Dust remover with explosion-resistant function

A dust collector and anti-explosion technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of surrounding environment threats, secondary explosions, etc., and achieve the effect of reasonable structural design and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

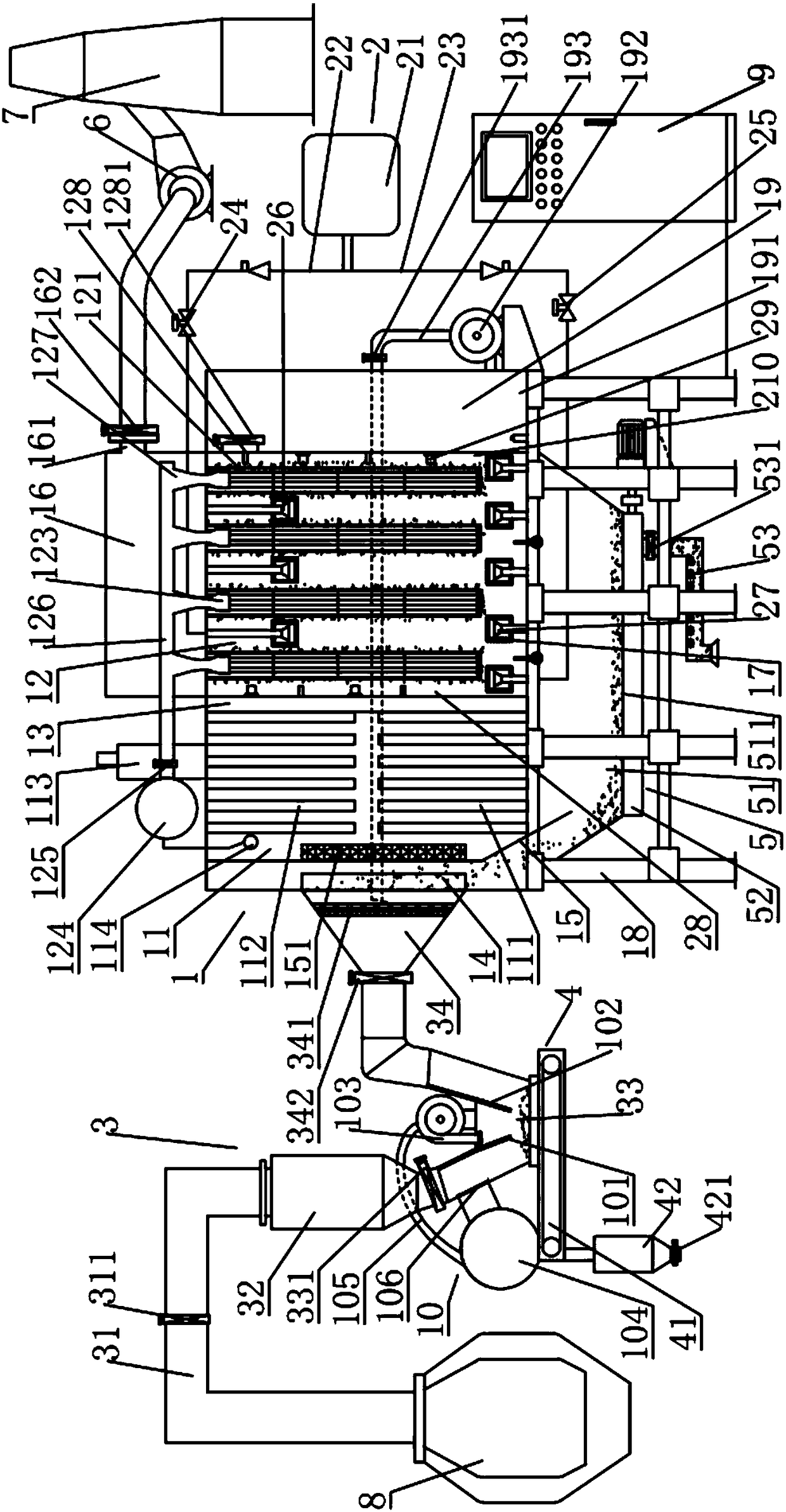

[0035] Such as figure 1 , 7The shown dust collector with explosion-proof function includes dust removal system 1, inerting injection system 2, cooling system 3, coarse ash conveying system 4, dust conveying system 5, first fan 6, chimney 7, dust discharge equipment 8 and An electric control box 9, the cooling system 3 is arranged between the dust removal system 1 and the dust discharge equipment 8, and the cooling system 3 is electrically connected to the electric control box 9, and the coarse ash conveying system 4 is connected to the cooling system 3, so The dust conveying system 5 is connected to the dust removal system 1, the inerting injection system 2 is arranged in the dust removal system 1, and both the dust removal system 1 and the inerting injection system 2 are electrically connected to the electric control box 9, and the first fan One end of 6 is connected to the clean air outlet of the dust removal system 1, and the other end of the first fan 6 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com