Composition providing polymer with inoxidizability and application thereof

An antioxidant, composition technology, applied in the direction of chemical characteristics of fibers, single-component polyolefin rayon, textiles and papermaking, etc. Problems such as broken wires are prone to occur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

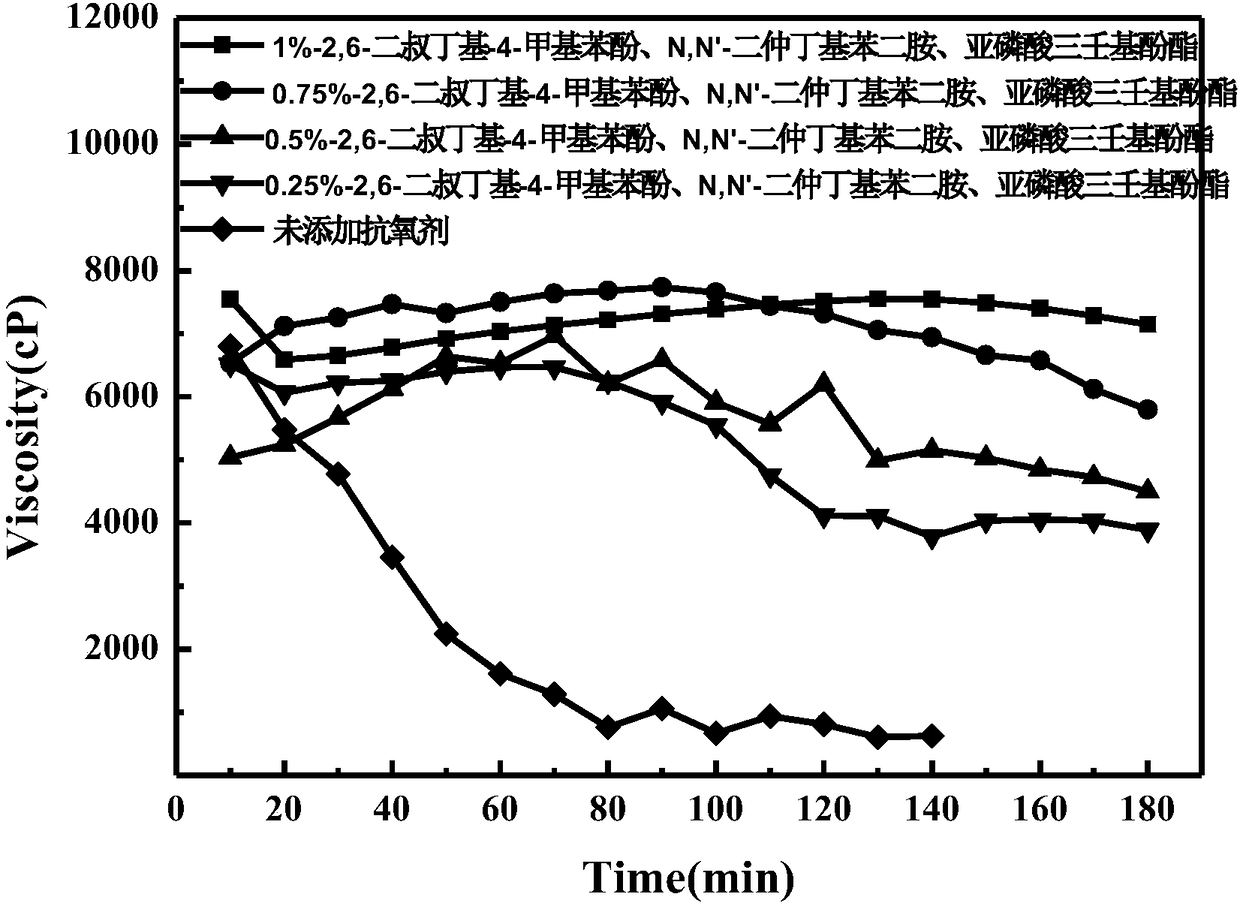

Examples

Embodiment 1

[0061] Mix 2,6-di-tert-butyl-4-methylphenol, hydroxylamine and trinonylphenol phosphite in a mass ratio of 17%: 17%: 66%, and stir evenly under heating at 80 °C to obtain a uniform liquid combination Add the homogeneous liquid composition to the white oil at 140°C (the addition amount of the liquid composition accounts for 1 wt% of the polymer system), after stirring evenly, add polyethylene at 140°C (the content of polyethylene is 2.3 wt % of white oil), stirring and dissolving, that is, a modified polymer mixture system was prepared, and its viscosity was measured.

[0062] After 2h, the viscosity showed a downward trend, and the viscosity value decreased from 4000cP to 3800cP.

[0063] The modified polymer mixture system did not crystallize during the spinning process, indicating that the composition of the present invention significantly improves the spinning quality of the polymer after it is applied to the polymer.

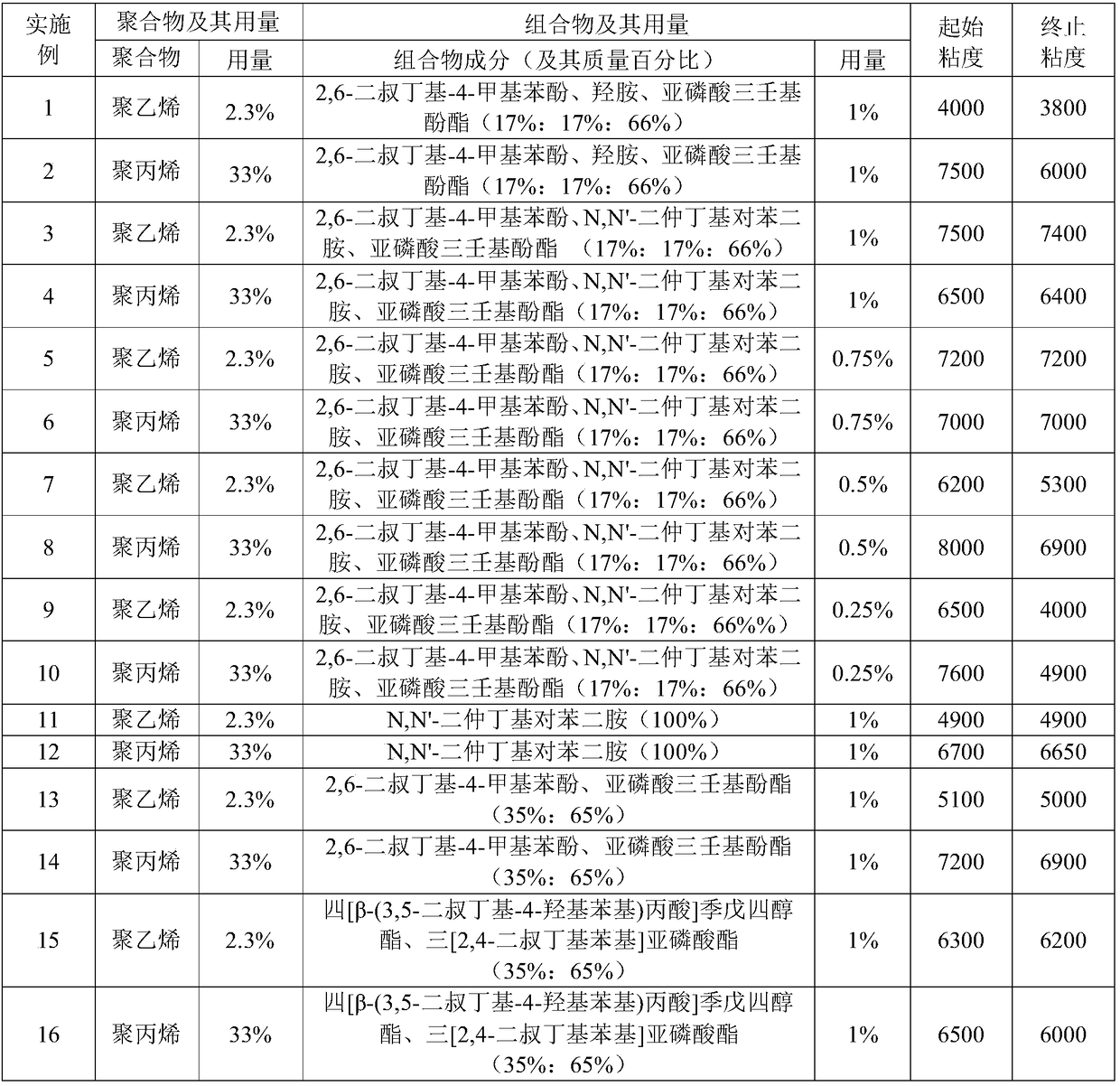

Embodiment 2~16

[0065] The mixing method in the polymer mixture system is the same as that in Example 1. In Examples 2 to 16, only the components, proportions and amounts of polymers and compositions are different from those in Example 1. The specific values are listed in Table 1.

[0066] Table 1 Experimental data of Examples 1-16

[0067]

[0068] The data of Examples 1-16 show that, using the liquid mixing method of the present invention, adding the antioxidant composition into the mixing system can significantly improve the oxidation resistance of the polymer. And the modified polymer did not crystallize during the spinning process, indicating that the composition of the present invention significantly improves the spinning quality of the polymer after it is applied to the polymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com