Paper feeding and surface hardening equipment and paper feeding and surface hardening method for gypsum board and gypsum board production line

A gypsum board and hard surface technology, which is applied to the gypsum board production line and the paper hard surface field of the gypsum board, can solve the problems of non-stick layering, large air bubbles on the paper, low lateral strength of the gypsum board, etc., and achieves good nail holding force. , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

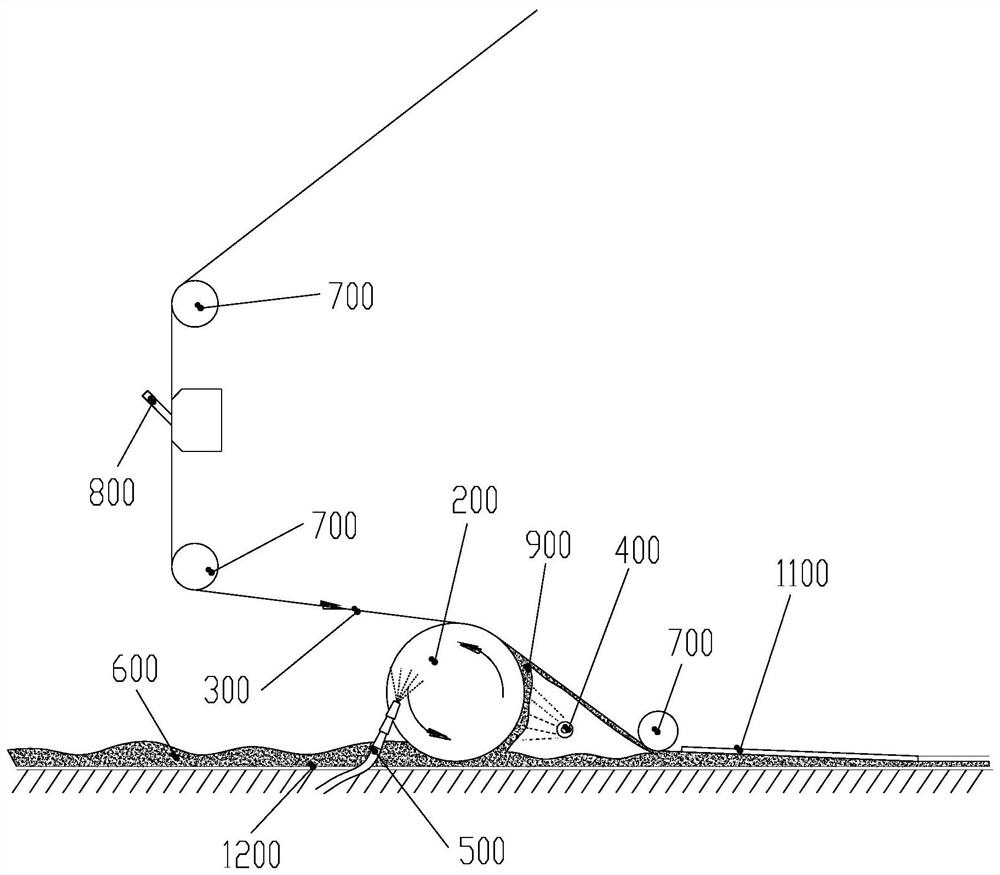

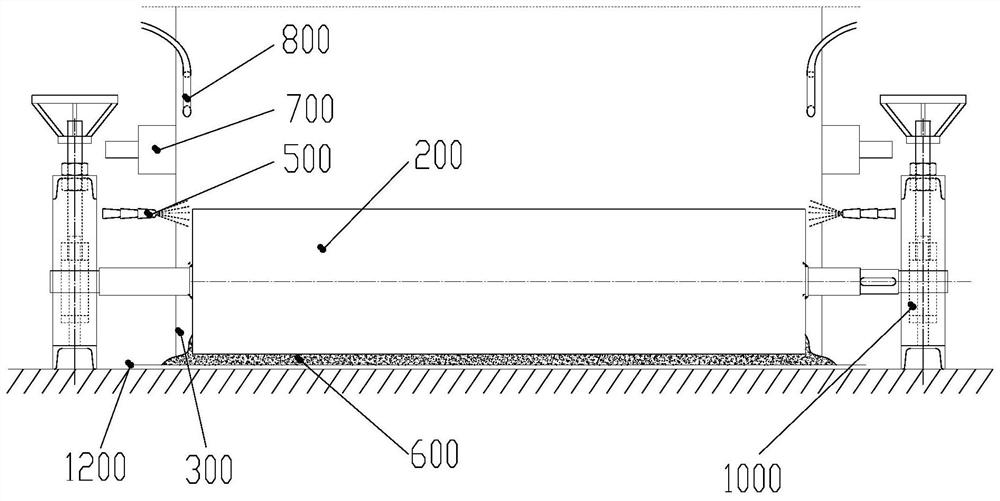

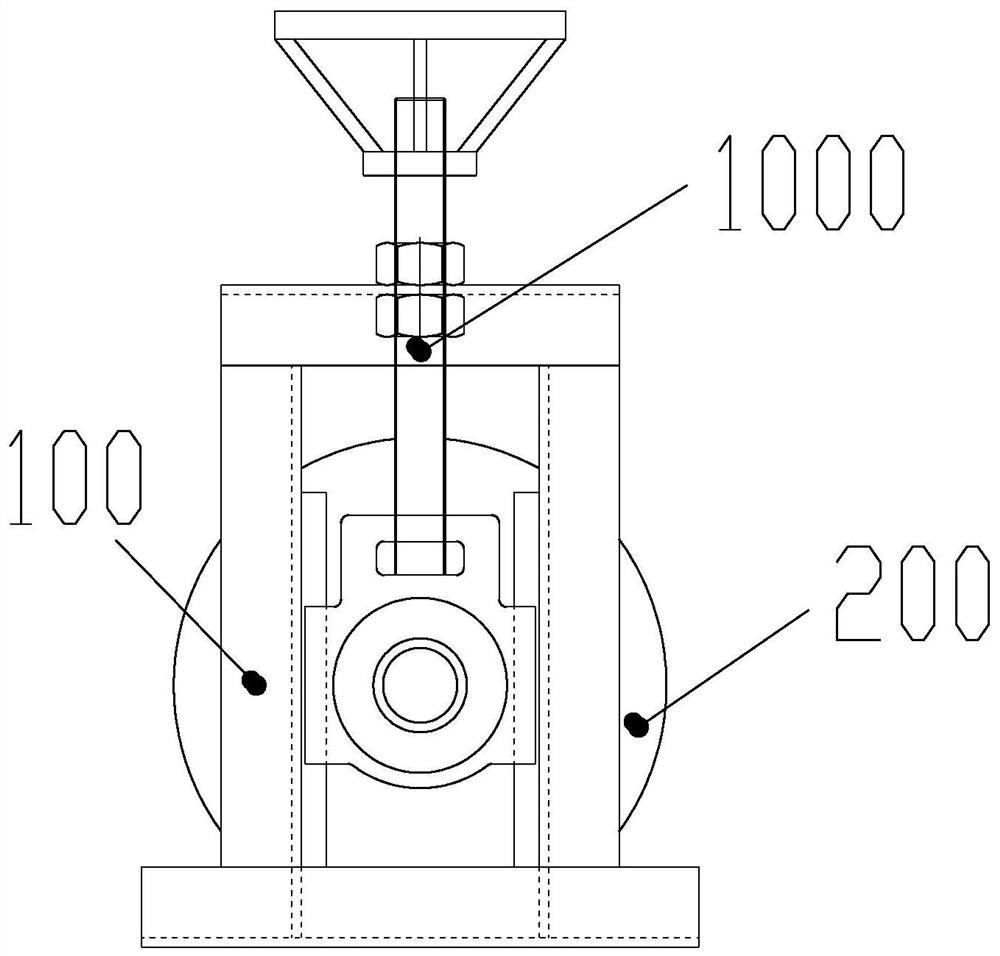

[0028] The paper hard surface equipment of the gypsum board that the embodiment of the present invention provides, such as Figure 1 to Figure 3 As shown, it includes: a frame body 100; an applicator roller 200, which is rotatably mounted horizontally on the frame body 100, and is used for adhering the slurry 900 and rolling the adhering slurry 900 on the underside of the upper paper 300 On the paper; and a defoaming device 400, which is arranged on the side of the applicator roller 200, and is used to defoam the slurry 900 that is rolled.

[0029] The paper hard surface equipment for gypsum board, the application roller 200 is located above the slurry 600 and is in contact with the slurry 600, the upper paper 300 is located above the application roller 200 and is in contact with the application roller 200, and the application roller 200 rolls on the slurry 900 Adhesive slurry 900, and roll-coat the adhering slurry 900 on the lower side of the upper paper 300, and the defoamin...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is: as Figure 4 As shown, the defoaming device 400 faces the lower paper surface of the upper paper 300, and after the application roller 200 roll-coats the slurry 900 on the lower paper surface of the upper paper 300, the defoaming device 400 faces the lower paper surface of the upper paper 300. The defoaming of the slurry 900 rolled on the surface can also achieve the purpose of this application, and its purpose does not deviate from the design concept of the present invention, so it will not be repeated here, and should also belong to the protection scope of this application.

[0040]The paper hard surface method (not shown in the figure) of the paper hard surface equipment of the gypsum board includes: controlling the rolling of the application roller 200, making the roller surface of the application roller 200 adhere to the slurry 900 on the slurry 600, and The adhering slurry 900 is rolled onto the lower pap...

Embodiment 3

[0044] The gypsum board production line that the embodiment of the present invention provides, such as figure 1 , figure 2 and Figure 4 As shown, the paper hard surface equipment comprising the gypsum board described in any of the above-mentioned embodiments.

[0045] The lower unit weight gypsum board produced by this gypsum board production line forms a layer of basically no air bubbles, dense, good nail-holding force, and uniform gypsum slurry on the lower side of the upper paper 300, and the upper side of the gypsum board does not exist Paper 300 has problems such as large air bubbles, non-stick layers, excessive heat on the side of paper 300, low transverse strength of gypsum board, etc., and the quality is better.

[0046] For example, as figure 1 , figure 2 and Figure 4 As shown, the gypsum board production line also includes a tensioning device 700, a sizing device 800 and a forming platen 1100, and the tensioning wheel of the tensioning device 700 is pressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com