Drying oven for carbon crystal plate

A technology of carbon crystal plates and ovens, which is applied in drying, drying machines, and drying solid materials, etc., can solve problems affecting production efficiency, loss of carbon crystal plates, cracking of carbon crystal plates, etc., and achieves easy placement and removal, Time-saving and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

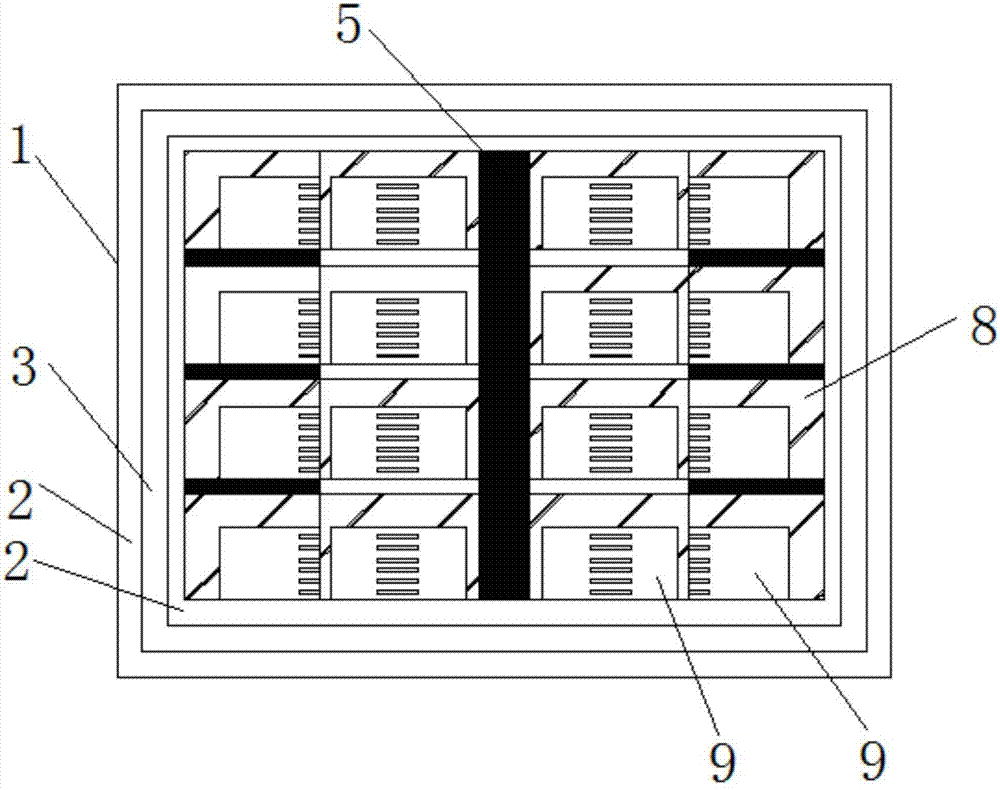

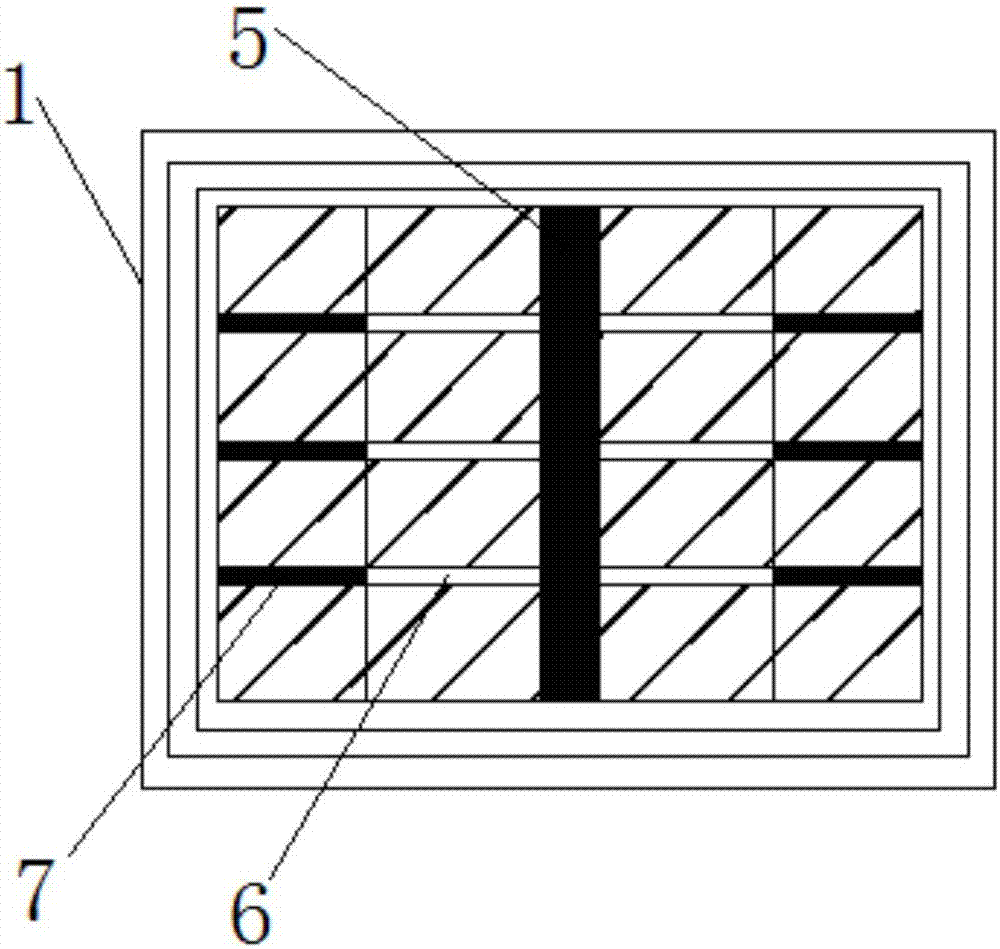

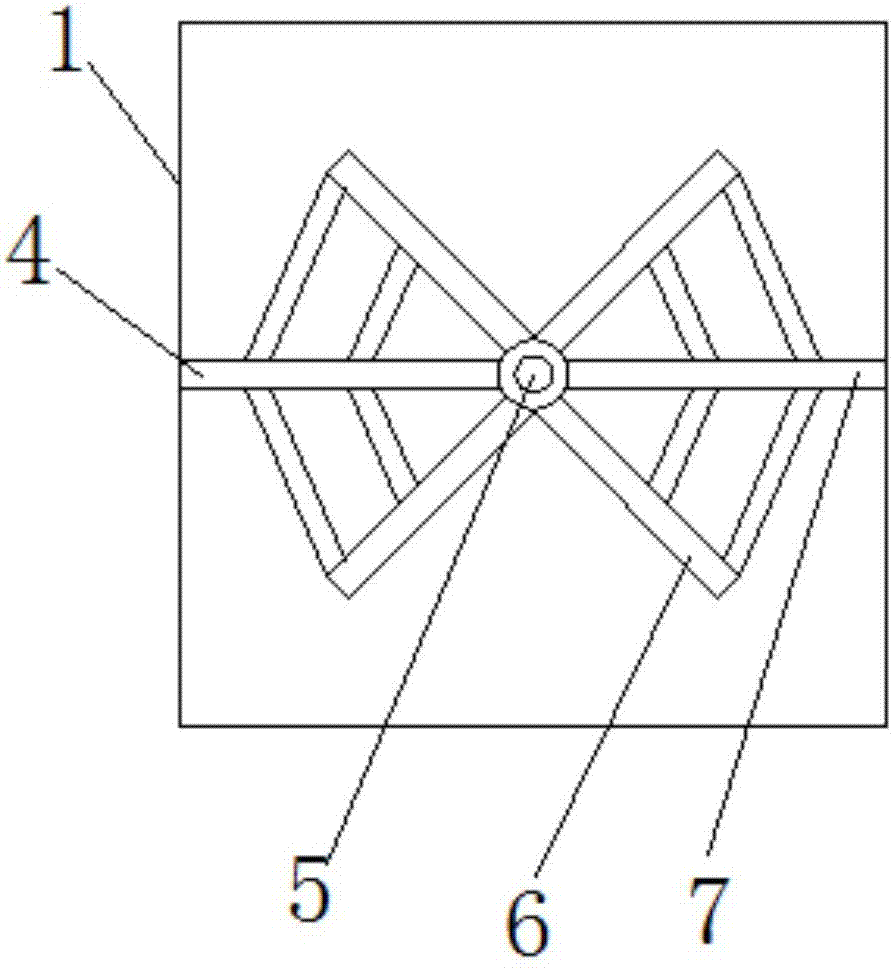

[0049] figure 1 It shows a schematic view of the state of use of the oven for carbon crystal plates according to an embodiment of the present invention. figure 2 A front view of an oven for a carbon crystal plate according to an embodiment of the present invention is shown. image 3 A top view of an oven for a carbon crystal plate according to an embodiment of the present invention is shown.

[0050] Such as Figure 1-3 As shown, the carbon crystal plate oven includes:

[0051] A box body 1, the box body 1 includes a steel structure frame layer 2 and a ceramic heat insulation layer 3, the ceramic heat insulation layer 3 is arranged inside the steel structure frame layer 2, and the steel structure frame layer 2 is made of white steel Made of material, grooves are arranged at the center point of the top and bottom of the box body 1;

[0052] Rotating bracket 4, said rotating bracket 4 includes a rotating shaft 5, a bracket 6, a heat insulating bracket 7 and a heat insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com