Production method of wide titanium steel composite plate

A production method and composite plate technology, applied in the direction of metal rolling, etc., can solve the problems that vacuum electron beam cannot be sealed and welded, the sealing and welding process is complicated, and the corners are cracked, so as to improve the welding quality, improve the efficiency of billet assembly, The effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

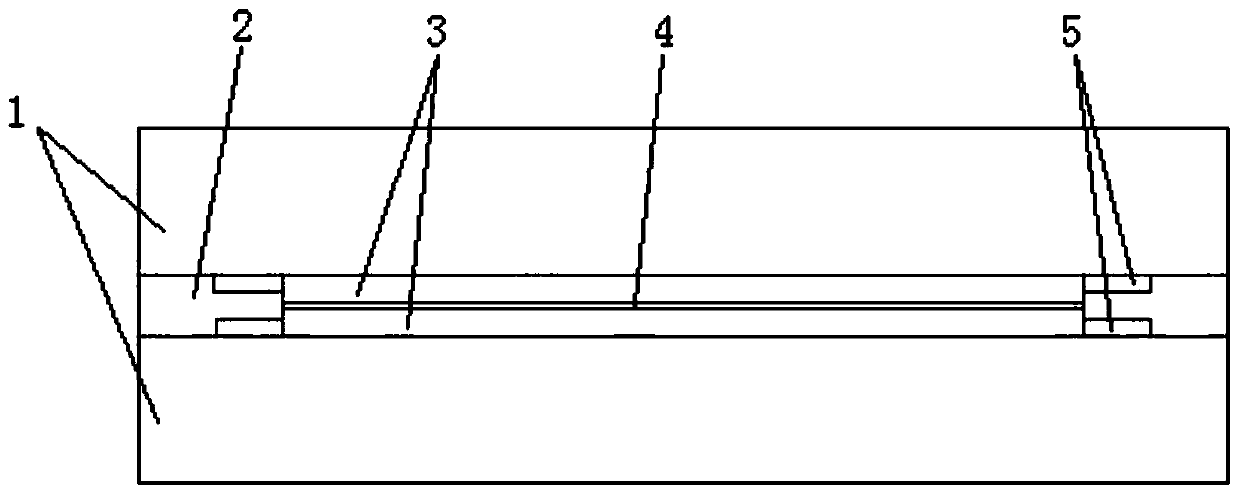

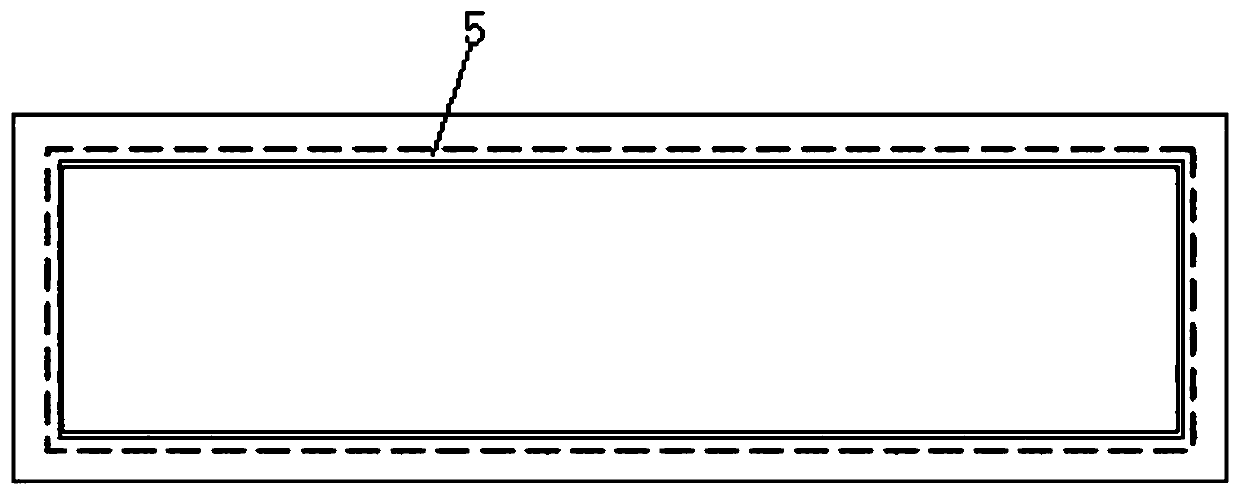

[0034] The invention relates to a production method of a wide-spec titanium-steel composite plate. The titanium-steel composite plate is composed of a titanium-steel cladding layer and a carbon-steel base layer with a width ≥ 3m. The production process of the titanium-steel composite plate includes the following steps:

[0035] (1) Select 2 carbon steel plates and 2 titanium plates as blanks, carbon steel plate length = titanium plate length + 60 ~ 300mm, carbon steel plate width = titanium plate width + 60 ~ 300mm; Specification processing, single-sided milling depth ≥ 5mm; the surface after processing is required to have no defects, and the surface roughness Ra<5.5μm;

[0036] (2) Select carbon steel with thickness = thickness of titanium plate × 2 + (3 ~ 8) mm to process it into a frame, the outer length and width of the frame are the same as the length and width of the carbon steel plate, and the inner length of the frame = titanium Plate length + 2 ~ 5mm, the width of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com