Patents

Literature

111results about How to "Stable quality and performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pipeline steel plate with low yield ratio, fine grains and high strength and production method thereof

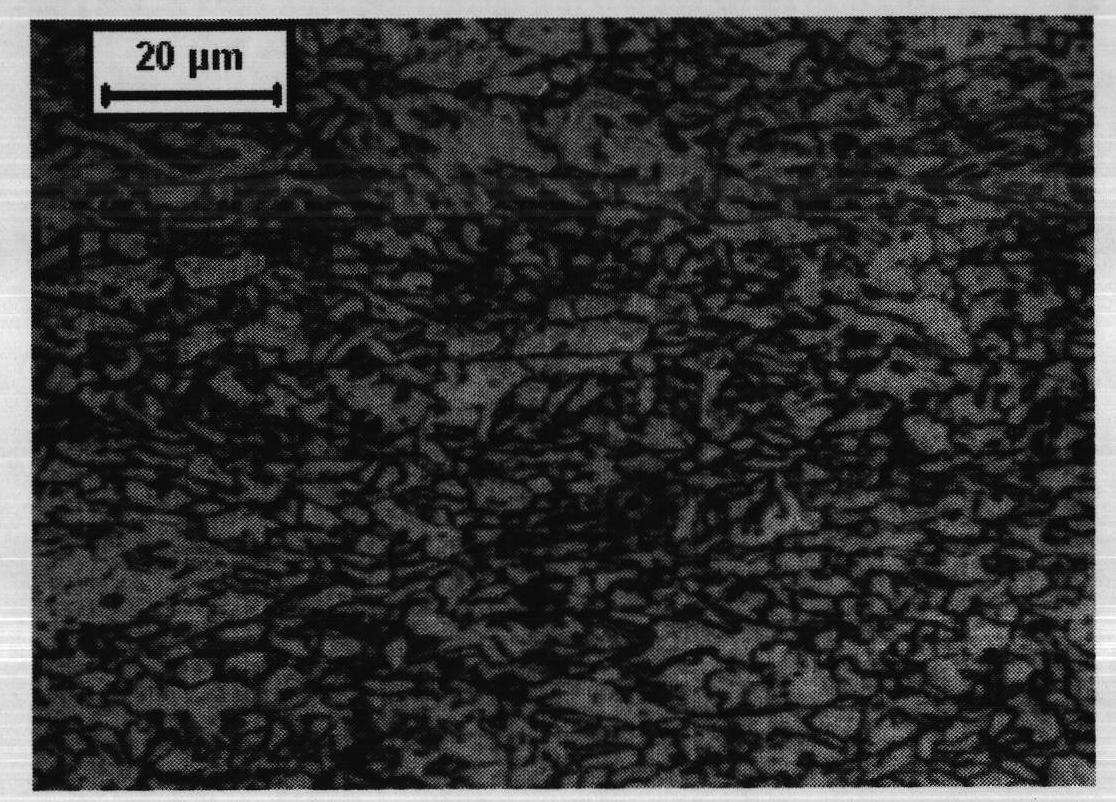

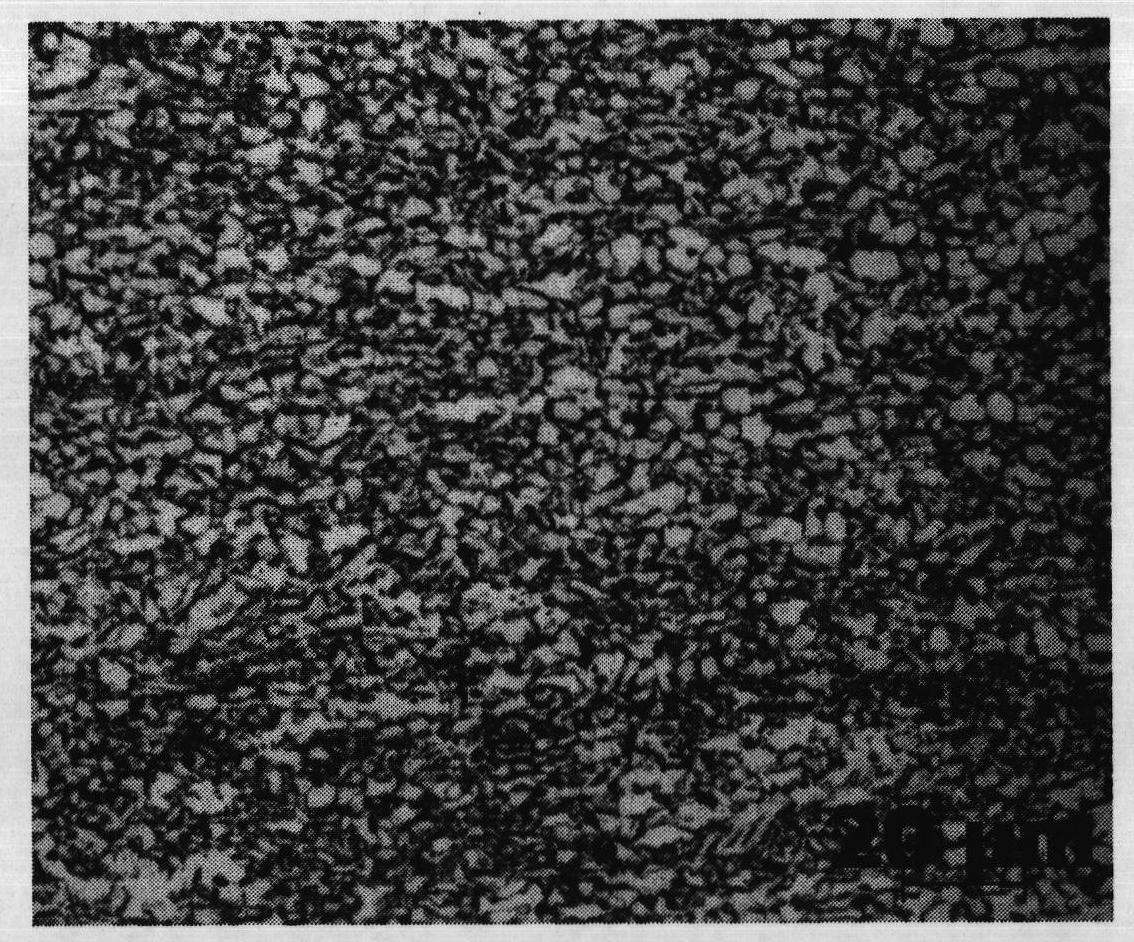

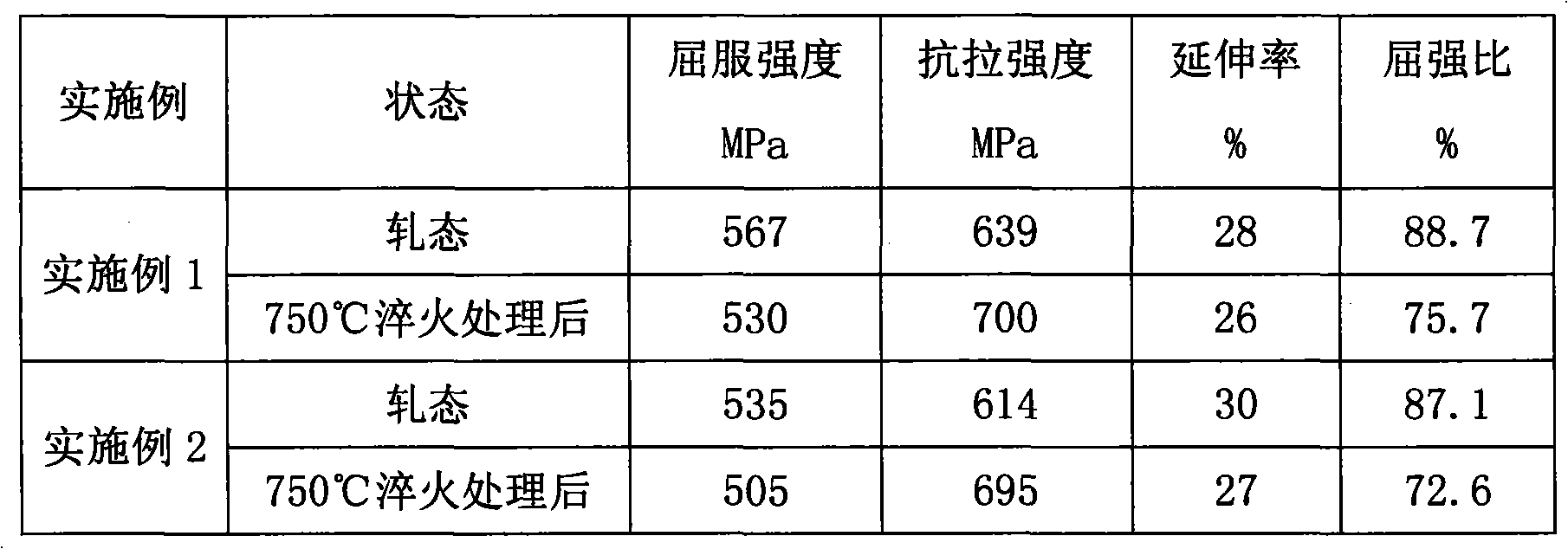

The invention discloses a pipeline steel plate with low yield ratio, fine grains and high strength and a manufacturing method thereof, and steel in the pipeline steel plate comprises the following chemical components by weight percent: 0.03-0.10% of C, 0.10-0.30% of Si, 1.20-1.80% of Mn, not more than 0.015% of P, not more than 0.005% of S, 0.040-0.060% of Nb, 0.006-0.020% of Ti, 0.10-0.40% of Cr, 0.10-0.30% of Ni, 0.010-0.050% of Al and the balance of Fe and inevitable impurities. The manufacturing method adopts a converter for smelting, adopts the TMCP (thermo mechanical control process) and the two-phase region subthermal quenching treatment at 720-750 DEG C, thereby obtaining the pipeline steel plate with low yield ratio, fine grains and high strength; and the manufacturing method has stable production process, strong operability, low cost and high performances.

Owner:NANJING IRON & STEEL CO LTD

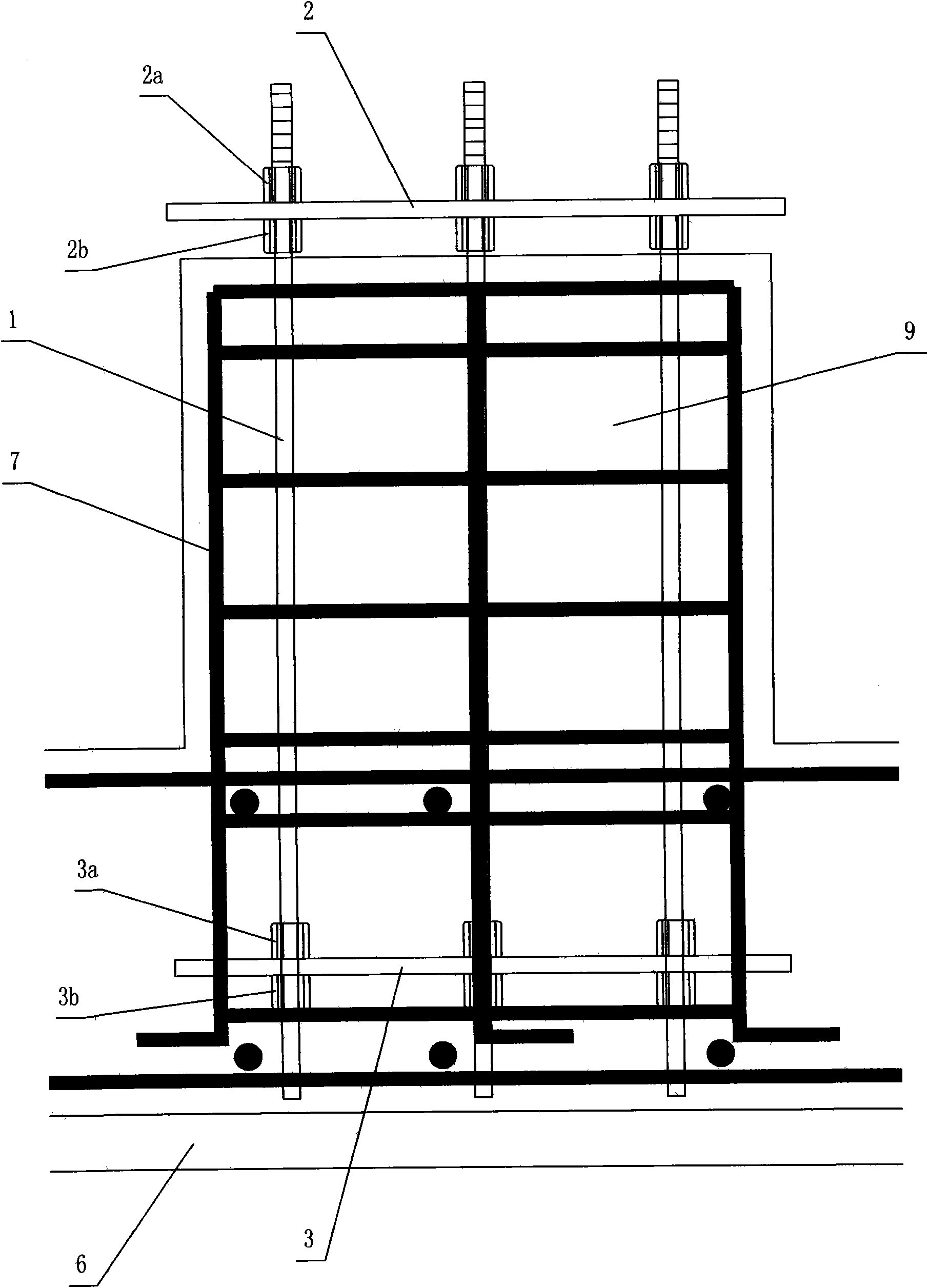

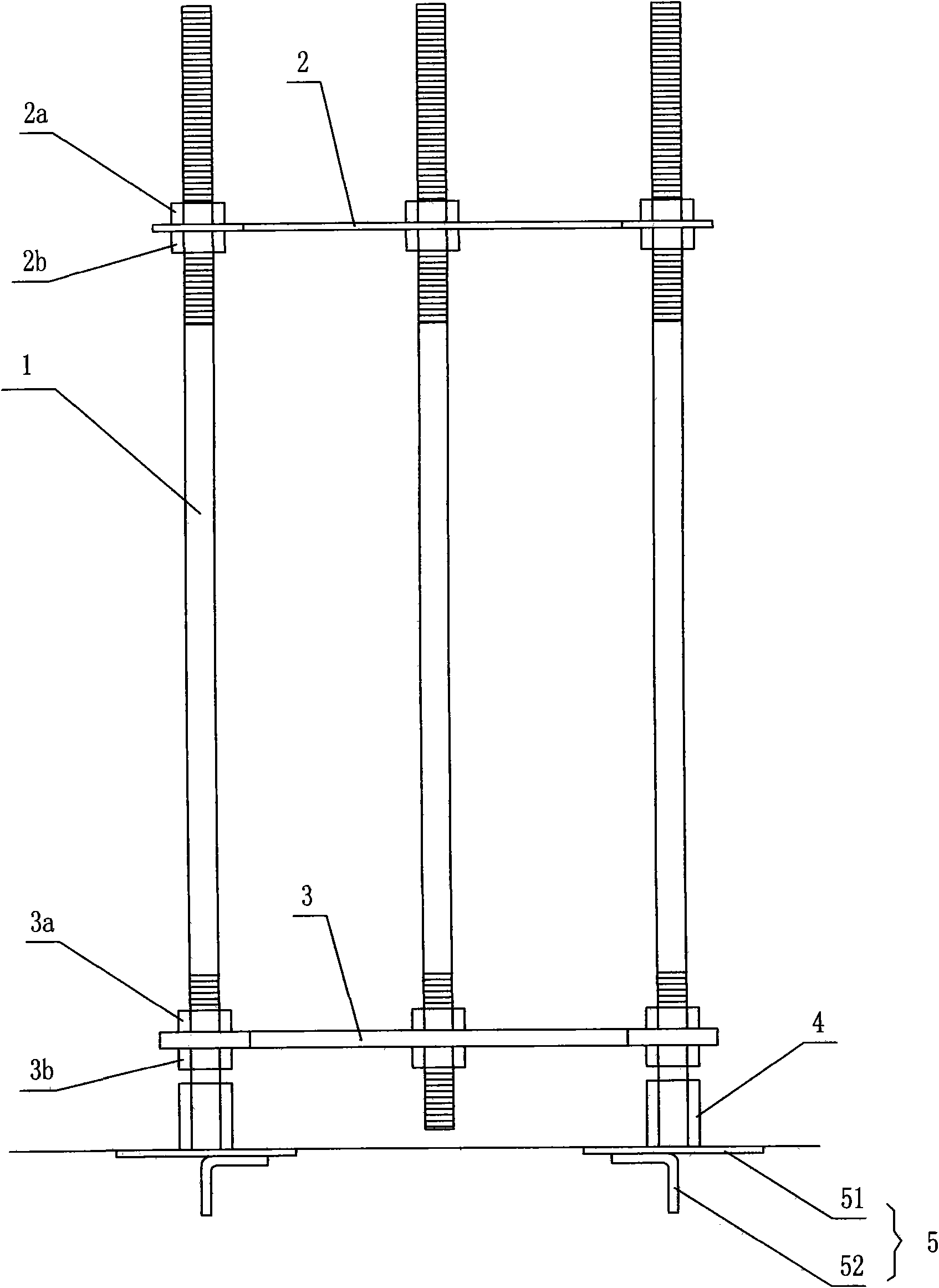

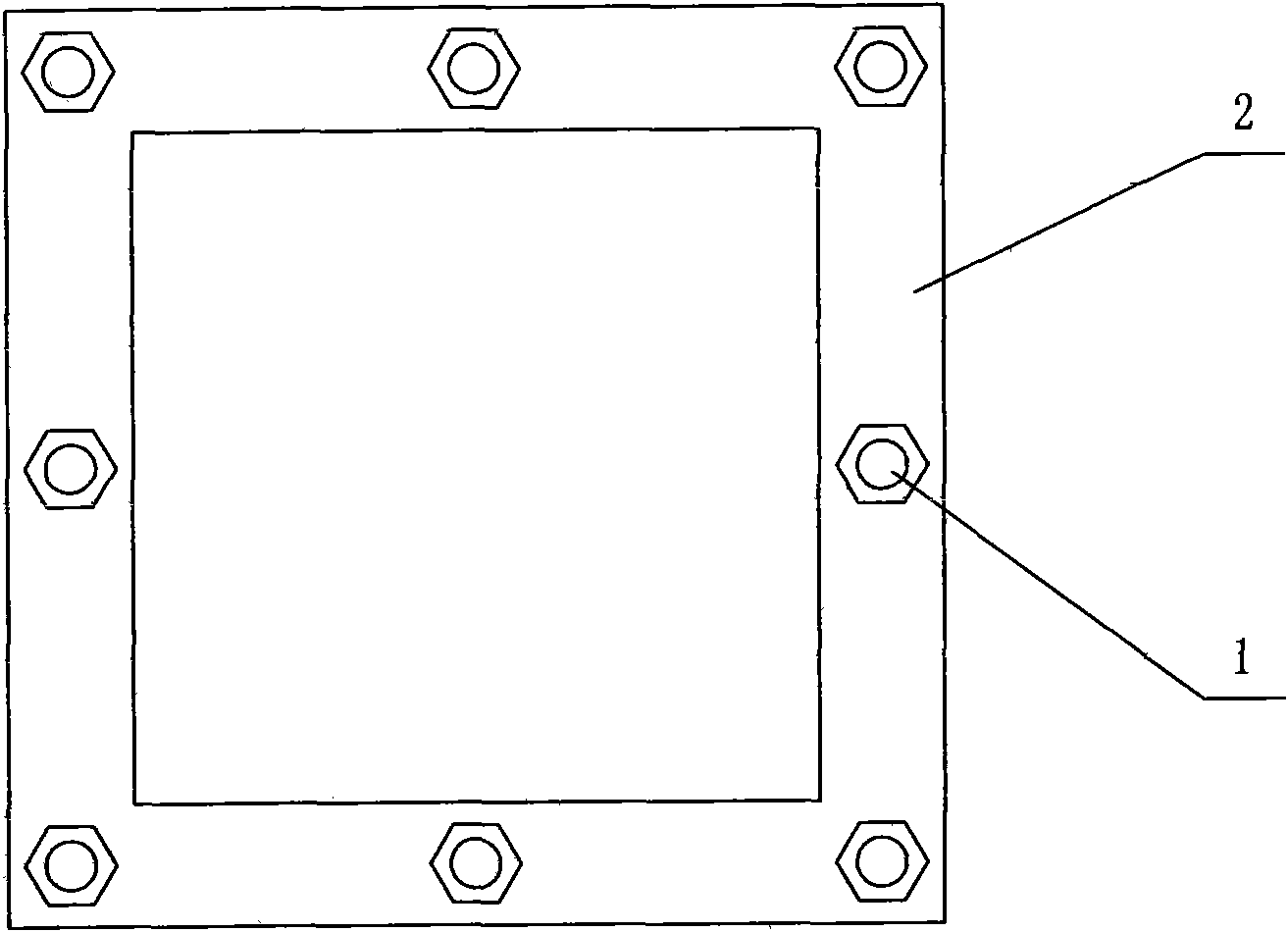

Steel structure assembled embedded part and construction method thereof

ActiveCN102061746AImprove quality and efficiencyImprove installation efficiencyBuilding material handlingArchitectural engineeringBuilding construction

The invention relates to a steel structure assembled embedded part and a construction method thereof, belonging to the technical field of building installation. The steel structure assembled embedded part comprises a plurality of embedded screws, the upper threaded parts of the embedded screws are jointly provided with a top template; the embedded screws are fixedly connected with the top template through clamping nuts 1 respectively positioned above the top template and packing nuts 1 positioned below the top template; the lower threaded parts of the embedded screws are jointly provided with a bottom template; the embedded screws are fixedly connected with the bottom template through clamping nuts 2 respectively positioned above the bottom template and packing nuts 2 positioned below the bottom template; the tail ends of the lower threaded parts of the embedded screws are provided with regulating bases, and the bottoms of the regulating bases are respectively fixed with embedded irons. The invention can decrease the work types of foundation construction, lower the technical requirements for construction, shorten the construction period and enable the foundation construction to have stable quality.

Owner:宝业集团浙江建设产业研究院有限公司

Q 390E class super-thick steel plate with thickness of 100mm and manufacturing method thereof

InactiveCN101864536AImprove low temperature toughnessReduce investmentTemperature control deviceChemical compositionImpurity

The invention discloses a Q 390E class super-thick steel plate with the thickness of 100mm and a manufacturing method thereof. The steel plate has the chemical composition of steel by weight percent: 0.08-0.13% of C, 1.20-1.60% of Mn, 0.10-0.25% of Si, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.10-0.40% of Ni, 0.010-0.030% of Nb, 0.020-0.050% of V, 0.02-0.040% of Al and balance of Fe and unavoidable impurities, and the chemical composition of the steel is in accordance with the mixture ratio relation of 0.26% <= C+ 6Nb+ 4V<= 0.40%. The rolling technology comprises the steps of: adopting a continuous casting billet with the thickness of 260mm, and controlling the heating temperature of 1200-1250 DEG C, the heat preservation time of 4.0-4.5h and the tapping temperature of 1180-1220 DEG C; controlling the rolling by two stages, controlling the rough rolling screw-down rate per pass of 10-20% and the finish rolling temperature of 1000-1050 DEG C, and rough rolling the billet into an intermediate billet with 1.5-2.0 times of finished product thickness; controlling the start rolling temperature of precision rolling to be 850-900 DEG C, and the screw-down rate per pass of 8-12%; and adopting laminar flow cooling after rolling, controlling the finish cooling temperature to be 500-650 DEG C, the cooling speed of 5-10 DEG C / s, the high temperature off-line temperature to be 450-550 DEG C, and the time of cooling in heap of 60-72h. The invention adopts the casting billet with the thickness of 260mm for rolling, is low in equipment investment and excellent in low temperature impact toughness at -40 DEG C, does not need heat treatment, and has lower production cost.

Owner:NANJING IRON & STEEL CO LTD +1

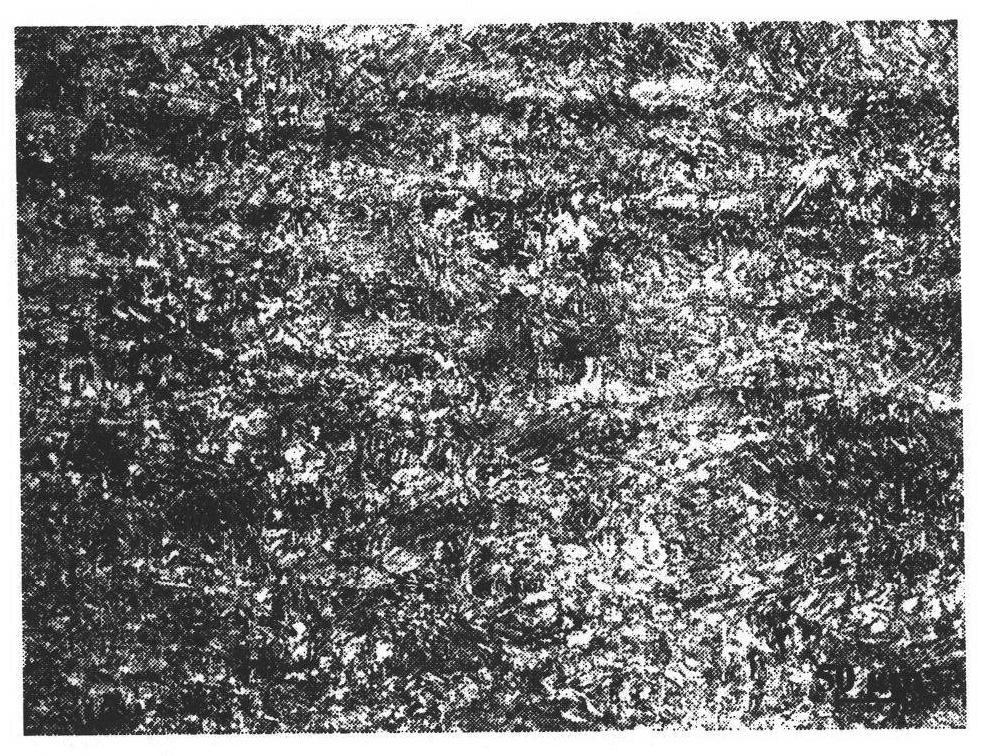

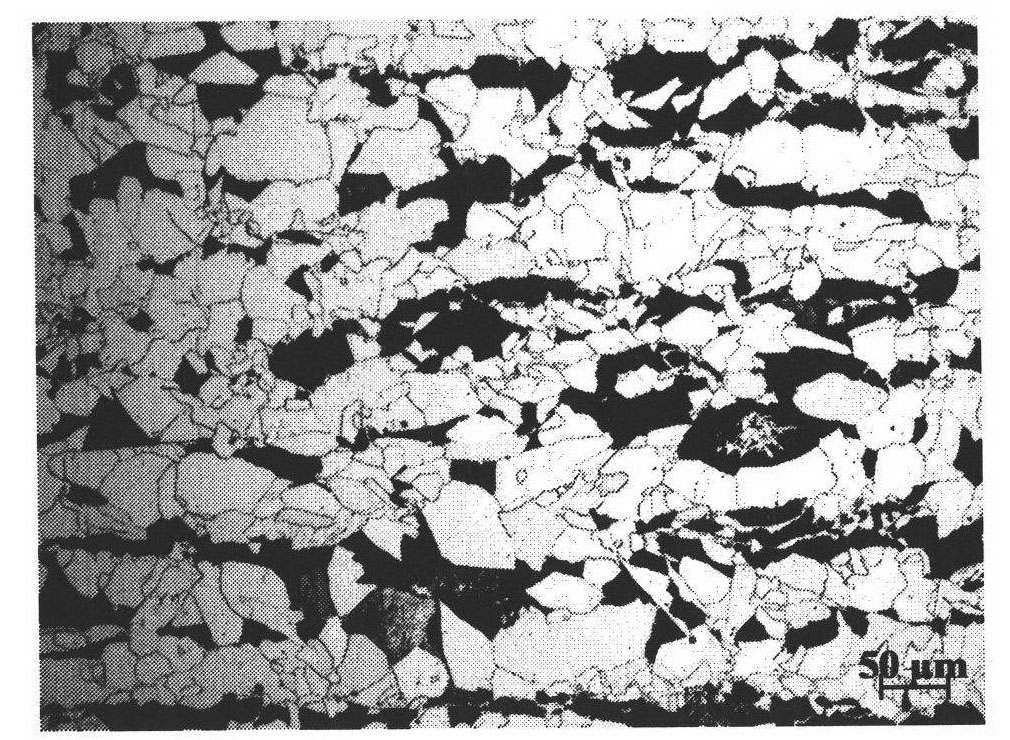

A kind of high plasticity high tenacity super high strength steel plate and its production method

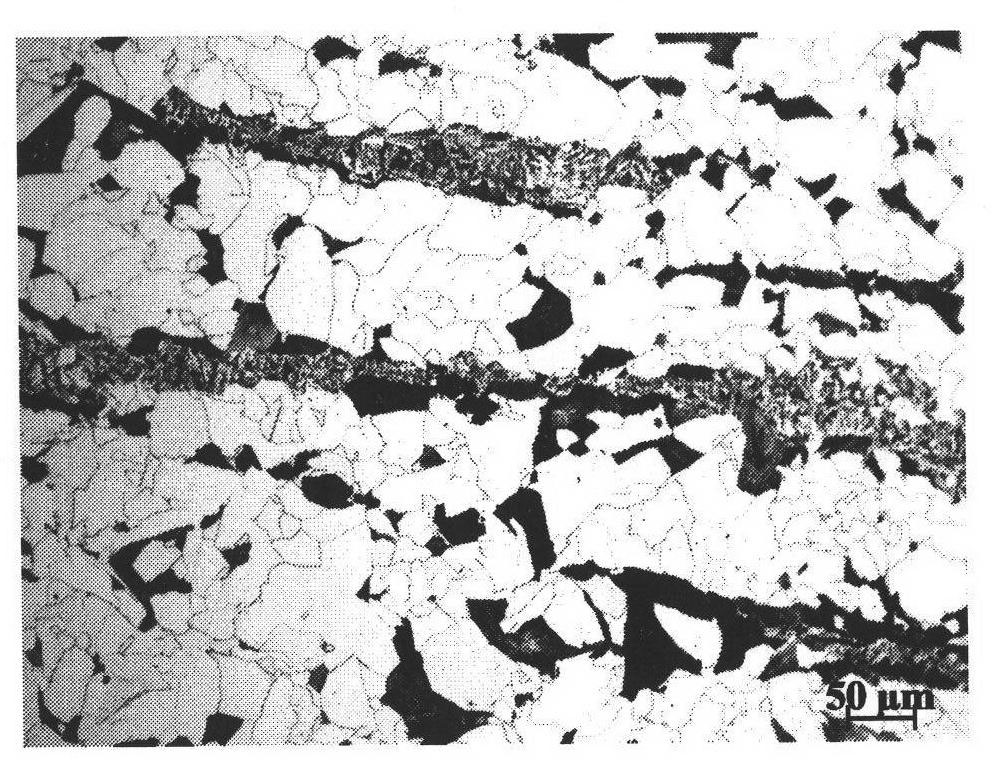

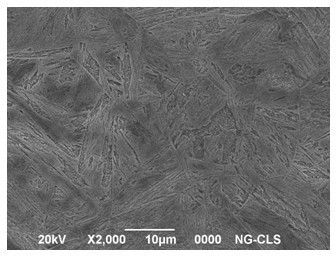

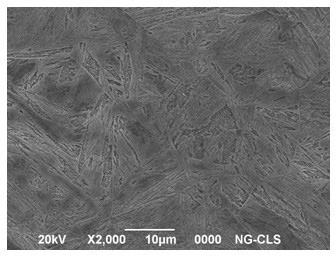

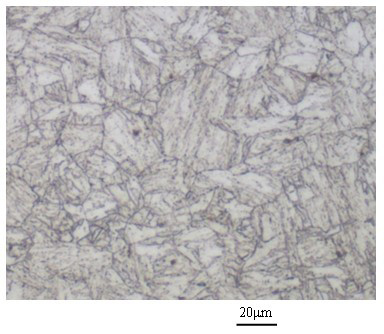

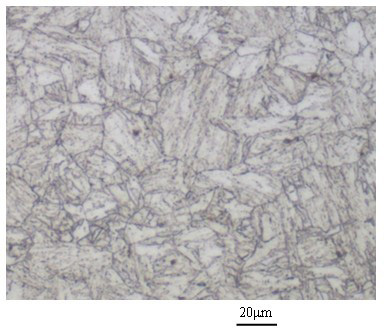

InactiveCN102286695AUniform tissueFully exert the strengthening effectTemperature control deviceHeat treatment process controlTemperingImpurity

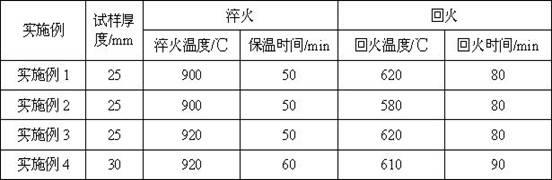

The invention discloses a high-plasticity, high-toughness, ultra-high-strength steel plate and a manufacturing method thereof. The chemical composition of the high-strength steel plate is calculated by weight percentage, C: 0.14-0.18%, Si: 0.10-0.30%, Mn: 0.80-1.30%, P : ≤0.015%, S: ≤0.005%, Nb: 0.010~0.050%, Ti: 0.006~0.020%, V: 0.020~0.060%, Cr: 0.30~0.60%, Mo: 0.20~0.80%, the balance is Fe and unavoidable impurities. Manufacturing method: Smelting in a converter. Through the TMCP process, followed by quenching and tempering treatment. The microstructure of the high ductility, high toughness and ultra-high strength steel plate obtained is tempered sorbite, the lamellar spacing is fine, and the original austenite grains are uniform and fine. It has the characteristics of stable production process, strong operability, low cost and high performance.

Owner:NANJING IRON & STEEL CO LTD

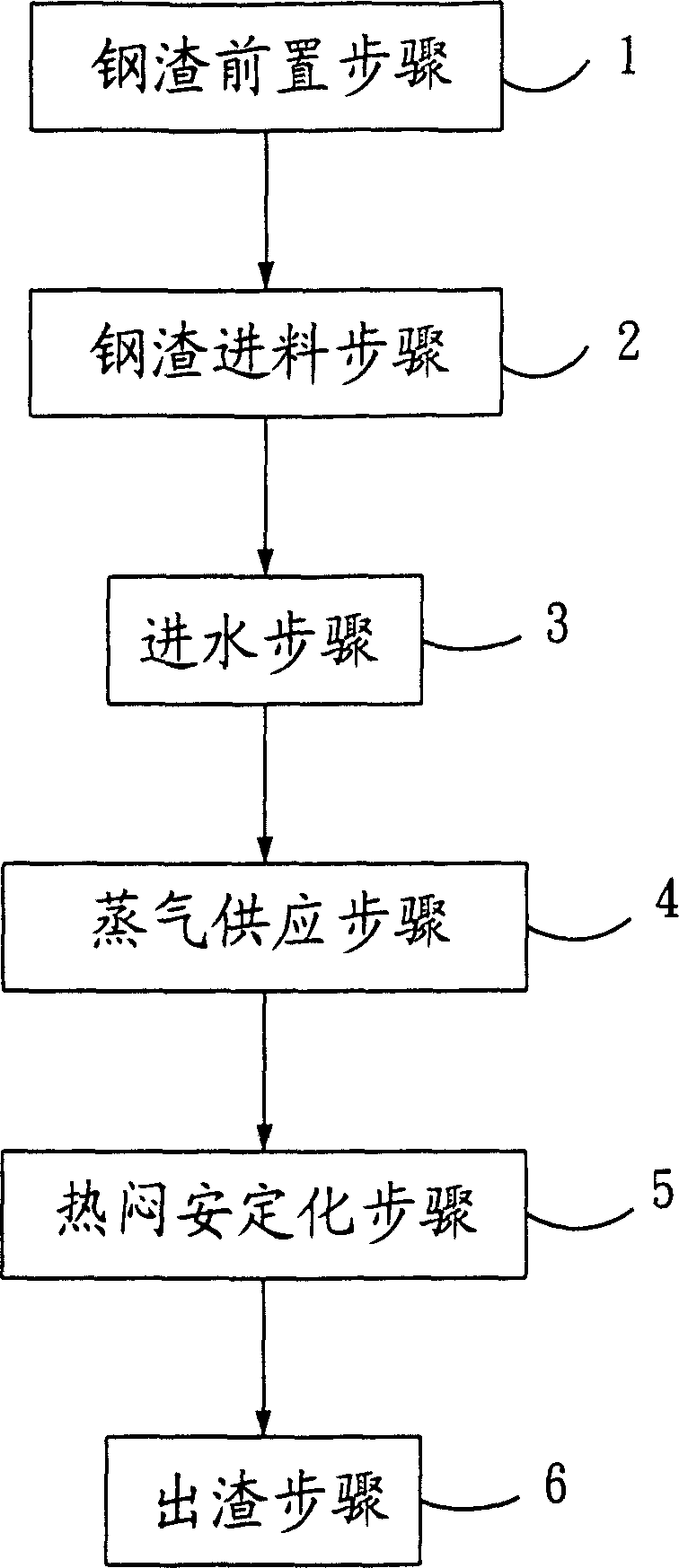

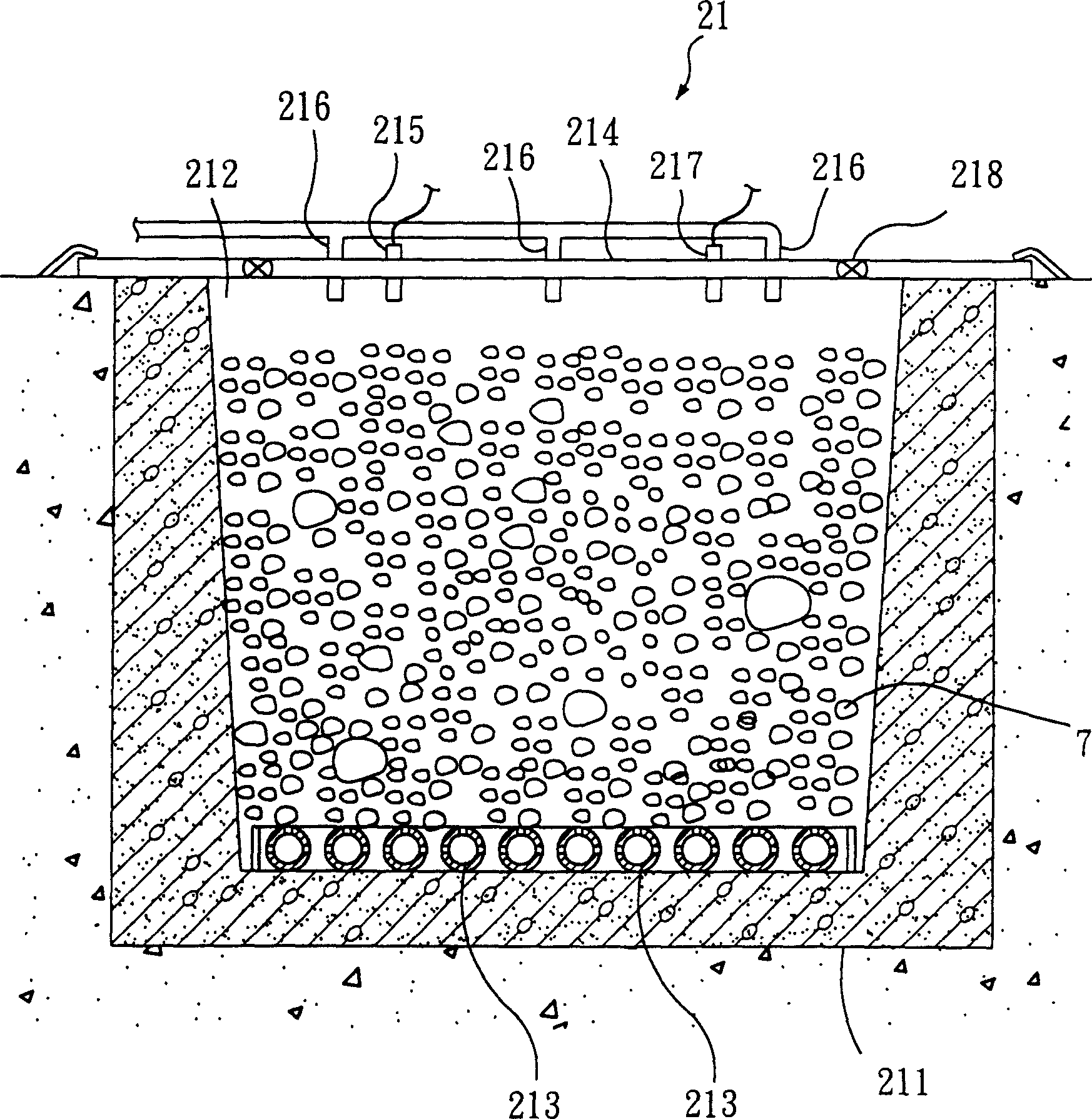

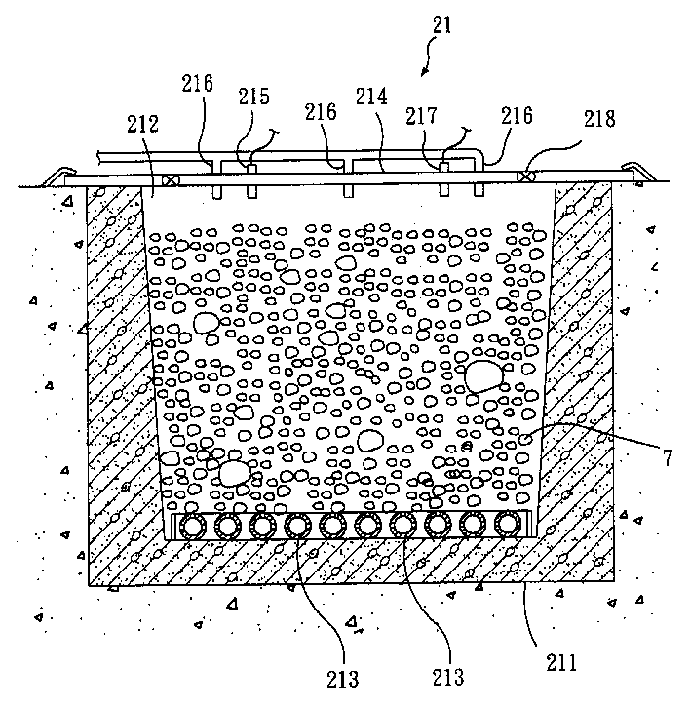

Slag thermal-sealed vapour maintenance treating method

InactiveCN1508268AThe pre-processing process is simpleSimple pre-workRecycling and recovery technologiesSlagWater spray

The invention is a slag heat-covering steam-preserving processing method, including the steps: preposing slag, feeding slag, feeding water, supplying steam, heat-covering stabilizing and flush practice. It directly places blocky slag in a heat-covering set, with the aid of water spray to crack the slag and associated with heat preservation by heat-covering and steam supplication and supplement, maintains the slag temperature within the set temperature of 100 deg.C-200 deg.C to provide enough stabilizing temperature, to make dissociative calcium oxide in the slag able to quickly hydrolyze into calcium oxide, and finally achieves the purpose to stabilize and crush.

Owner:CHINA HI-MENT CORP

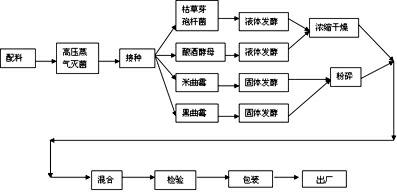

A straw decomposing agent and its production method

The invention relates to a straw decomposing agent produced from raw materials of bacteria and fungi, and a production method thereof. Bacillus subtilis, saccharomyces cerevisiae, Aspergillus oryzae and aspergillus niger are assembled as composite bacteria and are individually cultured through steps of preparation of medium, control of an inoculation amount, a fermentation temperature and a fermentation time, and adjusting of a PH value parameter, concentration and drying. The bacteria are blended and proportioned to prepare into a decomposing agent capable of returning crop straws into field on the spot. The decomposing agent has advantages of strong pertinence, good decomposing effect and stable quality and performance.

Owner:湖北金禾圣生物科技有限公司

Production method for as-cast high-performance ductile iron QT600-10 by precision-investment casting

ActiveCN105861917ALightweight design and developmentLightweight productivityFoundry mouldsFoundry coresInvestment castingDuctile iron

The invention provides a production method for as-cast high-performance ductile iron QT600-10 by precision-investment casting, wherein a matrix of the as-cast high-performance ductile iron QT600-10 is a mixture of ferrite and pearlite; the pearlite accounts for 35%-55%, the nodulizing grade ranges from grade I to grade II, and the size of graphite ranges from grade VI to grade VII; the material comprises the following final chemical components in percentage by mass: 3.3-3.6% of C, 2.8-3.0% of Si, 0.2-0.4% of Mn, less than or equal to 0.035% of P, less than or equal to 0.02% of S, 0.4-0.6% of Cu, 0.035-0.055% of Mg, 0.02-0.04% of RE and the balance Fe; and a dam type nodulizing treatment and three-time inoculation way is adopted. The produced as-cast high-performance ductile iron QT600-10 has tensile strength Rm greater than or equal to 600 MPa, and elongation after fracture A greater than or equal to 10%. By combining a precision-investment casting production way with a cooling way after shell casting, high-strength high-toughness ductile iron is produced by a precision-investment casting process, so that lightweight design development and production for car parts is realized by virtue of a near net-shape forming process.

Owner:DONGFENG PRECISION CASTING CO LTD

Low-compression ratio super-strength steel plate for ocean engineering and manufacturing method thereof

InactiveCN102691018AHigh strengthImprove plasticityHeat treatment process controlSolderabilityUltimate tensile strength

The invention discloses a low-compression ratio super-strength steel plate for ocean engineering and a manufacturing method thereof. The super-strength steel plate for ocean engineering comprises the following chemical components in percentage by weight: 0.04-0.07% of C, 0.10-0.30% of Si, 1.60-1.80% of Mn, less than or equal to 0.010% of P, less than or equal to 0.0080% of S, 0.030-0.050% of Nb, 0.020-0.060% of V, 0.006-0.015% of Ti, 0.90-1.30% of Ni, 0.30-0.60% of Cr, 0.20-0.40% of Cu, 0.40-0.60% of Mo, and the balance of Fe and inevitable impurities. The laboratory smelting, trial rolling on a rolling mill, TMCP (thermal mechanical control processing) technology and thermal refining are sequentially performed, thus the super strength, high toughness, weldability and manufacturability of the super-strength steel plate for ocean engineering are realized.

Owner:NANJING IRON & STEEL CO LTD

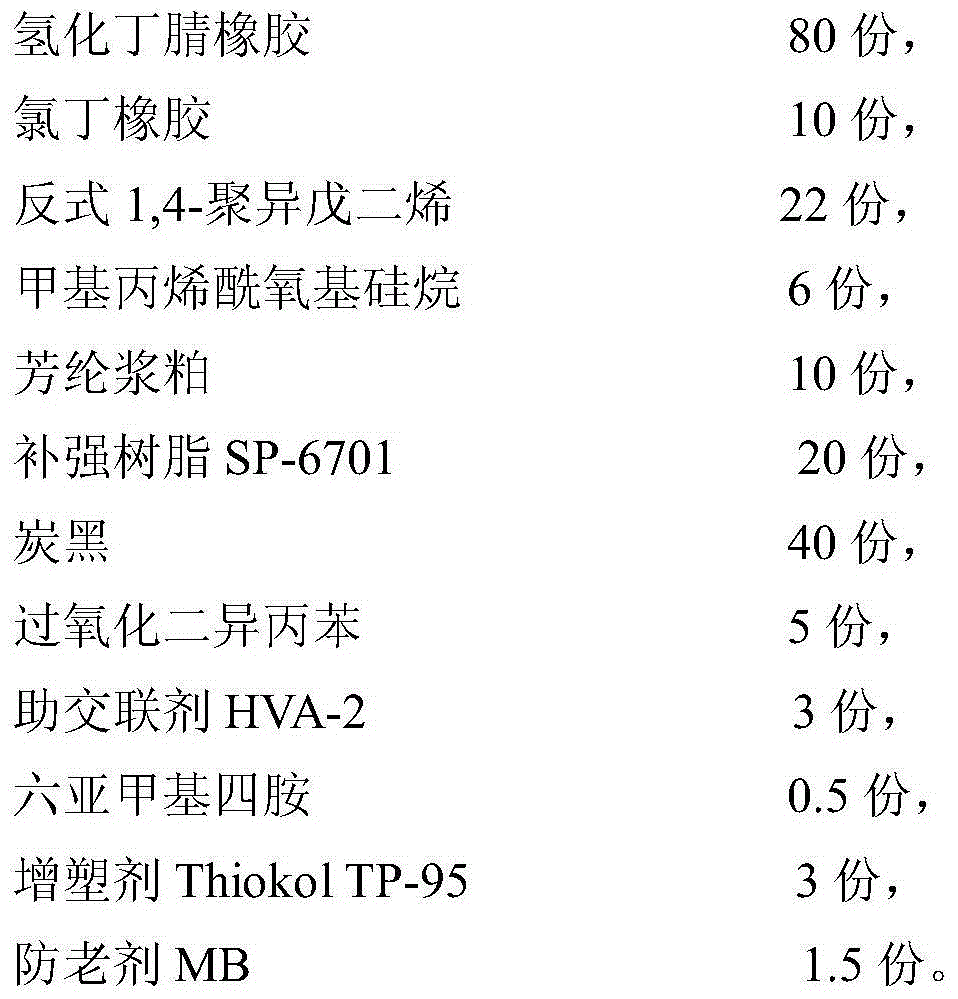

High-strength synchronous belt and manufacturing method thereof

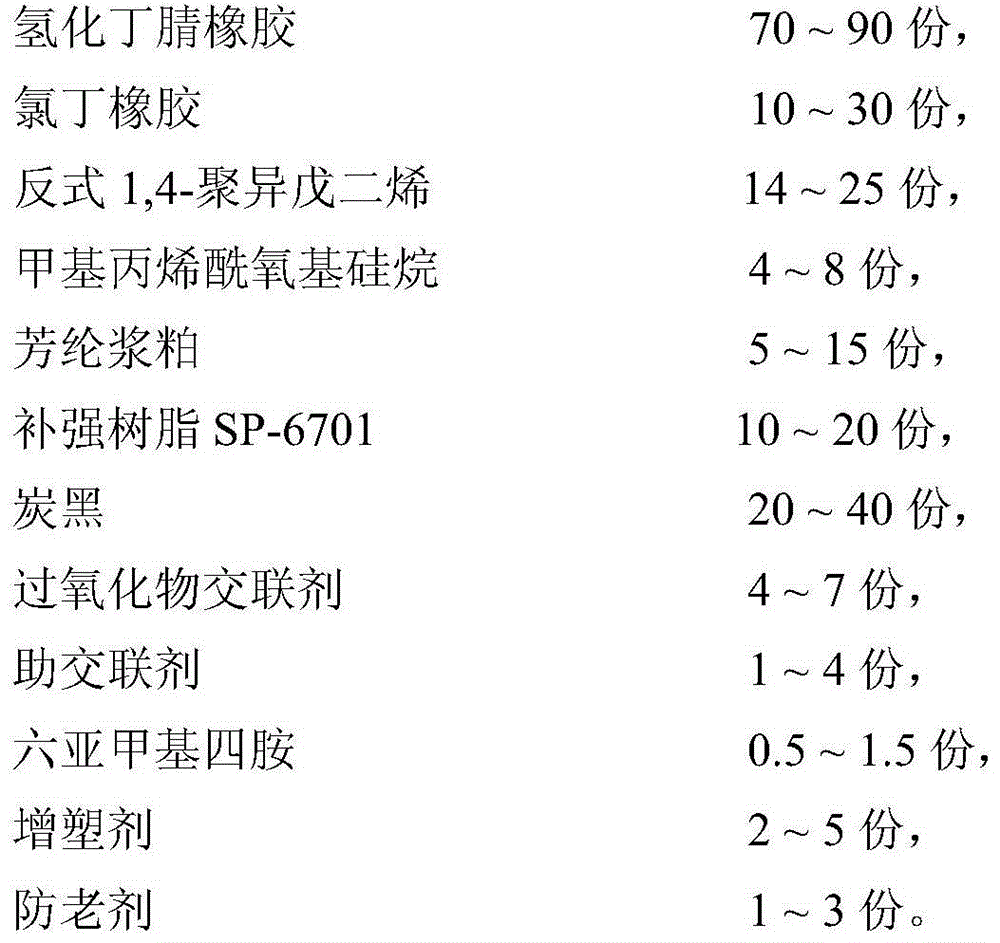

ActiveCN104675922AGood wear resistanceImprove heat resistanceDriving beltsMonocomponent synthetic polymer artificial filamentCarbon blackPlasticizer

The invention relates to a high-strength synchronous belt. The synchronous belt comprises a synchronous belt framework and an adhesive piece attached to the outer side of the synchronous belt frame. The adhesive piece comprises the following components in parts by weight: 70-90 parts of hydrogenated butadiene-acrylonitrile rubber, 10-30 parts of chloroprene rubber, 14-25 parts of trans 1, 4-polyisoprene, 4-8 parts of methylacryloyl silane, 5-15 parts of aramid pulp, 10-20 parts of reinforced fiber SP-6701, 20-40 parts of carbon black, 4-7 parts of peroxide crosslinking agent, 1-4 parts of assistant crosslinking agent, 0.5-1.5 parts of hexamine, 2-5 parts of plasticizer and 1-3 parts of antiaging agent. The invention also relates to a manufacturing method of the synchronous belt. According to the high-strength synchronous belt and the manufacturing method thereof, the hydrogenated butadiene-acrylonitrile rubber and the chloroprene rubber are used together, so that the performances of the hydrogenated butadiene-acrylonitrile rubber and the chloroprene rubber are complementary, and thus the wear resistance and the heat resistance of the adhesive piece of the synchronous belt can be effectively improved; the shear strength and the quality stability of the synchronous belt are improved by use of the trans 1, 4-polyisoprene, the methylacryloyl silane and the aramid pulp.

Owner:NINGBO FULONG SYNCHRONOUS BELT

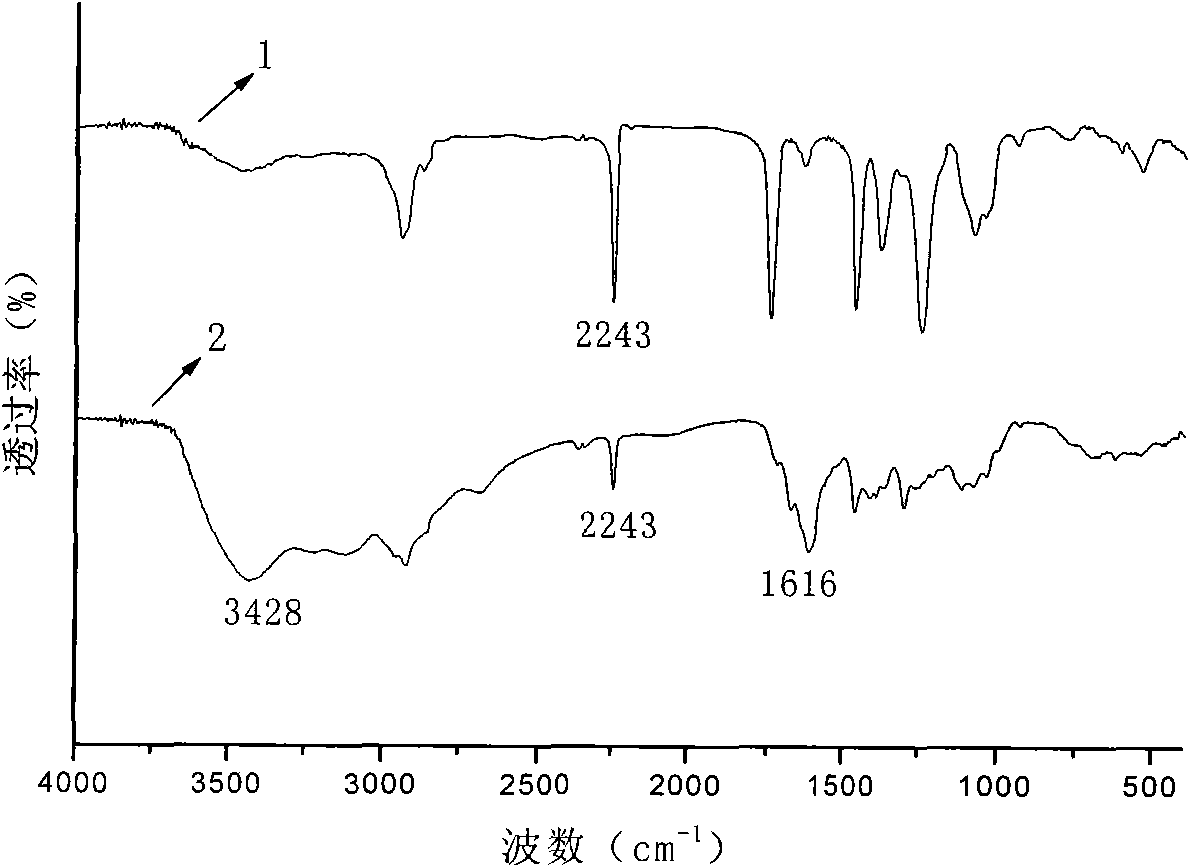

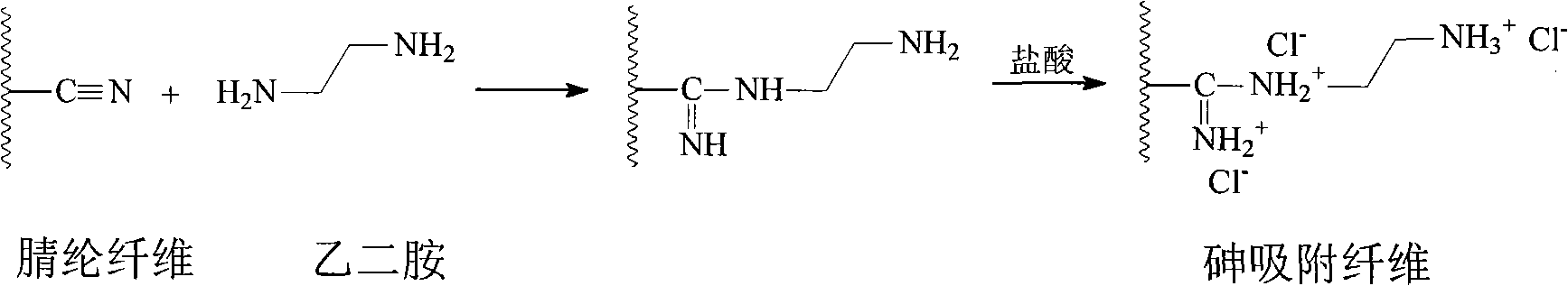

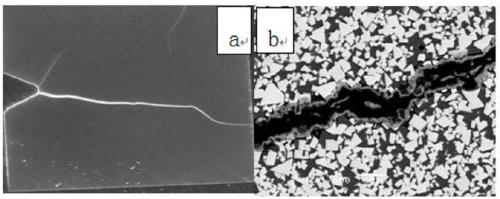

Arsenic adsorbing fiber and synthesizing method thereof

ActiveCN101569854ALarge specific surface areaSmall circulation resistanceOther chemical processesAlkali metal oxides/hydroxidesIon exchangeCarbon dioxide

The invention discloses an arsenic adsorbing fiber using acrylic fiber as a fundamental frame and a synthesizing method thereof, belonging to the technical field of polymer materials. In the structure of the fiber material, amido existing in a mode of hydrochloride is contained, and the amido can effectively adsorb arsenic radical in the water through an ion exchange reaction. The method for synthesizing the fiber is to lead the acrylic fiber to firstly perform a grafting reaction with a multi-amido compound to introduce amido, and the acrylic fiber reacts with the hydrochloric acid to transform the amido into the hydrochloride, and has simple reacting process and mild condition. The neutral fiber is stable in the air, cannot absorb carbon dioxide and other acid gases, and cannot affect the pH value of the water body when the arsenic adsorbing fiber is used in the water as an adsorbent.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

Smelting method of high-aluminum nitriding steel

ActiveCN105463299AReduce lossReduce exposed areaElectric furnaceProcess efficiency improvementAlloyHigh aluminum

The invention belongs to the technical field of alloy structural steel, and particularly relates to a manufacturing method of high-aluminum nitriding steel. The process route of EAF-CONVERTER smelting and LF+VD+CCM are adopted to smelt the high-aluminum nitriding steel, and according to the component requirement range of the obtained high-aluminum nitriding steel, the high-aluminum nitriding steel comprises 0.35% to 0.40% of C, 0.20% to 0.30% of Si, 0.40% to 0.50% of Mn, 1.40% to 1.50% of Cr, 0.15% to 0.25% of Mo, 0.75% to 1.00% of Al, not larger than 0.020% of P, not larger than 0.015% of S, and the balance Fe. Round steel obtained through rolling is even in steel texture, high in cleanness and stable in performance quality.

Owner:ZENITH STEEL GROUP CORP +1

Medicament for facilitating sleep and preparation method and application thereof

InactiveCN101991766AStable quality and performanceQuick resultsNervous disorderPlant ingredientsDrugKidney

The invention discloses a medicament for facilitating sleep and a preparation method thereof. The medicament comprises the following components in part by weight: 1,800 to 2,200 parts of spina date seed, 200 to 300 parts of tuber fleeceflower stem, 200 to 300 parts of silktree albizzia bark and 400 to 600 parts of lily. The activity of each component can be guaranteed to the largest degree by decocting and condensing the components at a low temperature. The formula of the medicament is unique and prepared according to a monarch medicament, a minister medicament, an assistant medicament and a guide medicament, and effectively takes effect on a disease source to nourish brain and calm the nerves, relieve convulsion and remove worry, restore normal coordination between heart and kidney, tonify spleen and stomach, nourish yin and clear away heat, sooth the liver and dispel melancholy, adjust internal organs of the body overall, keep the balance of yin and yang, and treat both the incidental and fundamental aspects.

Owner:STAR LAKE BIOSCI CO INC ZHAOQING GUANGDONG

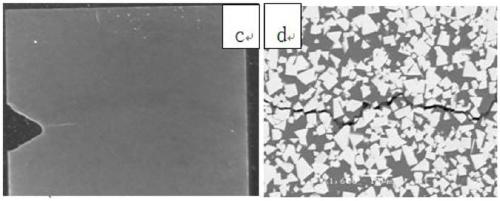

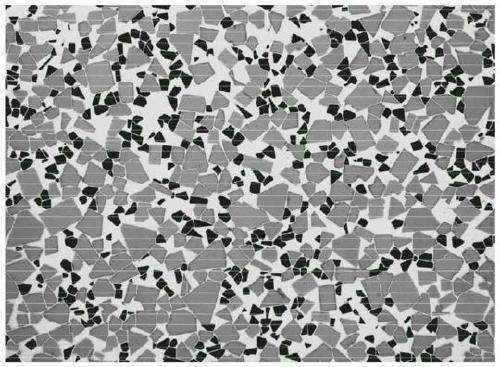

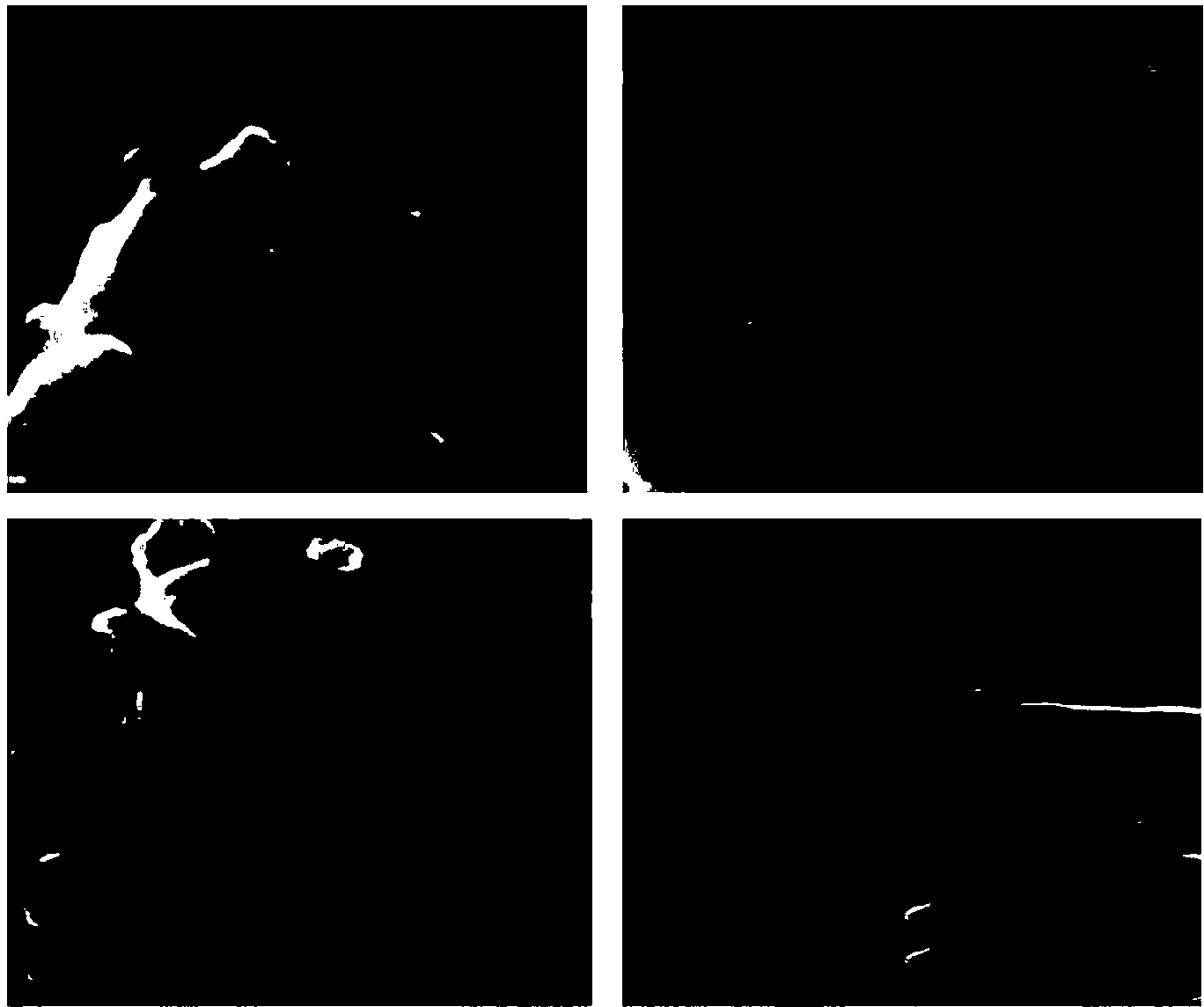

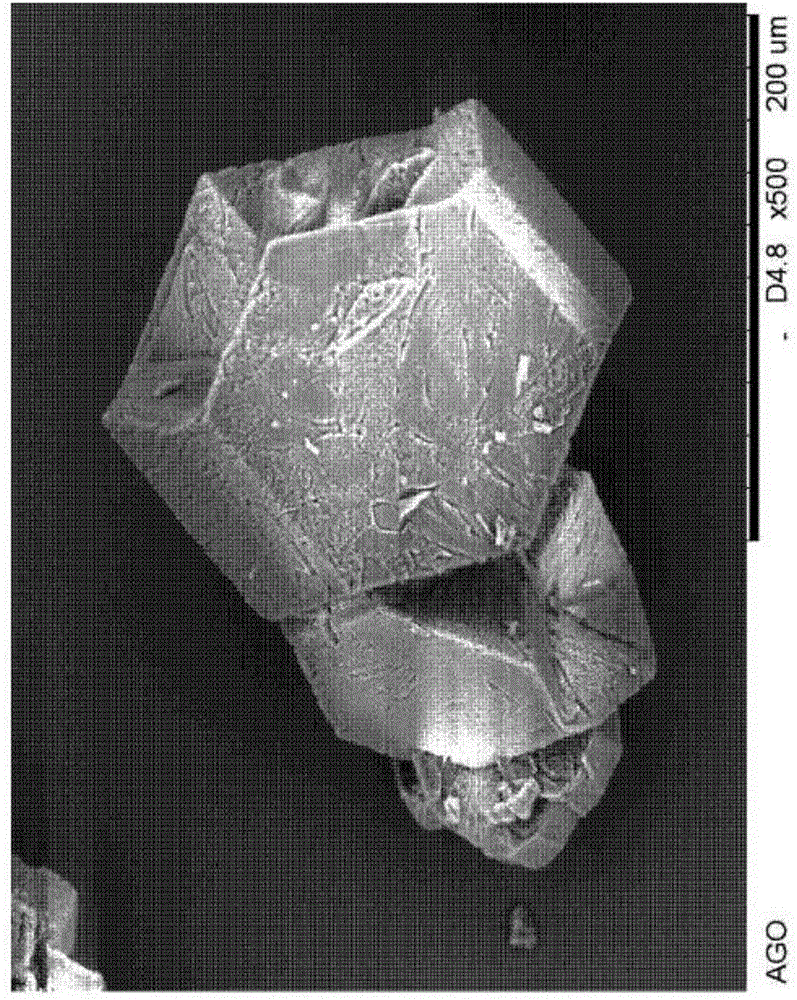

Hot cracking resistant mixed-crystal hard alloy and preparation method thereof

PendingCN109487142AThe average crystal diameter ratio is accurately controlledHigh strengthGranularityDiameter ratio

The invention discloses a hot cracking resistant mixed-crystal hard alloy and a preparation method thereof. The hot cracking resistant mixed-crystal hard alloy comprises a hard phase, a bonding phraseand optional temperature resistant components. The hard phase comprises coarse tungsten carbide (WC) and fine WC. The ratio of the average crystal diameter of the coarse WC to the average crystal diameter of the fine WC is (1.7: 2.1). The average grain size of the hard alloy is between 2.4 Mu m and 3.4 Mu m. According to the hot cracking resistant mixed-crystal hard alloy provided, control over the average crystal diameter ratio of of the coarse WC to the fine WC is accurate; intensity is high; rigidity is high; and the hot cracking resistant property is good. When the hard alloy is used in an environment of thermal mechanical corrosion fatigue, crack initiation is late; hot crack growth is slow; the hard alloy is especially suitable for rolling of threaded steel on a small profile rolling mill; blocks are not easy to drop; rolled steel is good in quality; and the service life is improved by more than 20%.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Preparation method of egg white peptide

ActiveCN102851342AReaction conditions are easy to controlStable quality and performanceFermentationProteinase activityCeramic membrane

The invention discloses a preparation method of egg white peptide. The method comprises steps of: (1) taking egg white, homogenizing and diluting to prepare an enzymolysis stock solution; (2) sending the enzymolysis stock solution circularly into a reactor fixed with protease for an enzymolysis reaction for 0.5-1 h; continuously feeding an enzymolysis solution into a ceramic membrane filter for filtering; and returning a concentrated solution to the reactor for continuous enzymolysis; and (3) collecting a filtrate, and conducting spray drying to obtain an egg white peptide powder. The method provided by the invention can be conducted continuously, and has advantages of easily controllable reaction conditions, stable quality and performance of a final product, simple equipment, small amount of enzyme, low cost and easy popularization.

Owner:浙江艾格生物科技股份有限公司

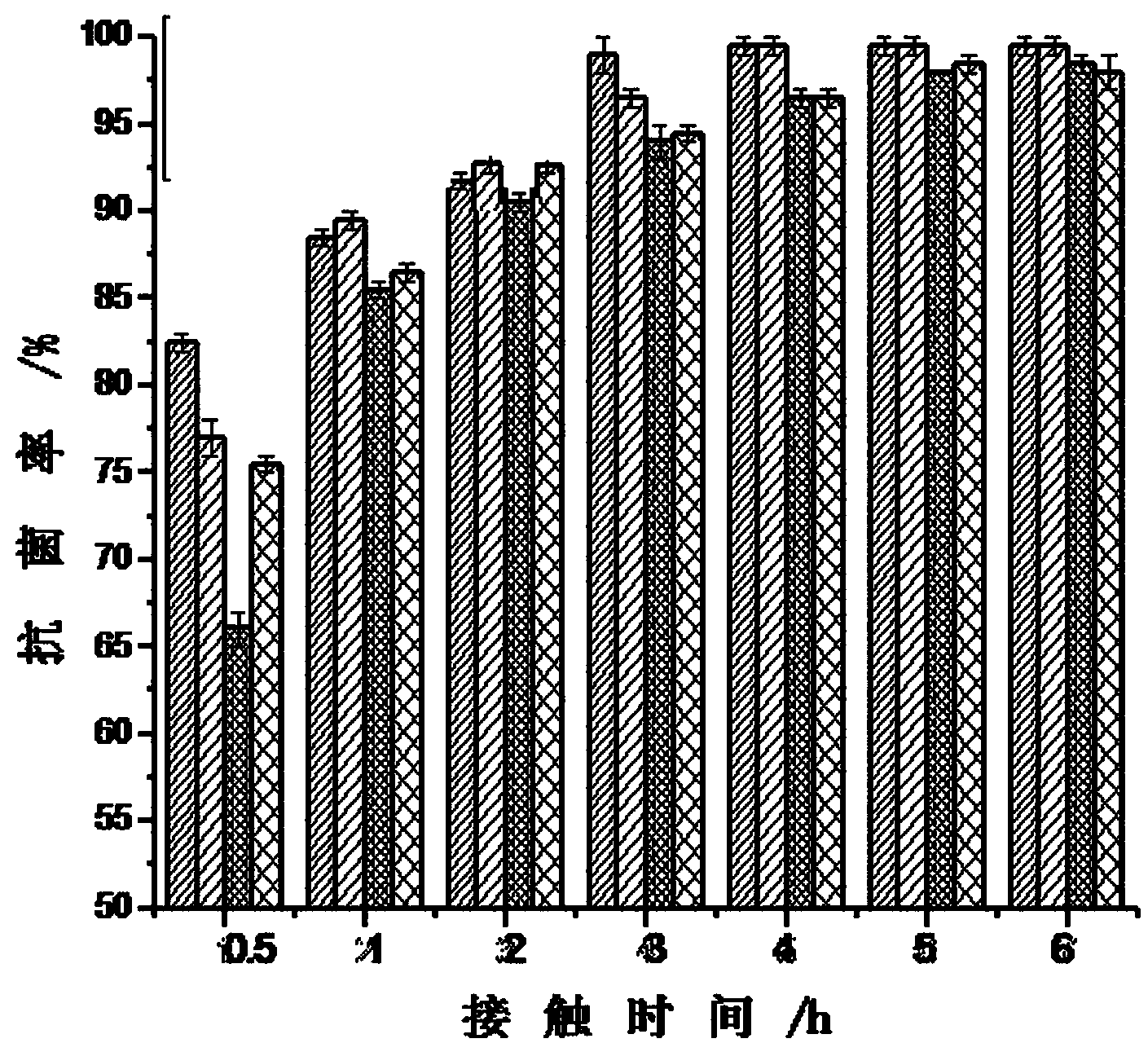

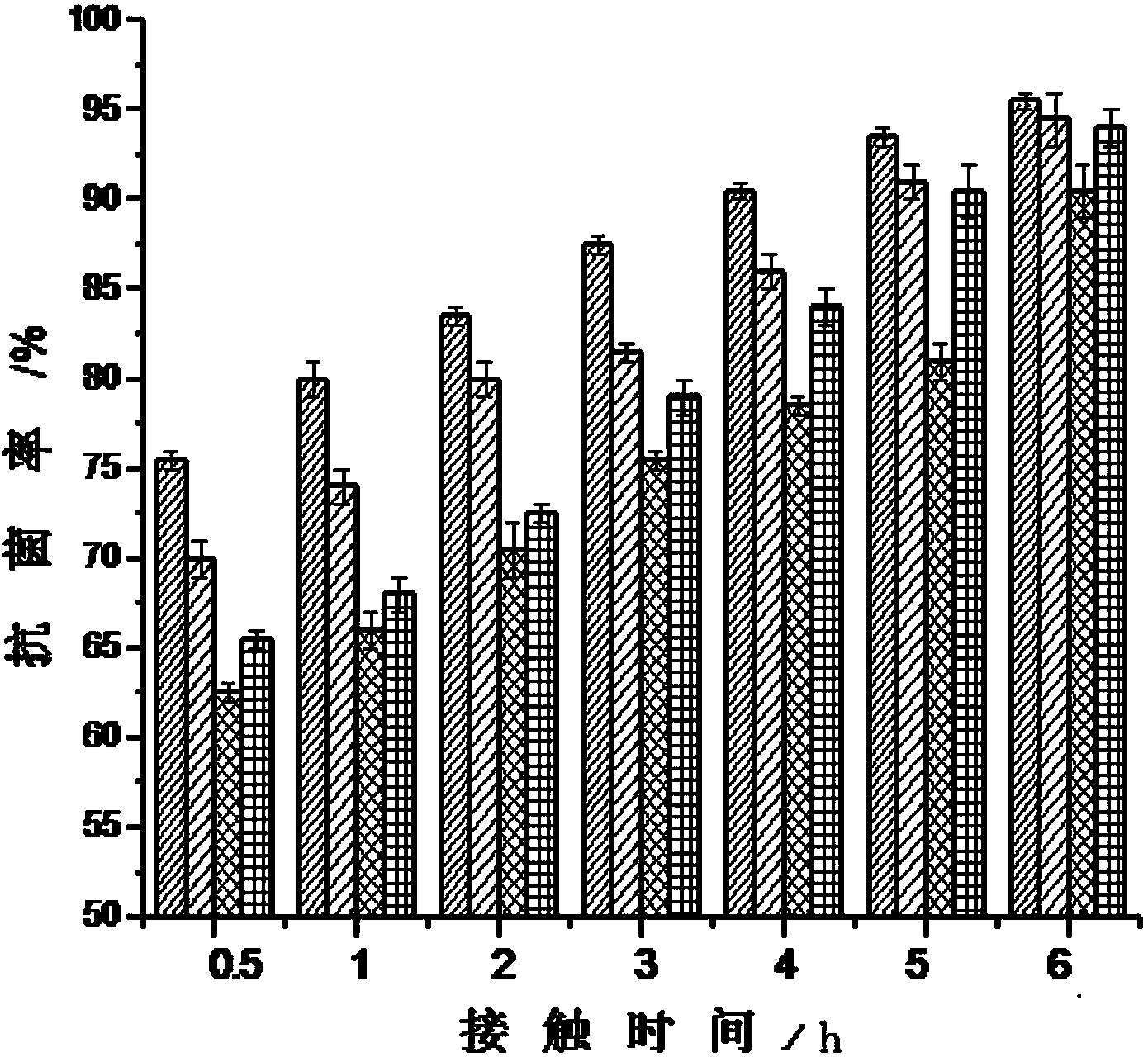

Silver-carried cotton fabric antibacterial material and preparation method thereof

The invention discloses a sliver-carried antibacterial material which takes pure cotton cloth and cotton blended cloth such as brocade cotton, polyester cotton and cotton polyester in cotton fabrics as a basal body and a preparation method thereof, and belongs to the technical field of functional high polymer materials. Silver is uniformly distributed in fiber skeletons of the antibacterial cotton fabrics. The preparation method of the sliver-carried cotton fabric comprises the following steps: applying a nonionic surfactant to treat pure cotton cloth, the brocade cotton, the polyester cotton and the cotton polyester in the cotton fabrics, soaking in silver ammonia liquor, and applying a reducing agent to reduce after heating reaction is ended, so that the sliver is uniformly distributed in the fiber skeletons of the antibacterial cotton fabrics. The preparation method is simple and easy to control, gentle in reaction condition, short in time consumption, low in energy consumption, low-carbon and environment-friendly, and the applied reaction agent is low in toxicity and environment-friendly. After being carried with sliver, the silver-carried cotton fabrics can well resist escherichia coli and staphylococcus aureus.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

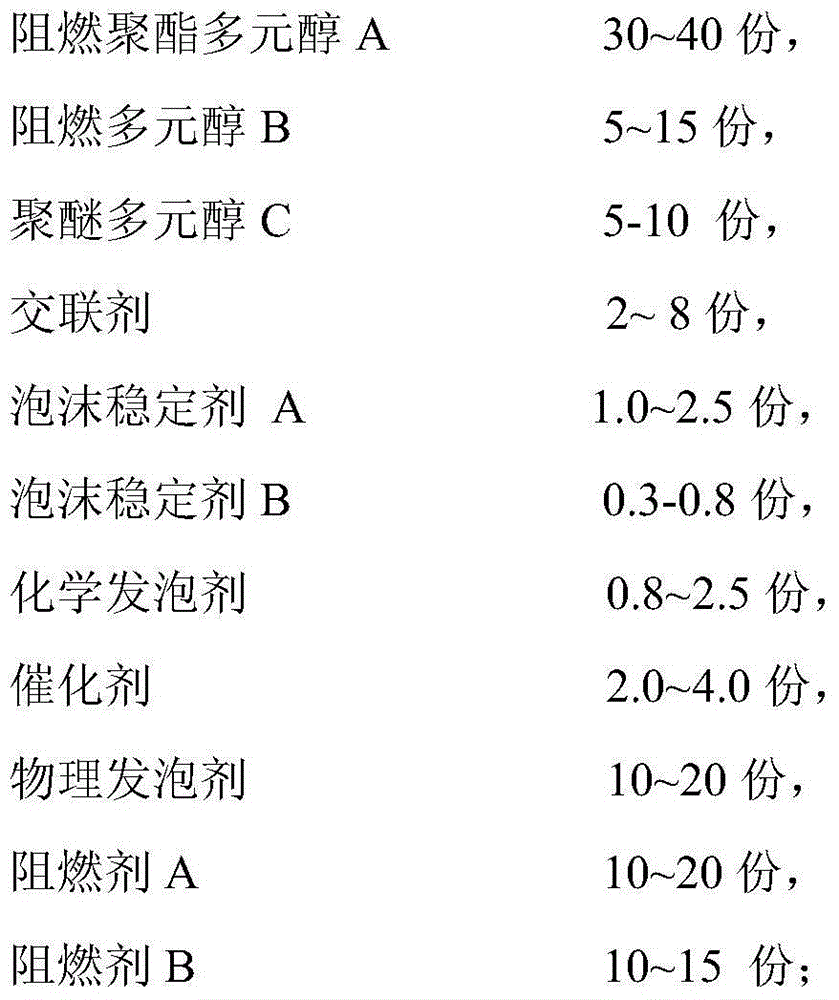

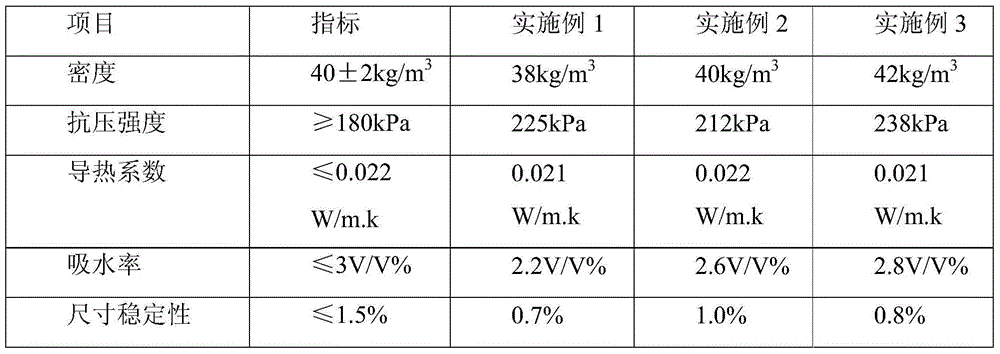

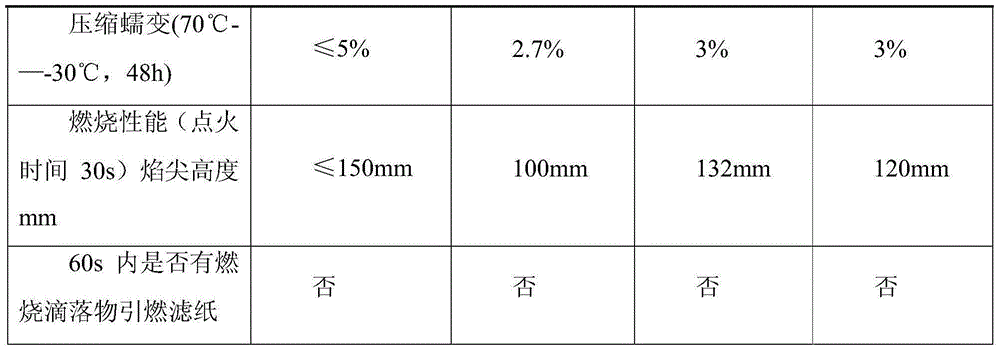

Combined polyether for flame-retardant bulk rigid polyurethane foams and application method of combined polyether

The invention relates to combined polyether for flame-retardant bulk rigid polyurethane foams and an application method of the combined polyether and belongs to the technical field of the combined polyether. The combined polyether for the flame-retardant bulk rigid polyurethane foams is prepared from the following components including flame-retardant polyester polyol A, flame-retardant polyester polyol B, flame-retardant polyester polyol C, a crosslinking agent, a foam stabilizer A, a foam stabilizer B, a chemical foaming agent, a catalyst, a physical foaming agent, a flame retardant A and a flame retardant B. The combined polyether for the flame-retardant bulk rigid polyurethane foams is wide in raw material source and is low in cost. With the adoption of the combined polyether, the flame-retardant bulk rigid polyurethane foams prepared by the combined polyether are good in flame retardancy, low in thermal conductivity, good in airtightness and stable in quality performance. The invention also provides the application method of the combined polyether for the flame-retardant bulk rigid polyurethane foams. The application method is simple in process, is easily operated, is low in volatilization and is high in production efficiency without three wastes.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Tensioning and anchoring device of prestressed CFRP plate reinforced beam and use method thereof

ActiveCN111749492ALimited retractionGive full play to high-strength performanceBuilding repairsMaterial strength using tensile/compressive forcesStructural engineering

The invention discloses a tensioning and anchoring device of a prestressed CFRP plate reinforced beam and a use method thereof. The device comprise a CFRP plate, an anchoring assembly and a tensioningassembly; the tensioning assembly comprises tensioning sliding chambers, a second clamp, a fixed plate and a tensioning mechanism; and the contact surfaces of a telescopic plate and the second clampare provided with sawteeth facing oppositely. According to the device and the method, two groups of clamps fixedly clamped at two ends of the CFRP plate are installed in two groups of sliding chambersto apply the prestress, so that the eccentric tension can be prevented, the self-locking of the CFRP plate after the prestress is applied is realized through the mutual matching of the sawteeth between the telescopic plate and the second clamp, and the retraction of the CFRP plate is limited. The CFRP plate is mechanically clamped through the clamps, the anchoring efficiency is high, the qualityperformance is stable, and the high-strength performance of the CFRP plate can be fully exerted. After the prestress is applied, a jack can be dismantled, the design is integrated, the operation process is simple and convenient, and the working efficiency is improved.

Owner:BEIBU GULF UNIV

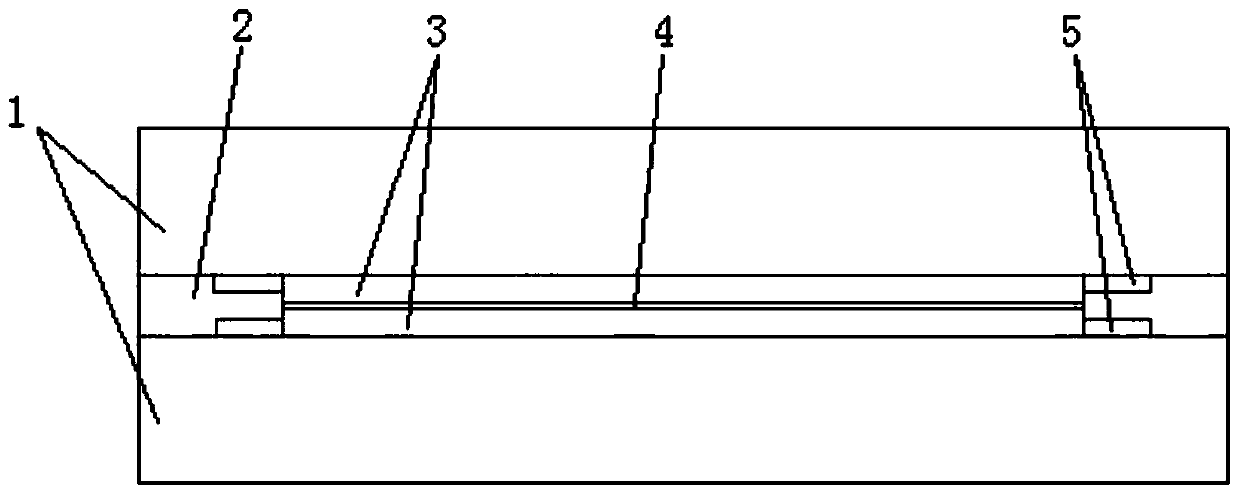

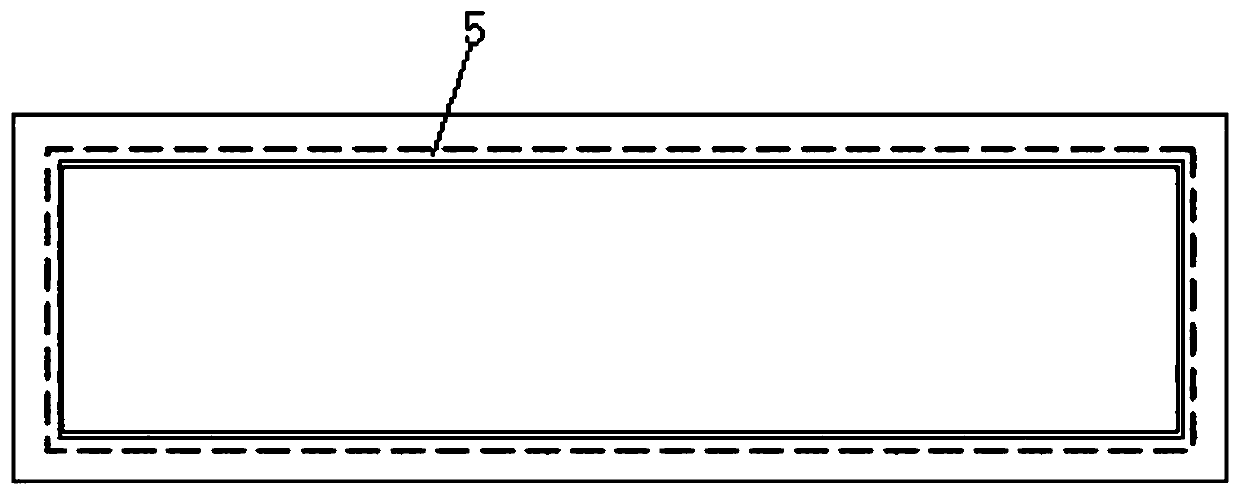

Production method for making hot stamping RFID electronic label

InactiveCN107247987ASimple structureShort processing cycleDuplicating/marking methodsCo-operative working arrangementsProduction lineHot stamping

The invention belongs to the information technology field and particularly relates to a production method for making a hot stamping RFID electronic label. An antenna is compounded on a PET layer, binding with a chip is carried out, a hot melt adhesive film is then compounded or coated, and the hot stamping label is acquired; die cutting of the hot stamping label is carried out, a knife edge of a die cutting cutter is provided with die cutting connection points, after die cutting, the connection points are distributed at periphery of the hot stamping label with intervals, and the label is connected with the PET layer through the connection points; on a label hot stamping machine, hot stamping of the hot stamping label onto a target object surface is carried out through a hot stamping head, under the action of a cooling device, cooling of a hot stamping adhesive film is realized, the PET film layer is pulled through a coiling shaft, the label is disconnected at the connection points, the label is marked on the target object surface, residual materials are removed, and making the hot stamping RFID electronic label is accomplished. The method is advantaged in that the RFID intelligent electronic label can be pasted to the target object surface in a hot stamping mode based on the PET film, the label PET has antennas at one surface or two surfaces, performance and quality are stable, and packaging production line large-scale application is facilitated.

Owner:孙涵

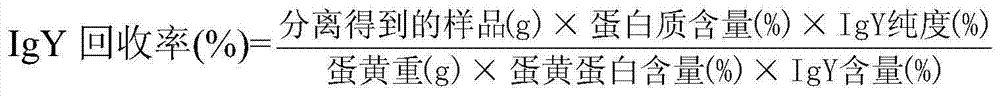

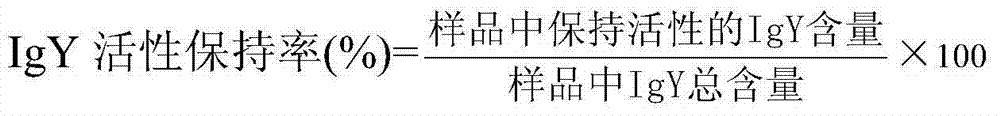

Preparation method of yolk globulin powder

InactiveCN104327184AReaction conditions are easy to controlStable quality and performanceEgg immunoglobulinsPeptide preparation methodsYolkDesalination

The invention discloses a preparation method of a yolk globulin powder. The preparation method includes following steps: (1) dissolving yolk in deionized water, stirring the yolk and performing precipitation to extract a raw liquid; (2) performing salting-out precipitation to the raw liquid for removing residual fat, precipitating protein and adding water for reducing the protein, and performing plate-frame filtration to remove impurities for obtaining a clear liquid; (3) purifying the clear liquid through membrane separation for desalination and dehydration; and (4) performing micro-filtration for sterilization, and performing low-temperature spray drying to obtain the yolk globulin powder. The method can be carried out continuously. A production process is easy to control. A finally product is stable in quality and performance, is low in cost, can achieve industrial production and is easy to popularize.

Owner:浙江艾格生物科技股份有限公司

Medicine composition of damp itch lotion and preparation method of medicine composition

ActiveCN102688327ASignificant effectLow costDermatological disorderPlant ingredientsMedicinal herbsDisease

The invention provides a medicine composition of a damp itch lotion and a preparation method of the medicine composition. The medicine composition is mainly prepared from 3-15 parts of radix sophorae flavescentis, 2-10 parts of fineleaf schizonepeta herb, 2-10 parts of divaricate saposhnikovia root, 2-12 parts of phellodendron amurense, 2-10 parts of mentha haplocalyx, 2-10 parts of selinum japenious seed, 2-12 parts of shaggy-fruited dittany root bark, 3-15 parts of syringa lobata lindl leaves, 3-15 parts of broom cypress fruit, 0.2-1 part of polyethylene glycol-400, 2-10 parts of glycerol and 2-12 parts of alcohol. The medicine composition comprises nine Chinese medicinal herbs, has effects of clearing away heat and toxic materials, dispelling wind and eliminating dampness, and killing parasites to relieve itching, and is prepared into the lotion for preventing and treating diseases such as pruritus vulvae, trichomonad vaginitis, mycotic vaginitis, senile vaginitis and vulvareczema.

Owner:HARBIN PHARM GROUP SANJING PHARMACEUTICAL CO LTD

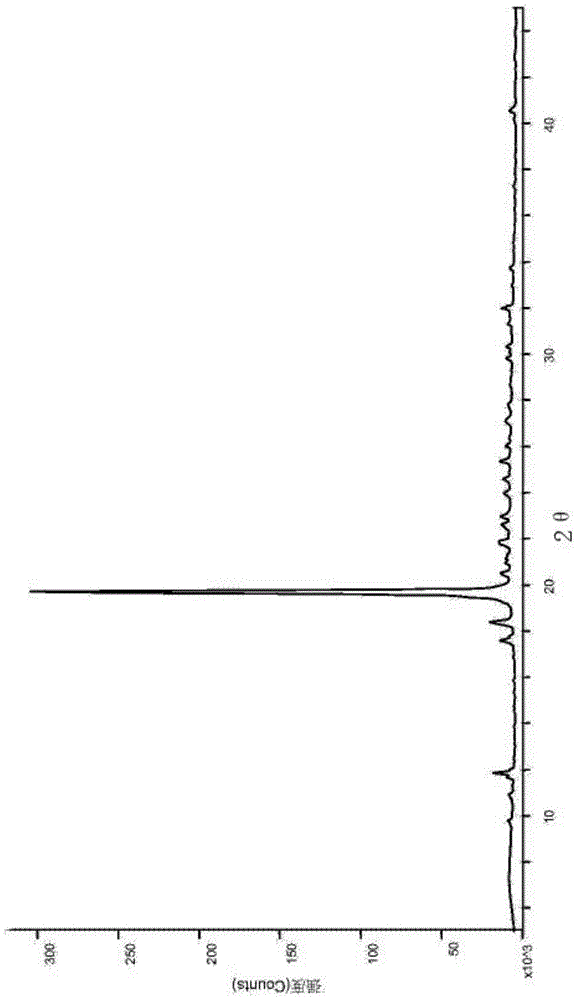

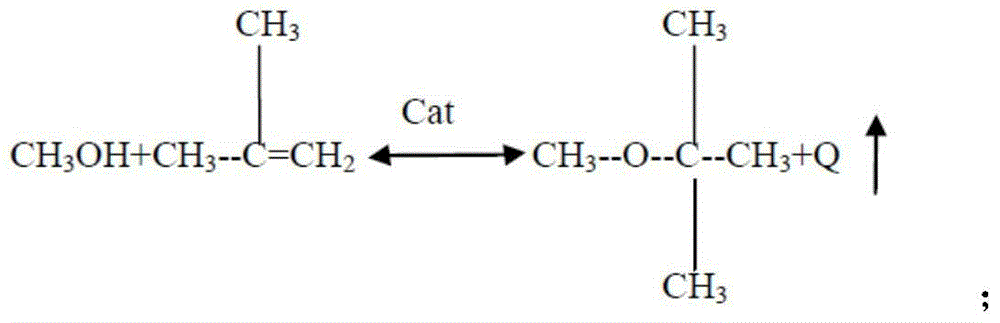

Synthesis method for petrochemical methyl tertiary butyl ether

ActiveCN104926619AHigh transparencyGood film formingOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsAlcoholSynthesis methods

The invention relates to a synthesis method for petrochemical methyl tertiary butyl ether, and belongs to the technical field of petrochemical engineering. According to the synthesis method, a raw material isobutene component delivered from an upstream installation and methyl alcohol delivered from an off-site tank field after being pressurized through a methyl alcohol feed pump are mixed in an isobutene-methyl alcohol mixer, and etherification reaction is performed further under the action of a catalyst to synthetize the methyl tertiary butyl ether. By adopting the method, the percent conversion of the isobutene reaches up to 99.8 percent; moreover, the used catalyst can be recycled; the obtained product is stable in quality, good in selectivity, and is suitable for industrial production.

Owner:SHIJIAZHUANG DINGYING CHEM ENG

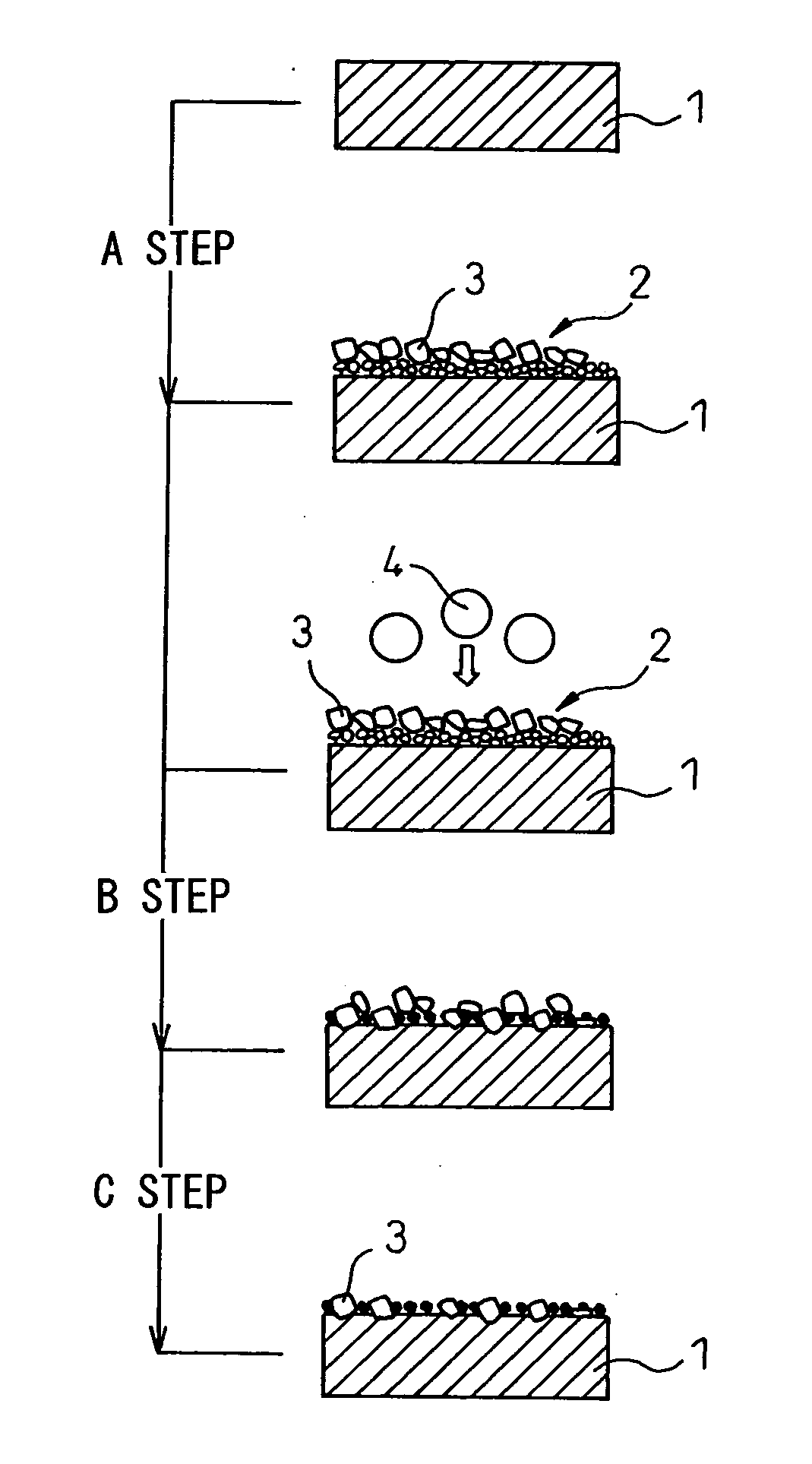

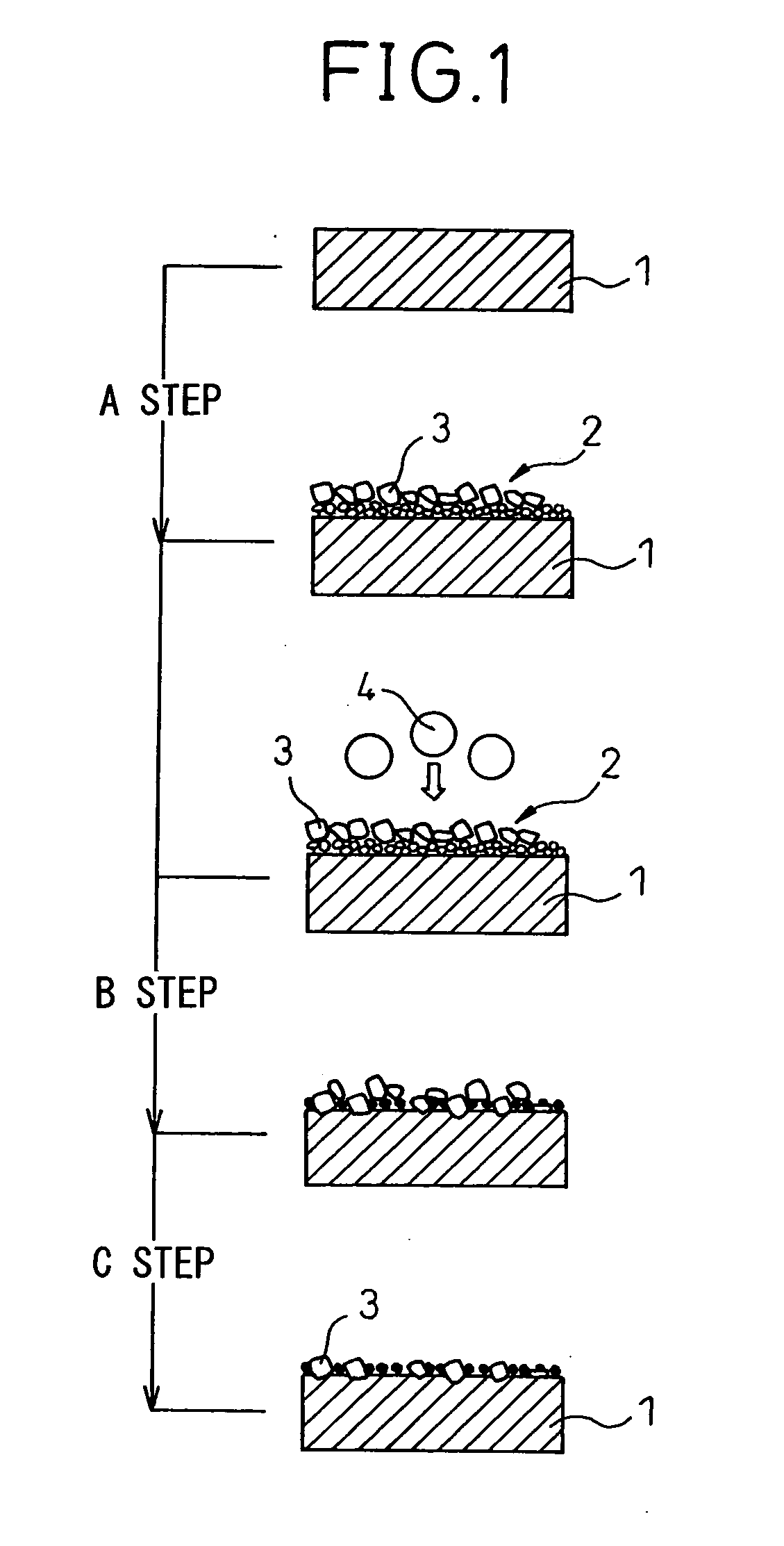

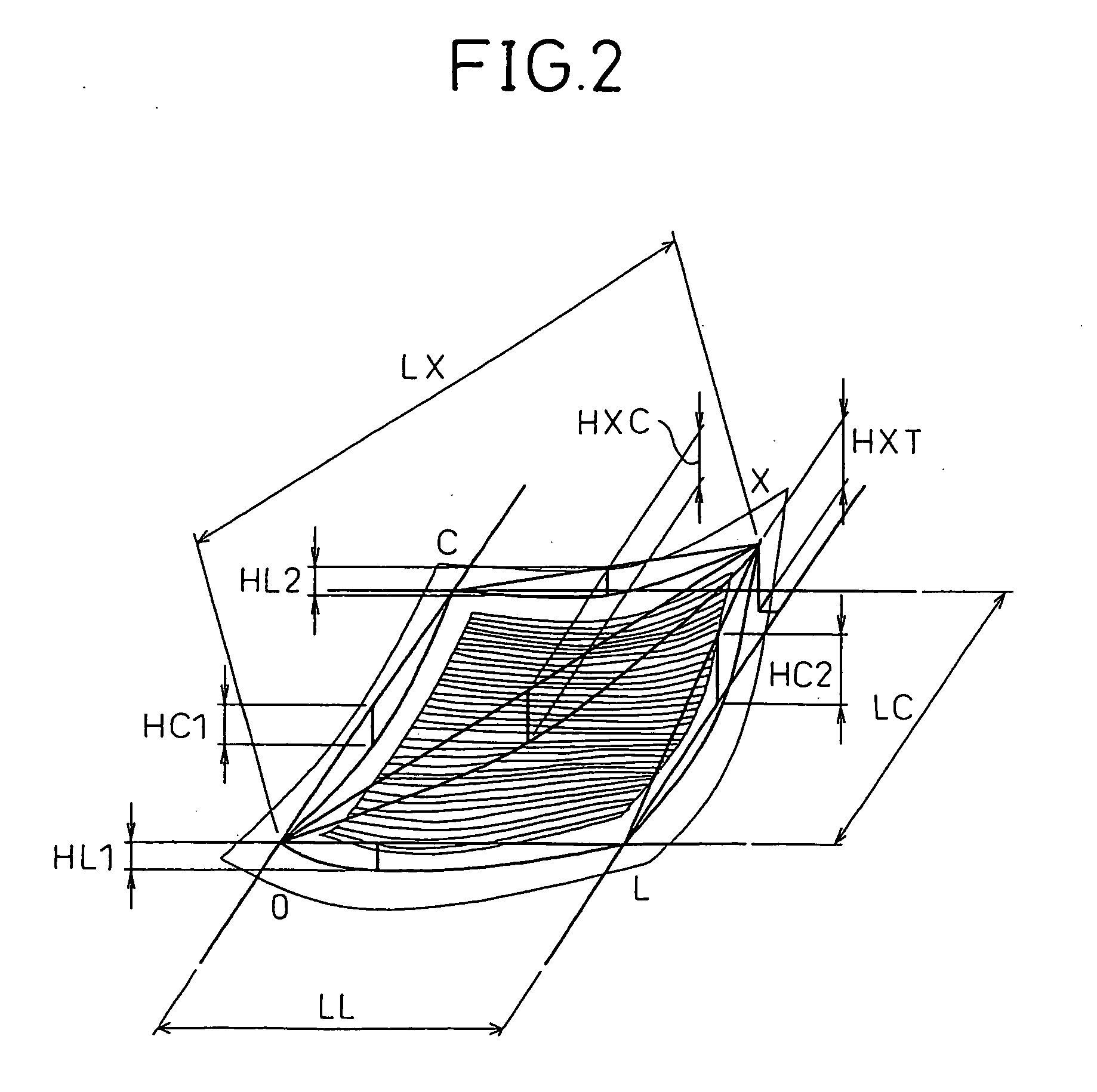

Method of treatment for imparting conductivity to surface of separator-use base member of solid polymer type fuel cell

InactiveUS20120064232A1Price of such material is lowReduce manufacturing costCell component detailsSpecial surfacesFuel cellsSpray coating

The present invention provides a method of treatment for imparting conductivity to a surface of a separator-use base member resulting in little distortion and superior conductive performance for a separator-use base member of a solid polymer type fuel cell made of any of a sheet of stainless steel, titanium, or titanium alloy, comprising a step of spray coating and drying on the surface of the separator-use base member a suspension prepared by mixing conductive compound particles 3 of an average particle size of 1 to 10 μm with ethanol or water so as to form a conductive compound particle-coated layer 2, a step of blasting the conductive compound particle-coated layer 2 with blast particles 4 having an average particle size of 50 to 200 μm so as to drive the conductive compound particles 3 in the inside direction of the separator-use base member 3 and anchor them there, and a step of cleaning off conductive compound particles 3 not anchored to the surface of the separator-use base member 1 at that step and impurities.

Owner:SINTOKOGIO LTD

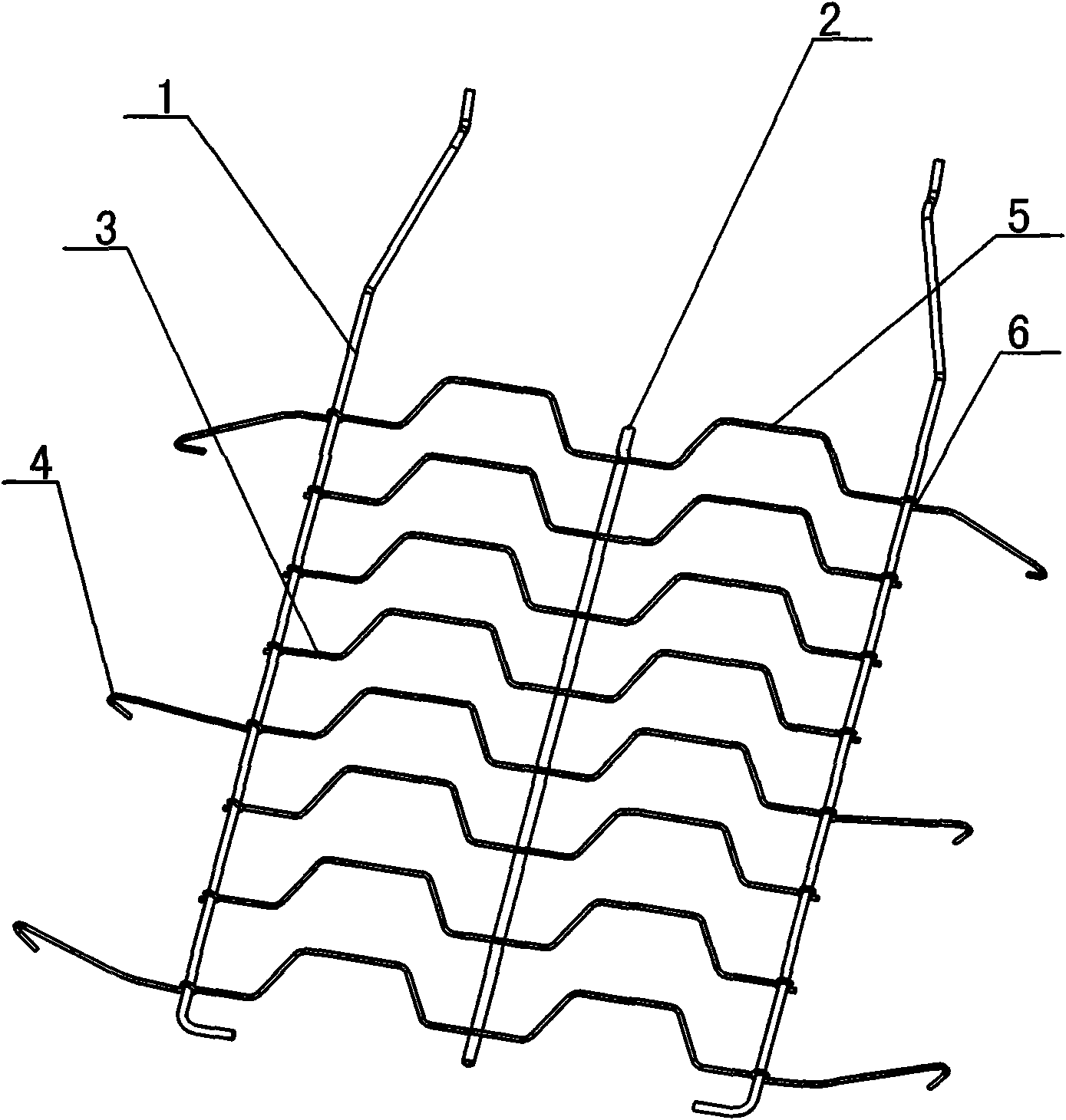

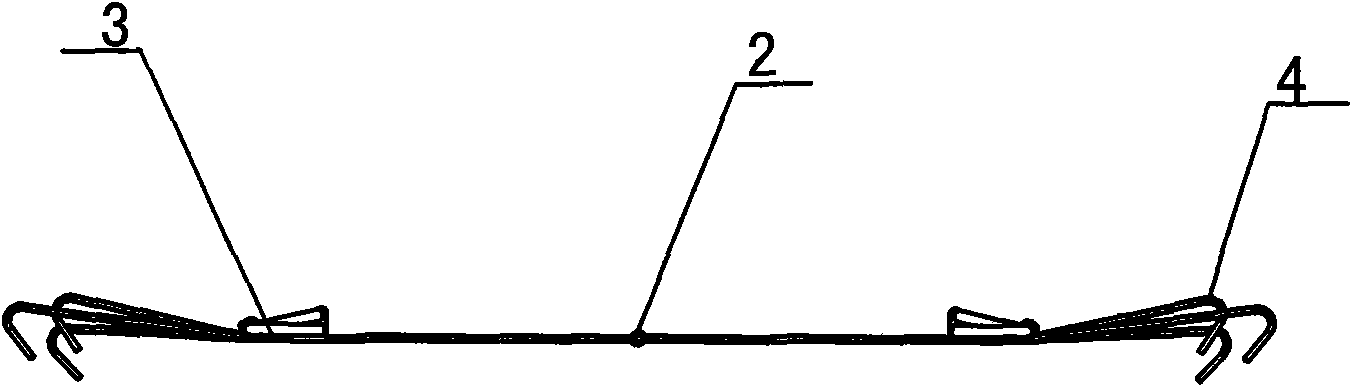

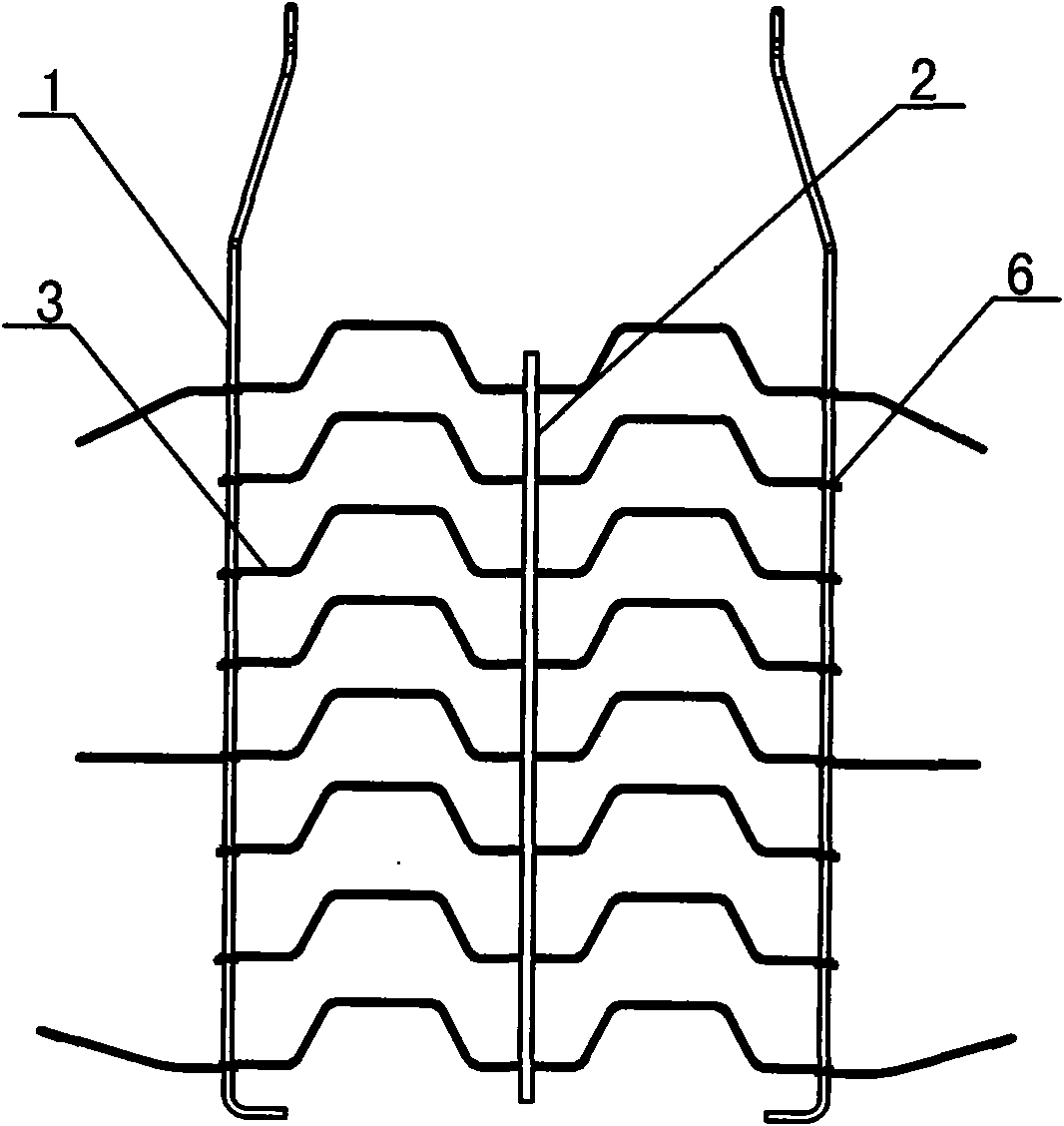

Seat backrest suspension device with hook

InactiveCN101549662AReduce thicknessAdjust for comfortSeat framesSeat suspension devicesEngineeringMechanical engineering

A seat backrest suspension device with hook comprises a device shell composed of two plastic coated steel wires with plastic coated layers, a plastic pipe between the plastic coated steel wires, a plurality of horizontal steel wires wound on the plastic coated steel wires according to a certain distance and passing through the plastic pipe. The horizontal steel wires form steel wire knotting segments at the winding part of the plastic coated steel wires and the horizontal steel wires between the plastic coated steel wires form steel wire waving segments and the outer ends of the horizontal extension parts of the horizontal steel wires are folded into hooks. Compared with the like products, the weight of the products is reduced by half and the cost is saved by half, the products have higher performance price ratio, stronger flexibility, increased comfort, obviously reduced seat thickness.

Owner:无锡礼恩派华光汽车部件有限公司

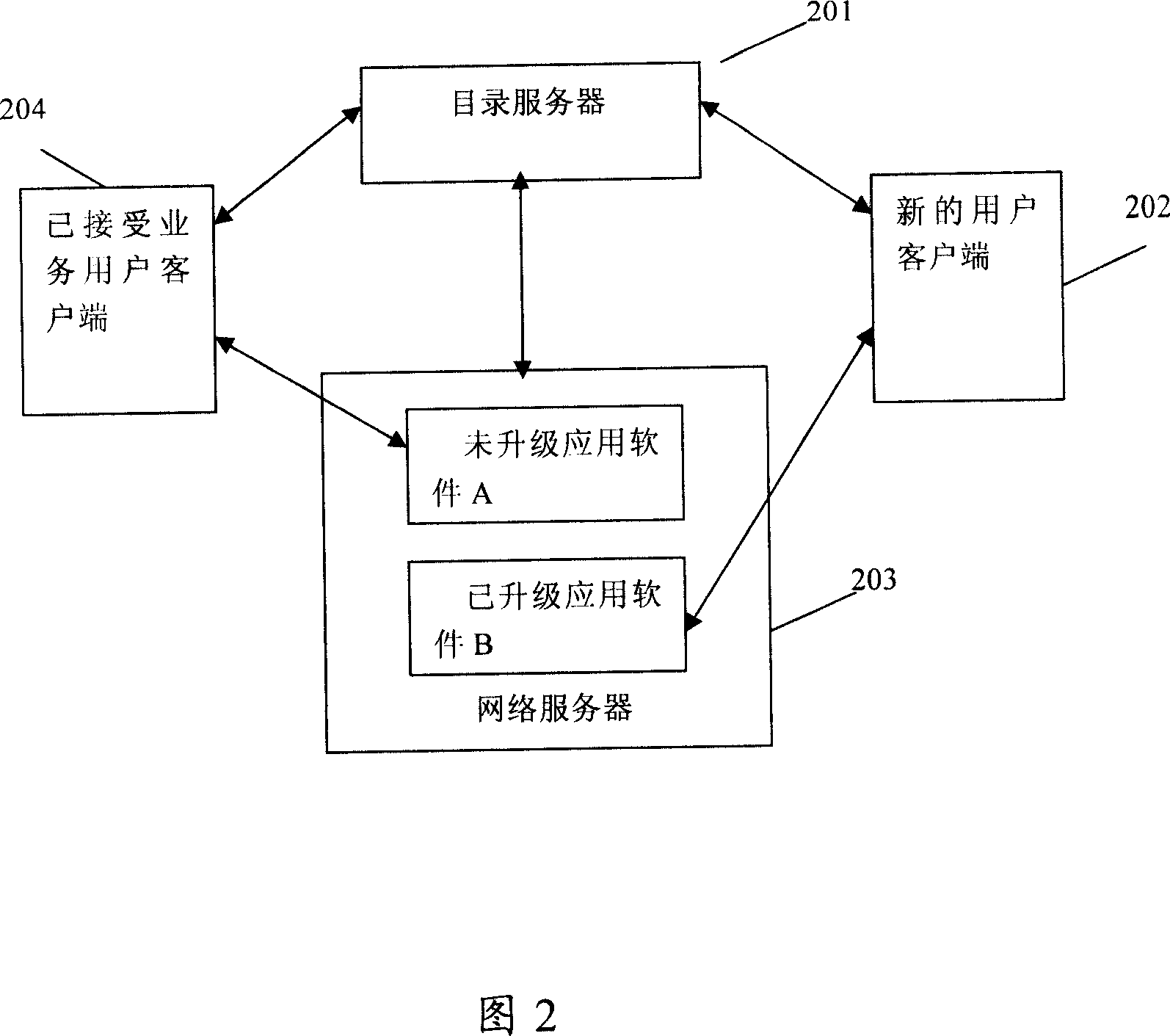

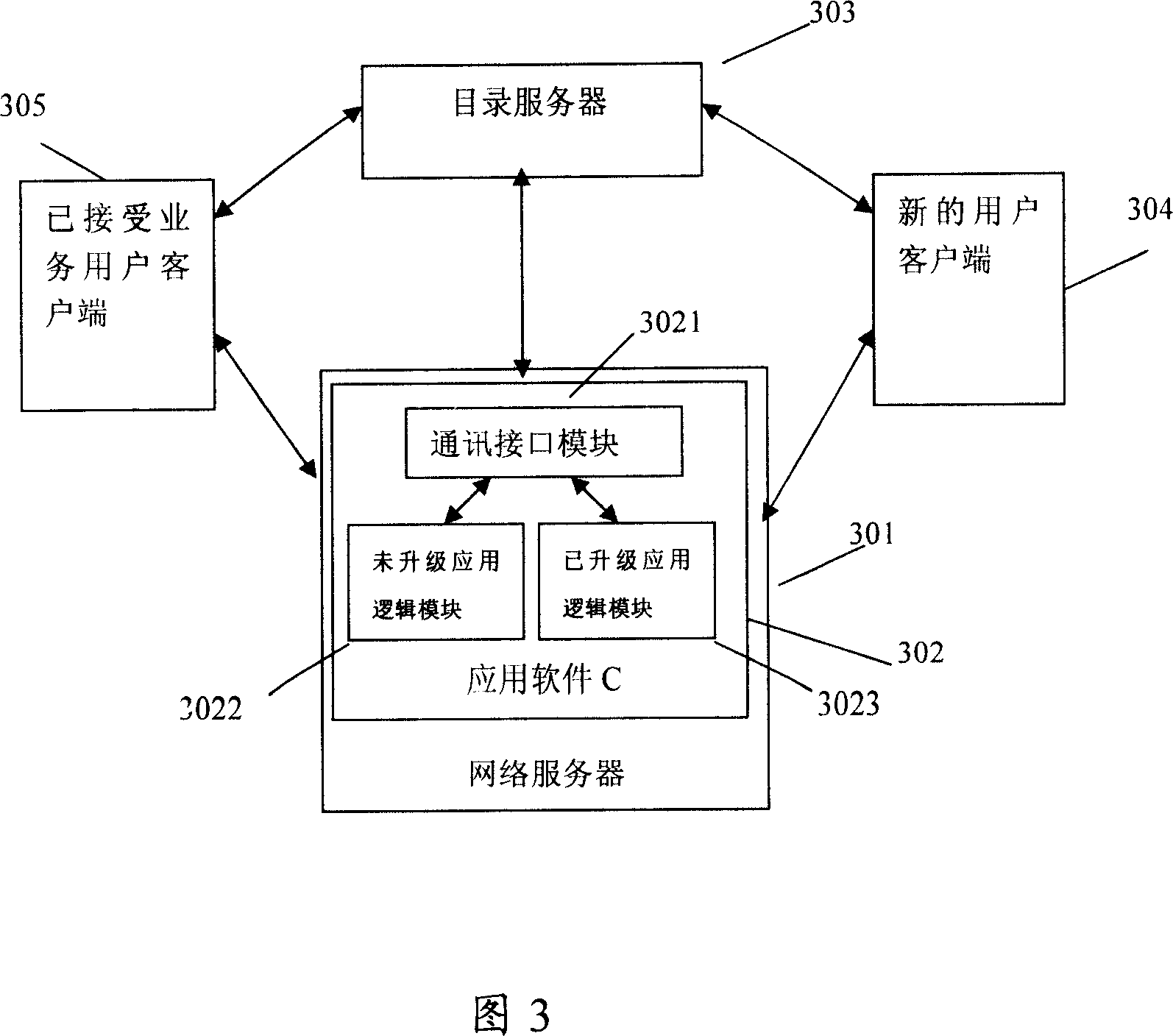

Method for network service in-line upgrading

ActiveCN1925414AThe upgrade process is smooth and stableStable quality and performanceData switching networksClient-sideDistributed computing

This invention discloses one network service online update method to sole current update high cost of hardware and comprises the following steps: a, adding updated logic module on the non updated logic module network servo; b, user terminal requires network service on list servo through recording to find out relative network servo and to send the logic module and customer end.

Owner:TENCENT TECH (SHENZHEN) CO LTD +1

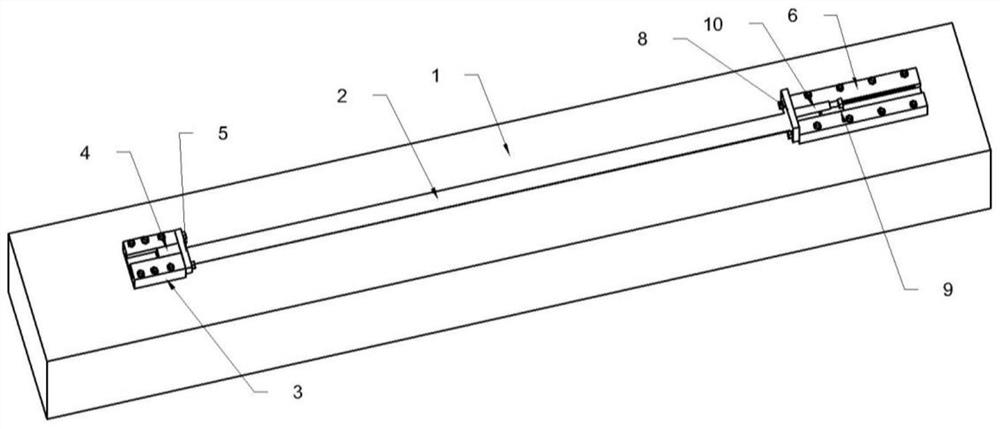

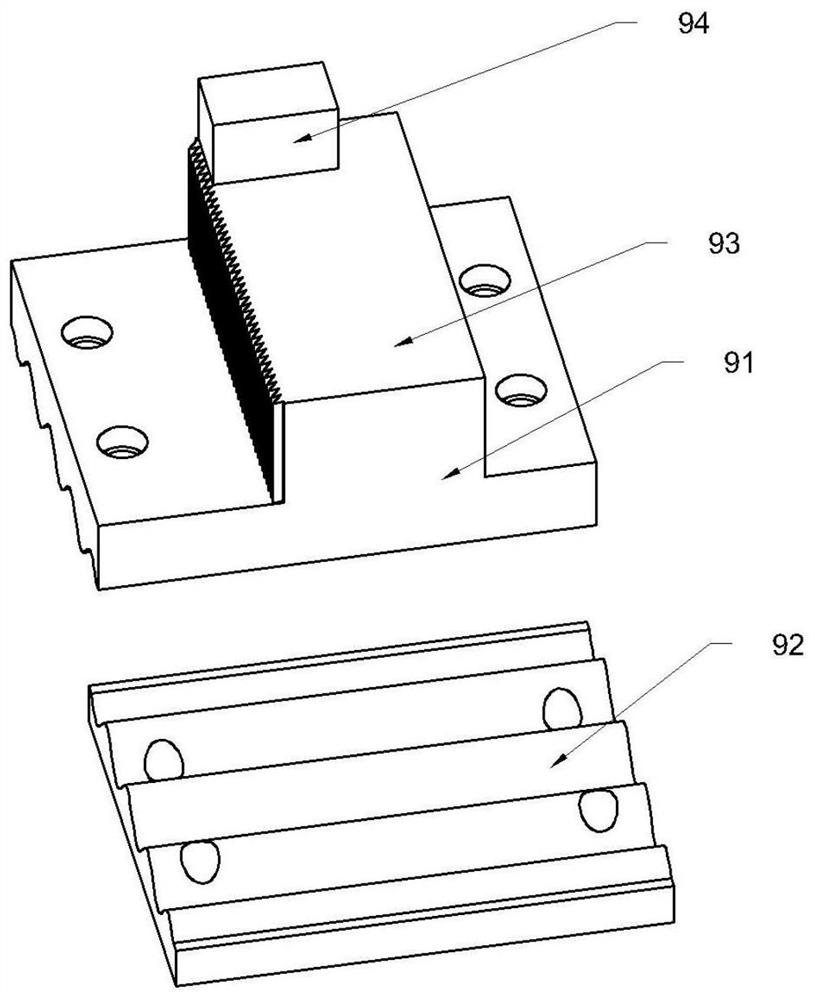

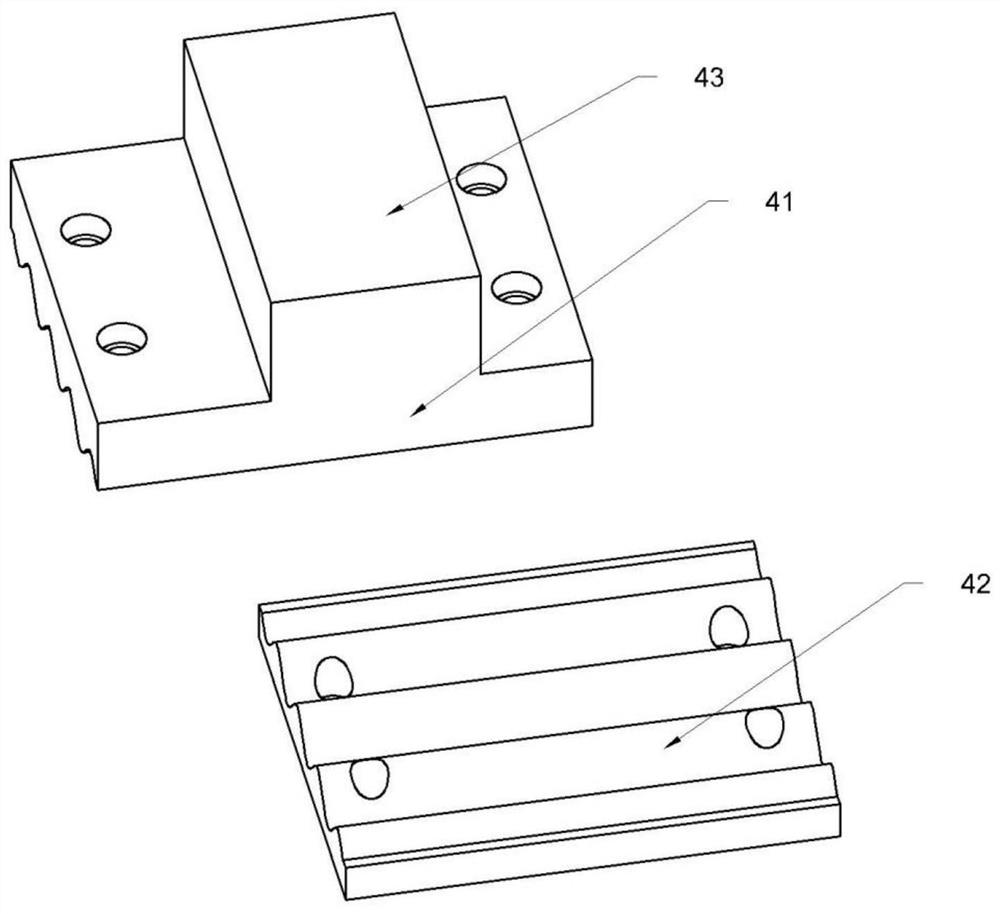

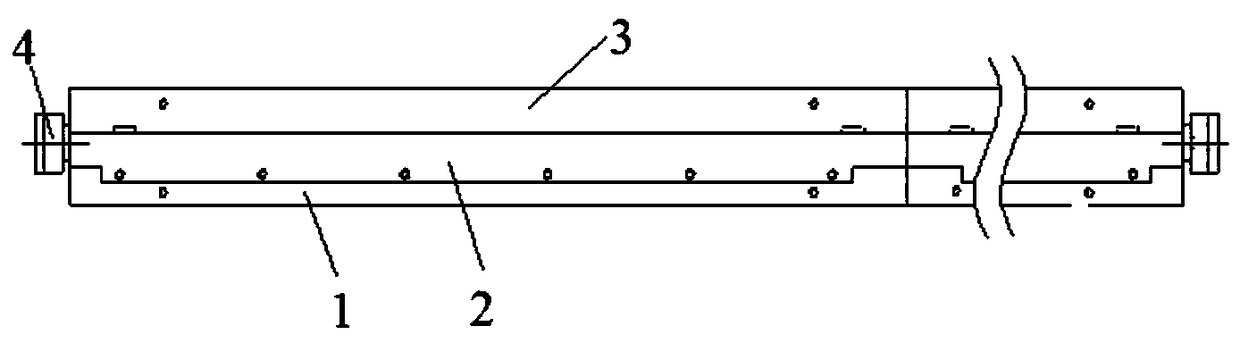

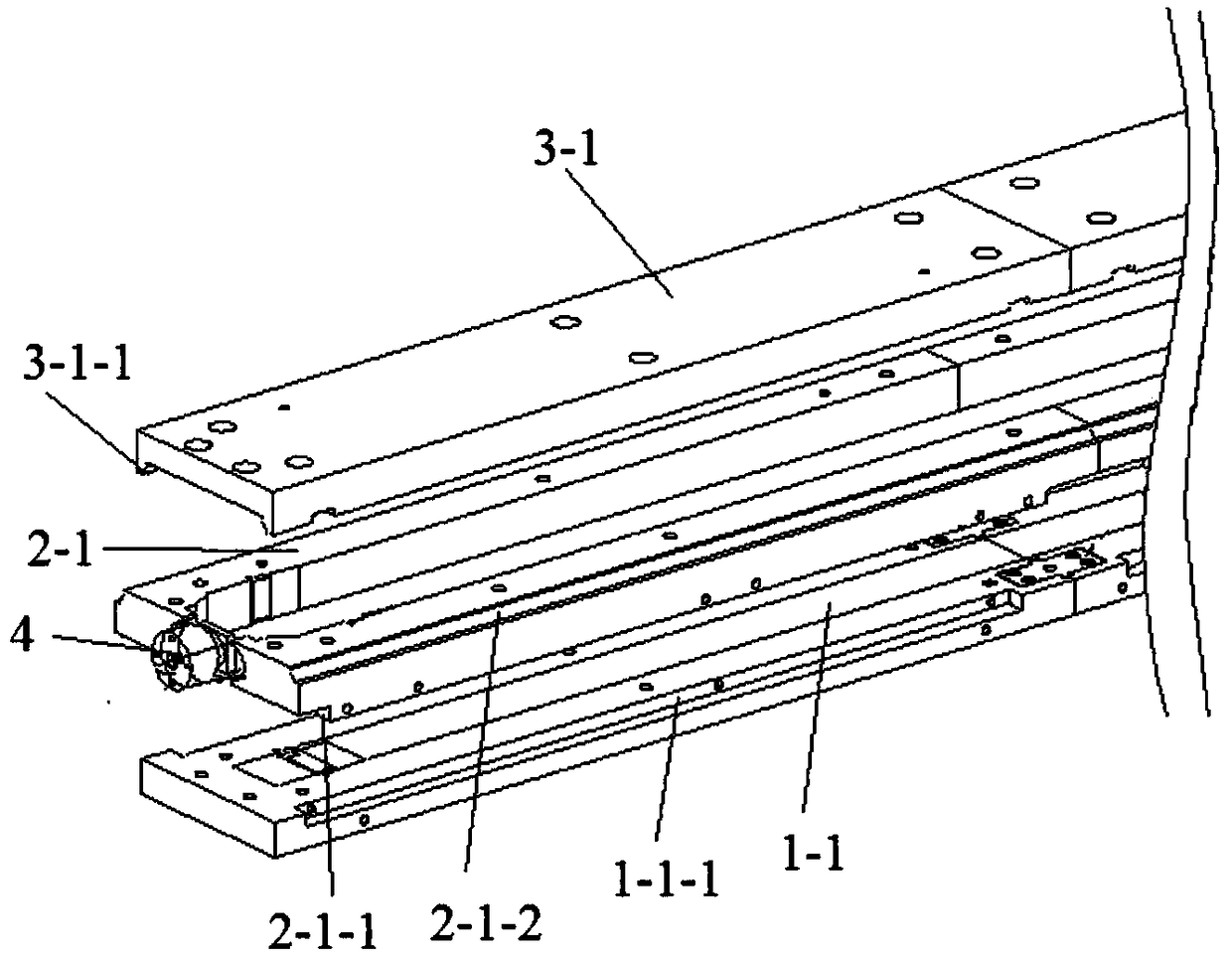

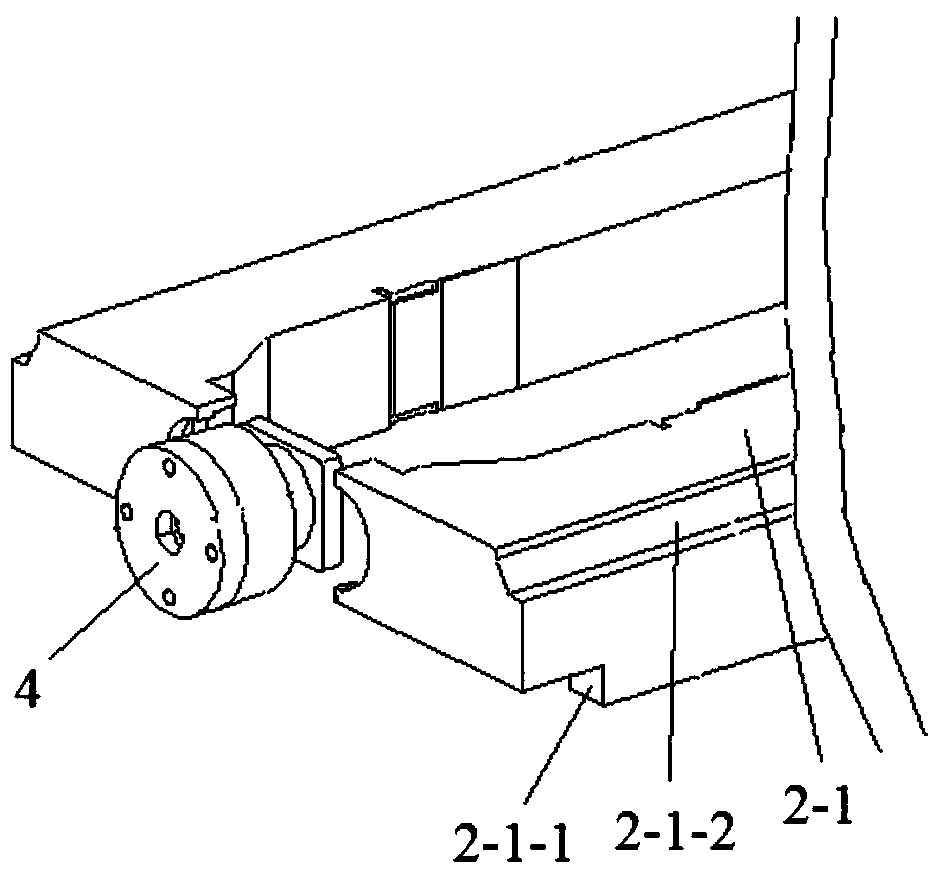

Manufacturing die and forming method of large-length-diameter-ratio carbon fiber composite pipe

InactiveCN109318507ALarge aspect ratioImprove forming efficiencyDiameter ratioCarbon fiber composite

The invention discloses a manufacturing die of a large-length-diameter-ratio carbon fiber composite pipe. The manufacturing die is composed of a lower die body, a middle die body and an upper die body. The lower die body is formed by connecting multiple lower die plate blocks, and the upper die body is formed by connecting multiple upper die plate blocks. Lower die grooves are formed in the two sides of the upper surface of each lower die plate block, the middle die body is composed of two middle die plate block units connected through a connector, each middle die plate block unit is formed byconnecting multiple middle die plate blocks, middle die convex blocks cooperating with the lower die grooves are arranged on the lower surfaces of the middle die plate blocks, middle die grooves areformed in the upper surfaces of the middle die plate blocks, and upper die convex blocks cooperating with the middle die grooves are formed in the two sides of the lower surfaces of the upper die plate blocks. The invention further discloses a forming method of the large-length-diameter-ratio carbon fiber composite pipe. According to the method, the carbon fiber composite material pipe with the length-diameter ratio larger than 60 is prepared through the combination of air bag pressurizing and the die pressing process. By means of the die, the length-diameter ratio of the pipe is increased, and the forming efficiency is improved. By means of the method, the dimensional precision and the surface quality of the pipe are improved.

Owner:XIAN KANGBEN MATERIAL

Power metallurgy iron-based engine valve seat and production method thereof

InactiveCN103551578AHigh hardnessImprove wear resistanceTurbinesOther manufacturing equipments/toolsQuality performanceInternal combustion engine

The invention discloses a power metallurgy iron-based engine valve seat. The power metallurgy iron-based engine valve seat is characterized by being made with, by weight, 2.4-2.8 parts of graphite, 3.2-3.4 parts of tungsten, 5.0-5.2 parts of molybdenum, 2.3-2.8 parts of cobalt, 7.4-7.6 parts of chromium, 0.4-0.8 part of copper powder, 86-88 parts of iron powder, 1.5-2.1 parts of V, 0.4-0.8 part of Tc, 0.5-0.8 part of Y, and 2-3 parts of aid. The power metallurgy iron-based engine valve seat is high in hardness, good in wear resistance, stable in quality performance, low in production cost and long in service life, allows an internal combustion engine to normally operate with leadless gasoline, and the cost of using the valve seat is reduced for users.

Owner:WUHU HONGKUN AUTO PARTS

Production method of wide titanium steel composite plate

ActiveCN110586683AReduce in quantityImprove welding efficiencyMetal rolling arrangementsTitaniumComposite plate

The invention relates to a production method of a wide titanium steel composite plate. The production method comprises the steps of machining and processing a blank, machining and processing a frame,coating an isolating agent on the titanium plate and then carrying out seal welding, assembling to form a titanium steel composite blank, centering the titanium steel composite blank, vacuumizing andwelding, inspecting welding seams, rolling and the like; and two titanium steel composite plate with target depth can be manufactured in one production process. According to the production method, theintegrated frame is adopted to replace a plurality of baffle strips for seal welding, so that the number of welding joints is reduced, the welding efficiency is improved, the welding heat input to corners is reduced, the heat influence on a base material structure in the welding process is reduced, and the welding quality is further improved; and an annular groove is formed in the frame, so thatthe phenomenon that the corner strength of a rolled finished composite plate is low due to the corner effect is avoided.

Owner:ANGANG STEEL CO LTD

Method for residue-juice separation after crushing fresh sweet potatoes

InactiveCN102617742ASolve the phenomenon of loss and wasteSolve storage prone to oxidationSlurryDehydration

The invention discloses a method for residue-juice separation after crushing fresh sweet potatoes. The method comprises the following steps: material choosing; cleaning; crushing and filtering; fine screening and sand removing; precipitating; cleaning; and dehydration transporting. The method which adopts technical processes of residue-juice separation, cleaning and precipitation makes starch in the juice be separated out through repeatedly cleaning, precipitating and separating on condition that the quality of starch is not influenced, so a loss waste phenomenon of starch is fundamentally solved; and the self oxygen insulation effect of the juice and the oxidation resistance of an antioxidant BHT in the precipitation process, and the pH value of about 6.2 of the juice make the shelf life be comprehensively increased to 300-350 days, so a problem of easy generation of oxidation and acetification during storage of the fresh juice is solved, and the quality of the fresh juice is guaranteed.

Owner:南阳天冠种业有限公司

Polypropylene composition for film and preparation method of composition

The invention discloses a polypropylene composition for a film, which comprises the following ingredients: 89.50-99.79 parts of ethylene-propylene polypropylene random copolymer resin, 0.05-0.15 partsof antioxidant 1010, 0.05-0.15 parts of auxiliary antioxidant 168, 0.01-0.15 parts of halogen absorbent, 0.05-0.5 parts of smooth agent and 0.05-0.5 parts of antiblocking agent. The polypropylene composition for the film has basically identical mechanical properties with the ethylene-propylene polypropylene random copolymer resin as a base material of the composition, and can be directly used fora cast film product without modification. The invention further provides a preparation method of the polypropylene composition for the film. The method has small influence on properties of a polypropylene base material; physical properties of the base material are basically consistent with those of a special material before and after preparation; and the property stability of the special materialfor the polypropylene cast film is ensured.

Owner:CHINA PETROLEUM & CHEM CORP

A kind of forming method of colloidal storage battery

InactiveCN102290610AMeets the highest requirements for market useImprove consistencyFinal product manufactureLead-acid accumulators constructionElectricitySulfate

The invention discloses a method for forming colloidal storage batteries, which includes the preparation of colloidal electrolyte: before the formation of batteries, sulfuric acid with a specific gravity of d15°C=1.26g / cm3-1.30g / cm3 and pre-configured colloidal liquid mother liquor are mixed at a volume ratio of 1.8-1.8~ Mix at a ratio of 2.5:1, then use a PVC anti-acid glue making machine to stir at a high speed of 500-1000 rpm for 15-25 minutes to make a colloidal electrolyte with a flow rate of 260-350g / min; The colloidal electrolyte is added to the semi-finished battery, and the formation method of three charges and two discharges is adopted. During the formation process, the charging power meets 8-11 times the rated capacity of the battery, and the colloidal electrolyte is completely transformed into a gel. The beneficial effect is that the production process is simplified, the battery consistency is improved, energy waste and environmental pollution are reduced, and the battery quality and performance are stable, the battery performance is consistent, and the like.

Owner:SHANDONG SACRED SUN POWER SOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com