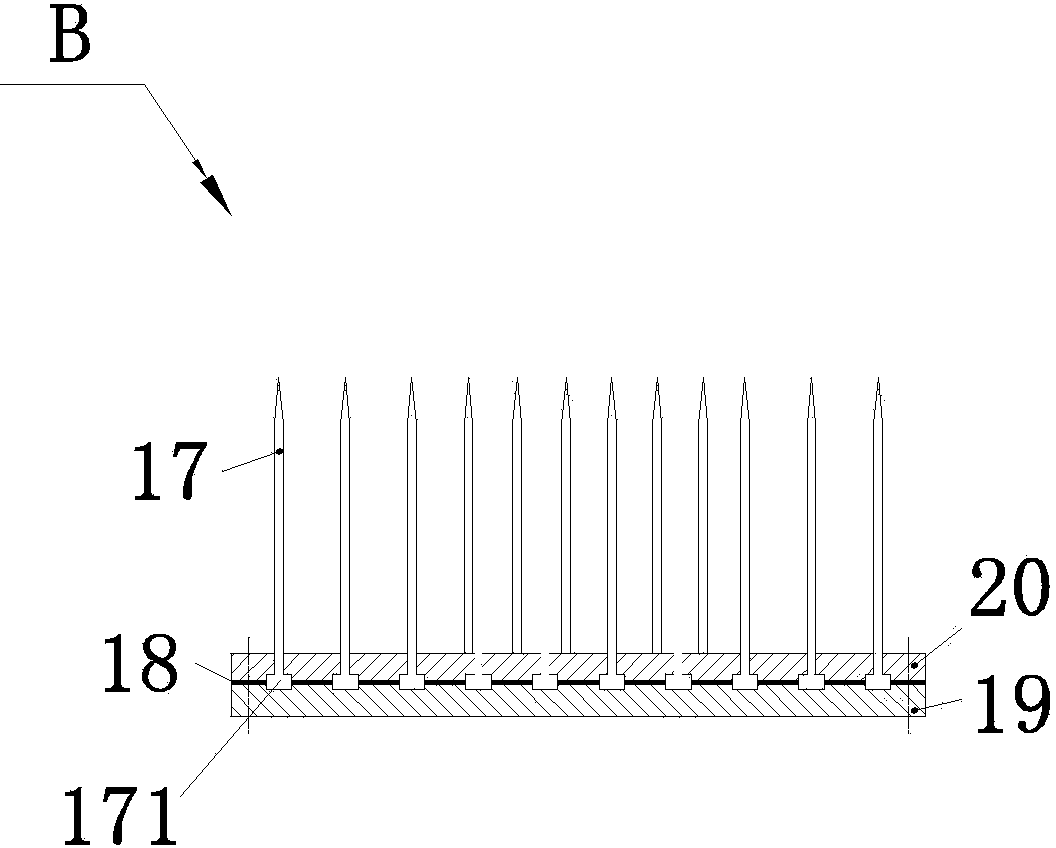

[0036] A liquid equalizing device A, the liquid equalizing device A is arranged horizontally on the two guide rails 5, the liquid equalizing device A includes a housing a, the housing a is composed of an upper plate 8 and a lower plate 11, the A liquid equalizing plate 10 is arranged between the upper plate 8 and the lower plate 11, the upper plate 8 and the liquid equalizing plate 10 seal and cooperate to form a solution chamber 15, and the lower plate 11 and the liquid equalizing plate 10 seal and cooperate to form a liquid equalizing chamber 14, Therefore, the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com