Base plate for non-overrun device of railway transport tank and manufacturing method thereof

A technology of railway transportation and manufacturing method, applied in the direction of manufacturing tools, chemical instruments and methods, wood-layered products, etc., can solve the problems of unsatisfactory service life, poor protection of forest resources, unbearable for users, etc., to achieve low production cost, Prolonged maintenance period and good nail grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

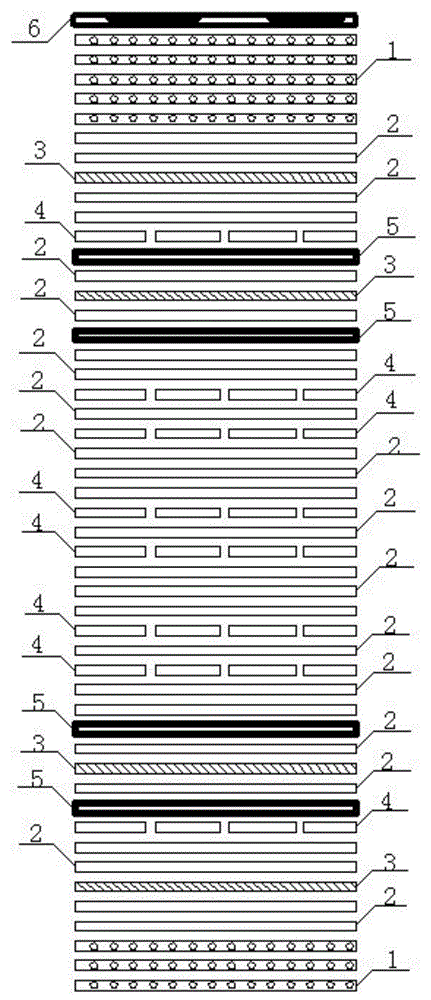

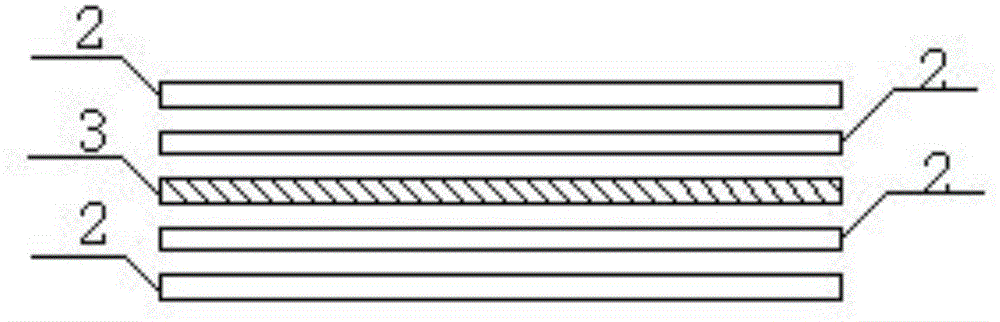

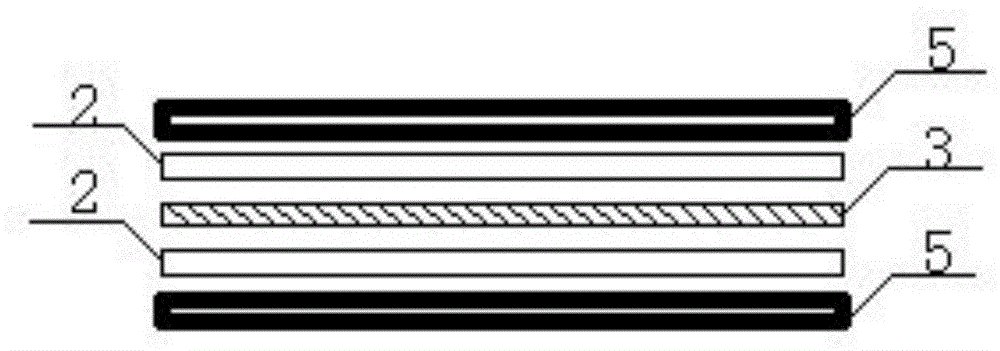

[0031] Bottom plates for non-overrunning devices for railway transport tanks, such as figure 1 As shown, including the uppermost layer is the stereotyped pattern mold 6, the next five layers are the first dipped bamboo curtain 1, the next layer is the first five-in-one plywood, and the next layer is the horizontal grain eucalyptus veneer 4, and the next layer is the second five-in-one plywood, and the next layer is the first longitudinal grain eucalyptus veneer 2, and the next layer is the third five-in-one plywood, and the next The first layer is the first longitudinal grain eucalyptus veneer 2, the next layer is the third five-in-one plywood, the next layer is the first longitudinal grain eucalyptus veneer 2, and the next layer is the third five One-in-one plywood, the next layer is the first longitudinal grain eucalyptus veneer 2, the next layer is the second five-in-one plywood, the next layer is horizontal grain eucalyptus veneer 4, and the next One layer is the first fi...

Embodiment 2

[0046] Bottom plates for non-overrunning devices for railway transport tanks, such as figure 1 As shown, including the uppermost layer is the stereotyped pattern mold 6, the next five layers are the first dipped bamboo curtain 1, the next layer is the first five-in-one plywood, and the next layer is the horizontal grain eucalyptus veneer 4, and the next layer is the second five-in-one plywood, and the next layer is the first longitudinal grain eucalyptus veneer 2, and the next layer is the third five-in-one plywood, and the next The first layer is the first longitudinal grain eucalyptus veneer 2, the next layer is the third five-in-one plywood, the next layer is the first longitudinal grain eucalyptus veneer 2, and the next layer is the third five One-in-one plywood, the next layer is the first longitudinal grain eucalyptus veneer 2, the next layer is the second five-in-one plywood, the next layer is horizontal grain eucalyptus veneer 4, and the next One layer is the first fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com