Seat backrest suspension device with hook

A technology for suspension devices and seat backs, which is applied in the direction of seat suspension devices, seat frames, etc., can solve the problems of long processing routes, reduced human comfort, and many steel wire parts, and achieve stable quality and performance and reduced weight , cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

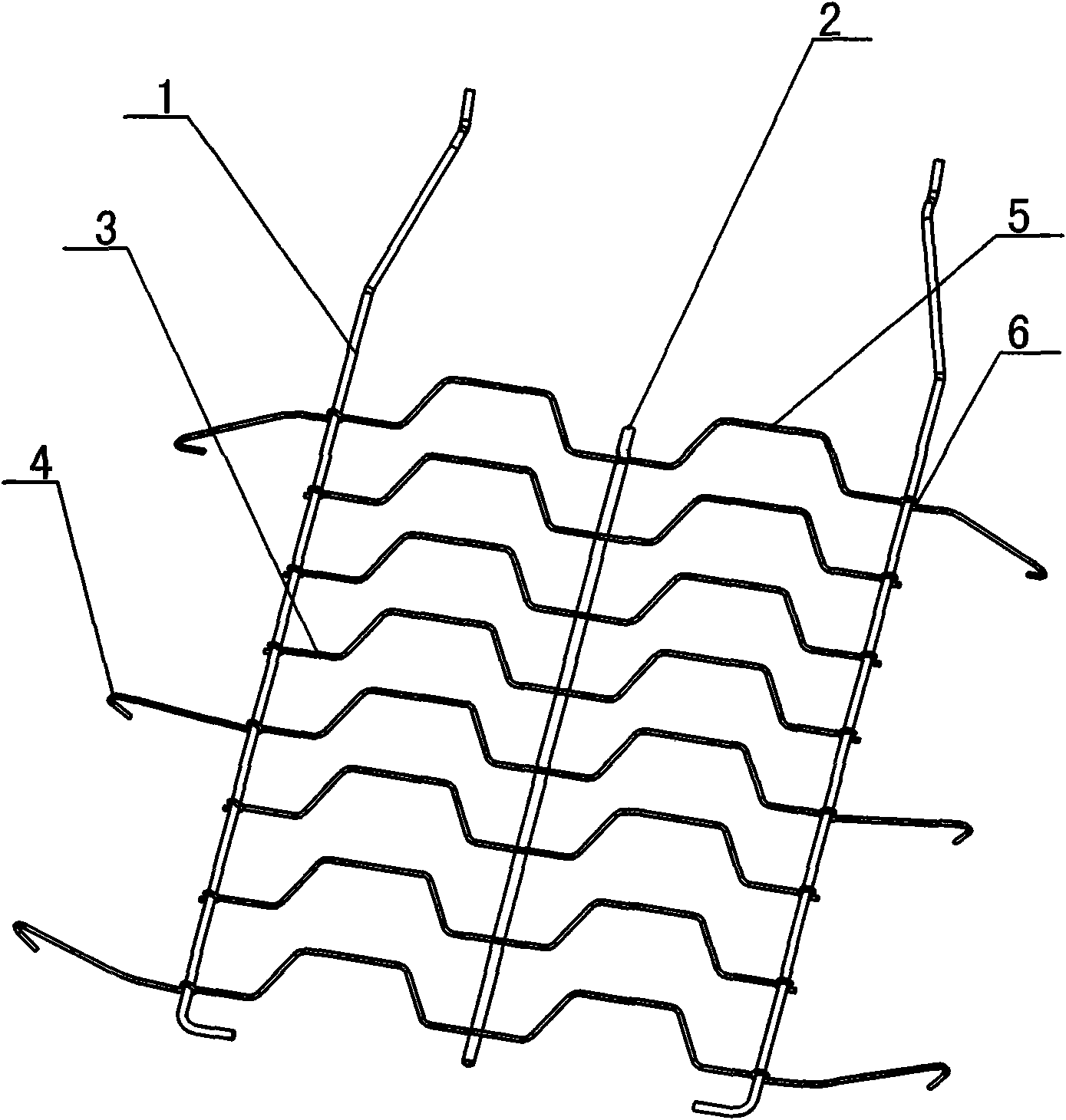

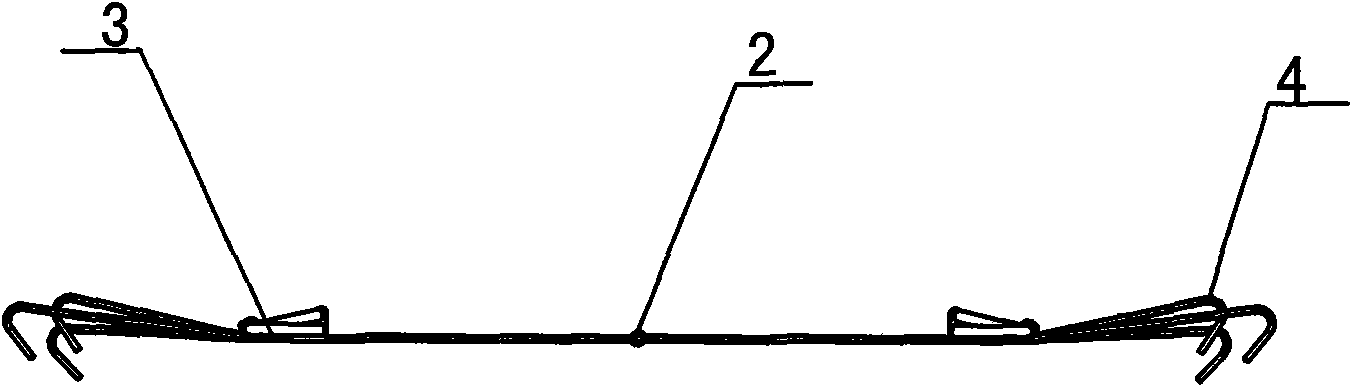

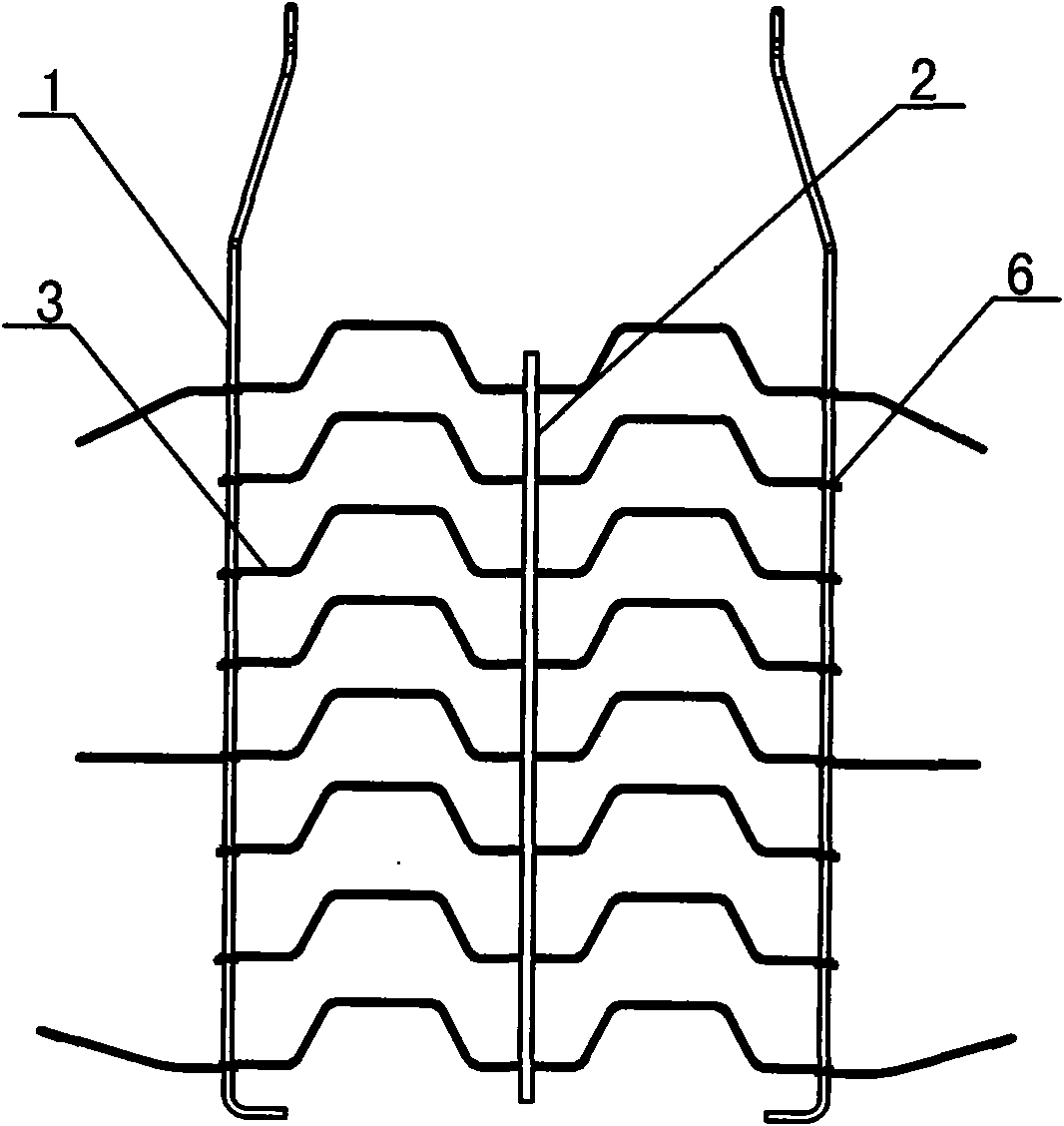

[0014] like Figure 1-4 As shown, the seat back suspension device with hooks of the present invention comprises two plastic-coated steel wires 1, a plastic pipe 2, and several transverse steel wires 3 connected to form two plastic-coated steel wires with a plastic-coated layer 1 constitutes the outer frame of the device, plastic pipes 2 are arranged between the plastic-coated steel wires 1, and several horizontal steel wires 3 are wound and arranged on the plastic-coated steel wires 1 according to a certain distance, and the horizontal steel wires 3 pass through the plastic pipes 2 to maintain the suspension system steel wires The stability of the lateral position; the horizontal steel wire 3 forms a steel wire knot section 6 at the winding place of the plastic-coated steel wire 1, and the horizontal steel wire 3 between the plastic-coated steel wires 1 is arranged as a steel wire wave section 5, and the horizontal steel wire 3 The outer end of the horizontal extension is fold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com