Continuous spinning set of polyester filament yarns

A spinning device and polyester filament technology, applied in the field of polyester filament continuous spinning device, can solve the problems of inconvenient installation and maintenance, low silk output efficiency, complex structure, etc., and achieve simple operation, simple structure, improved Effect of spinning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

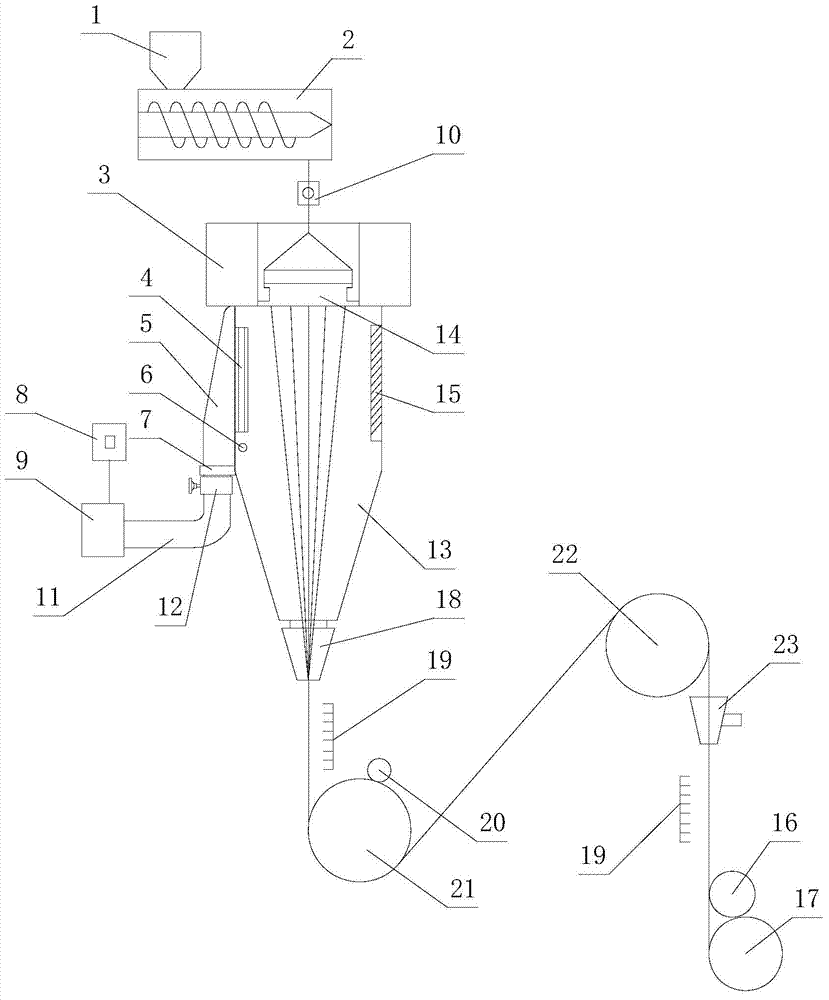

[0016] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0017] like figure 1 The polyester filament continuous spinning device shown includes a screw extruder 2, a hopper 1 is connected above the screw extruder 2, and a spinning assembly is arranged below the screw extruder 2; The cooled silk chamber 13, the first bundler 18, the first heat roller 21, the second heat roller 22, the second bundler 23 and the winding roller 17 are arranged in turn along the spinning route below the silk chamber 13, and the winding roller 17 The outer circumference is installed with a friction roller 16; the spinning assembly includes a spinning box 3 heated by heat transfer oil inside, and the spinning box 3 is equipped with a spinneret 14 for spinnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com