Patents

Literature

46 results about "Corner effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

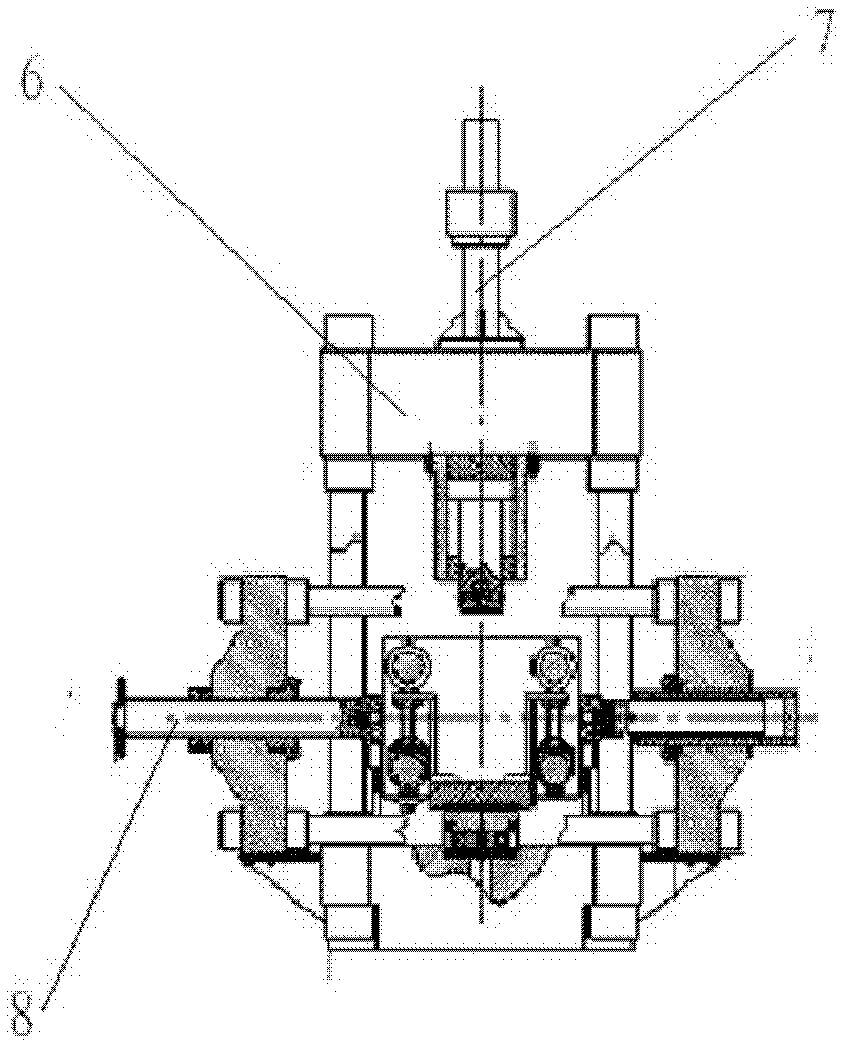

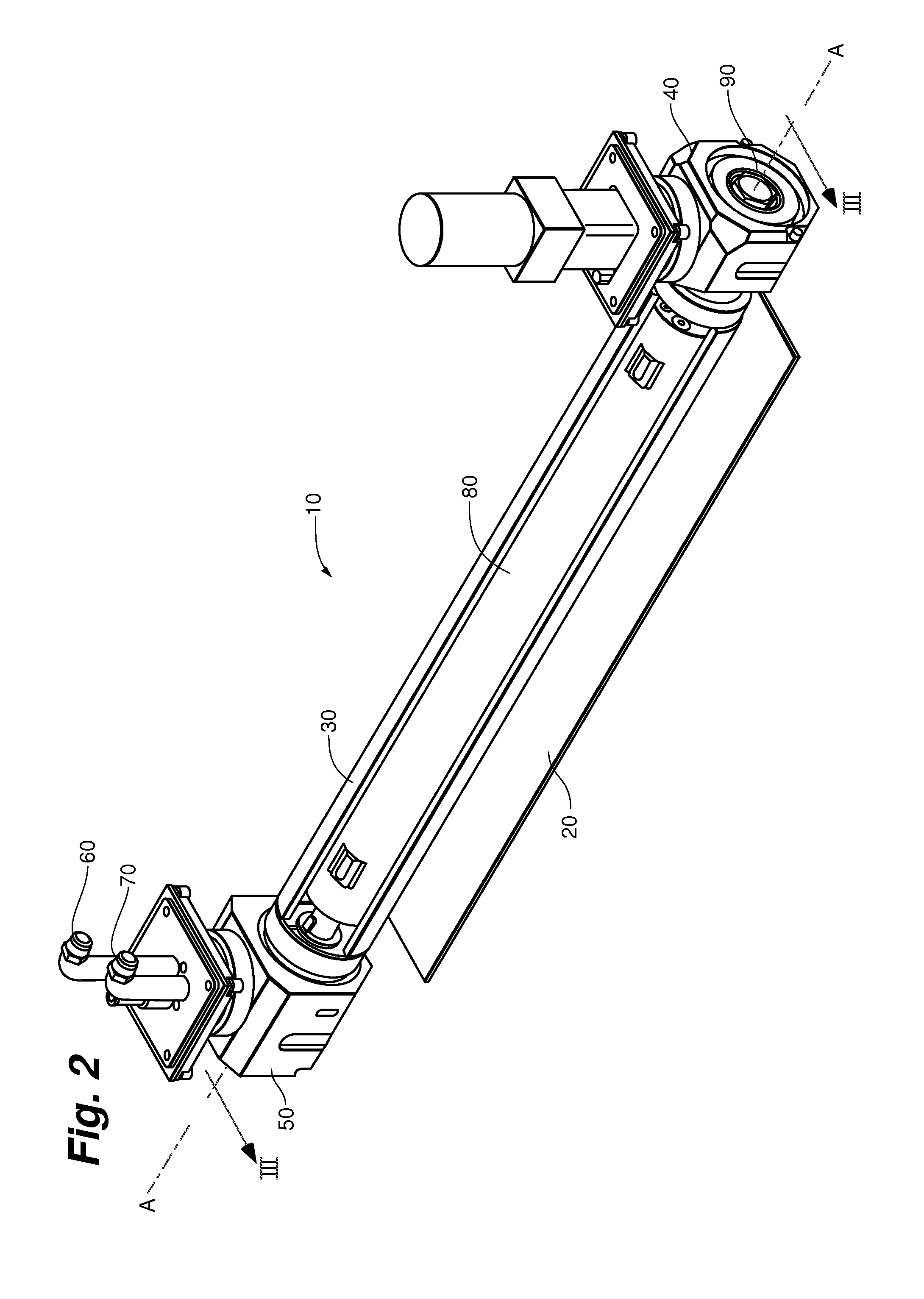

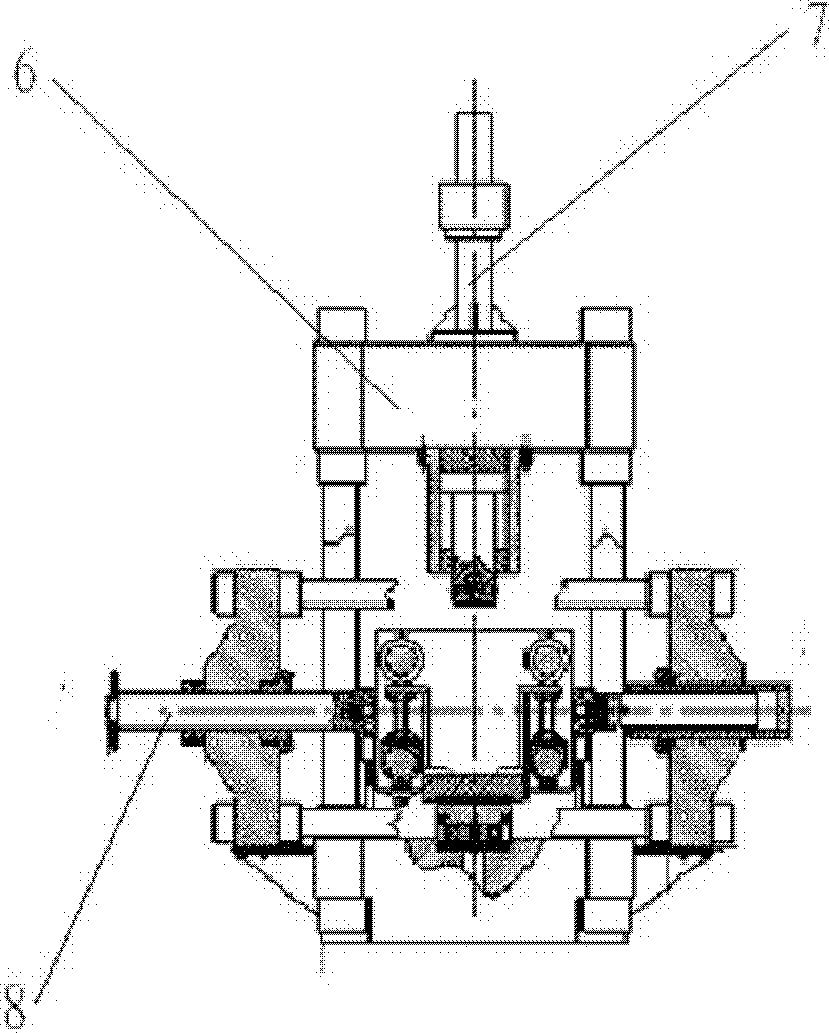

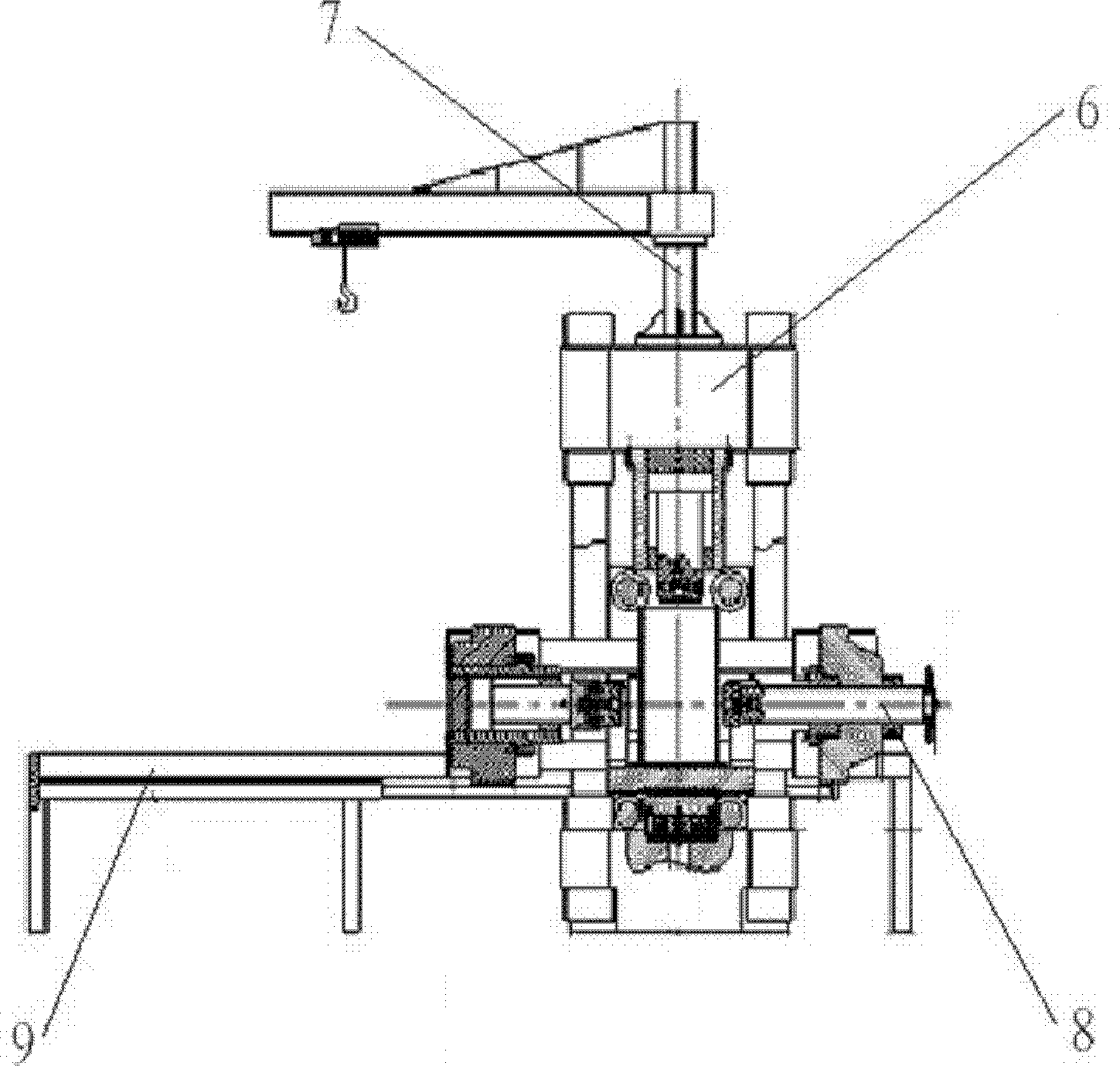

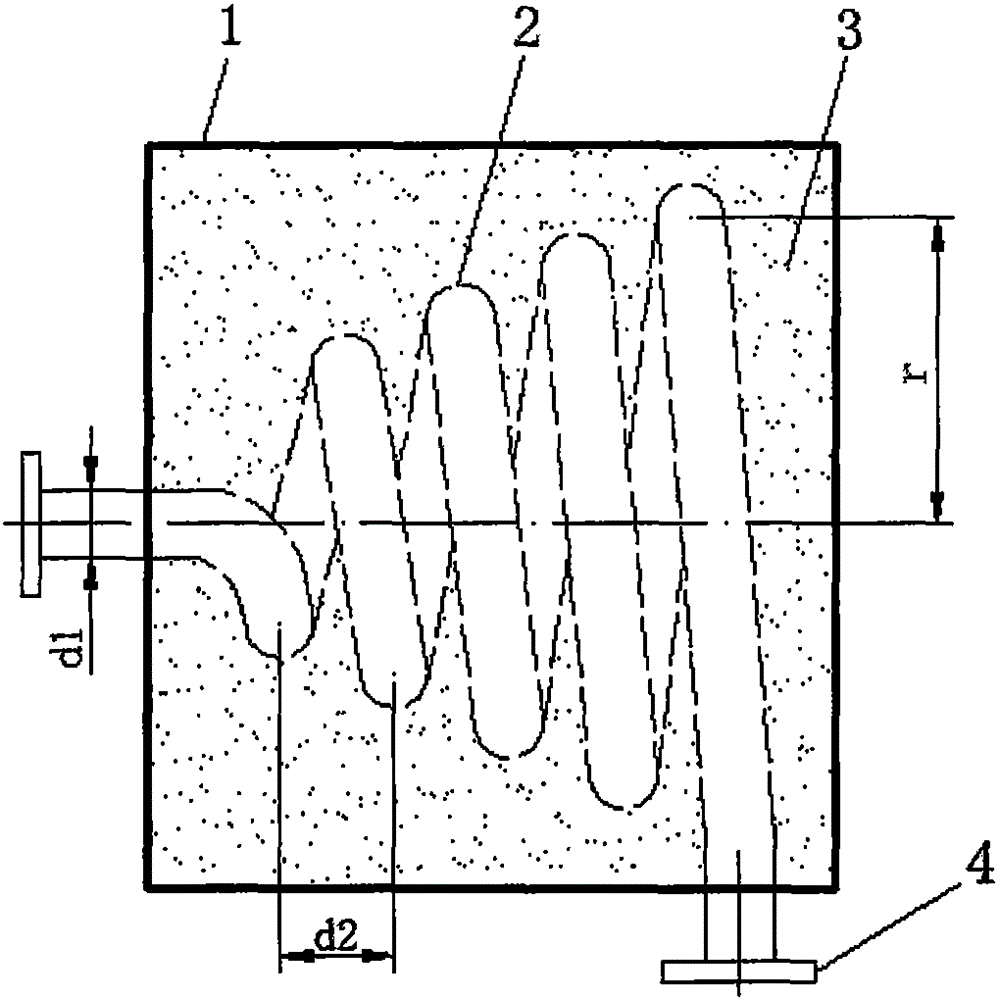

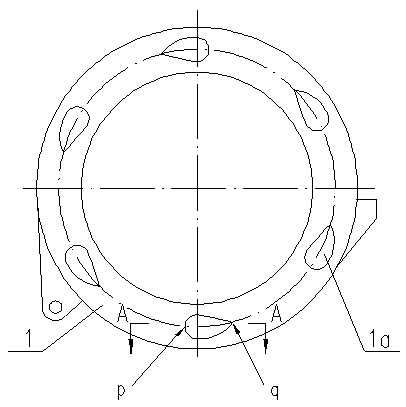

Rock shearing seepage coupling true triaxial test system

InactiveCN102607950AReduce the effects of frictionReduce corner effectsMaterial strength using tensile/compressive forcesTriaxial shear testFriction effect

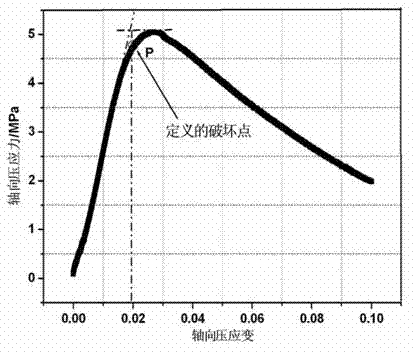

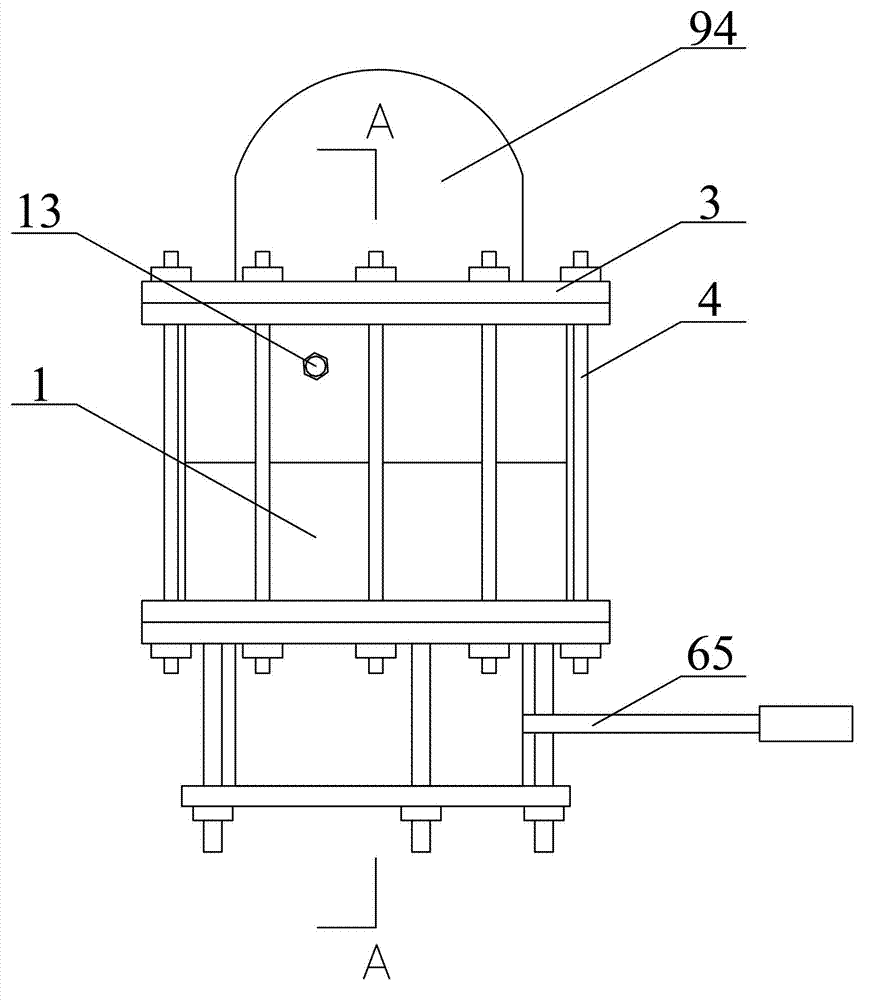

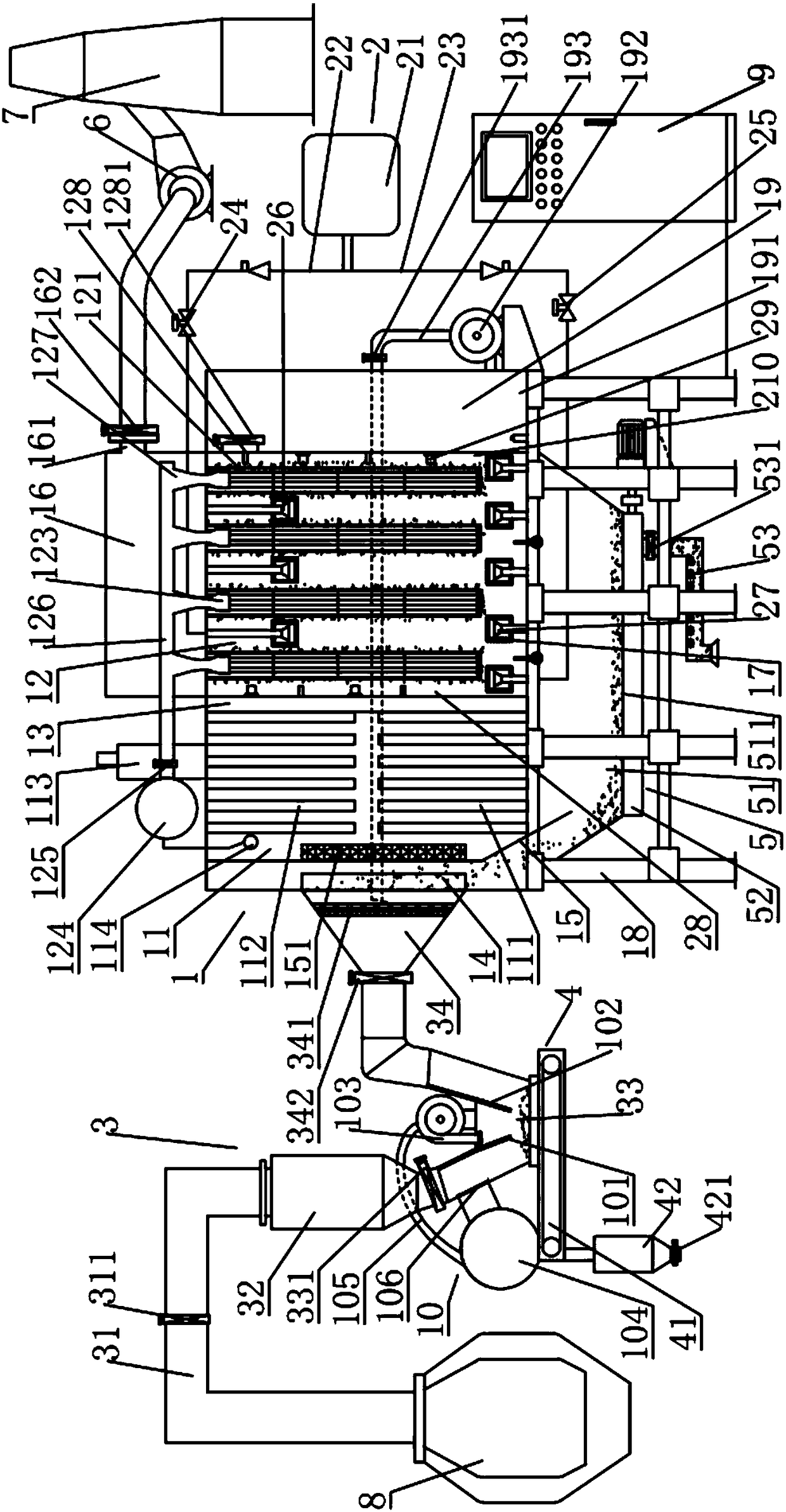

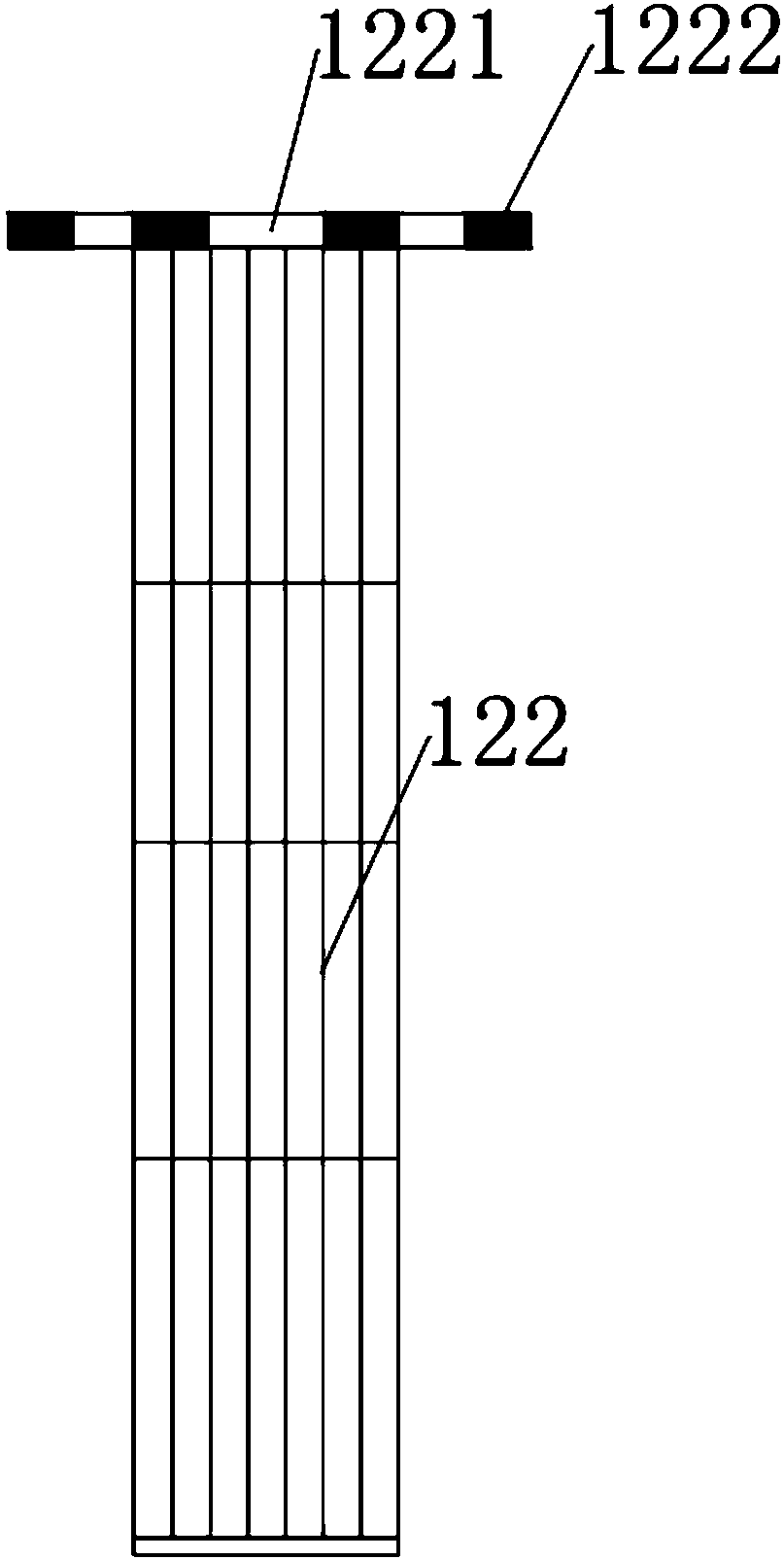

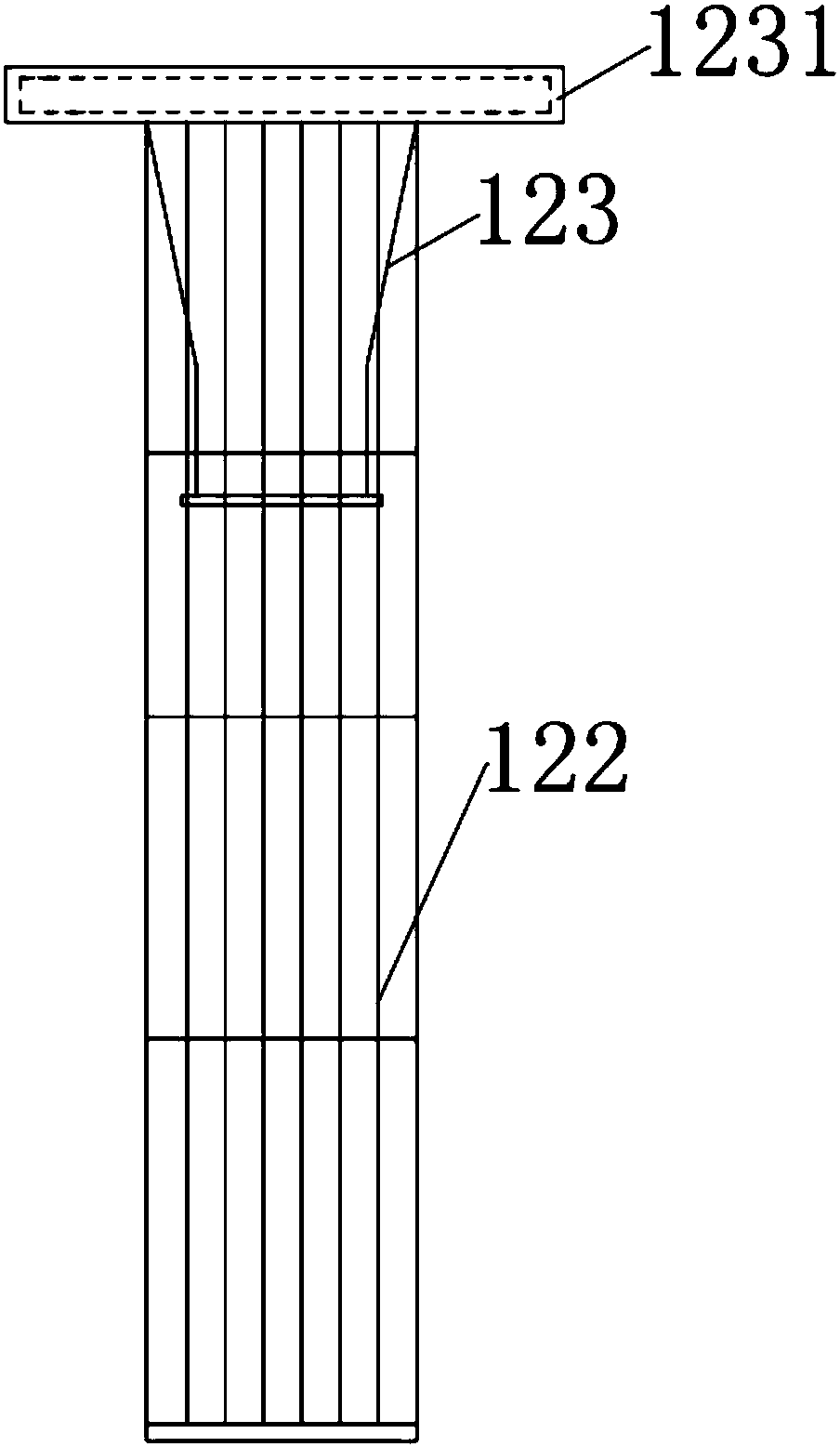

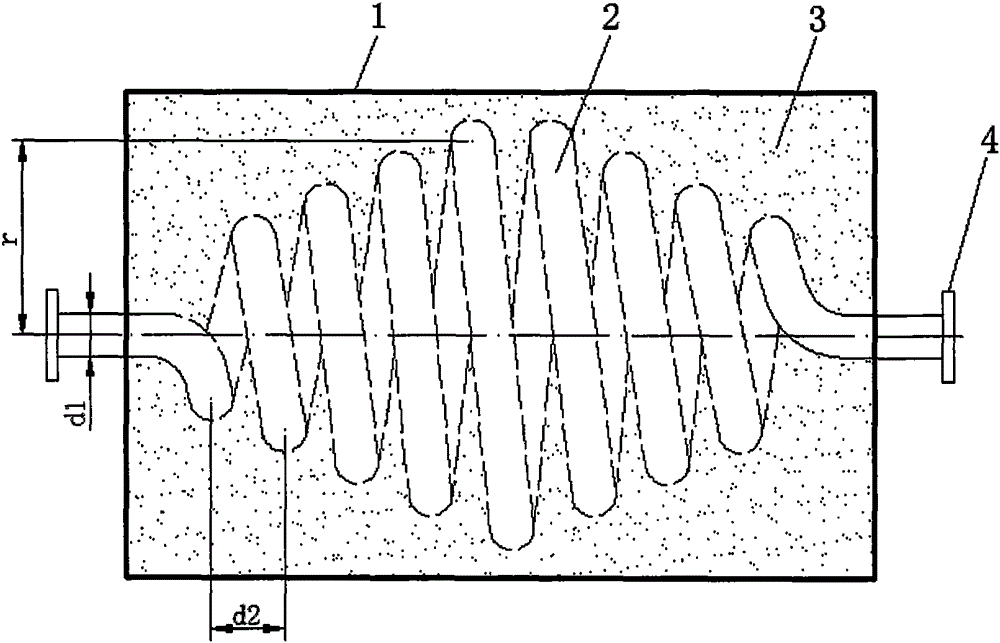

The invention relates to a rock shearing seepage coupling true triaxial test system, which comprises a loading assembly, a test box, a seepage assembly, a detection assembly and a control assembly. The whole system is high in rigid, safe and reliable in high-pressure water injection and sealability, good in sealing reliability, high in loading stability and protection strength and capable of effectively reducing the end-part friction effect and the corner effect and realizing the uniform triaxial stress state as far as possible; a loading test device and a mainshaft loading mechanism are designed in a split manner, and safe high-pressure water injection is achieved; a safety valve and a pressure-stabilizing control device are arranged on a water outlet; and the rock shearing seepage coupling true triaxial test system is stable to control.

Owner:SHANDONG UNIV OF SCI & TECH

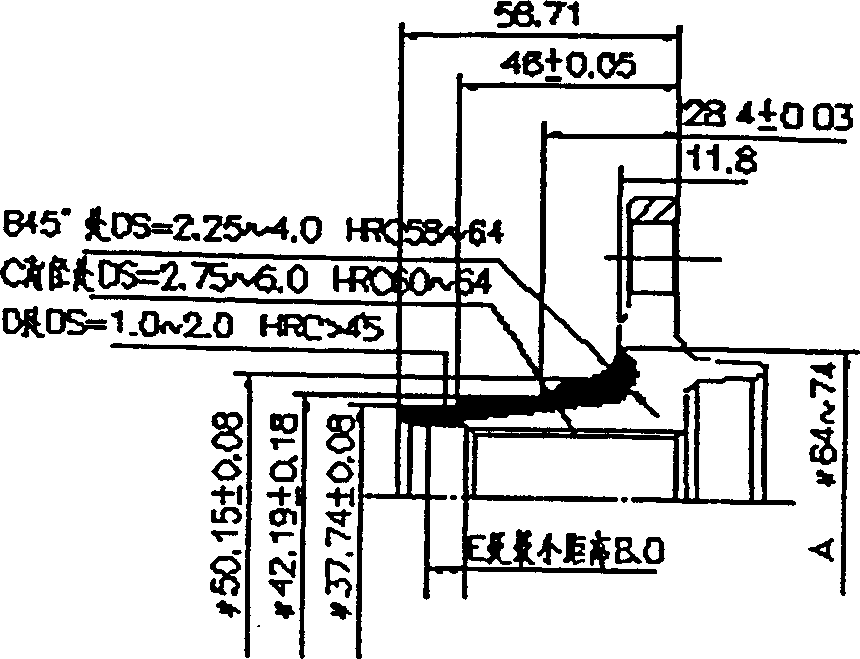

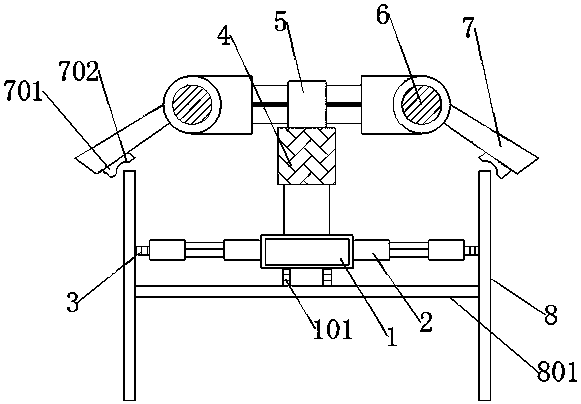

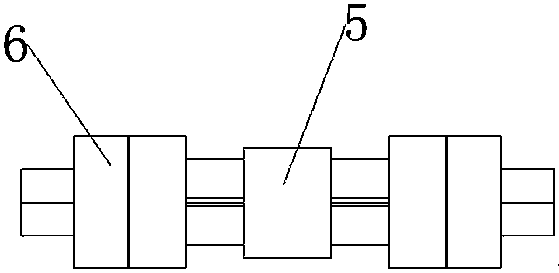

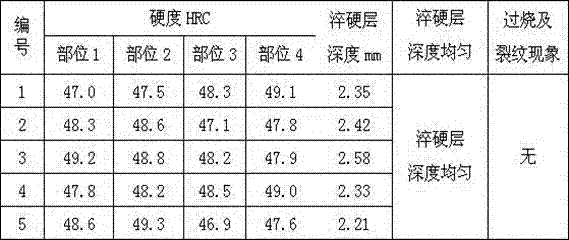

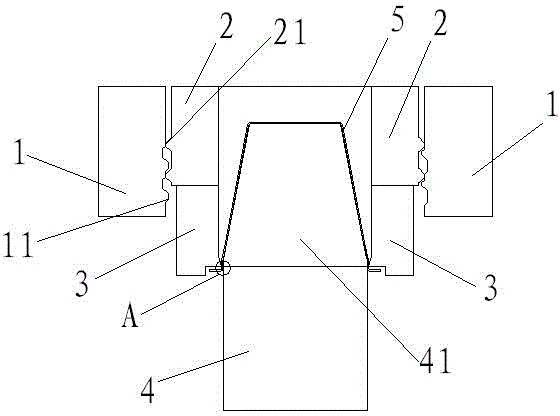

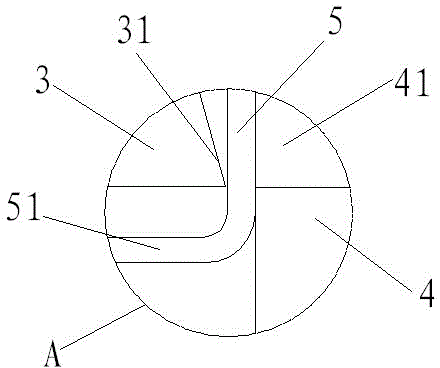

Heat treating process and inductor for key surface of hub

InactiveCN1403599AEasy to manufactureNo sharp corner effectIncreasing energy efficiencyFurnace typesIntermediate frequencyHardness

The present invention is heat treating process and inductor for key surface of hub. During the quenching, the workpiece is set inside the inductor, heated in the MF inducing heater and quenched through great power and short time inwards water spraying. The workpiece is set between the upper and the lower inducing coils. The inductor has two flow guide bodies, one semicircular upper coil and one semicircular lower coil with magnetic conductor. The present invention has the advantages of easy-to-manufacture inductor, ideal quenched hardness in all sections of the quenched part and no obvious "sharp corner effect", and no strict requirement on the quenching machine and part fixture.

Owner:ZHEJIANG WANXIANG PRECISION IND

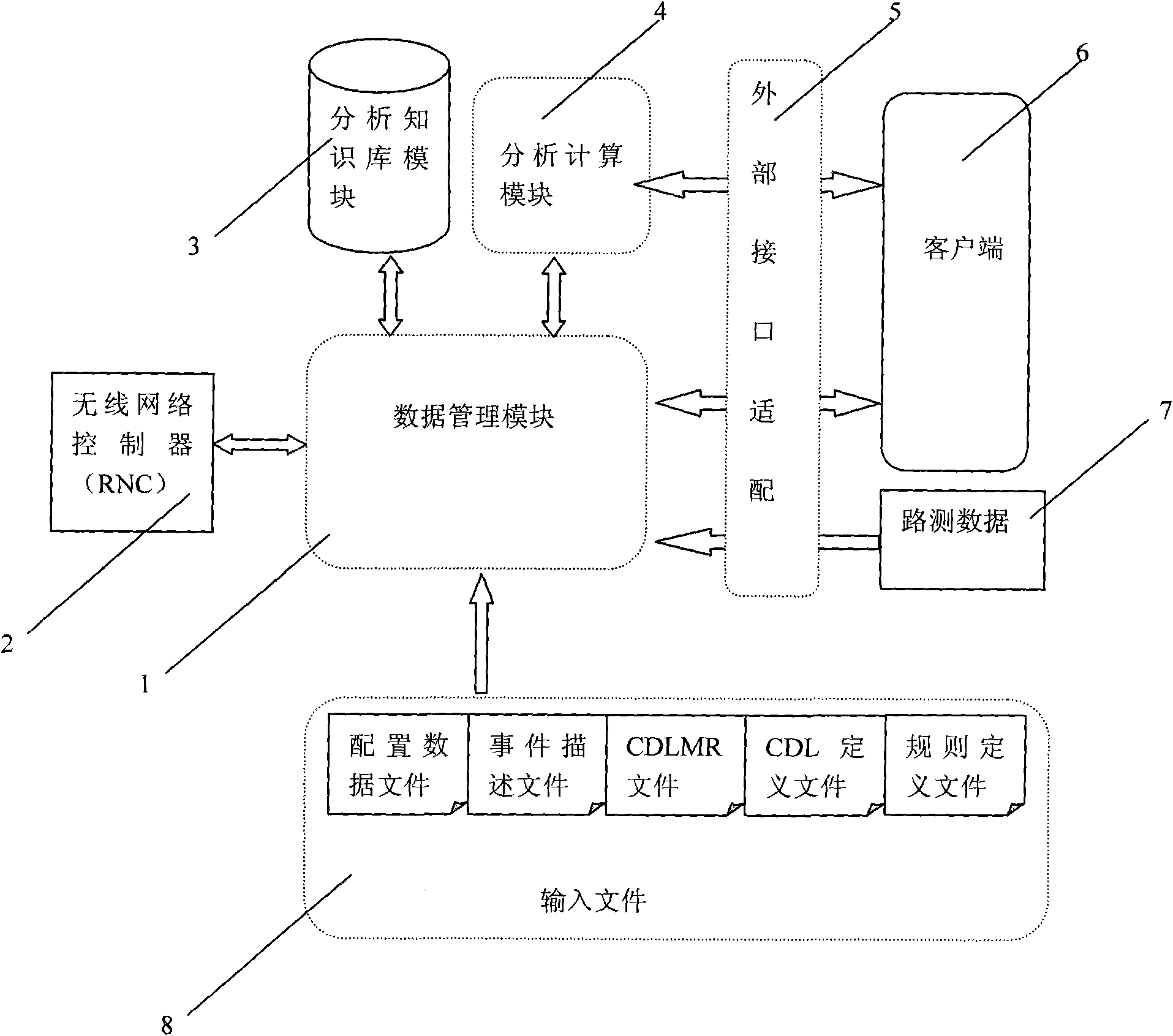

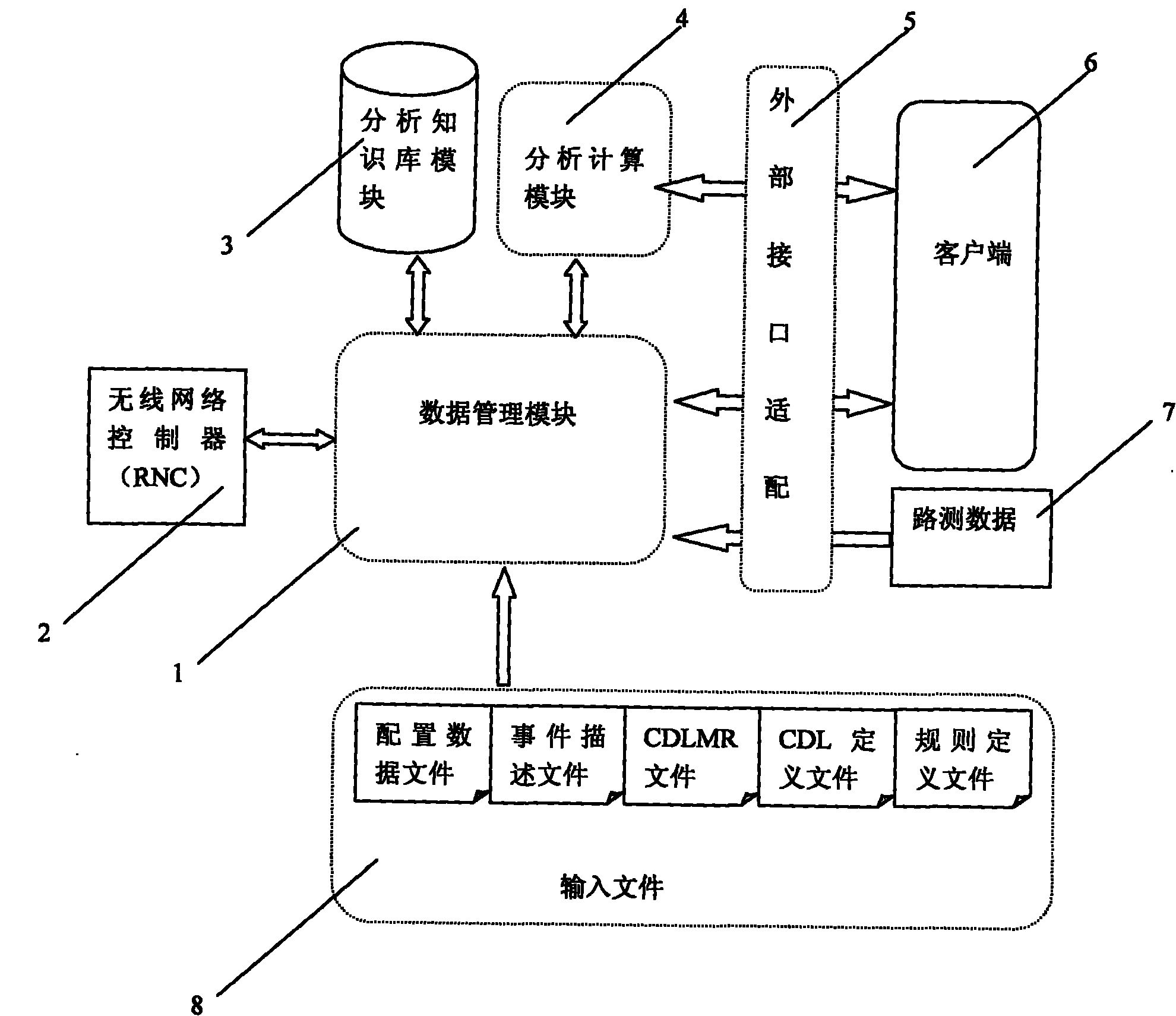

System and analysis method of TD-SCDMA (Time Division-Synchronization Code Division Multiple Access) wireless network based on geographical position coverage effect

InactiveCN101835173ASave manpower and telephone expensesGuaranteed to be scientificNetwork planningGeolocationCorner effect

The invention relates to a system and an analysis method of a TD-SCDMA (Time Division-Synchronization Code Division Multiple Access) wireless network based on a geographical position coverage effect. The system comprises a data management module which is connected with a radio network controller (RNC) through an operation maintenance interface, an analysis knowledge base module through an internal message interface and an analysis calculation module through the internal message interface as well as respectively connected with a client end and drive test data through an interface adaptor, and a file reading interface of the data management module can be also connected with an input file. The analysis method comprises the following steps of: 1. coverage strength analysis; 2. cell coverage analysis; 3. pilot frequency pollution analysis; and 4. street corner effect analysis. The invention has the characteristics of requiring no special test device, having zero cost, filling up an indoor signal test blank and saving manpower call expenditure of drive test vehicles.

Owner:陕西浩瀚新宇科技发展有限公司

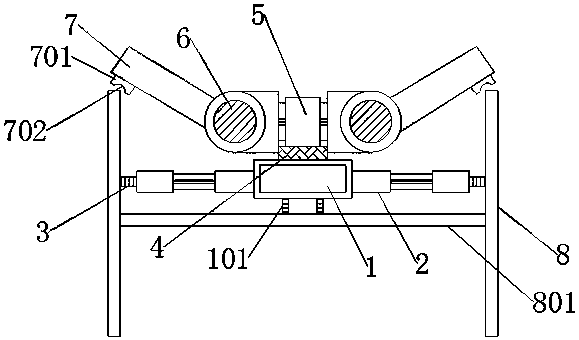

Triaxial test device for asphalt mixture and test method

ActiveCN103076225ASolve problems not suitable for asphalt mixEasy to operateMaterial strength using tensile/compressive forcesTriaxial shear testEngineering

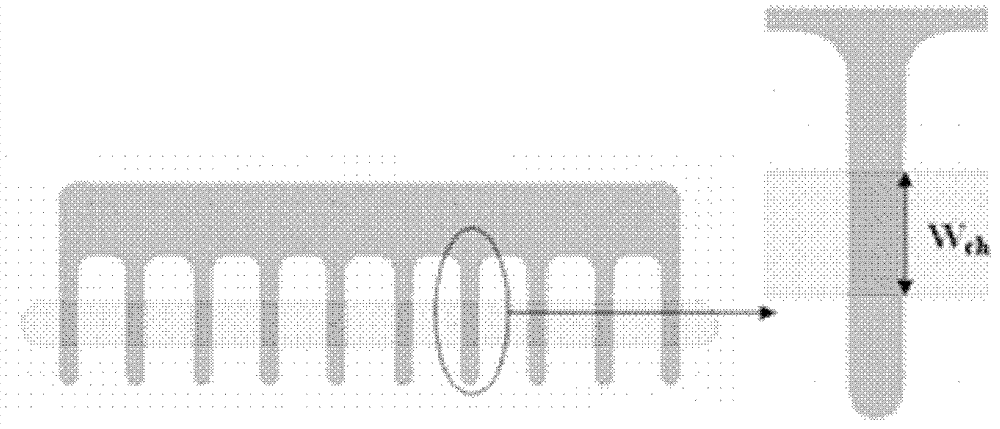

The invention discloses a triaxial test device for an asphalt mixture, which comprises an outer air bag assembly, an inner air bag assembly, an upper press plate, a lower press plate and an air pressure console, wherein an outer air bag of the outer air bag assembly is placed on the outside of a test piece and wraps the outer lateral surface of the test piece; an inner air bag of the inner air bag assembly is installed in an inner hole of the test piece and is in close contact with the inner hole surface of the test piece; and the air pressure console can provide stable air pressure for the inner air bag assembly and the outer air bag assembly. The device has the characteristics that the control is easy, and the corner effect in the turning corner position of a traditional cubic triaxial test piece can be prevented. The triaxial test method for the asphalt mixture solves the problem that existing triaxial test devices are not suitable for the asphalt mixture, so that the strength study for the asphalt mixture is expanded from single-dimensional stress state to three-dimensional stress state; therefore, the triaxial test device and method of the asphalt mixture have important significance for studying the mechanical property of the asphalt mixture, the design of the asphalt mixture and the prevention and treatment of asphalt road surface damage under the complicated stress state.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

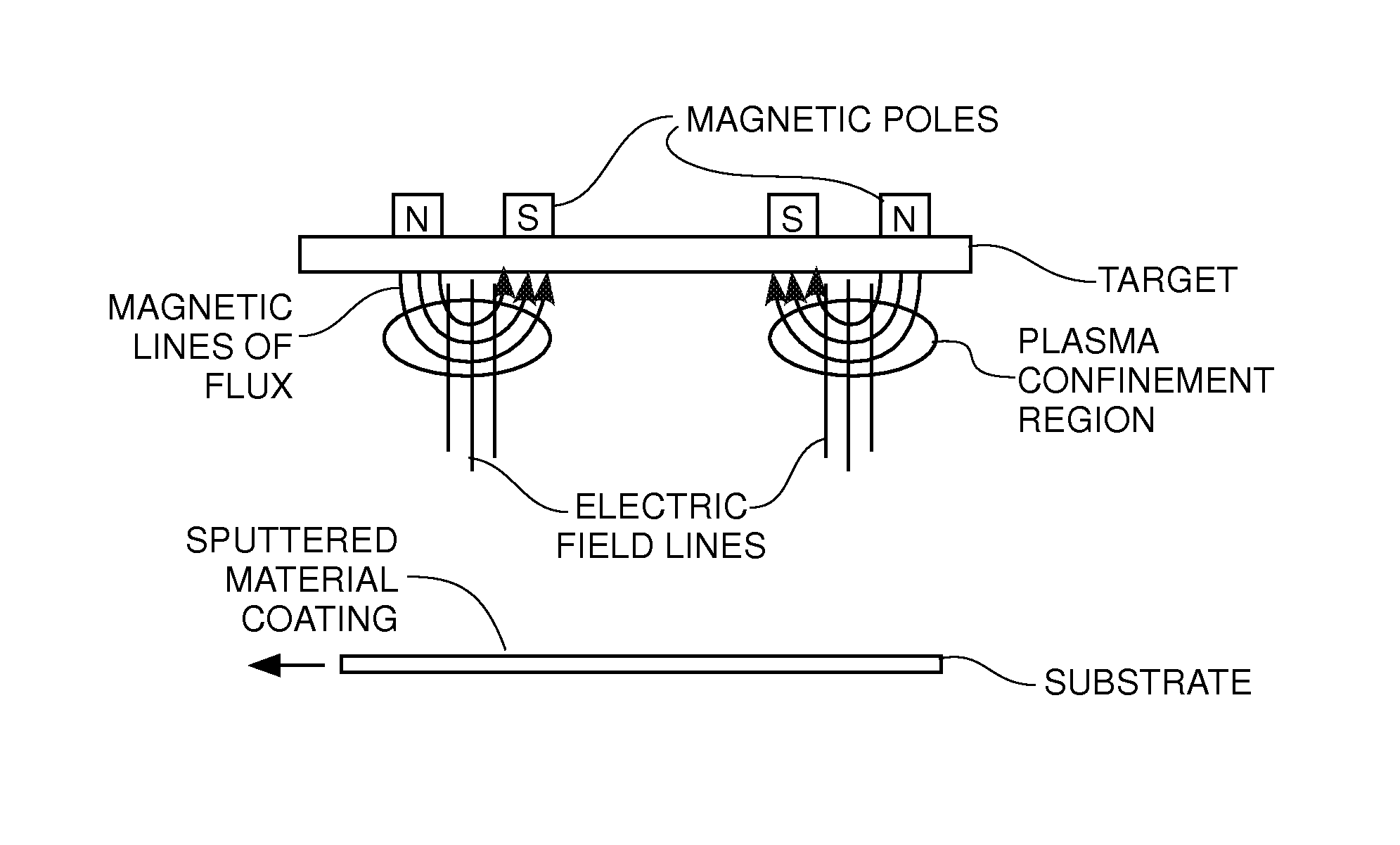

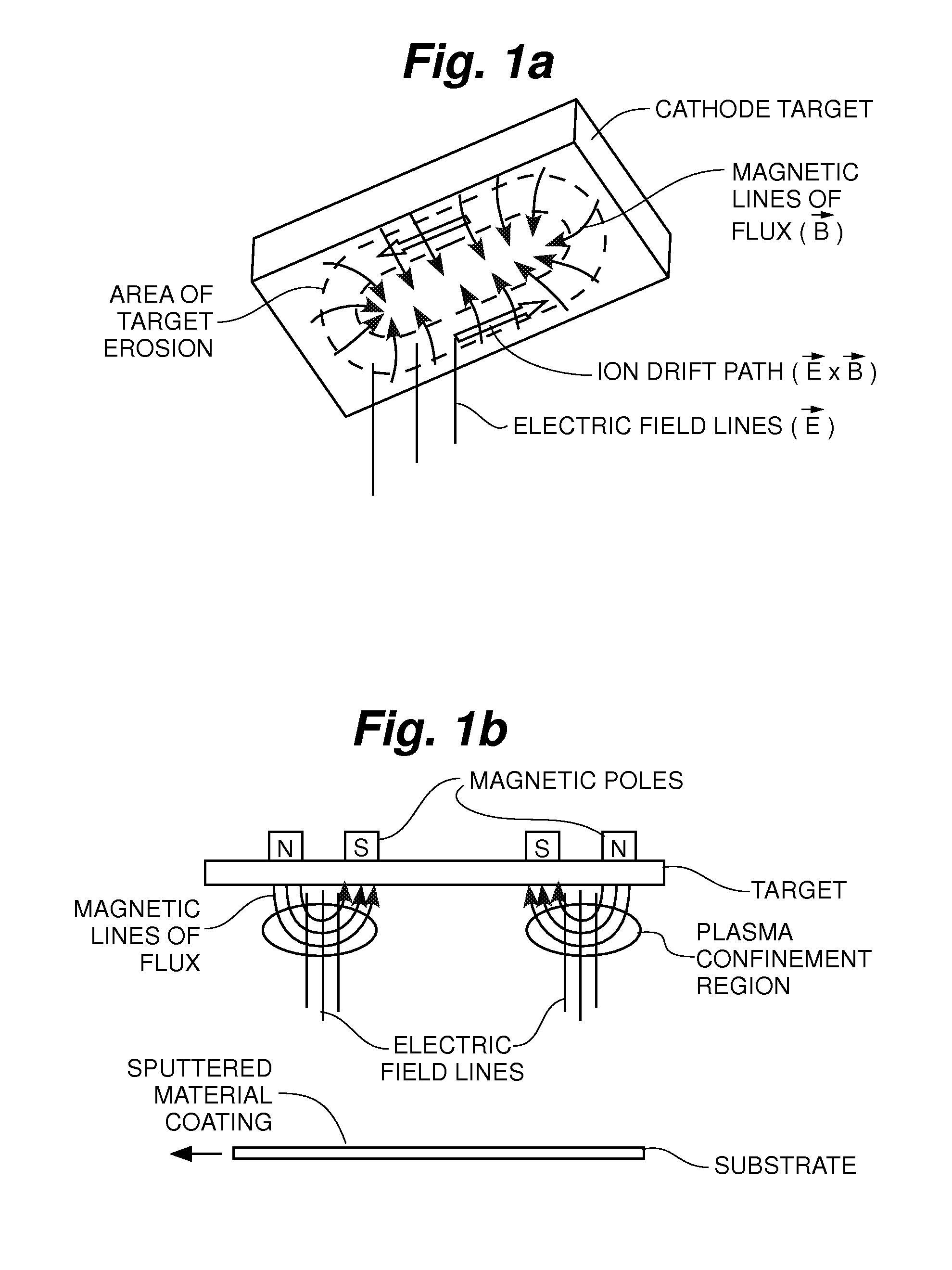

Apparatus for cylindrical magnetron sputtering

ActiveUS20140054168A1Improve target utilizationCellsElectric discharge tubesSputteringPlasma confinement

A cathode target assembly for use in sputtering target material onto a substrate includes a generally cylindrical target and a magnetic array. The magnetic array is adapted to provide a plasma confinement region adjacent an outer surface of the target. End portions of the magnetic array are adapted to make the shape and strength of the confinement field at the turns of the racetrack closely match the shape and strength of the confinement field along the straight part of the racetrack so as to significantly reduce cross-corner effect.

Owner:CARDINAL CG

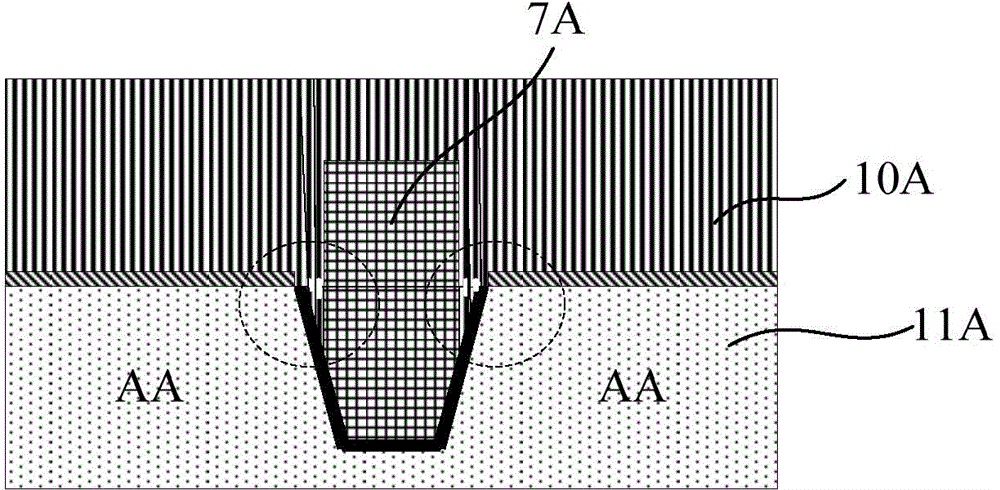

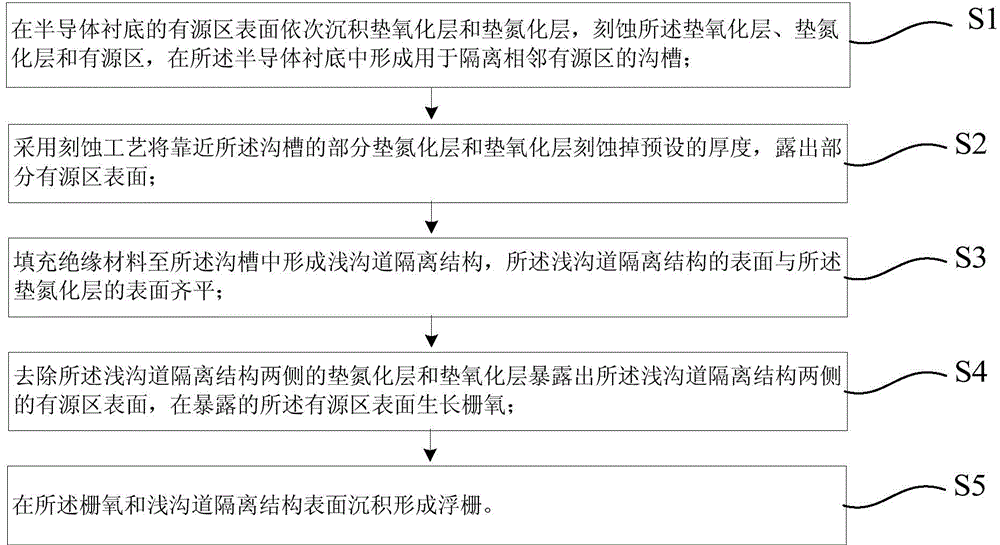

Semiconductor device preparation method

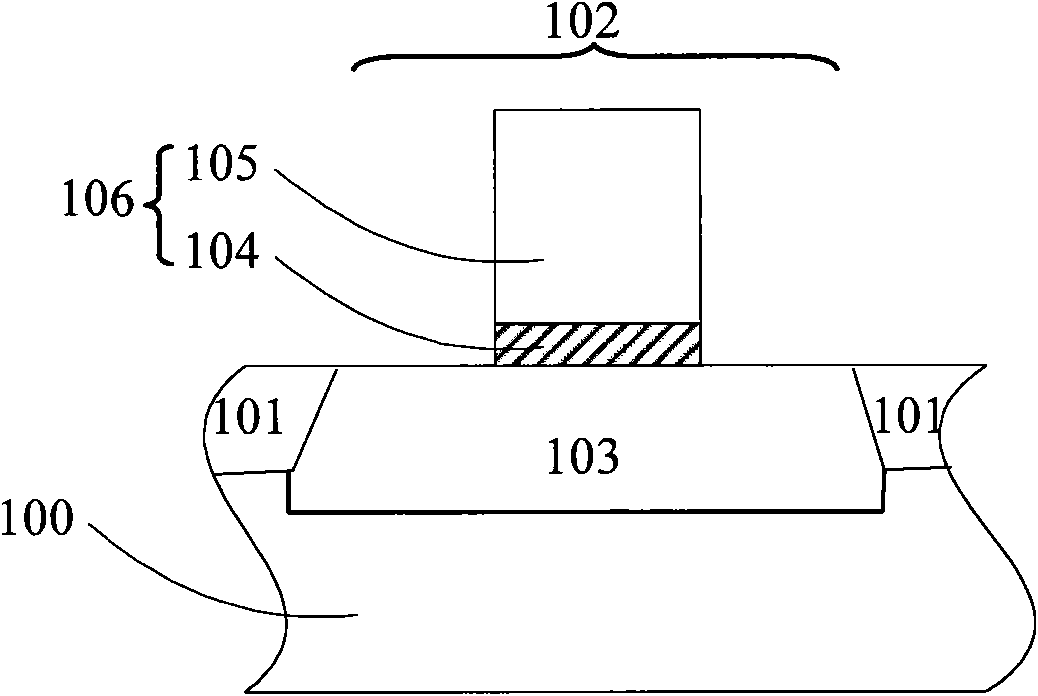

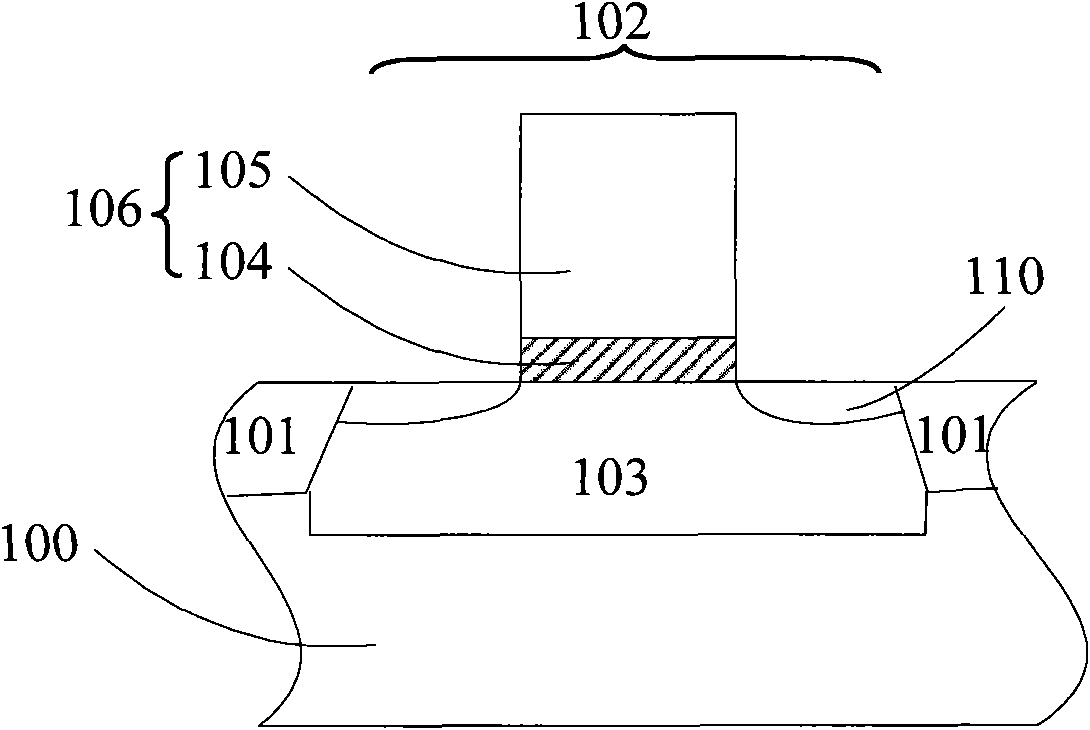

InactiveCN104835774AAvoid sharp corner effectSemiconductor/solid-state device manufacturingSemiconductor devicesGate oxideCorner effect

The invention provides a semiconductor device preparation method, at least comprising the steps of: successively depositing a pad oxide layer and a pad nitride layer on the active area (AA) surface of a semiconductor substrate and etching the pad oxide layer, the pad nitride layer and AAs to form a groove for separating adjacent AAs; employing the etching technology to etch part of the pad oxide layer and the pad nitride layer close to the groove by a preset thickness to expose part of the AA surface; filling insulating materials in the groove to form a shallow channel isolation structure; removing the pad oxide layer and the pad nitride layer on two sides of the shallow channel isolation structure to expose the AA surface on two sides of the shallow channel isolation structure and grow gate oxide on the AA surface; and depositing to form floating gates on a gate oxide surface. In the preparation method, the sidewalls of the pad oxide layer and the pad nitride layer are etched by a certain thickness before filling the insulating materials, allowing the insulating materials subsequently filled in the groove to cover the AA surface, guaranteeing corners of the AA surface to be covered by insulating materials thick enough, and avoiding sharp corner effects.

Owner:SEMICON MFG INT (SHANGHAI) CORP

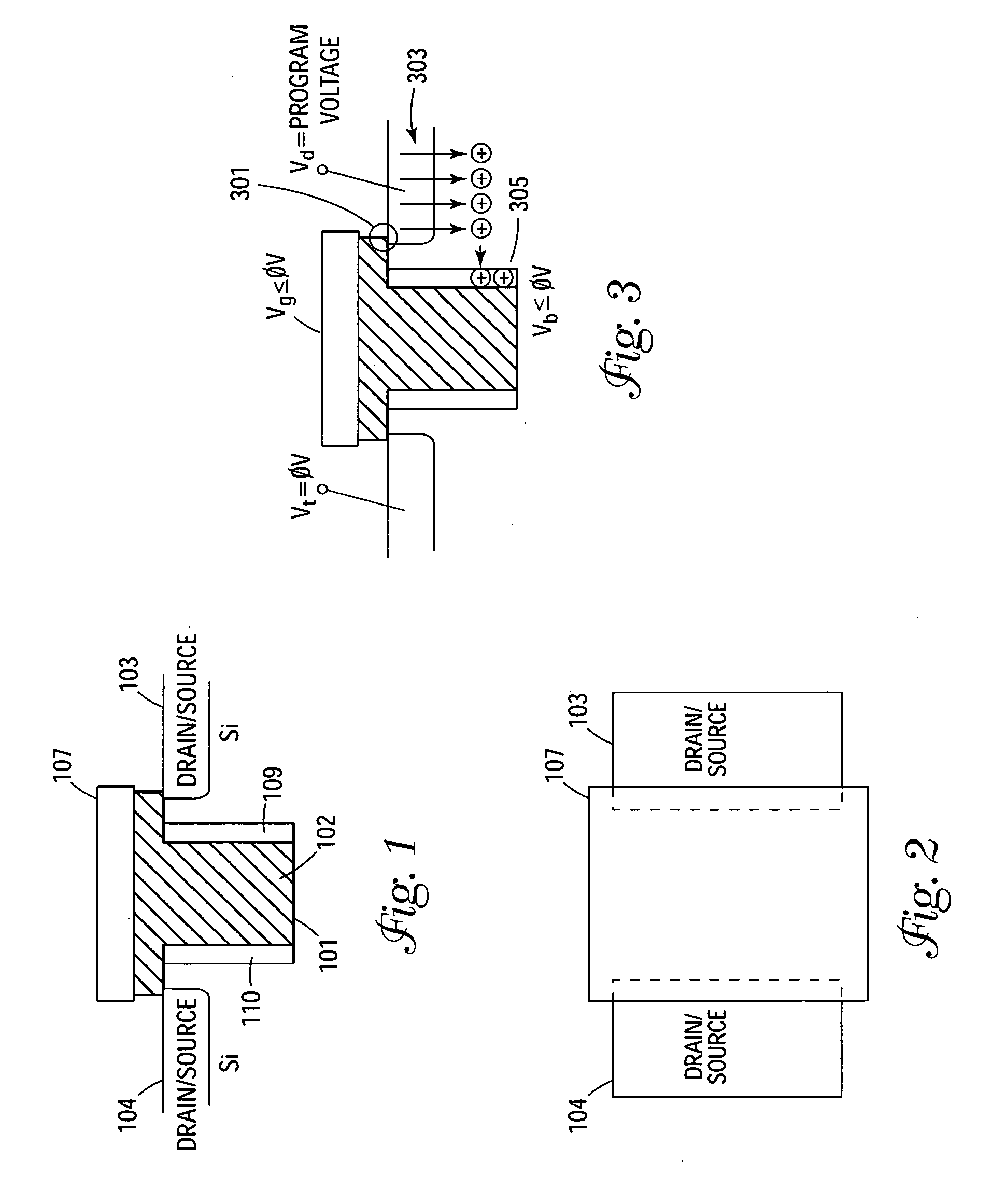

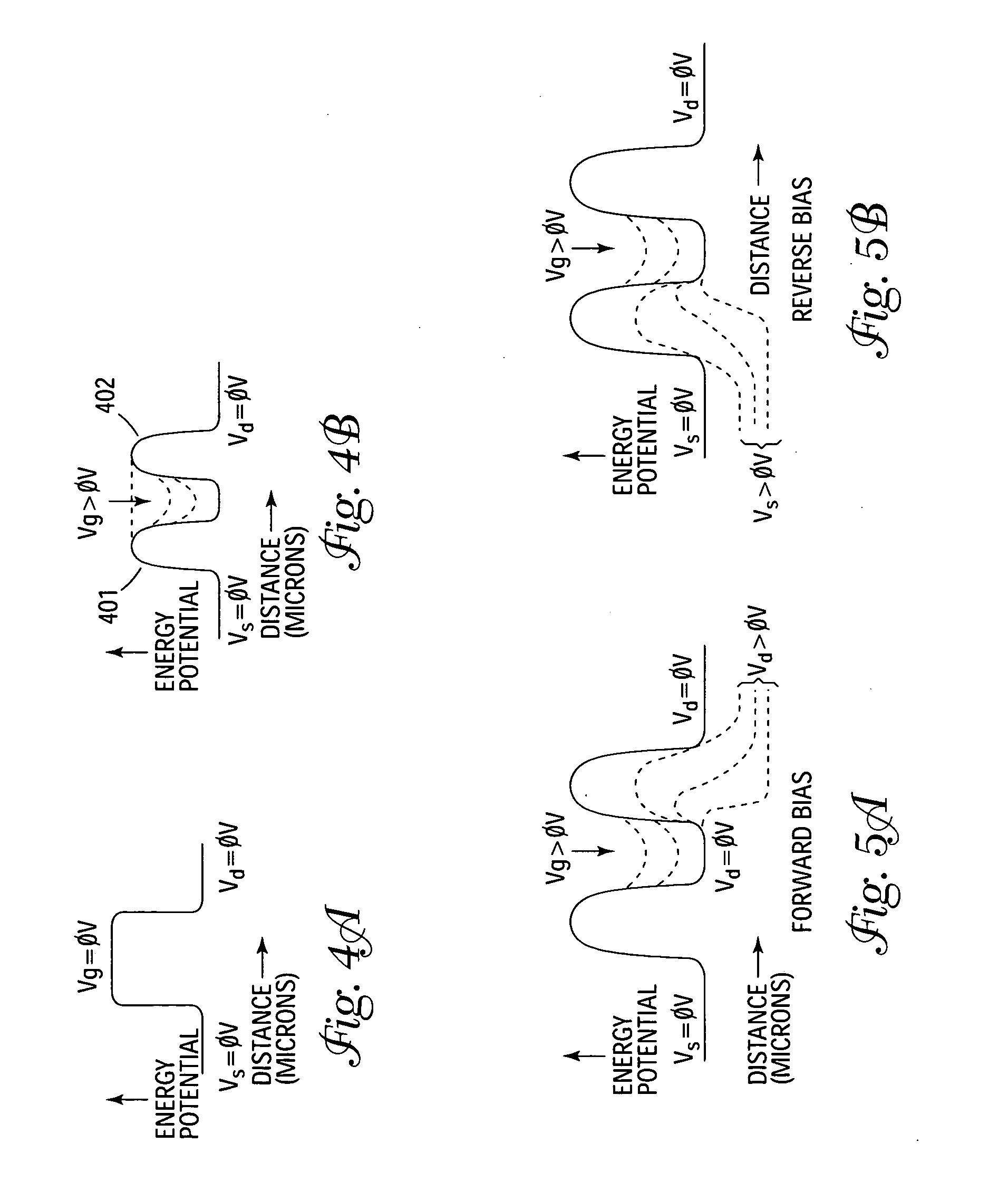

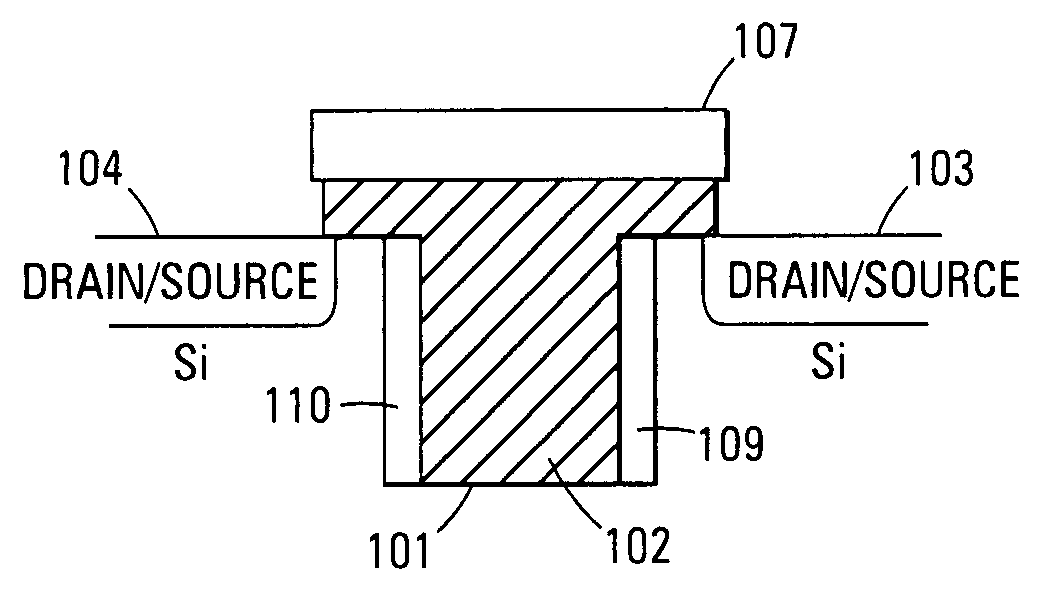

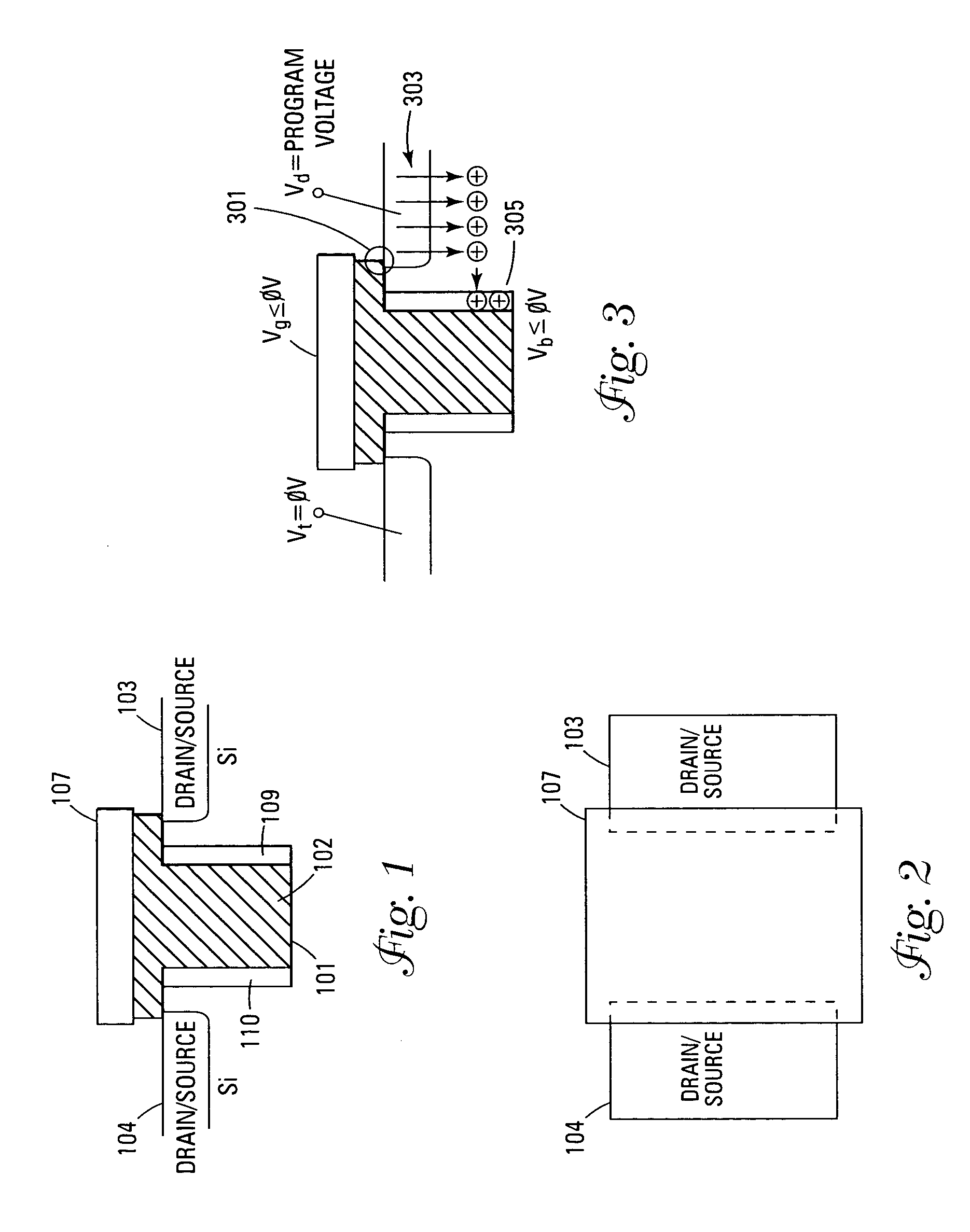

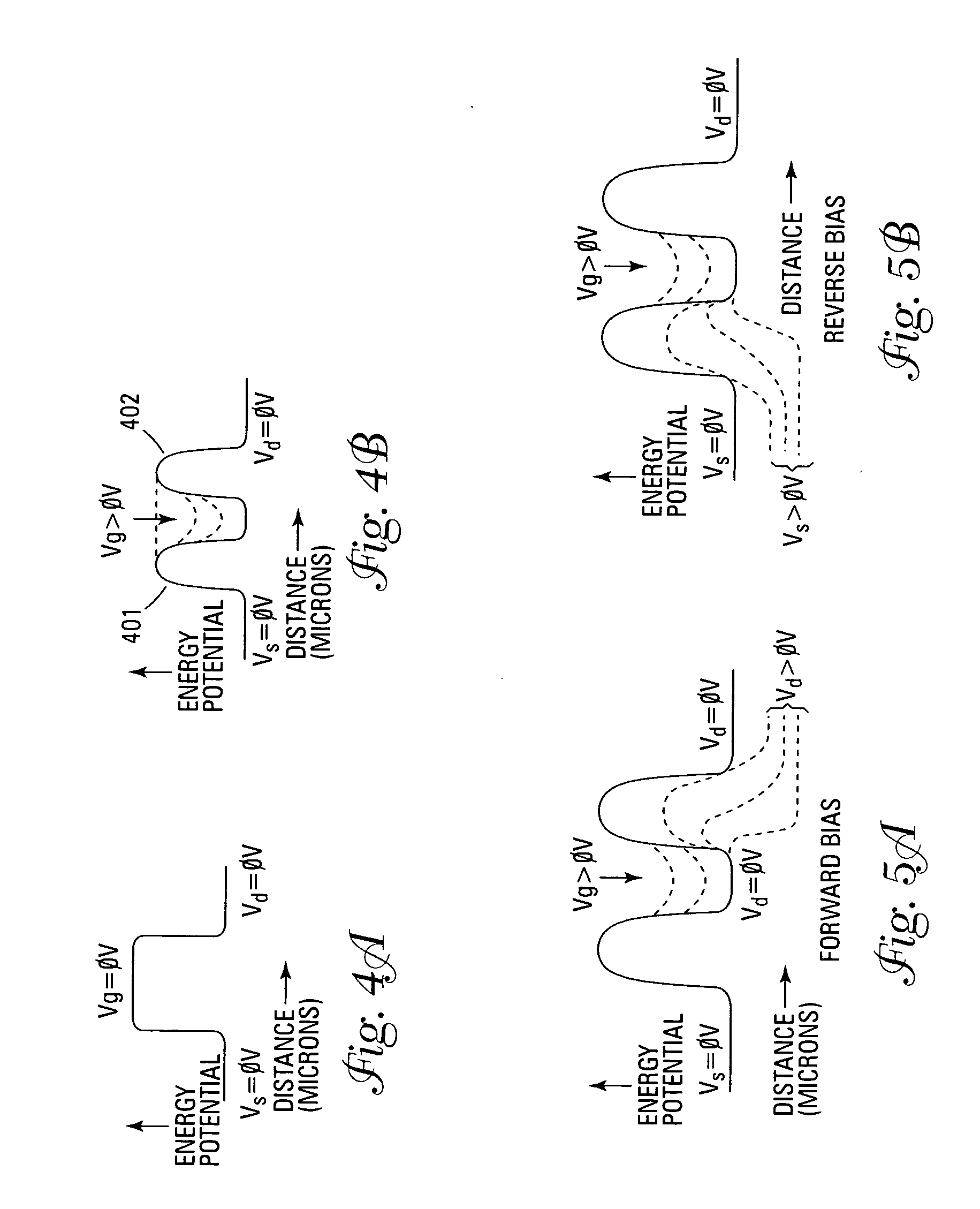

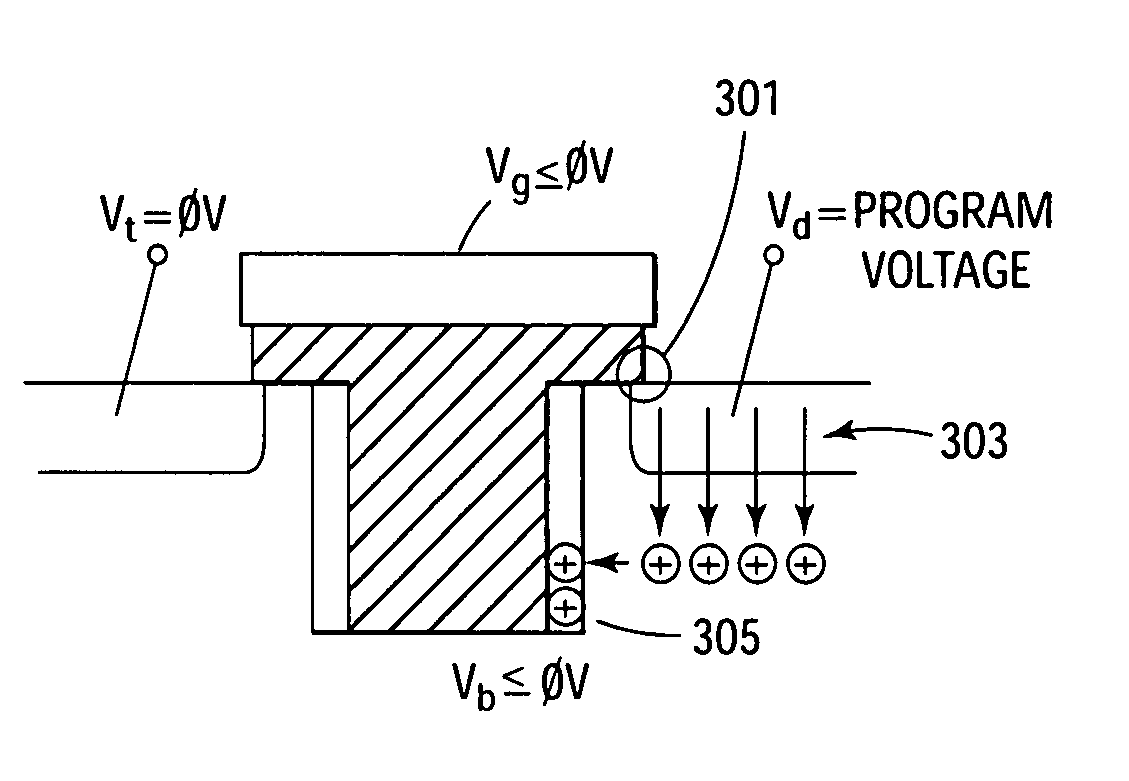

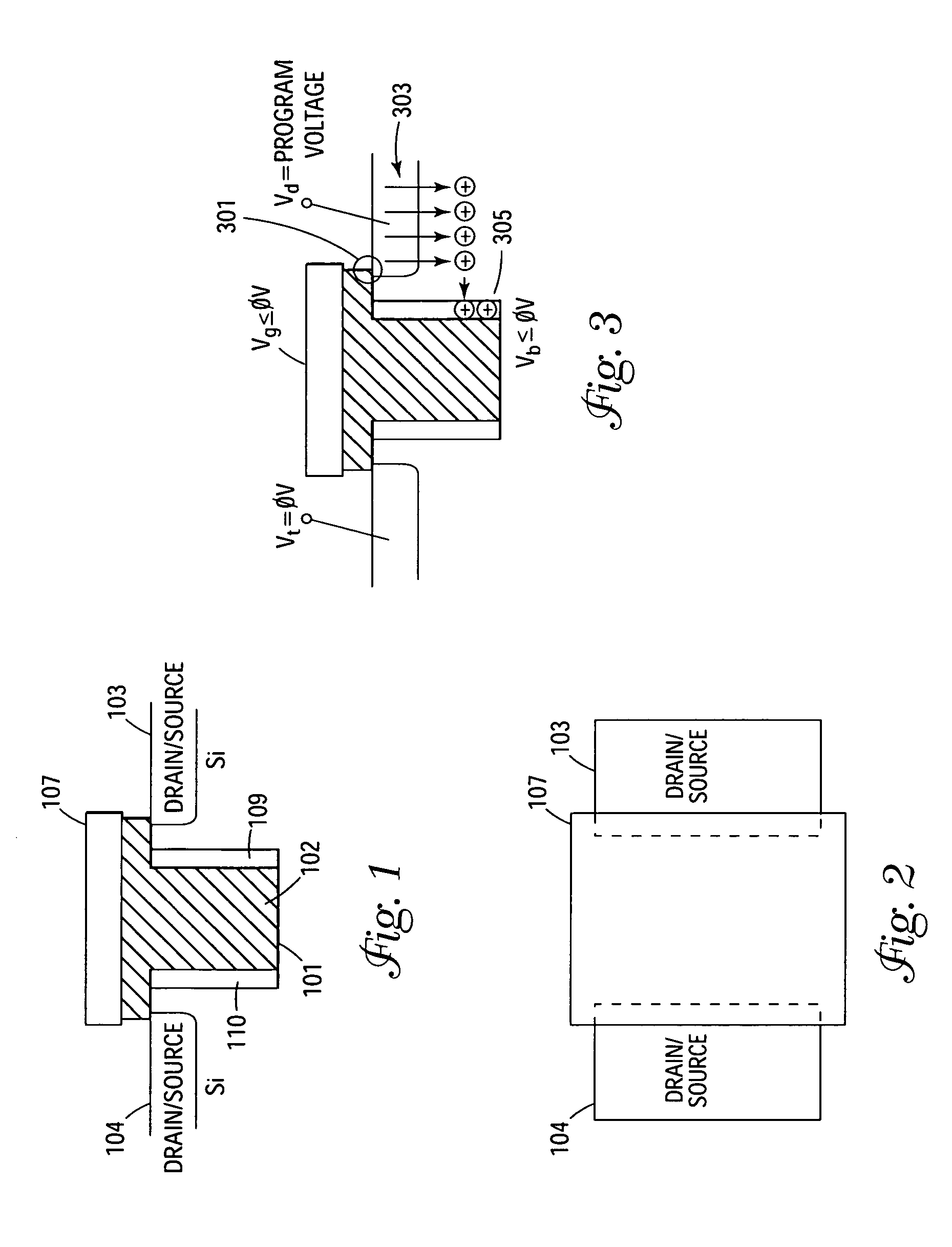

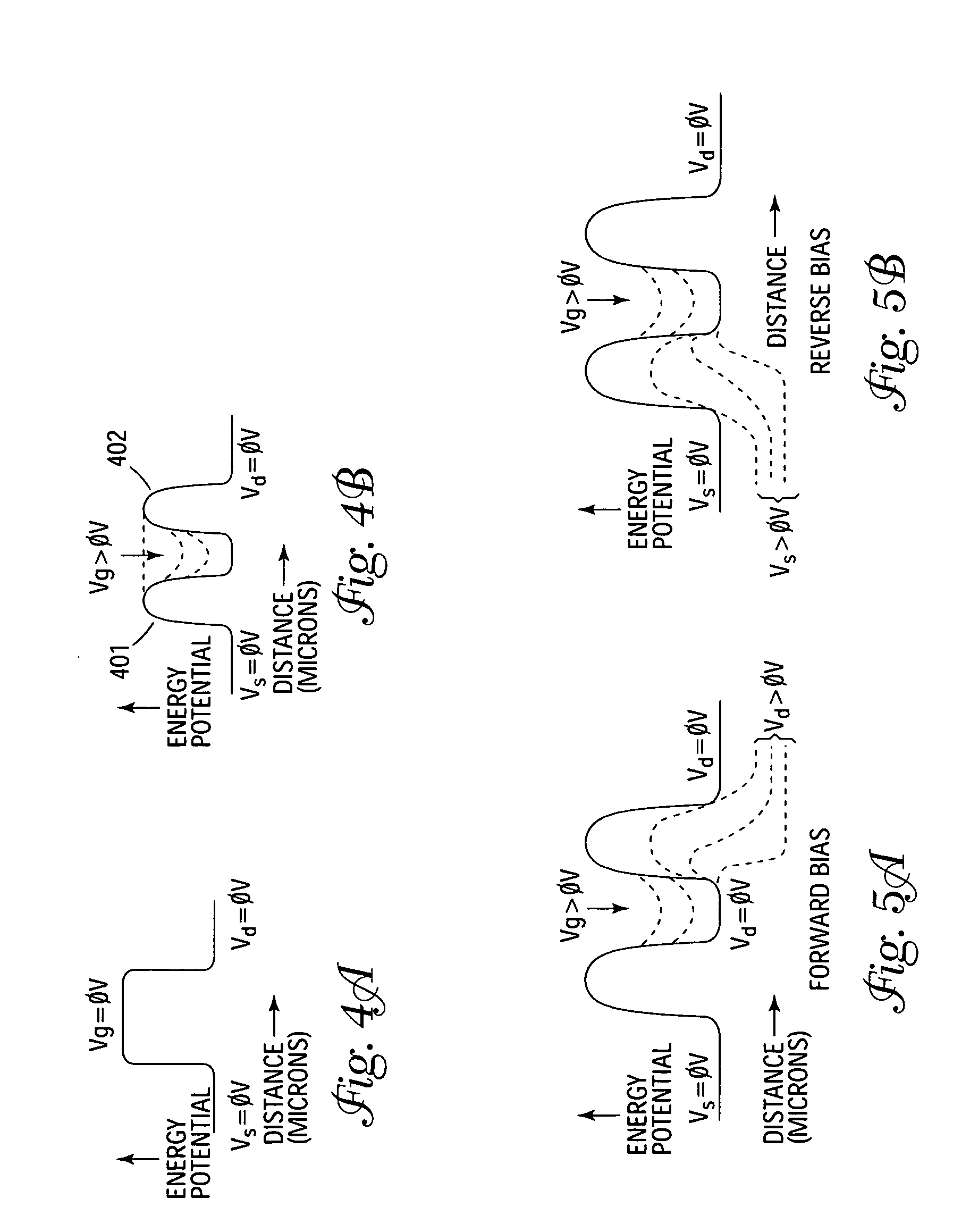

Trench corner effect bidirectional flash memory cell

A non-volatile memory cell structure that is capable of holding two data bits. The structure includes a trench in a substrate with two sides of the trench being lined with a trapping material. The trench is filled with an oxide dielectric material and a control gate is formed over the oxide-filled trench. Source / drain regions are adjacent the trench sides with the trapping material. An energy barrier between the drain and source regions has two local high points that correspond to the trench corners. To read the device, sufficient gate voltage is applied to invert the channel and a sufficient drain voltage is applied to pull down the drain-side barrier. If charges of opposite polarity are trapped in the source-side trench corner, the source barrier will be significantly lowered so that current flows between source and drain under read conditions.

Owner:MICRON TECH INC

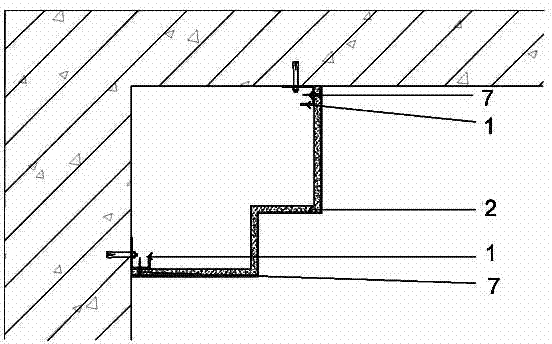

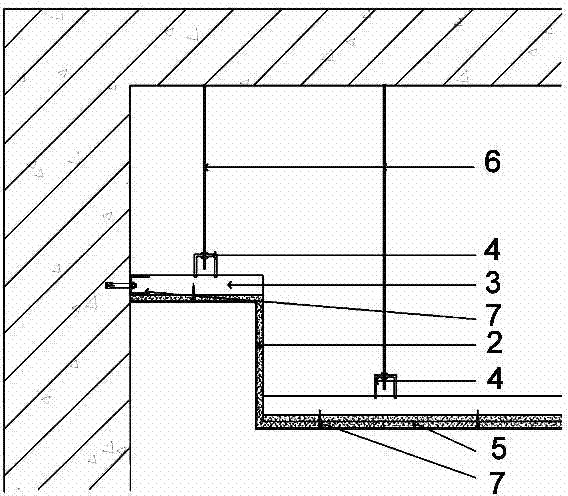

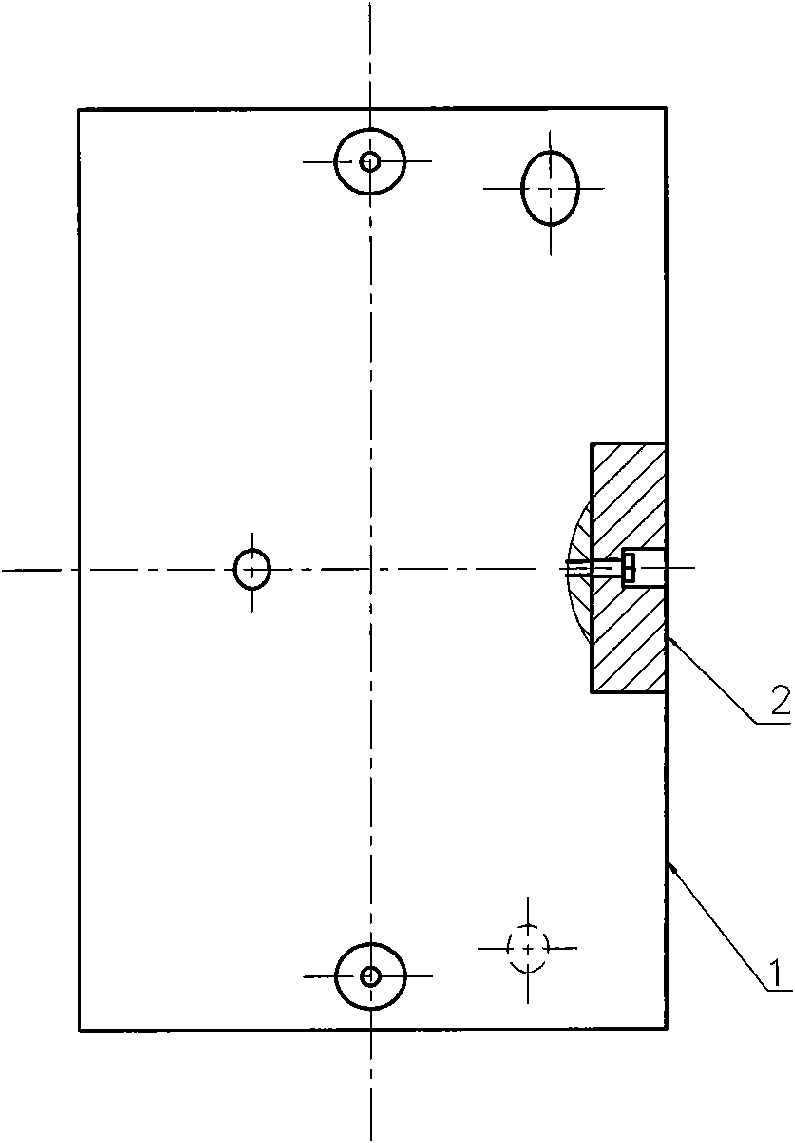

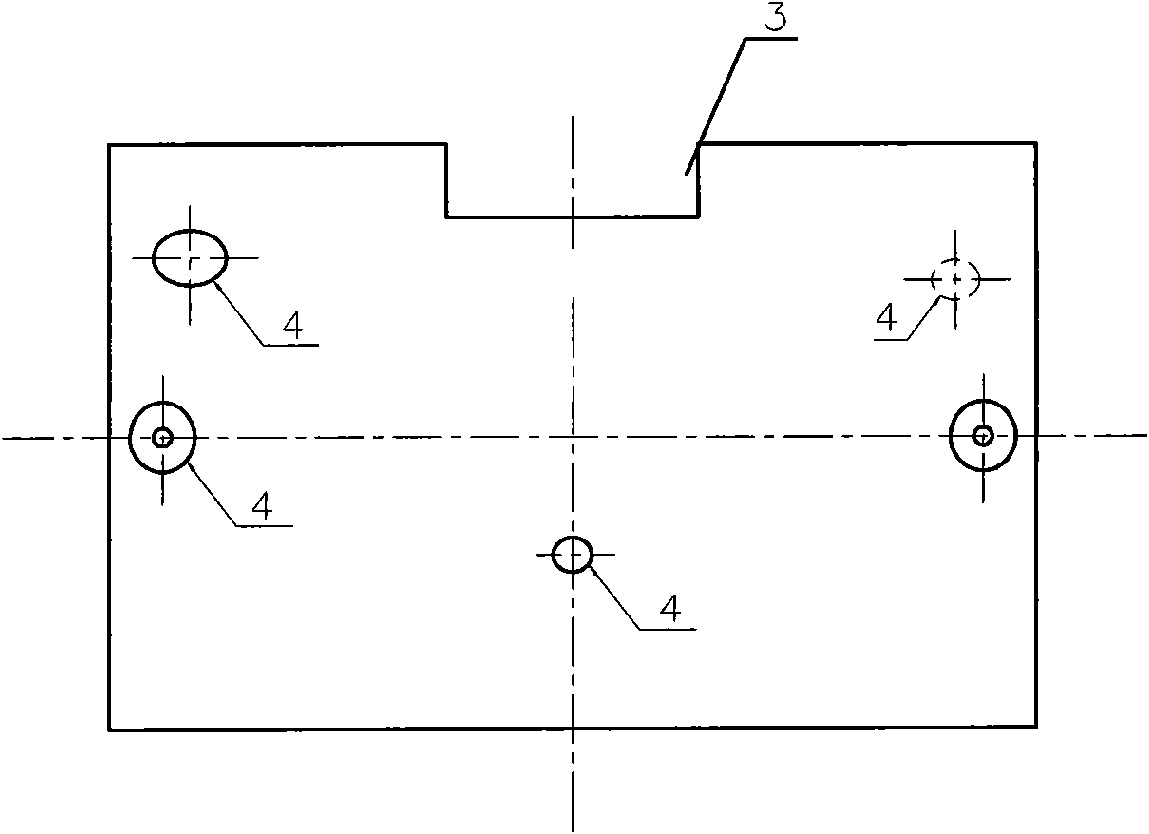

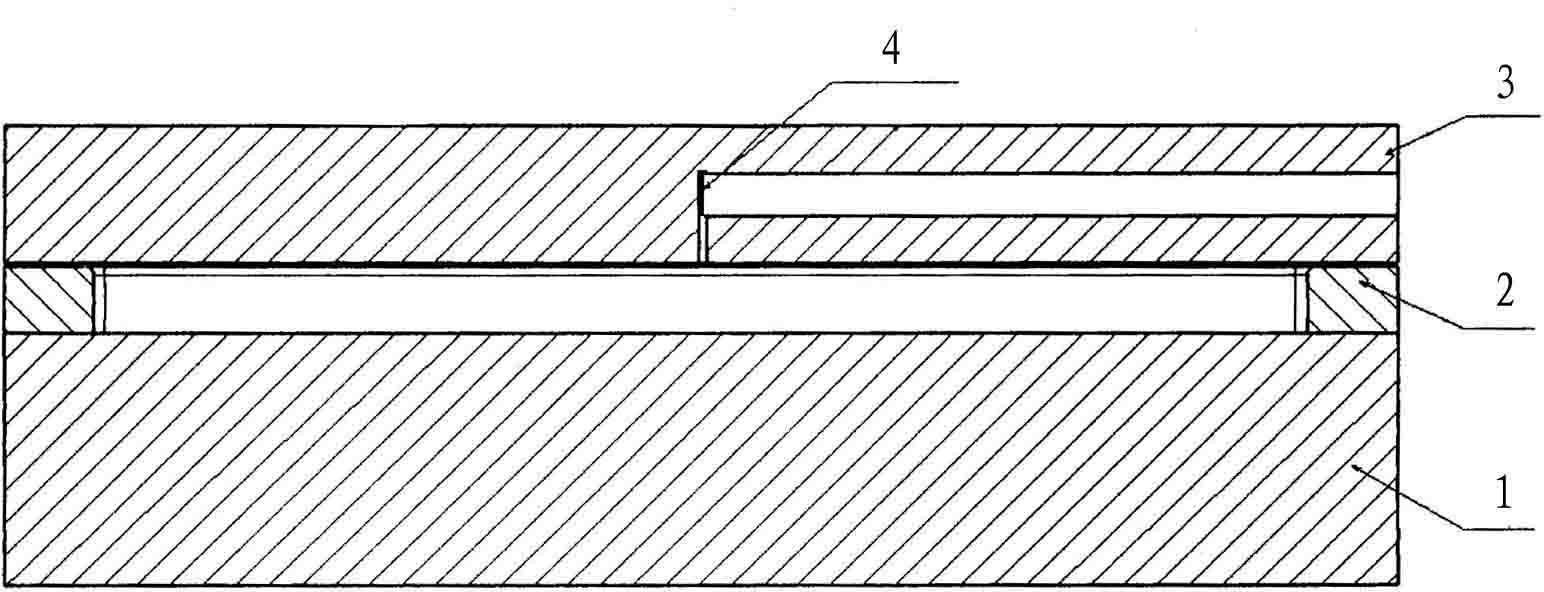

Mounting structure for prefabricated molded gypsum board

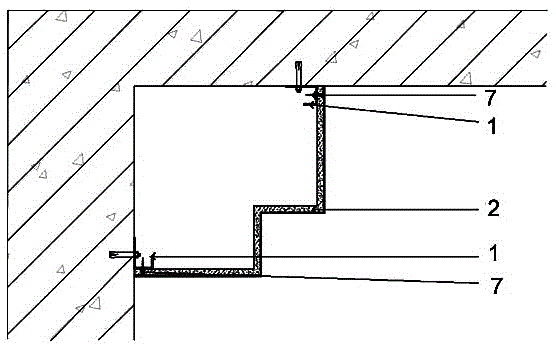

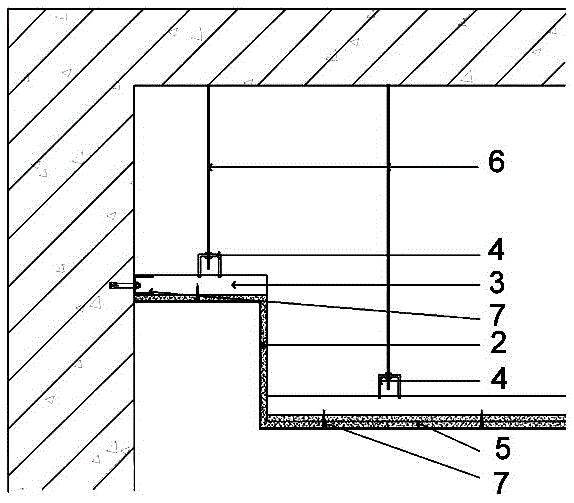

ActiveCN102953497AReduce loadThe yin and yang angles are crisp and beautifulCeilingsKeelArchitectural engineering

The invention discloses a mounting structure for a prefabricated molded gypsum board. The mounting structure comprises a prefabricated molded gypsum board (2) and a keel system, wherein the prefabricated molded gypsum board (2) is provided with at least one corner; the keel system is fixed on a building structure; and the prefabricated molded gypsum board (2) is connected with the keel system. According to the mounting structure for the prefabricated molded gypsum board provided by the invention, an assembling type construction technology is adopted, an external corner effect being overlapping, stiff and smooth is endowed, the construction is cost-saving and labor-saving, and the end-product construction for circular, arc and specially shaped suspended ceilings is achieved.

Owner:GOLD MANTIS CONSTR DECORATION

Trench corner effect bidirectional flash memory cell

ActiveUS20050051830A1Increase memory densityTransistorSemiconductor/solid-state device manufacturingTrappingEngineering

A non-volatile memory cell structure that is capable of holding two data bits. The structure includes a trench in a substrate with two sides of the trench being lined with a trapping material. The trench is filled with an oxide dielectric material and a control gate is formed over the oxide-filled trench. Source / drain regions are adjacent the trench sides with the trapping material. An energy barrier between the drain and source regions has two local high points that correspond to the trench corners. To read the device, sufficient gate voltage is applied to invert the channel and a sufficient drain voltage is applied to pull down the drain-side barrier. If charges of opposite polarity are trapped in the source-side trench corner, the source barrier will be significantly lowered so that current flows between source and drain under read conditions.

Owner:MICRON TECH INC

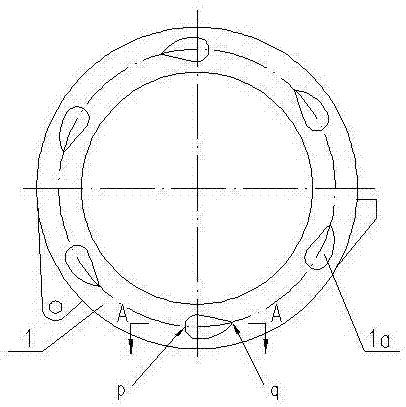

Cross head surface induction hardening method of marine diesel engine

InactiveCN101671766AReduce sharp corner effectPrevent quenching crackingFurnace typesIncreasing energy efficiencyNumerical controlInduction hardening

The invention relates to a cross head surface induction hardening method of a marine diesel engine, wherein, a notch on the cross head hardening surface of the marine diesel engine is filled by a technique block, and all the holes are sealed by moist clay; a cross head is mounted on a hardening machine; and a circular self-water spraying induction coil is mounted to be used for carrying out continuous hardening. Through filling the notch by the technique block and sealing the holes by the moist clay when hardening, the invention can reduce the sharp corner effect when hardening workpieces, thehardening speed at the sharp corner can be controlled by the numerical control technique, and the internal stress is reduced, thereby hardening cracks of the workpieces are avoided. After being treated by the induction hardening method, the hardening hardness of the cross head of the marine diesel engine is uniform and has no hardening soft belt; the hardness and the hardened layer of all the required hardening surfaces conform to the specification of drawings and technical files, and thereby, the difficult problem of hardening is solved, the quality is more stable, the hardening time of theparts is shortened, and the production efficiency is improved.

Owner:YICHANG MARINE DIESEL ENGINE

Dust remover with explosion-resistant function

PendingCN108514797AReasonable structural designQuality improvementCombination devicesDispersed particle filtrationEngineeringElectric control

The invention discloses a dust remover with an explosion-resistant function. The dust remover comprises a dust removal system, an inerting spray system, a cooling system, a coarse dust conveying system, a dust conveying system, a first fan, a chimney, dust discharging equipment, an electric control box and an explosion-resistant device. According to the dust remover, composite fire behavior sensors such as temperature sensing, smoke sensing and light sensing are arranged at different portions in the dust remover, temperature, smoke and light signals are fed back to a central control system, then the central control system makes an output response in real time and controls starting of an inerting device, inerting gas is quickly sprayed into a box body to change the explosion environment andcompletely end the burning trend, and the inerting function is achieved; meanwhile, when explosive dust in dust removal equipment is reversely exploded, explosion impact waves are transmitted from the interior of the dust removal equipment into the explosion-resistant device along a dust conveying pipe, the explosion-resistant device makes the intensity of the impact waves which enter into the internal structure of the explosion-resistant device quickly attenuated by using a gas storage tank, the critical pipe diameter and the corner effect until the waves vanish, and the explosion-resistantand anti-explosion effects are achieved.

Owner:JIANGSU TQSAFETY TECH CO LTD

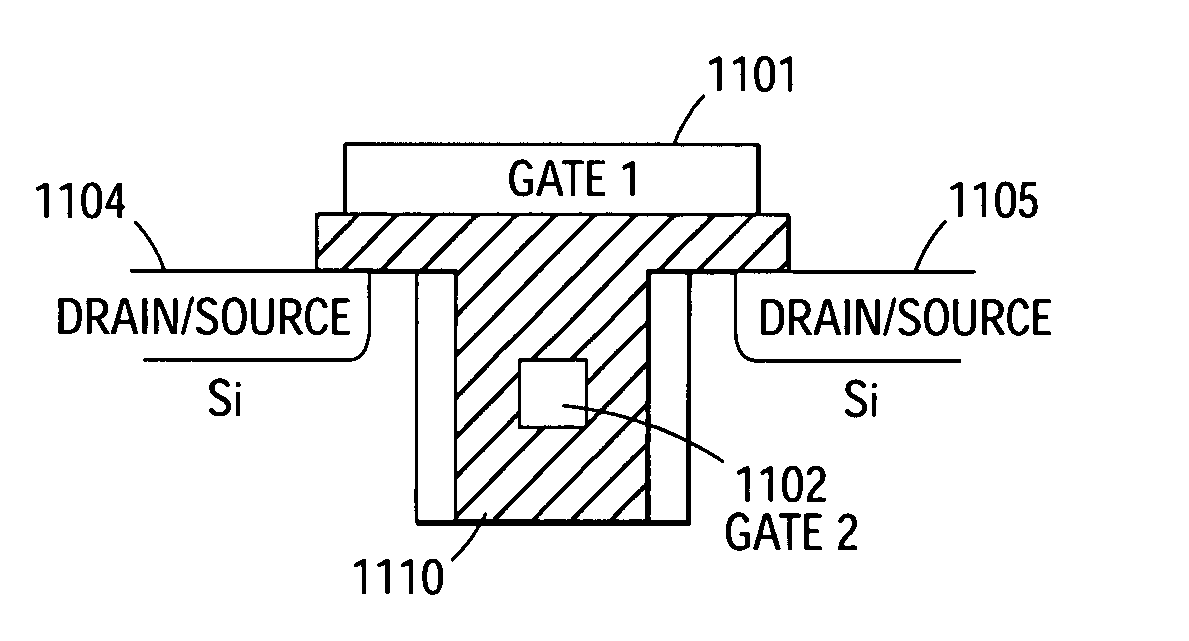

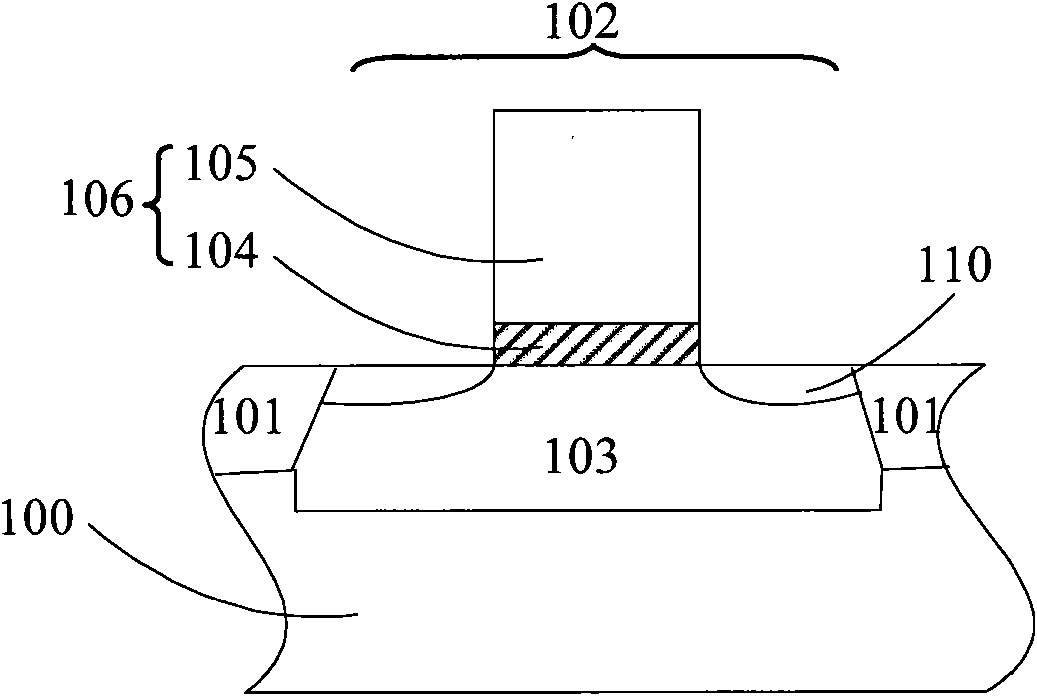

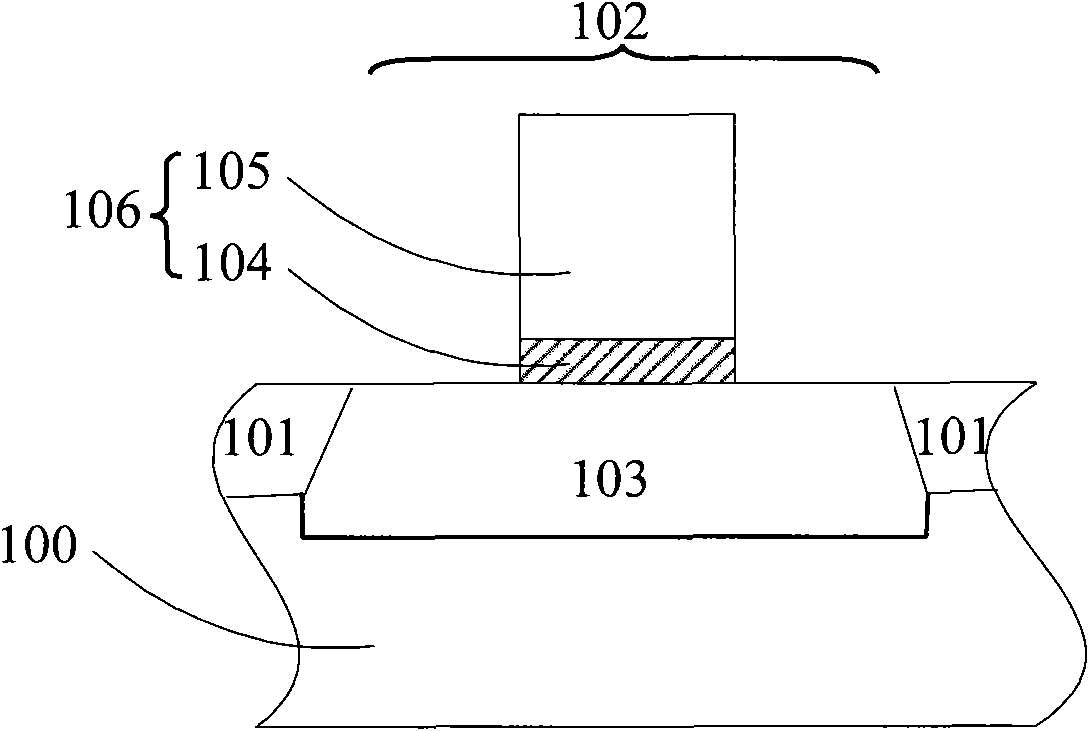

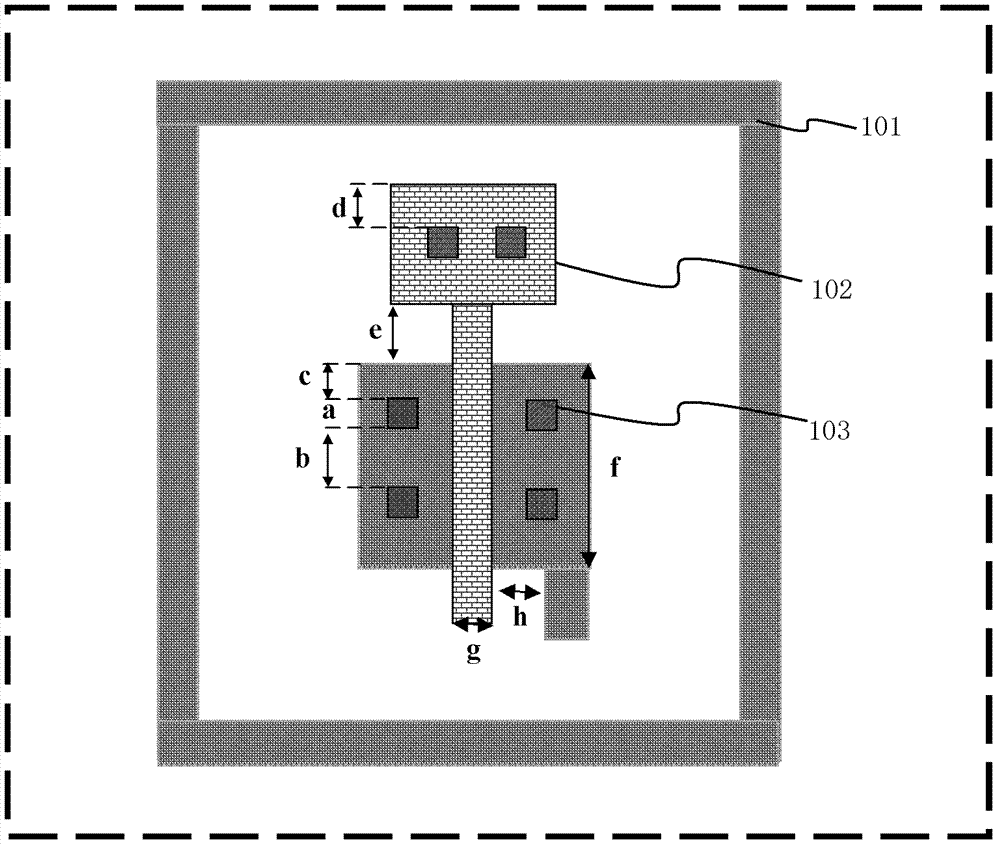

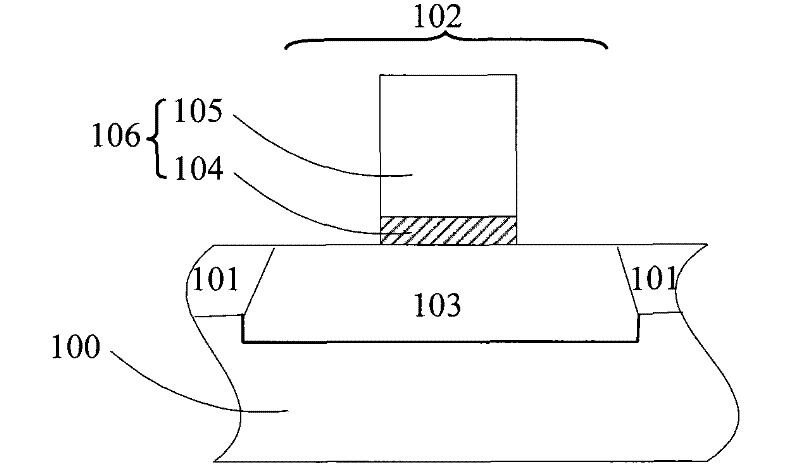

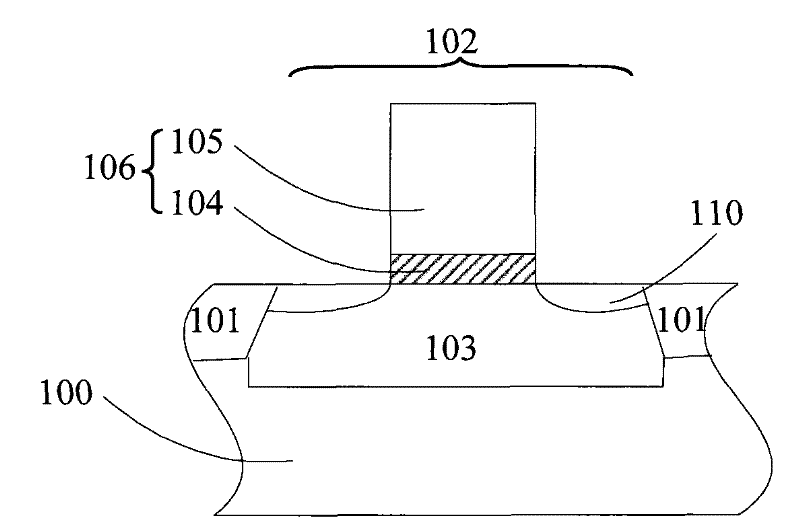

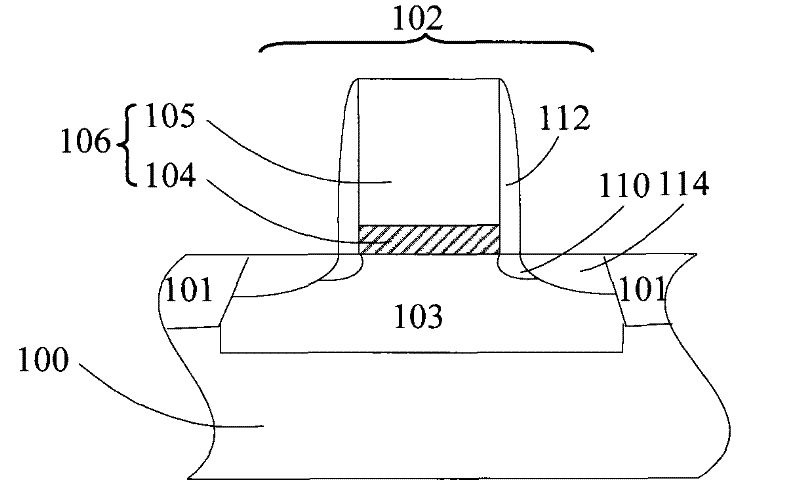

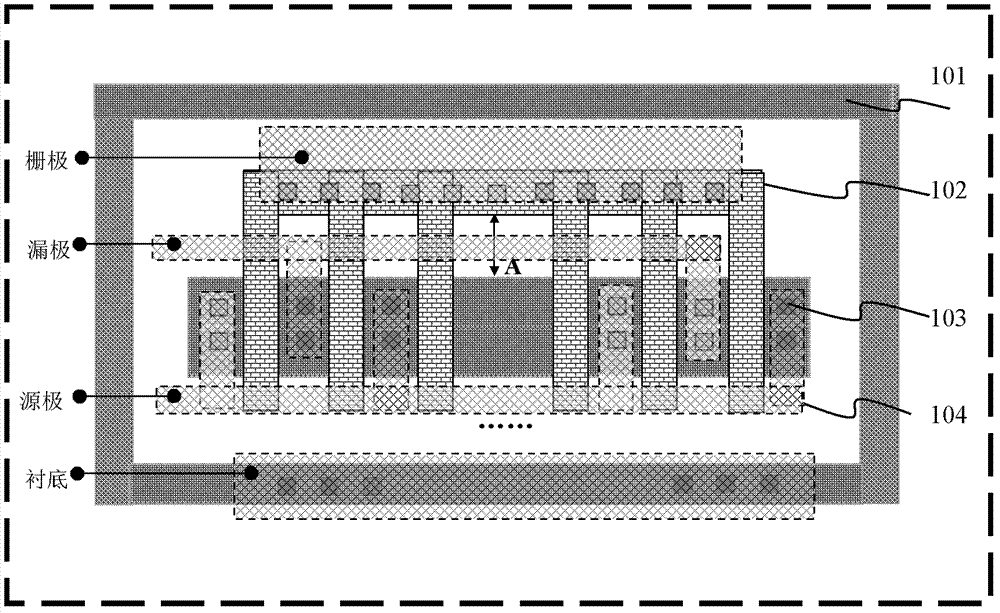

MOS (Metal Oxide Semiconductor) transistor and manufacture method thereof

InactiveCN101930920AReduce volumeSatisfy the degree of integrationSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringCorner effect

The invention relates to an MOS (Metal Oxide Semiconductor) transistor and a manufacture method thereof, wherein the MOS transistor comprises a semiconductor substrate, a first grid through hole, a second grid through hole, grid dielectric layers, grids, source / drain extension regions and side walls, wherein the semiconductor substrate sequentially comprises an oxidization layer, a first p-type polysilicon layer, a first n-type polysilicon layer, a second p-type polysilicon layer and a second n-type polysilicon layer; the first grid through hole is positioned in the first p-type polysilicon layer; the second grid through hole is positioned in the second p-type polysilicon layer; the grid dielectric layers are positioned on the second n-type polysilicon layer and the inner walls of the first grid through hole and the second grid through hole; the grids are positioned on the gird dielectric layers and in the first grid through hole and the second grid through hole; the source / drain extension regions are positioned in source / drain regions at two sides of the grids; the side walls are positioned at two sides of the grids and the two sides of the source / drain regions; wherein the first n-type polysilicon layer and the second n-type polysilicon layer have smooth corners after processed at high temperature. The invention improves the utilization ratio of the chip area, and solves the corner effect caused by strong corner current.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Production method of wide titanium steel composite plate

ActiveCN110586683AReduce in quantityImprove welding efficiencyMetal rolling arrangementsTitaniumComposite plate

The invention relates to a production method of a wide titanium steel composite plate. The production method comprises the steps of machining and processing a blank, machining and processing a frame,coating an isolating agent on the titanium plate and then carrying out seal welding, assembling to form a titanium steel composite blank, centering the titanium steel composite blank, vacuumizing andwelding, inspecting welding seams, rolling and the like; and two titanium steel composite plate with target depth can be manufactured in one production process. According to the production method, theintegrated frame is adopted to replace a plurality of baffle strips for seal welding, so that the number of welding joints is reduced, the welding efficiency is improved, the welding heat input to corners is reduced, the heat influence on a base material structure in the welding process is reduced, and the welding quality is further improved; and an annular groove is formed in the frame, so thatthe phenomenon that the corner strength of a rolled finished composite plate is low due to the corner effect is avoided.

Owner:ANGANG STEEL CO LTD

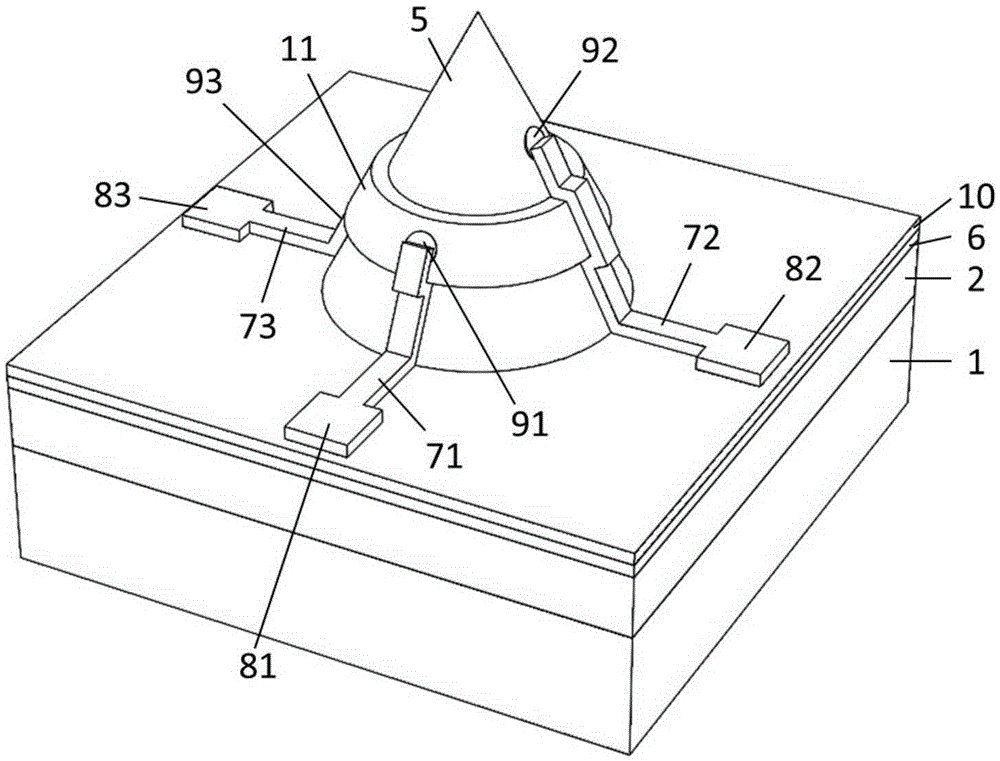

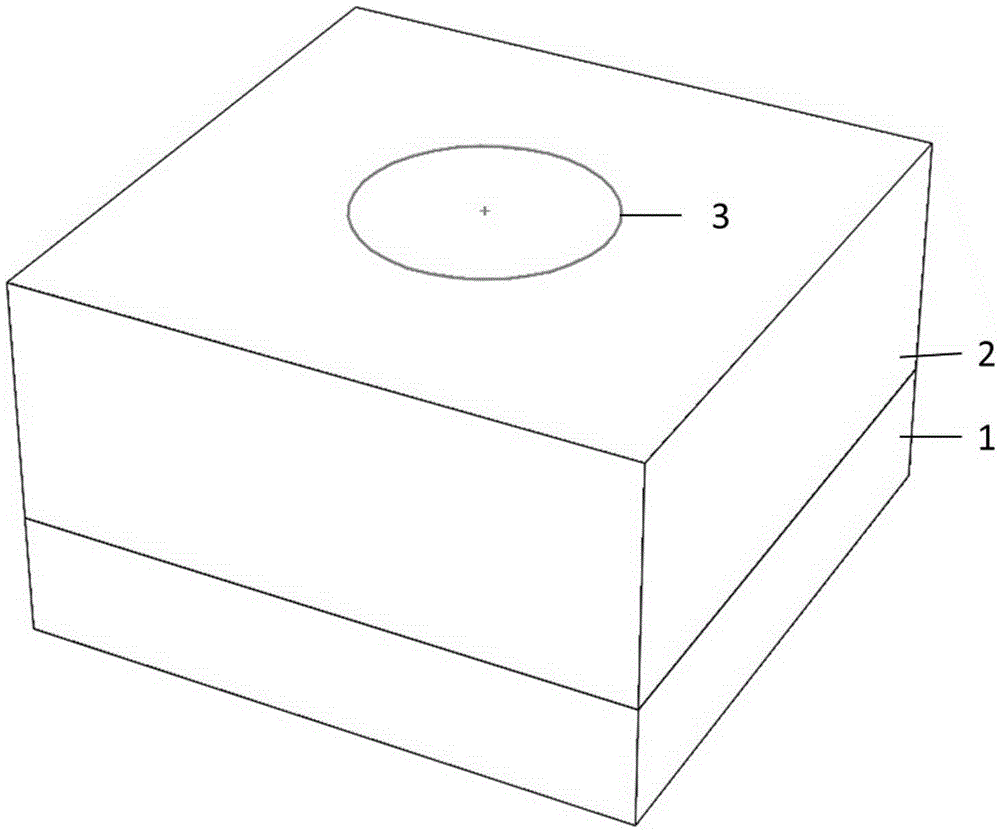

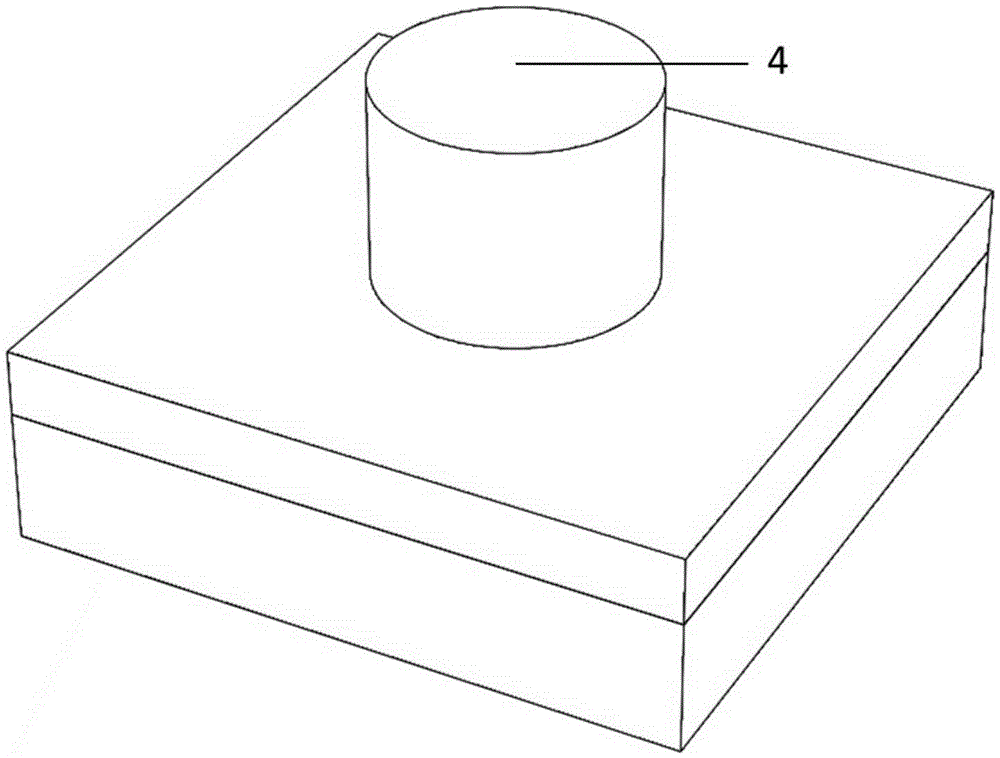

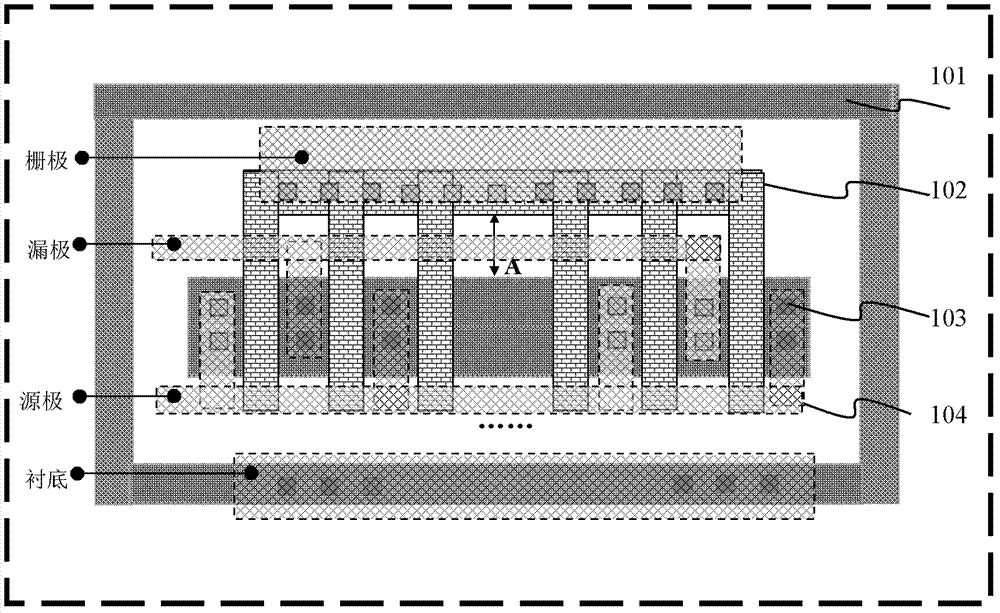

Preparation method of semiconductor field effect transistor device with three-dimensional gate-all-around structure

ActiveCN105304501AEffective Gating CharacteristicsImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesMicro nanoElectricity

The present invention provides a preparation method of a semiconductor field effect transistor device with a three-dimensional gate-all-around structure. A self-support three-dimensional micro-nano functional structure is taken as a carrier, and a micro-nano processing technology is employed to prepare the semiconductor field effect transistor device with the three-dimensional gate-all-around structure. The preparation method provided by the invention specifically comprises the following steps: a first dielectric layer is prepared on the surface of the self-support three-dimensional micro-nano functional structure; a three-dimensional gate-all-around metal electrode is prepared on the first dielectric layer; a second dielectric layer is prepared on the three-dimensional gate-all-around metal electrode to ensure electrical isolation of metal leads of a source electrode and a drain electrode and a grid; an electrode contact hole is prepared through etching on the second dielectric layer; and an electrode contact block is prepared and is connected with the electrode contact hole. The transistor device prepared by the method provided by the invention has effective grid-control characteristic, is able to isotropically regulate the field effect between a source electrode and a drain electrode and restrain a wall and corner effect; and moreover, a long and wide channel and smaller drain terminal parasitic capacitance are provided in the micro-nano grade so that the electric field diffusion of the drain terminal is reduced and the performance of the transistor device may be improved.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

MOS (Metal-oxide Semiconductor) transistor and making method thereof

InactiveCN101937848AReduce volumeIncrease profitSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricCorner effect

The invention relates to an MOS (Metal-oxide Semiconductor) transistor and a making method thereof. The MOS transistor comprises a silicon substrate, an oxide layer arranged on the silicon substrate, top silicon arranged on the oxide layer, a first gate through hole, a second gate through hole, a gate dielectric, a gate, a source / drain electrode extension region and a source / drain electrode, wherein the top silicon consists of a first p-type single crystal silicon layer, a first n-type single crystal silicon layer, a second p-type single crystal silicon layer and a second n-type single crystal silicon layer, the first gate through hole is arranged in the center of the first p-type single crystal silicon layer, a second gate through hole is arranged in the center of the second p-type single crystal silicon layer, the gate dielectric and gate are arranged on the inner wall of the first gate through hole, the inner wall of the second gate through hole and the second n-type single crystal silicon layer, the source / drain electrode extension region is arranged in a source / drain electrode region at both sides of the gate, the source / drain electrode is arranged in the source / drain electrode region at the both sides of the gate, and corners of the first n-type single crystal silicon layer and the second n-type single crystal silicon layer are smooth. The invention enhances the utilization ratio of the area of a chip and solves the corner effect caused by strong corner current.

Owner:SEMICON MFG INT (SHANGHAI) CORP

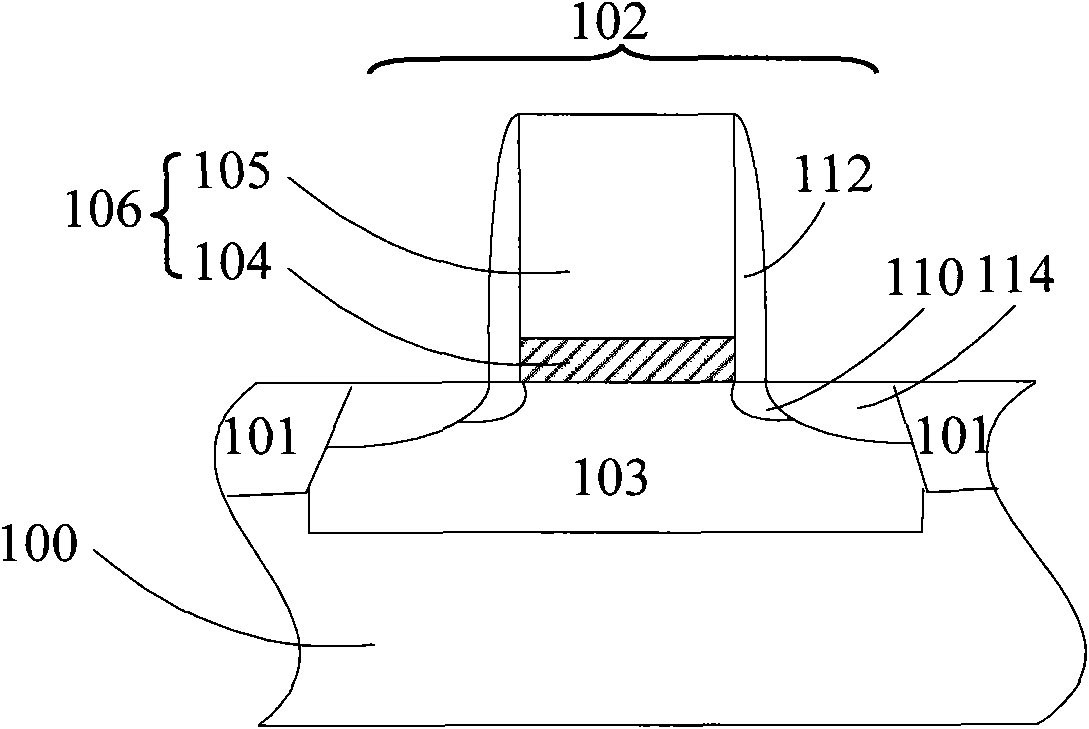

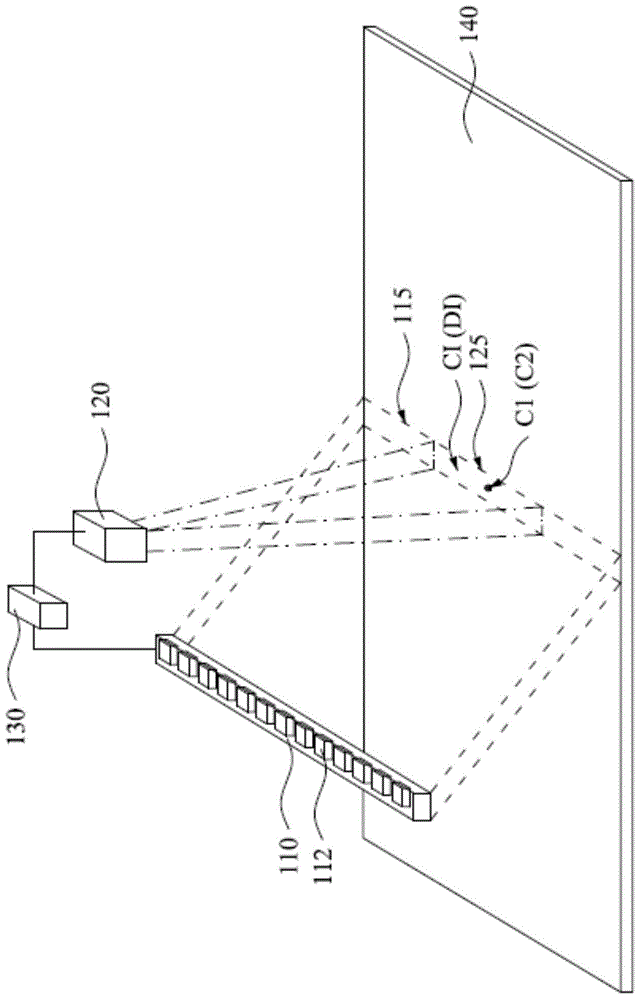

Detection system capable of correcting light source, and light source correction method thereof

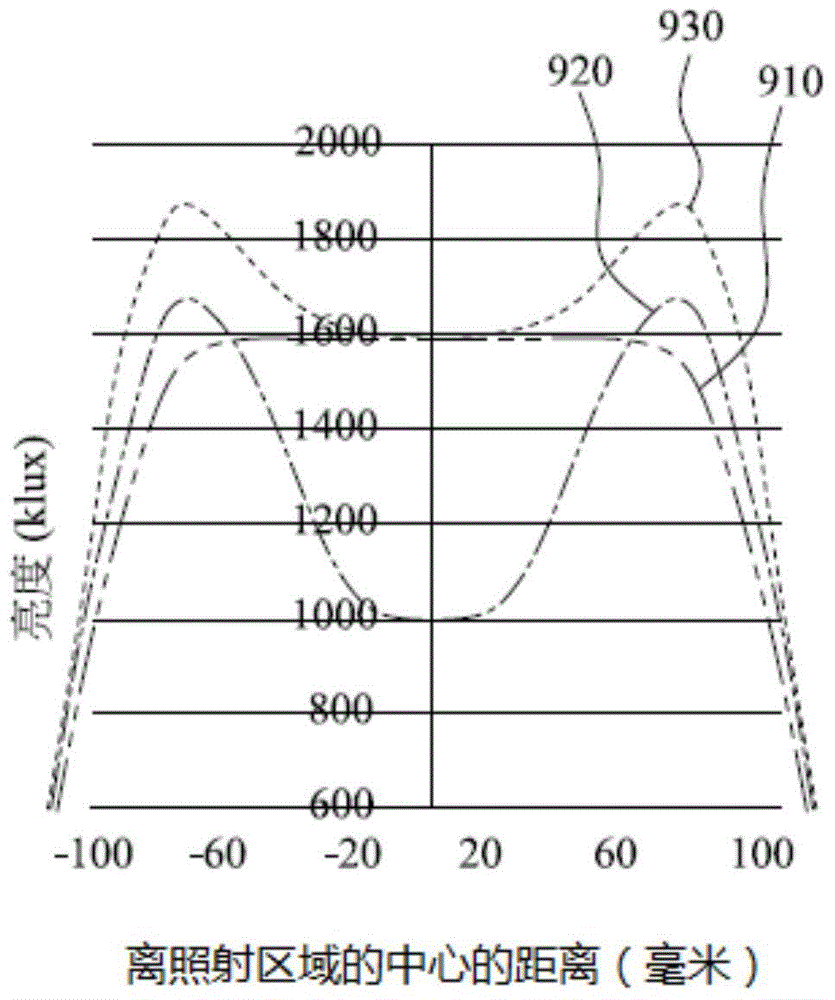

InactiveCN105744262AControl brightnessWith brightness distributionTelevision system detailsColor television detailsVisual field lossCorner effect

The invention discloses a light source correction method of a detection system. The detection system comprises a light source, an image shooting apparatus and a controller. The light source is provided with an irradiation area and the image shooting apparatus has a shooting visual field. The light source correction method comprises adjusting the shooting visual field to be in the irradiation area, unlatching multiple luminescence units of the light source by turns, the image shooting apparatus shooting a correction image when each luminescence unit is unlatched so as to obtain multiple correction images, according to brightness distribution of the correction images, the controller respectively adjusting brightness of the luminescence units so as to compensate the dark corner effect of the image shooting apparatus and enable detection images in the shooting visual field to have specific brightness distribution.

Owner:致茂电子(苏州)有限公司

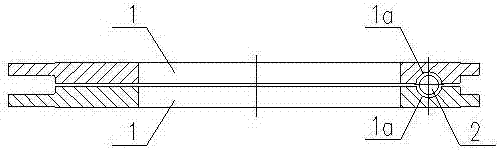

Machining process for false twister bearing spindle

The invention discloses a machining process for a false twister bearing spindle. The machining process mainly comprises a procedure of plating nickel and phosphorus on the surface of the spindle. The problems of the corner effect and the poor surface quality due to hard chromium plating on the surface of the spindle are solved. Due to the fact that nickel-phosphorus plating surface treatment is adopted, the machining process has the advantages that the thickness of a plated layer is small, and the plated layer is high in hardness, uniform, good in abrasion resistance and high in corrosion resistance.

Owner:HENGYANG TEXTILE MACHINERY MANUFACTORY

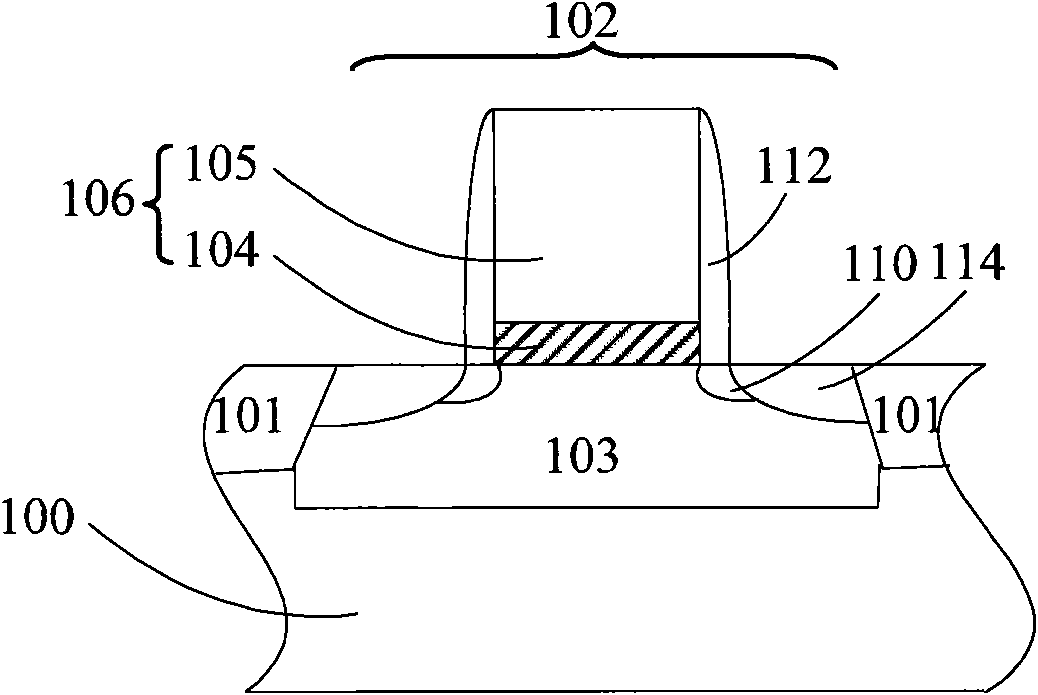

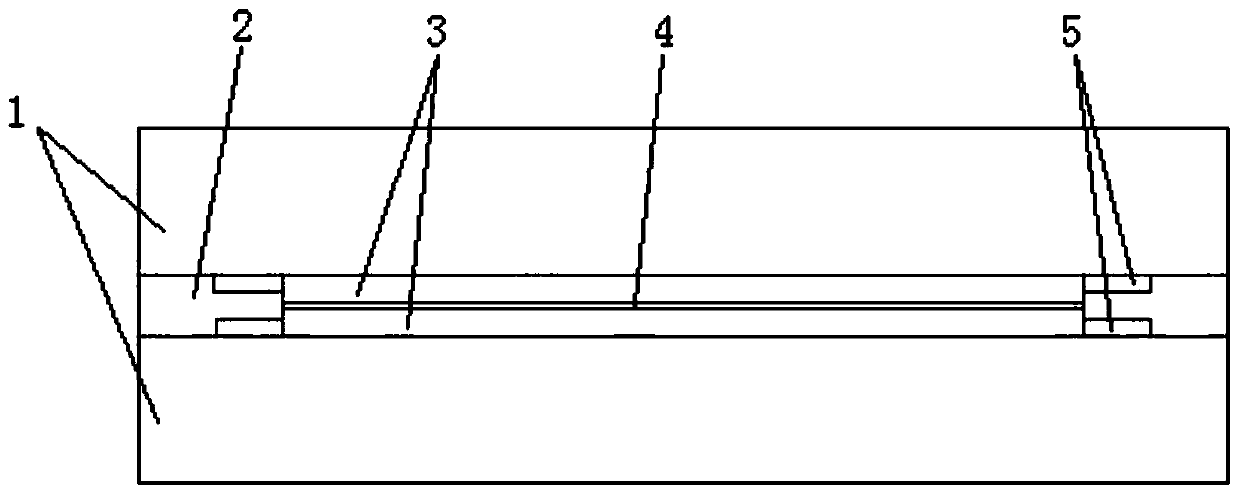

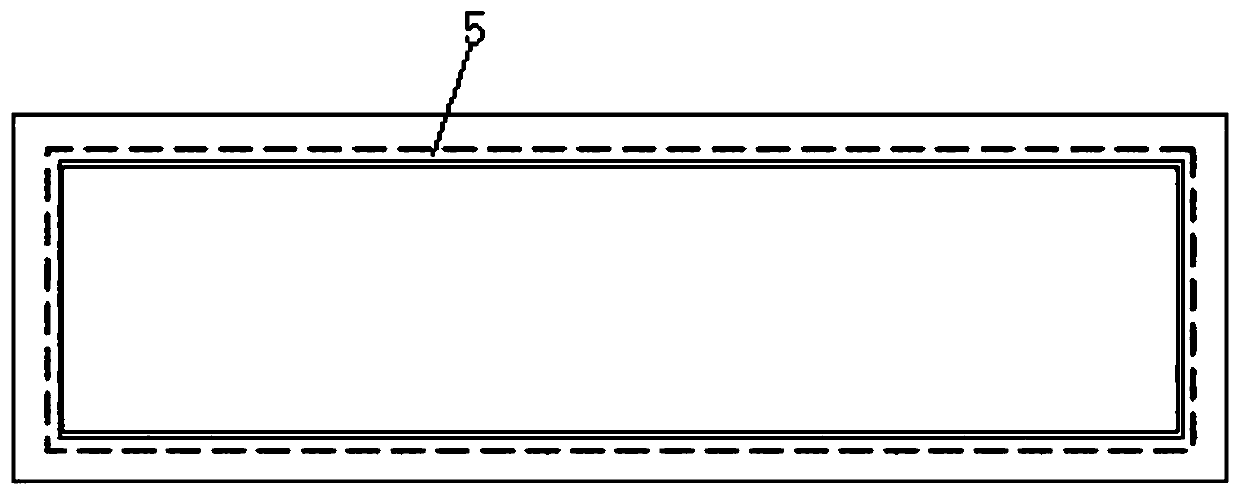

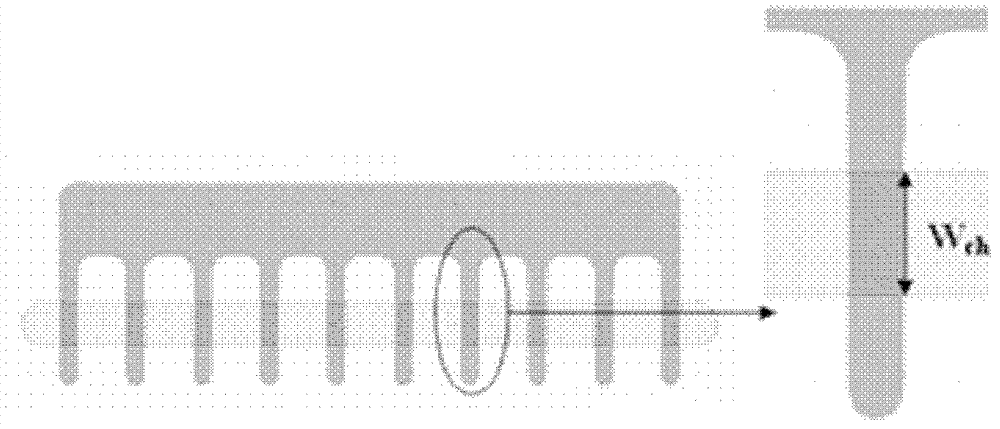

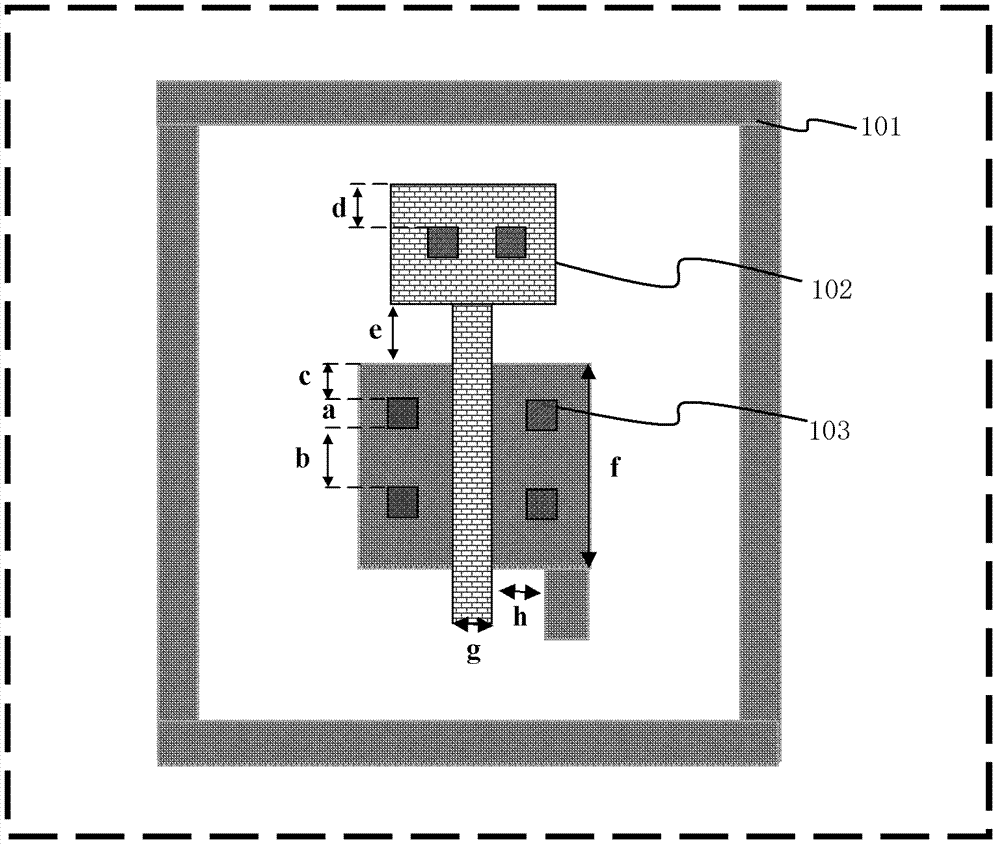

Test structure used for evaluating organic photo conductor (OPC) effects

ActiveCN103094251AEliminate the effects of propertiesEliminate the effects ofSemiconductor/solid-state device detailsSolid-state devicesCMOSEngineering

The invention discloses a test structure used for evaluating organic photo conductor (OPC) effects of a complementary metal-oxide-semiconductor (CMOS) polycrystalline silicon layer. The test structure comprises 2N pieces of CMOS devices; a corresponding CMOS semi-conductor process including the OPC process is adopted for production according to prearranged sizes; the 2N pieces of the CMOS devices serve as an array which is divided into two groups according to different layout modes; one group serves as an inspection group, and the other group serves as a reference group, in terms of the CMOS devices in the inspection group; the distance between L-shaped polycrystalline silicon and active areas of monocrystalline silicon is equal to e, and in terms of the CMOS devices in the reference group, the distance between L-shaped polycrystalline silicon and active areas of monocrystalline silicon is larger than or equal to 2e; and e is the minimum distance between the L-shaped polycrystalline silicon and the active area of the monocrystalline silicon of the same CMOS device in the design rule of the CMOS semi-conductor process. The invention further discloses a test structure used for evaluating the OPC effects of active area layers of the CMOS monocrystalline silicon. The test structure can visually detect whether the OPC eliminates influences of corner round corner effects on device characteristics according to device electric characteristic data.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Rock shearing seepage coupling true triaxial test system

InactiveCN102607950BReduce the effects of frictionIncrease stiffnessMaterial strength using tensile/compressive forcesTriaxial shear testFriction effect

The invention relates to a rock shearing seepage coupling true triaxial test system, which comprises a loading assembly, a test box, a seepage assembly, a detection assembly and a control assembly. The whole system is high in rigid, safe and reliable in high-pressure water injection and sealability, good in sealing reliability, high in loading stability and protection strength and capable of effectively reducing the end-part friction effect and the corner effect and realizing the uniform triaxial stress state as far as possible; a loading test device and a mainshaft loading mechanism are designed in a split manner, and safe high-pressure water injection is achieved; a safety valve and a pressure-stabilizing control device are arranged on a water outlet; and the rock shearing seepage coupling true triaxial test system is stable to control.

Owner:SHANDONG UNIV OF SCI & TECH

Polishing device for flange plate edge opening of steel structure H-shaped component

InactiveCN110434707AGuarantee coating qualityImprove coating qualityEdge grinding machinesGrinding drivesSheet steelEngineering

The invention discloses a polishing device for a flange plate edge opening of a steel structure H-shaped component, and relates to the technical field of steel structure machining polishing. The polishing device for the flange plate edge opening of the steel structure H-shaped component comprises driving equipment. The driving equipment comprises lower travelling wheels, lower telescopic rod pieces and lateral sliding wheels. The number of the lower travelling wheels is two and the lower travelling wheels are arranged under the driving equipment left and right. The two lower travelling wheelsare in driving connection with the driving equipment through driving rods respectively. The number of the lower telescopic rod pieces is two and the lower telescopic rod pieces are horizontally fixedto the left side and the right side of the driving equipment separately. The number of the lateral sliding wheels is two and the lateral sliding wheels are connected to the tail ends of the two lowertelescopic rod pieces in a rotating mode correspondingly. A lifting shaft is vertically fixed to the middle of the upper portion of the driving equipment. The polishing device has the beneficial effects that the rounded corner effect of the steel plate edge opening can be guaranteed, coating materials can also have rounded corners, the specified valve meeting the coating requirement is met, the coating quality of the steel structure is ensured, the problem that the coating quality of the steel plate edge opening is poor in the prior art is solved and the service life of the steel component isprolonged.

Owner:湖南金海集团有限公司

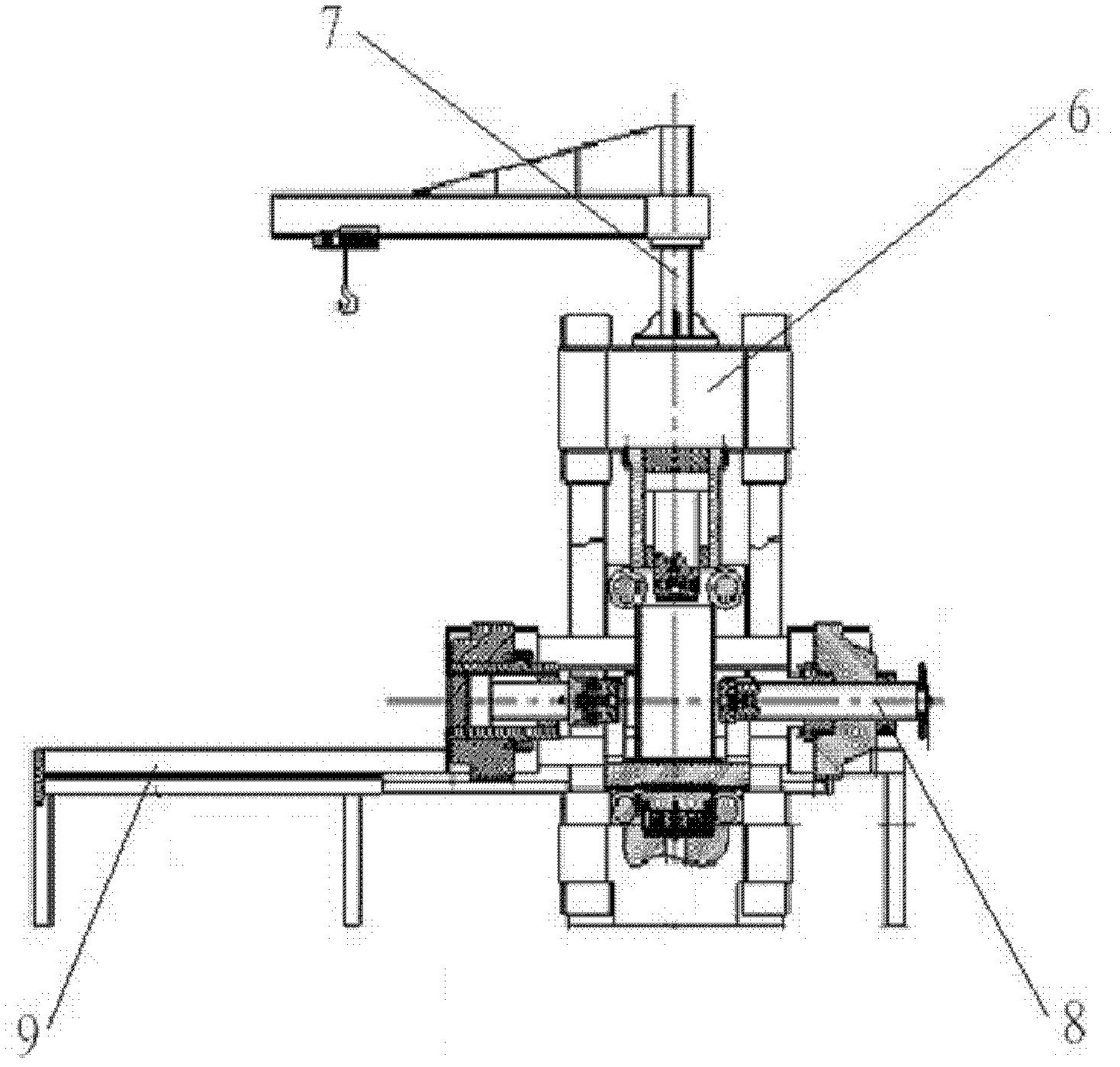

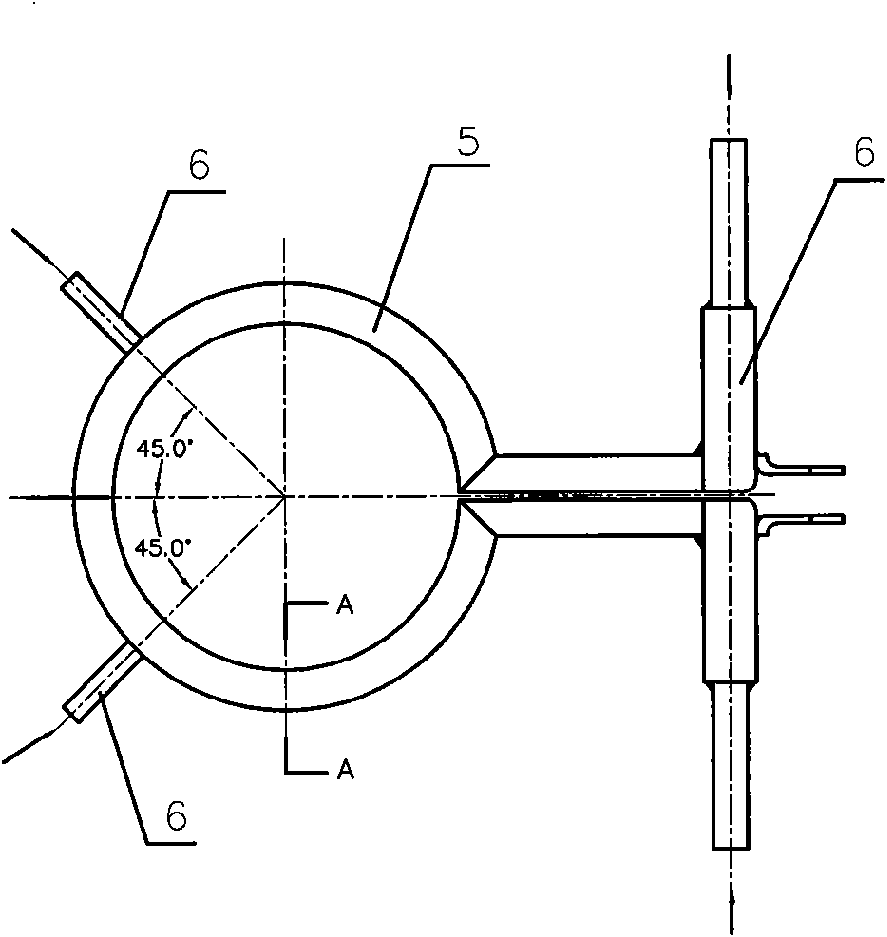

Induction quenching device used for cone sockets of brake platens and operation method

ActiveCN107312911AAvoid sharp corner effectSolve the problem that the sensing distance is difficult to controlFurnace typesIncreasing energy efficiencyHuman–machine interfaceInductor

Disclosed are an induction quenching device used for cone sockets of brake platens and an operation method. The induction quenching device comprises a quenching inductor, a revolution assembly, a cabinet body assembly and an electric control cabinet. The front end of the cabinet body assembly is fixedly connected with the quenching inductor, and the brake platens are placed at the upper end of the revolution assembly. In addition, the electric control cabinet is provided with a human-computer interface, a manual / automatic selecting knob and a heating button. A circular pipe is used for manufacturing the single-turn quenching inductor, so that the sharp corner effect is avoided during induction quenching of the cone sockets; the direction-adjustable and interval-adjustable lifting revolution tool assembly is arranged in the device, so that the problem that when induction quenching is conducted on the concave spherical surfaces of the cone sockets on arc surface wrapped with an effective induction coil, the induction interval is difficult to control is solved, the quenched layer is continuous and uniform in distribution, and accordingly the quenching quality is improved; the platens serves as the center for positioning, a height scale is used during induction quenching, and the position is precisely controlled through an index plate, so that the platens are rotationally positioned and heated in the induction quenching process, control over the quenching quality is guaranteed; and the operation method is simple, reliable and easy to carry out.

Owner:FIRST TRACTOR

Annular cutting and deburring die device

The invention provides an annular cutting and deburring die device, which comprises an upper template and a lower template, wherein the upper template is suspended directly above the lower template, and a male die is arranged on the lower template; a transmission mechanism is arranged below the upper template, and a female die is arranged below the transmission mechanism; an inwardly inclined cutting edge is arranged on the lower edge of the female die. Through the special processing of an ordinary annular cutting die, a novel process that burrs are prevented from being generated while the shape is cut off is provided. After the annularly cut and deburred product is added to be subjected to extrusion and deformation when the outer edge is cut off, the section of the final product has an C-corner effect, the section is smooth, and the deburring and the cutting are simultaneously carried out, so the working efficiency is improved.

Owner:金牌模具(常熟)有限公司

Explosion resistance and prevention device for combustible and flammable liquid and gas pipelines

InactiveCN106693235AReach the effect of anti-explosion and anti-explosionFire suppressionFire rescueEngineeringCorner effect

The invention discloses an explosion resistance and prevention device for combustible and flammable liquid and gas pipelines. The explosion resistance and prevention device is used for explosion resistance and prevention of the pipelines and comprises a conical spiral pipe, a shell and a fire retardant. The conical spiral pipe is provided with an inlet and an outlet. The conical spiral pipe is arranged in the shell. The inlet and the outlet extend out of the shell. The space between the interior of the shell and the conical spiral pipe is filled with the fire retardant. According to the explosion resistance and prevention device applied to the combustible and flammable liquid and gas pipelines, when the pipelines are combusted and exploded, because of the existence of the critical pipe diameter and the corner effect, the strength of impact waves entering the conical spiral pipe can be rapidly and continuously attenuated till the impact waves disappear, and the explosion resistance and prevention effects are achieved; when the device or the conical spiral pipe is influenced by the explosion and cracks, the fire retardant can put out a fire in time; and meanwhile, after the device or the conical spiral pipe deforms or cracks, a pipeline cut-off system can be excited (triggered) through a sensing device or an interlocking device, and therefore media in the pipelines cannot leak.

Owner:NANJING TIANBEN SAFETY TECH

Prefabricated plasterboard installation structures

ActiveCN102953497BReduce loadThe yin and yang angles are crisp and beautifulCeilingsKeelArchitectural engineering

The invention discloses a mounting structure for a prefabricated molded gypsum board. The mounting structure comprises a prefabricated molded gypsum board (2) and a keel system, wherein the prefabricated molded gypsum board (2) is provided with at least one corner; the keel system is fixed on a building structure; and the prefabricated molded gypsum board (2) is connected with the keel system. According to the mounting structure for the prefabricated molded gypsum board provided by the invention, an assembling type construction technology is adopted, an external corner effect being overlapping, stiff and smooth is endowed, the construction is cost-saving and labor-saving, and the end-product construction for circular, arc and specially shaped suspended ceilings is achieved.

Owner:GOLD MANTIS CONSTR DECORATION

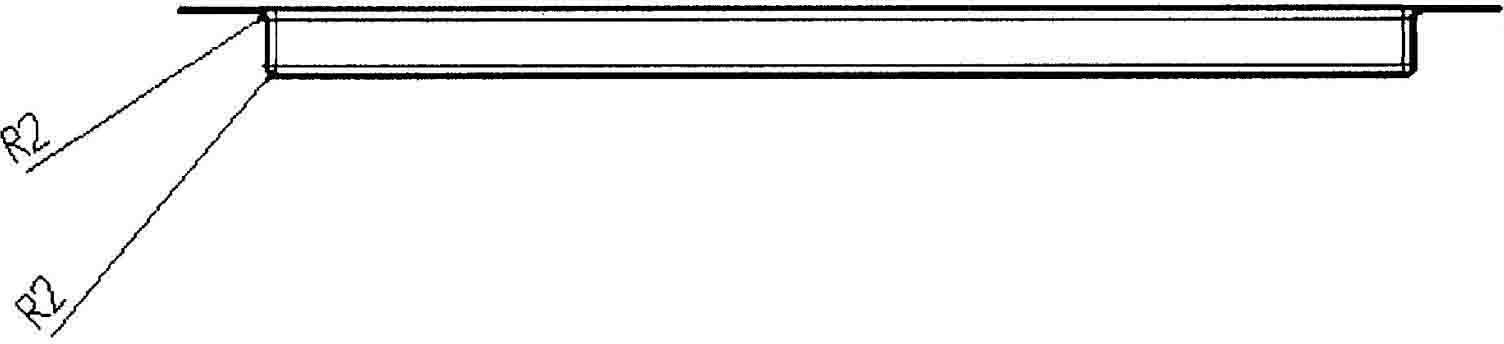

Die manufacturing process for small round corner box type parts

The invention relates to a die manufacturing process for small round corner box type parts, and the method comprises the following steps: 1) processing a split die: dividing the die into a base, a sleeve plate and an upper die for processing respectively, wherein a formed cavity is in the shape of the parts to be processed; 2) drilling an air hole which is communicated with the cavity on an upperdie plate; 3) placing the base, the sleeve plate and the upper die at the center of a platform of a superplastic forming machine from bottom to top; 4) connecting with a pipeline and a temperature-measuring thermocouple, performing aeration and heating-up, and forming; and 5) drawing out of the die and forming after cooling to 100 DEG C. The process adopts a design method of the split die and further adopts a superplastic forming process, thereby enabling the die for the small round corner box type parts to be easy to process and achieving a good small round corner effect.

Owner:SHENYANG AIRCRAFT CORP

MOS (Metal-oxide Semiconductor) transistor and making method thereof

InactiveCN101937848BReduce volumeIncrease profitSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricPower flow

The invention relates to an MOS (Metal-oxide Semiconductor) transistor and a making method thereof. The MOS transistor comprises a silicon substrate, an oxide layer arranged on the silicon substrate, top silicon arranged on the oxide layer, a first gate through hole, a second gate through hole, a gate dielectric, a gate, a source / drain electrode extension region and a source / drain electrode, wherein the top silicon consists of a first p-type single crystal silicon layer, a first n-type single crystal silicon layer, a second p-type single crystal silicon layer and a second n-type single crystal silicon layer, the first gate through hole is arranged in the center of the first p-type single crystal silicon layer, a second gate through hole is arranged in the center of the second p-type single crystal silicon layer, the gate dielectric and gate are arranged on the inner wall of the first gate through hole, the inner wall of the second gate through hole and the second n-type single crystalsilicon layer, the source / drain electrode extension region is arranged in a source / drain electrode region at both sides of the gate, the source / drain electrode is arranged in the source / drain electrode region at the both sides of the gate, and corners of the first n-type single crystal silicon layer and the second n-type single crystal silicon layer are smooth. The invention enhances the utilization ratio of the area of a chip and solves the corner effect caused by strong corner current.

Owner:SEMICON MFG INT (SHANGHAI) CORP

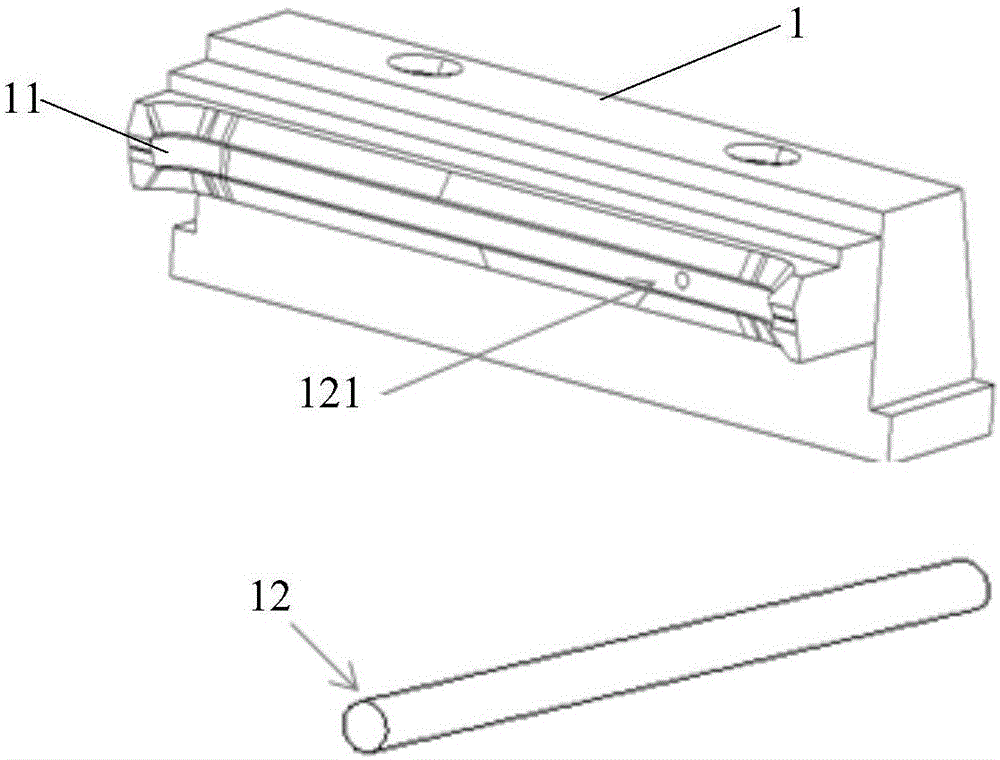

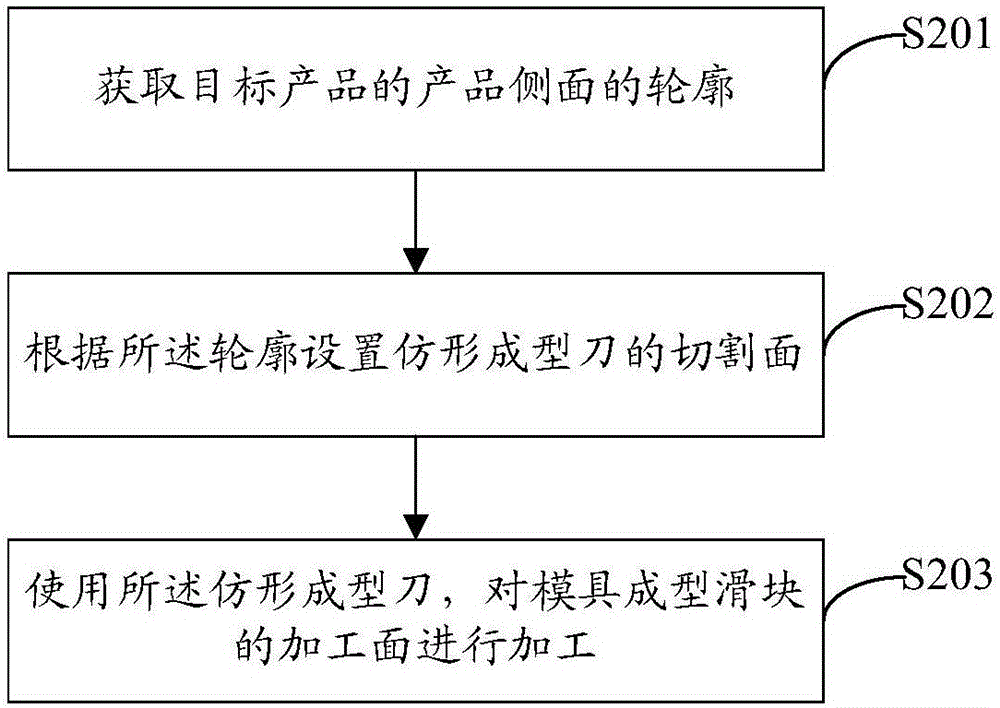

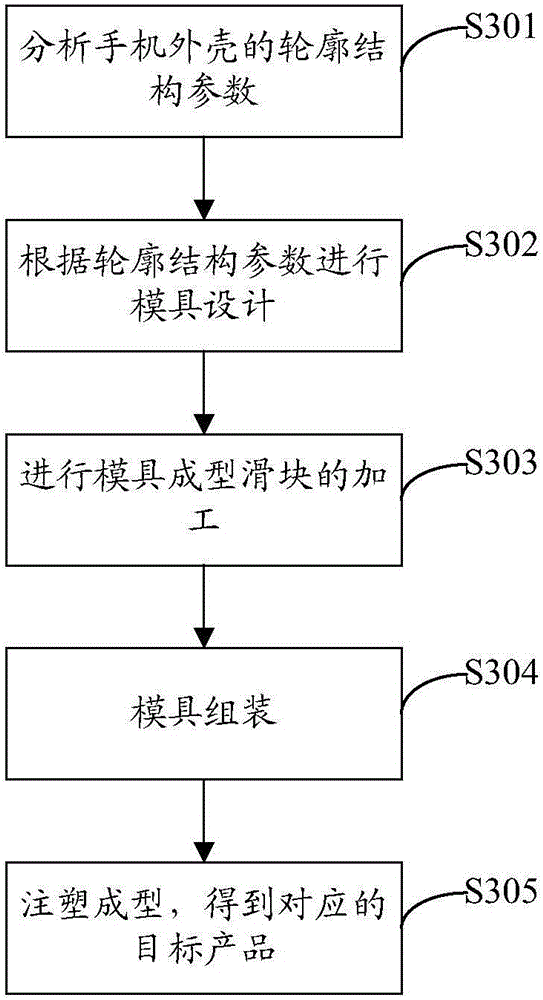

Mould molding slide block as well as production method thereof and production system thereof

The invention discloses a mould molding slide block as well as a production method thereof and a production system thereof. The mould molding slide block comprises a processing surface which is used for processing side surfaces of a target product, and is formed by directly processing through a copying molding knife; according to the outline of a target product, the processing surface of the mould molding slide block is processed by the copying molding knife, and mould parts are processed to have sharp-corner effects, so that processing advantages of sharp corners of the copying molding knife are sufficiently utilized, and the appearance effect of the target object is prevented from being affected due to the fact that sharp corners are changed into round corners as a result of natural consumption during electrical discharge machining of coppersmiths; and meanwhile, the target product obtained by injection molding of the mould molding slide block with sharp corners directly has sharp-edge effect, so that product appearance effect is further improved, and production cost is reduced.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Trench corner effect bidirectional flash memory cell

A non-volatile memory cell structure that is capable of holding two data bits. The structure includes a trench in a substrate with two sides of the trench being lined with a trapping material. The trench is filled with an oxide dielectric material and a control gate is formed over the oxide-filled trench. Source / drain regions are adjacent the trench sides with the trapping material. An energy barrier between the drain and source regions has two local high points that correspond to the trench corners. To read the device, sufficient gate voltage is applied to invert the channel and a sufficient drain voltage is applied to pull down the drain-side barrier. If charges of opposite polarity are trapped in the source-side trench corner, the source barrier will be significantly lowered so that current flows between source and drain under read conditions.

Owner:MICRON TECH INC

Induction hardening device and operation method for brake pressure plate cone socket

ActiveCN107312911BAvoid sharp corner effectSolve the problem that the sensing distance is difficult to controlFurnace typesIncreasing energy efficiencyHuman–machine interfaceInduction hardening

Disclosed are an induction quenching device used for cone sockets of brake platens and an operation method. The induction quenching device comprises a quenching inductor, a revolution assembly, a cabinet body assembly and an electric control cabinet. The front end of the cabinet body assembly is fixedly connected with the quenching inductor, and the brake platens are placed at the upper end of the revolution assembly. In addition, the electric control cabinet is provided with a human-computer interface, a manual / automatic selecting knob and a heating button. A circular pipe is used for manufacturing the single-turn quenching inductor, so that the sharp corner effect is avoided during induction quenching of the cone sockets; the direction-adjustable and interval-adjustable lifting revolution tool assembly is arranged in the device, so that the problem that when induction quenching is conducted on the concave spherical surfaces of the cone sockets on arc surface wrapped with an effective induction coil, the induction interval is difficult to control is solved, the quenched layer is continuous and uniform in distribution, and accordingly the quenching quality is improved; the platens serves as the center for positioning, a height scale is used during induction quenching, and the position is precisely controlled through an index plate, so that the platens are rotationally positioned and heated in the induction quenching process, control over the quenching quality is guaranteed; and the operation method is simple, reliable and easy to carry out.

Owner:FIRST TRACTOR

Test structure for evaluating opc effects

ActiveCN103094251BEliminate the effects of propertiesEliminate the effects ofSemiconductor/solid-state device detailsSolid-state devicesCMOSEngineering

The invention discloses a test structure used for evaluating organic photo conductor (OPC) effects of a complementary metal-oxide-semiconductor (CMOS) polycrystalline silicon layer. The test structure comprises 2N pieces of CMOS devices; a corresponding CMOS semi-conductor process including the OPC process is adopted for production according to prearranged sizes; the 2N pieces of the CMOS devices serve as an array which is divided into two groups according to different layout modes; one group serves as an inspection group, and the other group serves as a reference group, in terms of the CMOS devices in the inspection group; the distance between L-shaped polycrystalline silicon and active areas of monocrystalline silicon is equal to e, and in terms of the CMOS devices in the reference group, the distance between L-shaped polycrystalline silicon and active areas of monocrystalline silicon is larger than or equal to 2e; and e is the minimum distance between the L-shaped polycrystalline silicon and the active area of the monocrystalline silicon of the same CMOS device in the design rule of the CMOS semi-conductor process. The invention further discloses a test structure used for evaluating the OPC effects of active area layers of the CMOS monocrystalline silicon. The test structure can visually detect whether the OPC eliminates influences of corner round corner effects on device characteristics according to device electric characteristic data.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com