Die manufacturing process for small round corner box type parts

A manufacturing process and fillet box technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of poor machinability of small fillet molds, inability to form small fillet parts, and high processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

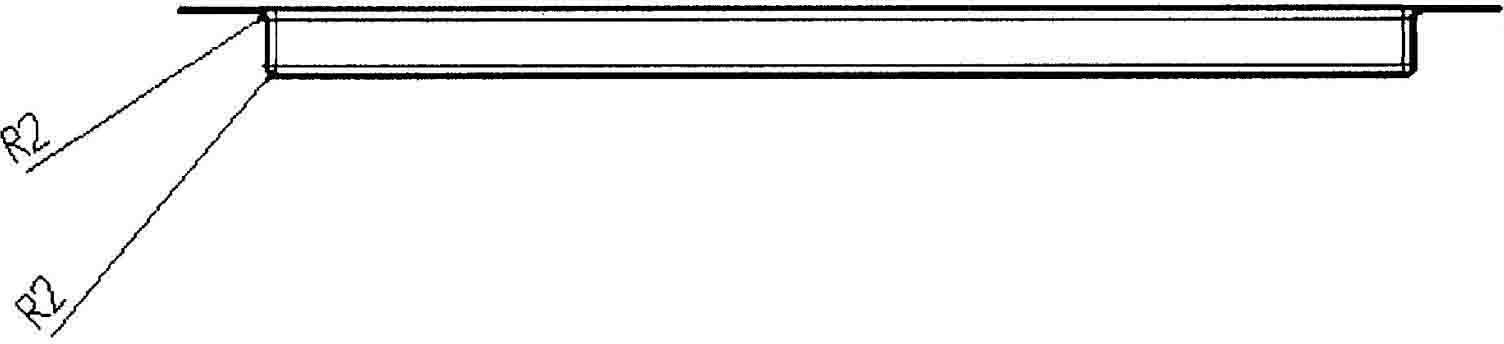

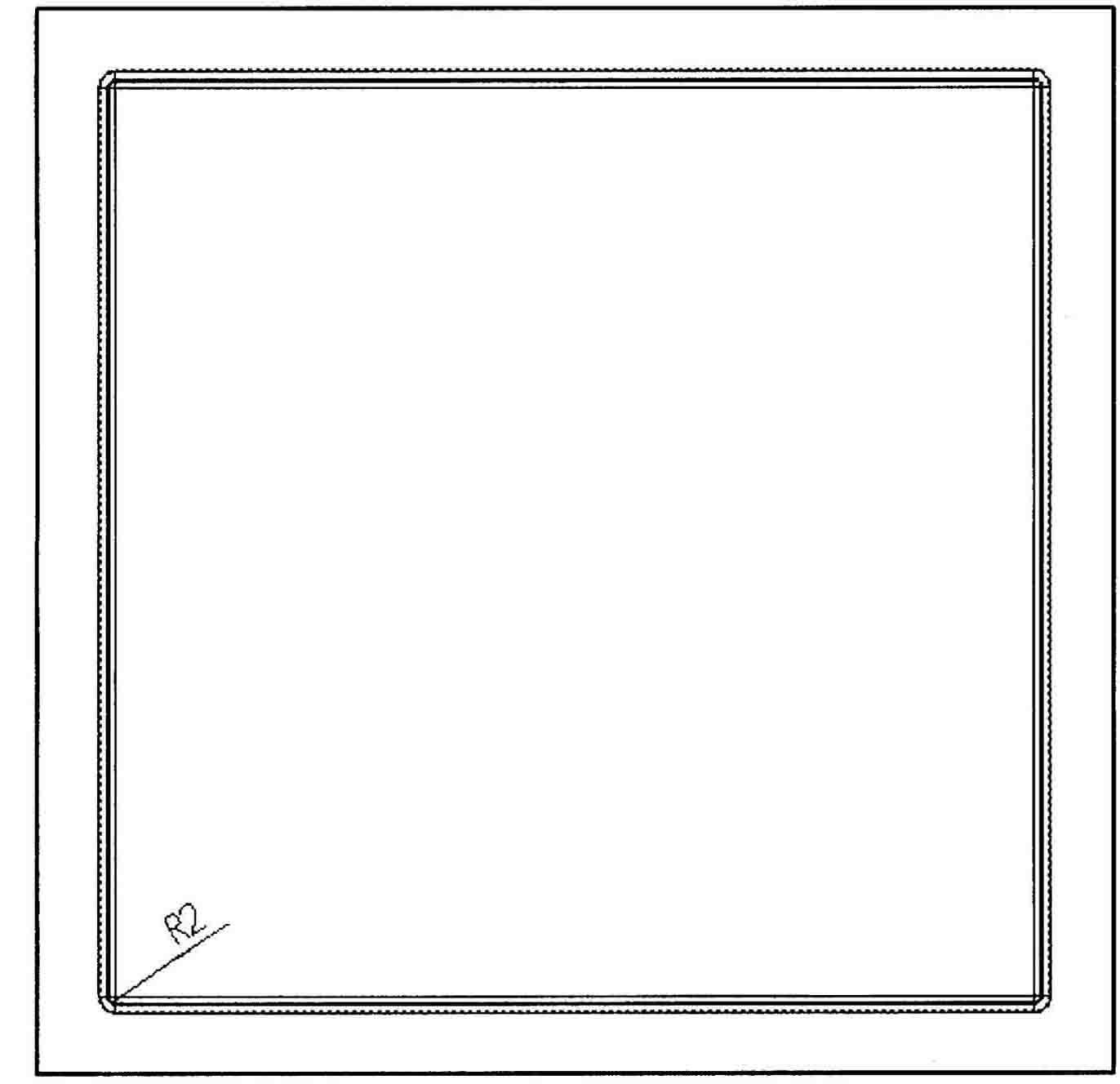

[0015] like figure 1 and figure 2 As shown, there are small rounded corners of R2 around the box parts. It is very difficult to make the overall concave-convex mold of such box parts, and the mold is easy to break.

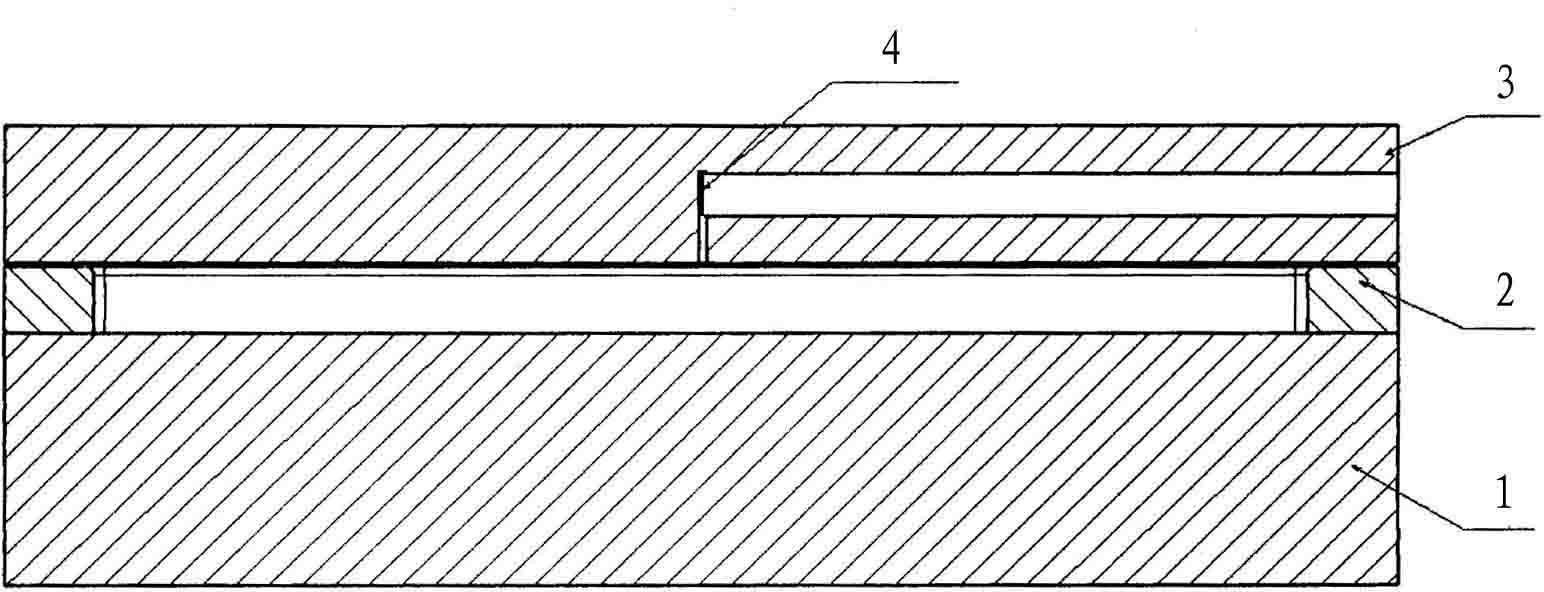

[0016] like image 3 As shown, make as figure 1 and figure 2 The mold making process of the small rounded corner box parts shown includes the following steps:

[0017] 1) Process the split mold: Divide the mold into the base, the cover plate and the upper mold and process them separately. The cavity formed by it is the shape of the part to be processed. The upper mold adopts ordinary milling and grinding technology, and the upper and lower surfaces are parallel. The thickness is 0.05mm; the base is a hexahedron, using common milling and grinding technology, the parallelism of the upper and lower surfaces is 0.05mm;

[0018] 2) Drill air holes leading to the cavity on the upper template, which are used to connect high-purity argon gas, and form the sheet by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com