Steel structure assembled embedded part and construction method thereof

A construction method and a technology of embedded parts, which are applied in the direction of building structure, construction, and building material processing, etc., can solve the problems affecting the construction of foundation steel bars and foundation formwork, affecting the progress of installation, and difficult adjustments, and achieve stable quality and stable results. Improve the quality of installation, the effect of simple and firm fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

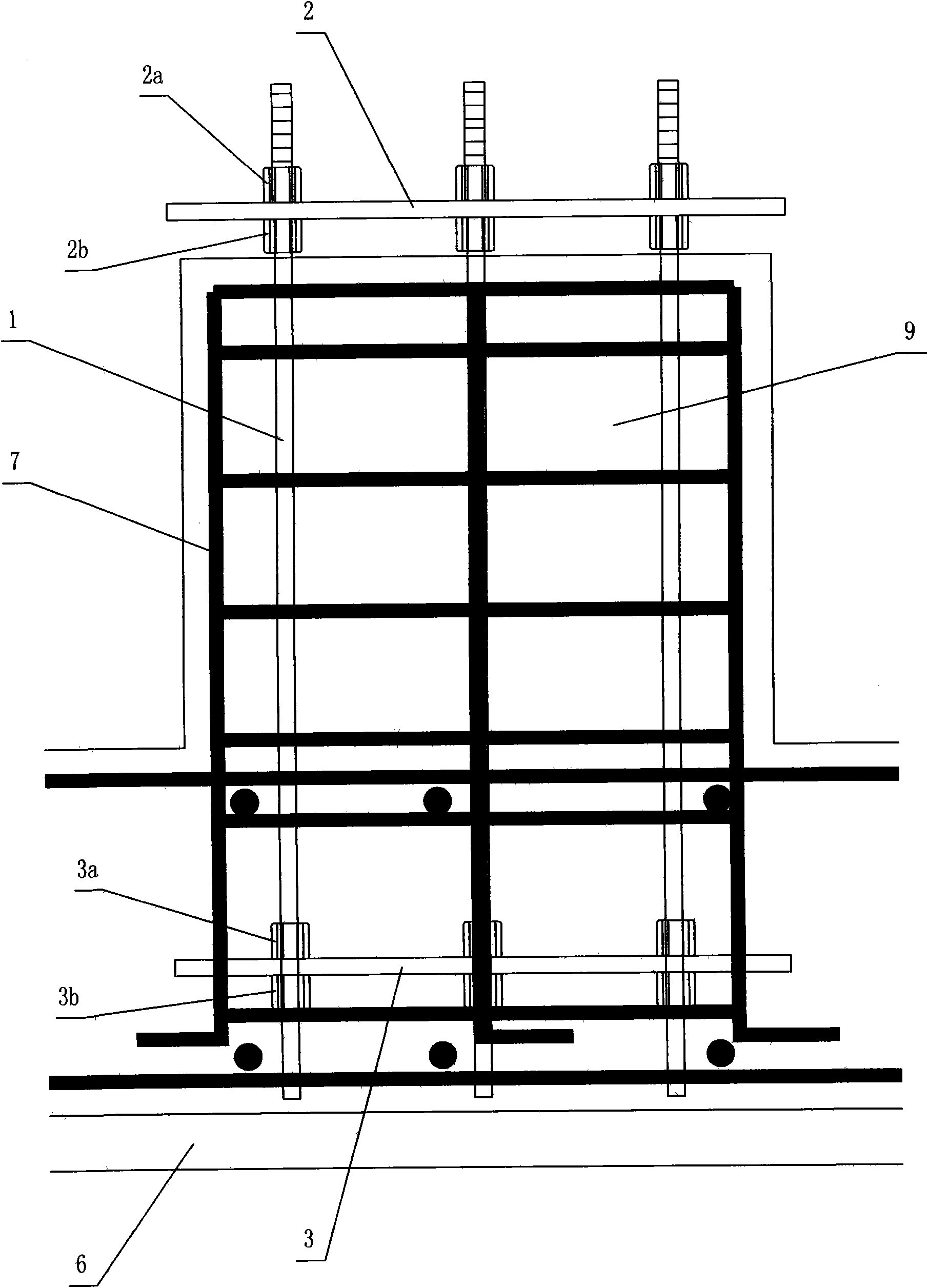

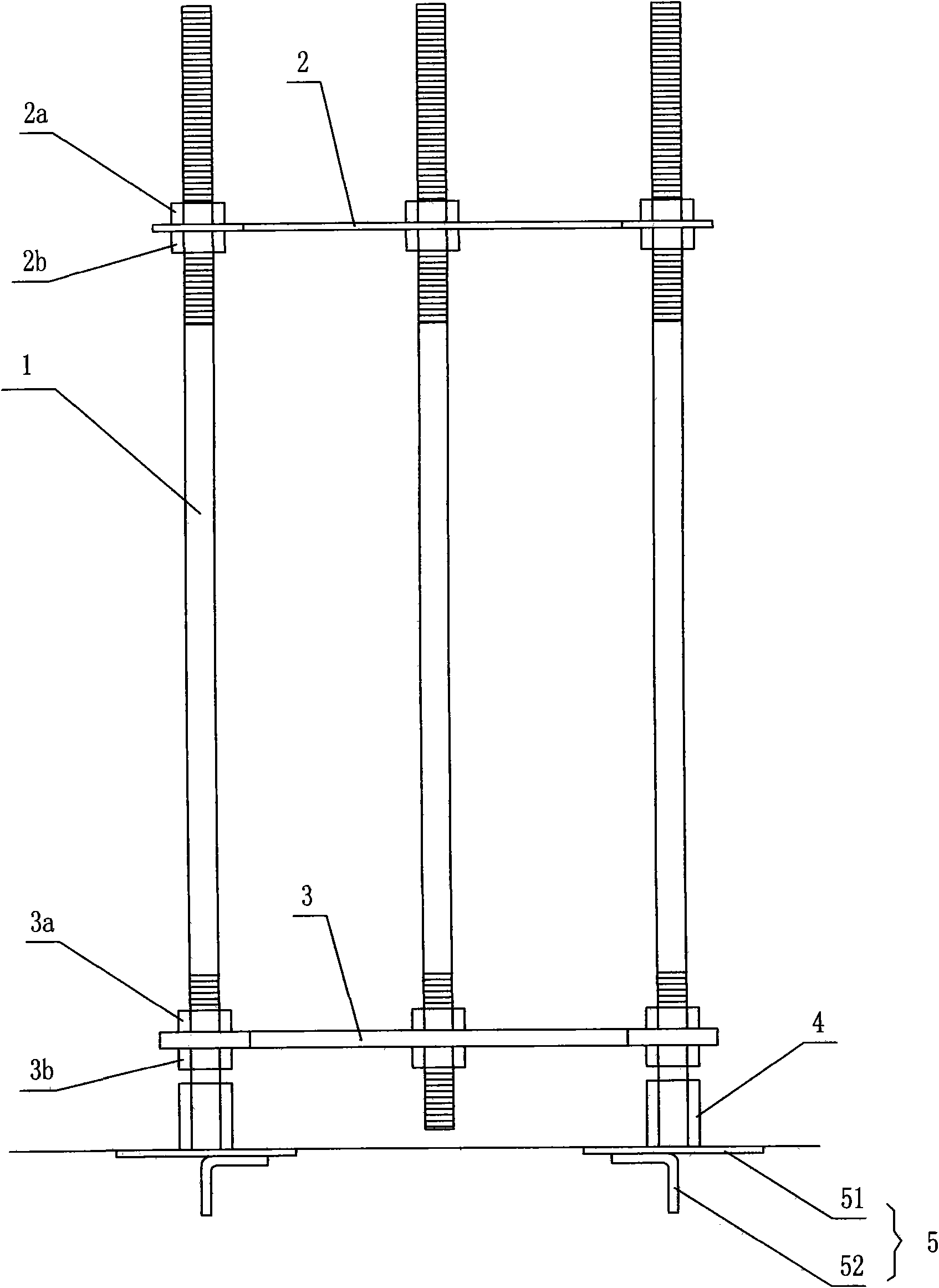

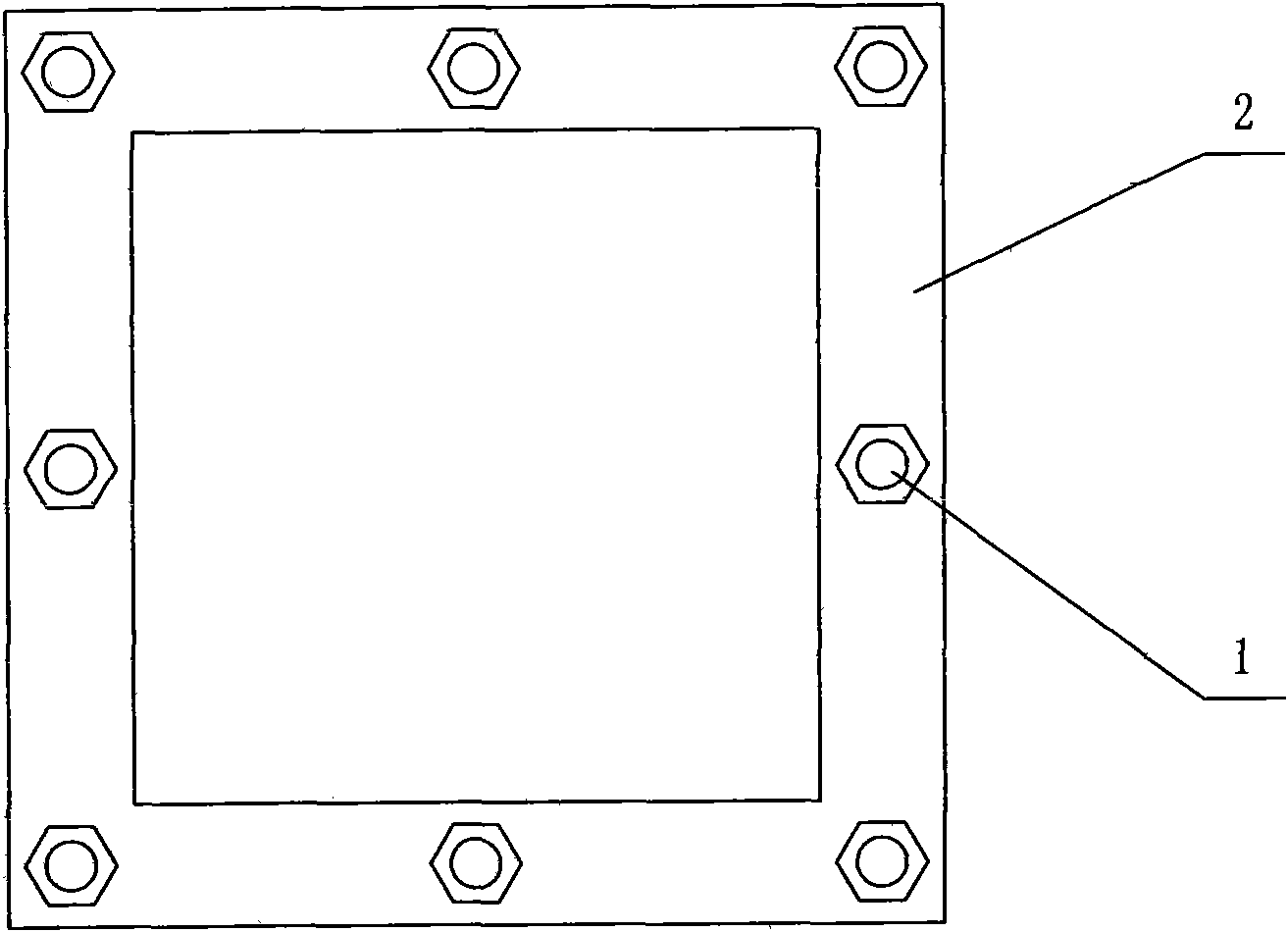

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 Shown is a schematic structural view of a preferred embodiment of the present invention, a steel structure composite embedded part of the present invention, including several embedded screws 1; a top formwork 2 is installed on the upper threaded portion of each embedded screw 1, Each pre-embedded screw 1 and the top formwork 2 are fixedly connected by clamping nuts 2a located above the top form 2 and packing nuts 2b below the top form 2; A bottom template 3 is installed, and each pre-embedded screw rod 1 is fixedly connected to the bottom template 3 by clamping nuts 2 3a above the bottom template 3 and packing nuts 2 3b below the bottom template 3; Adjustment bases 4 are installed at the end of the lower end of the threaded part, and a pre-embedded iron 5 is respectively fixed on the bottom of each adjustment base 4. Embedded iron 5 is made up of steel plate 51 and anchor fluk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com