Cross head surface induction hardening method of marine diesel engine

A marine diesel engine, surface induction technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of uneven quenching hardness of the crosshead, quenching crack quenching surface, low yield, etc., to achieve shortened quenching time, uniform hardness, The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

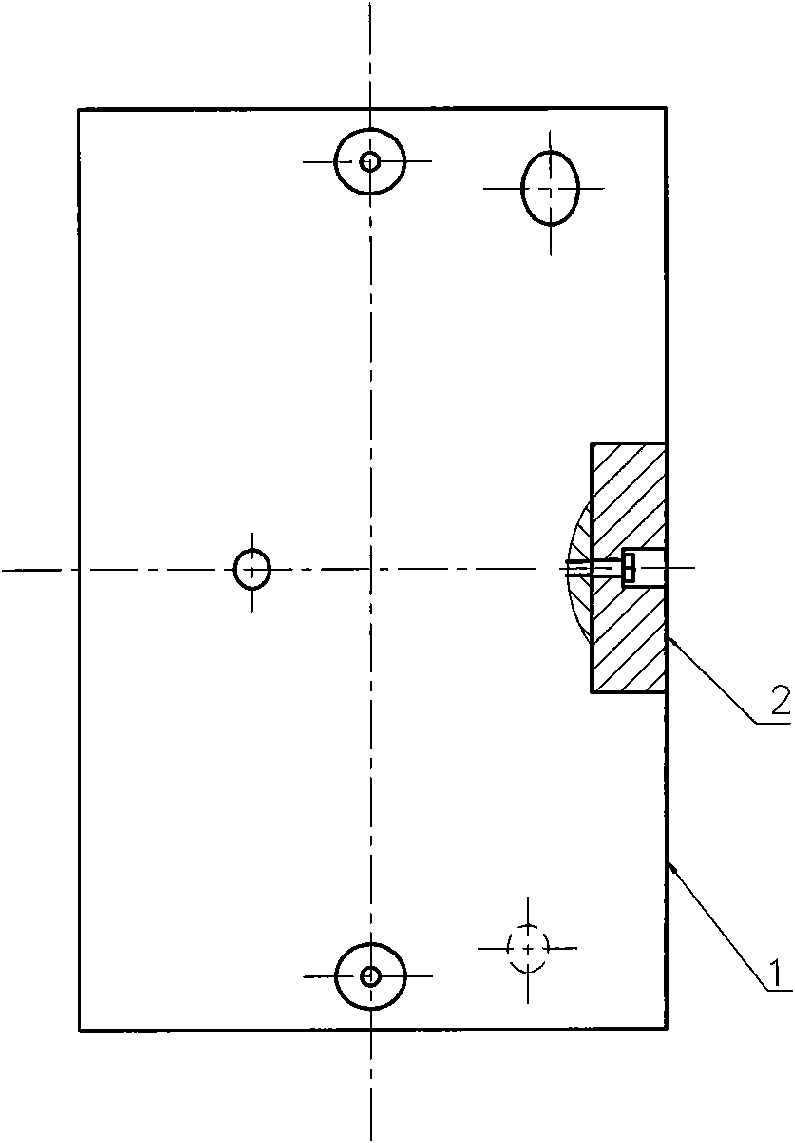

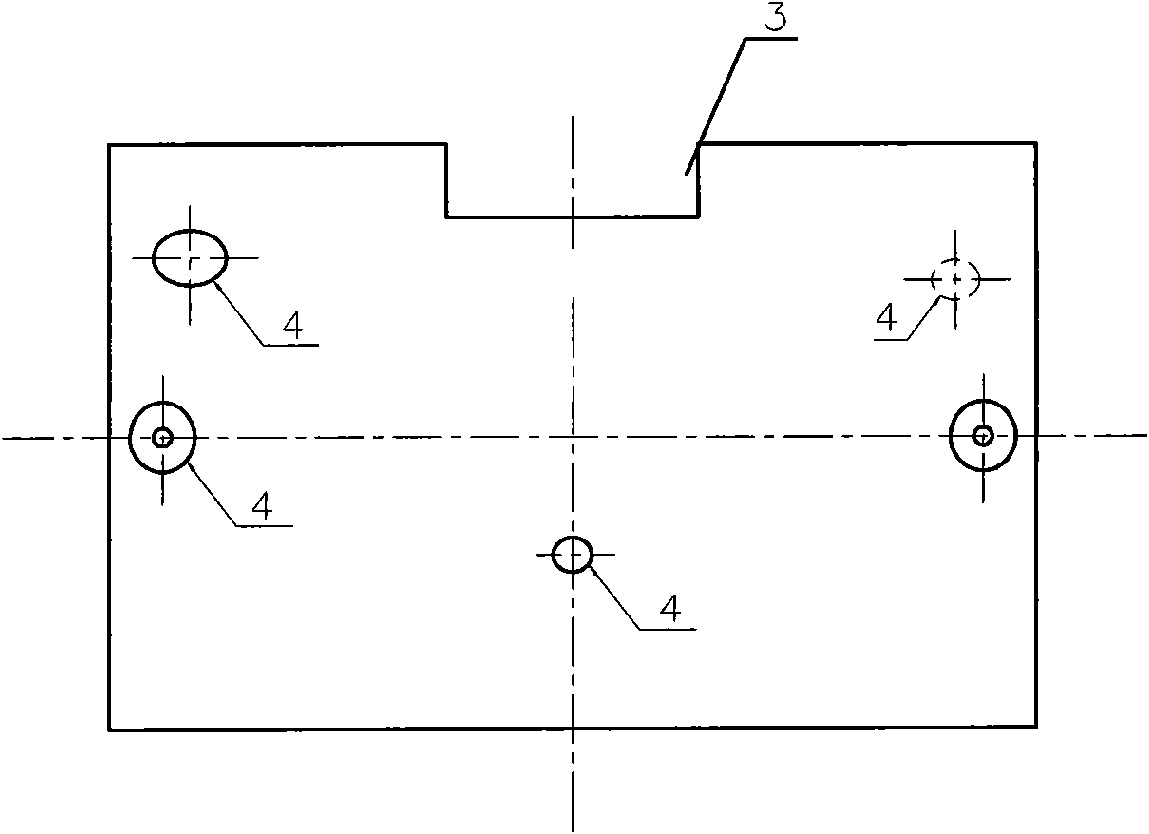

[0019] Embodiment: Take the S35ME-B marine diesel engine crosshead as an example, such as figure 2 shown.

[0020] Quenching equipment selection: 300kW CNC intermediate frequency quenching machine tool.

[0021] Parts clamping: Vertical clamping.

[0022] Induction coil: circular self-spray water induction coil, the distance between the inner surface of the induction coil and the quenched surface of the crosshead is 4-4.2mm.

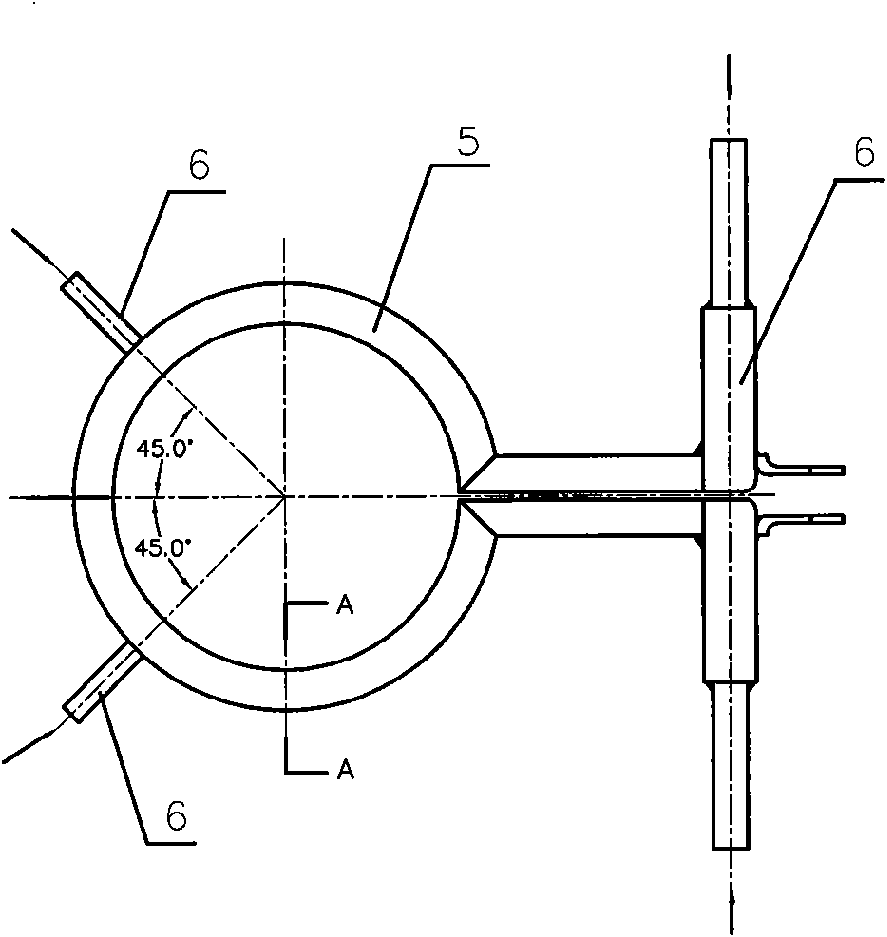

[0023] The induction coil includes a water spray ring 5, which is provided with a plurality of water inlet pipes 6, and is provided with a water spray hole 7 under the surface of the water spray ring 5, and the water spray angle is at an angle of 45° with the plane where the induction coil is located. The working principle of the induction coil is: the induction coil is energized to generate a magnetic field, the crosshead 1 forms an eddy current on the surface in the magnetic field, and the heat generated by the eddy current heats the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com