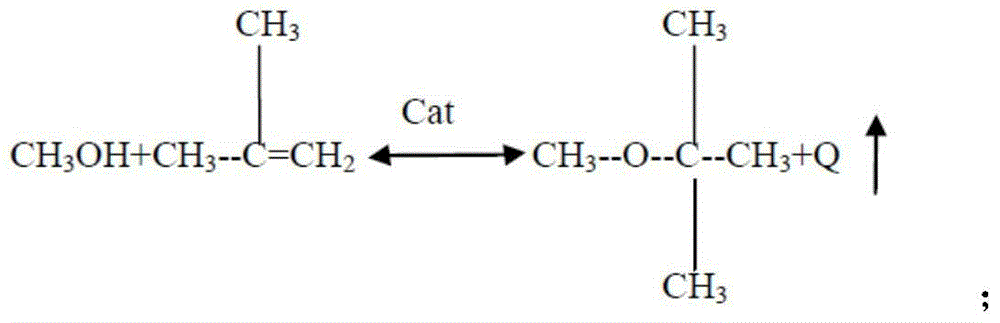

Synthesis method for petrochemical methyl tertiary butyl ether

A technology of methyl tert-butyl ether and refined methyl tert-butyl ether, which is applied in the field of synthesis and synthesis of petrochemical product methyl tert-butyl ether, and can solve problems such as unsatisfactory, many side reactions, and energy waste needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Embodiment 1 The synthetic method of petrochemical product methyl tert-butyl ether of the present invention

[0072] Including the following steps:

[0073] (1) 10 mol of raw material isobutylene sent from the upstream device enters the isobutylene raw material tank, where after sedimentation and separation of water, after the isobutylene raw material pump boosts the pressure, it is sent to the isobutylene-methanol mixer through a flow meter and a flow control valve;

[0074] (2) Send methanol to the isobutylene-methanol mixer after pressurized by the methanol feed pump from the tank area outside the device, and control 10.9mol of methanol through a flow meter and a flow regulating valve;

[0075] (3) Methanol and isobutene are fully mixed in the isobutene-methanol mixer, preheated to 33°C by the raw material preheater, and then enter the etherification reactor;

[0076] (4) Catalyst 22.4g is housed in etherification reactor, under the effect of catalyst and pressure 0...

Embodiment 2

[0082] Embodiment 2 The synthetic method of petrochemical product methyl tert-butyl ether of the present invention

[0083] Including the following steps:

[0084] (1) 10 mol of raw material isobutylene sent from the upstream device enters the isobutylene raw material tank, where after sedimentation and separation of water, after the isobutylene raw material pump boosts the pressure, it is sent to the isobutylene-methanol mixer through a flow meter and a flow control valve;

[0085] (2) Send methanol to the isobutylene-methanol mixer after pressurized by the methanol feed pump from the tank area outside the device, and control 10.8mol of methanol through a flow meter and a flow regulating valve;

[0086] (3) Methanol and isobutene are fully mixed in the isobutene-methanol mixer, and then enter the etherification reactor after being preheated to 30°C by the raw material preheater;

[0087] (4) Catalyst 16.8g is housed in etherification reactor, under the effect of catalyst and...

Embodiment 3

[0093] Embodiment 3 The synthetic method of petrochemical product methyl tert-butyl ether of the present invention

[0094] Including the following steps:

[0095] (1) 10 mol of raw material isobutylene sent from the upstream device enters the isobutylene raw material tank, where after sedimentation and separation of water, after the isobutylene raw material pump boosts the pressure, it is sent to the isobutylene-methanol mixer through a flow meter and a flow control valve;

[0096] (2) Methanol is sent to the isobutylene-methanol mixer after being pressurized by the methanol feed pump from the tank area outside the device, and 11mol of methanol is controlled through a flow meter and a flow regulating valve;

[0097] (3) Methanol and isobutene are fully mixed in the isobutene-methanol mixer, preheated to 35°C by the raw material preheater, and enter the etherification reactor;

[0098] (4) Catalyst 28g is housed in etherification reactor, under the effect of catalyst and pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com