Turbine blade capable of improving thermal cracking resistance and production process thereof

A technology for steam turbine blades and production processes, which is applied in the directions of blade support elements, mechanical equipment, engine elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a steam turbine blade that can improve thermal cracking resistance, the mass percentage of its chemical composition is: C: 0.31%, Si: 0.10%, Mn: 0.75%, Ni: 0.65%, Cr: 11.2%, Mo : 0.65%, V: 0.16%, Sr: 0.85%, Nb: 0.17%, Cu: 0.07%, Al: 0.27%, Ti: 0.13%, B: 0.06%, S: 0.02%, rare earth metal: 0.21%, The balance is Fe; the mass percentage of the chemical composition of rare earth metals is: cerium: 5%, praseodymium: 10%, neodymium: 10%, promethium: 5%, lutetium: 5%, europium: 5%, terbium: 13%, Holmium: 1%, Erbium: 6%, and the balance is lanthanum.

[0062]The production process of the steam turbine blade that can improve thermal cracking resistance in this embodiment is carried out according to the following procedures: hot forging → annealing → tempering → blade machining → stress relief heat treatment → quenching and tempering heat treatment → cooling → surface strengthening heat treatment → physical and chemical inspection →ultrasonic flaw detecti...

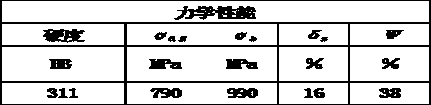

Embodiment 2

[0074] This embodiment provides a steam turbine blade that can improve thermal cracking resistance, the mass percentage of its chemical composition is: C: 0.32%, Si: 0.11%, Mn: 0.76%, Ni: 0.63%, Cr: 11.5%, Mo : 0.67%, V: 0.18%, Sr: 0.86%, Nb: 0.15%, Cu: 0.05%, Al: 0.28%, Ti: 0.15%, B: 0.07%, S: 0.02%, rare earth metal: 0.3%, The balance is Fe; the chemical composition mass percentage of rare earth metals is: cerium: 6%, praseodymium: 11%, neodymium: 11%, promethium: 6%, lutetium: 6%, europium: 6%, terbium: 14%, Holmium: 2%, Erbium: 8%, and the balance is lanthanum.

[0075] The production process of the steam turbine blade that can improve thermal cracking resistance in this embodiment is carried out according to the following procedures: hot forging → annealing → tempering → blade machining → stress relief heat treatment → quenching and tempering heat treatment → cooling → surface strengthening heat treatment → physical and chemical inspection →ultrasonic flaw detection→clea...

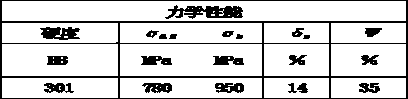

Embodiment 3

[0088] This embodiment provides a steam turbine blade that can improve thermal cracking resistance. The mass percentage of its chemical composition is: C: 0.35%, Si: 0.12%, Mn: 0.77%, Ni: 0.64%, Cr: 11.7%, Mo : 0.68%, V: 0.17%, Sr: 0.88%, Nb: 0.16%, Cu: 0.06%, Al: 0.29%, Ti: 0.14%, B: 0.08%, S: 0.01%, rare earth metal: 0.35%, The balance is Fe; the chemical composition mass percentage of rare earth metals is: cerium: 7%, praseodymium: 12%, neodymium: 12%, promethium: 7%, lutetium: 7%, europium: 7%, terbium: 16%, Holmium: 3%, Erbium: 9%, and the balance is lanthanum.

[0089] The production process of the steam turbine blade that can improve thermal cracking resistance in this embodiment is carried out according to the following procedures: hot forging → annealing → tempering → blade machining → stress relief heat treatment → quenching and tempering heat treatment → cooling → surface strengthening heat treatment → physical and chemical inspection →ultrasonic flaw detection→cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com