Mounting structure for prefabricated molded gypsum board

A technology for installing structures and gypsum boards, applied in building components, building structures, buildings, etc., can solve problems such as cracking of gypsum board ceilings, high repair costs, and bending of Yin and Yang corners, saving money and labor in construction, and optimizing the layout. , the effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

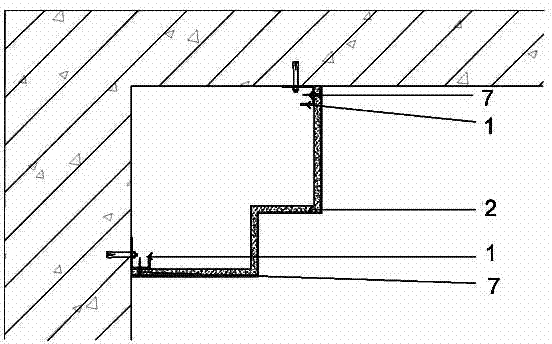

[0015] Embodiment one: if figure 1 As shown, a prefabricated gypsum board installation structure includes a prefabricated gypsum board 2 and a keel system. The keel system includes a side keel 1 fixed to the wall and a side keel 1 fixed to the top of the building. The prefabricated gypsum board 2 is In cascade modeling, one side of the prefabricated gypsum board 2 is connected to the side keel 1 fixed to the wall, and the other side of the prefabricated gypsum board 2 is connected to the side keel 1 fixed to the top surface of the building.

Embodiment 2

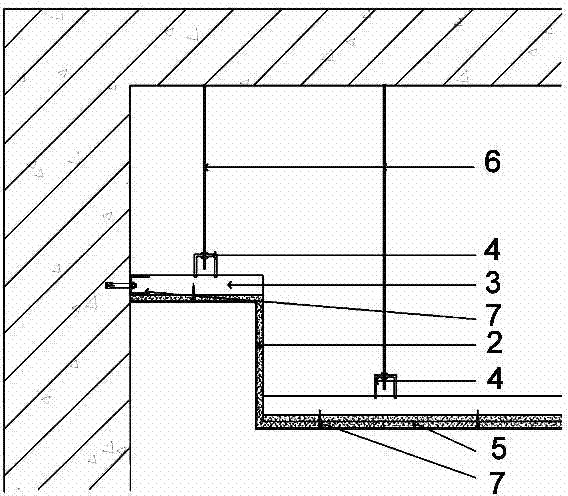

[0016] Embodiment two: if figure 2 As shown, a prefabricated gypsum board installation structure includes a prefabricated gypsum board 2 and a keel system. The keel system includes a screw 6, a main keel 4, and an auxiliary keel 3. The upper end of the screw 6 is fixed to the top surface of the building. 6. A main keel 4 is arranged at the lower end, and the main keel 4 is connected with the auxiliary keel 3. The prefabricated gypsum board 2 is Z-shaped, and the gypsum board surfaces of different heights of the prefabricated gypsum board 2 are respectively connected with the auxiliary keel 3 of different heights.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com