Preparation method of yolk globulin powder

A technology of egg yolk globulin powder and egg yolk, which is applied in the field of preparation of egg yolk globulin powder, can solve the problems of large consumption of reagents, unstable properties, and low recovery rate, and achieve easy control of reaction conditions, stable quality and performance, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

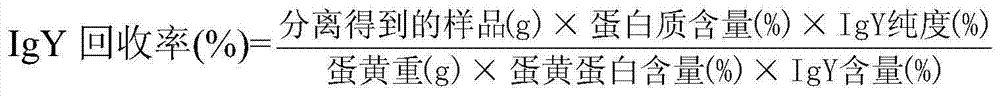

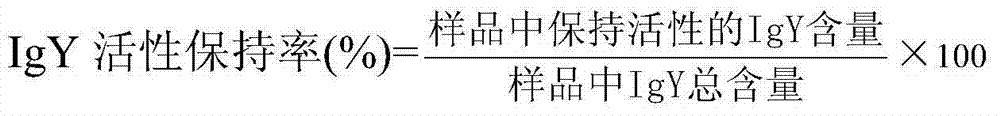

Embodiment 1

[0026] Take 4 kg of egg yolk, add 4 times the volume of deionized water, stir for 5 minutes, put it into the clarification tank, and let it stand for 4 hours to obtain the supernatant, extract the supernatant to the mixing tank, and the remaining egg yolk liquid can be used to prepare egg yolk powder; above The supernatant is in a stirring state, the stirring speed is 50-70r / min, add the saline solution according to the volume / weight ratio of 4:1, turn off the stirring when the saline solution is completely added, and let the supernatant stand for 3-4 hours to precipitate the protein . After the protein is completely precipitated, the upper liquid is extracted to remove fat. Add deionized water to reduce protein according to the ratio of upper liquid: deionized water volume ratio 1:5, and prepare for plate and frame filtration. Install the filter cloth on the plate and frame filter press. After pre-coating with diatomaceous earth, filter the reduced protein solution through t...

Embodiment 2

[0028] Take 20 kilograms of egg yolk, add 4 times the volume of deionized water, stir for 10 minutes, put it into a clarification tank, and let it stand for 6 hours to obtain a supernatant. After the supernatant is removed, the remaining egg yolk liquid is used to prepare egg yolk powder; add ammonium sulfate (sodium chloride) to a saturated concentration of 33%, stirring at a rate of 50-70 r / min for 5-10 min. When the salt solution is completely added, the stirring is turned off, and the supernatant is allowed to stand for 3 to 4 hours to precipitate the protein. After the protein is completely precipitated, the upper liquid is extracted to remove fat. Add deionized water to reduce protein according to the ratio of upper liquid: deionized water volume ratio 1:5, and prepare for plate and frame filtration. Install the filter cloth on the plate and frame filter press, after pre-coating with diatomite, filter the reduced protein solution through the plate and frame, the filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com