Patents

Literature

90results about How to "Prevent quenching cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

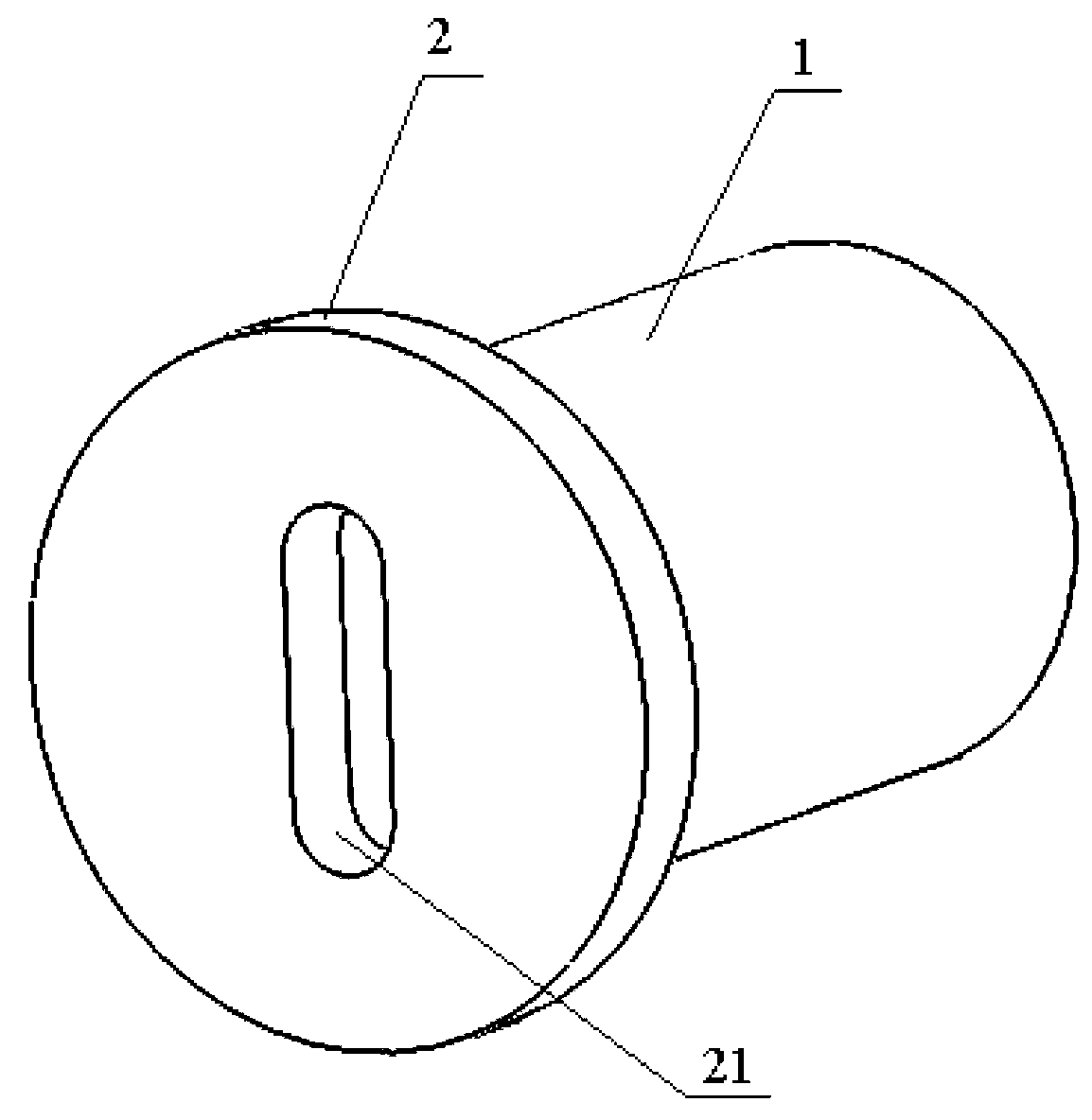

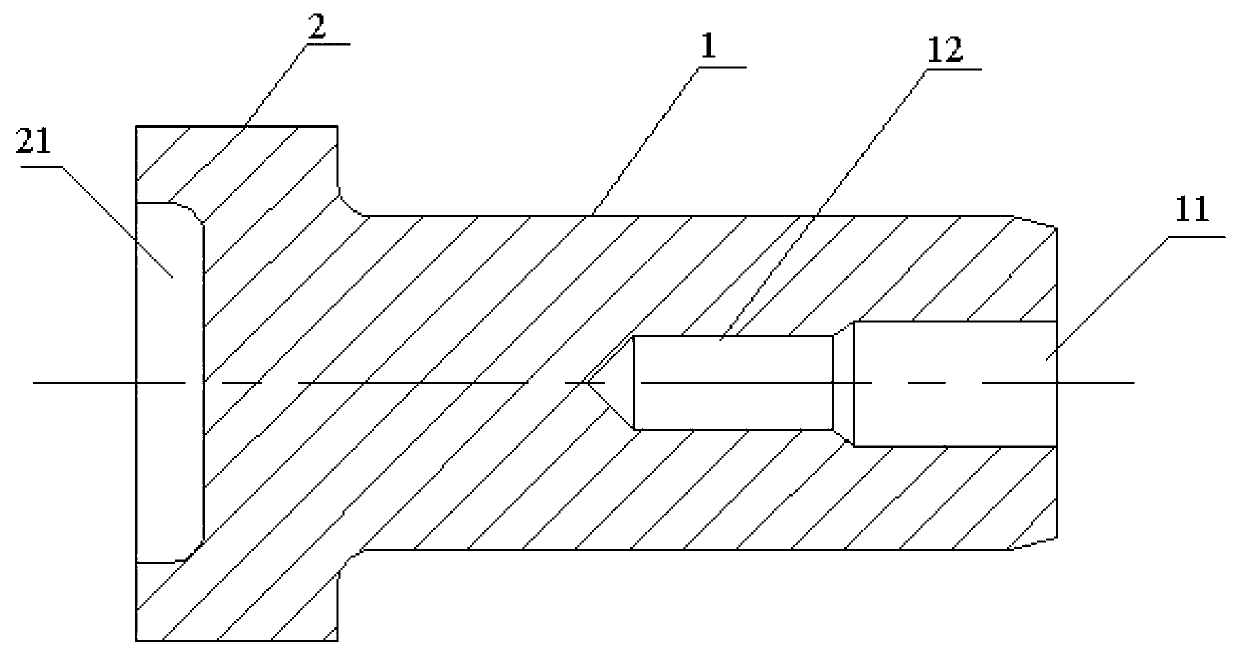

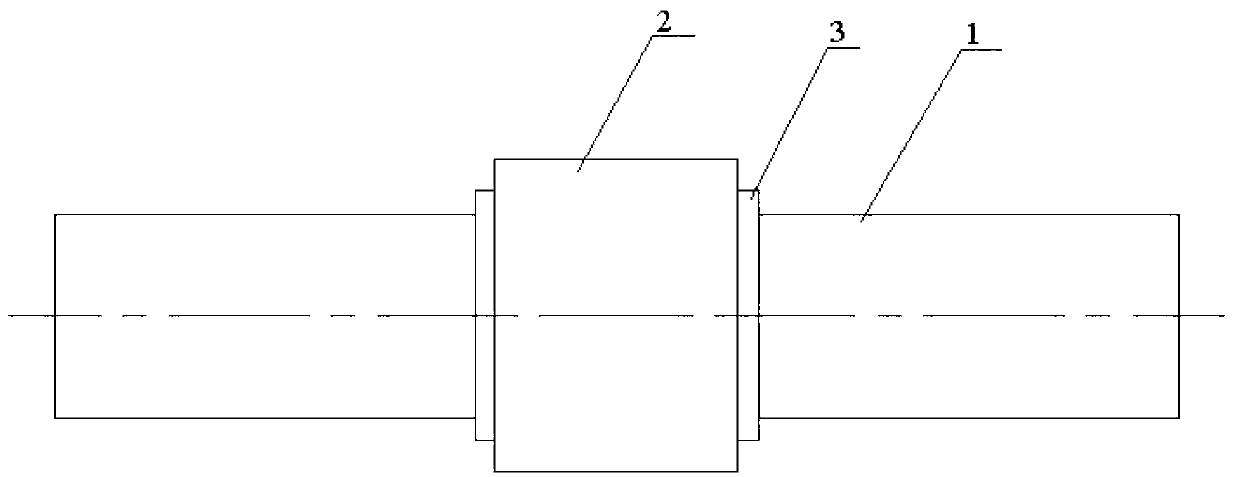

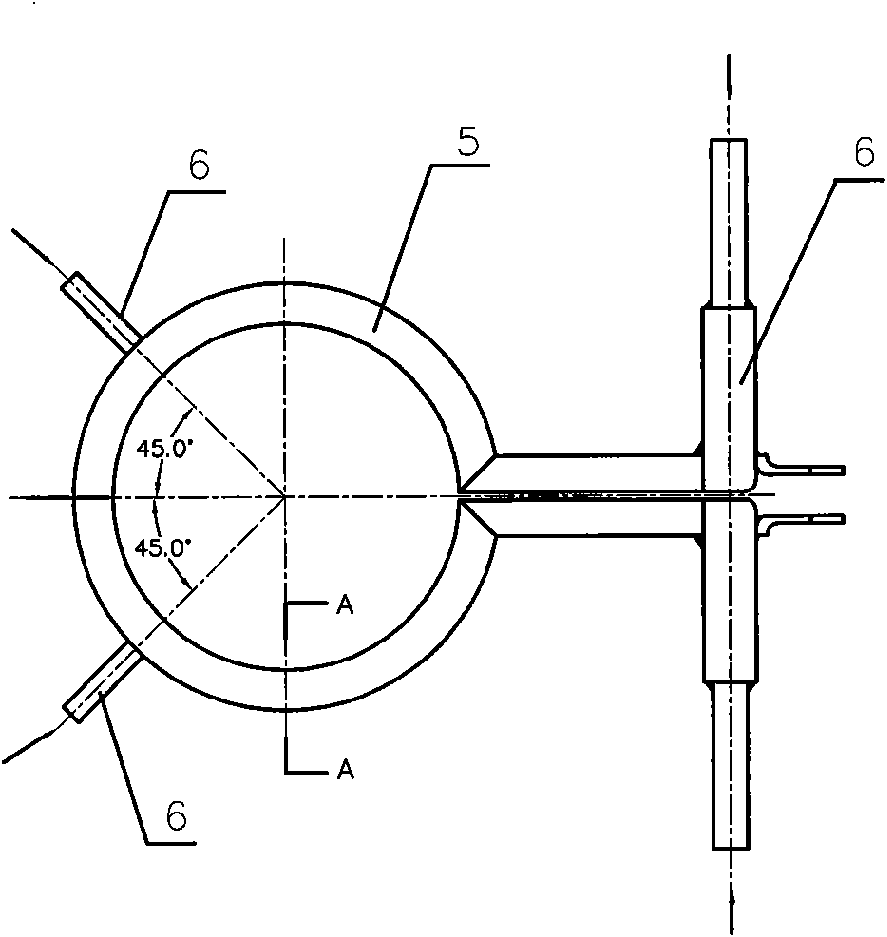

Simultaneous induction quenching technology for flange-output shaft neck and end face

ActiveCN101509061AEvenly distributedEasy loading and unloadingIncreasing energy efficiencyFurnace typesHardnessCooling capacity

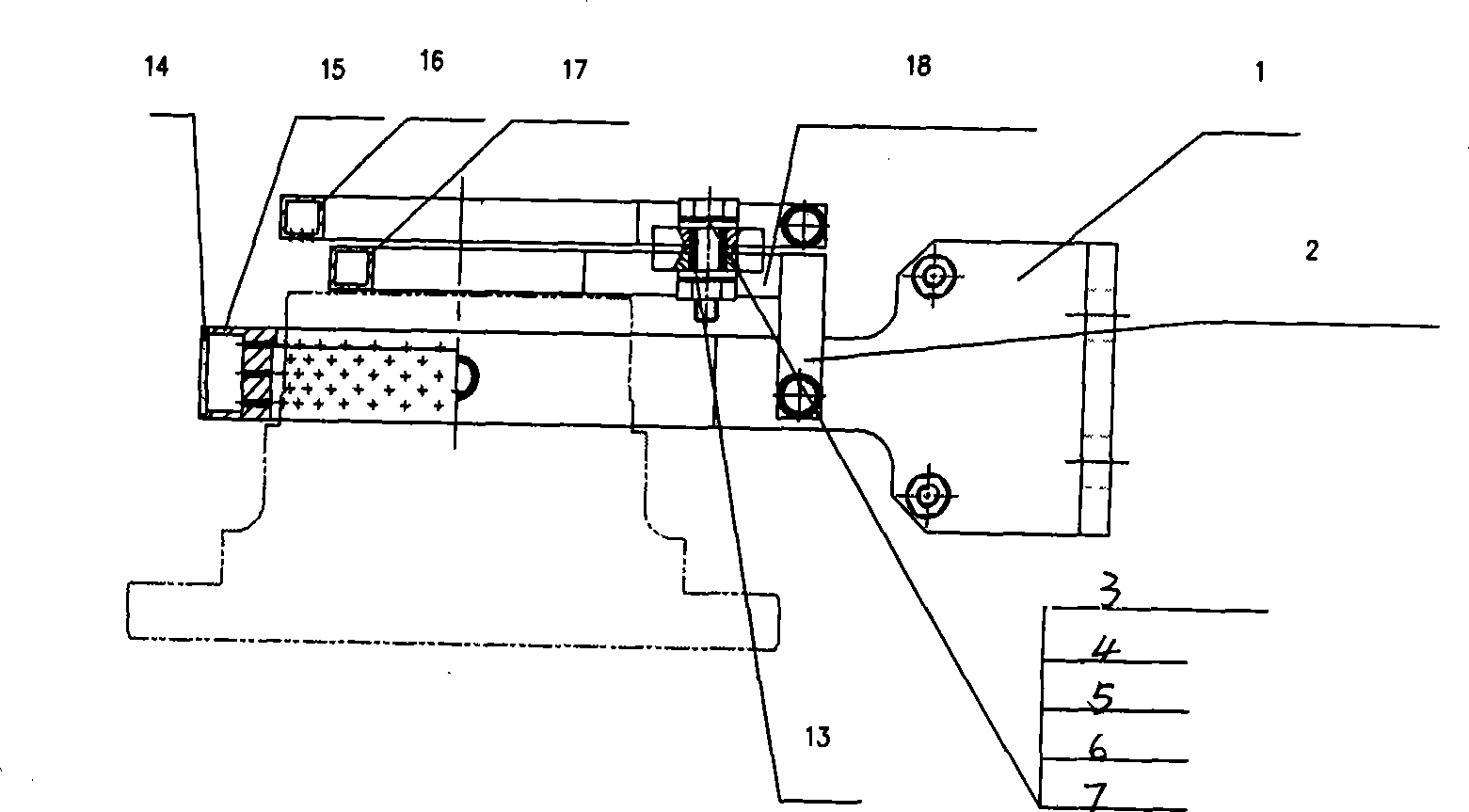

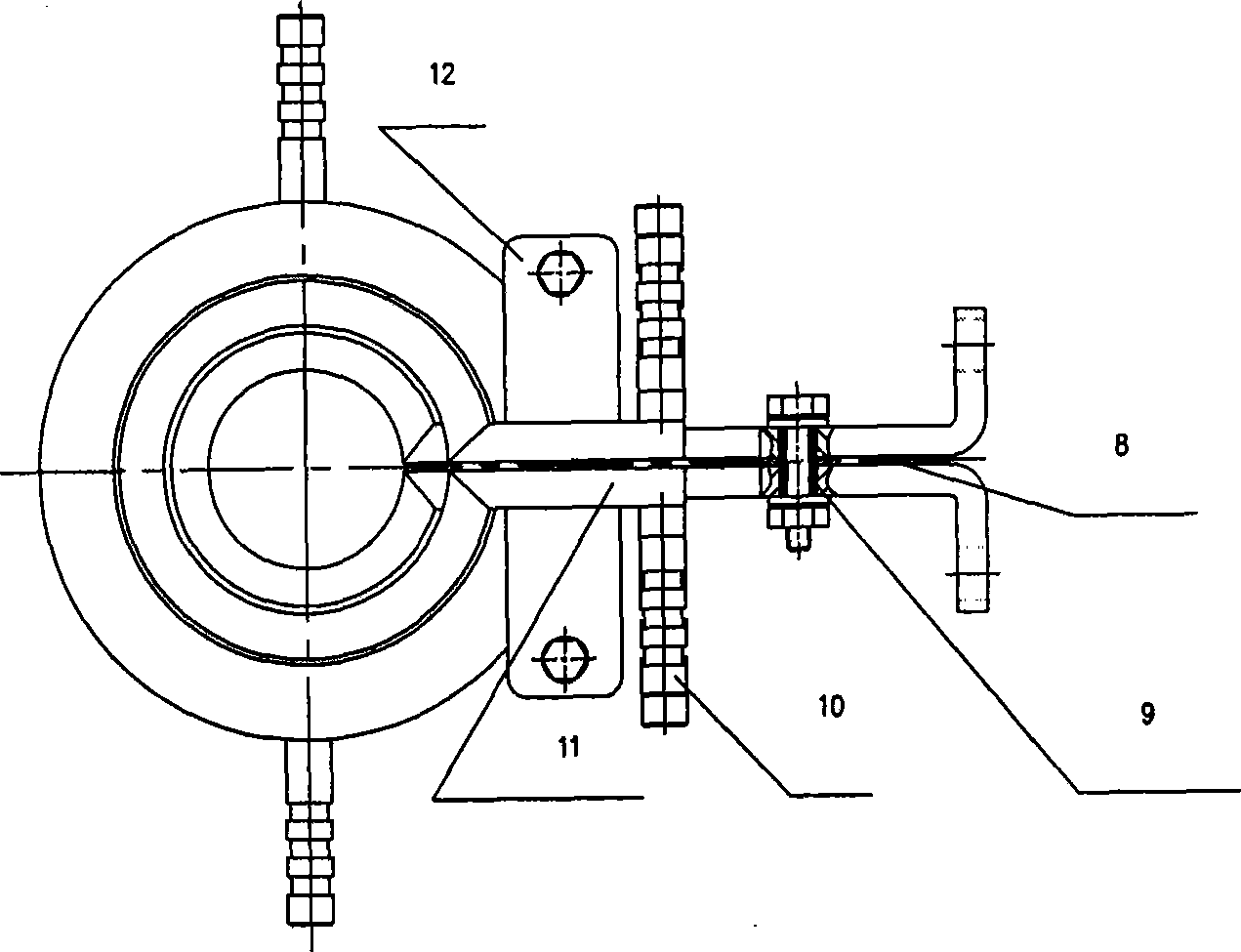

The invention relates to a technique for induction-quenching the axle journal and the end surfaces of a flange-output axle simultaneously. The invention is characterized in that the technique comprises the following steps: placing parts to be quenched with end surfaces upward on a rotary base; pressing down a start button to start rotating a workpiece, so that the metal parts adjacent to active wires are heated for 5 seconds; stop heating when the parts are heated to a temperature 50 DEG C higher than the austenitizing temperature of the material; cooling by spraying cooling water; and then, finishing the quenching process of the part by taking the part down from the rotary base when the cooling is finished. The technique ensures that hardening layers can be distributed evenly, prevents the quenching crack from generating, improves the cooling capacity and uniformity during the cooling process in quenching and ensures that the hardness of the quenched surface is even; the invention has the advantages of simple structure, short process time, high production efficiency, energy conservation and low process cost; the hardening layers are continuously distributed from the axle journal to the end surfaces without tempering soft zone, and evenly distributed except for the tip part; and the technique provides convenience for part assembly and disassembly and technique adjustment, so that spraying and part disassembling can be finished at two positions.

Owner:CHINA FIRST AUTOMOBILE

More than 630 MPa level high strength steel bar and application method thereof in reinforced concrete

The invention discloses a more than 630MPa level high strength steel bar comprising the following components: by weight, 0.28%-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80%-1.50% of Cr, 3.00%-4.00% of nickel, 0.40%-0.60% of molybdenum, 0-0.015% of P, 0-0.015% of sulfur, 0-2.0ppm of hydrogen, 0.10%-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements and the balance of Fe; the invention also designs an application method of the more than 630MPa level high strength steel bar in reinforced concrete; and the more than 630MPa level high strength steel bar has the advantages of high strength, steel saving, no pollution, good hardenability, low tendency to crack and low relaxation degree.

Owner:江苏森林建筑新材料股份有限公司

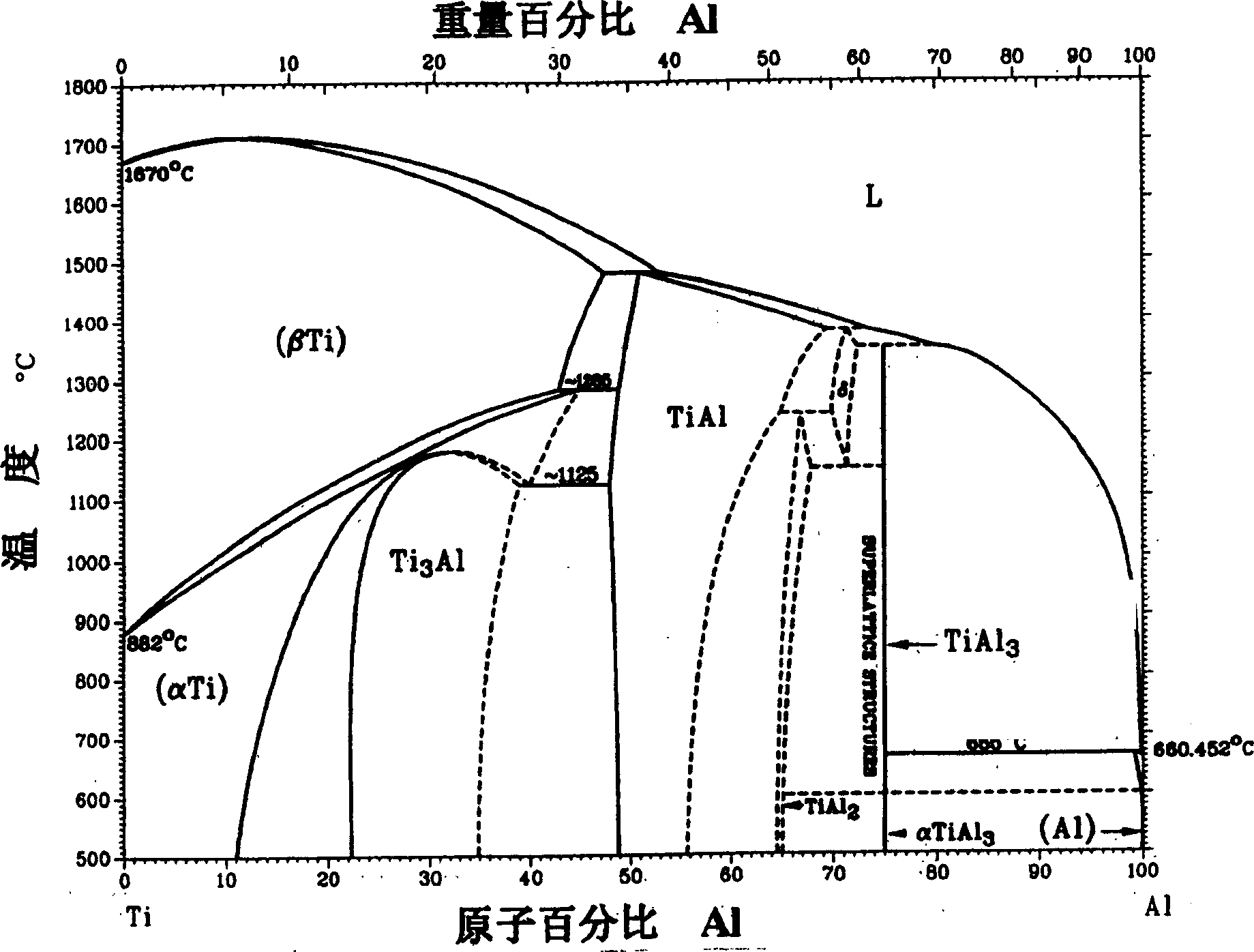

Heating technology for refining TiAl alloy ingot microscopic texture

Owner:UNIV OF SCI & TECH BEIJING

Turbine blade capable of enhancing impact toughness and production technique thereof

ActiveCN104060191AAvoid formingPrevent early brittle crackingFurnace typesHeat treatment furnacesMischmetalChemical composition

The invention provides a turbine blade capable of enhancing impact toughness, which comprises the following chemical components in percentage by mass: 0.13-0.15% of C, 0.8-0.9% of Si, 0.5-0.8% of Mn, 14-16% of Cr, 0.1-0.3% of Ni, 1.3-1.5% of Cu, 0.6-1.1% of Mo, 0.1-0.15% of W, 0.36-0.45% of V, 0.5-0.8% of Nb, 0.28-0.30% of Al, 0.16-0.18% of Ti, 0.08-0.10% of B, 0.45-0.48% of Na, at most 0.02% of S, at most 0.03% of P, 0.3-0.6% of rare-earth metal and the balance of Fe. The invention also provides a production technique of the turbine blade capable of enhancing impact toughness. The production technique can greatly enhance the impact toughness of the blade and prolong the service life of the blade.

Owner:南京赛达科技有限公司

Production method for thermal treatment prestressed steel strand

The invention discloses a production method for a thermal treatment prestressed steel strand. According to the production method for the thermal treatment prestressed steel strand, AISI4340MOD steel is selected as raw materials and theAISI4340MOD steel comprises the following componentsby mass percent, 0.3 to 0.32 % of carbon, 0.18 to 0.36 % of silicon, 0.50 to 0.70 % of manganese, 0.90 to 1.10 % of chromium, 0.20 to 0.30 % of molybdenum, 0 to 0.02 % of phosphorus, 0 to 0.025 % of sulfur, 0 to 1.8 ppm of hydrogen, 0 to 0.40 % of nickel, 0 to 0.03 % of vanadium, 0 to 0.30 % of copper, 0 to 0.9 % of residual elements and the remaining is ferrum. The production method for the thermal treatment prestressed steel strand has the advantages of improving the strength and hardenability of the steel strand, enabling the steel strand to be not easy to craze, low in looseness, uniform and smooth in surficial galvanization.

Owner:TIANSHUN GROUP

High-carbon microalloying steel ball and production process thereof

ActiveCN102758140APrevent quenching crackingAvoid problems such as quenching crackingFurnace typesHeat treatment process controlSurface layerHigh carbon

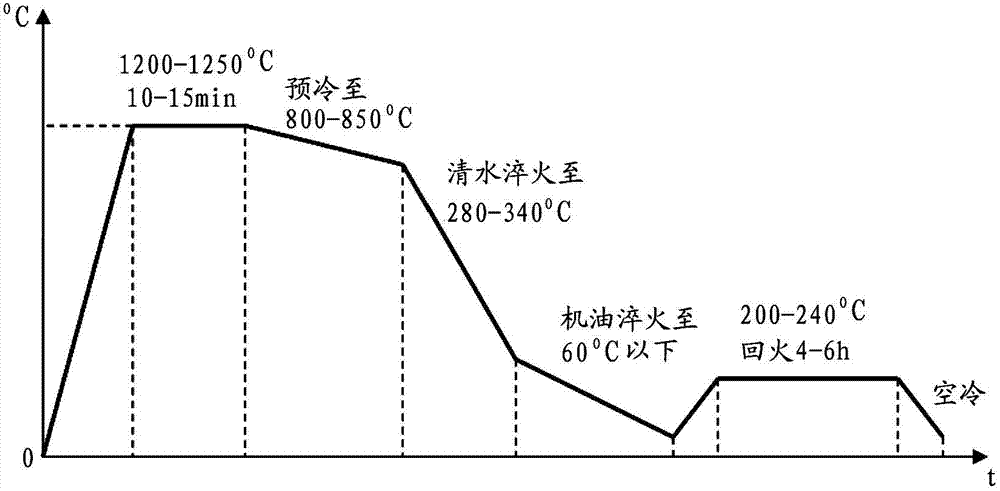

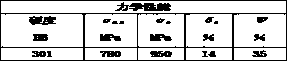

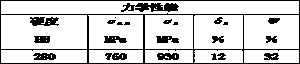

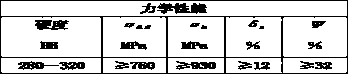

The invention discloses a production process of a high-carbon microalloying steel ball. The production process comprises the following steps of: heating a steel ball blank to be 1,200-1,250 DEG C and forging the steel ball blank to a steel ball of which the size is required; precooling the steel ball until the temperature of the surface layer of the steel ball is 800-850 DEG C; putting the steel ball into clear water at the temperature of 30-60 DEG C to quench until the temperature of surface layer of the steel ball is reduced to 280-340 DEG C, and taking out the steel ball; 1-2s later, putting the steel ball into mechanical oil at the temperature of 30-50 DEG C to quench until the temperature of surface layer of the steel ball is reduced be below 60 DEG C; taking out the steel ball and putting the steel ball into mechanical oil at the temperature of 200-240 DEG C to temper for not less than 4 hours; and taking out and finishing the steel ball to obtain a steel ball finished product, wherein according to the weight percentage, the steel ball contains 0.90-1.05 percent of C, 0.30-0.70 percent of Si, 0.80-1.20 percent of Mn, 0.25-0.40 percent of Cr and the balance being Fe and inevitable impurities. The high-carbon microalloying steel ball is prepared by using the production process, and the quenching and cracking of the steel ball can be effectively avoided; and compared with the conventional high-carbon microalloying steel ball, the prepared high-carbon microalloying steel ball has the same performance, and obviously reduces alloy contents and production cost.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Anti-cracking machining method of small axial surface carburizing and hardening stepped shaft with end face provided with groove

The invention discloses an anti-cracking machining method of a small axial surface carburizing and hardening stepped shaft with an end face provided with a groove. The groove is arranged in an end face of a shaft section B of the stepped shaft, a shaft section A and a side face, close to the shaft section A, of the shaft section B have carburizing and hardening requirements, other parts have no hardness requirements, 20Cr steel serves as blanks of the stepped shaft, the procedures of blanking, rough machining, carburizing treatment, semi finish machining, hardening, fine machining, cutting and groove milling are sequentially carried out on the blanks, and then the stepped shaft with different shaft sections having different mechanical properties are machined. The anti-cracking machining method is simple in structure and convenient to achieve; a protective step is arranged before carburizing, the protective step before the hardening is machined to be a fillet, and cracking caused by oversize stress when the carburizing and hardening are carried out on the root portion of the step can be effectively avoided; a shaft section B carburized layer is milled off before the hardening, the hardness of the shaft section B after the hardening is reduced, and machining efficiency of following steps is improved.

Owner:HEBEI HUABEI DIESEL ENGINE

Thermal treatment method of cam shaft

ActiveCN102925655AImprove wear resistanceImprove fatigue strengthFurnace typesIncreasing energy efficiencyHardnessCam

The invention discloses a thermal treatment method of a cam shaft, which solves the problem of non-uniform heating temperature and temperature gradient on a cam profile. The quenching comprises the following steps of: a, preheating: sheathing an induction coil of an induction heating device outside a cam, placing a shielding plate between a cam lifting part and the induction coil, and preheating for 33-45 seconds under the conditions with voltage of 340-480V and current of 160-230A; b, stopping heating, removing the shielding plate, and 5-8 seconds later, continuously heating for 8-14 seconds under the conditions with voltage of 410-500V and current of 200-250A; and c, cooling: cooling the cam with a quenching medium. Through the invention, the quenching hardness range of the produced cam shaft is reduced by 3.5HRC from that of common surface quenching, the depth range of a hardening layer is reduced by 3.7mm, the metallographic structure is obviously improved, and quenching cracks are avoided; and moreover, the wear resistance and fatigue strength of the cam shaft are obviously improved, and the service life of the cam shaft is obviously prolonged.

Owner:CHONGQING YUEJIN MACHINERY

Large-diameter forged wear-resisting steel ball special for mine and preparation method thereof

ActiveCN107739986AImprove hardenabilityHigh hardnessFurnace typesHeat treatment furnacesSteel ballWet grinding

The invention discloses a large-diameter forged wear-resisting steel ball special for a mine and a preparation method thereof and relates to the technical field of wear-resisting materials. The chemical components of the large-diameter forged wear-resisting steel ball special for the mine comprise, by weight, 0.8-1.2% of C, 0.6-0.9% of Si, 1.2-1.5% of Mn, 1.0-1.5% of Cr, 0.1-0.3% of Mo, 0.05-0.15%of V, 0.1-0.2% of Ti, 0.05-0.15% of Al, 0.05-0.15% of Cu, 0.05-0.15% of Zr, 0.05-0.15% of Hf, 0.08-0.2% of B, 0-0.02% of P, 0-0.01% of S, and the balance Fe and inevitable impurities. The preparationmethod comprises the steps of smelting, forging and heat treatment. The chemical components and contents thereof of the large-diameter forged wear-resisting steel ball special for the mine are reasonably optimized, stability of the undercooled austenite and hardenability of steel can be improved through the added hardening elements like Mn, Mo, Cr, V, Ti and Cu, the difference value of the core portion hardness and the surface hardness of the large-diameter wear-resisting steel ball is reduced, the prepared wear-resisting steel ball is smooth and defect-free in surface, high in hardness, goodin toughness and not prone to being broken, the performance of the prepared wear-resisting steel ball can be comparable with high-chromium grinding balls, the prepared wear-resisting steel ball can replace casting balls to be used for ore wet grinding, and the ore grinding efficiency is improved.

Owner:TONGLING MINGCHENG FOUNDRY

Production processing method for edge-digging scissors made of Cr12Mo1V1

The invention discloses a production processing method for edge-digging scissors made of Cr12Mo1V1. The production processing method comprises a first step of performing isothermal spheroidizing on a forged piece; a second step of performing rough milling, flaw detection and ingredient detection; a third step of performing destressing tempering, and performing finish milling to dimensions prior to quenching; a fourth step of performing quenching and tempering (enabling workpiece hardness to be HRC 58-62); a fifth step of performing coarse grinding, destressing tempering and semi-precision grinding; a sixth step of utilizing a low-speed wire to perform linear cutting on the arc cutting edge face, and performing precision grinding to obtain a finished product; and a seventh step of performing checking and oil coating, and placing the product in a warehouse. According to the method, cracking of an arc cutting edge during linear cutting can be avoided, and accordingly the edge-digging scissors production pass rate is guaranteed.

Owner:TAIER HEAVY IND

Special quenching liquid for preparing large axial forgings from 35CrMo

The invention discloses special quenching liquid for preparing large axial forgings from 35CrMo, and belongs to the technical field of heat treatment quenching. The quenching liquid disclosed by the invention is composed of a mixture of polypropylene-methacrylic acid and polyacrylamide, an ethylene oxide and epoxypropane random copolymer, polyamide polyethylene glycol, a defoaming agent and water. The quenching liquid is mainly suitable for quenching large axial forgings prepared from 35CrMo steel, the process is simple, the traditional double-liquid and triple-liquid quenching processes are changed to effectively avoid quenching crack of the large axial forgings of 35CrMo steel, the quenching effect is good, and the defects of common quick quenching oil that the hardness after quenching is insufficient, the internal organizational form is non-uniform and cracking is liable to produce can be overcome.

Owner:马鞍山金泉工业介质科技有限公司

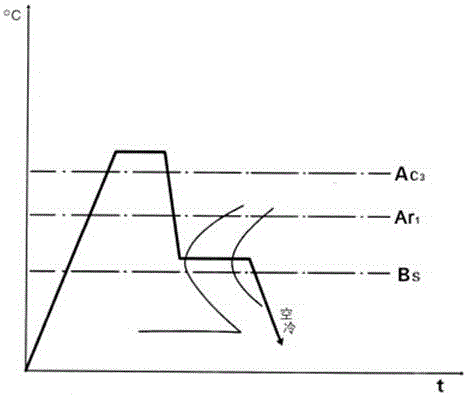

Normalizing method for forging waste heat of steel

ActiveCN105886717AImprove hardenabilityExtended service lifeMetal-working apparatusAusteniteMechanical property

The invention discloses a normalizing method for forging waste heat of steel. The normalizing method is characterized in that online controlled forging and cooling isothermal normalizing treatment for forging waste heat is implemented. The normalizing method comprises the following steps of controlled forging of the steel: controlling the forging temperature and the forging deformation degree of the steel, and refining grains by deforming and recrystallizing austenite; controlled cooling of the steel: controlling cooling rates, cooling uniformity and cooling efficiency of the steel at of all critical temperatures according to the principles of metallography and heat treatment; cooling the steel to a critical temperature and keeping the isothermality; finishing transformation of super-cooled austenite within the temperature range, thus obtaining fine grain structures; and after isothermal keeping, performing controlled cooling, namely controlling the cooling rate, the cooling uniformity, the cooling efficiency and a cooling final temperature after isothermal keeping, thus obtaining the normalizing method with structure and mechanical properties up to standards. According to the normalizing method disclosed by the invention, energy sources and resources can be saved, the normalizing treatment quality is improved, the normalizing treatment cost is reduced, the labor intensity of workers is reduced, labor productivity is improved, and the construction period is shortened.

Owner:王中忞

Turbine blade capable of improving thermal cracking resistance and production process thereof

ActiveCN104032236AReduced impact toughnessImprove impact toughnessBlade accessoriesMachines/enginesMischmetalChemical composition

The invention discloses a turbine blade capable of improving the thermal cracking resistance. The turbine blade comprises the following chemical components in percentage by mass: 0.31-0.35% of C, 0.10-0.12% of Si, 0.75-0.77% of Mn, 0.63-0.65% of Ni, 11.2-11.7% of Cr, 0.65-0.68% of Mo, 0.16-0.18% of V, 0.85-0.88% of Sr, 0.15-0.17% of Nb, 0.05-0.07% of Cu, 0.27-0.29% of Al, 0.13-0.15% of Ti, 0.06-0.08% of B, less than or equal to 0.02% of S, 0.21-0.35% of rare earth metal and the balance of Fe. By adopting the turbine blade, the impact toughness of a blade is greatly improved, the thermal cracking resistance of the blade is improved, and the service life of the blade is prolonged.

Owner:南京赛达科技有限公司

Process for heat-treatment on spring steel product for high-speed heavy-load trains

InactiveCN101597681AGrain refinementSolve Quenching CrackingIncreasing energy efficiencyFurnace typesSpring steelYield ratio

The invention discloses a process for heat-treatment on a spring steel product for high-speed heavy-load trains. The process comprises the following steps: heating spring steel to a temperature of between 960 and 1,100 DEG C; wrapping the steel into a spring; cooling the wrapped spring to a temperature 5 to 50 DEG C lower than Ar1; insulating the spring for 0 to 1 hour, and reheating the wrapped spring to a temperature 5 to 50 DEG C higher than Ac3; and quenching and tempering the spring to produce the spring steel product for the high-speed heavy-load trains. Compared with the prior art, the process has the advantages of high fatigue resistance, tensile strength and yield ratio, enough plasticity and toughness, easily wrapped forming under heat state, good hardenability and the like.

Owner:GUIZHOU UNIV

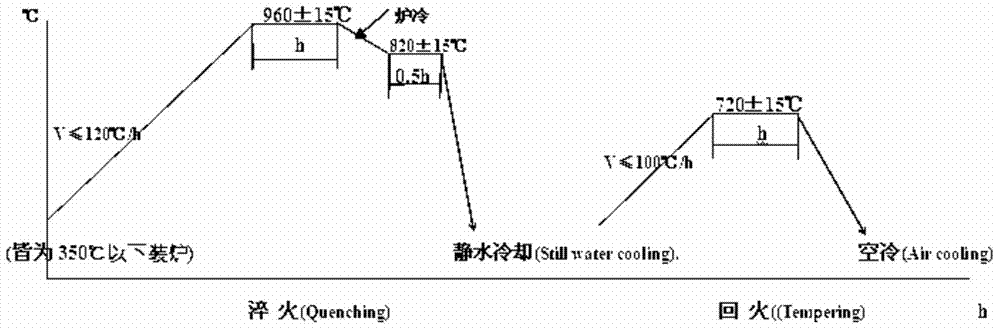

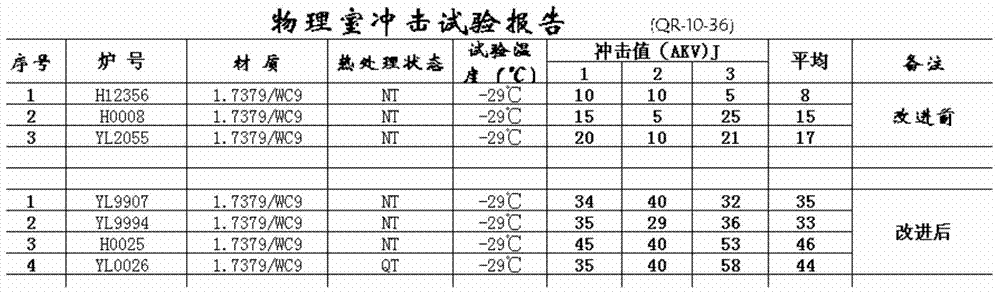

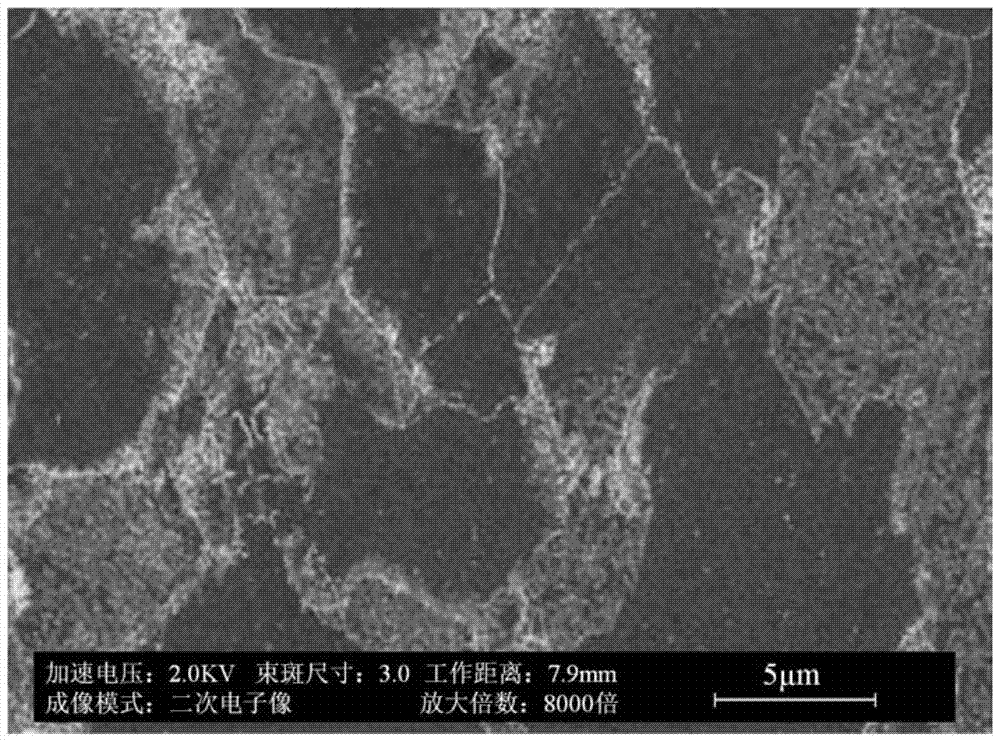

Heat treatment process for improving low-temperature toughness of castings

InactiveCN104263885AAvoid Quenching CracksImprove low temperature impact toughness and stabilityQuenchingHeating furnace

The invention discloses a heat treatment process for improving the low-temperature toughness of castings. According to the heat treatment process disclosed by the invention, conventional normalizing and tempering processes are replaced with quenching and tempering processes, so that the heat treatment process is easy to operate, economic and applicable; and on the premise of not changing existing heat treatment equipment (heating furnace) and quenching liquid (water) and avoiding the occurrence of cracks and the like, the heat treatment process can be performed, so that the cycle is shortened, the cost is saved, and the low-temperature impact toughness and stability of castings are significantly improved.

Owner:HUSN CASTING ANHUI YINGLIU GROUP

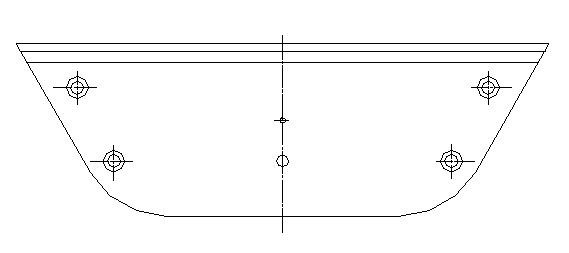

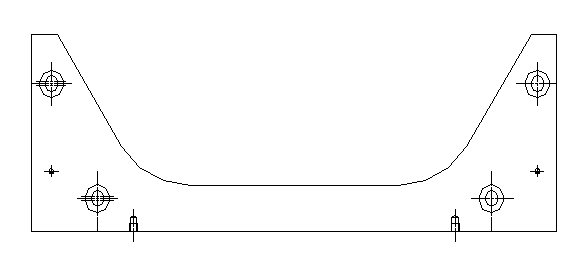

Cross head surface induction hardening method of marine diesel engine

InactiveCN101671766AReduce sharp corner effectPrevent quenching crackingFurnace typesIncreasing energy efficiencyNumerical controlInduction hardening

The invention relates to a cross head surface induction hardening method of a marine diesel engine, wherein, a notch on the cross head hardening surface of the marine diesel engine is filled by a technique block, and all the holes are sealed by moist clay; a cross head is mounted on a hardening machine; and a circular self-water spraying induction coil is mounted to be used for carrying out continuous hardening. Through filling the notch by the technique block and sealing the holes by the moist clay when hardening, the invention can reduce the sharp corner effect when hardening workpieces, thehardening speed at the sharp corner can be controlled by the numerical control technique, and the internal stress is reduced, thereby hardening cracks of the workpieces are avoided. After being treated by the induction hardening method, the hardening hardness of the cross head of the marine diesel engine is uniform and has no hardening soft belt; the hardness and the hardened layer of all the required hardening surfaces conform to the specification of drawings and technical files, and thereby, the difficult problem of hardening is solved, the quality is more stable, the hardening time of theparts is shortened, and the production efficiency is improved.

Owner:YICHANG MARINE DIESEL ENGINE

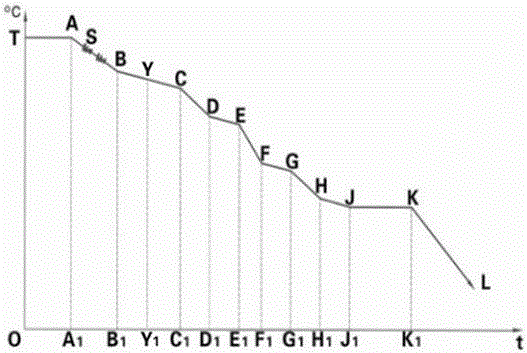

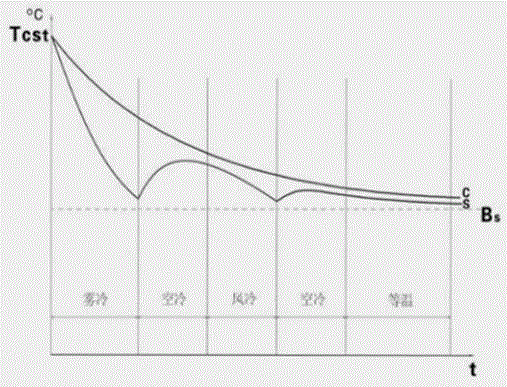

Optimization method of alloy steel water quenching process

ActiveCN109929969AHardenability MarginEasy Quenching CrackHeat treatment process controlCooling curveHardenability

The invention provides an optimization method of an alloy steel water quenching process. The method comprises the following steps of firstly predicting and obtaining a structure with a required performance; determining the temperature to be cooled of the structure by virtue of an isothermal transformation cooling curve of an alloy steel part material; dividing the alloy steel part into a fast cooling region and a slow cooling region along the section from surface to center, wherein the fast cooling region is a part from the surface of the alloy steel part to the required performance part or deeper, the slow cooling region is a part of the required performance part or the deeper part to a central; determining water cooling time for reducing to a preset temperature of the fast cooling regionby means of numerical simulation, optimizing water cooling time by combining the temperature returning temperature and surface stress state of the required performance part; and finally, giving out the alloy steel water quenching process. According to the method, the purpose that low / high hardenability workpiece with limited material hardenability and large size can obtain high quenching coolingperformance or the purpose of avoiding generation of quenching cracks in quenching and cooling process are met.

Owner:SHANGHAI JIAO TONG UNIV

Medium-frequency induction quenching process in heavy-duty rack with super modulus

ActiveCN103627880AHigh hardnessMeet the performanceFurnace typesIncreasing energy efficiencyStressed stateHeavy duty

The invention relates to heat treatment for a rack with super modulus and particularly relates to a medium-frequency induction quenching process for a heavy-duty rack with the super modulus. An inductor is a profiling inductor in the shape which is in adaptation with the shape of the section of a tooth space of the rack, and the medium-frequency induction quenching process comprises the following steps: A) placing the rack on a medium-frequency induction quenching machine tool; B) simultaneously heating a tooth face and a tooth root of the tooth space of the rack through the inductor; C) performing air-cooling, wherein the cooling rate is greater than the critical cooling rate, and the surface temperature of a heating zone of the rack after air-cooling is positioned in a martensite transformation zone; and D) implementing liquid-cooling after temperature gradient in a depth range of a hardened layer of a surface layer of the heating zone of the rack is stable to complete structural transformation, wherein the cooling rate of liquid-cooling is greater than the critical cooling rate. According to the process, the higher hardness and the deeper hardened layer of the rack can be ensured, the stress state at the tooth root can be effectively improved, the cracking and the delayed cracking of the tooth root can be avoided, and the process is suitable for quenching the rack with the super modulus, particularly the cast rack with the super modulus.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Heat treatment method capable of improving elongation rate of PCrNi3MoVA material forge piece

The invention relates to a heat treatment method capable of improving an elongation rate of a PCRni3MOVA material forge piece. The method comprises the following steps that normalizing is conducted toheat to 610-650 DEG C firstly, then heating up to 880-900 DEG C is conducted, then heat preservation is conducted, and cooling to a room temperature is conducted; quenching is conducted to heat to 610-650 DEG C firstly, then heating up to 860-880 DEG C is conducted, the heat preservation is conducted, cooling and quenching are conducted, taking out of a furnace is conducted, and water cooling, air cooling, secondary water cooling and oil cooling are conducted for cooling and quenching; tempering at a high temperature is conducted to heat to 320-350 DEG C firstly, then preserving heat is conducted, and then heating up to 580-610 DEG C is conducted; after the furnace cooling to 400 DEG C is conducted, and taking out of the furnace is conducted for the air cooling. According to the method, the heat treatment mode of normalizing, cooling and quenching and high-temperature tempering is adopted, the material forge piece with a effective section phi 101 mm to phi 250 mm can be subjected to heat treatment, the elongation rate of the material forge piece subjected to the heat treatment can reach 16%-19%, technical requirements of an ultra-high pressure container forge piece can be met, andthe production process is high in operability.

Owner:武汉重工铸锻有限责任公司

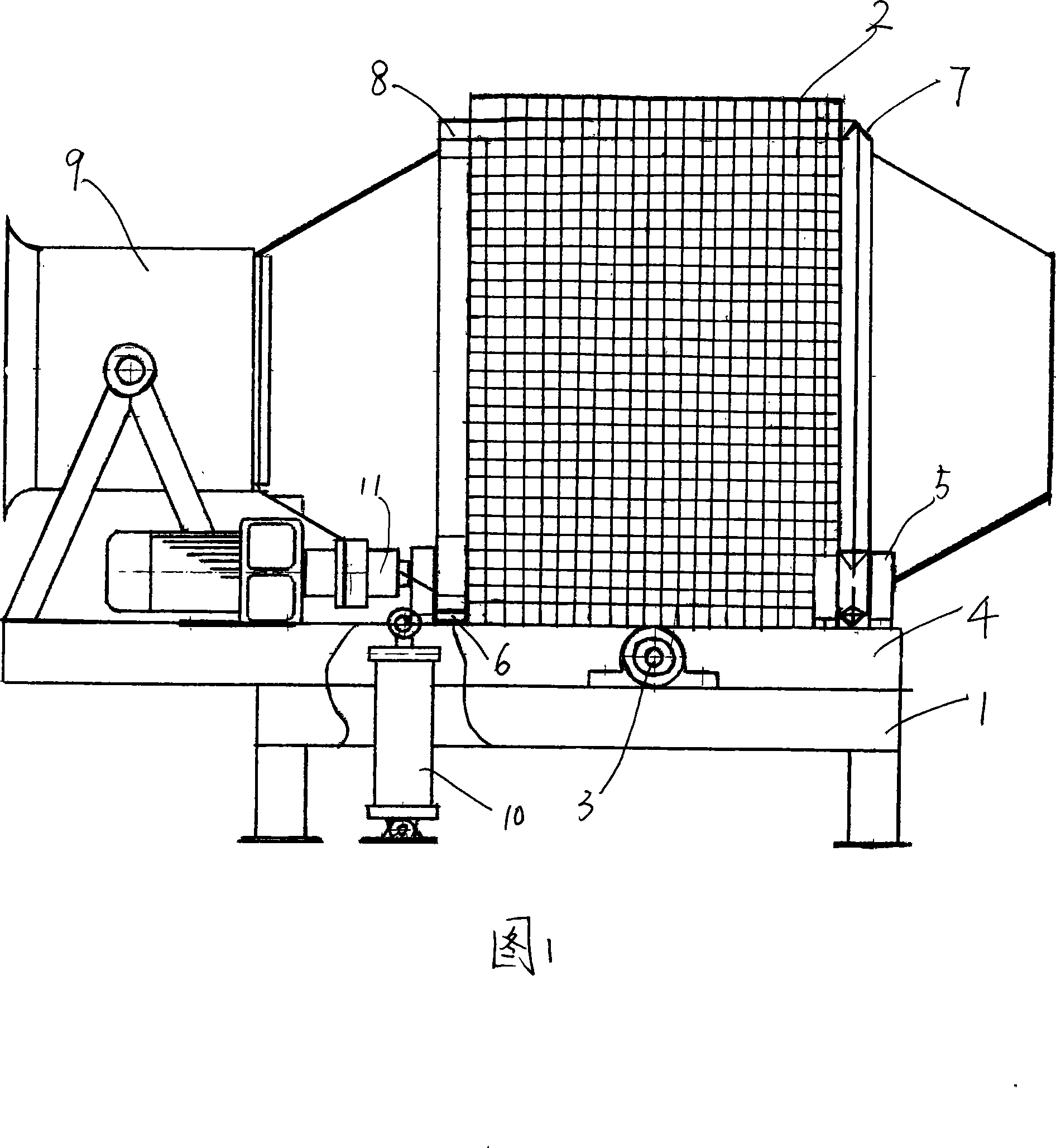

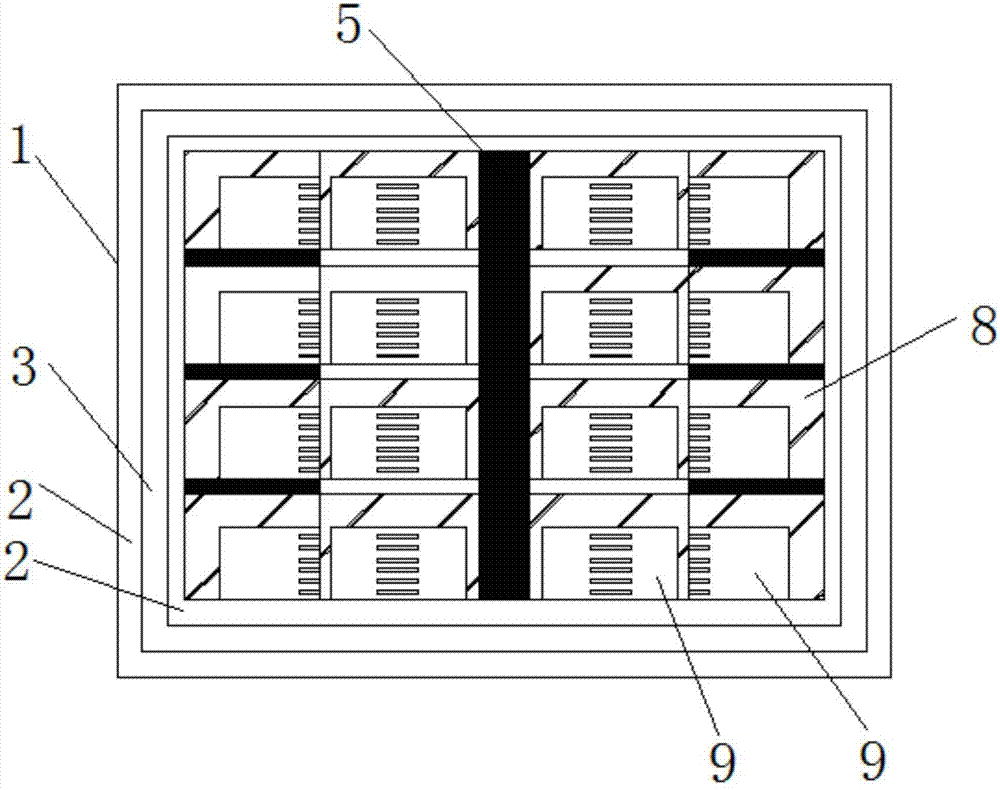

Drum-type quenching machine

ActiveCN101240364ATo achieve the purpose of quenchingUniform hardness surfaceFurnace typesHeat treatment furnacesQuenchingHardness

The invention discloses a drum type quenching machine composed of frame and drum, which is characterized in: the frame is equipped with a drum bracket by a rotating shaft, the drum bracket being equipped with V-shaped riding wheel group at least consisting of front and rear V-shaped riding wheels and gear riding wheel group at least consisting of front and rear gears; the drum outer wall is equipped with V-shaped rims riding inside of the V-shaped riding wheel group and transmission rims riding on the gear riding wheel and engage with each other; the drum inner wall is fixed with screw blades; the drum bracket is equipped with V-shaped wheel sleeves outside of the V-shape rim of the drum; one end of the drum bracket is connected with jack-up air cylinder or oil cylinder at the lower part. The drum quenching machine meets the norms and technology requirements of current cast ball quenching treatment, is successfully used in wear-resisting cast ball industry, the quenched casting has even hardness and reaches the oil quenching norm. The uniformity of hardness of batch processing is better than that of oil quenching, completely avoiding the appearance of quenching crack.

Owner:ANHUI NINGGUO XINNING IND

Long-life steam turbine blade and production process thereof

ActiveCN104046919AReduced impact toughnessImprove impact toughnessBlade accessoriesFurnace typesMaterials scienceIndustrial engineering

The invention discloses a long-life steam turbine blade. The long-life steam turbine blade consists of the following chemical components in percentage by weight: 0.29-0.31% of C, 0.16-0.19% of Si, 0.75-0.77% of Mn, 0.73-0.85% of Ni, 9.5-10.1% of Cr, 0.55-0.64% of Mo, 0.15-0.17% of Sn, 0.11-0.15% of V, 0.82-0.84% of Sr, 0.15-0.17% of Nb, 0.02%-0.03% of Cu, 0.13%-0.15% of T, 0.06-0.08% of B, not greater than 0.01% of Ca, not greater than 0.03% of S, not greater than 0.03% of P, 0.16%-0.18% of rear-earth metal, and the balance of Fe. The production process disclosed by the invention is carried out by hot-forging, annealing, blade mechanical machining, distressing thermal treatment, tempering thermal treatment, cooling, surface-enhanced thermal treatment, physical and chemical inspecting, ultrasonic-wave flaw detecting, and cleaning-packaging. The production process disclosed by the invention can greatly improve impact toughness of the blade, can improve water erosion resistance and corrosion resistance of the blade, and can prolong the service life of the blade.

Owner:南京赛达科技有限公司

Heat treatment process of low-alloy large mold steel

InactiveCN105821300AAvoid Quenching CracksImprove the qualified rate of finished productsAlloy elementQuenching

The invention discloses a heat treatment process of low-alloy large-scale die steel, which contains chemical components and the content of each component: carbon 0.1%-0.2%, silicon 0.2%-0.5%, chromium 0.5%-0.8%, nickel 0.05% %-0.1%, molybdenum 0.02%-0.08%, titanium 0.01%-0.04%, and the rest are iron; the heat treatment process of the low-alloy large die steel includes the following steps: a, annealing; b, quenching: cooling to Put the low-alloy large-scale die steel below 500°C into the quenching liquid, cool to below 150°C, and release the quenching liquid; c, tempering. Through the above method, the present invention can effectively avoid the generation of quenching cracks by optimizing the content of alloy elements and rationally controlling the heating temperature, holding time, heating rate and other process parameters during the heat treatment process, thereby improving the qualified rate of finished products.

Owner:TAICANG HUTAI HOT PROCESSING PLANT

Hardening and tempering method in pump body manufacturing

InactiveCN101892362AIncreased impact valueImprove hardenabilityQuenching agentsPotassium nitrateManufacturing technology

The invention discloses a hardening and tempering method in pump body manufacturing, and belongs to the technical field of pump body machining and manufacturing. The method comprises the processes of normalizing, hardening, primary high-temperature tempering, secondary high-temperature tempering and medium-temperature tempering, namely two-time high-temperature tempering and once medium-temperature tempering are performed after hardening. Simultaneously, sodium nitrate, sodium nitrate and potassium nitrate serve as a medium, namely a mixed solution consisting of 25 weight percent of the sodium nitrate, 20 weight percent of the sodium nitrite, 20 weight percent of the potassium nitrate and 35 weight percent of water, so as to improve the hardenability of a product, and simultaneously reduce a surface pulling stress to be crucially effective in stopping hardening cracks. The method of the invention effectively improves an impact value of a pump body at the temperature of -40 DEG C and the mechanical property of the pump body, has high safety in a hardening and tempering processes, improves working environment and reduces the labor intensity of production staff.

Owner:JINXI IND GRP

Turbine blade capable of enhancing water corrosion resistance and production technique thereof

ActiveCN104060192AThe segregation of alloying elements is weakenedImprove impact toughnessFurnace typesHeat treatment furnacesCorrosionSteam turbine blade

Owner:南京赛达科技有限公司

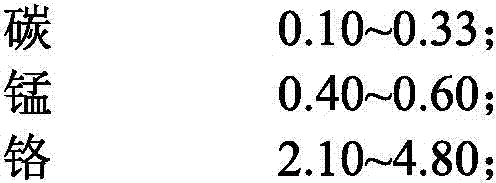

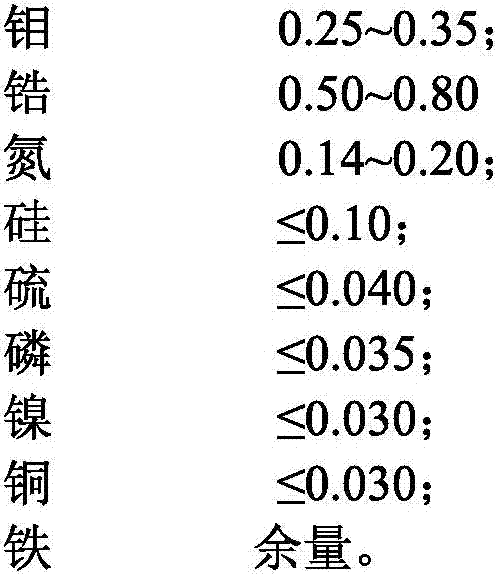

Steel for deep sea oil extraction equipment connector and manufacturing method for forge piece of steel

ActiveCN107326297APrevent quenching crackingImprove corrosion resistanceMetal-working apparatusWater coolingQuenching

The invention discloses steel for a deep sea oil extraction equipment connector and a manufacturing method for a forge piece of the steel. The manufacturing method comprises the following steps that special steel serves as a blank, the surface of the blank is coated with a layer of glass-like coating, then the blank is forged through a composite forging method combining free forging and multi-ram forging, and a secondary forge blank of the connector is obtained; normalization is conducted on the forge blank of the connector, and quenching heat treatment is conducted on the connector forge blank through a repeated water cooling-air cooling intermittent quenching process; and the quenched connector forge blank is subjected to secondary tempering treatment comprising the steps of tempering, air cooling, retempering and the second time of air cooling, and the steel forge piece of the deep sea oil extraction equipment connector. Through the combination of the forging process and the heat treatment process, quenching cracking of the complex-shape large forge piece is prevented effectively, the comprehensive mechanical performance, especially the low-temperature toughness, of the steel forge piece for the deep sea oil extraction equipment connector is improved substantially, and the steel forge piece can be suitable for a deep sea low-temperature operation condition environment very well.

Owner:ZHANGJIAGANG HAIGUO HEAVY FORGING +1

A method for manufacturing steel forgings for key parts of deep-sea oil tree

ActiveCN105671280BImprove corrosion resistanceSmall sizeMetal-working apparatusMedium frequencyMolten steel

The invention discloses a manufacturing method for a steel forging used for a critical component of a deep sea Christmas tree. The manufacturing method comprises the following steps that 1, F22 alloy steel and Fe-Ga intermediate alloy serve as the raw materials and are smelted to be high-quality molten steel in a medium frequency electric furnace; 2, liquid die forging is conducted on a hydraulic press, demolding is conducted at the temperature of about 1200 DEG C, a blank is forged through the forging mode that free forging and restrained forging are composited, and thus a secondary forging blank is obtained; 3, quenching heat treatment is conducted on the secondary forging blank through the mode that water cooling and air cooling are cycled and alternated for two times; and 4, secondary tempering treatment is conducted on the quenched secondary forging blank through the steps of tempering, water cooling, re-tempering and re-water-cooling, so that the steel forging used for the critical component of the deep sea Christmas tree is obtained. According to the manufacturing method for the steel forging used for the critical component of the deep sea Christmas tree, quenching cracks of the complex-shaped large forging is effectively prevented by combining the forging process with the heat treatment process; in addition, the comprehensive mechanical property, especially the low-temperature toughness of the manufactured steel forging used for the critical component of the deep sea Christmas tree is substantially improved, and the steel forging can be well applied to a deep sea low-temperature working condition environment.

Owner:NANJING INST OF TECH

Corrosion-resistant alloy material for prestressed steel strand and processing process of corrosion-resistant alloy material

InactiveCN104313485APrevent quenching crackingPrevent quenching tendencyProcess efficiency improvementCorrosion resistant alloyPre stress

The invention discloses a corrosion-resistant alloy material for a prestressed steel strand and a processing process of the corrosion-resistant alloy material. As the following components are added in percentage by weight: 0.26-0.28 percent of Si, 1.0-1.2 percent of Mn and 0.35-0.45 percent of Cr, atom activity of carbon and nitrogen elements can be improved, therefore, air mass energy formed by atoms and dislocation form strong interaction; meanwhile, as refining is carried out by an LF furnace and degassing is carried out in a vacuum degassing furnace, corrosion resistance and abrasion resistance are remarkably improved. The corrosion-resistant alloy material for the prestressed steel strand and the processing process of the corrosion-resistant alloy material are capable of improving the corrosion resistance, abrasion resistance and oxidation resistance; the corrosion-resistant alloy material can be applied to various severe environments, is high in strength, good in hardenability, not easy to crack and uniform and smooth in surface zinc plating.

Owner:TIANSHUN GROUP

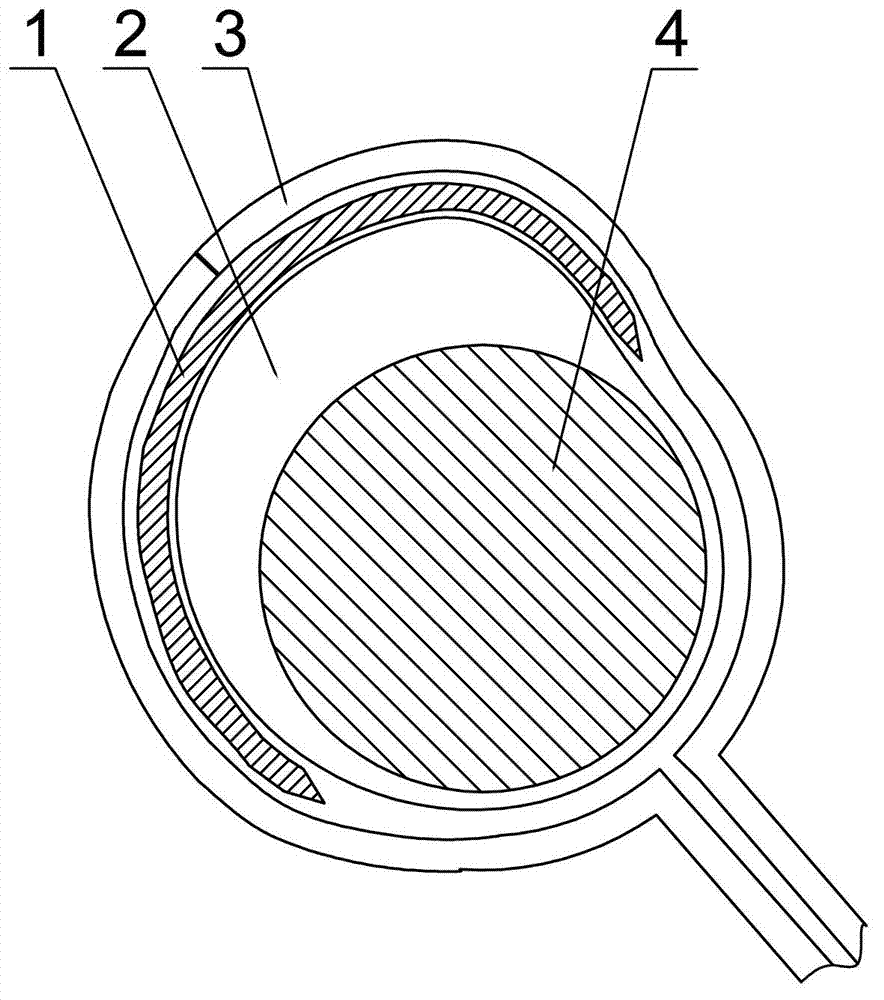

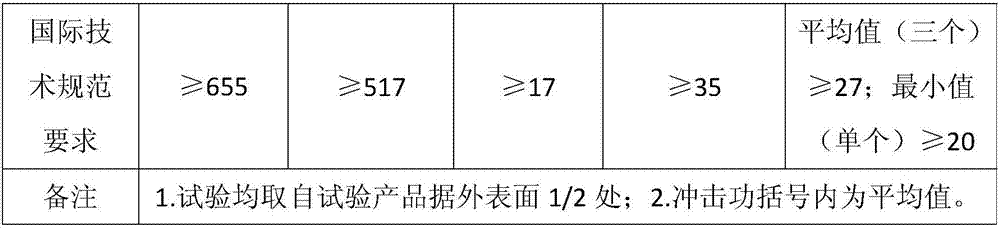

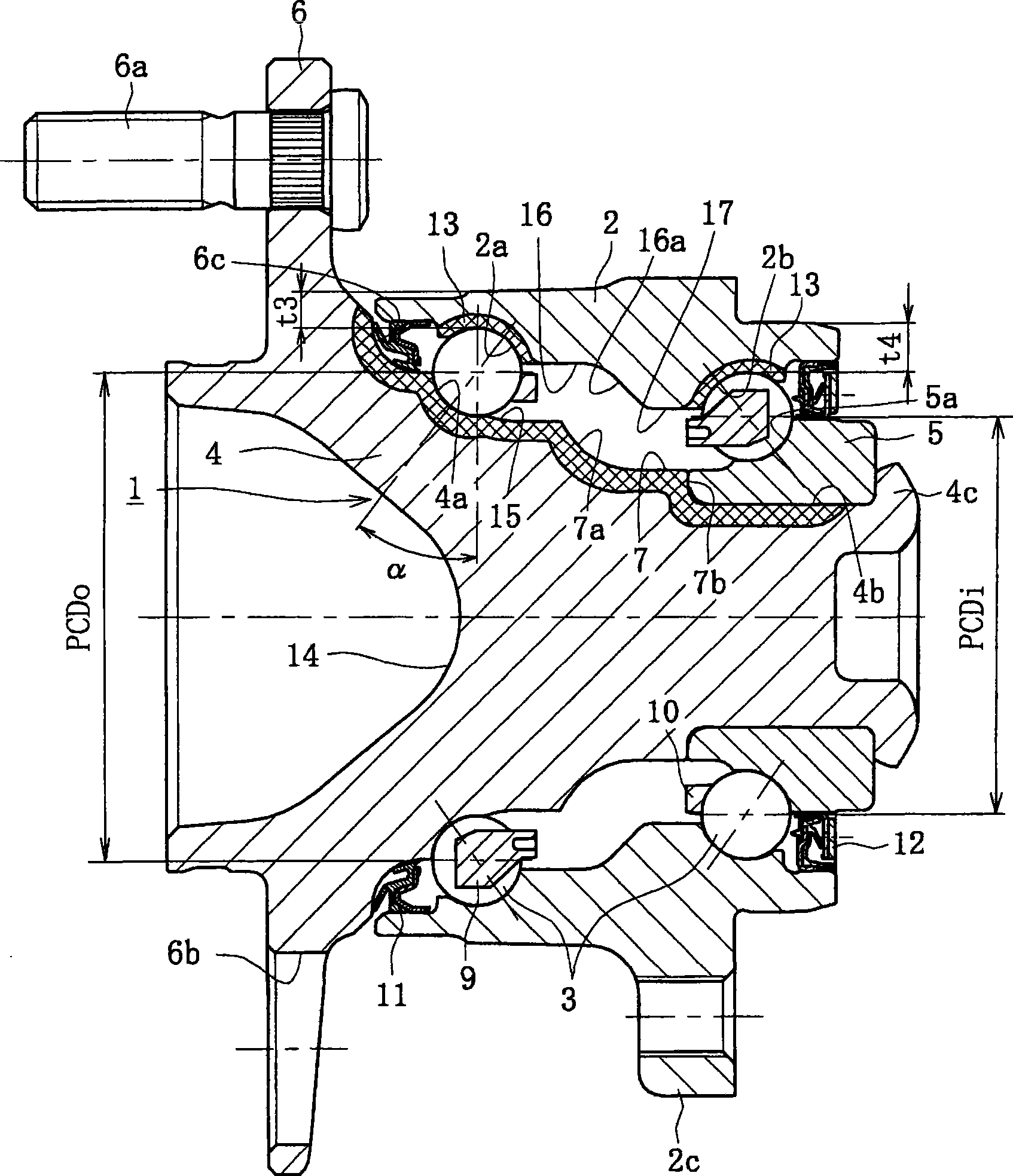

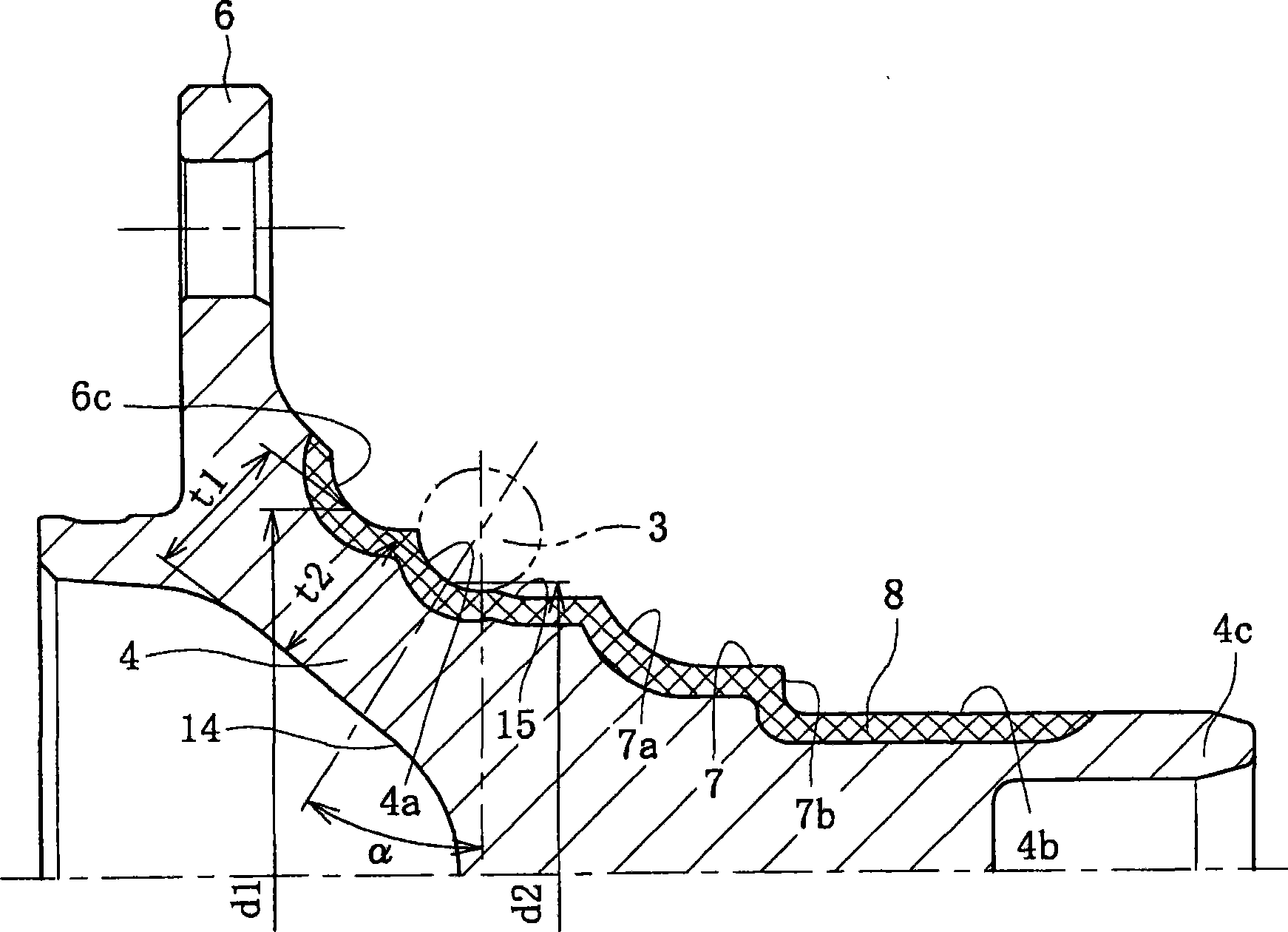

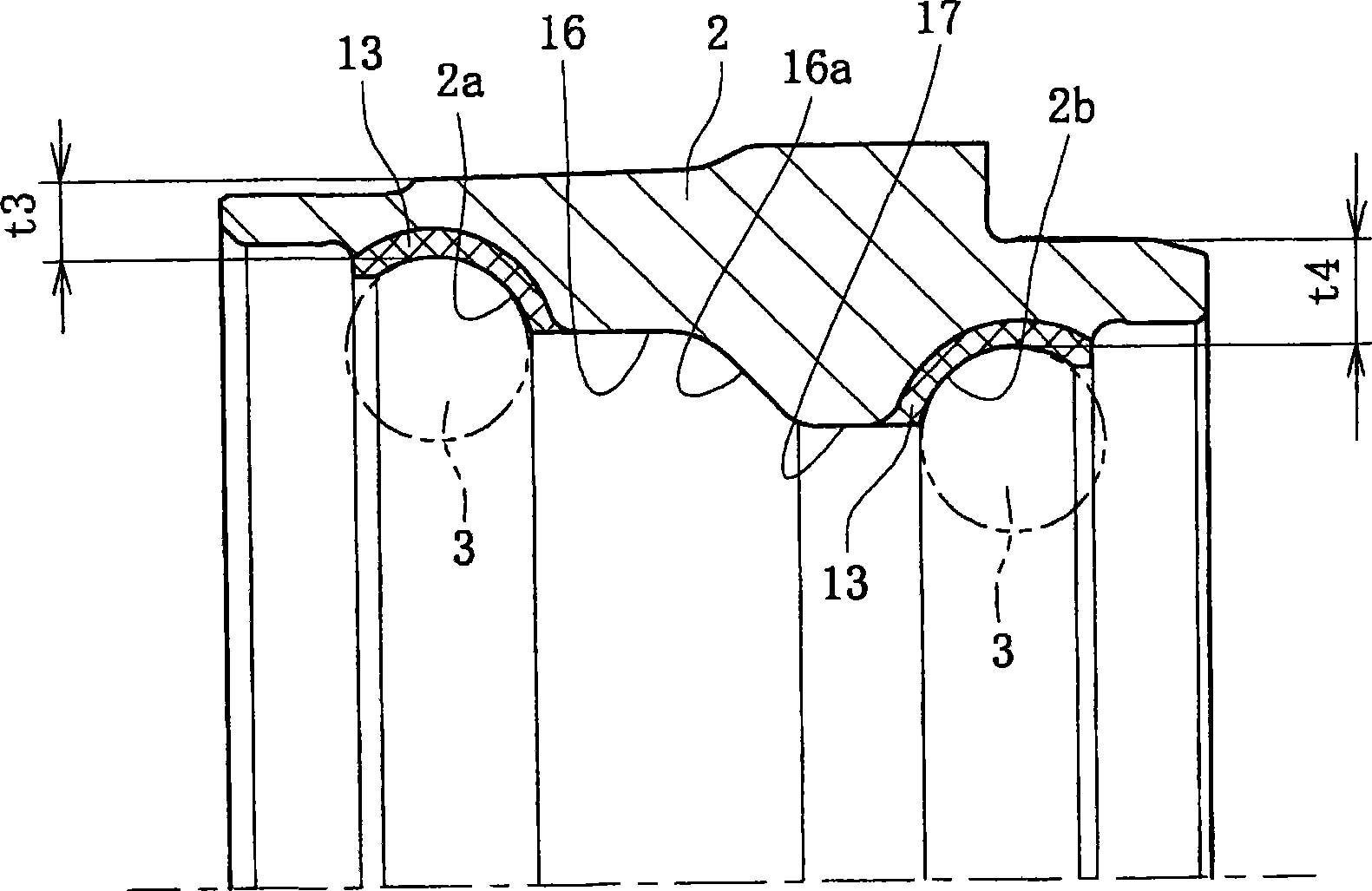

Bearing device for wheel

To provide a bearing device for a wheel, which could have realized a prolonged service life of the bearing by solving contradictory problems of a weight reduction / higher level of compactness and a higher level of rigidity. [MEANS FOR SOLVING PROBLEMS] A bearing device for a wheel, comprising a double-row angular ball bearing having three groups of double-row balls (3). Among the three groups of double-row balls (3), the pitch diameter PCDo of the outer-side group of balls (3) is set to a value larger than the pitch diameter PCDi of the inner-side group of the balls (3). At the same time, an outer member (2) is formed of a medium to high carbon steel containing 0.40 to 0.80% by weight of carbon. Double-row outer rolling faces (2a, 2b) have a predetermined hardened case (13) having a surface hardness range of 58 to 64 HRC formed by high frequency hardening. The effective hardening depth of the hardened case (13) is set to at least 2 mm, and the minimum thickness (t3, t4) of this site isset to at least 4 mm.

Owner:NTN CORP

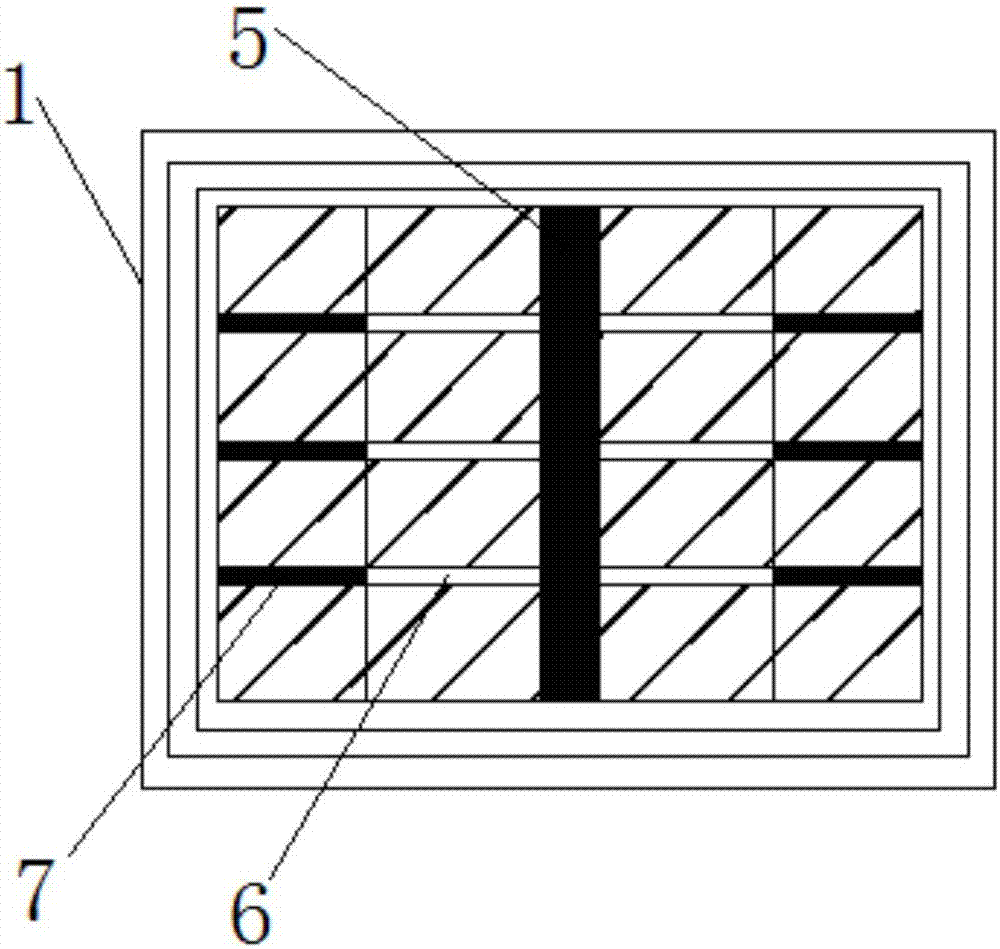

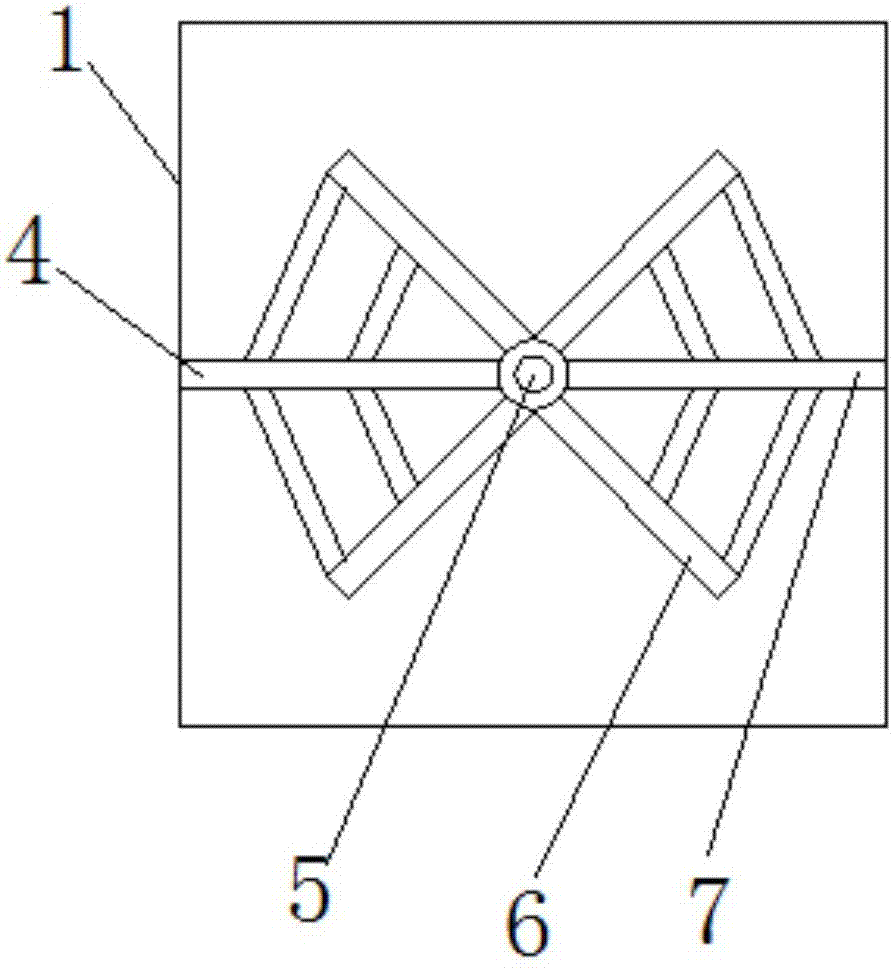

Drying oven for carbon crystal plate

ActiveCN107101483AGood heat insulationPrevent quenching crackingDrying gas arrangementsDrying chambers/containersEngineeringMechanical engineering

The invention discloses a drying oven for a carbon crystal plate. The drying oven for the carbon crystal plate comprises an oven body, a rotating bracket and multiple trays. The rotating bracket comprises a rotating shaft, a bracket, a heat insulation bracket and a heat insulation plate; the rotating bracket is arranged in the oven body through the rotating shaft and a groove, the bracket and the heat insulation bracket are arranged on the rotating shaft, the heat insulation plate is arranged on the bracket and the heat insulation bracket, the rotating bracket can rotate with the rotating shaft as the axis, the multiple trays are arranged on a bearing drawer on the rotating bracket through multiple bracket cross beams and multiple heat insulation bracket cross beams, the bearing drawer comprises a bearing drawer shell and multiple drawing plates, the multiple drawing plates are arranged in the bearing drawer shell in a sliding manner, and can be pulled out of or stretch into the bearing drawer shell, and the bearing drawer is placed on the trays. According to the drying oven for the carbon crystal plate, cooling and drying of the carbon crystal plate can be carried out in the oven body, and shock chilling cracking of the carbon crystal plate can be avoided.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

AISI4340 prestress steel bar manufacturing method

The present invention discloses a AISI4340 prestress steel bar manufacturing method, wherein a AISI4340MOD steel is adopted as a billet material, the billet material is subjected to smelting and finish rolling to obtain a prestress steel bar forging stock with the required size, the prestress steel bar forging stock is sequentially subjected to a hydrogen diffusion heat treatment, rough processing, water cooling quenching and air cooling quenching, a polyethylene corrosion resistance coating is coated on the outer surface of the steel bar forging stock, and a polyethylene heat shrink sleeve is arranged outside the polyethylene corrosion resistance coating. According to the AISI4340 prestress steel bar manufacturing method designed by the present invention, the obtained AISI4340 prestress steel bar has characteristics of high strength, good ductility, strong delayed fracture resistance, steel saving, low relaxation, easy welding, good upsetting property and the like, and further has effects of substantially enhanced corrosion resistance sealing property, and effectively improved mechanical strength.

Owner:TIANSHUN GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com