Patents

Literature

175results about How to "Balanced production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

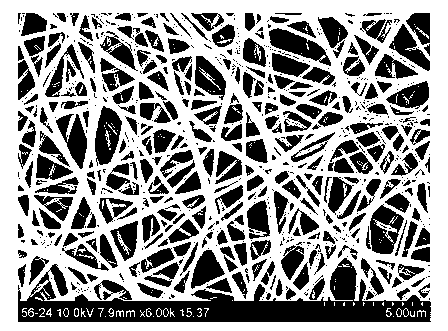

Tip-end type needle-free electrostatic spinning equipment

ActiveCN103255485AImprove uniformityTake advantage ofFilament/thread formingSpinningHigh-voltage direct current

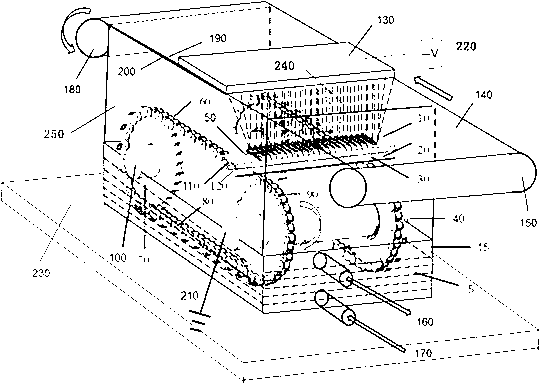

The invention discloses tip-end type needle-free electrostatic spinning equipment which comprises a spinning solution storage box, base cloth, a spinning device and a negative-high-voltage direct-current power source, wherein the spinning device comprises a spinning box body, a needle plate, a chain, a negative electrode and a connecting device. The spinning box body is fixedly connected at the top end of the spinning solution storage box, and the chain is connected on the inner wall of the spinning box body. The connecting device is connected with a transmission device to achieve rotation of the chain, a lowermost link of the chain is submerged in spinning solution of the spinning solution storage box, and the needle plate is fixedly connected on the chain. The base cloth covers the top end of the spinning box body. The spinning solution storage box, the spinning box body and the base cloth form an enclosed spinning space. The negative electrode is attached to the top surface of the base cloth. The spinning device is earthed, the negative electrode is connected with the negative-high-voltage direct-current power source, and a high-voltage electrostatic field is formed between the negative electrode and metal card clothing. The tip-end type needle-free electrostatic spinning equipment can improve the yield and the uniformity of nanofiber products, the fineness of nanofiber manufactured through the tip-end type needle-free electrostatic spinning equipment is small, and the variation of the fineness is less.

Owner:JIANGSU FILTERTEX FILTER MATERIAL +1

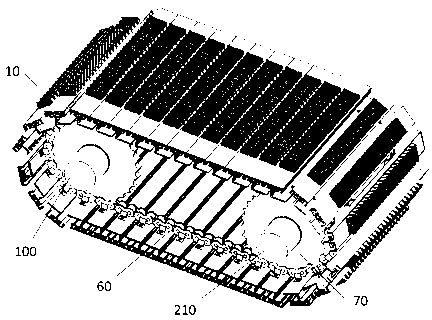

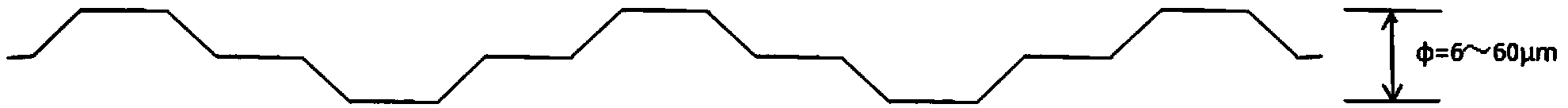

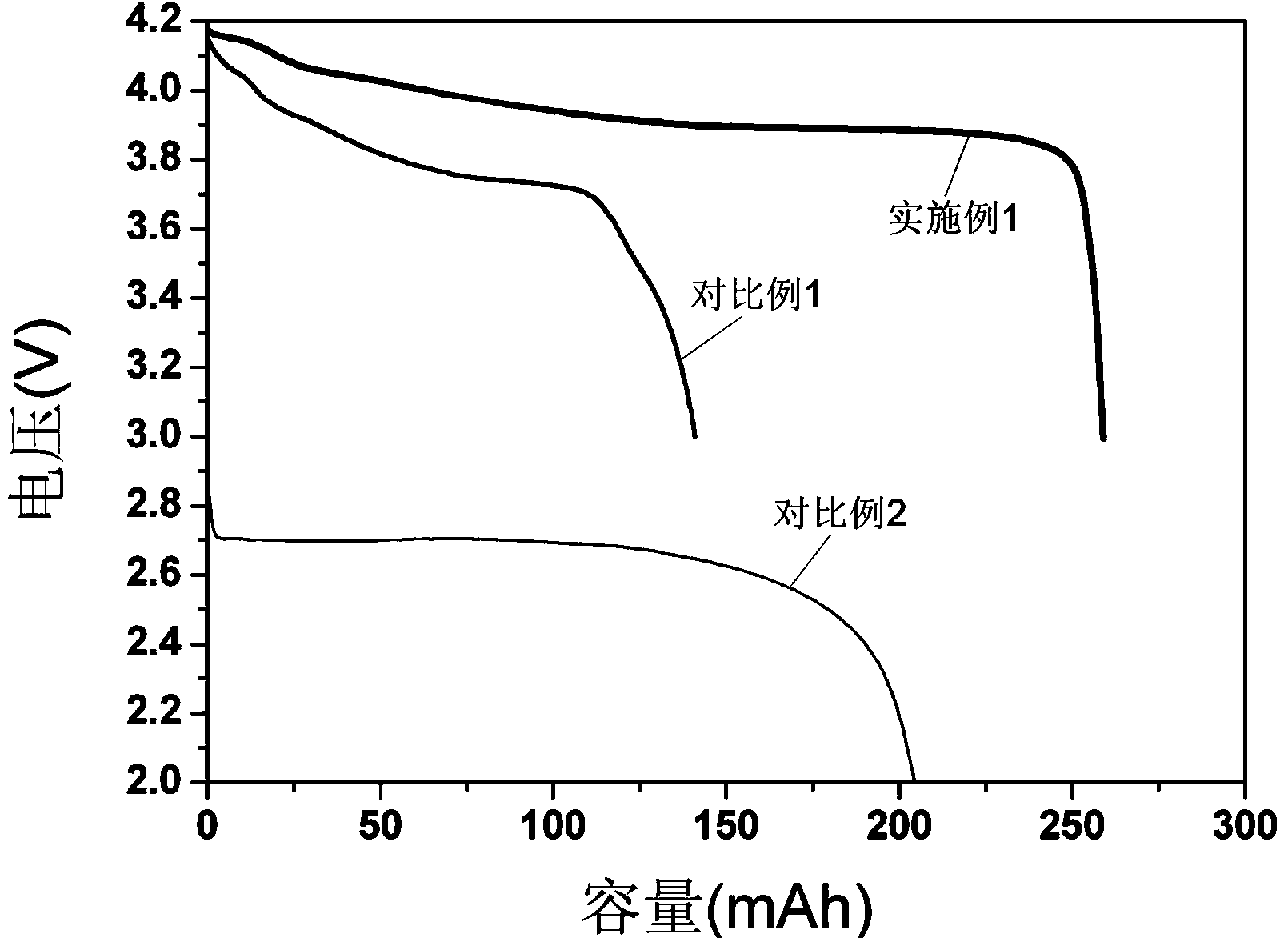

Lithium battery and preparation method thereof

ActiveCN103730683AIncrease energy densitySave spaceFinal product manufactureElectrode carriers/collectorsConvex structureMetal foil

The invention discloses a lithium battery. The lithium battery comprises a positive plate, a negative current collecting substrate, an isolating membrane and an electrolyte, wherein the isolating membrane and the electrolyte are arranged between the positive plate and the negative current collecting substrate; the positive plate comprises a positive current collecting body, a positive diaphragm and a positive polar lug, the positive diaphragm is attached to the positive current collecting body and contains a positive active material, and the positive polar lug is welded on the positive current collecting body; the negative current collecting substrate is made of a metal foil or a metal mesh with a thickness of 6-25 mu m, is 6-60 mu m in thickness and has a plane or concave-convex structure; and the electrolyte contains a lithium salt and a solvent, the lithium salt is lithium hexafluorophosphate, and the concentration of the lithium salt in the electrolyte is 1.5-7mol / L. The lithium battery disclosed by the invention has the characteristics of high power, high energy and low self-discharge rate. Meanwhile, the invention also discloses a preparation method and applications of the lithium battery.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

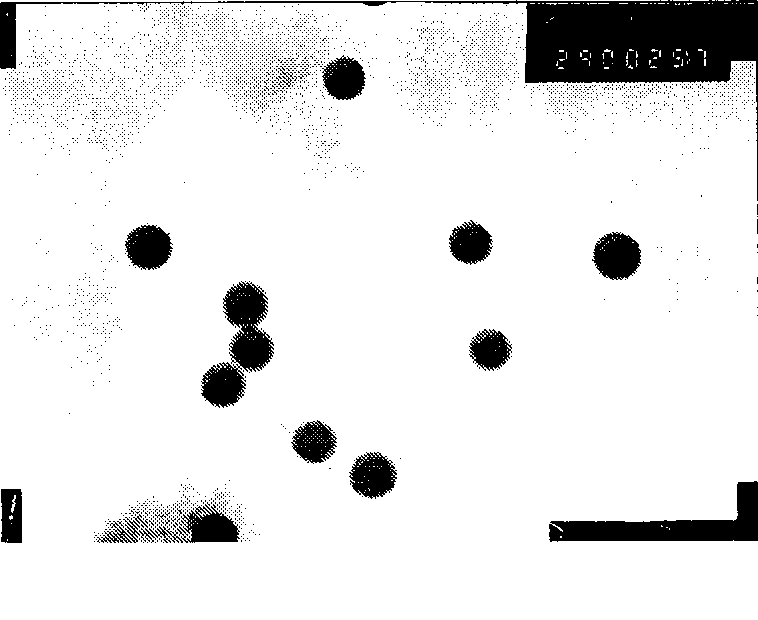

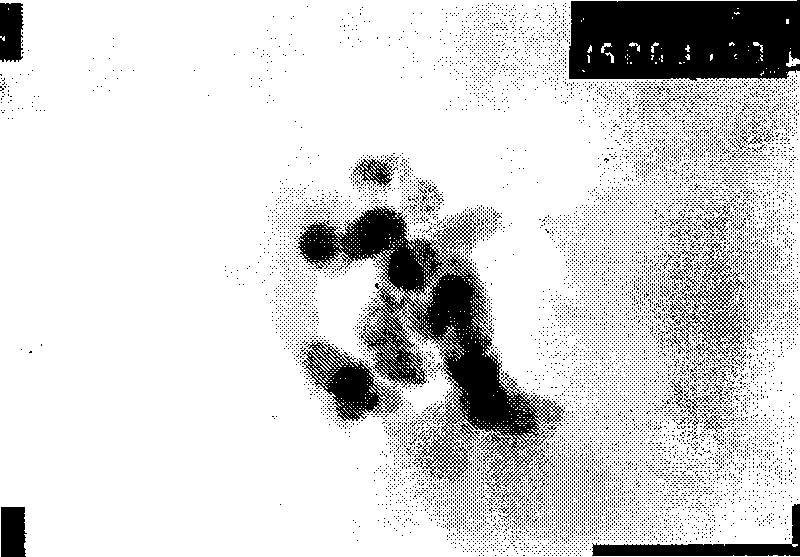

Nano-zinc oxide/acrylic ester grafting composite emulsion and preparation thereof

InactiveCN101372527AUniform particle sizeImprove coating efficiency and grafting rateNano zinc oxideNanometre

The invention relates to the manufacturing field of nano composite emulsion materials, in particular to graft nano zinc oxide / polyacrylate composite emulsion and a manufacturing method thereof. Firstly an initiator azobisisovaleric acid is anchored on the surface of nano zinc oxide particles, two portions of hexadecane are added to 100 portions of mixed monomers, and 5 portions of nano ZnO particles anchoring the azo initiator are added and ultrasonically oscillated for 20 minutes to form an oil phase pre-dispersion solution. The pre-dispersion solution is added to an emulsifier aqueous solution and dispersed by a high-shear dispersion homogenizer at high speed for 30 minutes to form a mini-emulsion. The mini-emulsion is transferred to a reactor, heated to the temperature of 75 DEG C, with polyreaction initiated for 3 hours, and then heated to the temperature of 85 DEG C, polymerized for 2 hours, cooled to room temperature and discharged. The invention solves the problems of high cost and poor stability of the nano composite emulsion prepared by coupling agents, and low encapsulation efficiency and graft ratio of nano polymer composite particles. The composite emulsion has the advantages of simple preparation process, low cost, even particle size, good performance, high encapsulation efficiency and graft ratio of the nano-particles, forms nano monodisperse state in the polymer, and is suitable for the fields of coating materials, leather finishing materials, adhesives and functional plastics.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

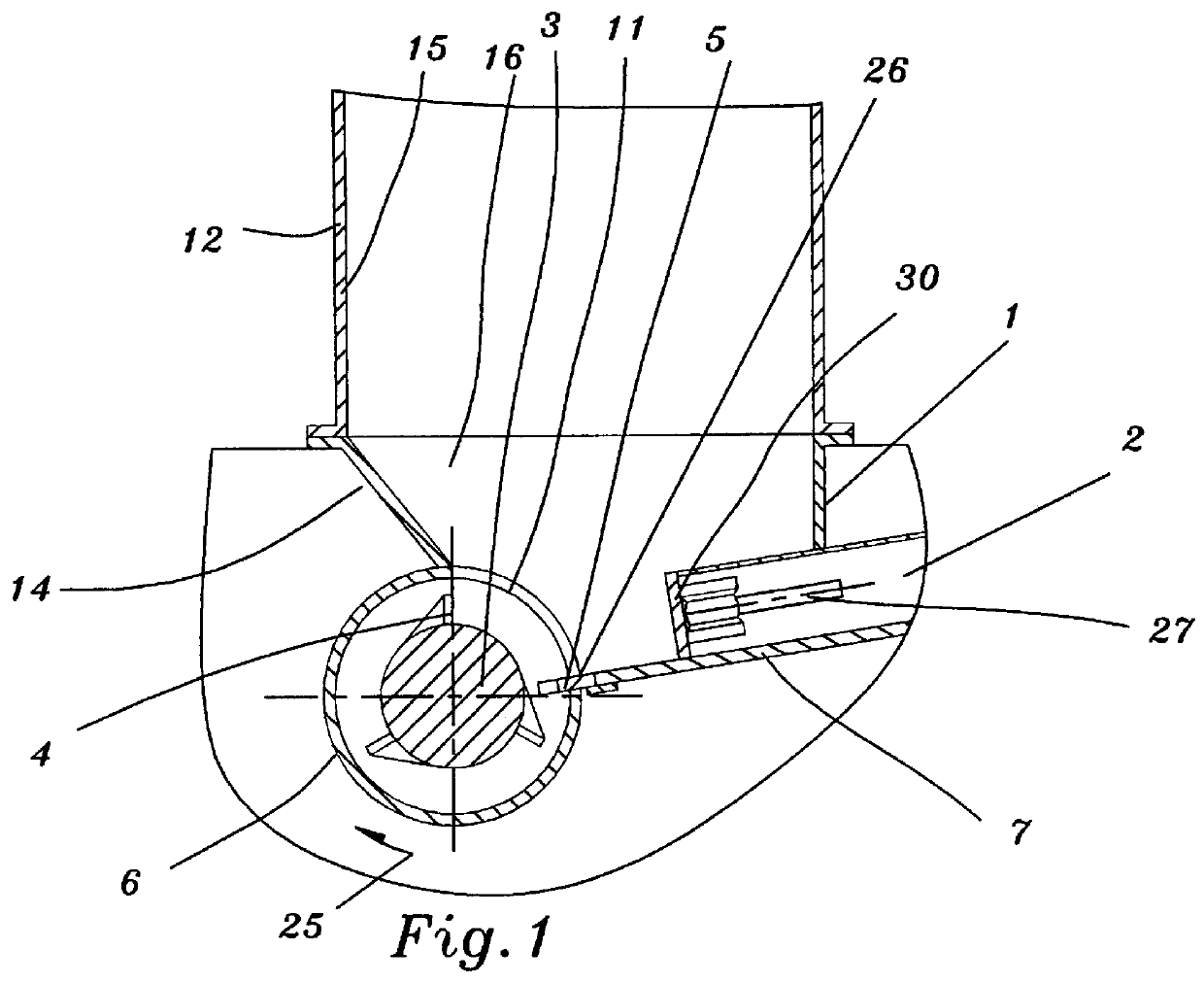

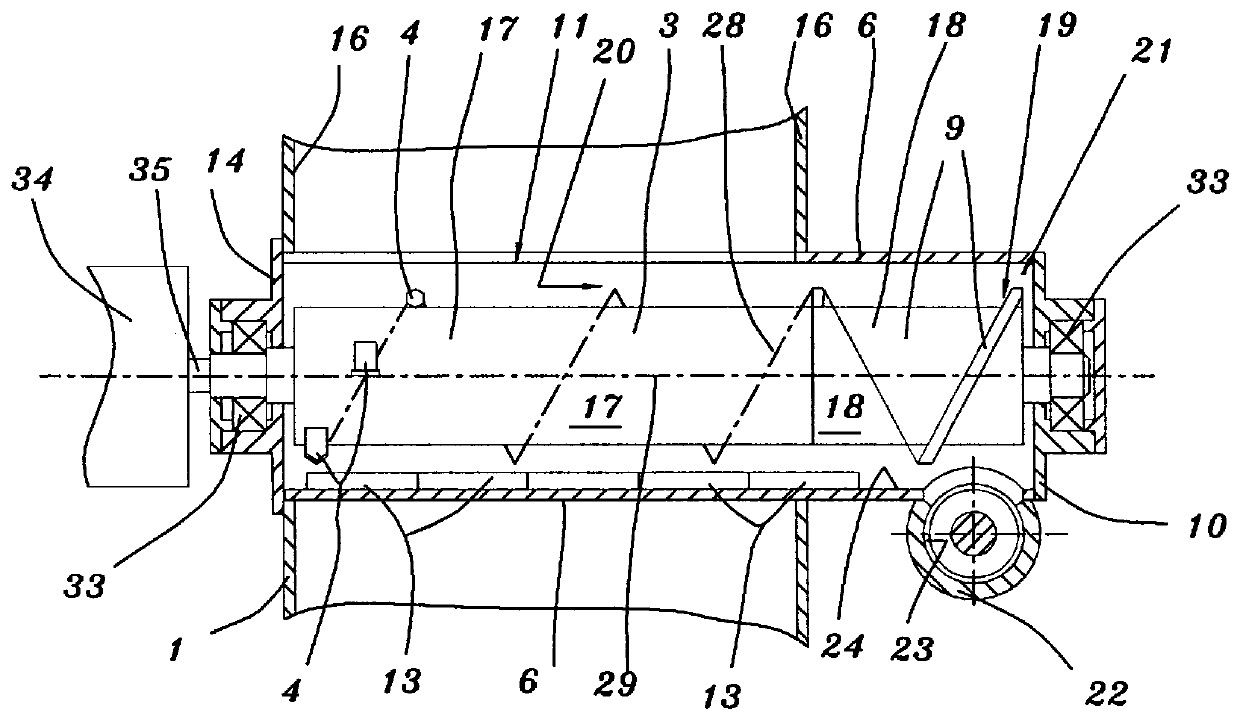

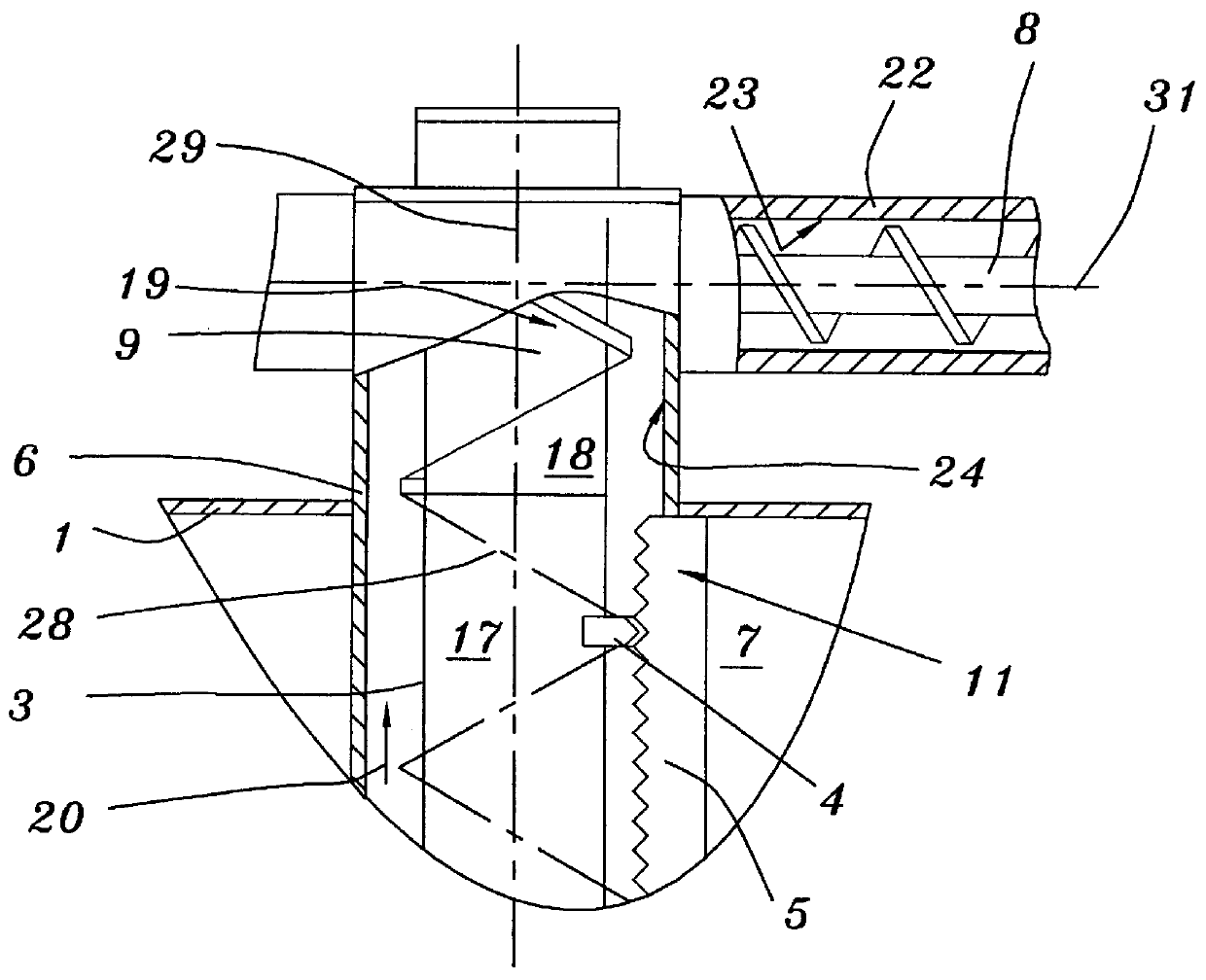

Processing device for crushing, conveying and plastifying thermoplastic synthetic material

InactiveUS6126100AIncrease costImprove processingGrain huskingGrain polishingHelical lineSynthetic materials

A unit for processing thermoplastic synthetic material comprising a machine housing (1) with a delivery cone (12) in whose feed shaft (14) a driven slider (30) presses synthetic material which is to be processed and which is located on a base plate (7) through a feed inlet (11) of a conveyor tube (6) against a processing drum (3) which is placed perpendicularly in the conveyor tube (6) in relation to the direction of the movement of the slider (30). The slider (30) extends over the entire length of the feed inlet (11) which itself extends over the entire blade supporting section (17) of the processing drum (3). Blades (4) are placed thereon in a helical line and operate in conjunction with a fixed counter blade (5) which is fastened to the opening edge (25) of the feed inlet (11). The blades (4) and the associated screw conveyor (9) convey disintegrated synthetic material in axial direction (20) though the conveyor tube (6) towards an outlet (10), which leads downwards into the screw tube (22) of the extruder screw (8) through which the synthetic material is delivered.

Owner:MANFRED DOBERSBERGER +1

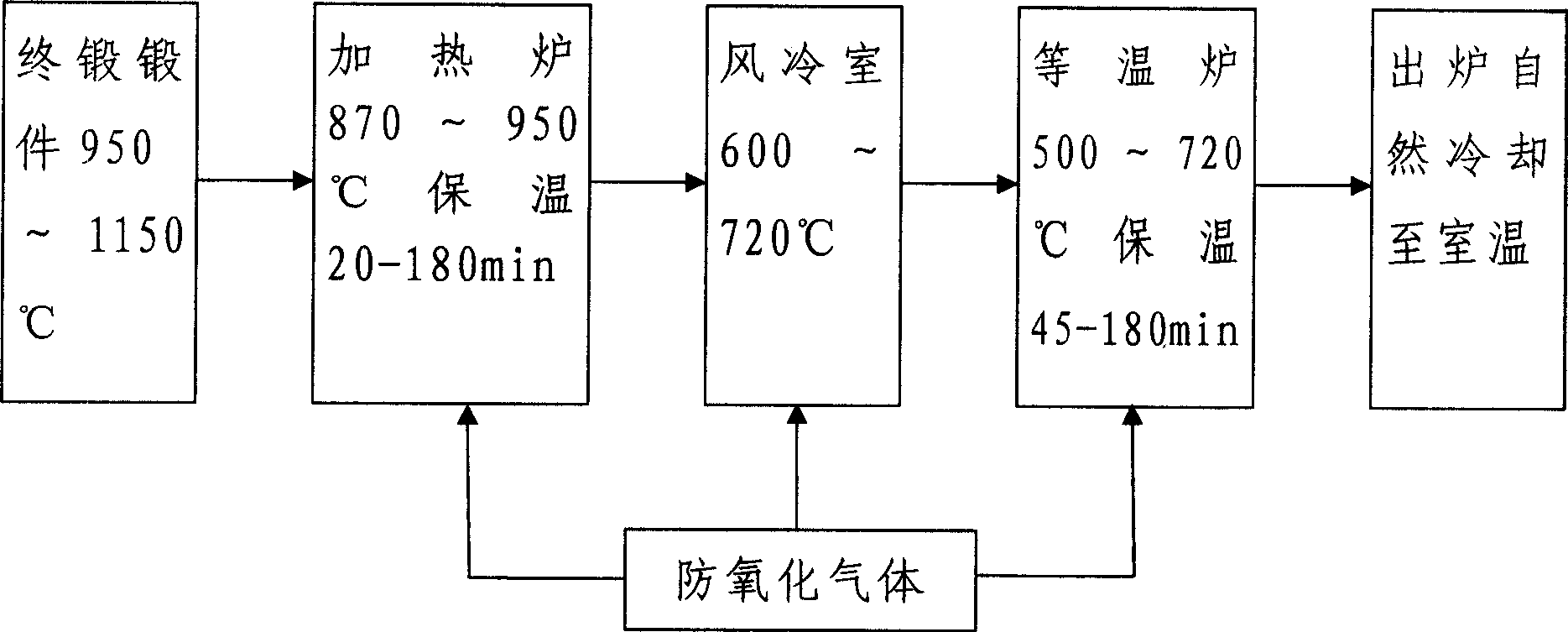

Treatment process for isothermal normalizing with exhaust heat of forgeable piece smithing

The invention discloses a process for carrying out isothermal normalizing treatment through utilizing the residual forging heat of a forging piece. The process is carried out under the condition that the temperature of the residual heat of the forging pieces in final forging is between 950 and 1,050 DEG C. The forging pieces are transported to a heating furnace in sequence through a conveyor belt; the temperature of the heating furnace is controlled between 870 and 950 DEG C; in the atmosphere of the heating furnace filled with antioxidation gas, the forging pieces are kept at the temperature for 20 to 180 minutes; the forging pieces are transported to an air-cooled chamber in sequence through the conveyor belt; the forging pieces are subjected to air cooling to a temperature of between 600 and 720 DEG C through nitrogen gas; and the forging pieces are transported to an isothermal furnace filled with nitrogen gas in sequence through the conveyer belt, are kept at the furnace temperature of between 500 and 720 DEG C for 45 to 180 minutes, is discharged and is naturally cooled. The process needs no secondary heating, is assisted with the antioxidation gas to protect the surface of the forging pieces from producing an oxidation layer and feasibly protects the surface quality of the forging pieces in the normalizing treatment stage. The process is in particular suitable for the forging production of a precise hot mold.

Owner:JIANGSU AIRSHIP GEAR

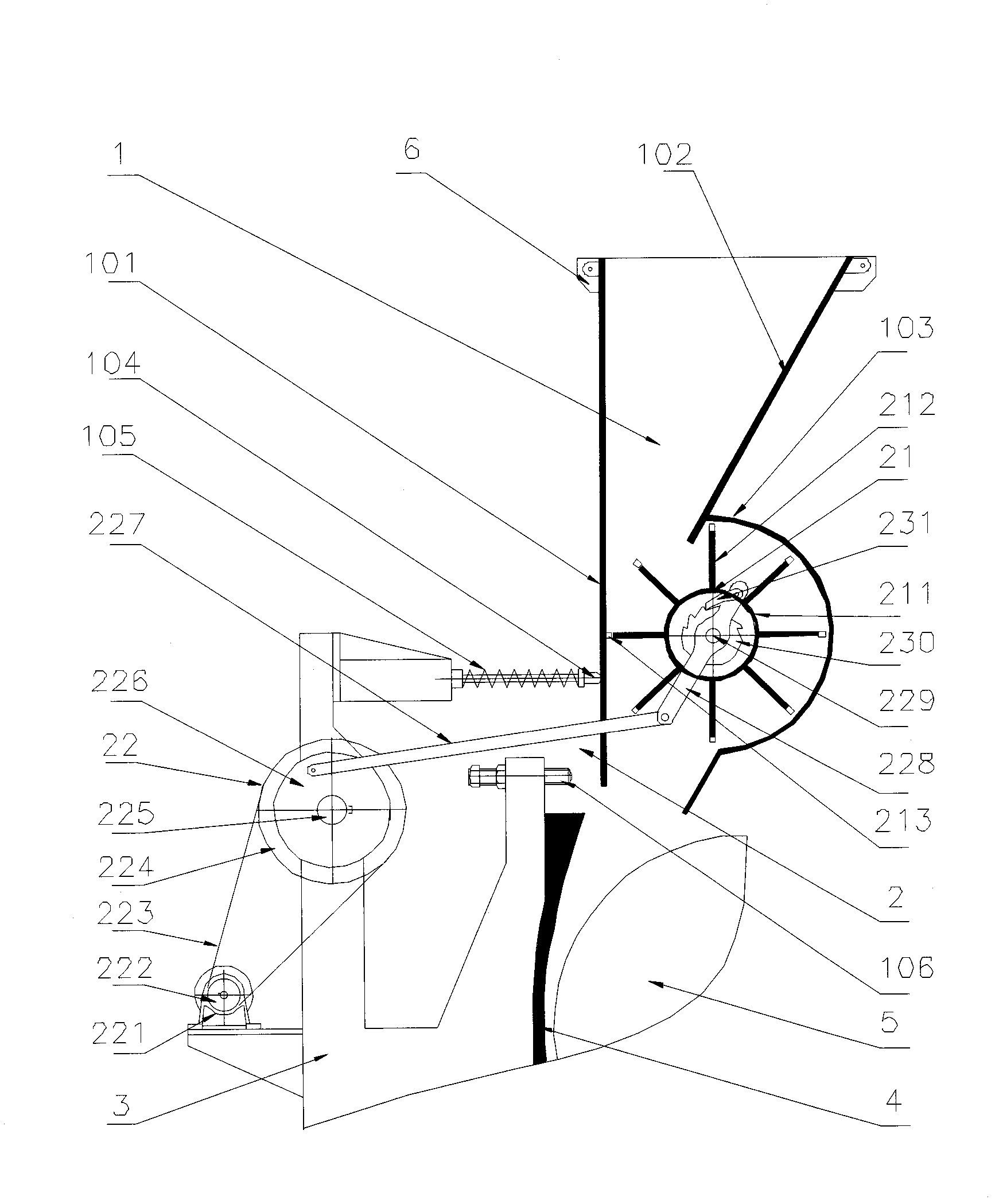

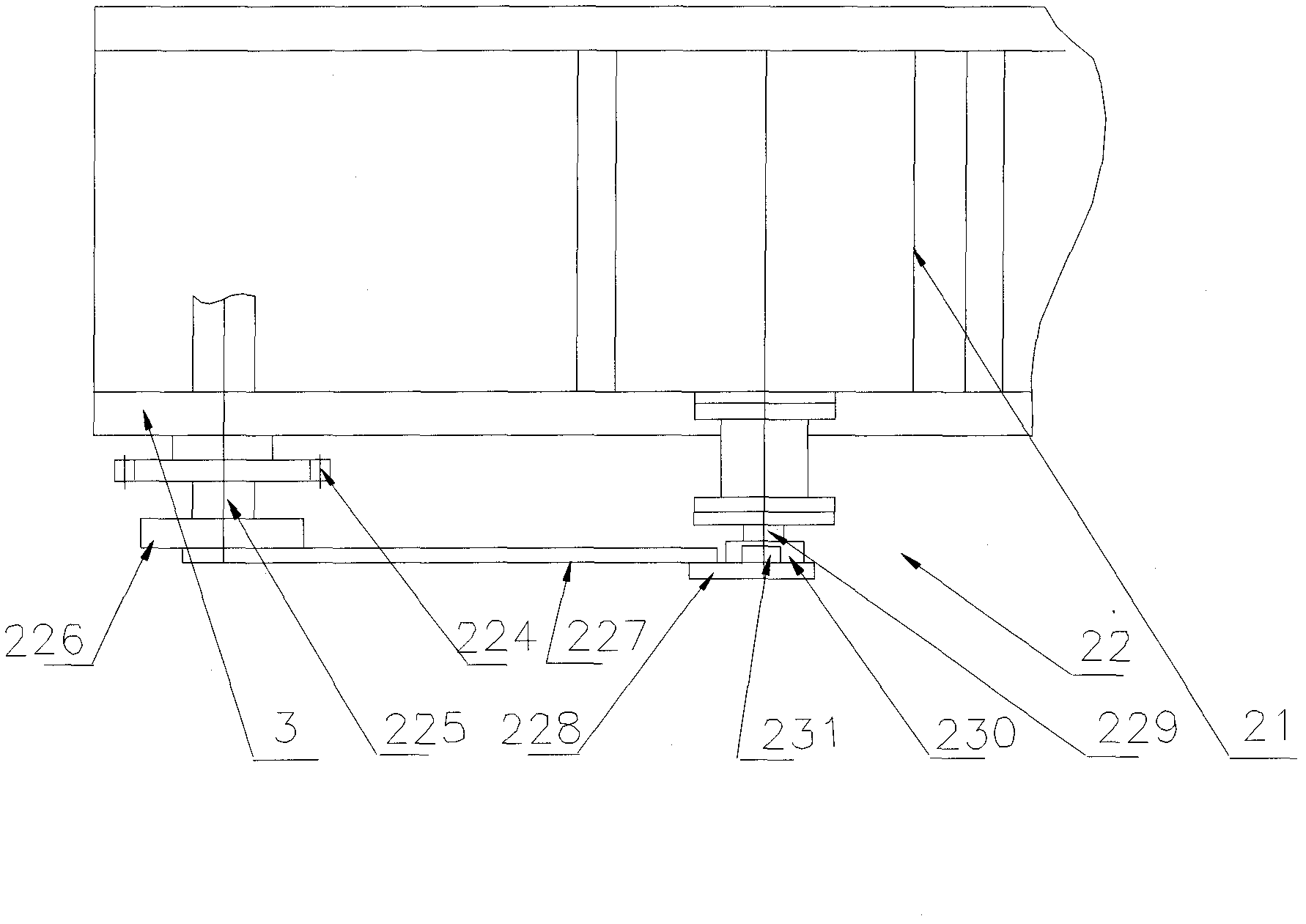

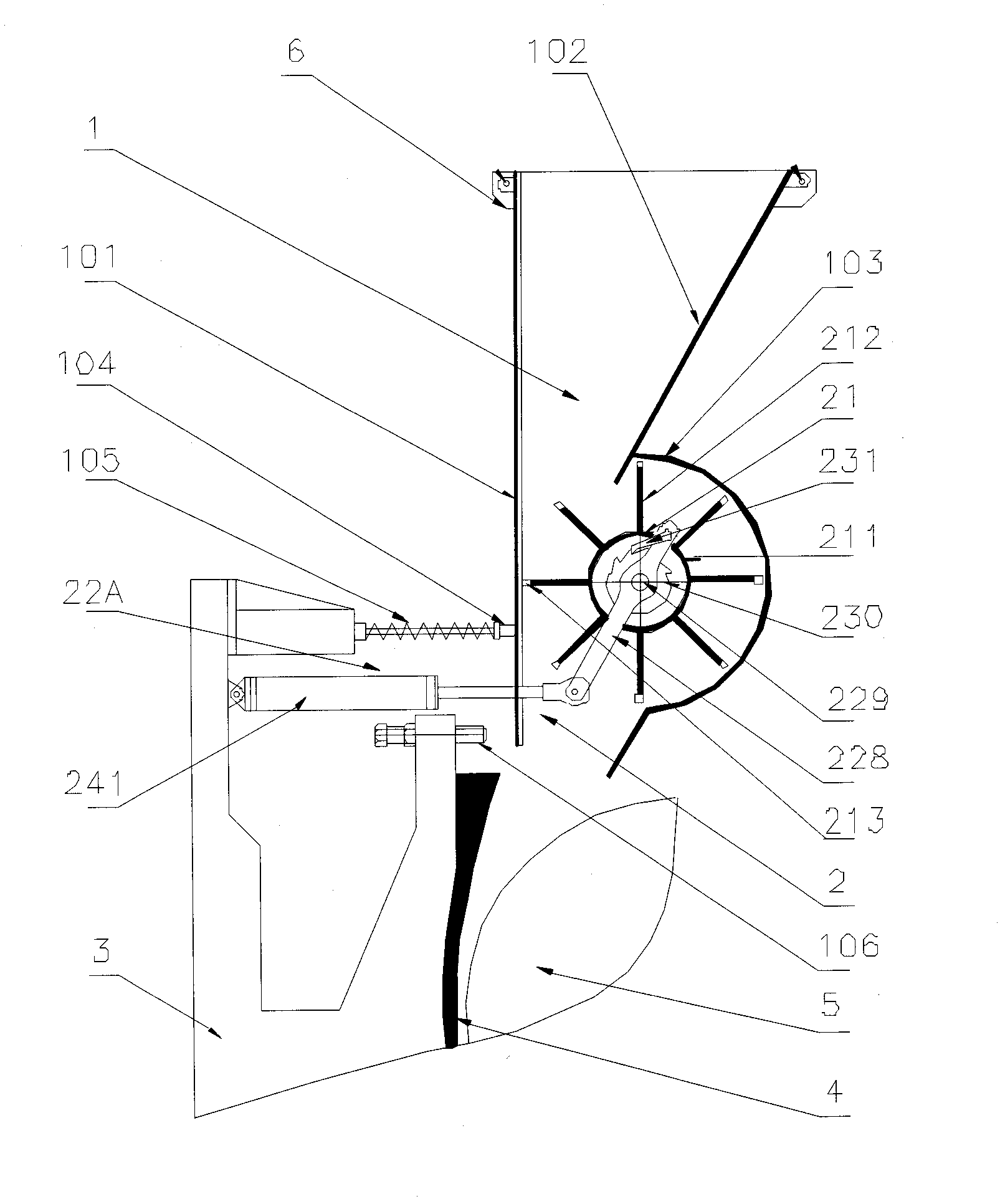

Feeding device of material crushing apparatus

A feeding device of a material crushing apparatus comprises a deformed bunker and an intermittent feeding mechanism, wherein one side of the deformed bunker is provided with a pendulous movable straight plate, the upper end of the movable straight plate is hinged to a fixed hopper lower edge, the other side of the deformed bunker is provided with a fixed semicircular plate and a movable inclined plate, the fixed semicircular plate makes a semicircular cavity, the upper end of the movable inclined plate is hinged to the fixed hopper lower edge, the lower end of the movable inclined plate is laid on the upper edge of the fixed semicircular plate in an inclined manner, and the outside of the movable straight plate is provided with a bunker plate resetting device; and the intermittent feeding mechanism comprises a uniform feeder and a stepping driving part, the uniform feeder is positioned in the cavity of the fixed semicircular plate and comprises a central ring and a plurality of separation plates fixed on the central ring in an equant manner, the central ring is arranged on the wheel shaft of a frame, the length of each of the separation plates can realize a case that the outer ends of the separation plates can successively move the movable inclined plate and the movable straight plate in the rotation of the separation plates, the outer end of the one of the separation plates props against the movable straight plate in the pause of the separation plates, and the stepping driving part intermittently pushes the uniform feeder to rotate. The feeding device realizes the uniform and quantitative feeding and the smooth production, and is suitable for the feeding of large-granule materials.

Owner:卢小平 +1

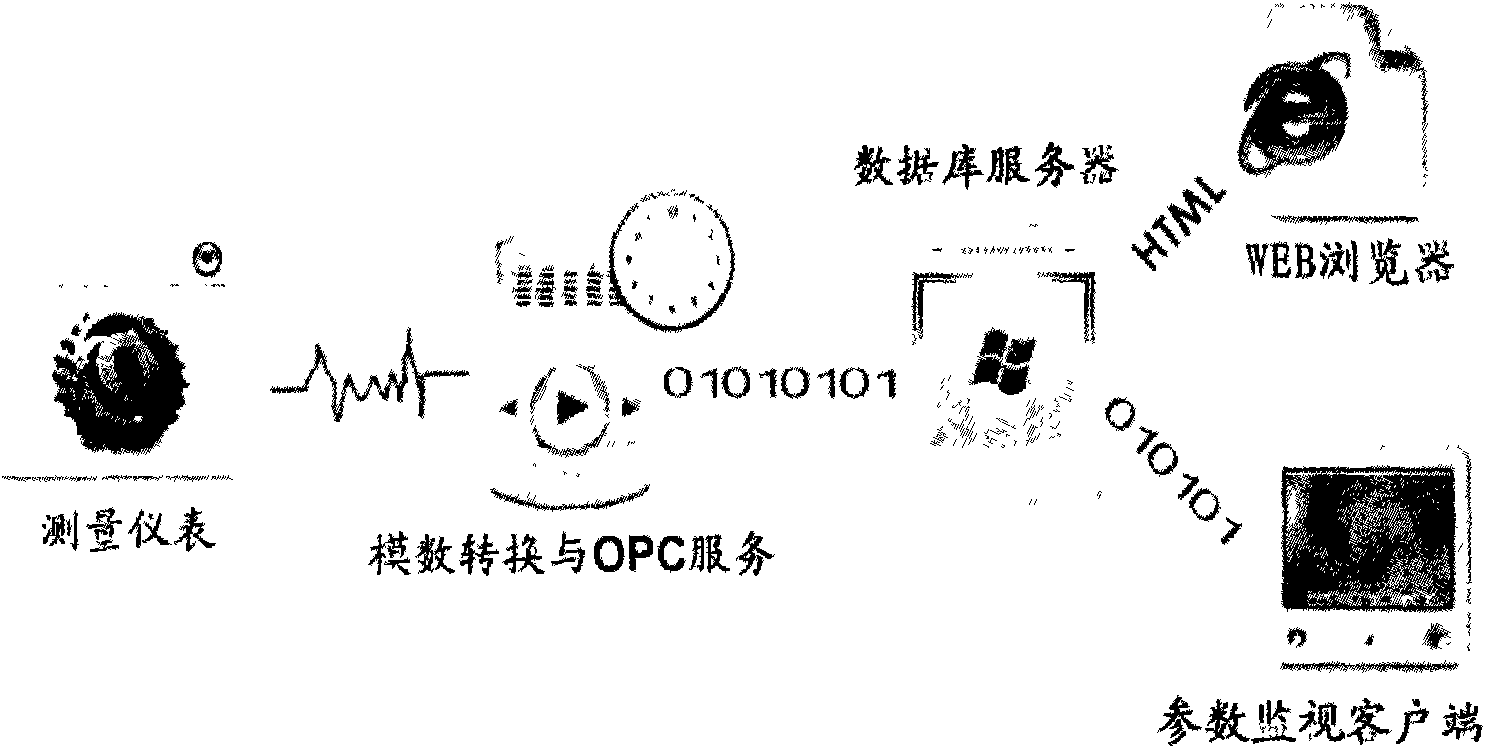

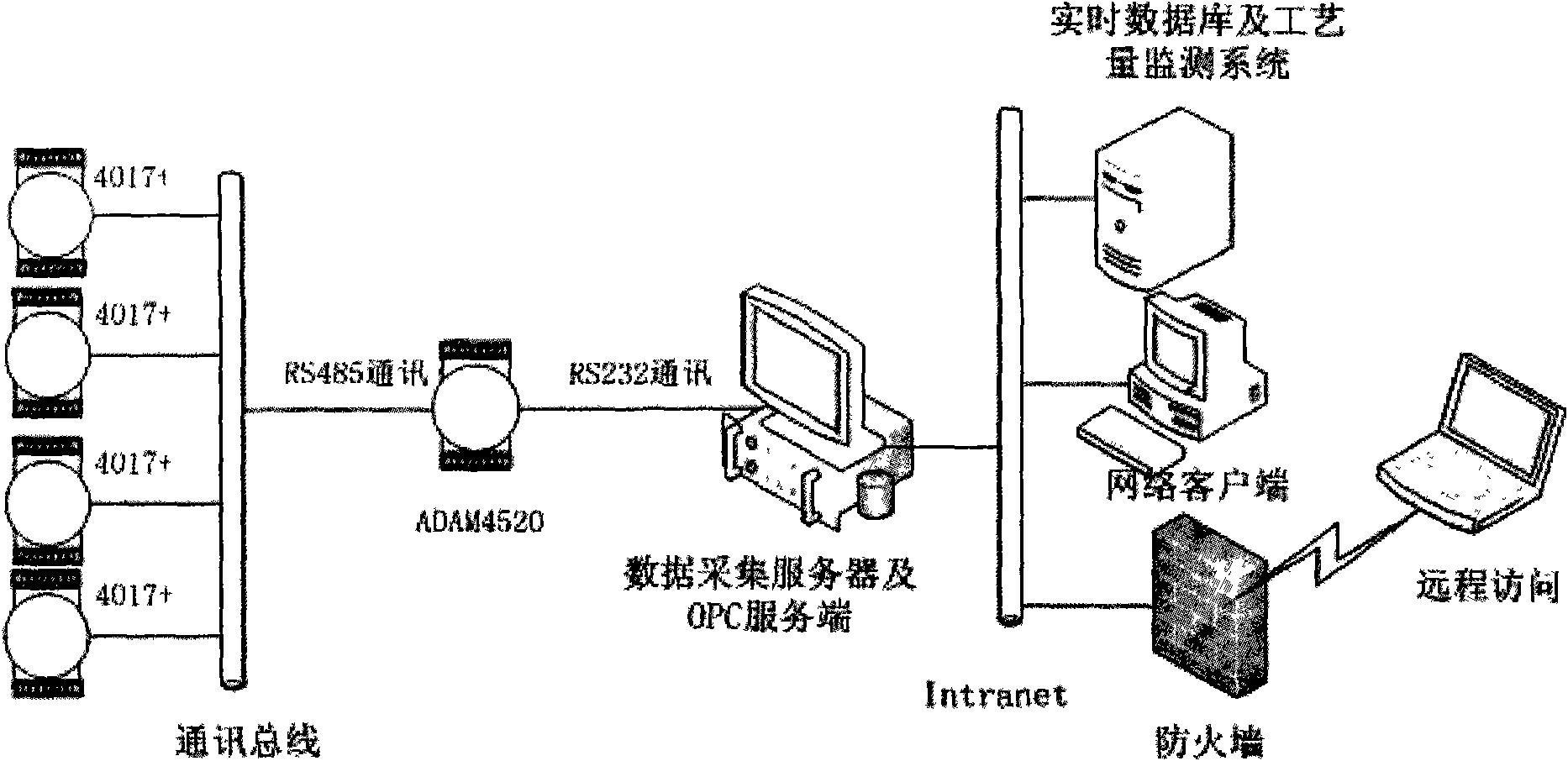

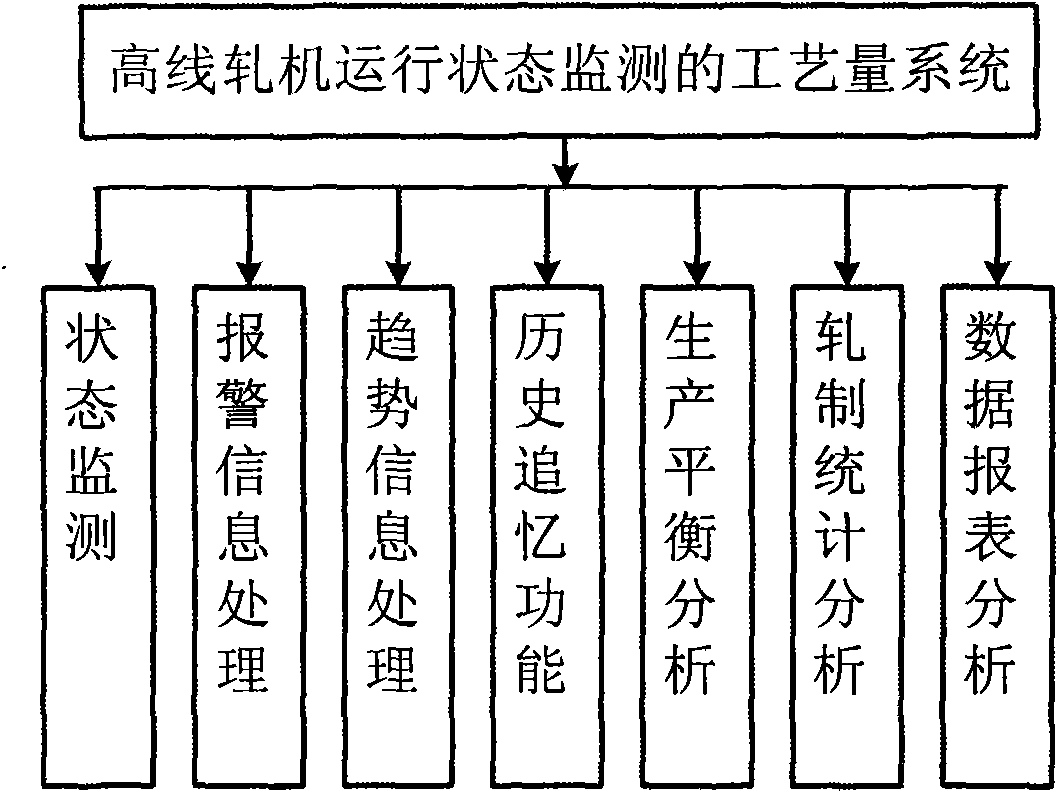

Equipment operating and process quality state monitoring system for high-speed rolling mill

ActiveCN102059256AState of economic productionImprove spinning qualityMeasuring devicesMetal rolling arrangementsProcess qualityData acquisition

The invention discloses an equipment operating and process quality state monitoring system for a high-speed rolling mill, belonging to the technical field of high-speed wire rolling. Hardware comprises sensors for electric quantity, rotation speed and the like, a 4017+ intelligent data acquisition module, an RS485-RS232 communication conversion module and an industrial control computer. A rolling current signal, a rolling rotation speed signal and other signals are measured by the sensors, then subjected to A / D (Analog to Digital) conversion by the data acquisition module and then stored into the industrial control computer through the RS485-RS232 communication conversion module, the acquired data are issued to a network by utilizing an OPC (OLE (Object Linking and Embedding) for Process Control) protocol, and a user extracts the recorded information from an IE browser or a client side through the network for observing and analyzing. Software comprises an OPC communication module, an operation state real-time monitoring module, an alarm information recording and analyzing module, a trend information analyzing and processing module, a historical recall functional module and an industrial signal logic analysis module. The equipment operating and process quality state monitoring system has the advantages of improving the reliability for equipment operation, prolonging the service life and effectively lowering the cost.

Owner:SHOUGANG CORPORATION

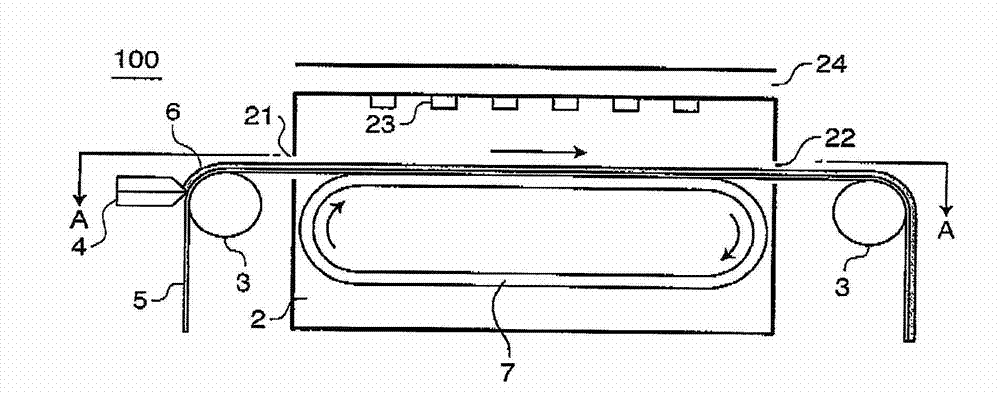

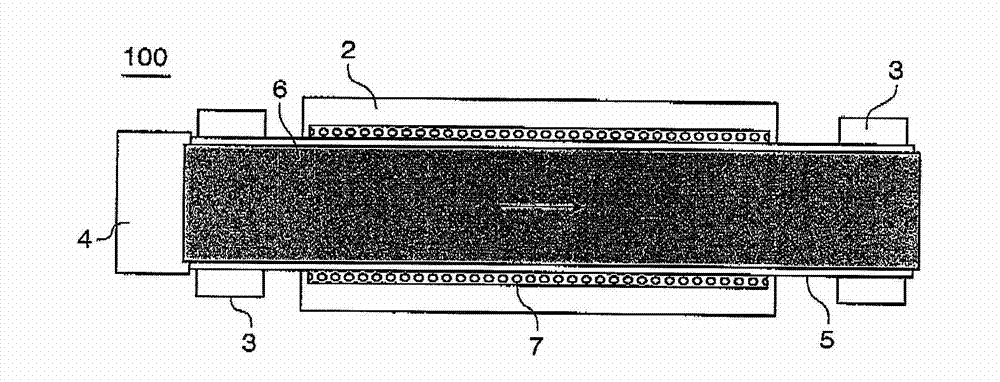

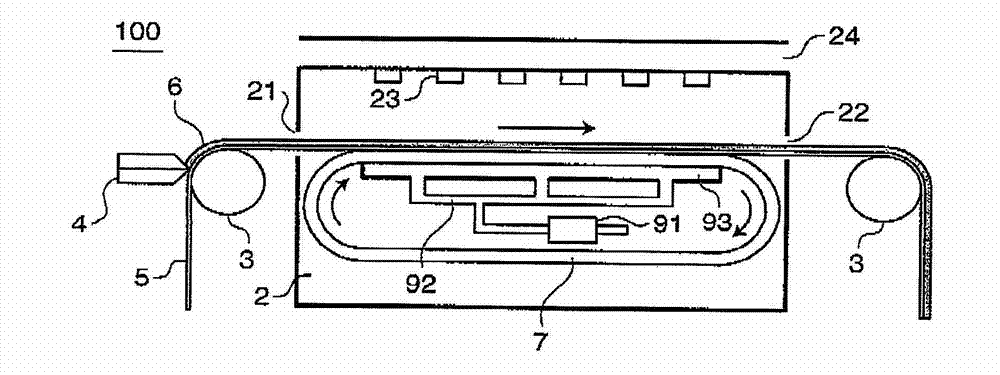

Electrode dryer and method for drying electrode

InactiveCN102773208APrevent saggingAvoid wrinklesElectrode manufacturing processesPretreated surfacesEngineeringCoating

An electrode dryer includes a drying furnace; and a conveyance member for longitudinally conveying a band-like electrode base material coated with a coating material from an entrance to an exit of the drying furnace, the drying furnace including an air-permeable mounting member for horizontally supporting the electrode base material to be conveyed in the drying furnace; and a suction member for sucking the electrode base material through the air-permeable mounting member.

Owner:SHARP KK

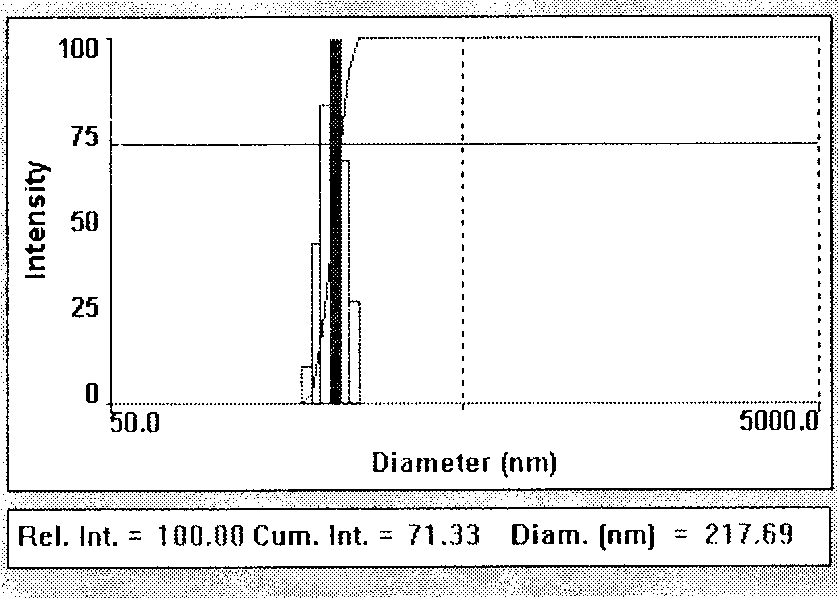

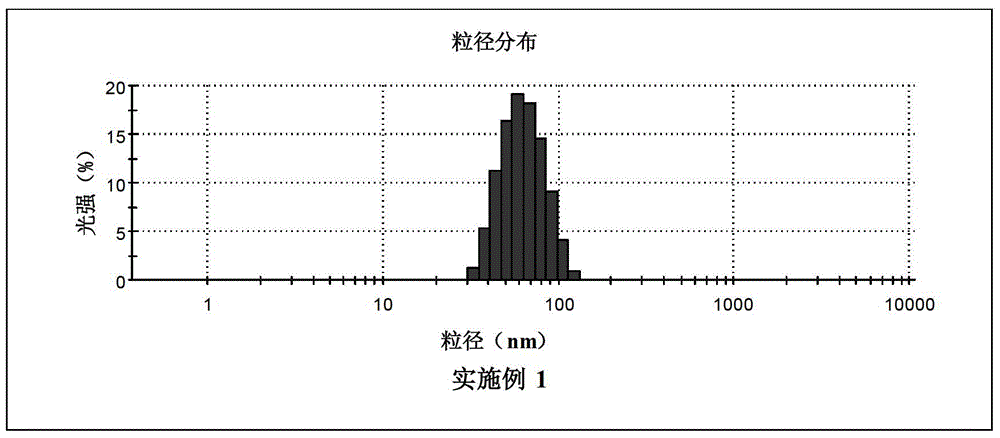

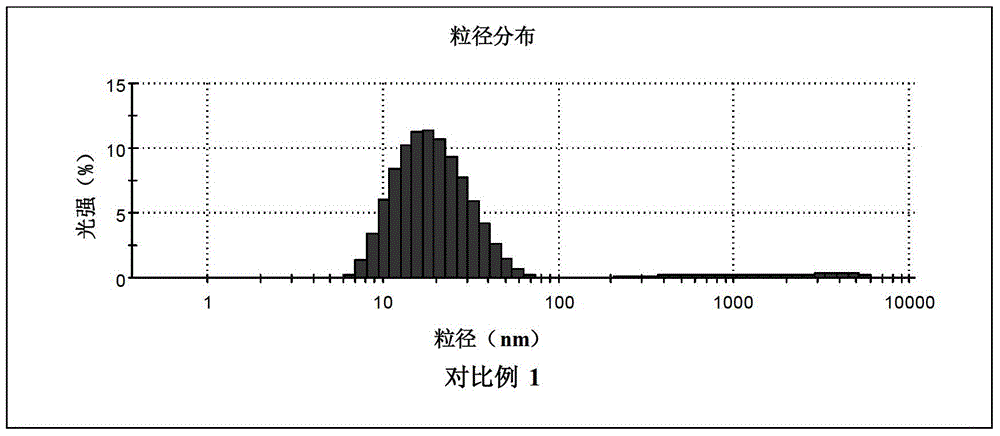

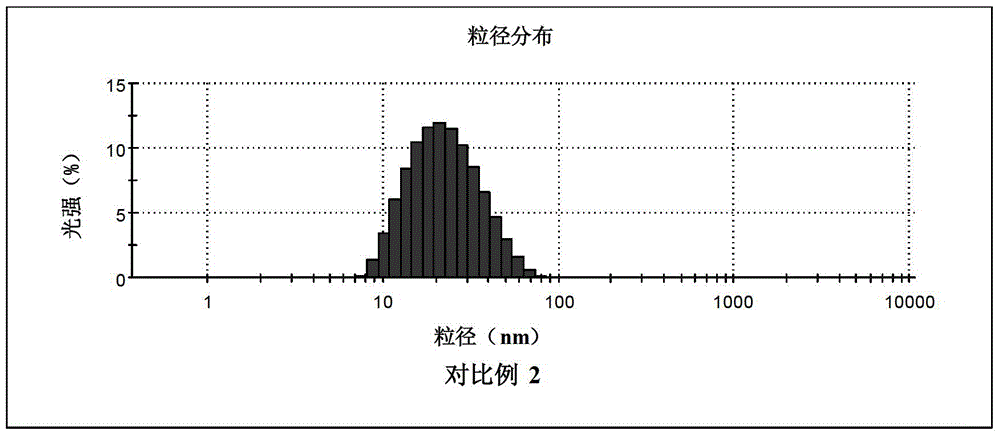

Micro-channel preparation method of nano silicon dioxide with uniform particle size

ActiveCN104370289AReduce volumeLarge specific surface areaMaterial nanotechnologySilicaSilicon dioxideAqueous solution

The invention discloses a micro-channel preparation method of nano silicon dioxide with a uniform particle size. The method comprises the following steps: injecting an alcoholic solution or water solution of soluble silicate, an alcoholic solution or water solution of an alkali, and inert gas into a micro-channel reactor according to a certain volume ratio, mixing the substances in the micro-channel reactor, and then making the mixture carry out reactions in the reactor so as to obtain a solution containing nano silicon dioxide particles with a controllable, stable and uniform particle size. The provided micro-channel preparation method can obtain nano silicon dioxide particles with a controllable, stable, and uniform size, which is controlled in a range of 1 to 600 nm.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

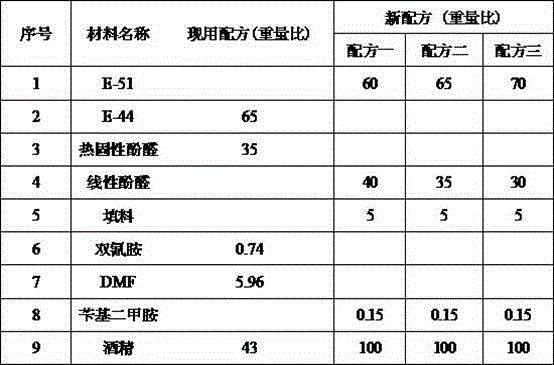

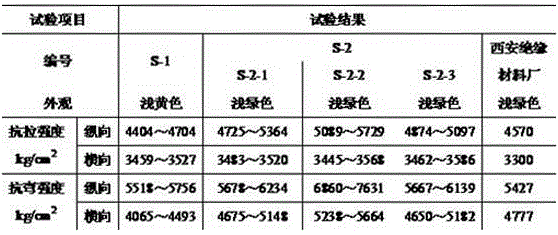

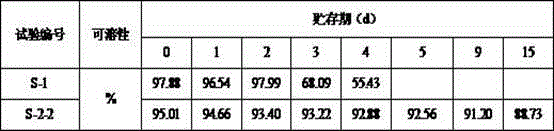

Epoxy phenolic resin adhesive and epoxy phenolic adhesive tape and laminated board manufactured by adhesive

ActiveCN102942892ALong shelf lifeConvenient sourceNon-macromolecular adhesive additivesLayered productsWeather resistanceFirming agent

Disclosed are an epoxy phenolic resin adhesive and an epoxy phenolic adhesive tape and a laminated board manufactured by the adhesive. The epoxy phenolic resin adhesive comprises solid components, liquid components and organic solvent components, the solid and liquid components comprise, by weight, 60% to 70% of E epoxy, 30% to 40% of phenolic resins, 3% to 6% of fillers, 0.5% to 0.8% of curing agents and 0.1% to 0.2% of accelerants, and the solid and liquid components account for 50% to 70% of the total weight. The prepared epoxy phenolic adhesive tape comprises a glass fiber cloth and the adhesive coated on the glass fiber cloth, the thickness of the glass fiber cloth is in a range from 100mum to 140mum, the thickness of the adhesive is in a range from 150mum to 200mum, and the adhesive is the epoxy phenolic resin adhesive. The adhesive has the advantages of low viscosity, good manufacturability, heat stability, weather resistance and chemical medicine resistance, long storage period, high heat resistance and extremely low toxicity. The epoxy phenolic adhesive tape prepared by the adhesive can still be normally used after being stored at the temperature of 40 DEG C for a half month. The epoxy phenolic laminated board prepared by the adhesive tape has the advantages of simple preparation technology and excellent relevant mechanical performance index.

Owner:JIUJIANG FLEX

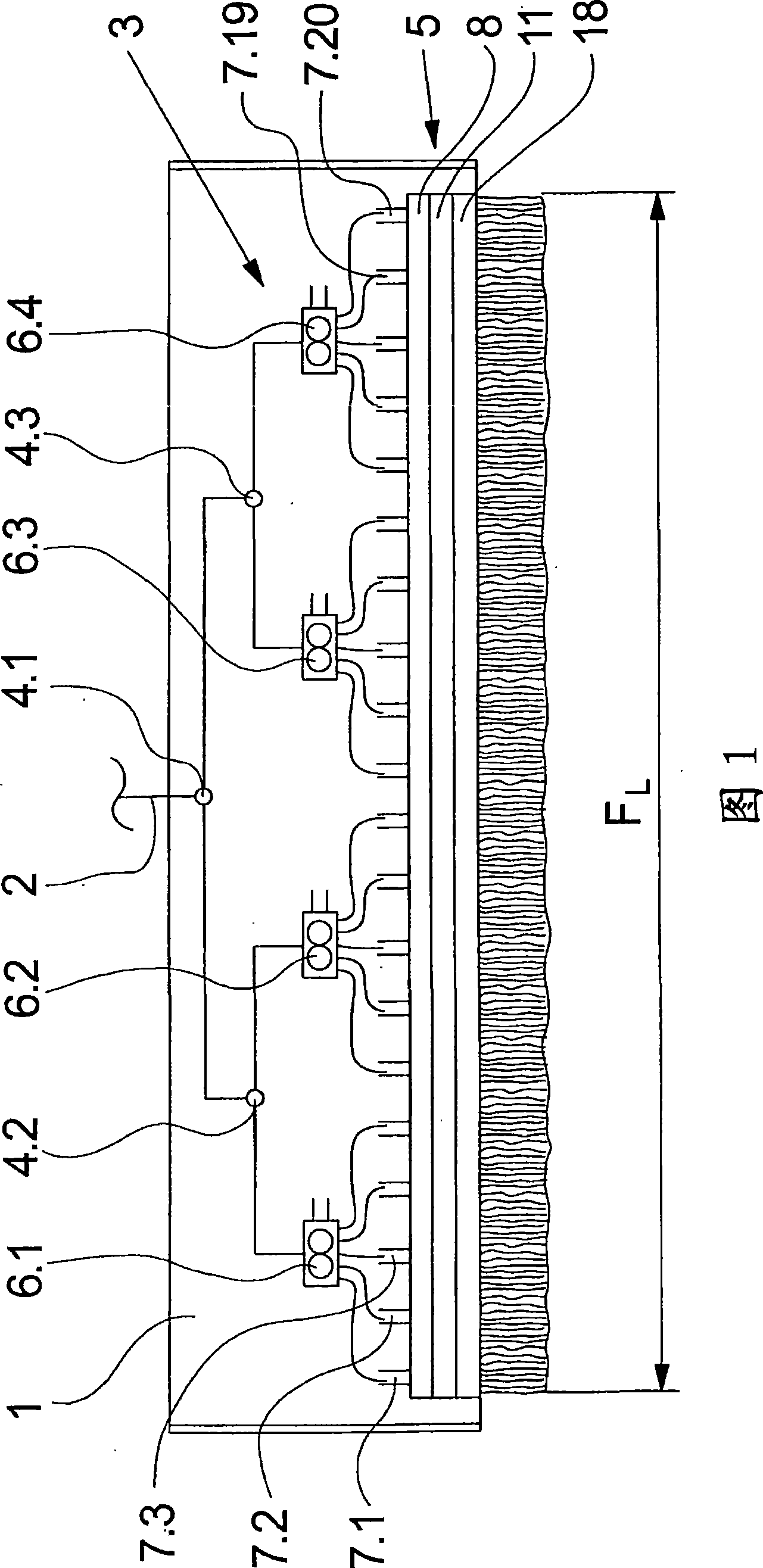

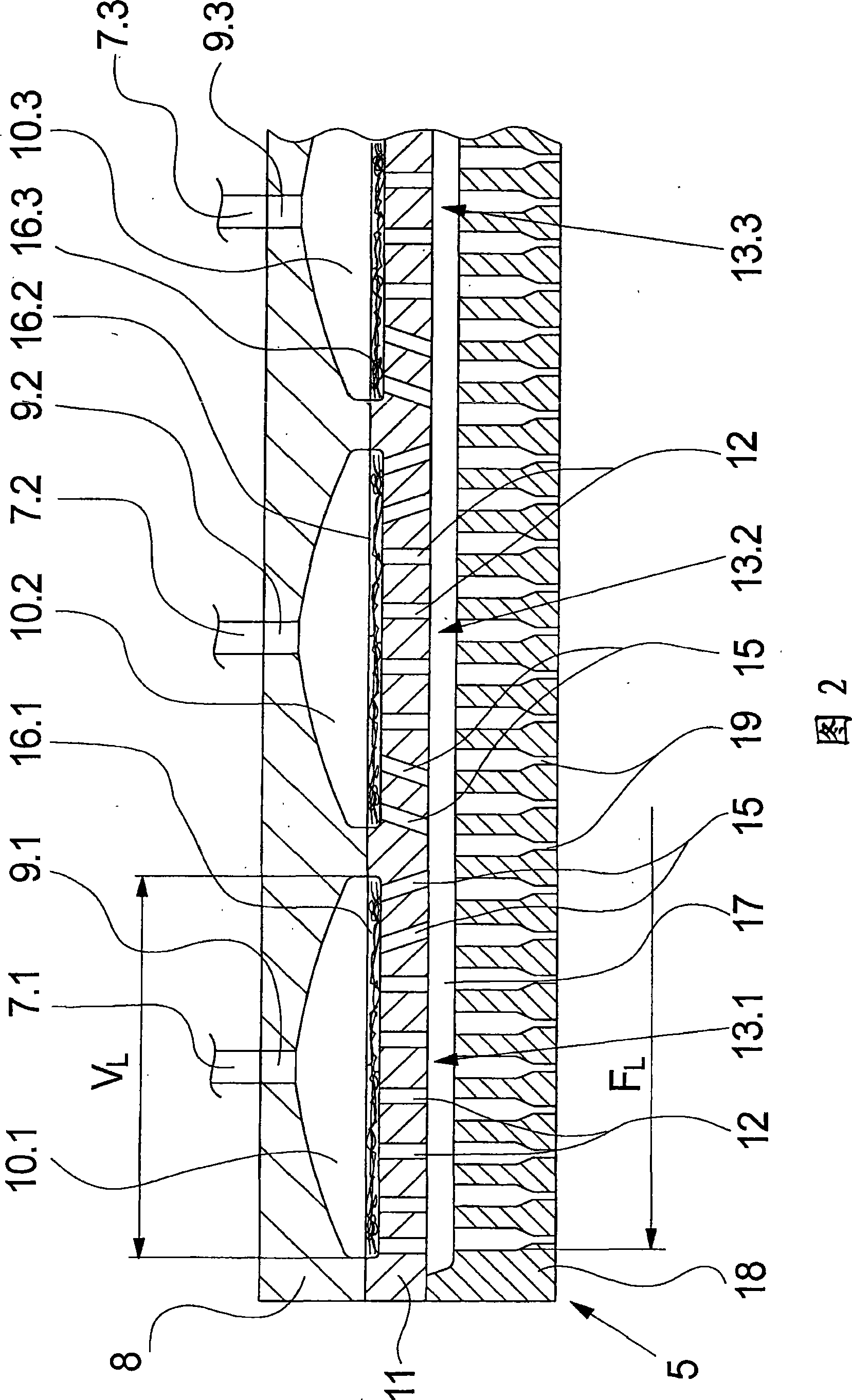

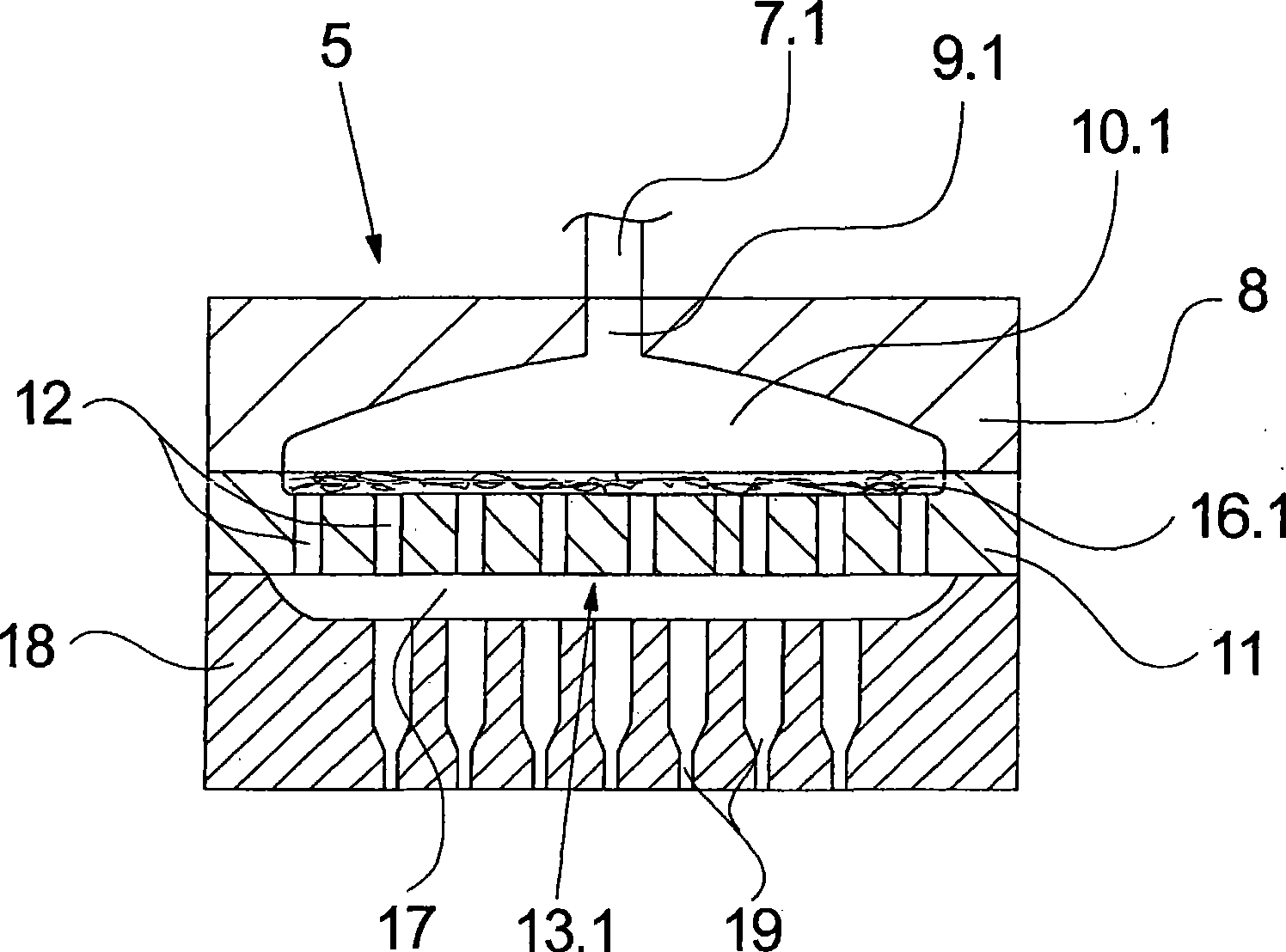

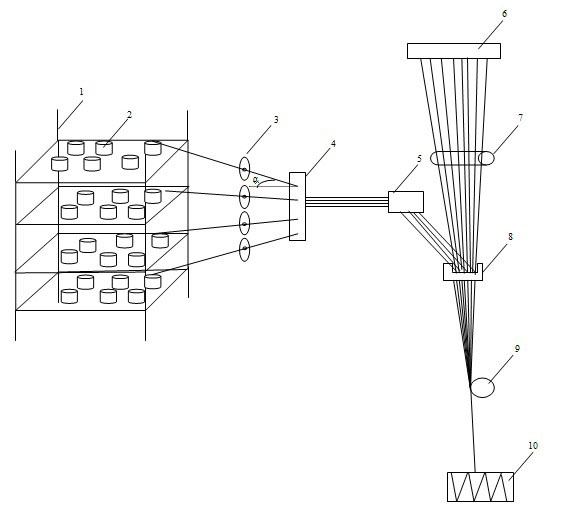

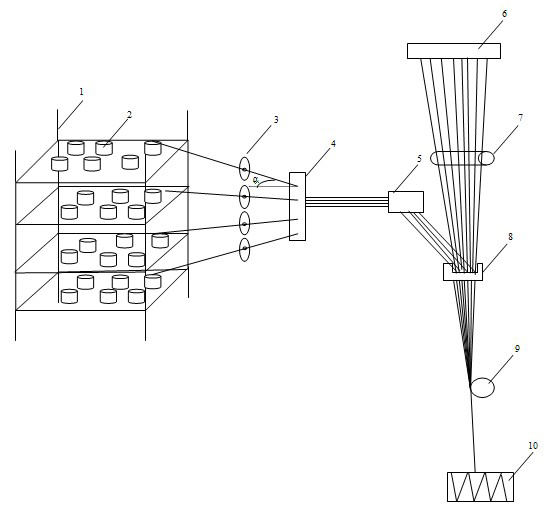

Device for melt spinning of a linear filament bundle

ActiveCN101443489AEvenly distributedConstant dwell timeSpinnerette packsMelt spinning methodsPolymer meltMelt spinning

The invention relates to a device for melt spinning of a linear filament bundle with a spinning beam for mounting a longitudinal spinning nozzle group. The spinning nozzle group comprises a nozzle plate on an underside with a number of nozzle drillings and an inlet plate on an upper side with at least one inlet channel, a distribution chamber being arranged between the inlet plate and the nozzle plate, connected to the inlet channel in the inlet plate and the nozzle drillings in the nozzle plate. According to the invention, a residence time for the polymer melt within the nozzle group is kept as constant as possible with a large production range by means of the inlet plate having several residence chambers connected to inlet channels, arranged at a separation from each other in the longitudinal direction of the spinning beam.

Owner:OERLIKON TEXTILE GMBH & CO KG

Method for preparing silk protein composite cellulose fibers

ActiveCN102505170AHigh recycling valueLow viscosityArtificial filaments from viscoseProtein solutionSulfonate

The invention discloses a method for preparing silk protein composite cellulose fibers, which includes steps: firstly, adding degummed waste silk into LiBr solution, dissolving the waste silk to prepare silk protein solution in which silk protein accounts for 3-15%, by weight; secondly, adding the silk protein solution into sodium hydroxide solution with cellulose sulfonate to obtain blended solution of silk protein and cellulose, wherein blended silk protein solution accounts for 5-50% of that of the sodium hydroxide with cellulose sulfonate by weight; and thirdly, spinning the blended solution by coagulating bath and obtaining the silk protein composite cellulose fibers by post-processing. By the method, recovery value of the waste silk is improved greatly, special effects of whitening and skin caring of the silk protein composite cellulose fibers can be realized, and the fibers are smooth and soft to touch as silk, and have the skin caring and whitening effects that the effects of protein powder fibers or blended fibers of protein powder and cellulose solution cannot match.

Owner:赛得利(盐城)纤维有限公司

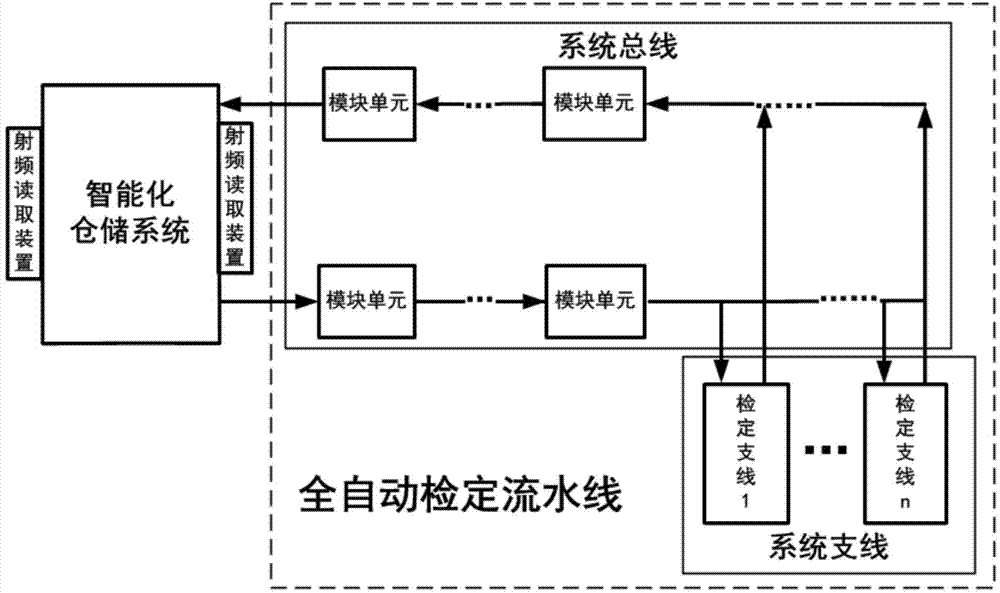

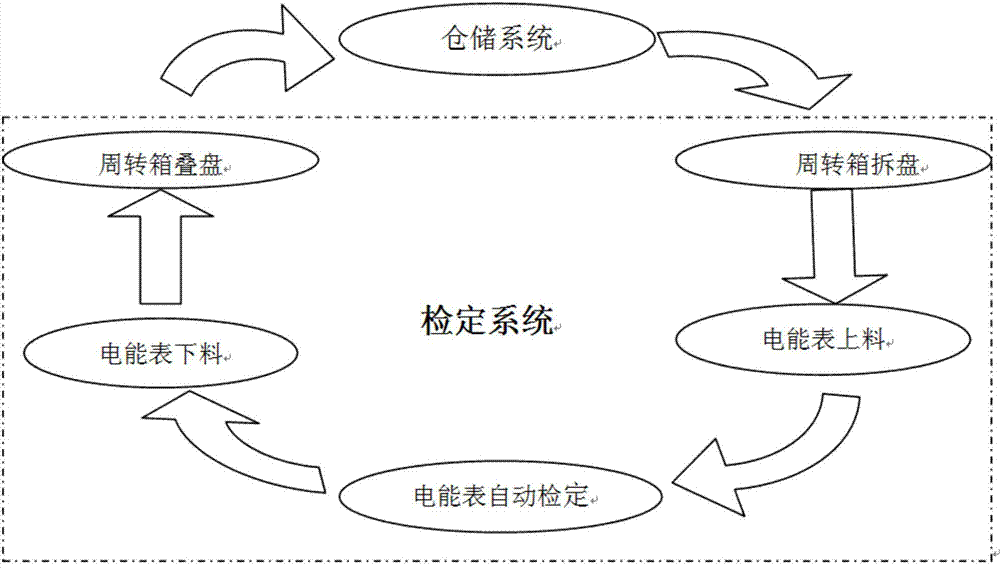

Automated operating device for storage and verification of electric energy meter of electric power system and operating method thereof

ActiveCN103489092AOptimizationImprove management toolsSensing record carriersLogisticsModularityRadio frequency

The invention discloses an automated operating device for storage and verification of an electric energy meter of an electric power system and an operating method thereof. The automated operating device comprises an intelligent warehousing system, an RFID (radio frequency identification) property recognition system and a full-automatic verification assembly line, wherein the intelligent warehousing system comprises a high level three-dimensional good shelf and a physical distribution transport system, the RFID property recognition system comprises a radio frequency chip arranged on the electric energy meter to be verified and a radio frequency read device arranged in the intelligent warehousing system, the full-automatic verification assembly line comprises a system bus and a system branch line, the system bus is combined by modularized units which are connected with each other in series, and the system branch line comprises a plurality of verification branch lines which are connected in parallel. The automated operating device for storage and verification of the electric energy meter of the electric power system and the operating method have the advantages of realizing automated storage and verification of the newly purchased electric energy meter from the process of warehousing and verification to the process of delivery, and improving intelligent management level in metering storage and verifying production.

Owner:STATE GRID CORP OF CHINA +1

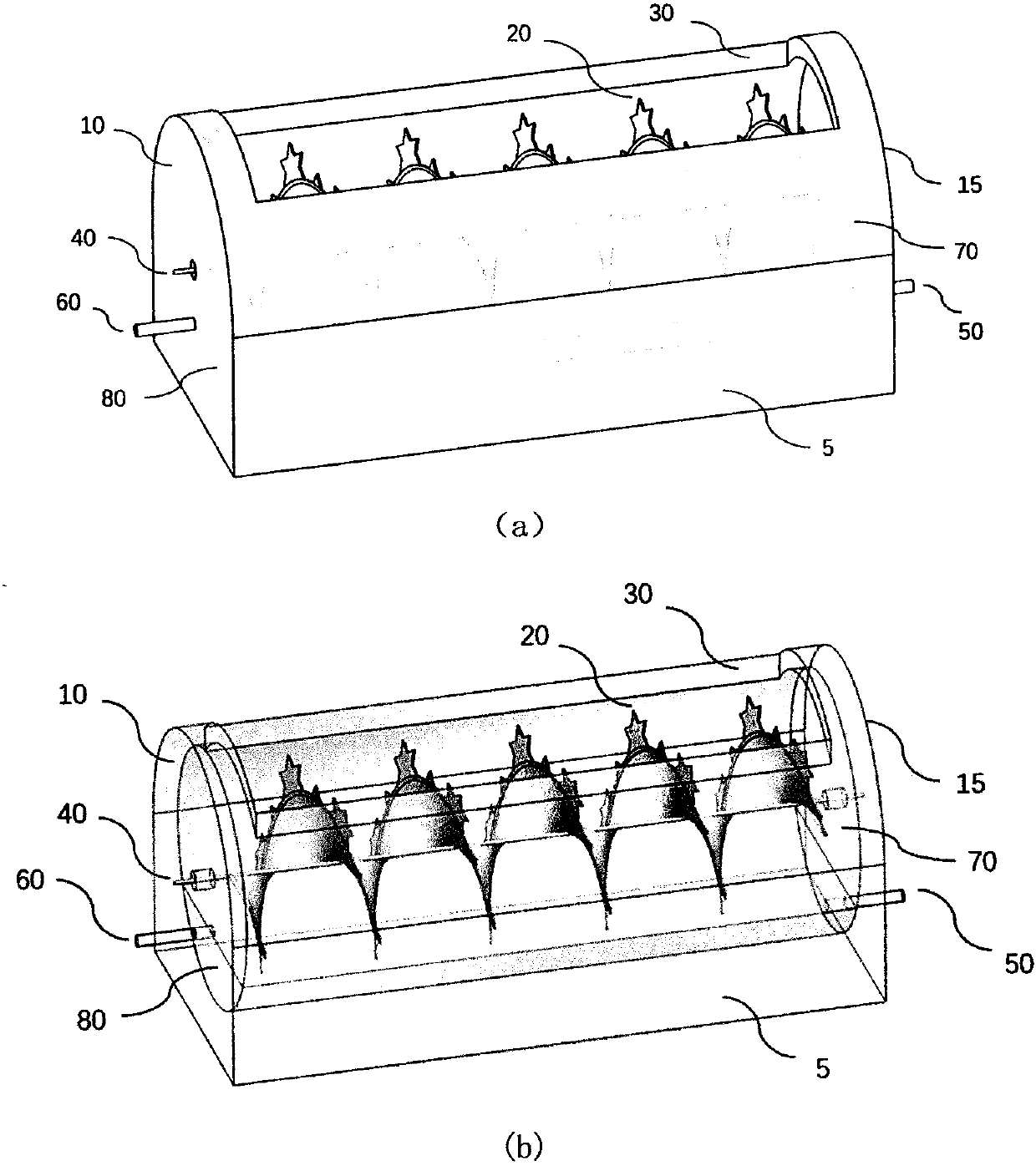

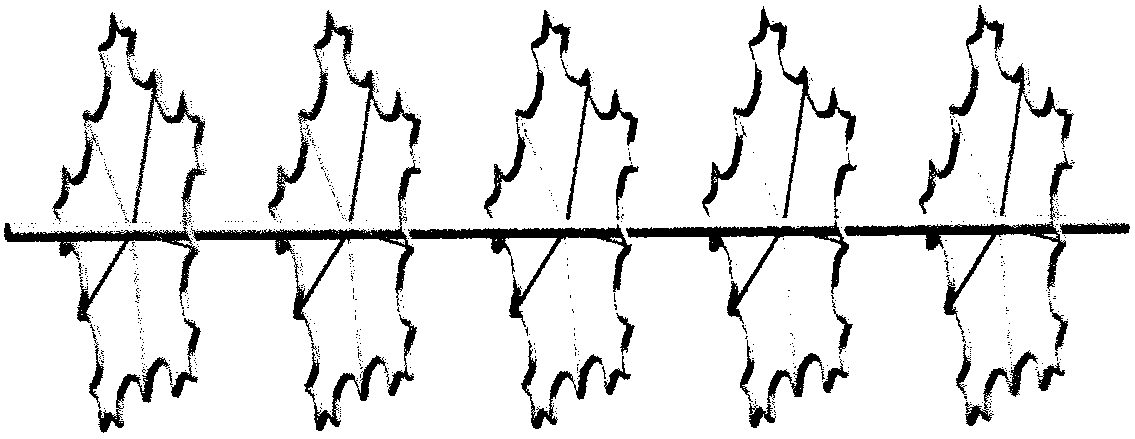

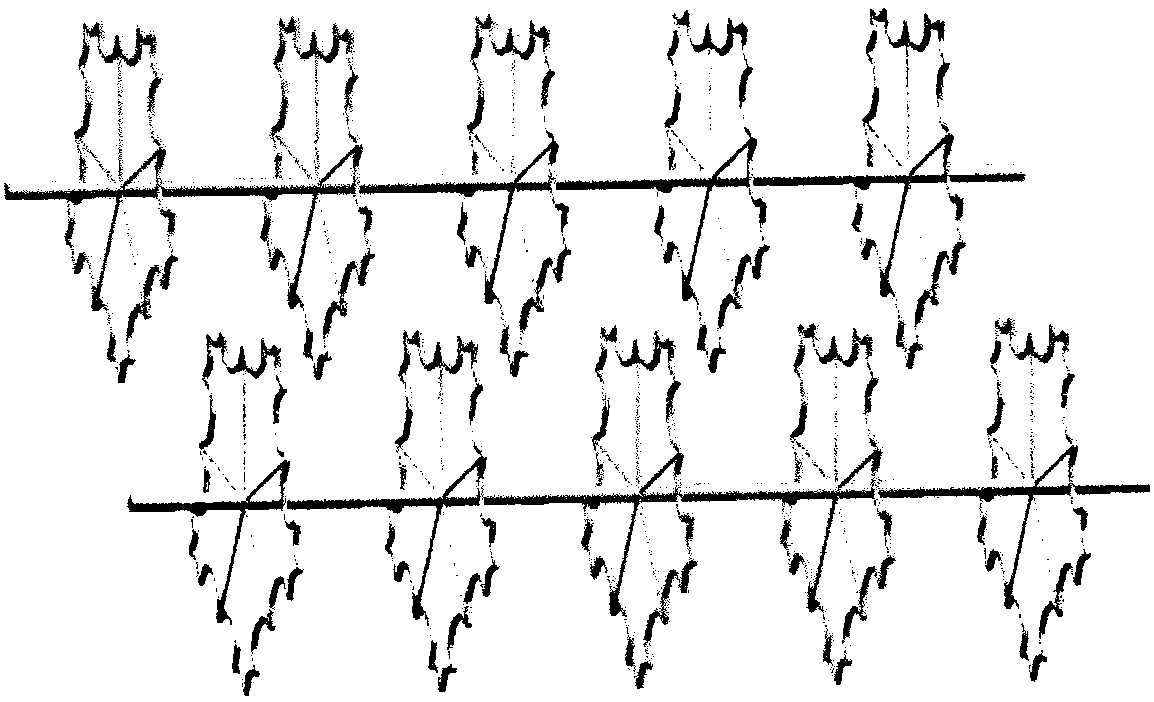

Needle-free electrostatic spinning assembly based on fractal structures

InactiveCN107620127AIncrease field strengthLow fineness variationFilament/thread formingNeedle freeElectrospinning

The invention discloses a needle-free electrostatic spinning assembly based on fractal structures and provides an electrostatic spinning technology which can effectively improve the fineness, uniformity and yield of nanometer fibers. The needle-free electrostatic spinning assembly is characterized in that electrostatic spinning heads are formed by using fractal structure units, and the electrostatic spinning heads of different types are obtained through the fractal structures of different forms; different-scale continuous production of the nanometer fibers can be achieved by adjusting the specification and number of the spinning heads of the fractal structures and the working width and length of the spinning heads. The needle-free electrostatic spinning assembly has the advantages that thespecially designed spinning heads of the fractal structures can improve the field intensity and the distribution uniformity, improve the fineness, uniformity and yield of the nanometer fibers, the phenomena that in an existing needle-free electrostatic spinning device, the field intensity is low, the energy consumption is high and the field intensity is nonuniform are avoided, the spinning voltage can be effectively reduced, the cost can be reduced, the energy utilization rate can be improved, and industrialized application and popularization are facilitated.

Owner:WUHAN TEXTILE UNIV

Method for establishing adventitious root cultivation system of Psammosilene tuniceoides W. C. Wu et C. Y. Wu and expanding cultivation method of Psammosilene tuniceoides W. C. Wu et C. Y. Wu

ActiveCN102771397AContinuous productionBalanced productionPlant tissue cultureHorticulture methodsPlantletCallus

According to the invention, young leaves or stems of plants of Psammosilene tuniceoides W. C. Wu et C. Y. Wu are taken as an explant to successfully induce callus of the Psammosilene tuniceoides W. C. Wu et C. Y. Wu, and a callus culture system of the Psammosilene tuniceoides W. C. Wu et C. Y. Wu under the conditions of light and dark cultivation is established to induce the differentiation of the callus to produce adventitious roots, thus establishing an adventitious root cultivation system of the Psammosilene tuniceoides W. C. Wu et C. Y. Wu. Moreover, the content of total saponins of the Psammosilene tuniceoides W. C. Wu et C. Y. Wu is determined, and the conditions and parameters of plant cell culture are further optimized, thus establishing a high-yield cell culture system of the Psammosilene tuniceoides W. C. Wu et C. Y. Wu. Therefore, the plant cells of the Psammosilene tuniceoides W. C. Wu et C. Y. Wu are cultured in a large scale to produce the adventitious roots which substitute for the original plant of the Psammosilene tuniceoides W. C. Wu et C. Y. Wu to be used as medicine.

Owner:成都市三禾田生物技术有限公司

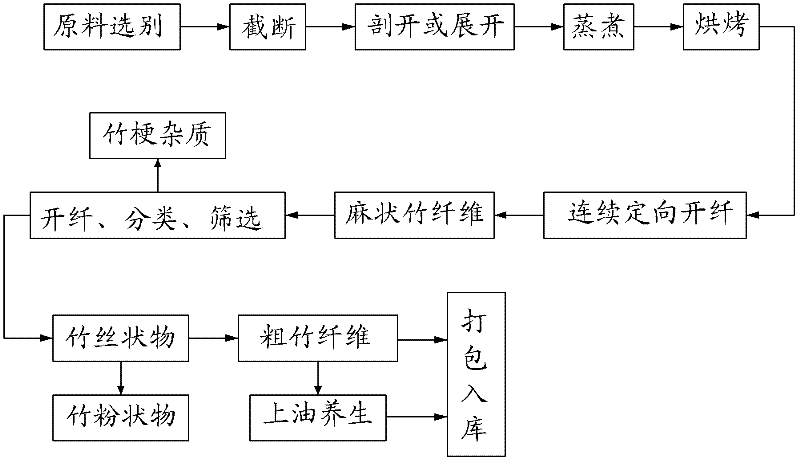

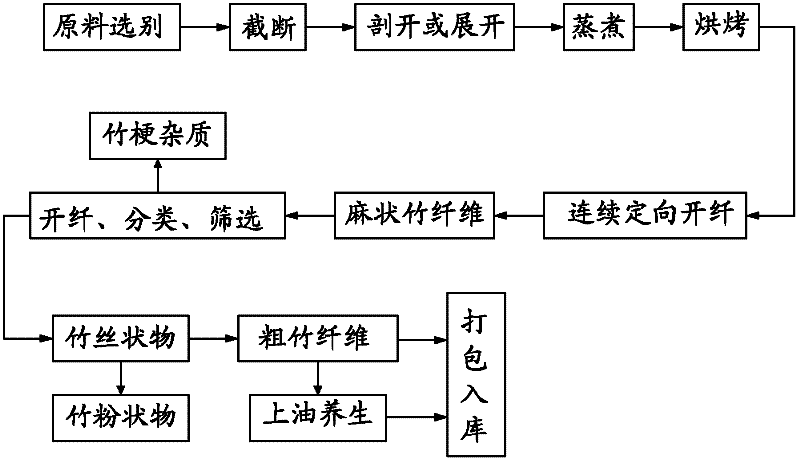

Non-pollution production method of bamboo fibers

ActiveCN102517642AEfficient productionNo harmVegetable materialMechanical fibre separationFiberPollution

The invention provides a non-pollution production method of bamboo fibers, wherein the method is used for producing coarse bamboo fibers with lengths of 60-120 mm and diameters of 0.18-0.35 mm. the method comprises the steps of: firstly, selecting the raw materials; and then, cutting the bamboos into regulated lengths; splitting or flattening the bamboos; adding a reusable neutral softening solution in the bamboos to stew and soften the bamboos; roasting the softened bamboos on a drying machine; directionally opening fibers from the roasted bamboos; drying the bamboos, opening fibers for the second time, classifying and sorting to obtain bamboo fibers with stable quality. The method of the invention has the advantages of non waste liquid drainage during the production process, simple technique, high production efficiency, reliable product quality, and capability of greatly improving the fiber yield and reducing the production cost, so that the method is an ideal method for producing bamboo fibers.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Low-cost preparation method of carbon fiber precursor fibers, preoxidized fibers or carbon fibers

ActiveCN109440230AUniform structureStable structureWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberCarbon fibers

A low-cost preparation method of carbon fiber precursor fibers, preoxidized fibers or carbon fibers is characterized in that an acrylonitrile polymer is dissolved through a solvent to obtain a uniformspinning solution; the spinning solution forms fine spinning flow through spinning pores, and then the fine spinning flow enters a coagulating bath component which is below the spinning solution geltemperature point to obtain primary fibers; the primary fibers are processed by stretching, washing, drying and oiling to obtain the carbon fiber precursor fibers; and the carbon fiber precursor fibers are pre-oxidized and carbonized to obtain the preoxidized fibers or carbon fibers. The method has the advantages of being low in cost, high in fiber performance and stable to produce in a high-powerstretching condition.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

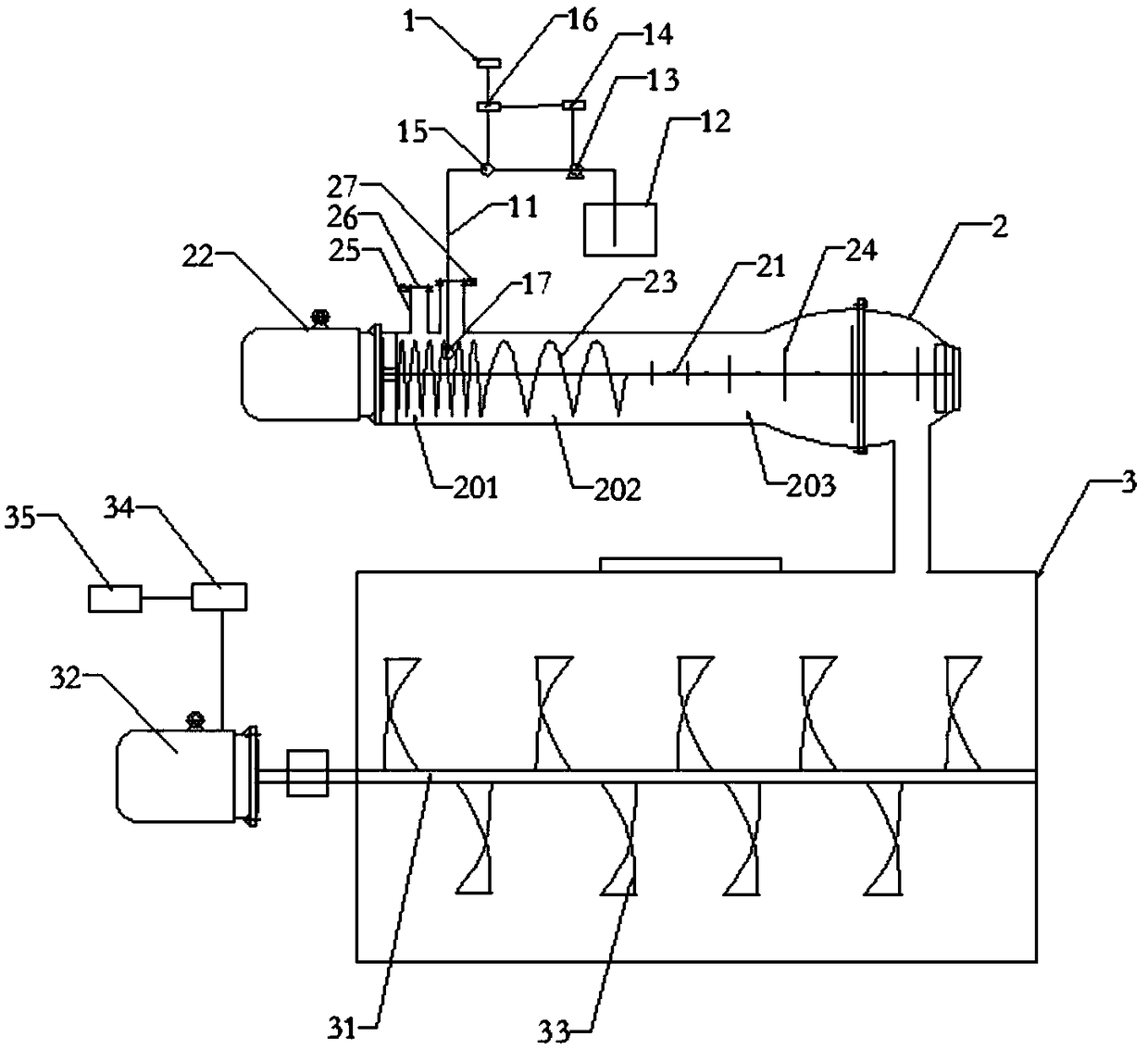

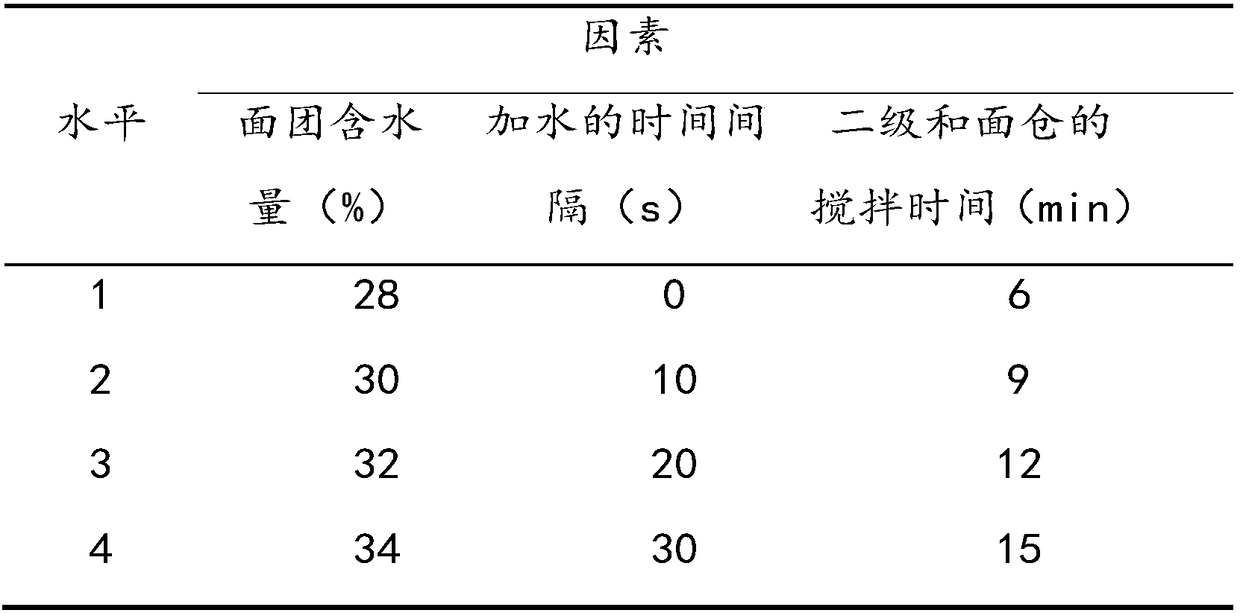

Dough kneading device, dough kneading method and noodle making machine

ActiveCN108260615AIncrease contact areaStir wellMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsGlutenPulp and paper industry

The invention belongs to the technical field of mechanical dough kneading and relates to a dough kneading device, a dough kneading method and a noodle making machine. The dough kneading device provided by the invention comprises a water supply mechanism, a primary dough kneading chamber and a secondary dough kneading chamber, wherein a first stirring shaft is arranged in the primary dough kneadingchamber, and one end of the first stirring shaft is connected with a first power mechanism; the interior of the primary dough kneading chamber is divided into three mutually communicating stirring areas, namely a first stirring area, a second stirring area and a third stirring area sequentially, paddles are arranged in the first stirring area and the second stirring area, and a stirring rod is arranged in the third stirring area; at least one material inlet is formed in the primary dough kneading chamber and the material inlet communicates with the first stirring area; and the water supply mechanism comprises a water pipe, one end of the water pipe extends into the first stirring area by virtue of the material inlet, and the water pipe at the end is connected with a water atomization device. The dough kneading device can enable wheat flour to quickly absorb water and be thoroughly mixed with water and is helpful to form dough with proper expansion of gluten, loos particles and uniformcolor for high quality fine dried noodles.

Owner:想念食品股份有限公司

All-year-round artificial propagation method of Tilapia aurea

ActiveCN102640717AIncrease spawn rateImprove fertilization rateClimate change adaptationPisciculture and aquariaAnimal scienceBroodstock

The invention discloses an all-year-round artificial propagation method of Tilapia aurea. The method can improve spawning rate, fertilizing rate and hatching rate of parent fishes, and produce high-quality fries with full length of 2 cm satisfying sale specification after culture for 18-20 days. The method provided by the invention can solve the long-term shortage problem of spring early fries in culture of Tilapia aurea, and ensure all-year-round supply of fries to realize balanced production.

Owner:广东省淡水名优鱼类种苗繁育中心

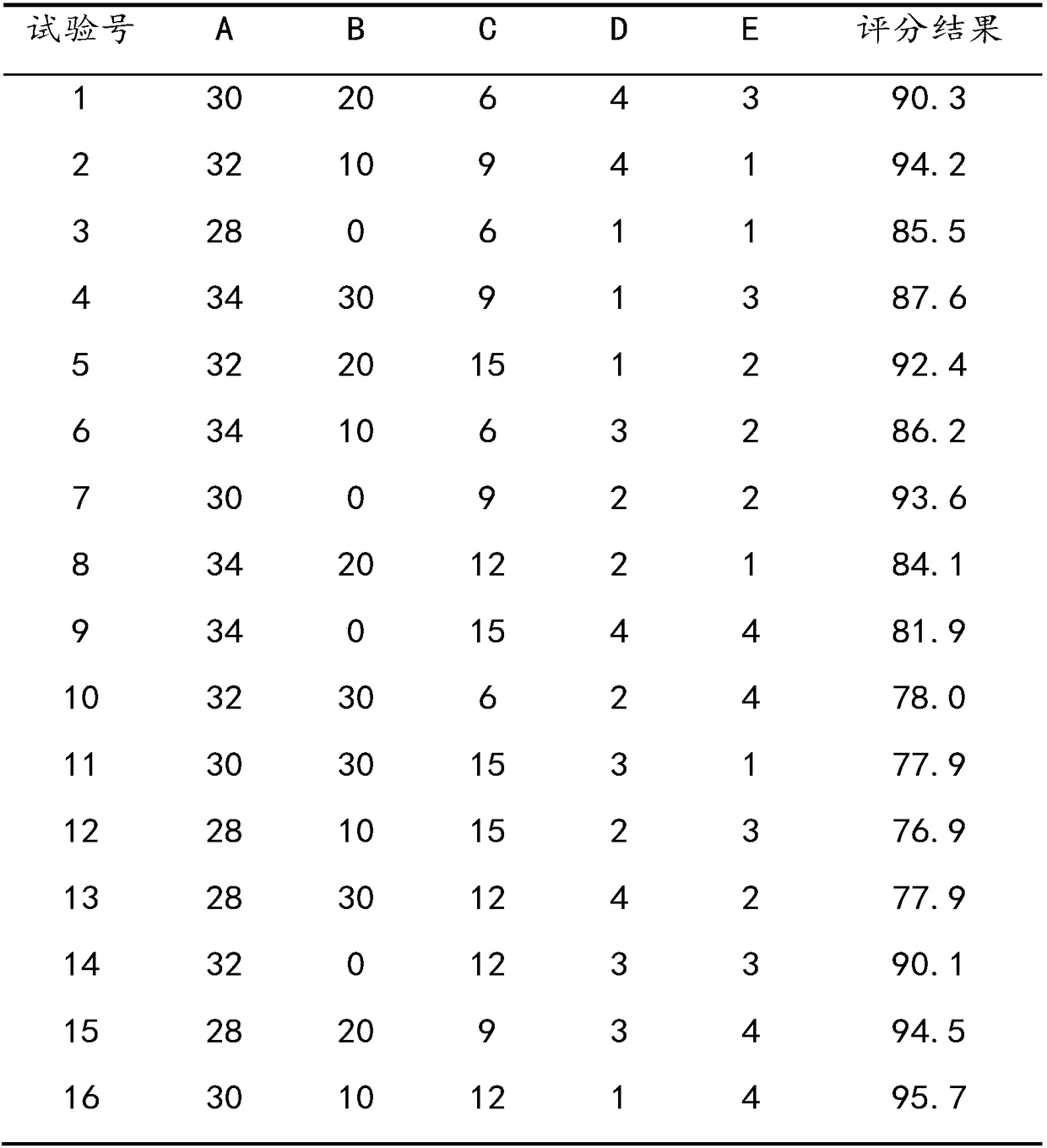

Light calcined magnesia calcinator suspension calcination device

The invention discloses a light calcined magnesia calcinator suspension calcination device. The device comprises a kiln body, the bottom of the kiln body is provided with a gas material inlet pipe, the top of the kiln body is provided with a gas material outlet pipe, the side wall of the kiln body is provided with a fuel inlet, the fuel inlet is communicated with a fuel nozzle in the kiln body, a magnesite ore powder and an air preheating device are arranged in front of the gas material inlet pipe and a gas material separation device is arranged in rear of the gas material outlet pipe. The light calcined magnesia calcinator suspension calcination device solves the problem of blocky material solid-gas phase counter-current movement of the existing light calcined magnesia calcination reverberatory kiln. Reaction products and waste gas go through the gas material outlet pipe on the top, are discharged and then enter the gas material separation device. The materials are in a suspension state, rise along with hot gas, fast react and can be uniformly sintered so that the product has high activity and good quality. The light calcined magnesia calcinator suspension calcination device realizes large scale, continuous and fast production of light calcined magnesia, has a simple structure, is convenient for operation, can be controlled flexibly and realizes uniform sintering. The product has high activity and good quality.

Owner:UNIV OF SCI & TECH LIAONING +3

Construction method for support part to early dismount for super large area deep foundation pit

ActiveCN101294388AShorten the construction periodBalanced productionExcavationsPre stressingEngineering

The invention belongs to the building construction technology field, and discloses a construction method used for early-dismantling the supporting local part of a super large excavation. The method includes the following steps: firstly, according to the construction area of the high part, the concrete first horizontal steel support influencing the high rise building construction is determined, and is taken as an object to be dismantled; secondly, after a foundation base plate is completed, a bracing bar is arranged on the lower side of the horizontal support to be dismantled; and thirdly, after the supporting bar is pre-stressed, the relevant first horizontal steel support to be dismantled in the step one is dismantled. Adopting the construction method of the invention can carry out balanced engineering construction on a continuous basis, save energy and reduce energy consumption, thereby laying a good foundation for accomplishing the construction period in advance or on time, and providing possibility to the early construction of the local high part of the super large excavation.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

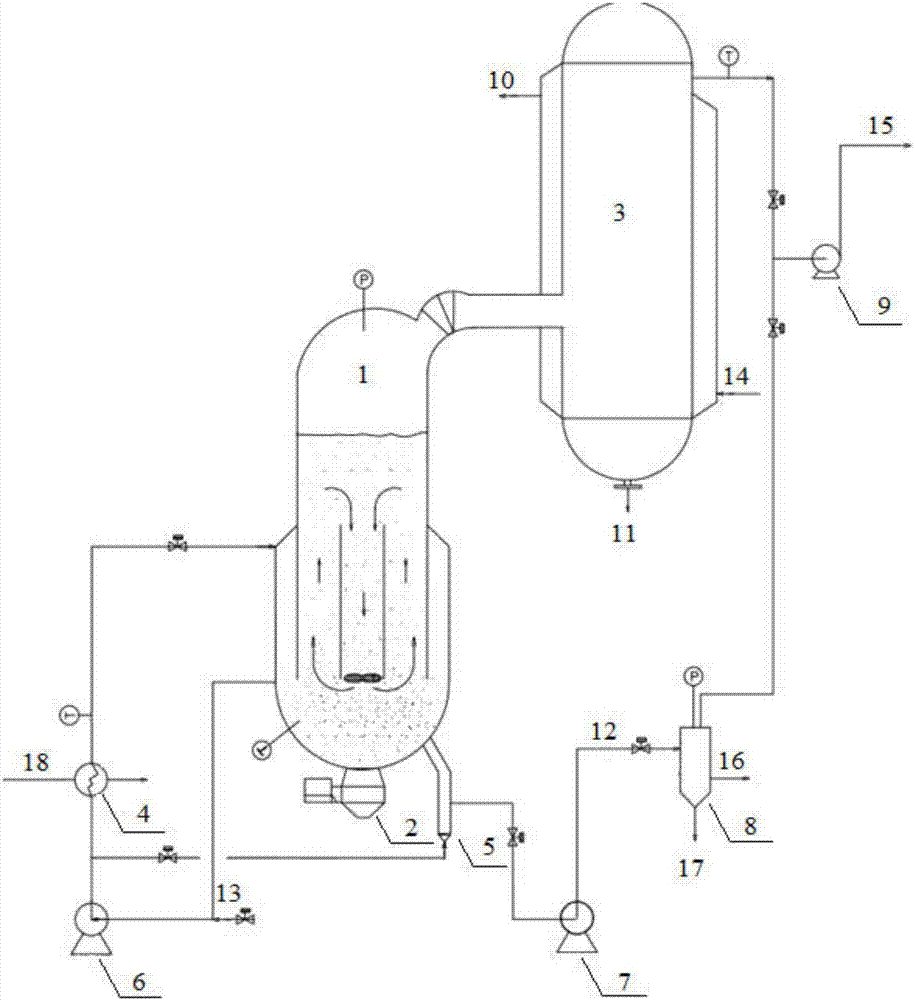

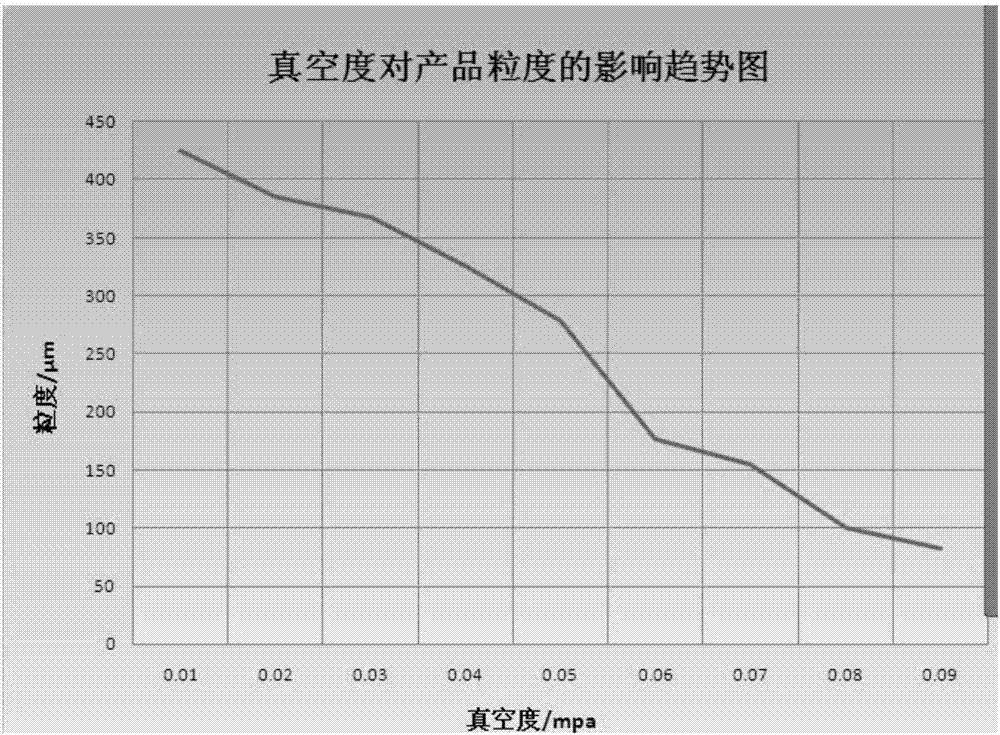

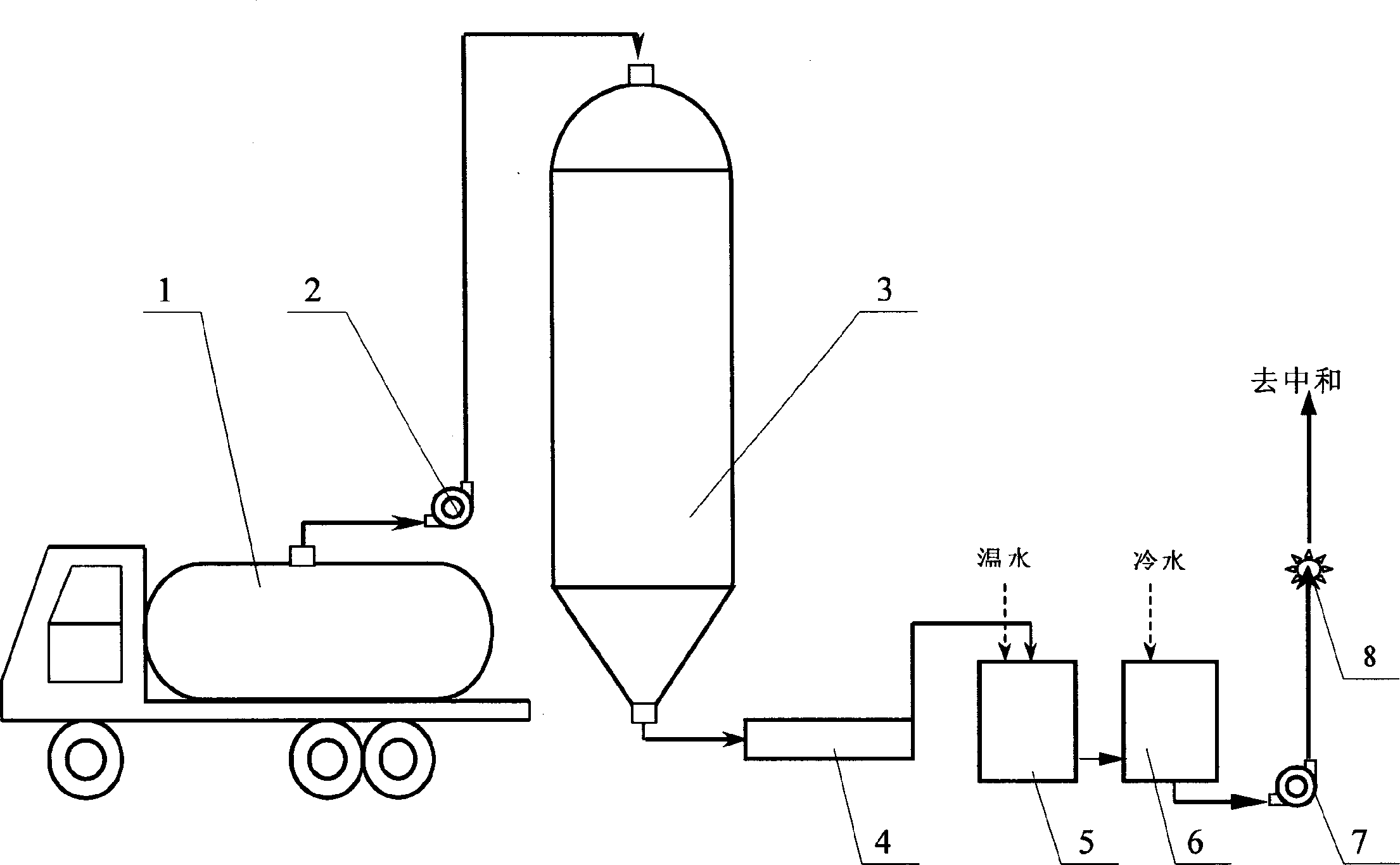

Method and device for continuous preparation of lithium hexafluorophosphate

ActiveCN107244681AEfficient productionEfficient evaporation crystallization method and advanced DBT type continuous productionCell electrodesSecondary cellsEvaporationCirculating pump

The invention relates to a device and method for continuous preparation of lithium hexafluorophosphate. The device comprises a continuous evaporation crystallizer, a condensation recoverer, a heater, an ex-situ circulation pump, a product crystal delivery pump and a separation apparatus. Specifically, the continuous evaporation crystallizer is internally equipped with a stirrer, and the lower part of the continuous evaporation crystallizer is equipped with an elutriating leg; the ex-situ circulation pump, the heater, and the continuous evaporation crystallizer are connected in order; the elutriating leg is connected to the product crystal delivery pump; the product crystal delivery pump is connected to the separation apparatus; and the condensation recoverer is connected to the upper part of the continuous evaporation crystallizer. The invention employs an effective evaporative crystallization method and the advanced DBT type continuous efficient evaporation crystallizer to make the crystalline particles of lithium hexafluorophosphate more uniform, and effectively lowers the product investment cost and energy consumption per ton, thus realizing continuous, efficient and large-scale production of lithium hexafluorophosphate.

Owner:东营石大胜华新能源有限公司

Method for preparing polygonin through tissue culture and inducement of hairy roots of giant knotweed

InactiveCN1759665AShorten the production cycleQuality improvementSugar derivativesSugar derivatives preparationPOLYGONUM CUSPIDATUMRhizobium rhizogenes

A process for preparing the polygonoside from the trichiform root of rhizome polygoni cuspidati by tissue culture and inducing includes such steps as tissue culture of wild rhizome polygoni cuspidati, activating culture of Agrobacterium rhizogene, inducing the trichiform root of rhizome polygoni cuspidati by the T-DNA fragment on rooting plasmide of Agrobacterium rhizogene, optimalizing culture of said trichiform root, and extracting polygonoside from said trichiform root.

Owner:HEBEI MEDICAL UNIVERSITY

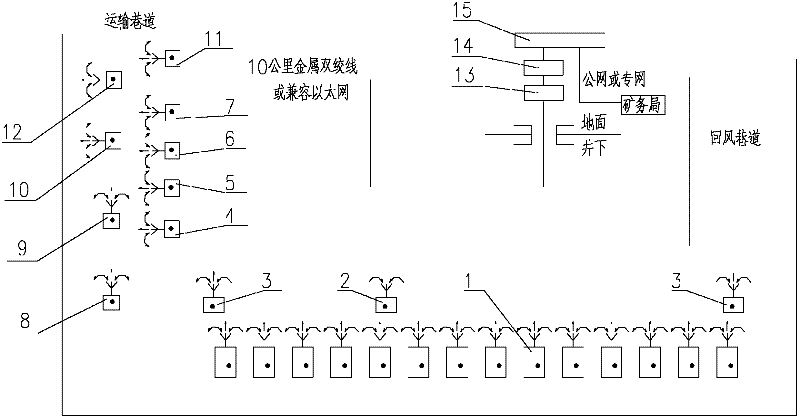

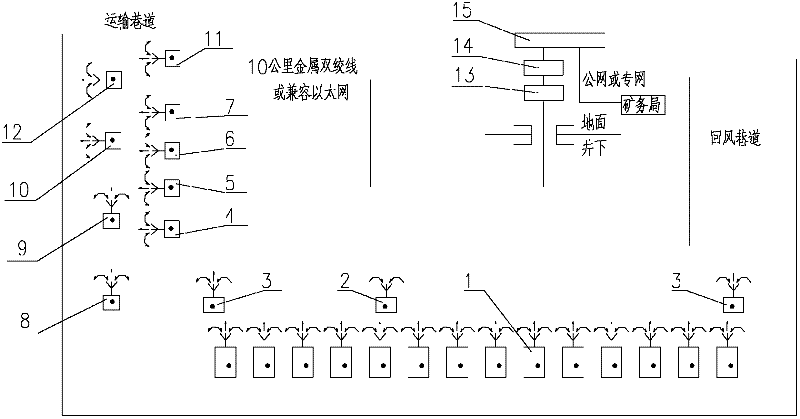

Coal face integrated intelligent production control system

InactiveCN102520686ABalanced productionTotal factory controlProgramme total factory controlCommunication interfaceEmulsion

The invention discloses a coal face integrated intelligent production control system mainly comprising a hydraulic support control unit, a coal cutter control unit, a scraper conveyor control unit, a transfer machine control unit, a crusher control unit, a belt conveyor control unit, a scale control unit, an infinite switch, an emulsion pumping station control unit, a three-machine coordinator, a coal bunker control unit, an underground center control station, a lightning arrester, a communication interface, a ground center control station and the like. And the system is characterized in that: the scale control unit transmits a signal to the underground center control station and the coal bunker control unit transmits a bunker position signal to the underground center control station; the underground center control station controls the three-machine coordinator to control a hydraulic support and operation speeds of a coal cutter, a scraper conveyor, a transfer machine, a crusher, and a belt conveyor so as to realize balanced production.

Owner:高九华

Flame-retardant straw artificial composite board and manufacturing method thereof

InactiveCN104772796AEnvironmental protection is goodGood flame retardantLaminationLamination apparatusZinc borateSulfate

The invention provides a flame-retardant straw artificial composite board. The flame-retardant straw artificial composite board comprises a naked panel and a decorative finish layer which is arranged on at least one surface of the naked panel, wherein the naked panel comprises the following raw materials in parts by weight: 7 to 8 parts of crop straw particles, 0.8 to 1 part of adhesion agent and 0.8 to 1 part of flame retardant, wherein the flame retardant comprises magnesium oxide, calcium sulfate, aluminum hydroxide, brucite and zinc borate. The flame-retardant straw artificial composite board has very high chemical, physical and mechanical properties of flame retardancy, water resistance, insect resistance and the like, and can be applied to various fields instead of wood-based panels. The invention also provides a manufacturing method for the flame-retardant straw artificial composite board. According to the manufacturing method, the raw materials are subjected to curing and shaping processing by adopting a normal temperature cold pressing molding technology; energy resources are greatly saved; the product performance can also be improved; the product has the functions of preventing water and preventing fire; meanwhile, the equipment cost can also be greatly reduced; the overall production process is green and pollution-free.

Owner:杨光伟

Method and equipment for manufacturing composite fiber containing continuous glass fiber

The invention relates to a method for manufacturing a composite fiber containing a continuous glass fiber. The composite fiber is formed by mutually mixing offline terylene and an online continuous glass fiber; the glass fiber is drawn on line, and the terylene is finished yarn; a plurality of bundles of terylene with different yarn feed angles are drawn to be converged into sheet shapes after being subjected to tension adjustment; and the converged terylene yarn bundles are separated and then compounded with the glass fiber processed with an impregnating compound. The invention has the advantages of simplified process equipment and improved production smoothness; and meanwhile, the introduction of chemical fiber yarn-feed tension adjustment ensures that better practicability and better effect on the baked yarn clew moulding effect are achieved.

Owner:JUSHI GRP CO

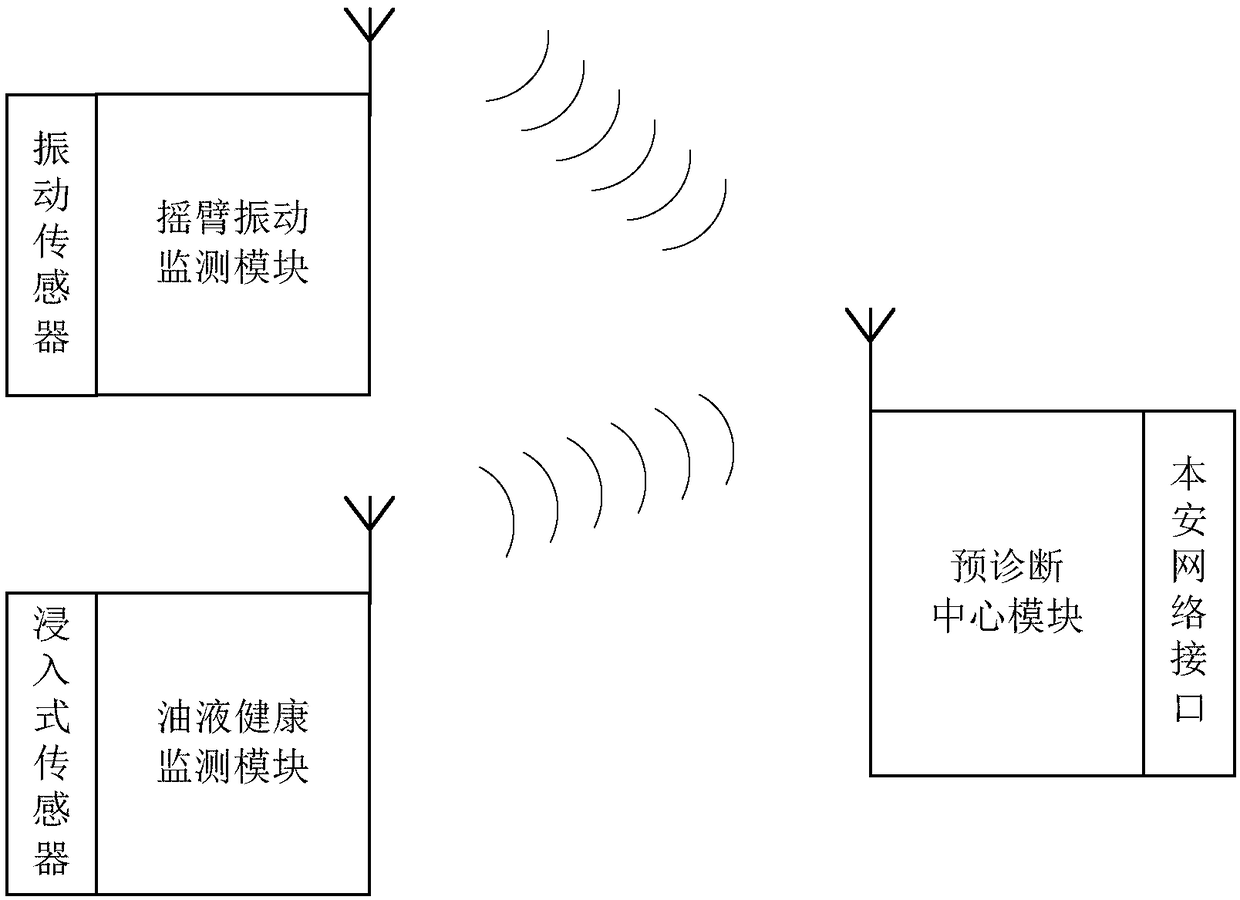

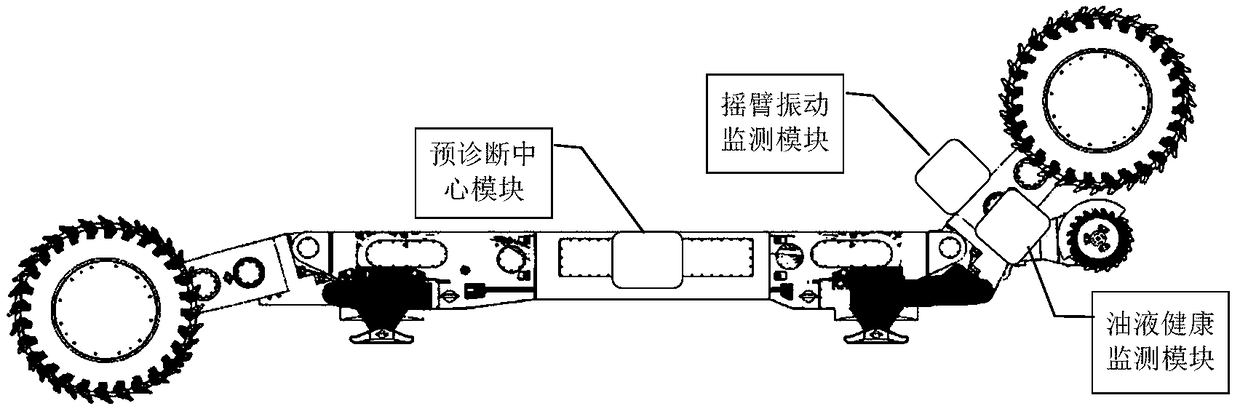

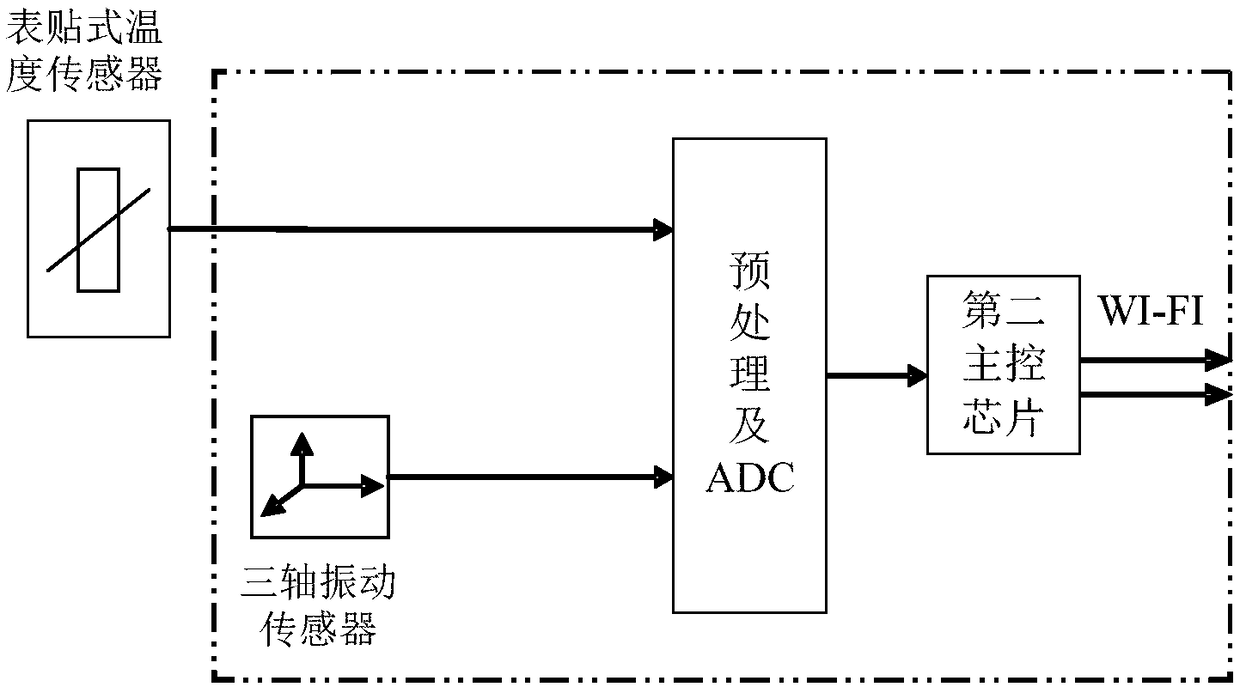

Drum coal mining machine rocker arm comprehensive state parameter online monitoring device

PendingCN109163871AShorten the timeReduce the occurrence of failureParticle size analysisThermometer applicationsCoal miningMonitoring data

The invention relates to a drum coal mining machine rocker arm comprehensive state parameter online monitoring device, comprising an intrinsic safety type rocker arm vibration monitoring module, an intrinsic safety type oil liquid health monitoring module and an intrinsic safety type pre-diagnosis center module. The two modules communicate with the pre-diagnosis center module in a wired communication mode and / or a wireless communication mode and transmit monitoring data information to the pre-diagnosis center module. The oil liquid health monitoring module comprises a first sensor signal processing circuit, an immersive electromagnetic abrasive particle sensor, an immersive dielectric sensor and an immersive temperature sensor. Sensing elements of the electromagnetic abrasive particle sensor, the immersive dielectric sensor and the immersive temperature sensor are directly immersed into lubricating oil liquid in a rocker arm drive system shell. Signal output ends of the electromagneticabrasive particle sensor, the immersive dielectric sensor and the immersive temperature sensor are connected with a sensing signal input end of the first sensor signal processing circuit. According to the drum coal mining machine rocker arm comprehensive state parameter online monitoring device, health condition of a rocker arm can be automatically detected and a fault can be positioned, so reliability of the rocker arm and an operating ratio of a coal mining machine are improved.

Owner:SHANGHAI BRANCH TIANDI SCI&TECH CO LTD +1

Novel firecracker sealing agent

The invention discloses a novel firecracker sealing agent, which is prepared by uniformly stirring and mixing the following three raw materials in percentage by weight: 20 to 40 percent of portland cement, 60 to 80 percent of powdery stone and hardening agent, wherein the addition of the hardening agent is 3 to 5 percent of the weight of the portland cement. The sealing agent not only reduces preparation cost, but also improves curing strength and greatly shortens curing time of the sealing agent because the portland cement and the powdery stone with wide sources and low price are used as main raw materials for preparing the firecracker sealing agent and a small amount of hardening agent is added into the raw materials. The curing time is between 6 and 12 hours and is shortened by 4 folds than that of the conventional firecracker sealing agent to make all the working procedures for manufacturing firecrackers achieve level production. Thus, the production efficiency of the firecrackers is improved, the production cost of the firecrackers is reduced and the processing and production of mass firecrackers are realized.

Owner:吴家福

Efficient lime clarifier for sugar solution and its prepn and use

InactiveCN1810993AImprove working environmentProtect environmentSugar juice purificationSucroseGranularity

The present invention is efficient lime clarifier for sugar solution and it preparation and use, and relates to sugar production technology. The lime clarifier as powdered lime compound consists of CaO not less than 85 wt%, MgO not more than 4.5 wt%, SiO2 not more than 2.0 wt%, Fe2O3 not more than 0.3 wt%, Al2O3 not more than 0.5 wt%, CaSO4 not more than 1.0 wt% and cane sugar and NaCl not more than 0.001 wt%. It has the physical and chemical indexes of activity 250-300 mL and granularity not greater than 125 microns. The lime clarifier is prepared through the steps of preparing material, calcining, crushing and sieving. It has the advantages of high activity, high effective CaO content, fast deposition reaction speed, complete lime slaking, high lime utilization rate, high sugar juice clarifying effect and simple preparation process.

Owner:黄永春 +3

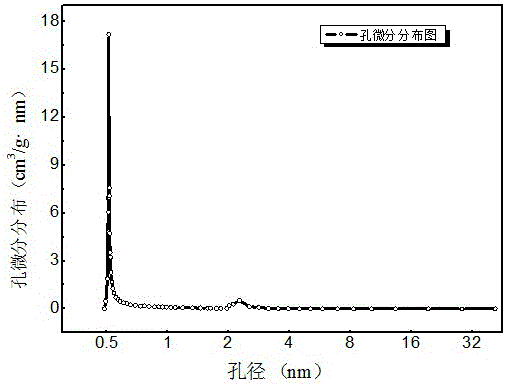

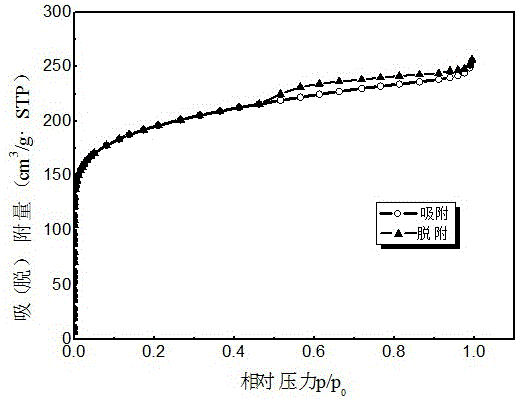

Uniform ultra-microporous activated carbon for gas separation and preparation method of uniform ultra-microporous activated carbon

InactiveCN106517189AReduce dosageReduce corrosionHydrogen separation by selective and reversible uptakeCarbon compoundsActivation methodMass ratio

The invention relates to uniform ultra-microporous activated carbon for gas separation and a preparation method of the uniform ultra-microporous activated carbon. According to the technical scheme of the preparation method, mixing semi-coke with KOH in a mass ratio being 1: (0.01-0.2), adding water and an activating aid to impregnate the mixture for 1-36 h; increasing the temperature to 800-950 DEG C in a programmed manner under N2 protection, controlling thermal decomposition, and introducing water for activation of part of steam for 0.5h-1.5h; finally, washing the mixture with acid and water until the mixture is neutral to obtain the uniform ultra-microporous activated carbon. The pore size is distributed centrally between 0.45 and 0.55 nm, the pores belong to ultra-micropores and have microporosity of 70% or more, and the adsorption capacity of hydrogen is 77cm<3> / g or higher. The semi-coke is taken as a raw material, low in price and low in energy consumption and needs not to be carbonized; an activation method integrates KOH impregnation pretreatment and activation of part of steam, little KOH is consumed, and the activation method has the characteristics of being low in cost and pollution, helpful for reducing corrosion of equipment and the like. The activated carbon prepared with the method has the characteristics of uniform pore size distribution, extremely rich ultra-microporous structure and the like, and can be used in gas separation fields such as pressure swing adsorption hydrogen making or hydrogen storage and the like.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com