Steel for deep sea oil extraction equipment connector and manufacturing method for forge piece of steel

A steel forging and equipment technology, applied in the field of high-performance metal material processing, can solve the problems of loose materials, coarse grains, and inability to guarantee the service life of joints, etc., and achieve the effects of preventing quenching cracking and improving low-temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

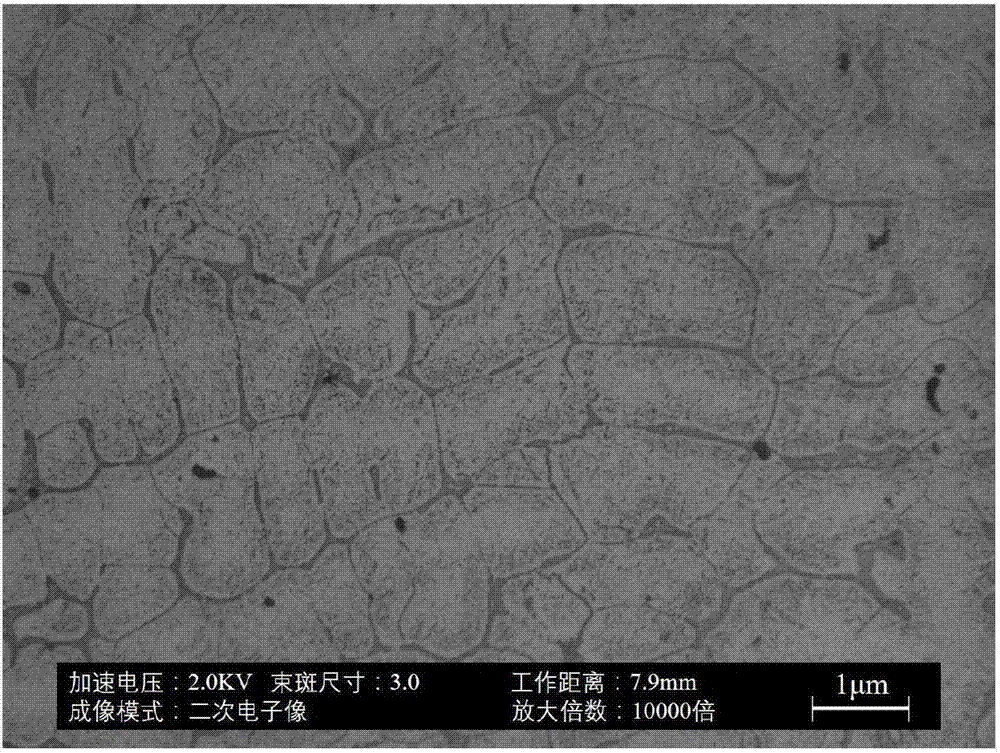

Image

Examples

Embodiment 1

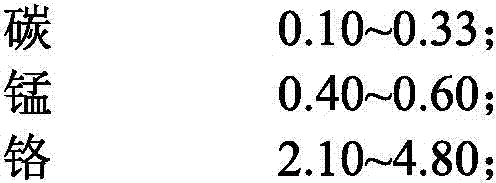

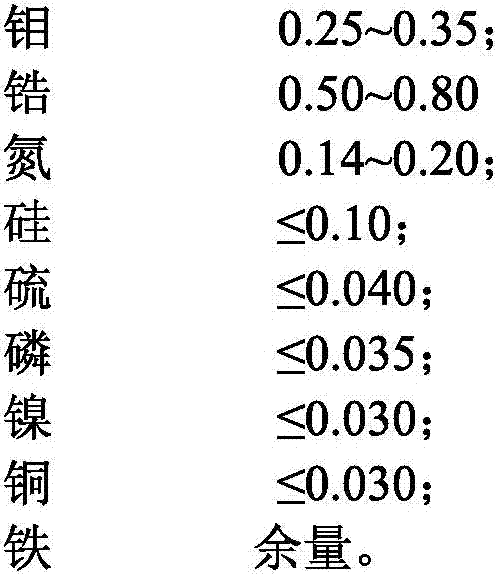

[0033] (1) According to the size of the deep sea oil production equipment joint, select the appropriate steel blank. Described iron and steel material comprises each component of following mass percent (wt.%):

[0034]

[0035]

[0036] According to the size of the required structural parts, select the blank, and coat a layer of glass-like coating on the surface of the blank. The main component of the glass-like coating is (wt.%): 45% SiO 2 +5% Al 2 o 3 +9.5% Fe+0.5% A1+10% clay+30% water glass. Then enter the furnace and heat it to 1150°C for 3 hours to prepare for forging.

[0037] Coating a layer of glass-like coating on the surface of the steel material can effectively prevent the formation of scale on the surface of the steel material during the subsequent hot forging process, as well as the loss of carbon on the surface of the material during the forging process, making the composition of the steel material stable and its performance improved. Assure. The mass...

Embodiment 2

[0046] (1) According to the size of the deep sea oil production equipment joint, select the appropriate steel blank. Described iron and steel material comprises each component of following mass percent (wt.%):

[0047]

[0048] According to the size of the required structural parts, select the blank, and coat a layer of glass-like coating on the surface of the blank. The main component of the glass-like coating is (wt.%): 45% SiO 2 +5% Al 2 o 3 +9.5% Fe+0.5% Al+10% clay+30% water glass. Then enter the furnace and heat it to 1150°C for 3 hours to prepare for forging.

[0049] (2) The billet obtained in step (1) is first forged by free forging to obtain a forged billet; the initial forging temperature is 1150° C., the final forging temperature is 900° C., and the forging ratio is greater than 4:1.

[0050] (3) The primary billet obtained in step (2) is subjected to secondary forging by multi-directional die forging to obtain a secondary forging billet; the initial forging...

Embodiment 3

[0055] (1) According to the size of the deep sea oil production equipment joint, select the appropriate steel blank. Described iron and steel material comprises each component of following mass percent (wt.%):

[0056]

[0057] According to the size of the required structural parts, select the blank, and coat a layer of glass-like coating on the surface of the blank. The main component of the glass-like coating is (wt.%): 45% SiO 2 +5%Al 2 o 3 +9.5% Fe+0.5% Al+10% clay+30% water glass. Then enter the furnace and heat it to 1150°C for 3 hours to prepare for forging.

[0058] (2) The billet obtained in step (1) is first forged by free forging to obtain a forged billet; the initial forging temperature is 1150° C., the final forging temperature is 900° C., and the forging ratio is greater than 4:1.

[0059] (3) The primary billet obtained in step (2) is subjected to secondary forging by multi-directional die forging to obtain a secondary forging billet; the initial forging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com