Flame-retardant straw artificial composite board and manufacturing method thereof

A manufacturing method and technology of composite panels, which are applied in the directions of manufacturing tools, chemical instruments and methods, flat products, etc., can solve the problems of flammable smoke, low height, poor outdoor weather resistance, etc., and achieve the effect of good environmental protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

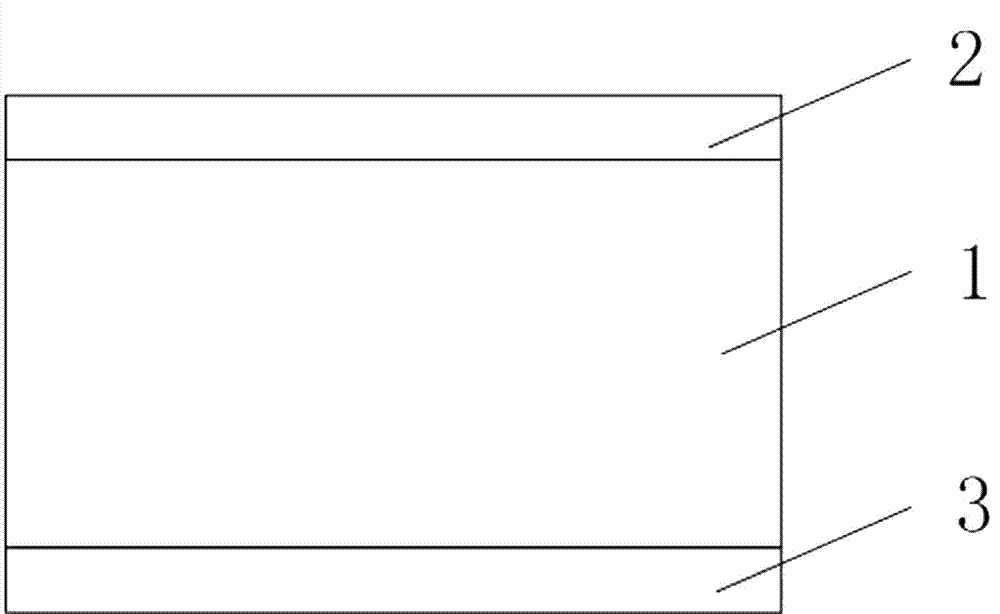

[0039] refer to figure 1 , Embodiment 1 of the present invention provides a fire-retardant straw man-made composite board, its size area is about 1000mm×2000mm, its thickness is about 8 mm, the fire-retardant straw man-made composite board is a 3-layer composite structure, which includes about 6 mm Thick bare panel 1 and two veneer veneer layers 2,3. The bare panel 1 is sandwiched between the two veneer layers 2, 3 as a base panel. The two facing layers 2, 3 are glued on the bare panel 1 by phenolic resin.

Embodiment 2

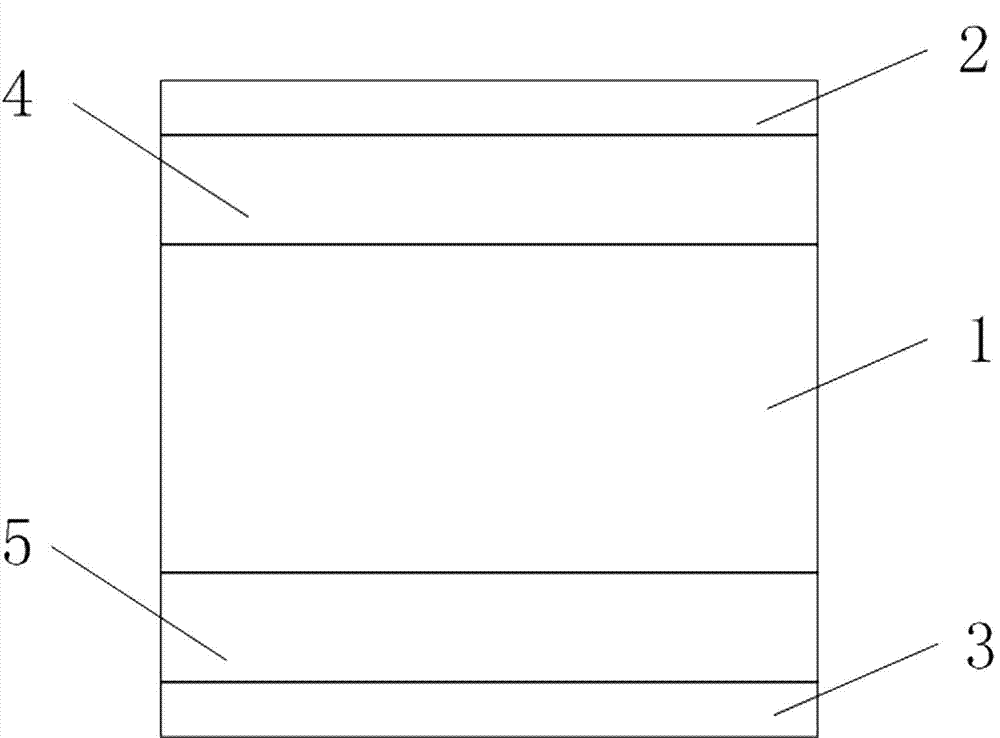

[0041] see figure 2 , Embodiment 2 of the present invention provides a fire-retardant straw man-made composite board, its size area is about 1220mm×2440mm, its thickness is about 12 mm, the fire-retardant straw man-made composite board is a 5-layer composite structure, which includes about 6 mm Thick bare panel 1 and two layers of middle panels 4,5 and two layers of veneer veneer 2,3 with a total thickness of about 6 mm. The bare panel 1 acts as a base panel and is sandwiched between two layers of the middle panels 4 and 5 . The two facing layers 2 and 3 are the two outer surfaces of the flame-retardant straw man-made composite board, and are attached to the two middle boards 4 and 5 respectively. Wherein, the bare panel is mainly composed of 9 Kg of straw particles with a particle size of about 2 to 30 mm, 1.15 Kg of binder and 1 Kg of flame retardant, wherein the binder is phenolic resin glue, and the flame retardant The agent includes magnesium oxide 0.25kg; calcium sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com