Heat treating process and inductor for key surface of hub

A surface heat treatment and hub unit technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of insufficient depth, difficult heating, and failure to meet the requirements of drawings, etc., to achieve easy production, low precision, and low requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

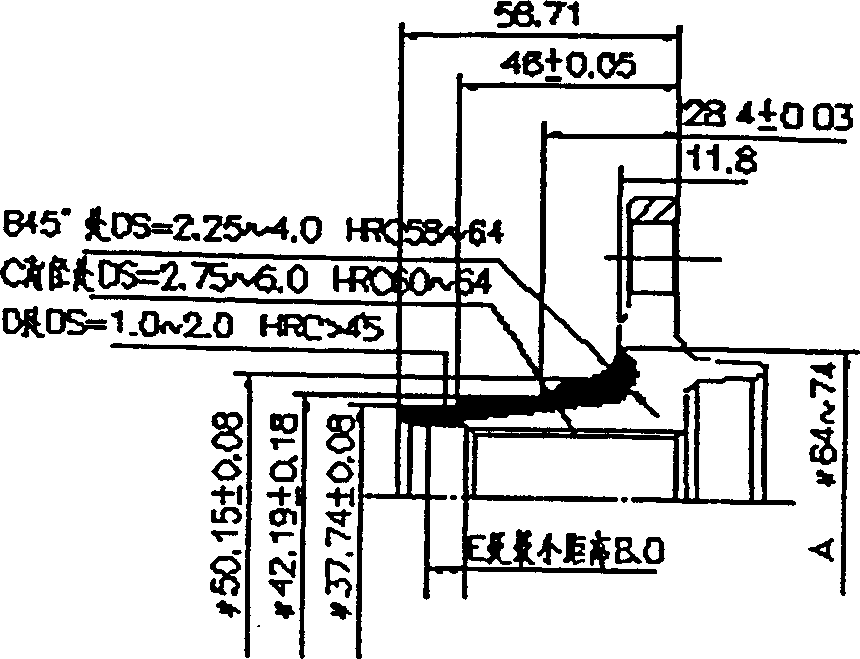

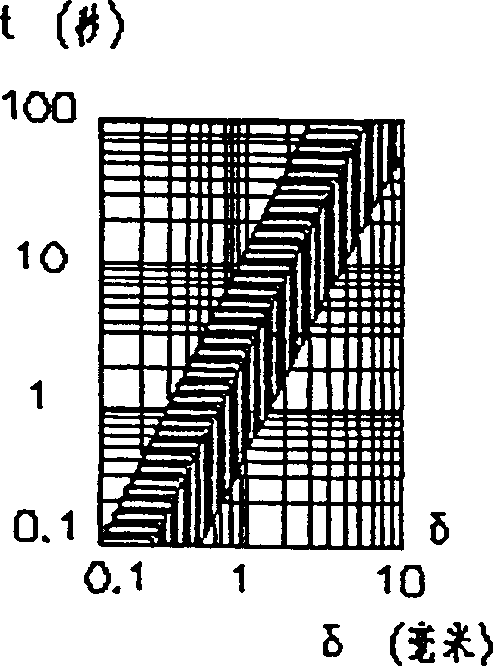

[0032] The heat treatment method for the key surface of the wheel hub unit is to put the workpiece to be quenched into the inductor, heat it through the medium frequency induction heater, and use high power, short time, and internal water spray method for quenching. The radial gap between the workpiece and the upper induction coil is 5 to 10 mm. , the radial gap with the lower induction coil is 3-5 mm, and the axial gap is 1.5-2.5 mm.

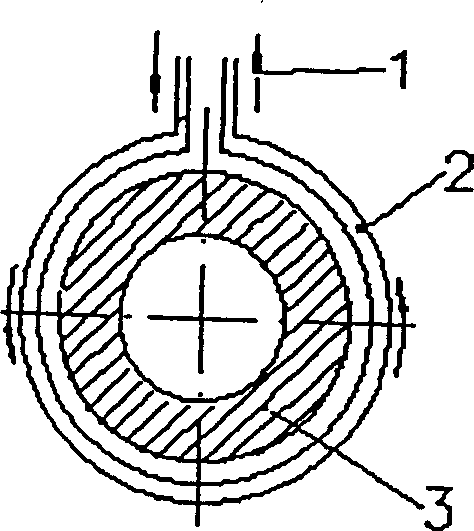

[0033] The inductor used for surface induction heating has two guide bodies 4, an upper induction coil 5, and a lower induction coil 6, and a magnet guide 7 is arranged outside the lower induction coil. It communicates with the left semicircle of the lower induction coil, the left semicircle of the upper induction coil, the right semicircle of the lower induction coil, the right semicircle of the upper induction coil and another guide body, and passes through water.

[0034] Said upper and lower induction coils are square special-shaped copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com