Patents

Literature

43results about How to "Good nail grip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pure china-fir three-layer real-wood integrated material and making method

The invention provides three-layer solid wood materials of pure Chinese fir and its preparation method. It is characterized in that: after planed and thickness defining, complete tenon process and finger joint of the Chinese fir square stocks. Then, dissect them into slice strips along their length direction and put the slice strips with the same lengths together to form plates. Based on the wood texture, press them to 18mm three-layer solid wood plates through vertically crossed by sizing layer-by-layer. The products have compact structure and light texture, eliminate the wood internal stress, have characteristics of large intensity, good flexibility, corrosion resistance and are moisture proof and uneasy to distort and crack.

Owner:林文信

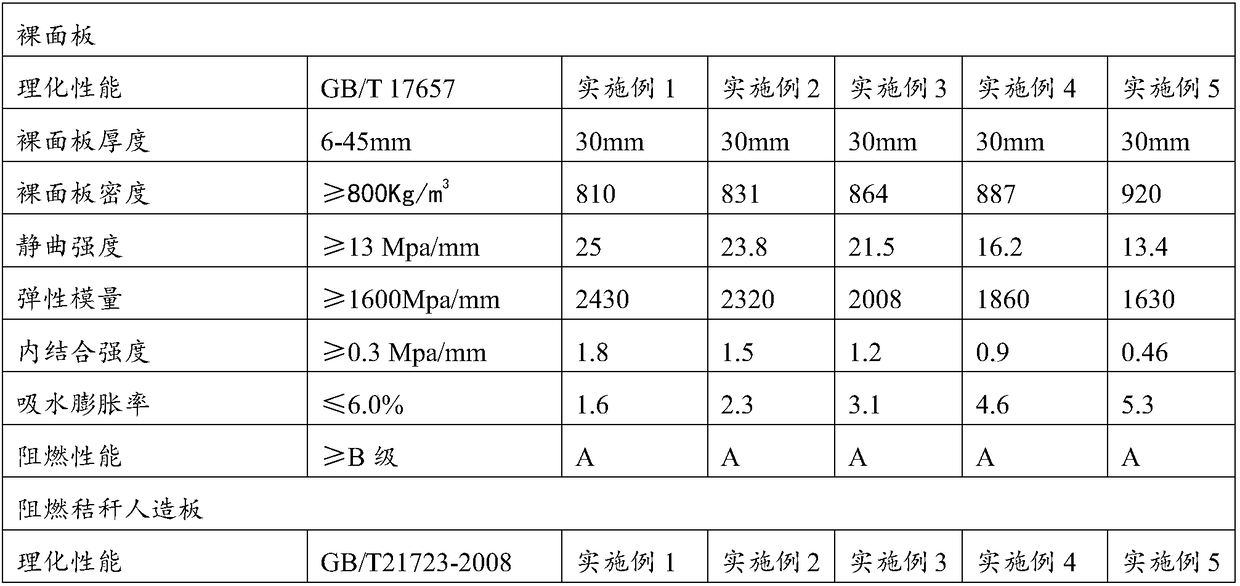

Flame retardant composite board and manufacture method thereof

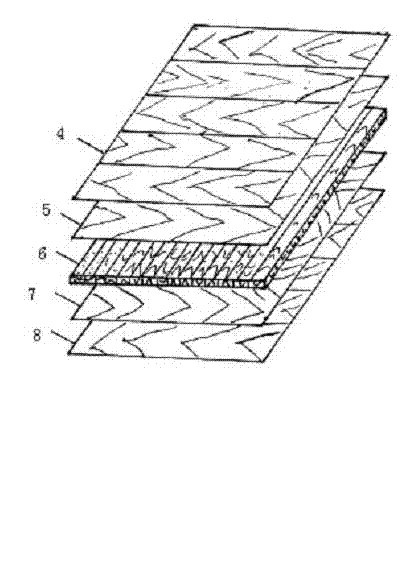

InactiveCN104552488AHigh mechanical strengthGood nail gripWood veneer joiningDomestic articlesBruciteComposite plate

The invention provides a flame retardant composite board. The flame retardant composite board comprises a homogeneous naked panel and a facing layer arranged on at least one surface of the homogeneous naked panel, wherein the homogeneous naked panel is prepared from raw materials of, based on weight parts, 65-98.5 parts of plant straw particles, 3-10 parts of binder and 3-10 parts of fire retardant, wherein the fire retardant is prepared from raw materials of magnesium oxide, calcium sulfate, aluminum hydroxide, brucite, zinc molybdate and zinc borate. The flame retardant composite board has good chemical properties of fire retarding, water prevention, insect prevention and the like, and good physical and mechanical properties, can replace wood artificial boards, and is used in various fields. The invention further provides a manufacture method of the flame retardant composite board. The manufacture method of the flame retardant composite board mainly adopts a normal temperature cold press molding technology to solidify and shape the raw materials of the naked panel, not only greatly saves energy, but also improves product performance, enables the flame retardant composite board to have water prevention and fire prevention functions, and simultaneously can substantially reduce equipment cost, achieves a whole green production process, and does not cause pollution during the whole production process.

Owner:信阳美丽真好秸秆新材科技有限公司

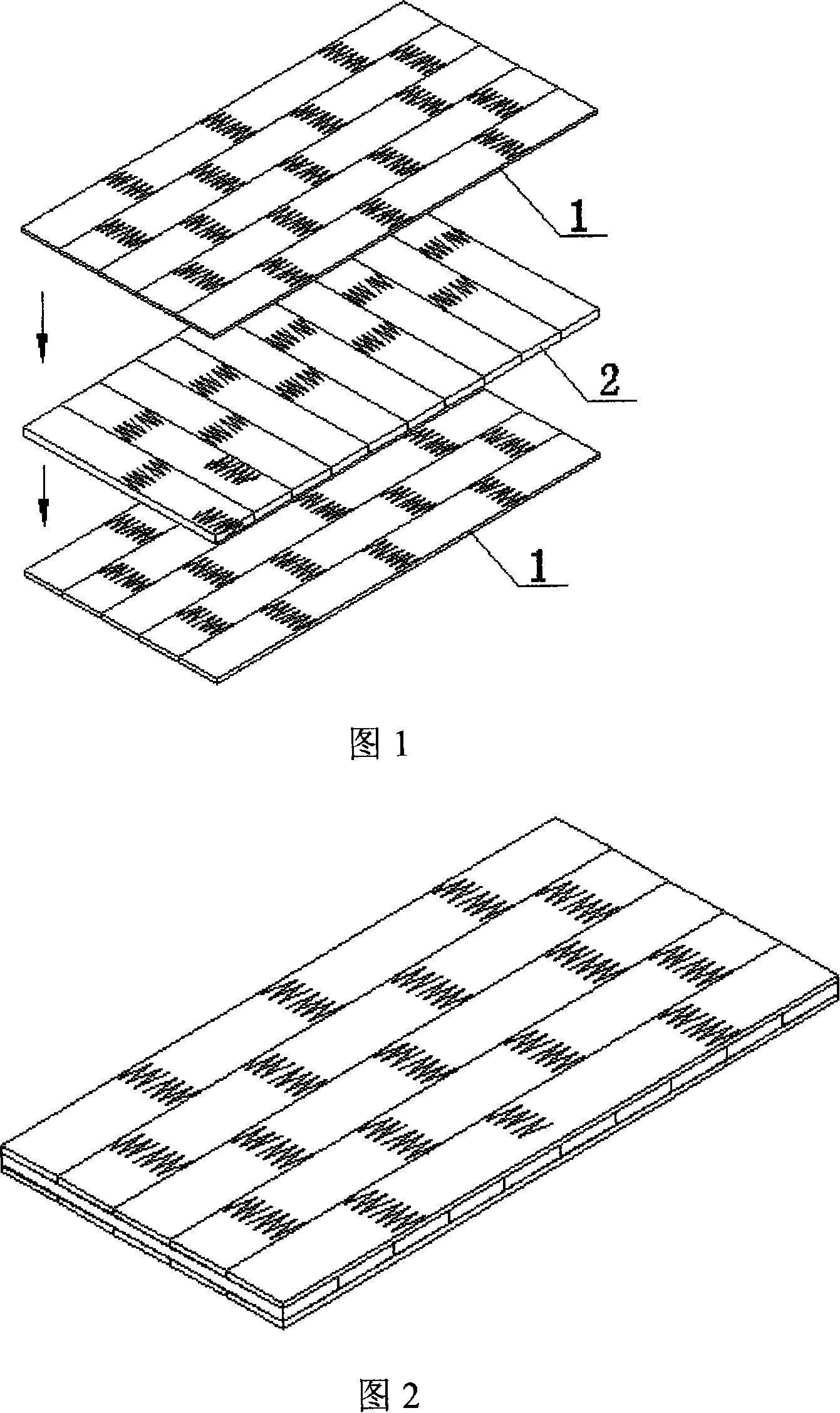

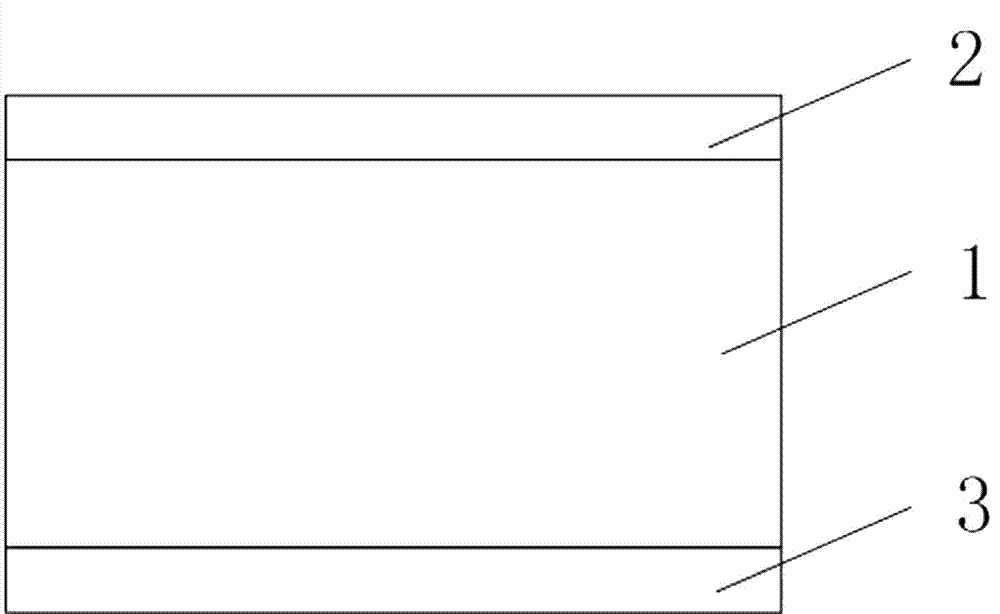

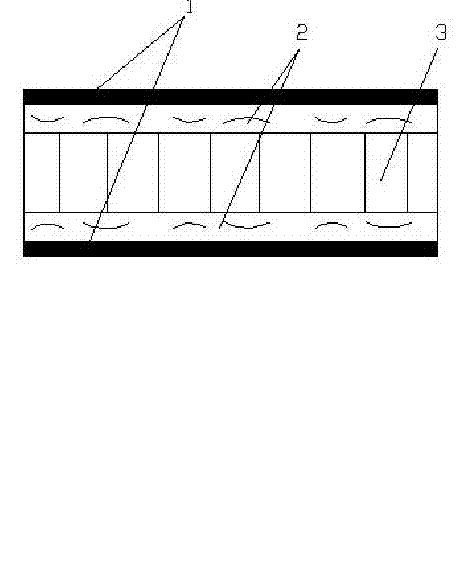

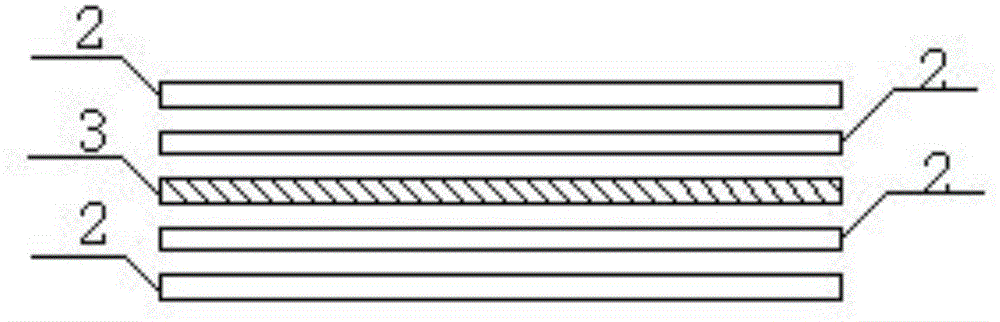

Novel laminated wood and manufacturing method thereof

ActiveCN101863058AKeep textureLight textureOther plywood/veneer working apparatusPlywood pressesWood veneerPulp and paper industry

The invention relates to a novel laminated wood. The novel laminated wood comprises a fir core veneer layer positioned at a central position, two cotton wood veneer layers which are respectively adhered on both upper and lower surfaces of the fir core veneer layer and two laminated wood layers which are adhered on the other surface of the two cotton wood veneer layers respectively, wherein the directions of wood grains of every two adjacent two veneer layers are vertical to each other. The invention also relates to a method for preparing the laminated wood. The method comprises the steps of producing the laminated wood layers, producing the cotton wood veneer layers, producing the fir core veneer layer, sizing, laminating, molding and the like. The novel laminated wood has the advantages of good stability, low cost and environment protection and can be widely used for preparing indoor decoration, such as furnitures, floors, door panels, ceilings and the like.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

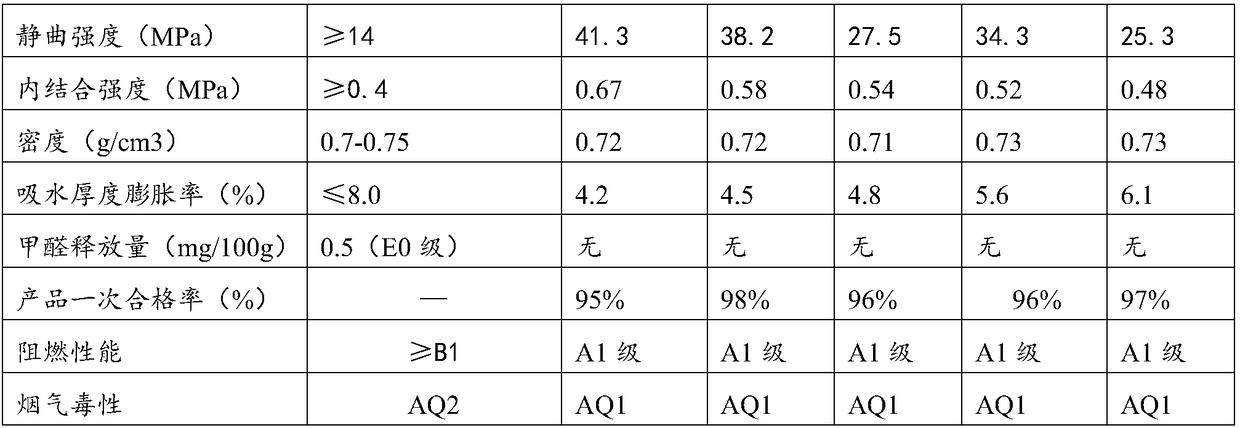

Flame-retardant straw artificial composite board and manufacturing method thereof

InactiveCN104772796AEnvironmental protection is goodGood flame retardantLaminationLamination apparatusZinc borateSulfate

The invention provides a flame-retardant straw artificial composite board. The flame-retardant straw artificial composite board comprises a naked panel and a decorative finish layer which is arranged on at least one surface of the naked panel, wherein the naked panel comprises the following raw materials in parts by weight: 7 to 8 parts of crop straw particles, 0.8 to 1 part of adhesion agent and 0.8 to 1 part of flame retardant, wherein the flame retardant comprises magnesium oxide, calcium sulfate, aluminum hydroxide, brucite and zinc borate. The flame-retardant straw artificial composite board has very high chemical, physical and mechanical properties of flame retardancy, water resistance, insect resistance and the like, and can be applied to various fields instead of wood-based panels. The invention also provides a manufacturing method for the flame-retardant straw artificial composite board. According to the manufacturing method, the raw materials are subjected to curing and shaping processing by adopting a normal temperature cold pressing molding technology; energy resources are greatly saved; the product performance can also be improved; the product has the functions of preventing water and preventing fire; meanwhile, the equipment cost can also be greatly reduced; the overall production process is green and pollution-free.

Owner:杨光伟

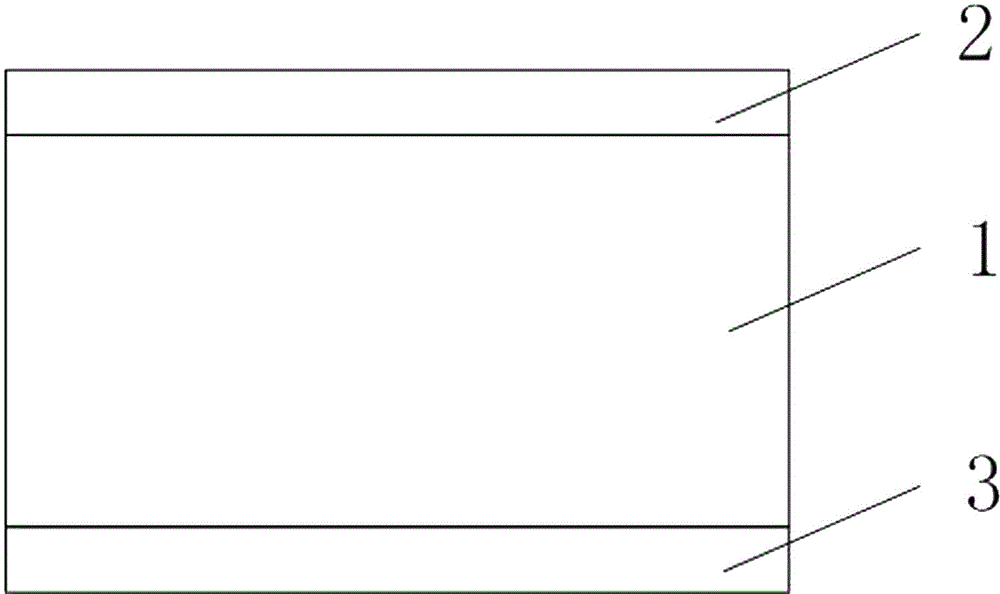

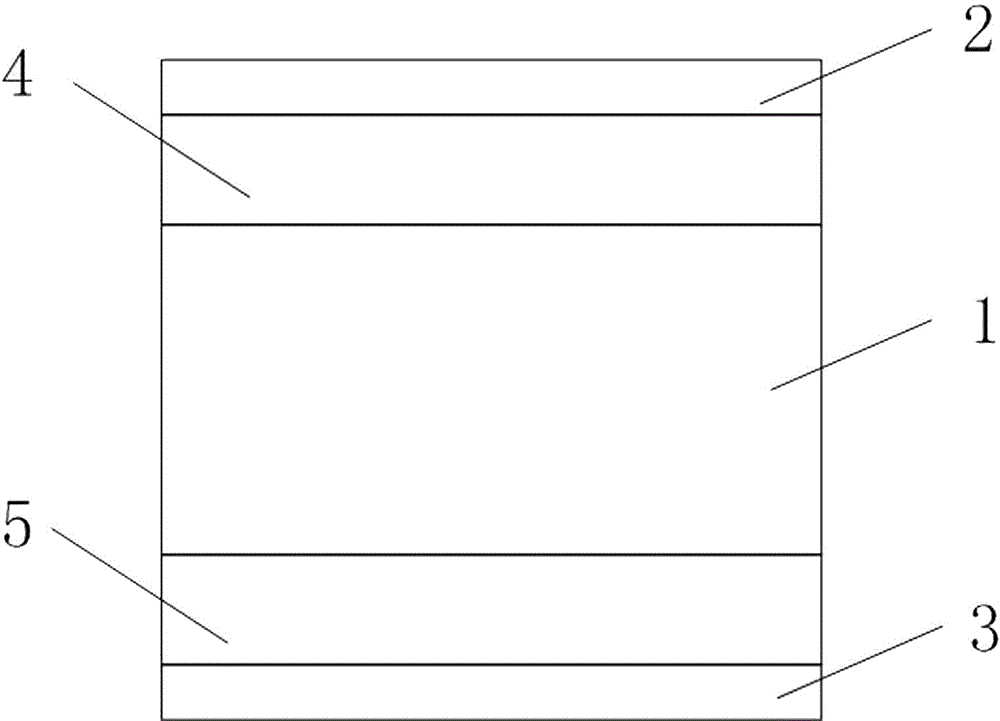

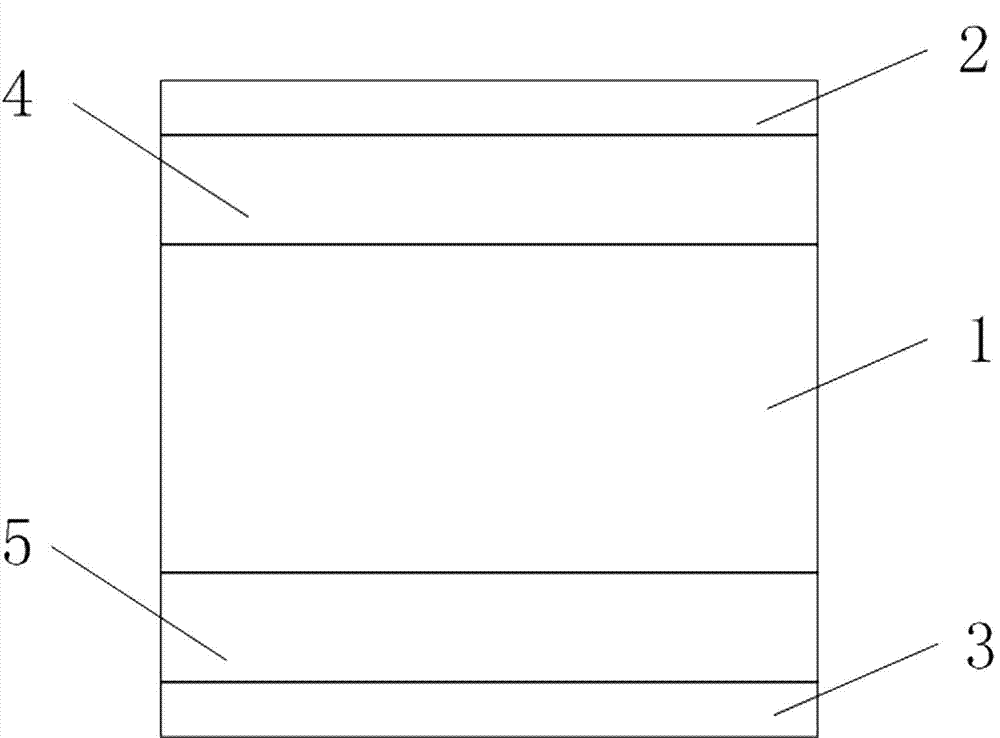

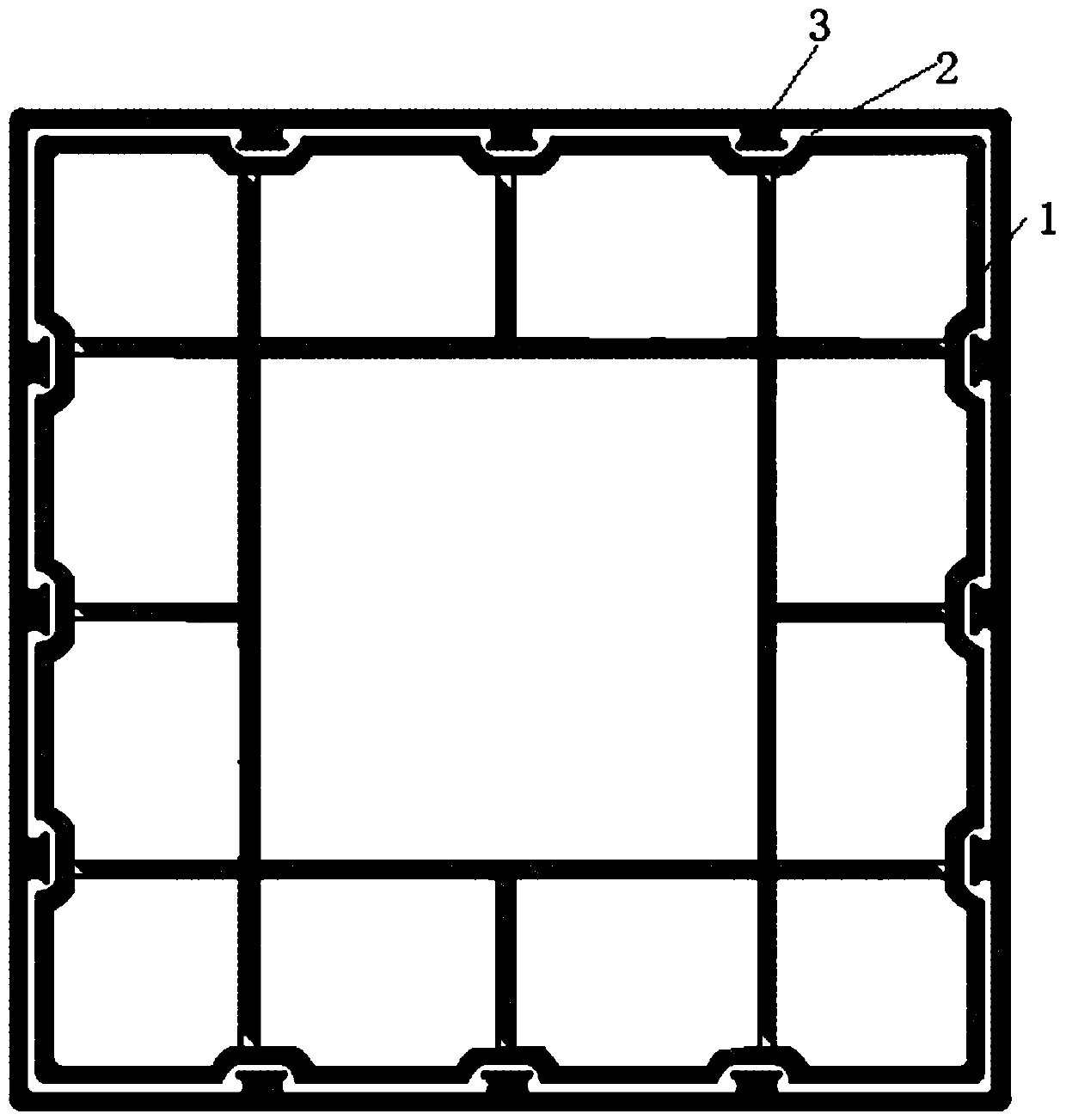

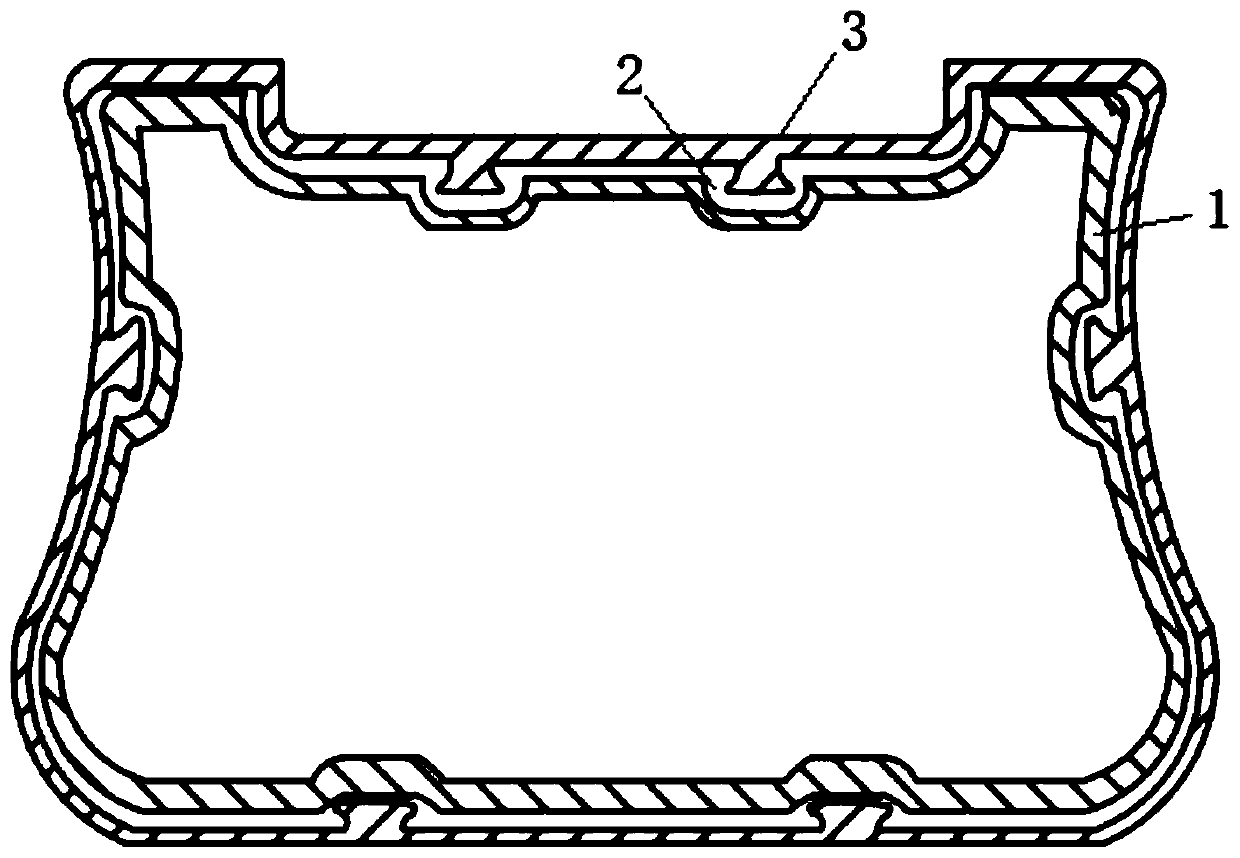

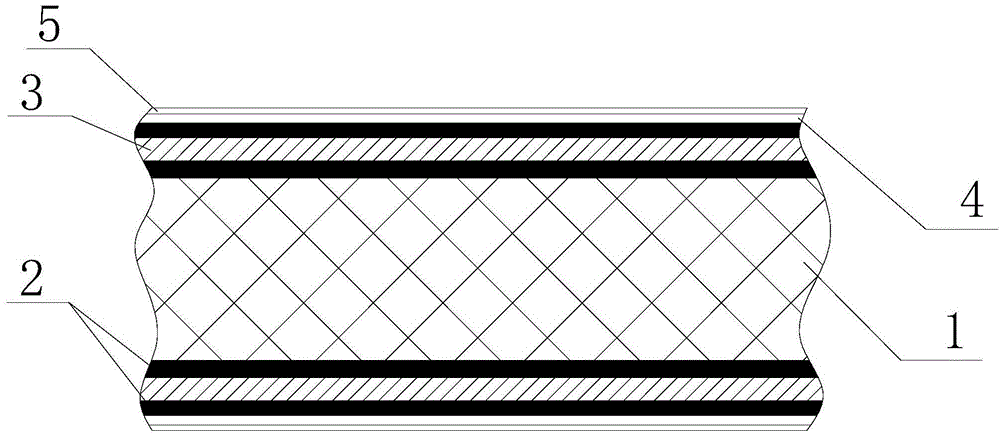

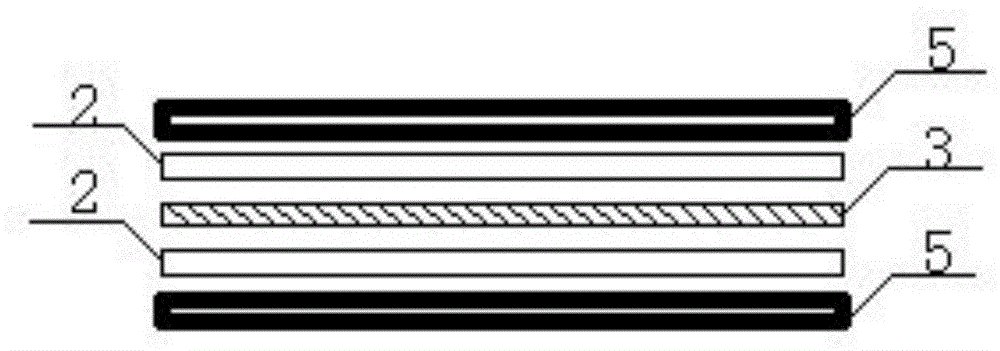

Multifunction formboard

InactiveCN101070729AReasonable material structureImprove performanceConstruction materialSolid waste managementWear resistantFlexural strength

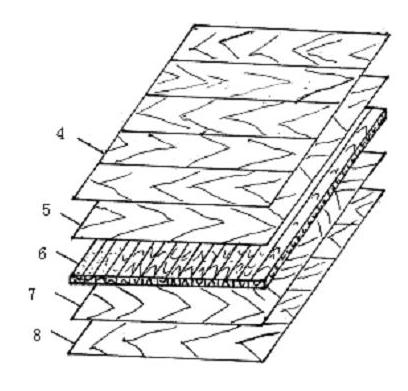

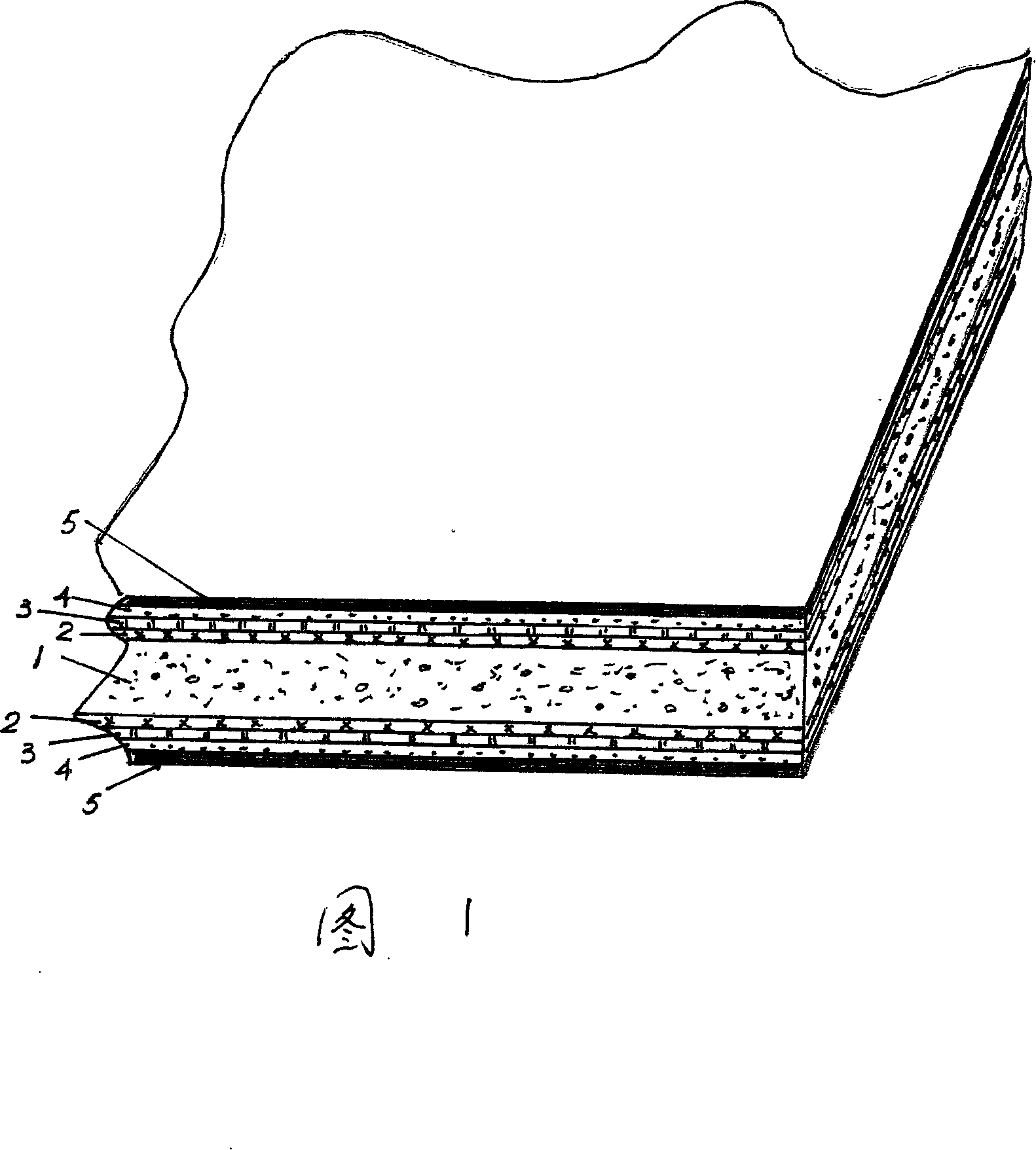

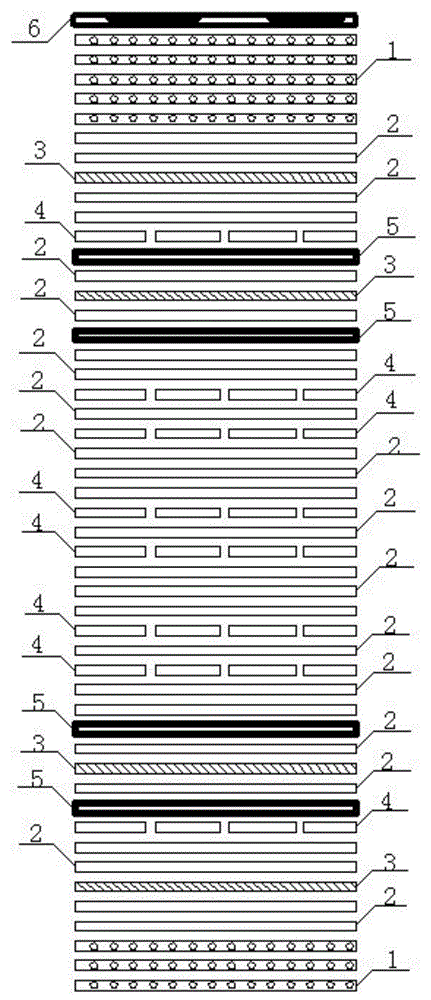

The invention is layered symmetric structure, the center of which is a center layer (1), forming layer (2), strengthening layer (3), waterproof layer (4) and wear-resistant layer (5) are respectively distributed symmetric above and under the center of the structure (1) , the modified magnesite and composite materials have conspicuous advantages: (1) good mechanical properties, and high compressive resistance, high flexural strength, not easy to deform, which is conducive to enhancing life; (2) waterproof performance is particularly conspicuous. Blisters are not afraid of flooding, improving the utilization rate of repeat; (3) It increases the ability of wear-resisting, the surface can be maintained for a long time in the formation and thus concrete structures on the surface cleanliness; (4) It is easy to grip nails, small density, light weight, easy to construction; (5) It is formaldehyde-free, non-radioactive, environmental safety; (6) and it has a wide range of uses, in addition to concrete formwork for the construction, production of building blocks can be used, as other pad, parapet panels, decorative plates, etc.

Owner:蔡祖树

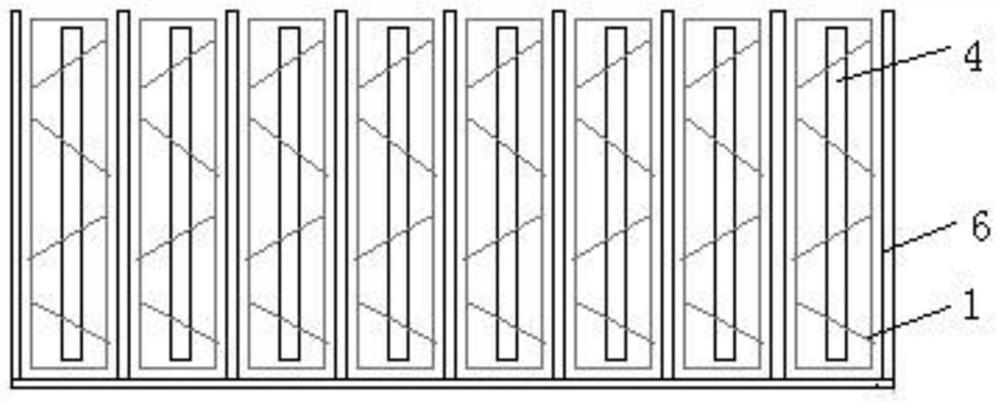

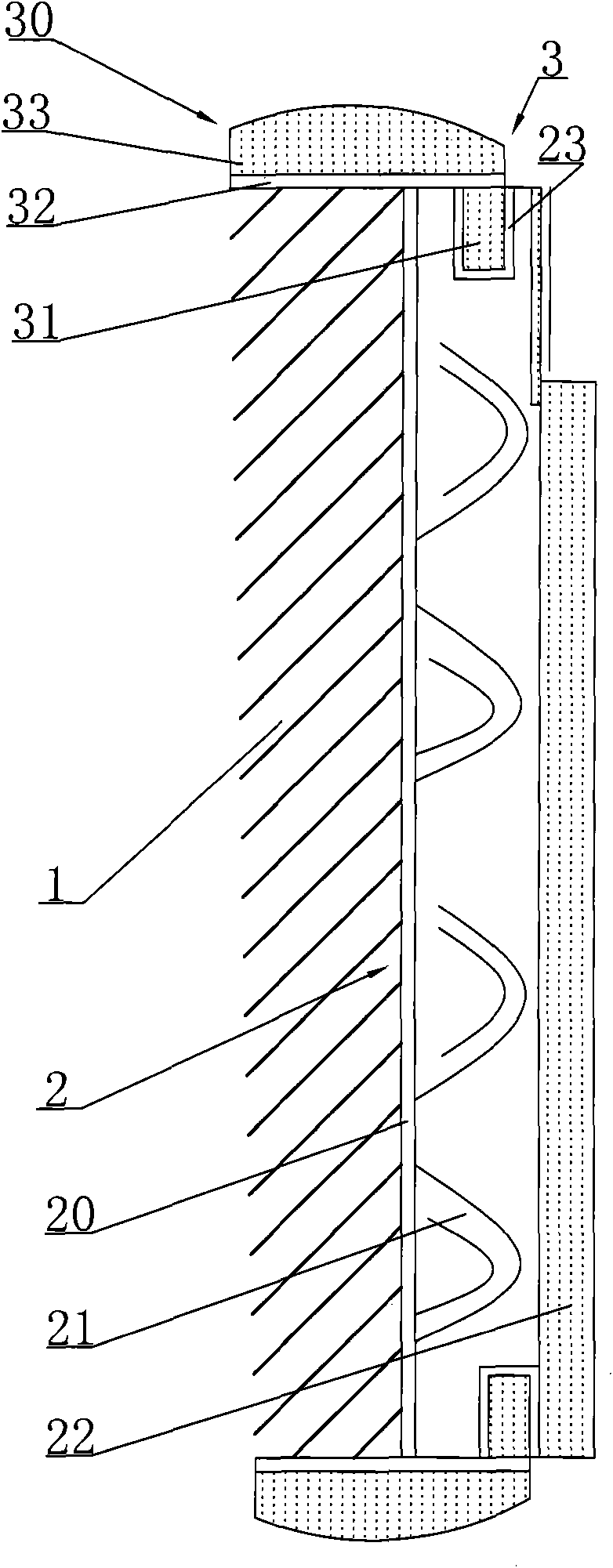

Plug-in type low-carbon heat preservation energy-saving board

The invention relates to a plug-in type low-carbon heat preservation energy-saving board, which is characterized in that the board is an integral board formed by sequentially connecting a decorative finishing layer, a finishing layer, a middle layer glass fiber mesh, a low-carbon board, a stainless steel welded mesh, a bottom layer glass fiber mesh, a soundness glue layer and an SPS extrusion molding heat preservation board. The invention has the advantages that the board not only is an excellent substitute for coatings, ceramic tiles, stones, timbers and metal boards, but also has a heat preservation function which simultaneously simplifies the complicated construction steps specified in three-step energy-saving requirements of national regulation, and ensures that the heat preservation and energy saving as well as decorative effects are achieved synchronously; and the installation process is simple and fast, special matched adjustable dry hanging connecting pieces are provided, and a hollow plug-in pipe is embedded in a plane material decorative layer in advance, which enables the installation process to be firm and reliable.

Owner:易科美德(天津)环保建材有限公司

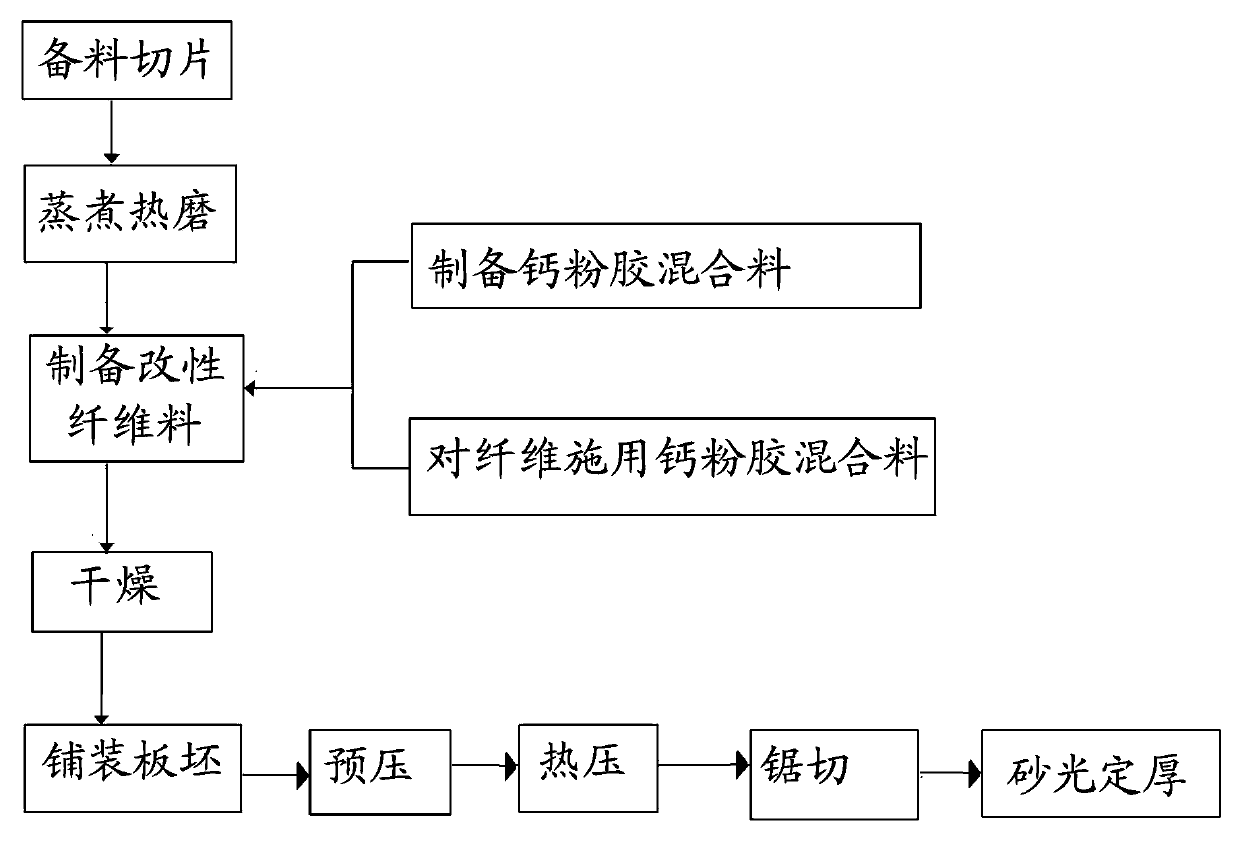

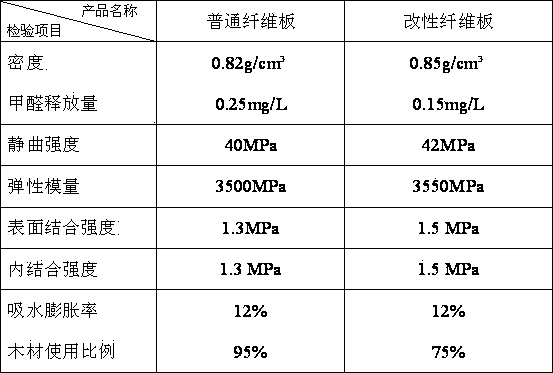

Modified fiber board production process

The invention relates to a modified fiber board production process. The modified fiber board production process includes steps of chipping, digesting, hot grinding, preparation of modified fibers, drying, preparation of blank materials, cold pressing, hot pressing, saw cutting, sanding, thickness determination and the like. In the step of preparation of modified fibers, calcium powder is added into fibers and used for replacing part of wood fibers, the calcium powder is mixed with glue prior to being mixed with the fibers during filling so as to enable clearances of the fibers to be filled by mixture of the calcium powder and the glue, and accordingly physical and chemical performances of fiber boards are improved, and improvement of board density, reduction of wood consumption and improvement of elasticity modulus indexes and static bending strength of the boards are achieved while reduction of fiber board production cost and effective saving of wood resources are realized. Wood consumption is reduced by about 20% as compared with that of common fiber boards, and the modified fiber boards produced according to the process have the advantages of high strength, high nail holding ability, excellent bending resistance and high stability and flame retardance.

Owner:湖北益嘉林业发展有限公司

Flame-retardant straw-based panel and manufacturing method thereof

InactiveCN108247805APromote environmental protectionImprove flame retardant performanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEngineering

The invention discloses a flame-retardant straw-based panel. The flame-retardant straw-based panel comprises a bare panel, and a facing layer which is arranged on at least one surface of the bare panel, wherein the bare panel comprises the following components in parts by weight: 5-80 parts of straw particles, 2-25 parts of adhering agent, and 5-65 parts of flame retardant. The flame-retardant straw-based panel has outstanding comprehensive performances such as high efficiency performance, flame retarding performance, smokeless performance and nontoxic performance. The invention also providesa manufacturing method of the flame-retardant straw-based panel. The method is characterized in that the bare panel is manufactured by a hot compression and fixation technology; the step of forming isavoided, so that the production efficiency is greatly improved, and the production cost is decreased.

Owner:吕晓峰

Method for producing high-strength and high-pressure decorative plate

ActiveCN103373043ANot easy to fall offNot easy to mildewLaminationLamination apparatusPulp and paper industryHigh pressure

The invention discloses a production method of a high-strength high-pressure decorating plate. Firstly various needed strengthening thermosetting resins are prepared, kraft paper is socked in the strengthening thermosetting resins for gluing, and a soaking base plate blank is obtained after soaking and drying; monochrome paper or printing paper is soaked in the prepared strengthening thermosetting resins for gluing, and pre-socking decorative paper is obtained after soaking and drying; or metal drawbench aluminum foil with the pre-gluing back serves as the decorative paper; the wood pulp kraft paper is soaked in the prepared strengthening thermosetting resins for gluing, and pre-soaking buffer paper is obtained after soaking and drying; the soaking base plate blank, the pre-soaking decorative paper and the pre-soaking buffer paper are cut, paved according to requirements of prepared decorative plates, filled in a hot press for pressing, cooling, releasing, disassembling and plate discharging after paving, and treated to obtain the high-strength high-pressure decorating plate product. By means of the technical scheme, the production method can produce the high-strength high-pressure decorating plate which is fire-resistant, water-tolerant, moisture-resistant, impact-resistant, pollution-resistant, attractive and durable.

Owner:HENAN YONGWEI SECURITY

Straw composite plate and preparation method thereof

InactiveCN109777137AWaterproofWaterproof and moisture-proofFlat articlesDomestic articlesCross-linkAdhesive

The invention relates to a straw composite plate and a preparation method thereof. The straw composite plate is prepared from the following raw materials in percentage by weight: 55 to 60 percent of crop straw, 10 to 15 percent of weed straw, 7 to 10 percent of mushroom bran, 7 to 9 percent of landscaping discarded branches, 6 to 8 percent of wood dust, 0.1 percent of ammonium dihydrogen phosphate, 0.5 to 1.5 percent of polyvinyl acetate, 1 percent of polyvinyl alcohol and 0.4 percent of magnesium chloride. The preparation method comprises the following processes: crushing the raw materials; stirring the raw materials; preheating a mould; paving the raw materials; spraying adhesive; performing hot pressing; demoulding; processing a plate blank; pressing a film; attaching a film or sprayingpaint. According to the straw composite plate and the preparation method thereof, the mushroom bran, the branches and the like are added into the straw for preparing the straw composite plate for thefirst. Meanwhile, a flame retardant and a moisture proof agent are added into auxiliary materials. The polyvinyl alcohol is added into the raw materials, so that the composite plate has the advantageof water resistance and moisture resistance; the flame retardant is added, so that molecular oxygen in the composite plate is locked, so that the purpose of retarding flame is achieved; a cross-linking agent is added, so that the materials are closer; the composite plate does not deform easily, and the nail holding force is good.

Owner:SHENYANG UNIV

Fabrication method for veneer based external wall panels

ActiveCN105965617ASimplified coating stepsSimple production processWood compressionWood treatment detailsWood veneerEngineering

The invention provides a fabrication method for veneer based external wall panels. The fabrication method for the veneer based external wall panels is characterized by comprising the steps that wood veneers with the moisture content of 1-15% and the thickness of 1-3.2 mm serve as raw materials and are soaked in or coated with mixed resin modified liquid; the obtained wood veneers are dried until the moisture content is 5-15%; then three to nine layers of the dried wood veneers are assembled to plate blanks; the plate blanks are put into a relief mould for mould pressing, wherein the mould pressing hot-press temperature is 130-150 DEG C, the hot-press pressure is 1-3 MPa, and the pressing time is 1.0-1.5 minutes for every 1 mm of thickness of the plate blanks; and the pressed plate blanks are sawed into strips of a certain specification, the front faces and the side edges of the strips are coated with weather-proof waterproof paint, and then the strips are fabricated to be the outdoor purpose external wall panels with an excellent decoration effect and anticorrosion and weather-proof functions.

Owner:NINGBO ZHONGJIA LOW CARBON NEW TECH RES INST

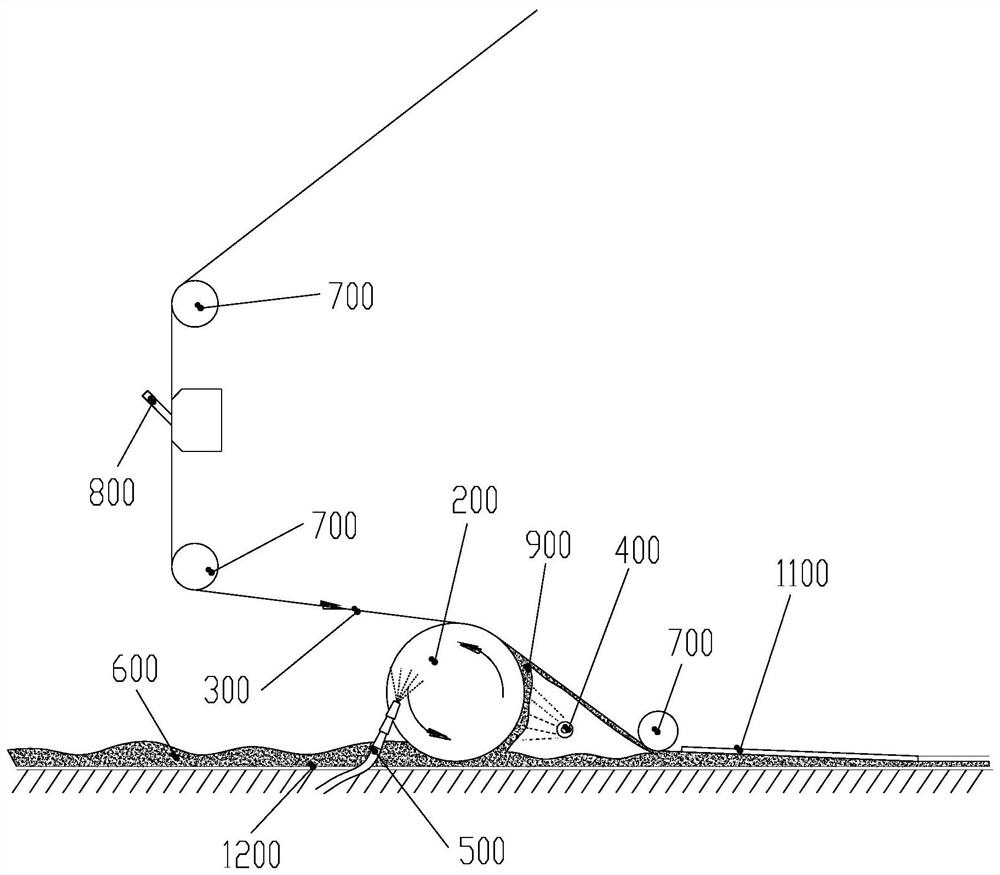

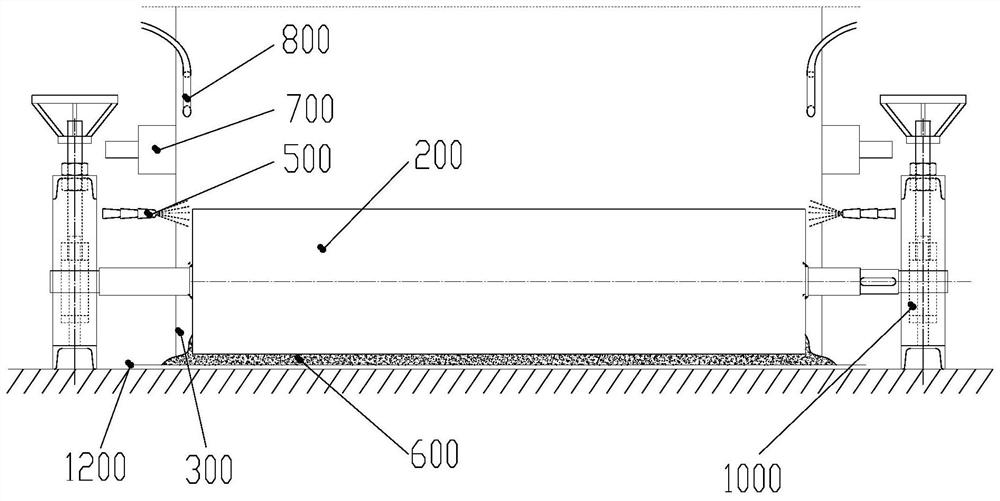

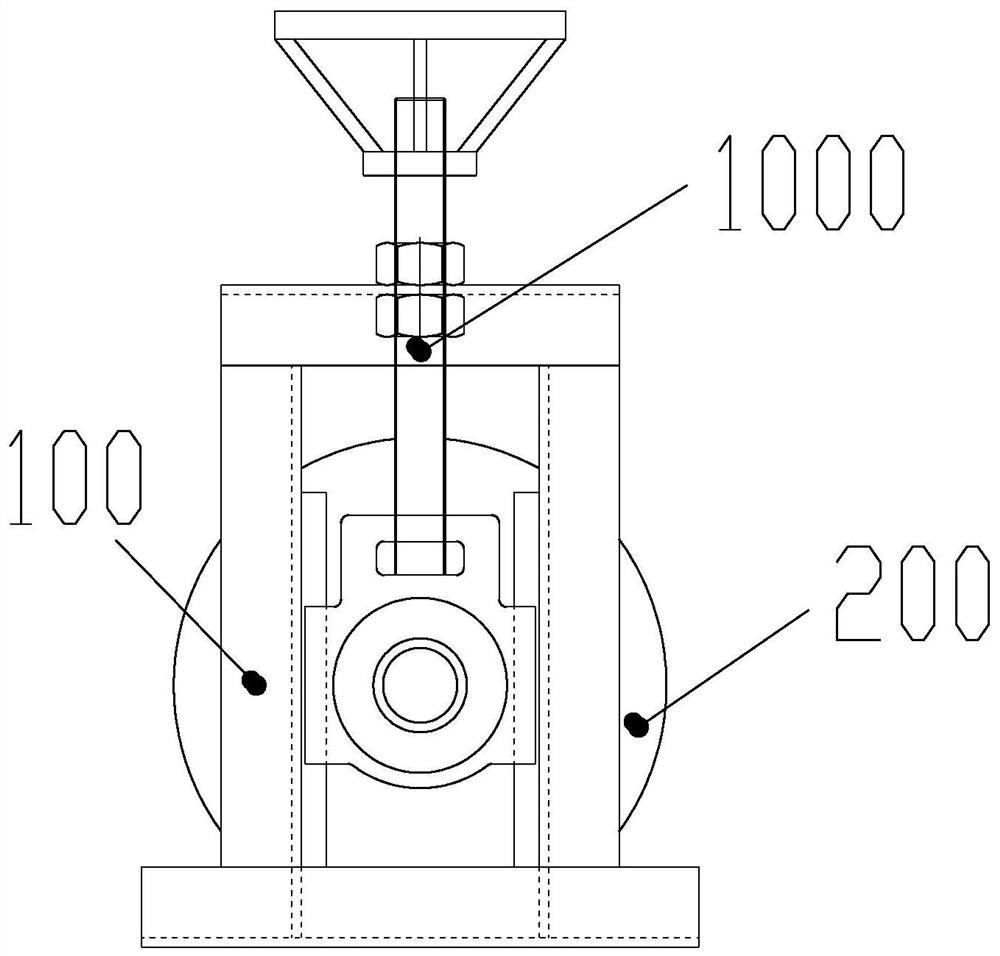

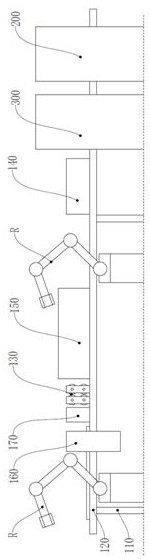

Paper feeding and surface hardening equipment and paper feeding and surface hardening method for gypsum board and gypsum board production line

ActiveCN112207968AGood nail gripImprove qualityAuxillary shaping apparatusSurface layering apparatusMetallurgyEngineering

The invention discloses paper feeding and surface hardening equipment and a paper feeding and surface hardening method for a gypsum board and a gypsum board production line. The paper feeding and surface hardening equipment comprises a frame body; a smearing roller which is rotatably and transversely arranged on the frame body and is used for adhering slurry and coating the adhered slurry onto thelower side paper surface of upper paper in a rolling manner; and a defoaming device which is arranged beside the smearing roller and is used for defoaming the roll-coated slurry. According to the paper feeding and surface hardening equipment, the smearing roller is located above the slurry, the upper paper is located above the smearing roller, the smearing roller rolls on the slurry to adhere theslurry, the adhered slurry is roll-coated onto the lower side paper surface of the upper paper, and the defoaming device is used for defoaming the roll-coated slurry. A layer of gypsum slurry which is basically free of bubbles, compact, good in nail-holding power and uniform is formed on the lower side paper surface of the upper paper, the manufactured gypsum board with low piece weight does nothave the problems that the upper paper has large bubbles, layering is not sticky, the side edge of the upper paper is burnt, and the transverse strength of the gypsum board is low, and the quality ismade better.

Owner:GUCHENG NEW BUILDING MATERIALS LTD

Method used for preparing light calcium silicate boards from waste silica fume

InactiveCN104844136AReduce moisture contentRaise the response ratioSolid waste managementCalcium silicateFiber

The invention provides a method used for preparing light calcium silicate boards from waste silica fume, production cost of calcium silicate boards is reduced, and both economic benefits and social benefits are achieved. The method comprises following steps: A, silica fume collected from different ferroalloy plants is subjected to component analysis, and mixing and combination are carried out based on analysis indexes so that indexes of silica fume obtained via mixing and combination are capable of satisfying production requirements; B, full decomposition of composite fiber is realized using a pulping machine, a thickening agent is dissolved in water so as to obtain an aqueous solution, decomposed fiber and the thickening agent aqueous solution are added into pulping water, an obtained mixed material is stirred to be uniform, weighed silica fume, quartz sand, slaked lime, cement, and coal ash microsphere are added, and a slurry needed by calcium silicate board production is prepared using a mixinghollander, wherein the coal ash microsphere is obtained via pre-wetted treatment; and C, the slurry is subjected to board preparation machine moulding, pressurization, maintenance and sizing, high pressure steaming, drying, sanding, and the like so as to obtain the light calcium silicate boards.

Owner:娜仁满都拉

Novel laminated wood and manufacturing method thereof

ActiveCN101863058BKeep textureLight textureOther plywood/veneer working apparatusPlywood pressesWood veneerEnvironmental resistance

The invention relates to a novel laminated wood. The novel laminated wood comprises a fir core veneer layer positioned at a central position, two cotton wood veneer layers which are respectively adhered on both upper and lower surfaces of the fir core veneer layer and two laminated wood layers which are adhered on the other surface of the two cotton wood veneer layers respectively, wherein the directions of wood grains of every two adjacent two veneer layers are vertical to each other. The invention also relates to a method for preparing the laminated wood. The method comprises the steps of producing the laminated wood layers, producing the cotton wood veneer layers, producing the fir core veneer layer, sizing, laminating, molding and the like. The novel laminated wood has the advantages of good stability, low cost and environment protection and can be widely used for preparing indoor decoration, such as furnitures, floors, door panels, ceilings and the like.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Double-layer co-extruded aluminum-wood plastic profile and preparation method thereof

ActiveCN111391434AImprove structural performanceImprove creep resistanceSynthetic resin layered productsCoatingsButenePlastic materials

The invention provides a double-layer co-extruded aluminum-wood plastic profile and a preparation method. The profile comprises: an aluminum base material; an ethylene-1-butene copolymer layer, whichis coated on the aluminum base material; and a wood-plastic material, which is co-extruded on the ethylene-1-butene copolymer layer. The preparation method comprises the following steps: 1, mixing theraw materials of the wood-plastic material, and then performing granulation and extrusion granulation; and 2, heating the aluminum base material by heating equipment, then conveying the aluminum basematerial into a co-extrusion mold of co-extrusion equipment, coating the aluminum base material with the ethylene-1-butene copolymer and the wood-plastic material obtained in step 1 in a co-extrusionmode, fusing the contact surfaces of ethylene-1-butene and the wood-plastic material, and performing infiltrating on a wood-plastic base material layer, thus obtaining the aluminum-wood plastic profile. According to the invention, the wood-plastic material is combined with the aluminum base material, so that the mechanical properties of the product can be improved; compared with a common wood-plastic profile at present, the aluminum-wood plastic profile is not prone to deformation, the nail-holding power and the structural performance of the product are improved, and the wood-plastic profilehas the decorative performance and the structural performance of wood at the same time.

Owner:吉林庭然景观材料科技有限公司

Fiber plastic profile outdoor floor and preparation method thereof

The invention discloses a fiber plastic profile outdoor floor and a preparation method thereof, and belongs to the technical field of composite materials. According to the fiber-plastic profile outdoor floor, the fiber-plastic composite material made of the waste textile fabric and the waste plastic serves as the raw material, the cost is low, the floor is green and environmentally friendly, meanwhile, recycling of the waste textile fabric and the waste plastic is achieved, and in addition, the environment-friendly effect is achieved. The fiber-plastic composite material used by the fiber-plastic profile outdoor floor provided by the invention has more excellent mechanical properties than a single component in the fiber-plastic composite material.

Owner:上海纤苏新材料科技有限公司

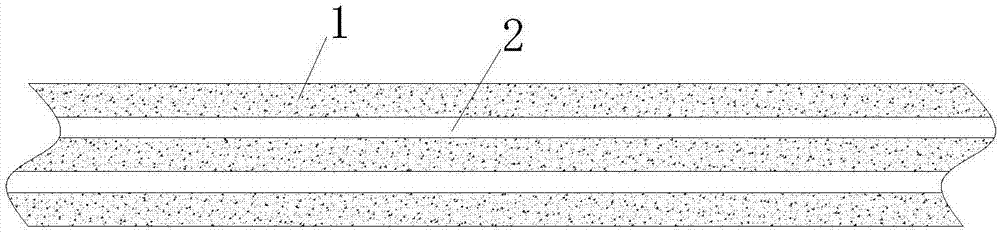

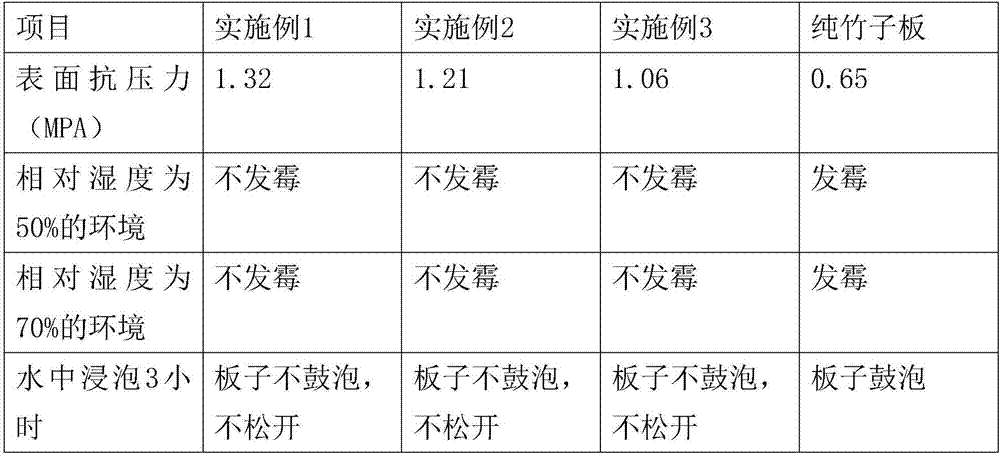

Manufacturing process for pine bamboo board

InactiveCN107020672AGood nail gripGood weather resistanceWood treatment detailsLaminationWeather resistanceEngineering

The invention relates to the technical field of package materials, in particular to a manufacturing process for a pine bamboo board. The pine bamboo board is formed by alternately gluing shaving boards and bamboo fibre boards; each shaving board is formed by bonding wood chips layer by layer; each bamboo fibre board is formed by bonding bamboo chips which are formed by planing bamboo wood layer by layer. According to the pine bamboo board manufactured by the manufacturing process, bamboo wood processing raw materials are recycled and utilized; a bamboo fibre board is clamped between every two layers of the shaving boards, so that the nail-holding power of the manufactured pine bamboo board is very great compared with that of a package board which is manufactured by pure bamboo, and the manufactured pine bamboo board has certain toughness; the pine bamboo board has very good weather resistance, and moreover, the antibacterial performance of the shaving boards and bamboo fibre boards is high, so that the bamboo board cannot mildew in a humid environment; moreover, the surface compressive resistance of the bamboo board is higher.

Owner:合肥睐格包装科技有限公司

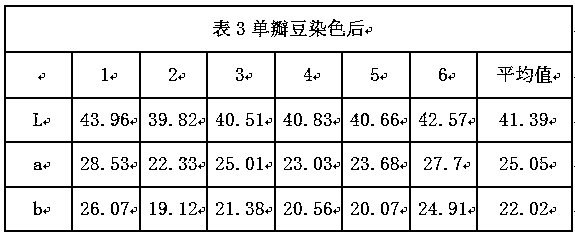

Coating technique of imitated scented rosewood

ActiveCN108608541ALow equipment requirementsReduce manufacturing costNatural patternsWood treatment detailsEngineeringRosewood

The invention relates to a coating technique of imitated scented rosewood. The coating technique comprises the following steps: 1) veneer pretreatment; 2) decorative design drawing with potassium permanganate; 3) treatment with sodium hydroxide; 4) dyeing; 5) porefilling and coloring; 6) brushing with primer; 7) clear coating; and 8) wood final treatment. The coating technique has the advantages that 1) monopetalanthus has luster, crisscross lines, fine and uniform structure, intermediate strength, high rotary cutting performance, corrosion resistance and the like, and is easy to process; 2) the color is bright and full, the imitation chroma difference is small, the dyeing is strong, an extremely small color difference exists between the scented rosewood and the dalbergia odorifera, and the destructive effect on wood is extremely small; 3) the device requirement is low, the operation is easy, the controllability is high, the production cost is low, and the imitated scented rosewood canbe used for large-scale industrial production, and has a good actual application prospect; 4) sandalwood is added on the basis of imitating rosewood color to bring smell enjoyment; and 5) healthy andenvironmental-friendly natural dye is selected to meet the current requirement on environmental-friendly and green ecology.

Owner:海太欧林集团华南有限公司

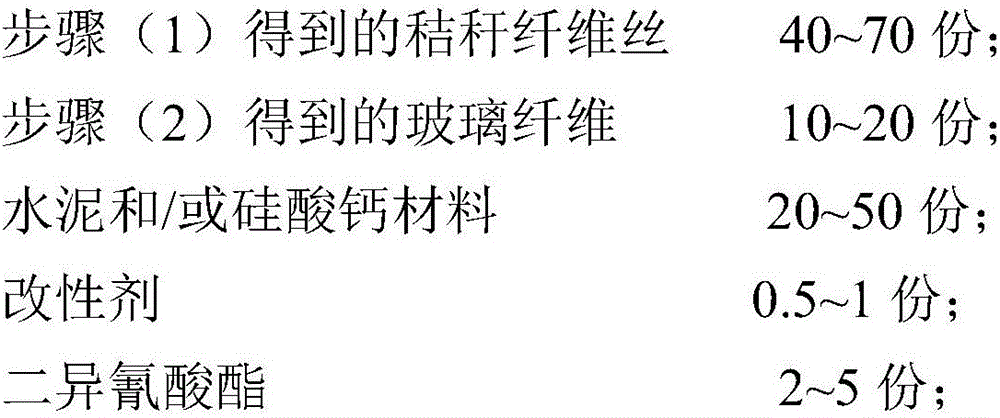

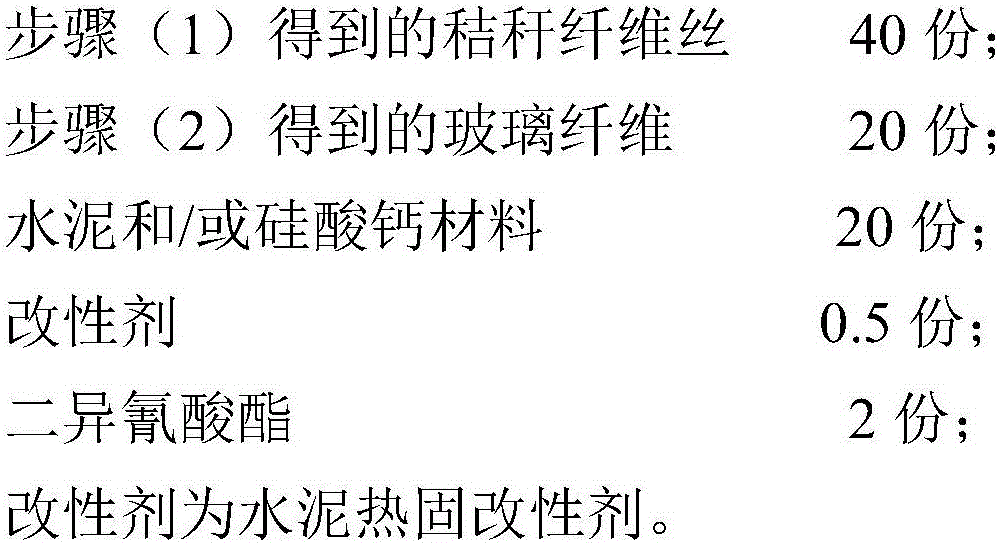

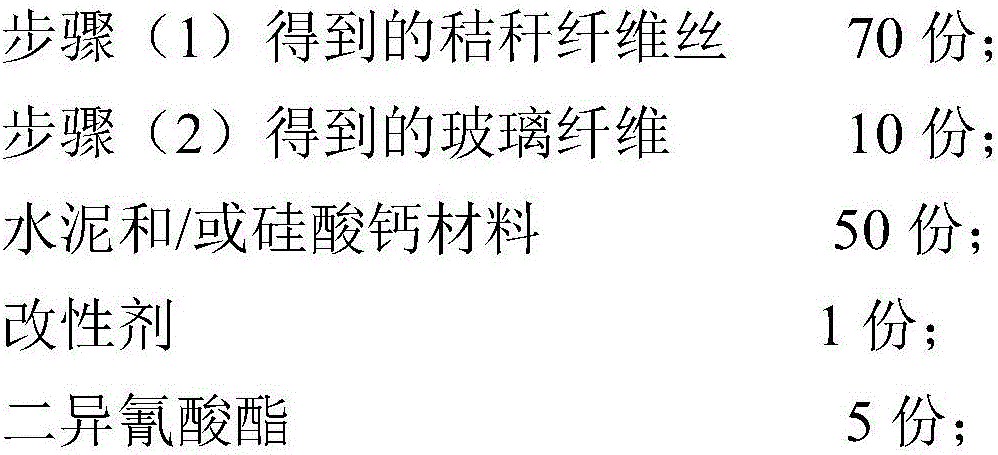

Preparation and application of composite straw glass fiber inorganic material decorative integrated plate

InactiveCN105904575AHigh surface hardnessEasy to prepareSolid waste managementCeramic shaping apparatusCalcium silicateFiber

The invention provides preparation and application of a composite straw glass fiber inorganic material decorative integrated plate. The preparation method comprises the steps of mixing raw materials by weight ratio, and pre-compressing the raw materials to obtain a straw fiber inorganic blank material; the raw materials comprise a 40-70 parts of straw fiber, 10-20 parts of glass fiber, 20-50 parts of cement and / or calcium silicate material, 0.5-1 part of cement thermosetting modifier, and 2-5 parts of diisocyanate. A decoration paper dipped by melamine resin is paved on a surface layer of a stainless steel rust template; the pre-compressed straw fiber inorganic blank material is paved in the middle; then they are molded at once to form a composite straw glass fiber inorganic material decorative integrated plate. The molding condition is that the temperature is between 150 and 190 DEG C; the pressure is between 20 and 25 MPa, and the hot pressing time is between 30 and 90s. <{EN2}>The preparation materials are cheap; the method is simple and effective; and the decorative integrated plate with high intensity, flame retardation and waterproof performance is prepared by one time hot pressing molding.

Owner:YANGZHOU KANGYU IND

Hipboard

InactiveCN105773735AImprove smellReduce harmWood veneer joiningWood layered productsAgricultural engineeringLaser

The invention provides a hipboard. The hipboard is a composite board laterally zygomorphic with a board core as center, and consists of the board core, bamboo charcoal layers, PVC layers, an imidazolidine laser and an adhesive veneer; two bamboo charcoal layers are respectively arranged on the left and right two sides of the board core; the PVC layers are arranged between the two bamboo charcoal layers; and finally, the imidazolidine laser and the adhesive veneer are arranged in sequence. The hipboard can effectively improve the pungent smell, reduce the harm to human bodies, improves the board stability, enables the board to be not easy to deform, and is better in nail holding capacity.

Owner:TIANJIN XIANGXUN AVIATION SCI & TECH CO LTD

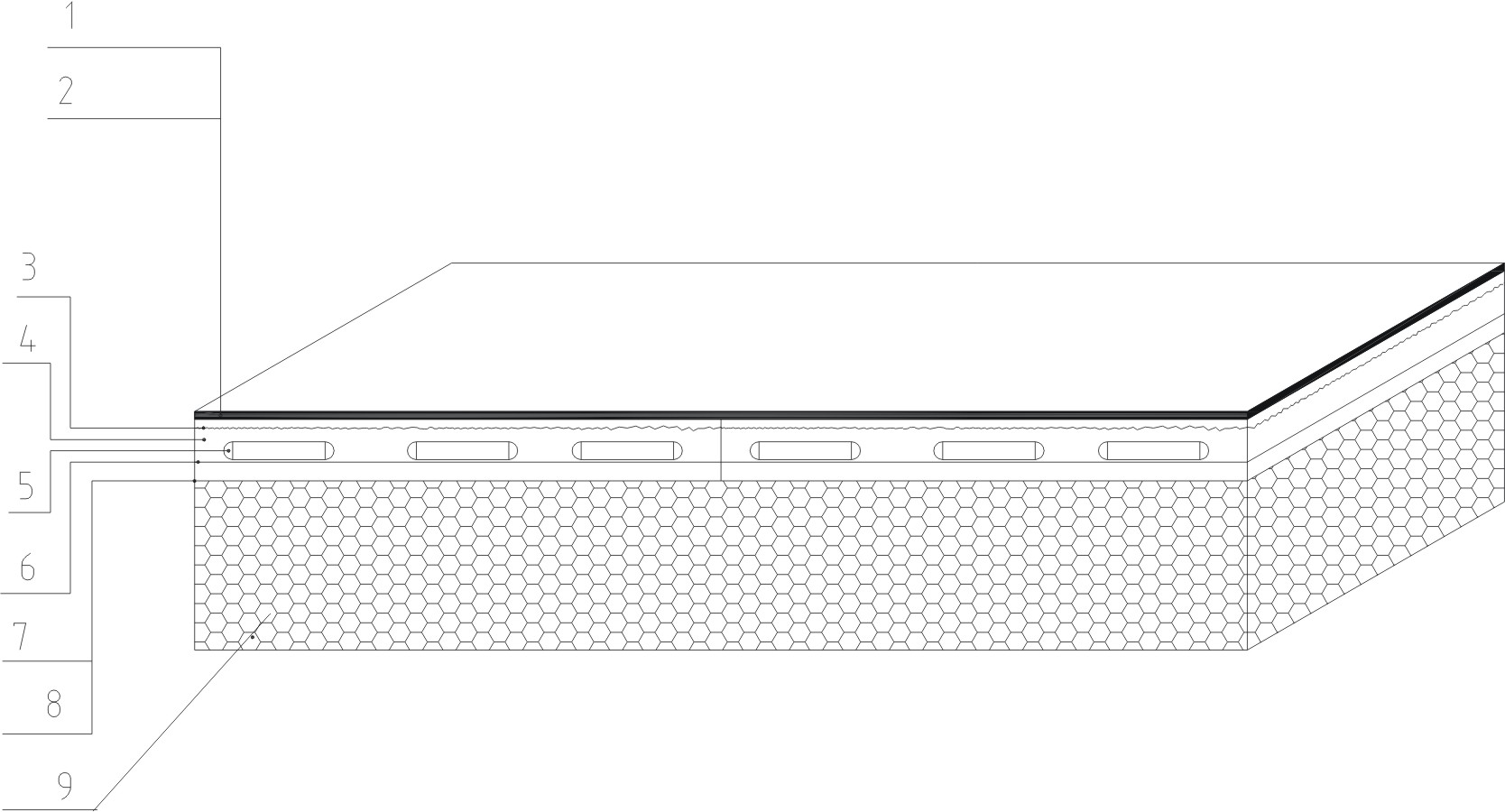

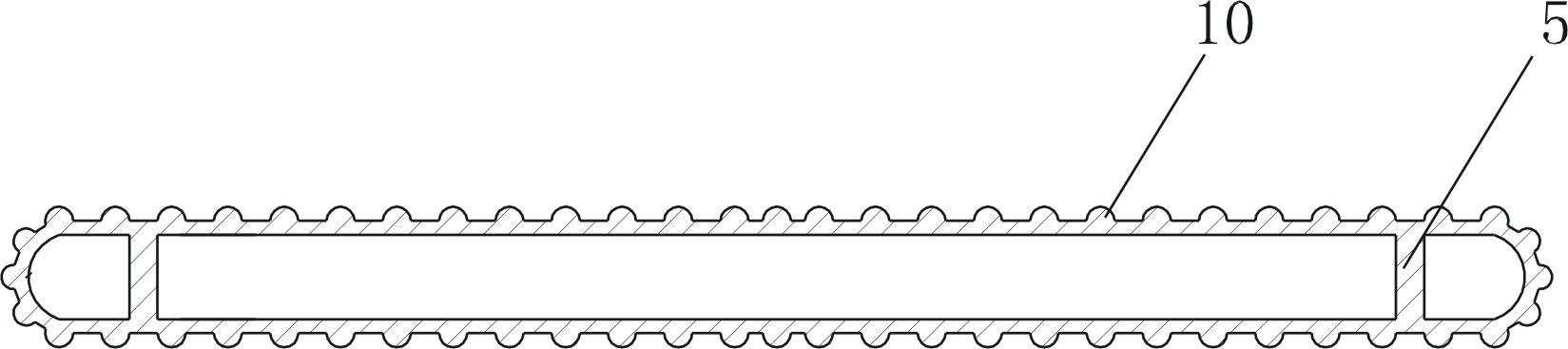

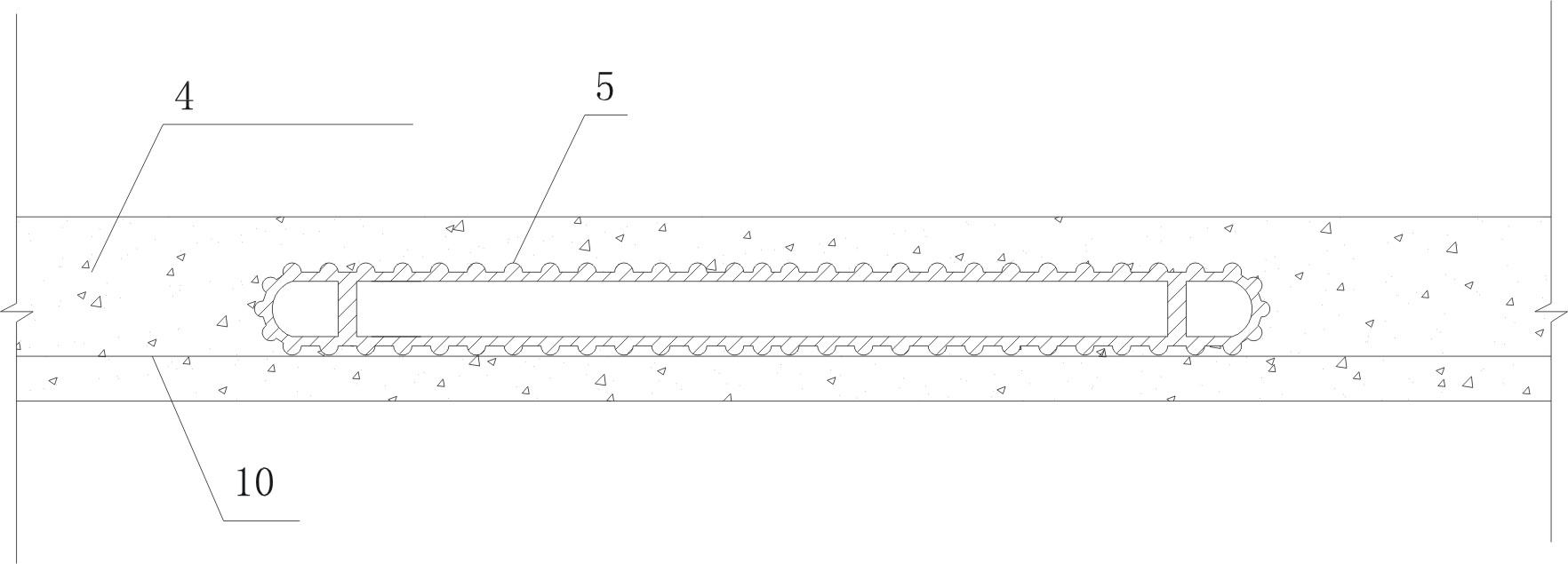

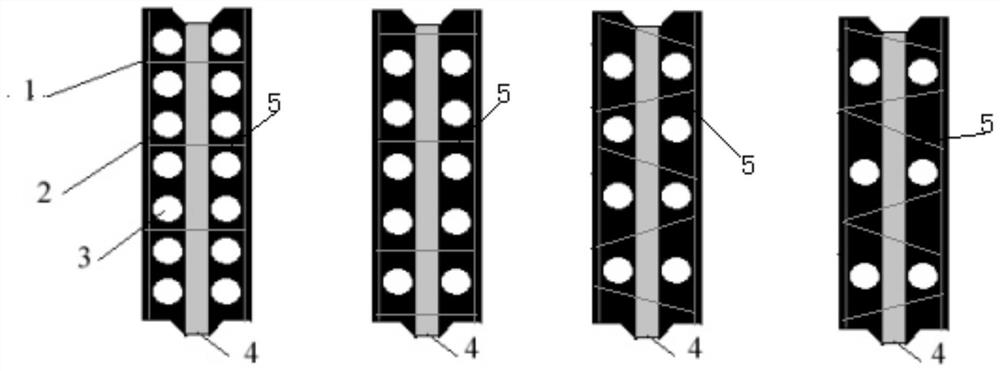

Method for preparing high-performance composite wallboard by using waste construction waste or industrial waste residue

PendingCN114182874AReduce manufacturing costGood environmental effectConstruction materialCeramicwareInsulation layerProcess engineering

The invention relates to a method for preparing a high-performance composite wallboard by using waste construction wastes or industrial waste residues, the composite wallboard is composed of hard layers with holes, a middle sandwich heat insulation layer and a reinforcing steel reinforcement cage, the upper and lower mesh surfaces of the reinforcing steel reinforcement cage are respectively embedded in the middle of the hard layers with the holes; comprising the following steps: step 1, preparing a base material of a hard layer with holes; step 2, assembling a mold; thirdly, a plastic core-pulling pipe is inserted, and the plastic core-pulling pipe is inserted into the mold along the hole of the plug on one side of the mold and comes out of the other end of the plug with the hollow part; and 4, pouring a hard layer base material with holes, and solidifying and demolding to form the product. According to the invention, the existing construction waste or industrial waste residue is used as the raw material to manufacture and produce the composite wallboard, so that a large amount of waste construction waste or industrial waste residue can be reasonably utilized, waste is turned into wealth, the production cost of the composite wallboard can be greatly reduced, and a good environment-friendly effect is achieved.

Owner:杨博

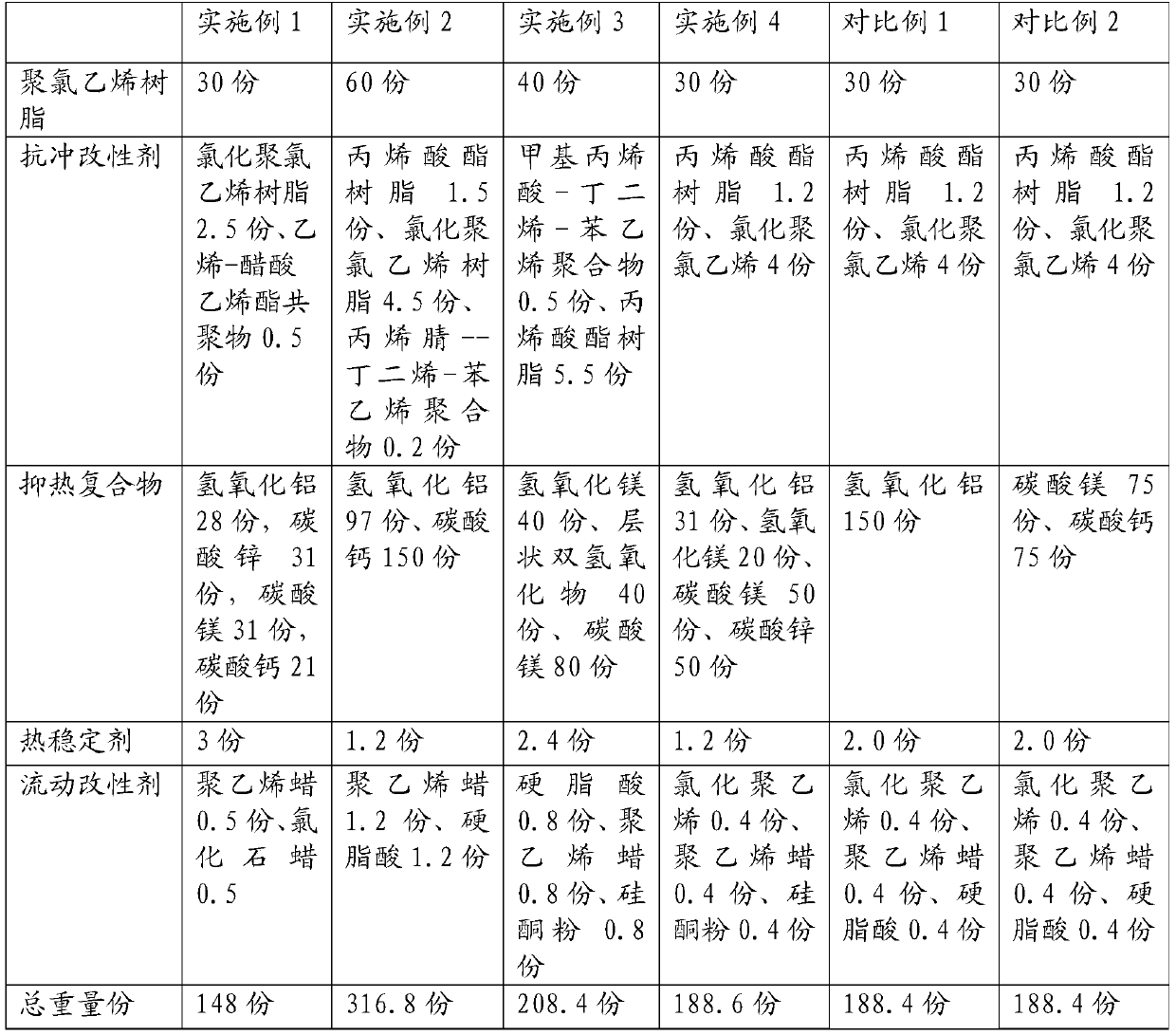

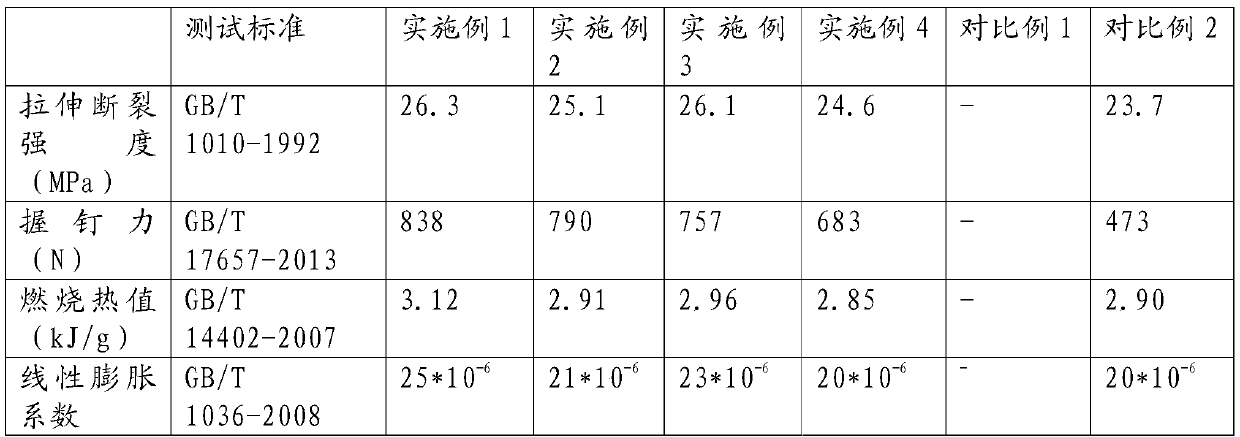

Low-combustion-heat polyvinyl chloride composite and preparing method thereof

The invention provides a low-combustion-heat polyvinyl chloride composite and a preparing method thereof. The low-combustion-heat polyvinyl chloride composite has the combustion heat of A2 grade, hasgood mechanical performance and forming processing performance, and is simple in formula and low in preparing cost. The composite comprises polyvinyl chloride resin, an impact modifier, a heat-inhibiting compound, a thermal stabilizer and a flow modifier, wherein the heat-inhibiting compound is the combination of hydroxide and carbonate. The composite comprises, by weight, 30-60 parts of polyvinylchloride resin, 3-6.2 parts of the impact modifier, 28-100 parts of hydroxide, 80-150 parts of carbonate, 1.2-3 parts of the thermal stabilizer and 1-2.4 parts of the flow modifier.

Owner:ZHEJIANG YASHA DECORATION +1

A kind of manufacturing method of veneer-based exterior wall hanging board

ActiveCN105965617BSimple production processGood nail gripWood compressionWood treatment detailsWood veneerEngineering

The invention provides a fabrication method for veneer based external wall panels. The fabrication method for the veneer based external wall panels is characterized by comprising the steps that wood veneers with the moisture content of 1-15% and the thickness of 1-3.2 mm serve as raw materials and are soaked in or coated with mixed resin modified liquid; the obtained wood veneers are dried until the moisture content is 5-15%; then three to nine layers of the dried wood veneers are assembled to plate blanks; the plate blanks are put into a relief mould for mould pressing, wherein the mould pressing hot-press temperature is 130-150 DEG C, the hot-press pressure is 1-3 MPa, and the pressing time is 1.0-1.5 minutes for every 1 mm of thickness of the plate blanks; and the pressed plate blanks are sawed into strips of a certain specification, the front faces and the side edges of the strips are coated with weather-proof waterproof paint, and then the strips are fabricated to be the outdoor purpose external wall panels with an excellent decoration effect and anticorrosion and weather-proof functions.

Owner:NINGBO ZHONGJIA LOW CARBON NEW TECH RES INST

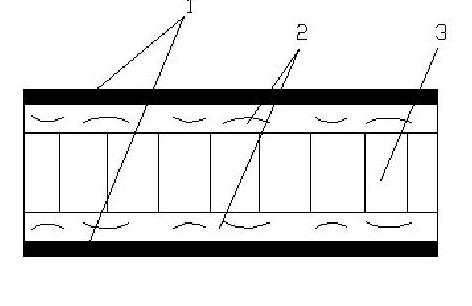

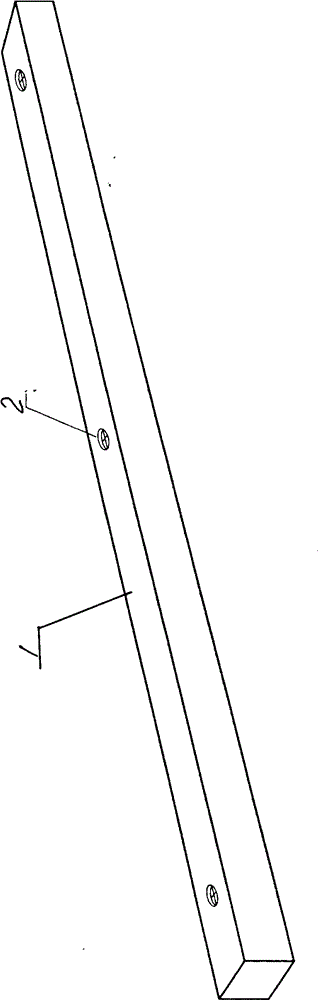

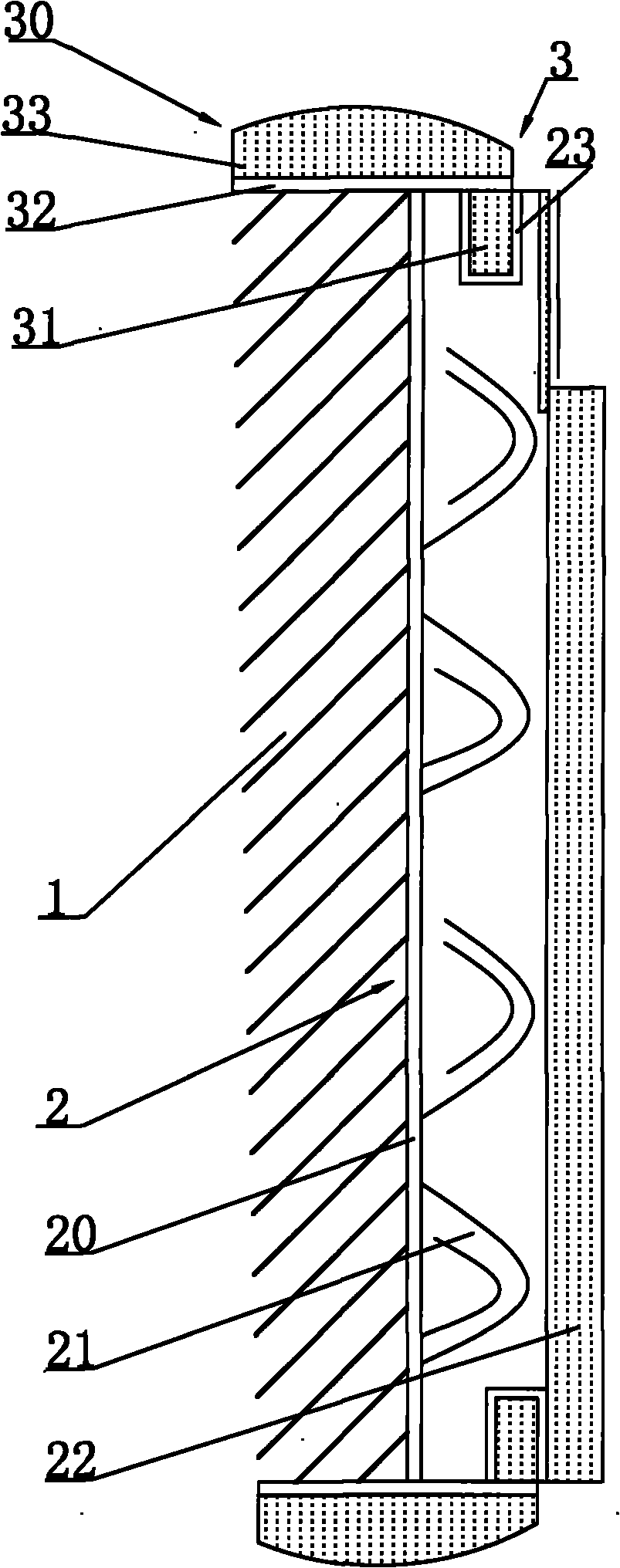

Method for manufacturing novel material floor keel by utilizing wastes

The invention relates to a method for manufacturing a novel material floor keel by utilizing wastes. The method is characterized by comprising the following steps: selecting 8% of attapulgite waste residue with the granularity of 80-200 meshes, 10% of fly ash, 3% of straw, 7% of mineral slag, 5% of sludge from a paper plant, 7% of waste plastic (bags) and 10% of perlite as raw materials; selecting 10% of cement, 5% of lime, 2% of talc powder and 3% of gypsum powder as auxiliary materials; selecting 2% of 50-100mm glass fiber yarn as aggregate; mixing the raw materials, the auxiliary materials and the aggregrate with 28% of magnesium chloride liquid material so as to prepare a slurry; and after mixing and soaking for 8-24 hours, stirring, discharging by a mold plate and drying, thus obtaining profile floor keel (1). The novel material manufactured by the method disclosed by the invention has the characteristics of low cost, high strength, waterproof and fireproof properties and capability of being cut and processed randomly. The novel material floor keel is of an environmentally-friendly product in the real sense.

Owner:HUAIAN JIANRUI TECH DEV

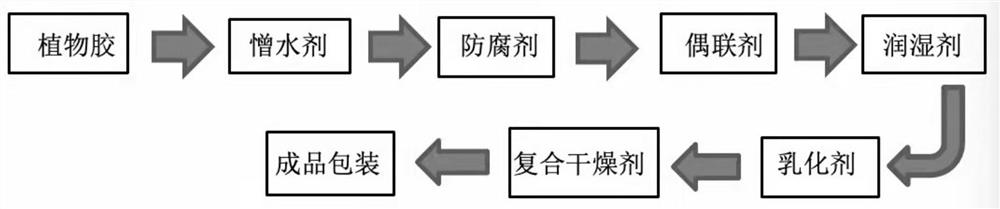

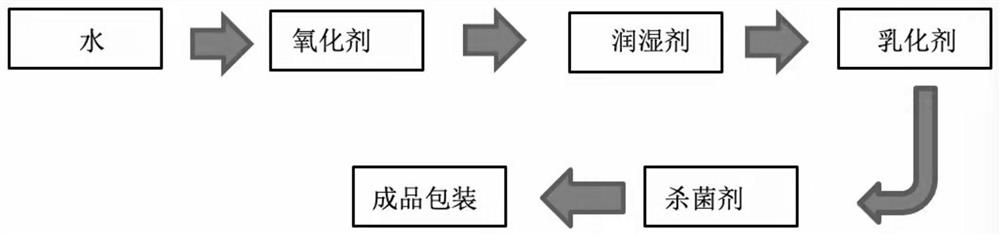

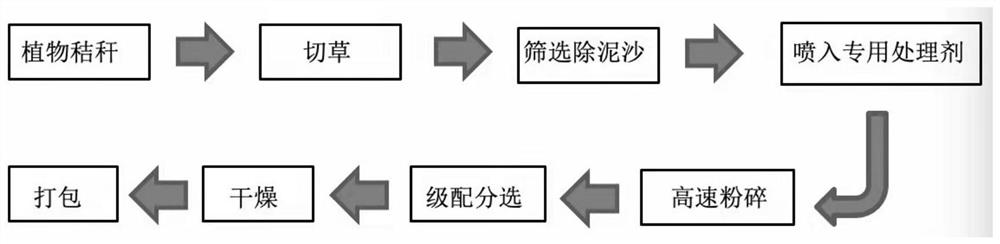

Plant straw ecological board and preparation method thereof

ActiveCN113580314ASolve the problem of volatilityReduced hot pressing production processSolid waste managementPolyureas/polyurethane adhesivesAdhesivePlant stalk

The invention discloses a plant straw ecological board and a preparation method thereof. The preparation method comprises the following steps of preparing a special adhesive for the plant straw ecological board, preparing a special treating agent for the plant straw, treating the plant straw by using the special treating agent for the plant straw to prepare straw crushed aggregates, mixing plant crushed aggregates (the straw crushed aggregates, bagasse and wood residues) and a reinforcing agent, spraying the special adhesive for the plant straw ecological board into the mixture, and manufacturing the board through a hot pressing process or a cold pressing process. The plant straw ecological board and the preparation method thereof provided by the invention have the beneficial effects that the preparation method is simple, the cost is relatively low, the plant straw ecological board is very suitable for industrial production, and the obtained plant straw ecological board is high in bonding strength, good in toughness, resistant to water soaking, good in nail-holding power, waterproof, mildew-proof, mothproof, stable in quality, free of formaldehyde and other toxic and harmful volatile matters, ultralow in VOC, green, environment-friendly and safe to use.

Owner:安徽纳微技术研发中心有限公司

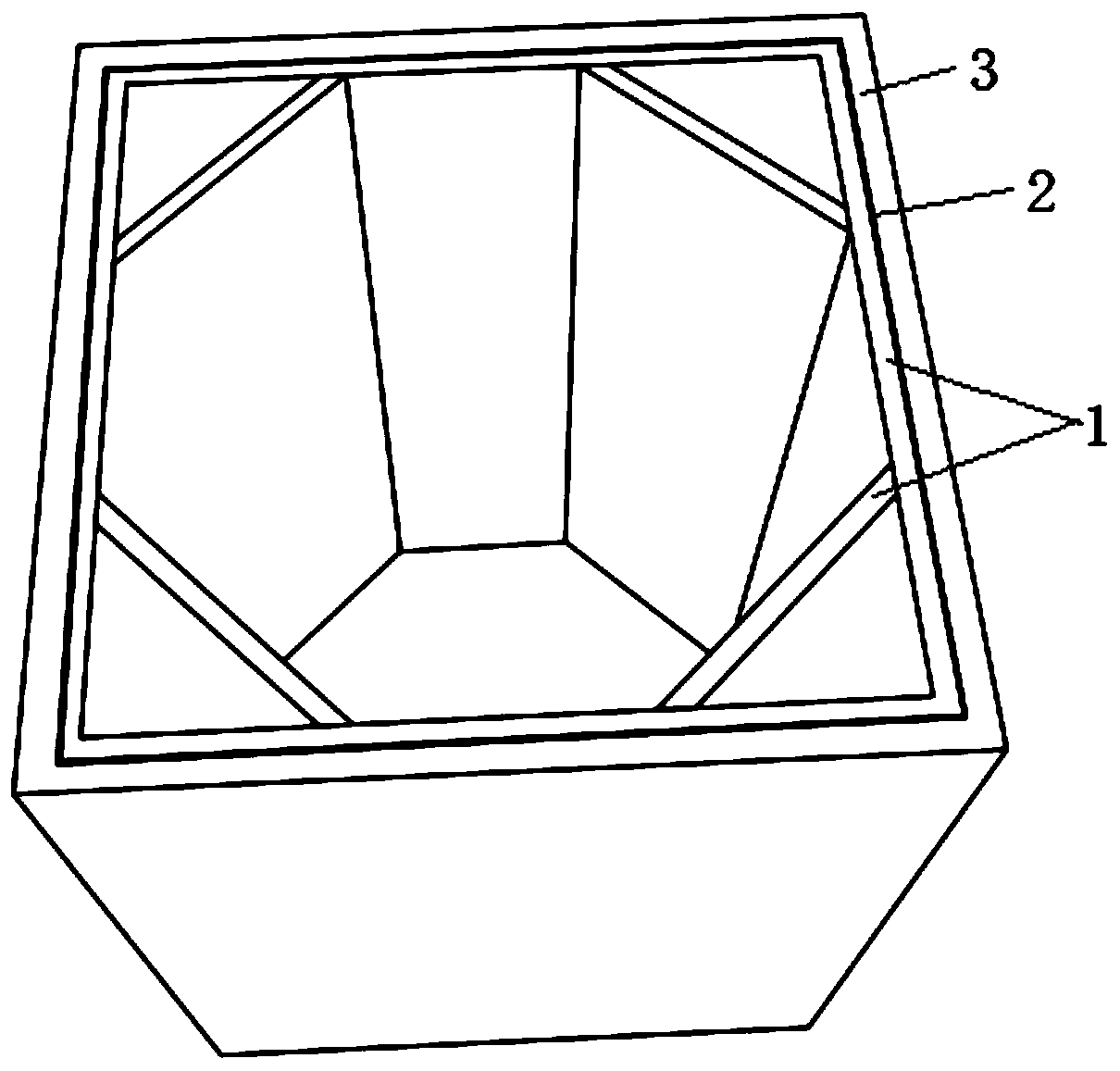

Composite door frame

InactiveCN102041949AImprove bending strengthHigh impact strengthCorner/edge jointsWood layered productsEngineeringMedium density fiberboard

The invention relates to a composite door frame which consists of a single edge or multiple edges, wherein each edge at least comprises a main part fixed to a corresponding wall body and auxiliary parts fixed to wall bodies; and the main part comprises an inner triply wood layer, a middle China fir layer and an outer MDF (Medium Density Fiberboard) layer. The door frame has the advantage of higher strength and is difficult to deform and crack. In addition, the door frame has an attractive appearance and lower cost.

Owner:WUJIANG CITY KEENDELL WOODEN DOOR FACTORY

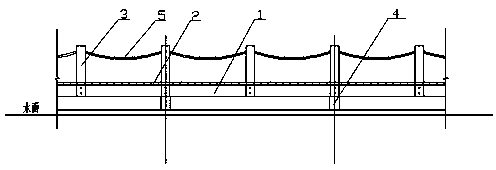

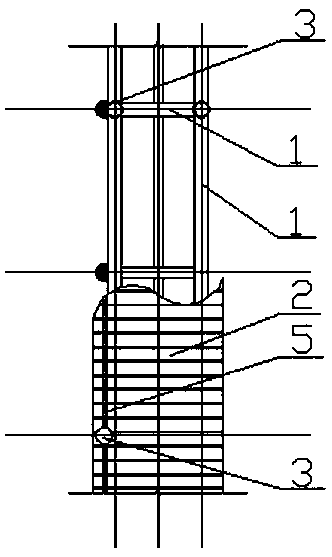

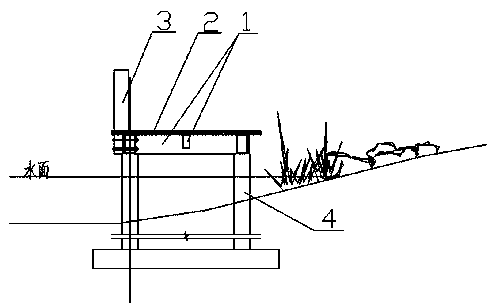

An ecological wooden plank road structure and its technology

ActiveCN106758682BSuppresses changes in moisture contentReduce the degree of deformation and crackingPortable bridgeSidewalk pavingsEngineeringWood plank

The invention provides an ecological wooden trestle structure and a process thereof. The ecological wooden trestle structure comprises a trestle structure and a foundation structure, wherein the trestle structure is positioned above the water surface, and the foundation structure is arranged under the water surface; the foundation structure is horizontally arranged under the water surface and connected with the trestle structure through a steel-pipe post; the trestle structure comprises a square steel pipe, a wooden plate and wooden rail posts which are arranged from bottom to top in sequence; the square steel pipe is rectangular and horizontally arranged on the steel-pipe post; the wooden plate is horizontally fixed on the surface of the square steel pipe through a stainless steel self-tapping screw; the wooden rail posts are vertically embedded in the square steel pipe in an equally spaced manner and fixedly connected with each other through opposed penetration bolts; and hemp ropes are also arranged on the wooden rail posts; and the hemp ropes are suspended between the wooden rail posts and have certain radians downwards. The trestle in the ecological wooden trestle structure can be suitable for humid environments for a long time and the deformation and cracking degree of the wood in the wooden trestle is low, the service life of the ecological wooden trestle structure is 5-10 times longer than that of a traditional wooden trestle, and the ecological wooden trestle structure has ecological, environment-friendly and economic characteristics.

Owner:SUZHOU JIYE ECOLOGICAL LANDSCAPE CO LTD

Base plate for non-overrun device of railway transport tank and manufacturing method thereof

InactiveCN103552136BImprove surface strengthAbundant resourcesWood veneer joiningWood layered productsWood veneerEngineering

The invention discloses a base plate for a non-overrun device of a railway transport tank and a manufacturing method thereof. The base plate comprises a stock pattern mould which is arranged on a top layer, first dipped bamboo curtains which are arranged on the next five layers, first five-in-one plywood which is arranged on the next layer, a transverse texture eucalyptus wood veneer which is arranged on the next layer, second five-in-one plywood which is arranged on the next layer, a first longitudinal texture eucalyptus wood veneer which is arranged on the next layer, third five-in-one plywood which is arranged on the next layer, a first longitudinal texture eucalyptus wood veneer which is arranged on the next layer, third five-in-one plywood which is arranged on the next layer, a first longitudinal texture eucalyptus wood veneer which is arranged on the next layer, third five-in-one plywood which is arranged on the next layer, a first longitudinal texture eucalyptus wood veneer which is arranged on the next layer, second five-in-one plywood which is arranged on the next layer, a transverse texture eucalyptus wood veneer which is arranged on the next layer, first five-in-one plywood which is arranged on the next layer and first dipped bamboo curtains which are arranged on the next three layers. According to the base plate for the non-overrun device of the railway transport tank, the nail holding power is good, the machining is convenient, the strength is large, the hardness is high, and the abrasion resistance and the corrosion resistance are good.

Owner:ZHUJI GUANGYU BAMBOO IND +1

Low-foaming PVC crust plate material

InactiveCN108384153AHigh mechanical strengthImprove waterproof performanceFoaming agentFilling materials

The invention relates to a low-foaming PVC crust plate material, which is prepared from a PVC template recovery material, calcium powder, stabilizing agents, filling materials, foaming regulators, foaming agents, pigments, polyethylene wax and wood powder. The proportioning of each ingredient of the low-foaming PVC crust plate material is reasonable, so that the prepared PVC crust plate material has the better nail holding force on wood screws than wood materials; the bending intensity and the room temperature impact intensity are better than those of wood materials; the adhesion connection iseasy; the anti-deformation capability is high.

Owner:GUILIN QUANZHOU LIAOYUAN SCI & TECH

Production method of decorative plate

PendingCN113580283AImprove the decorative effectNo reduction in productivityOther plywood/veneer working apparatusSpecial ornamental structuresSolid woodAdhesive glue

The invention discloses a production method of a decorative plate. The production method comprises the following steps that S1, cleaning is conducted, specifically, a multi-layer plate is put into a flat pasting machine, the multi-layer plate is cleaned through a dust removal device of the flat pasting machine, the surface of the multi-layer plate is rolled and brushed through a brush roller, and meanwhile the plate face is flushed and blown through negative pressure dust removal and blast airflow; S2, gluing is conducted, specifically, the multi-layer plate is subjected to the cleaning process and conveyed to a gluing roller through a conveying device, and glue is smeared on the surface of the multi-layer plate through the gluing roller; S3, drying is conducted, specifically, the multi-layer plate with the glued surface is conveyed into a dryer, and the drying time is set according to the quality of the glue and the plate till moisture of the glue is fully evaporated; and S4, plate covering is conducted, specifically, after moisture of glue on the multi-layer plate is removed, the multi-layer plate is conveyed to a plate covering station, the glued face of the multi-layer plate is covered with a solid wood plate, rolling is conducted, and a pine plate and the multi-layer solid wood plate are fully pasted. According to the scheme, the produced novel composite decorative plate can be modeled by pine wood and shaped by multi-layer solid wood, is attractive and practical, and has better nail-holding power and decorative effect.

Owner:佛山市骏品装饰材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com