High-temperature oil agent for polyester industrial yarns, and preparation method thereof

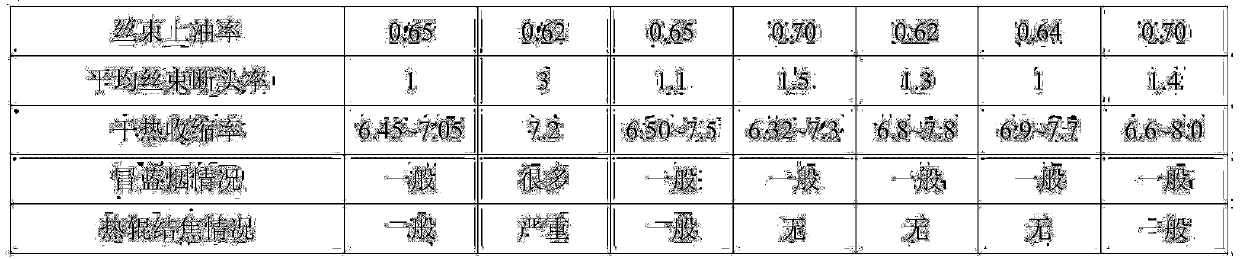

A polyester industrial yarn and high-temperature oil technology, which is applied in textiles and papermaking, fiber types, fiber treatment, etc., can solve problems such as poor high-temperature heat resistance, serious coking of hot rollers, and many broken ends of tows, achieving good lubricity, Less coking and better spinning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

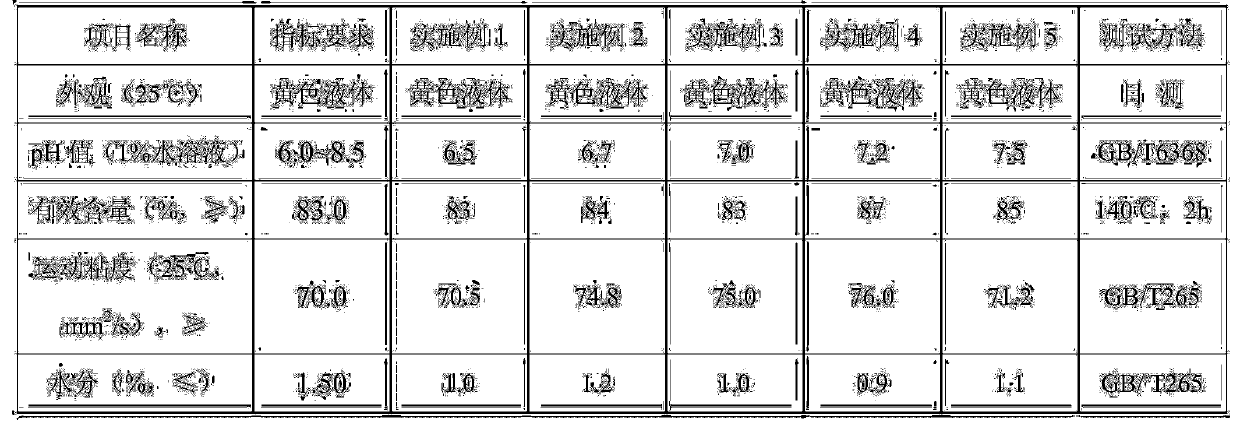

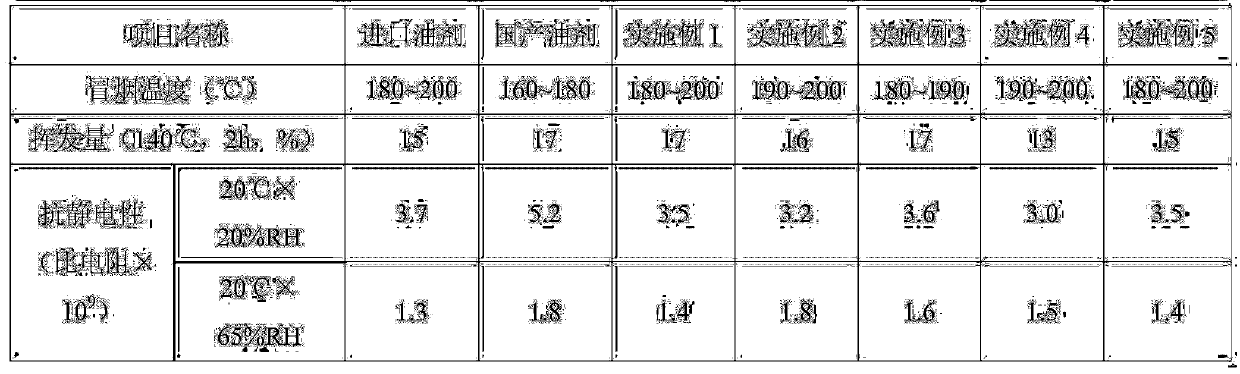

[0032] The monomers and mass percentages of each component of high temperature oil for polyester industrial yarn are as follows:

[0033] (smoothing agent) pentaerythritol oleate 46%, hydrogenated castor oil polyoxyethylene ether HEL-40 (emulsifier) 18%, (bundling agent) oleic acid triethanolamine soap 3%, PO / EO=60 / 40Mw=4000 Propylene glycol block polyether (antistatic agent) 6%, 5% T151 (as a coking dispersant), ethylene glycol (humectant) 3%, normal C14-16 alkane solvent 18%, triphenyl phosphite 0.1% , laurylamine polyoxyethylene ether AC-1201 (as a pH adjustment stabilizer) 0.2%, water 0.7%.

Embodiment 2

[0035] The monomers and mass percentages of each component of high temperature oil for polyester industrial yarn are as follows:

[0036] Smoothing agent 50% (the smoothing agent is composed of pentaerythritol oleate 25%, oleic acid glyceride 10%, polyethylene glycol 400 oleate 15%, the percentage of the three refers to the percentage of the whole system, that is, the sum is exactly equal to 50%, the following percentages refer to the percentage of the whole system), emulsifier 15% (wherein the emulsifier is composed of 10% hydrogenated castor oil polyoxyethylene ether HEL-40, polyethylene glycol 200 oleate 5% ), sizing agent 6% (wherein the sizing agent is composed of 4% hydrogenated castor oil polyoxyethylene ether HEL-20, oleic acid triethanolamine soap 2%), antistatic agent 8% (wherein the antistatic agent is composed of 2% secondary alkyl Sodium sulfonate SAS-60, PO / EO=60 / 40M w=4000 propylene glycol block polyether 6% composition), dispersant 4% (dispersant is T151), wet...

Embodiment 3

[0038] The monomers and mass percentages of each component of high temperature oil for polyester industrial yarn are as follows:

[0039] Smoothing agent 55% (the smoothing agent is composed of trimethylolpropane oleate 20%, dioctyl sebacate 10%, polyethylene glycol 200 oleate 25%), emulsifier 13% (the emulsifier 3% hydrogenated castor oil polyoxyethylene ether HEL-40, PO / EO=30 / 70M w =2800 propylene glycol block polyether 10% composition), sizing agent 6% (hydrogenated castor oil polyoxyethylene ether HEL-20), antistatic agent 6% (wherein antistatic agent consists of 4% secondary alkyl sulfonate sodium SAS- 60. Potassium lauryl polyoxyethylene alkyl phosphate 2%), dispersant 4% (wherein the dispersant is composed of polyisobutylene succinate pentaerythritol 3%, 1% T151), humectant 2% (wherein moisturizing The agent is composed of glycerin 1%, ethylene glycol 1%), diluting solvent 12% (diluting solvent is composed of normal C14~C16 alkane solvent 10%, D100 naphthenic solvent 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com