A method for manufacturing steel forgings for key parts of deep-sea oil tree

A technology of deep-sea christmas tree and manufacturing method, which is applied in the direction of metal processing equipment, etc. It can solve the problems that the performance is difficult to meet low temperature toughness and high and low temperature fatigue strength, reduce the effective life of parts, and it is difficult to forge through, so as to maintain mechanical properties and prevent quenching Effect of cracking and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

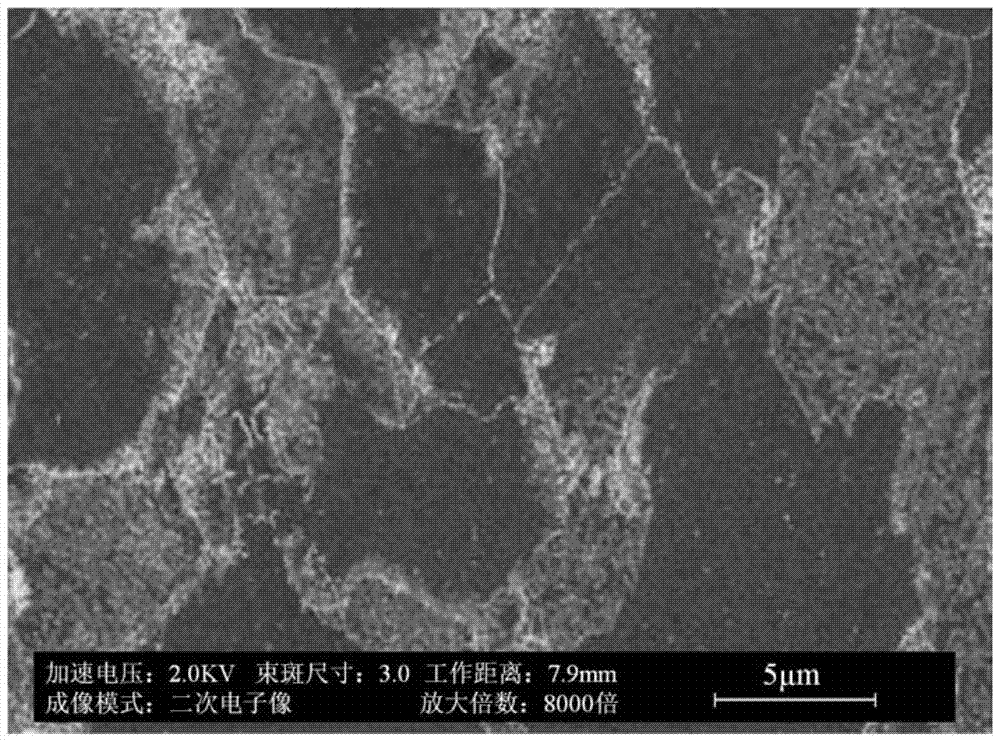

Image

Examples

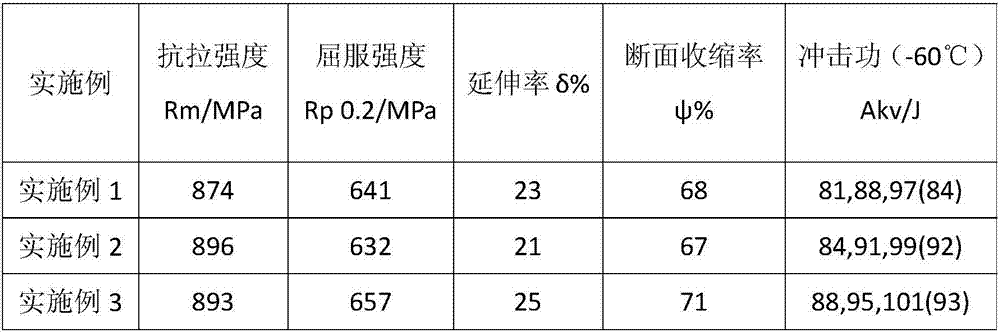

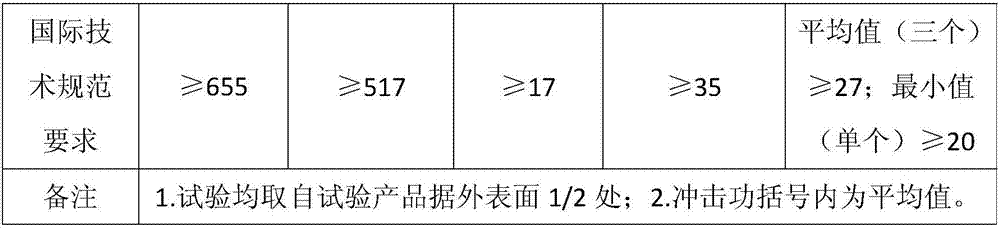

Embodiment 1

[0028] (1) Ingredients: F22 alloy steel and Fe‐Ga master alloy are selected as raw materials, and the ingredients are mixed according to weight (wt.%) 10:1;

[0029] (2) Smelting: The raw materials are smelted into high-quality molten steel by using an intermediate frequency electric furnace. During the smelting process, the chemical composition of the molten steel is inspected in real time. The excess chemical composition is adjusted by diluting until the chemical composition of the molten steel meets the requirements, that is, it becomes high-quality molten steel. After the molten steel is smelted, it is purified by blowing argon to improve the purity of the molten steel;

[0030] (3) Liquid die forging: Pour the smelted molten steel into a pressure casting holding furnace filled with nitrogen for heat preservation; then pour the molten steel in the holding furnace into the mold of a liquid die forging machine for liquid die forging. Preheat to 300°C, and demould immediately...

Embodiment 2

[0034] (1) Ingredients: F22 alloy steel and Fe‐Ga master alloy are selected as raw materials, and the ingredients are mixed according to weight (wt.%) 10:1;

[0035] (2) Smelting: The raw materials are smelted into high-quality molten steel by using an intermediate frequency electric furnace. During the smelting process, the chemical composition of the molten steel is inspected in real time. The excess chemical composition is adjusted by diluting until the chemical composition of the molten steel meets the requirements, that is, it becomes high-quality molten steel. After the molten steel is smelted, it is purified by blowing argon to improve the purity of the molten steel;

[0036] (3) Liquid die forging: Pour the smelted molten steel into a pressure casting holding furnace filled with nitrogen for heat preservation; then pour the molten steel in the holding furnace into the mold of a liquid die forging machine for liquid die forging. Preheat to 350°C, and demould immediately...

Embodiment 3

[0040] (1) Ingredients: F22 alloy steel and Fe‐Ga master alloy are selected as raw materials, and the ingredients are mixed according to weight (wt.%) 10:1;

[0041] (2) Smelting: The raw materials are smelted into high-quality molten steel by using an intermediate frequency electric furnace. During the smelting process, the chemical composition of the molten steel is inspected in real time. The excess chemical composition is adjusted by diluting until the chemical composition of the molten steel meets the requirements, that is, it becomes high-quality molten steel. After the molten steel is smelted, it is purified by blowing argon to improve the purity of the molten steel;

[0042] (3) Liquid die forging: Pour the smelted molten steel into a pressure casting holding furnace filled with nitrogen for heat preservation; then pour the molten steel in the holding furnace into the mold of a liquid die forging machine for liquid die forging. Preheat to 400°C, and demould immediately...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com