Patents

Literature

43results about How to "Avoid brittle cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature resistant turbine blade and production process thereof

ActiveCN104099516AImprove performanceImprove impact toughnessBlade accessoriesSolid state diffusion coatingChemical compositionSteam turbine blade

The invention discloses a high-temperature resistant turbine blade. The turbine blade comprises the following chemical components in percentage by weight: 0.19-0.21% of C, 0.55-0.57% of Mn, 0.20-0.22% of Si, 0.38-0.40% of Al, 0.30-0.32% of V, 0.40-0.42% of Ti, 0.12-0.14% of Ni, 0.06-0.08% of Sn, 0.25-0.27% of Zr, no more than 0.025% of S, no more than 0.025% of P, no more than 0.20% of Cu, 0.20-0.22% of lanthanide serial rare earth, and the balance Fe. The invention further designs a production process of the turbine blade. The production process has the advantages of simplicity and low cost, helps to largely improve the impact toughness of the blade, enhance the high temperature resistance of the blade and prolong the service life of the blade through the nitridation surface treatment.

Owner:南京赛达科技有限公司

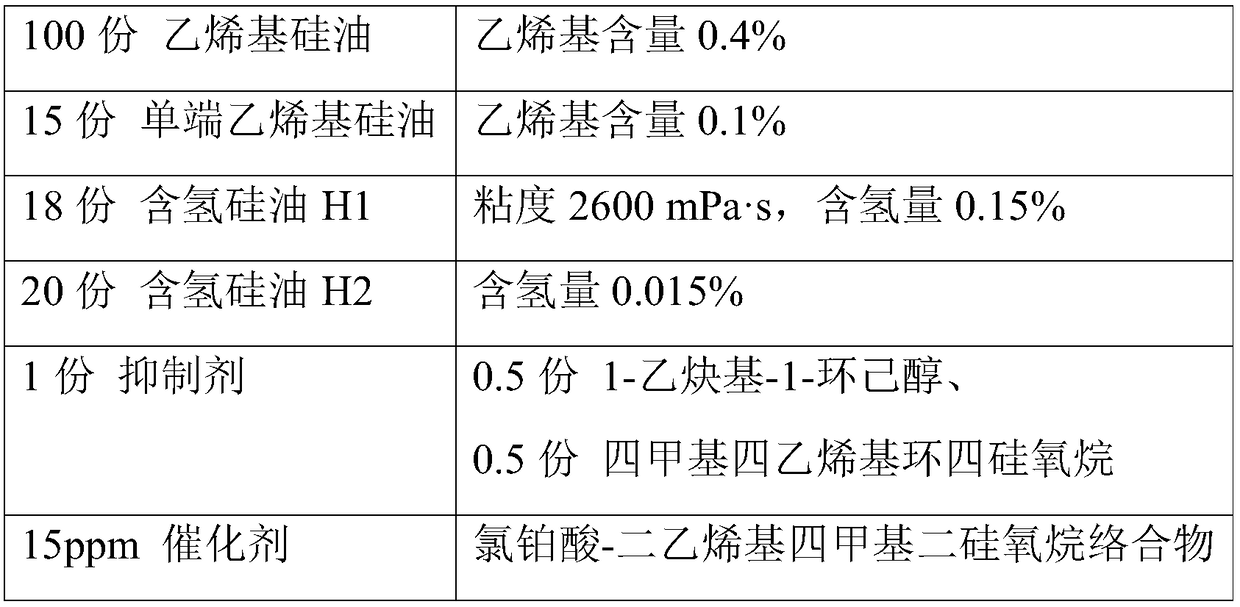

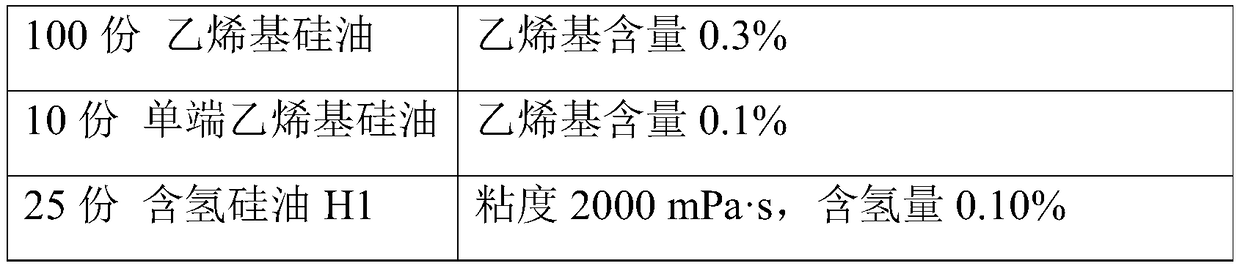

Low-oil-permeability high-strength addition-type silica gel and preparation method thereof

The invention relates to low-oil-permeability high-strength addition-type silica gel and a preparation method thereof. The addition-type silica gel is prepared from the following raw material components in parts by weight: 100 parts of alpha,omega-vinyl polydimethylsiloxane, 5 to 15 parts of single-ended vinyl polydimethylsiloxane, 15 to 30 parts of polymethylhydrosiloxane H1, 10 to 25 parts of polymethylhydrosiloxane H2, 0.01 to 2 parts of inhibitor, and platinum catalyst containing 0.5 to 50 ppm of platinum by mass, wherein nSi-H / nSi-Vi is greater than 1 in the addition-type silica gel. Theaddition-type silica gel has not only higher tensile strength and elongation at break, but superior oil permeability resistance, and stable adhesive performance and dielectric property, and can meet the encapsulating protection requirements of high-end precise electronic parts and components.

Owner:GUANGZHOU BAIYUN CHEM IND

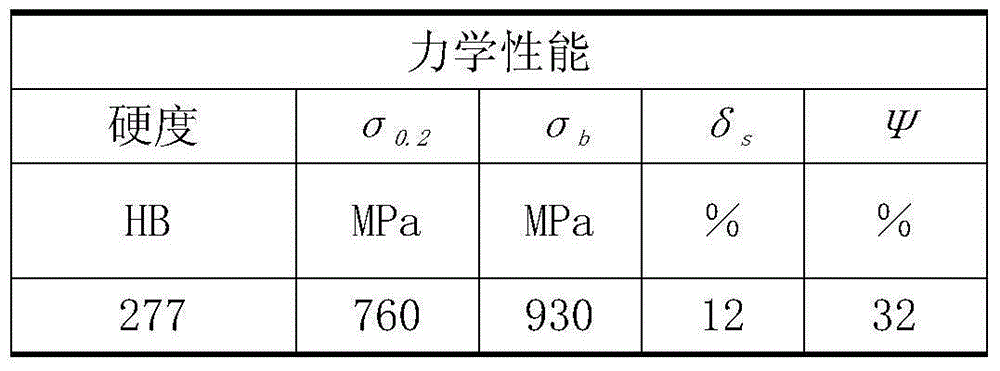

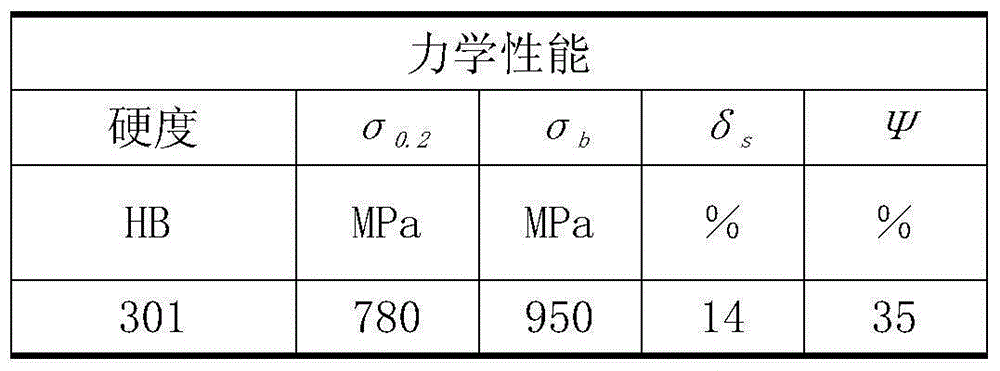

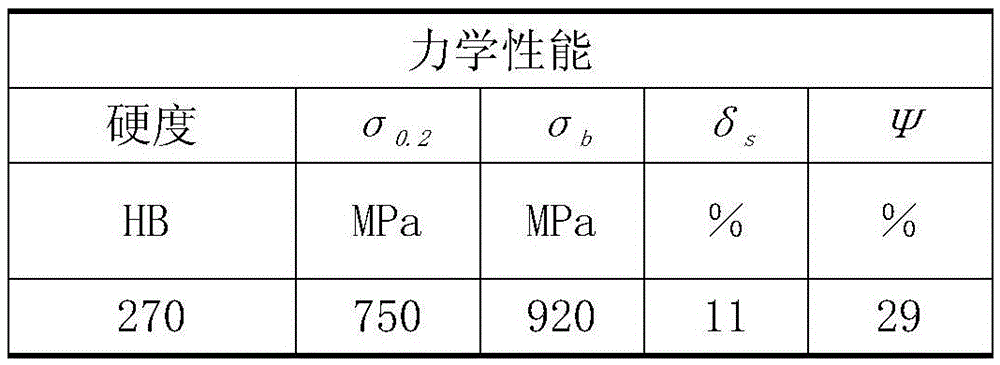

Turbine blade capable of enhancing impact toughness and production technique thereof

ActiveCN104060191AAvoid formingPrevent early brittle crackingFurnace typesHeat treatment furnacesMischmetalChemical composition

The invention provides a turbine blade capable of enhancing impact toughness, which comprises the following chemical components in percentage by mass: 0.13-0.15% of C, 0.8-0.9% of Si, 0.5-0.8% of Mn, 14-16% of Cr, 0.1-0.3% of Ni, 1.3-1.5% of Cu, 0.6-1.1% of Mo, 0.1-0.15% of W, 0.36-0.45% of V, 0.5-0.8% of Nb, 0.28-0.30% of Al, 0.16-0.18% of Ti, 0.08-0.10% of B, 0.45-0.48% of Na, at most 0.02% of S, at most 0.03% of P, 0.3-0.6% of rare-earth metal and the balance of Fe. The invention also provides a production technique of the turbine blade capable of enhancing impact toughness. The production technique can greatly enhance the impact toughness of the blade and prolong the service life of the blade.

Owner:南京赛达科技有限公司

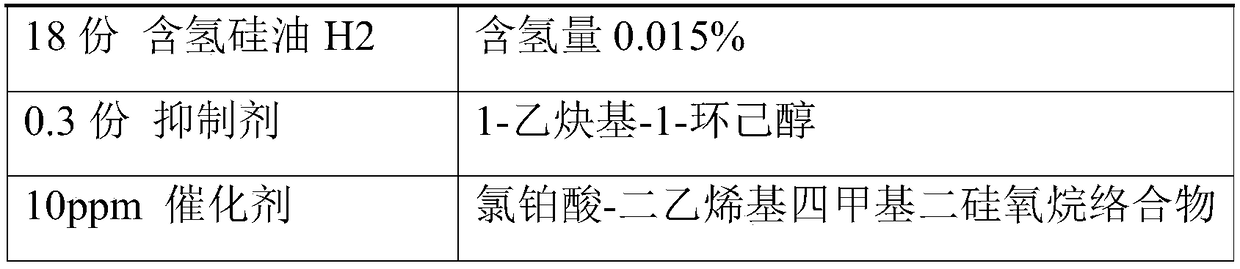

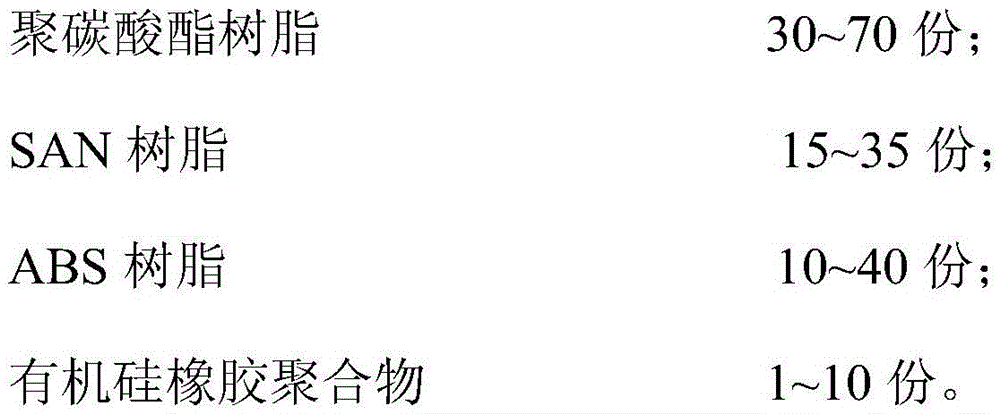

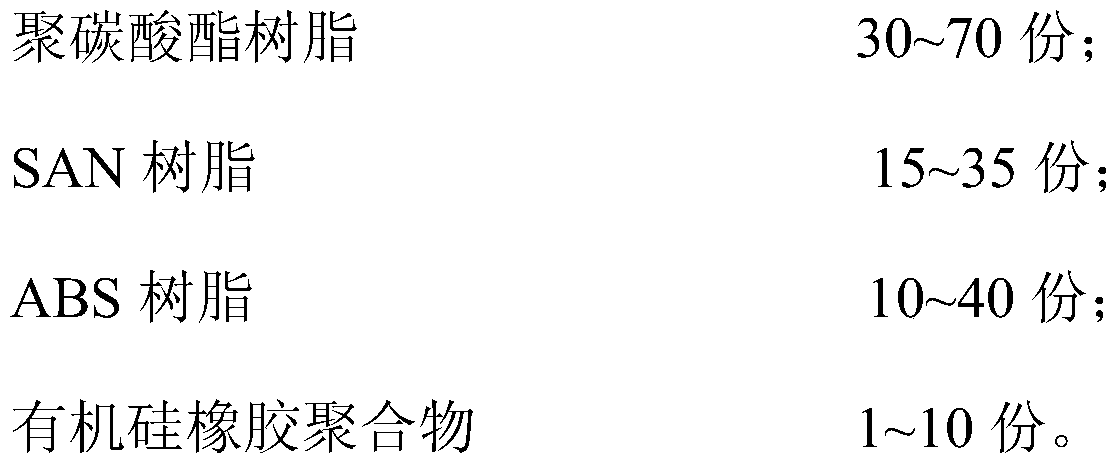

Electroplated PC (Poly Carbonate)/ABS (Acrylonitrile Butadiene StyreneAcrylonitrile Butadiene Styrene) alloy material and preparation method thereof

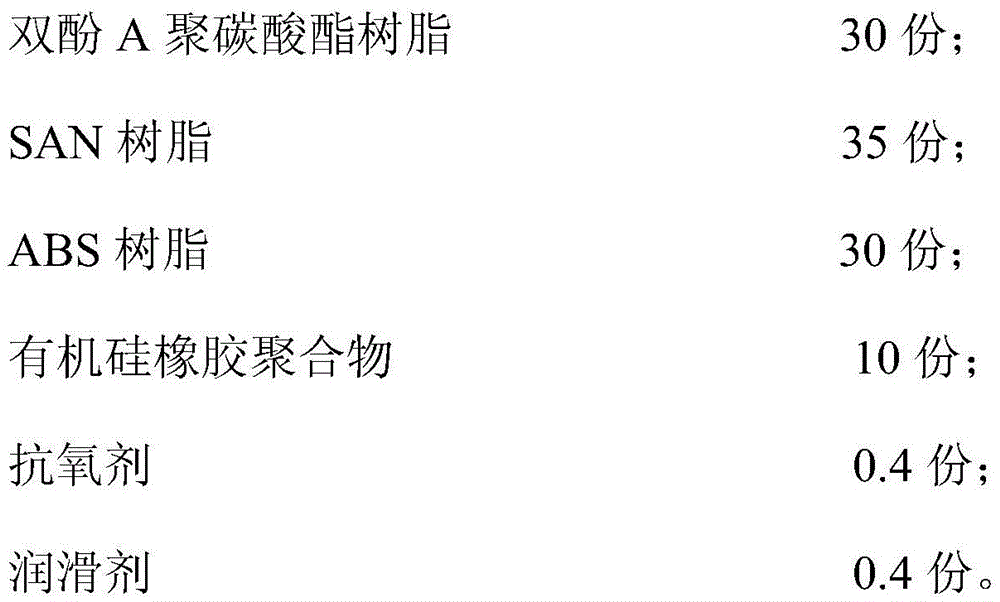

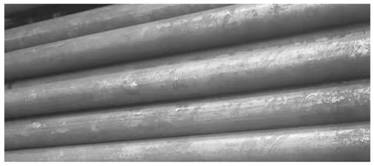

The invention provides an electroplated PC (Poly Carbonate) / ABS (Acrylonitrile Butadiene StyreneAcrylonitrile Butadiene Styrene) alloy material and a preparation method thereof. The electroplated PC / ABS alloy material is prepared from the following raw materials in parts by mass: 30 to 70 parts of panlite, 15 to 35 parts of SAN resin, 10 to 40 parts of ABS resin and 1 to 10 parts of organic silicon rubber polymer. The organic silicon rubber polymer is added in the electroplated PC / ABS alloy material provided by the invention, the synergistic effect among the raw materials is fully utilized, and the optimizing process on the content of the raw materials is performed, so that the solution resistance and the toughness of the PC / ABS alloy material are improved, and hardening, embrittlement and cracking after coarsening electroplating are prevented.

Owner:SHENZHEN HALCYON NEW MATERIALS

High-lubricity self-defoaming easy-to-clean environment-friendly oily wire-cutting fluid

ActiveCN108034486AAvoid brittle crackingReduce surface roughnessLubricant compositionAlcoholBoiling point

The invention discloses a high-lubricity self-defoaming easy-to-clean environment-friendly oily wire-cutting fluid. The wire-cutting fluid comprises the following components in percentage by weight: 40-50% of a high-boiling-point alcohol antifreeze agent, 5-10% of a multifunctional foam inhibitor, 30-40% of a non-ionic cleaning lubricant, 2-6% of a polymer surfactant, 1-3% of a wetting penetrant,and the balance of water. The high-lubricity self-defoaming easy-to-clean environment-friendly oily wire-cutting fluid provided by the invention has excellent lubricating, cleaning and cooling performance, and excellent defoaming performance is achieved, so that the problems of much foam and low cutting efficiency existing in a wire-cutting process are effectively improved; in addition, the high-lubricity self-defoaming easy-to-clean environment-friendly oily wire-cutting fluid prepared by the method provided by the invention is an oily system, and is diluted for use by adding pure water in ause process, so that the discharge amount of COD is effectively reduced, and the environment-protection requirements are met.

Owner:苏州禾川化学技术服务有限公司

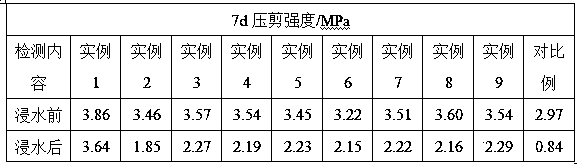

Dual-component room-temperature cured type waterproof building adhesive

InactiveCN108314985AHigh bonding strengthAvoid pollutionNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAdhesive

The invention discloses a dual-component room-temperature cured type waterproof building adhesive and belongs to the technical field of adhesives. The dual-component room-temperature cured type waterproof building adhesive disclosed by the invention is prepared from a component A and a component B, wherein the component A is prepared from epoxy resin, modified unsaturated polyester resin, linseedoil microcapsule and filler; the component B is prepared from a curing agent, a coupling agent and an accelerating agent; the filler is prepared from graphene oxide, modified sea-foam stone powder andmodified microcrystalline cellulose; the component A and the component B are separately packaged to form the dual-component room-temperature cured type waterproof building adhesive. The dual-component room-temperature cured type waterproof building adhesive disclosed by the invention has excellent waterproofness.

Owner:汪逸凡

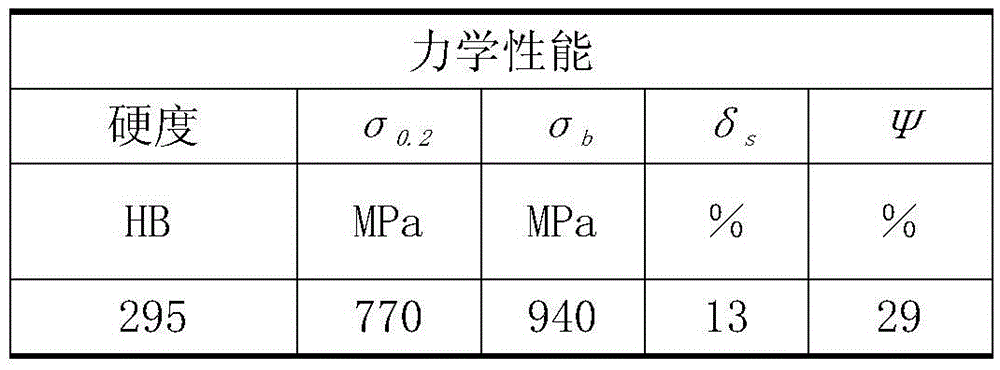

Turbine blade capable of improving thermal cracking resistance and production process thereof

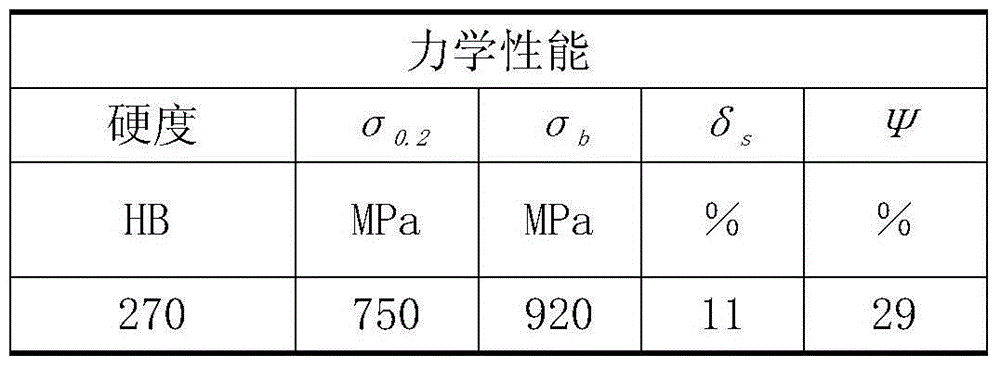

ActiveCN104032236AReduced impact toughnessImprove impact toughnessBlade accessoriesMachines/enginesMischmetalChemical composition

The invention discloses a turbine blade capable of improving the thermal cracking resistance. The turbine blade comprises the following chemical components in percentage by mass: 0.31-0.35% of C, 0.10-0.12% of Si, 0.75-0.77% of Mn, 0.63-0.65% of Ni, 11.2-11.7% of Cr, 0.65-0.68% of Mo, 0.16-0.18% of V, 0.85-0.88% of Sr, 0.15-0.17% of Nb, 0.05-0.07% of Cu, 0.27-0.29% of Al, 0.13-0.15% of Ti, 0.06-0.08% of B, less than or equal to 0.02% of S, 0.21-0.35% of rare earth metal and the balance of Fe. By adopting the turbine blade, the impact toughness of a blade is greatly improved, the thermal cracking resistance of the blade is improved, and the service life of the blade is prolonged.

Owner:南京赛达科技有限公司

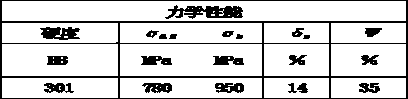

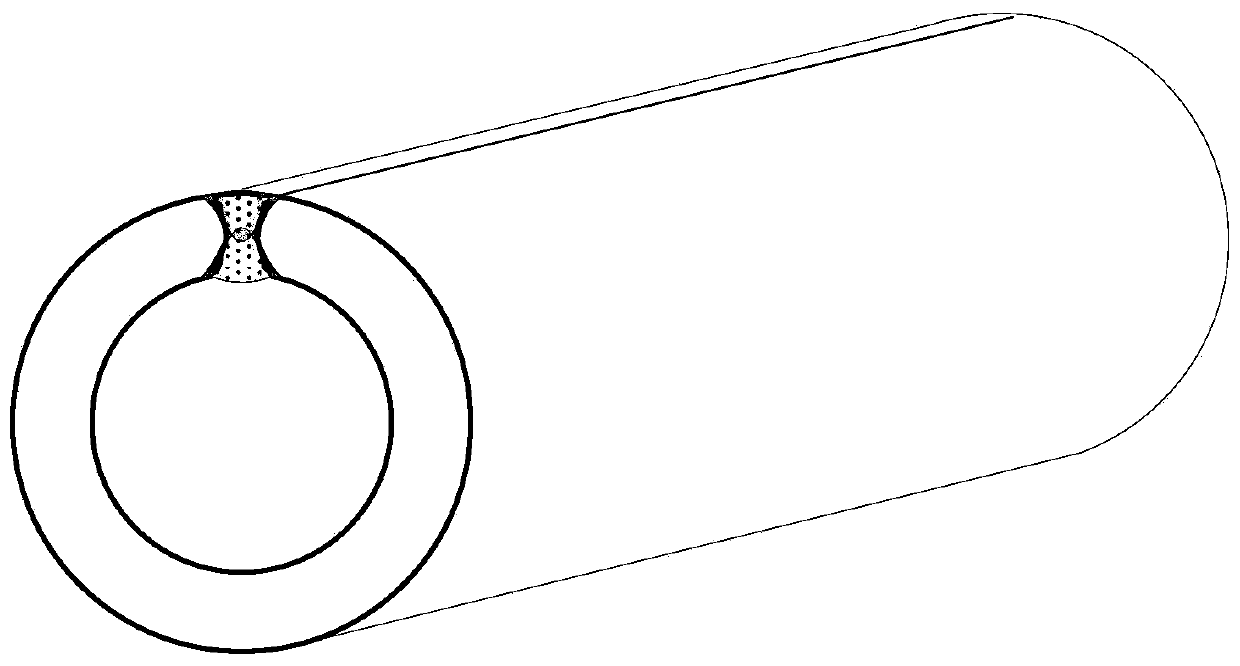

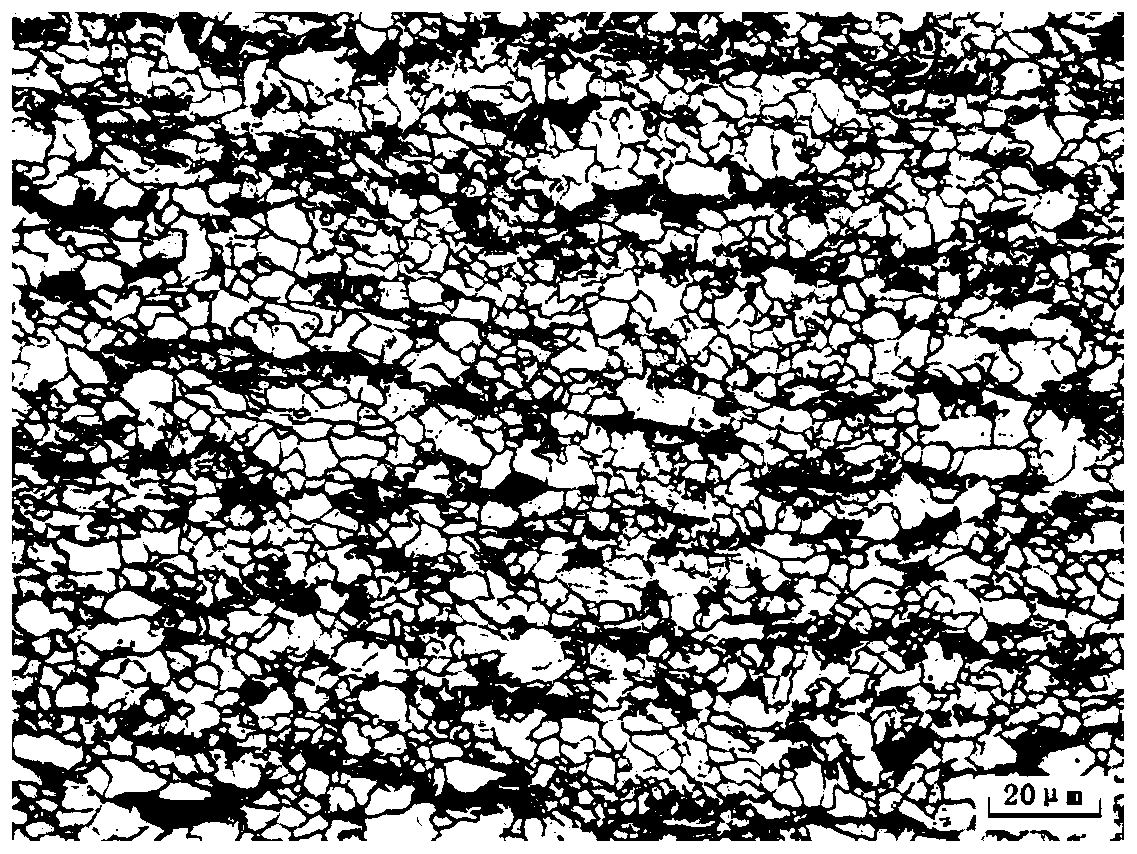

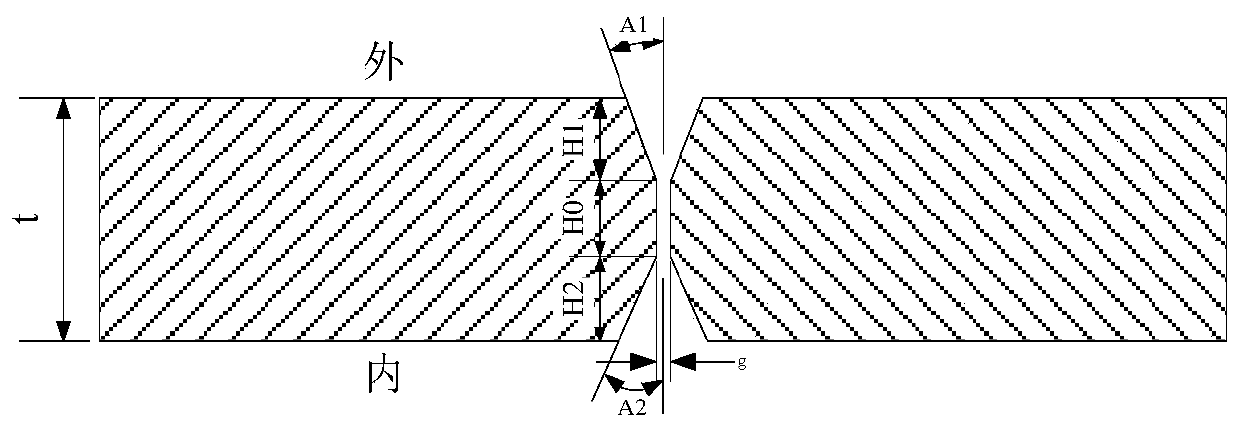

Marine high-strain welded steel pipe based on double-phase structure and preparing method thereof

ActiveCN110000517AWith mechanical propertiesCorrosion resistanceArc welding apparatusDouble phaseHigh intensity

The invention discloses a marine high-strain welded steel pipe based on a double-phase structure and a preparing method thereof. The marine high-strain welded steel pipe is made by a wide and thick steel plate having the double-phase structure, the steel grade of the high-strain welded steel pipe is L485MO, the thickness is larger than or equal to 25.4mm, the width of the steel plate is pi(1-epsilon)D-2t, D refers to the outer diameter of the steel pipe, t refers to wall thickness, epsilon refers to a cold expanding rate, the radius-to-thickness ratio is smaller than or equal to 30, the yield-to-strength ratio Rt0.5 / Rm is smaller than or equal to 0.85, A is larger than or equal to 25%, and UEL is larger than or equal to 7%. The manufactured steel pipe has the characteristics of high strength, high tenacity, high strain capability, low yield-to-strength ratio, low strain aging influence, H2S corrosion resistance, large wall thickness, small radius-thickness ratio, high diameter precision, small outer diameter error and small out-of-roundness error, can fully meet the technical requirements of marine service on the high-strain thick-walled delivery steel pipe, can be used for deep-sea oil and gas exploitation and saves marine development cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-strength vibration-reduction epoxy mortar with nano improver

The invention discloses high-strength vibration-reduction epoxy mortar with a nano improver. The high-strength vibration-reduction epoxy mortar consists of three components A, B and C, wherein the component A is a substrate mixture; the component B is an auxiliary mixture; the component C is a curing mixture; the component A consists of the following various raw materials in parts by weight: 80-100 parts of modified epoxy resin, 45-70 parts of cement and 100-300 parts of quartz sand; the component B consists of the following various raw materials in parts by weight: 10-50 parts of a nano improver, 3-5 parts of a silane coupling, 0-1 part of a defoaming agent and 10-15 parts of a diluent; the component C consists of the following various raw materials in parts by weight: 40-55 parts of a curing agent and 1-5 parts of a toughening agent; the weight ratio of the component A, the component B to the component C is (80-100):(5-100):(50-600). The high-strength vibration-reduction epoxy mortar disclosed by the invention has the advantages of being high in strength, good in vibration reduction effect, good in binding force with a concrete substrate, good in compatibility and the like, and can be used as a secondary grouting material of complex industrial vibration equipment.

Owner:SINOPEC PETROLEUM ENG & CONSTR ZHONGYUAN

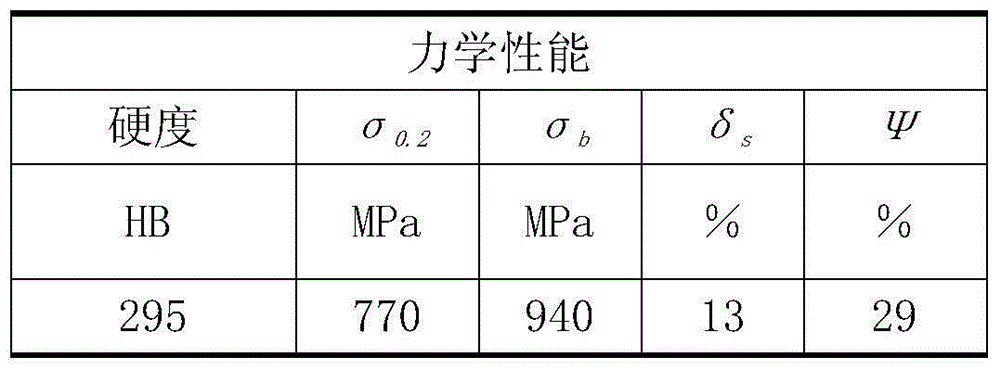

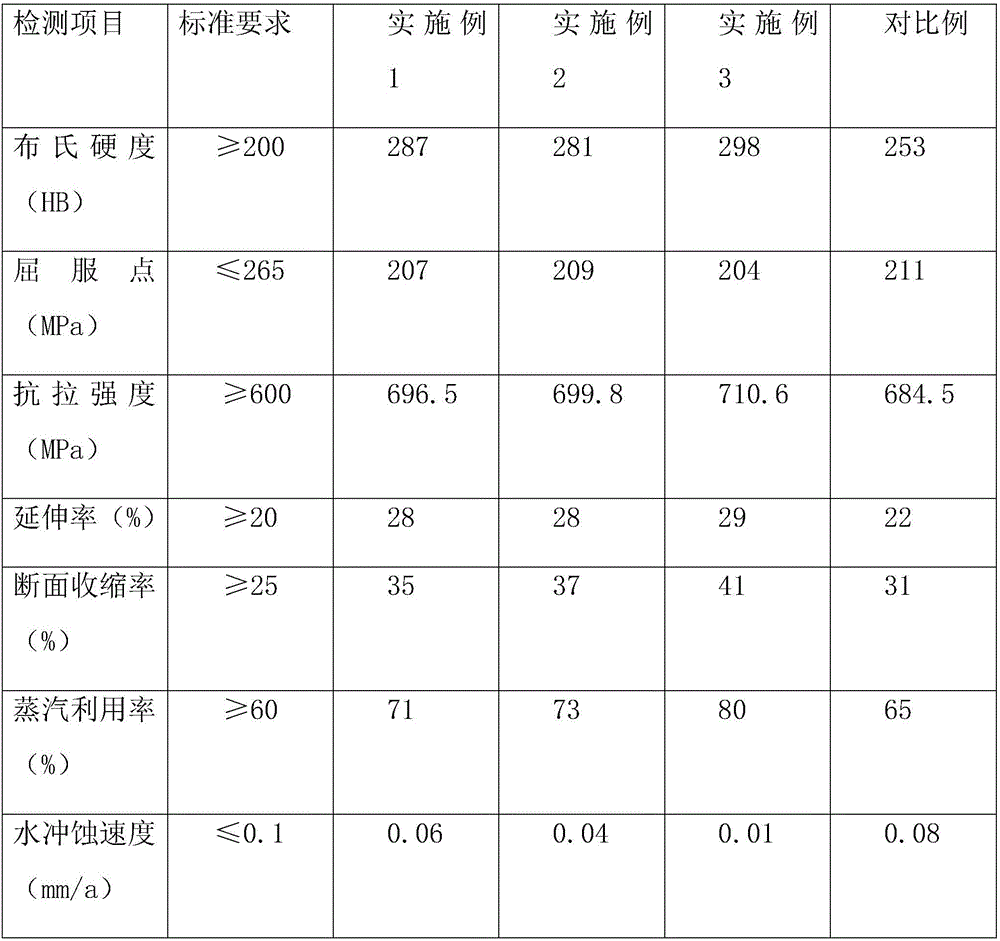

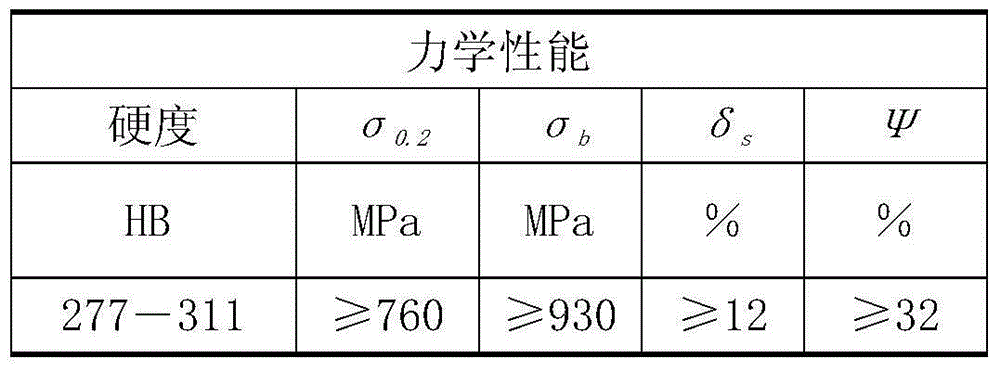

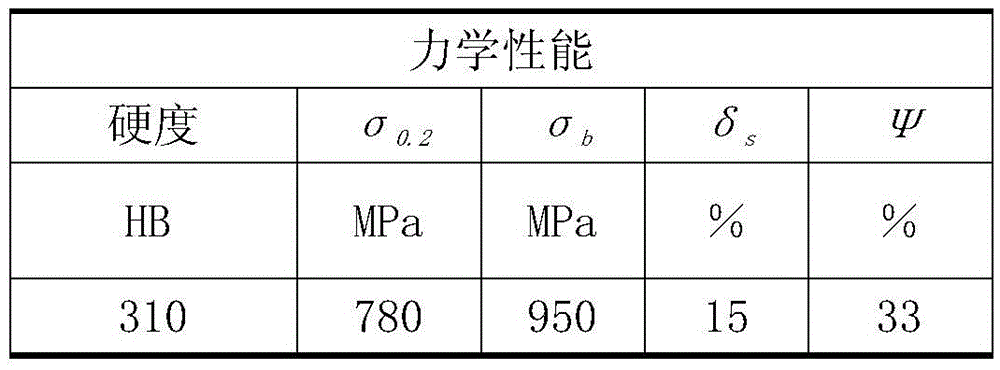

Long-life steam turbine blade and production process thereof

ActiveCN104046919AReduced impact toughnessImprove impact toughnessBlade accessoriesFurnace typesMaterials scienceIndustrial engineering

The invention discloses a long-life steam turbine blade. The long-life steam turbine blade consists of the following chemical components in percentage by weight: 0.29-0.31% of C, 0.16-0.19% of Si, 0.75-0.77% of Mn, 0.73-0.85% of Ni, 9.5-10.1% of Cr, 0.55-0.64% of Mo, 0.15-0.17% of Sn, 0.11-0.15% of V, 0.82-0.84% of Sr, 0.15-0.17% of Nb, 0.02%-0.03% of Cu, 0.13%-0.15% of T, 0.06-0.08% of B, not greater than 0.01% of Ca, not greater than 0.03% of S, not greater than 0.03% of P, 0.16%-0.18% of rear-earth metal, and the balance of Fe. The production process disclosed by the invention is carried out by hot-forging, annealing, blade mechanical machining, distressing thermal treatment, tempering thermal treatment, cooling, surface-enhanced thermal treatment, physical and chemical inspecting, ultrasonic-wave flaw detecting, and cleaning-packaging. The production process disclosed by the invention can greatly improve impact toughness of the blade, can improve water erosion resistance and corrosion resistance of the blade, and can prolong the service life of the blade.

Owner:南京赛达科技有限公司

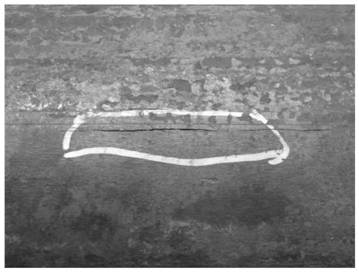

Precipitation strengthening heat treatment process of austenitic heat-resistant steel containing Nb

ActiveCN111705195APromote nucleationAvoid brittle crackingProcess efficiency improvementHeat conservationAustenite

The invention discloses a precipitation strengthening heat treatment process for austenitic heat-resistant steel containing Nb. The precipitation strengthening heat treatment process includes the steps that heat preservation is carried out at 1,200-1,300 DEG C for 1-6 hours for carrying out the first time of solution heat treatment, then cooling is carried out until the temperature reaches to 400-700 DEG C at a temperature drop rate of 5-20 DEG C / min for carrying out non-isothermal aging heat treatment, then the temperature is raised up to 950-1100 DEG C and heat preservation is carried out for 0.5-2h for carrying out secondary time of solution heat treatment, and finally water-cooling is carried out to room temperature. Two times of solution heat treatment processes are adopted and combined with non-isothermal aging strengthening heat treatment, the high temperature strengthening effect is good, the precipitation of high-density fine dispersed MX phase is ensured, and the formation ofgrain boundary M23C6 phase and the brittle cracking caused thereby are avoided, so that the strength of the austenitic heat-resistant steel is significantly improved.

Owner:CENT OF EXCELLENCE FOR ADVANCED MATERIALS +1

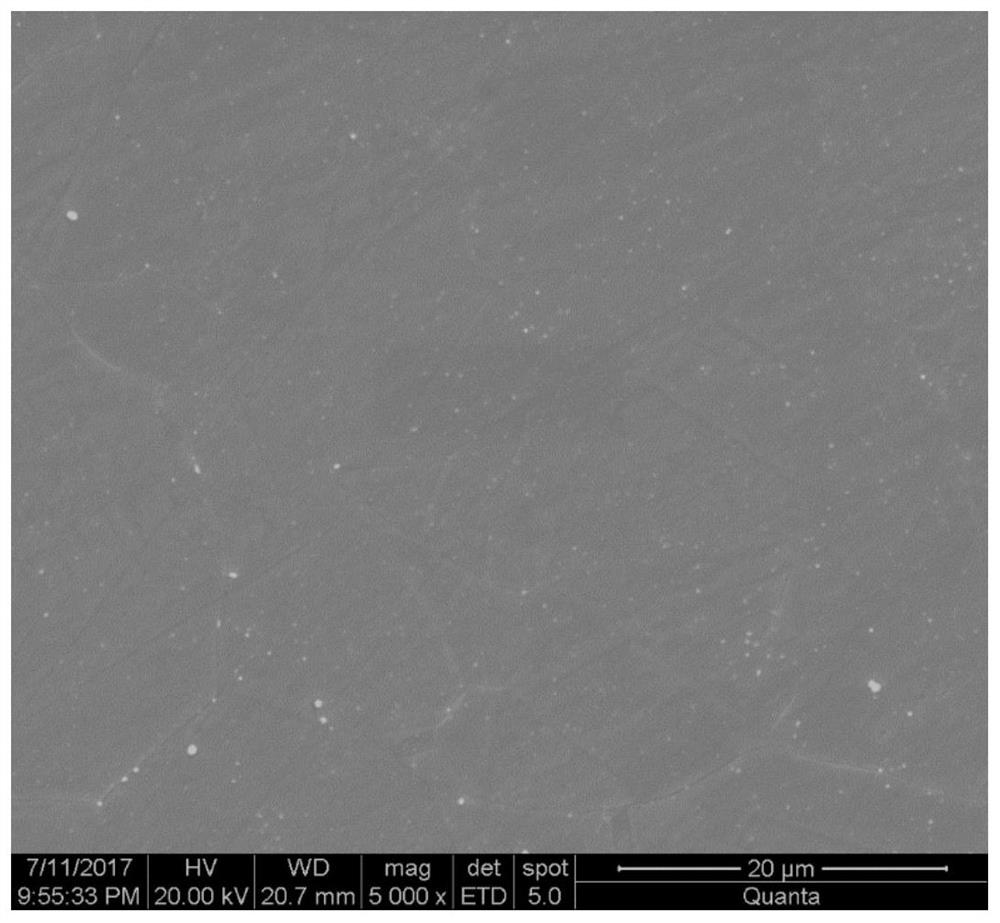

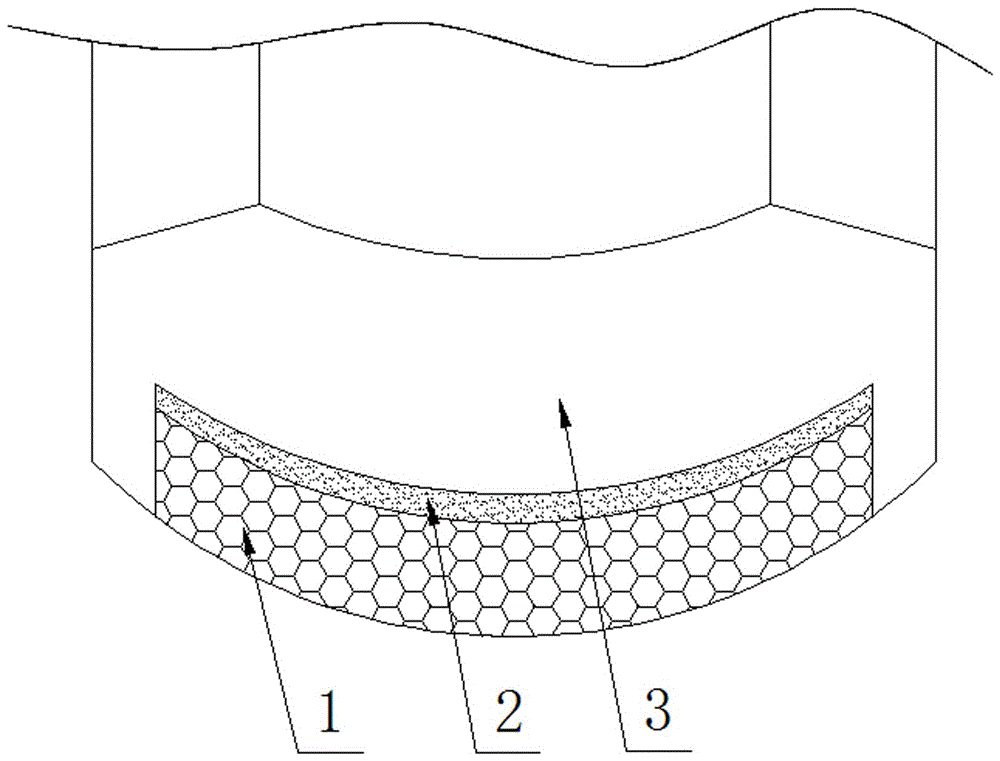

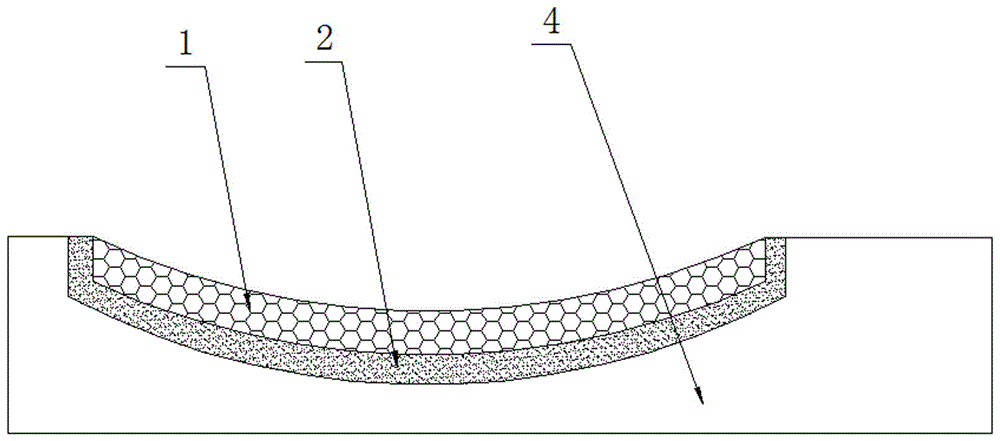

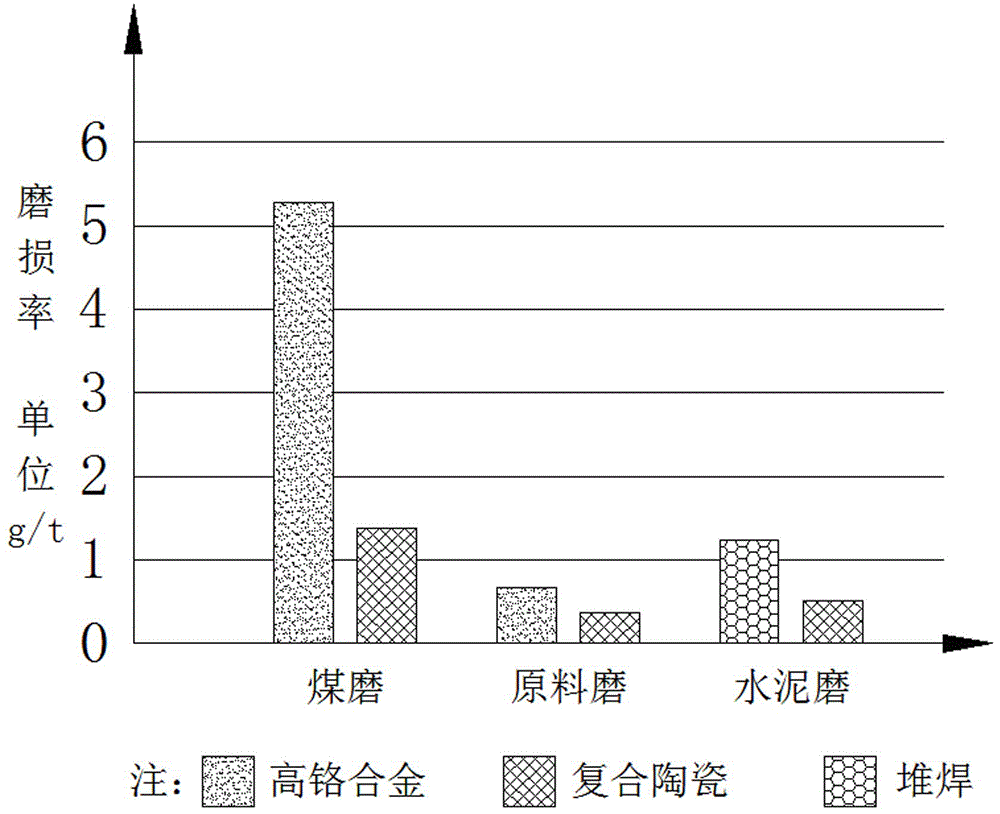

High-efficiency ceramic grinding roller and ceramic lining plate

The invention belongs to the technical field of coal mill equipment, and particularly relates to a high-efficiency ceramic grinding roller and a ceramic lining plate. A grinding mechanism with the relative movement function is formed by the ceramic grinding roller and the ceramic lining plate. The ceramic grinding roller comprises a grinding roller base body, an adhesive layer and a composite ceramic layer. The ceramic lining plate comprises a lining plate base body, an adhesive layer and a composite ceramic layer. Materials of the composite ceramic layers are formed by one or more of silicon carbide, silicon nitride, tungsten carbide, aluminum oxide and zirconium oxide in a compounded mode. The adhesive layers are adhesives resistant to high temperature and high in viscidity. The grinding roller base body and the lining plate base body are made of metal. The composite ceramic layer of the ceramic grinding roller is formed by splicing ceramic modules. Gaps capable of increasing the surface friction force of ceramic are formed between the ceramic modules. The high-efficiency ceramic grinding roller and the ceramic lining plate are simple in structure, reasonable in design, high in hardness, long in service life, economical, practicable and easy to apply and popularize on a large scale, and the cost is reduced.

Owner:张弘

Turbine blade capable of enhancing water corrosion resistance and production technique thereof

ActiveCN104060192AThe segregation of alloying elements is weakenedImprove impact toughnessFurnace typesHeat treatment furnacesCorrosionSteam turbine blade

Owner:南京赛达科技有限公司

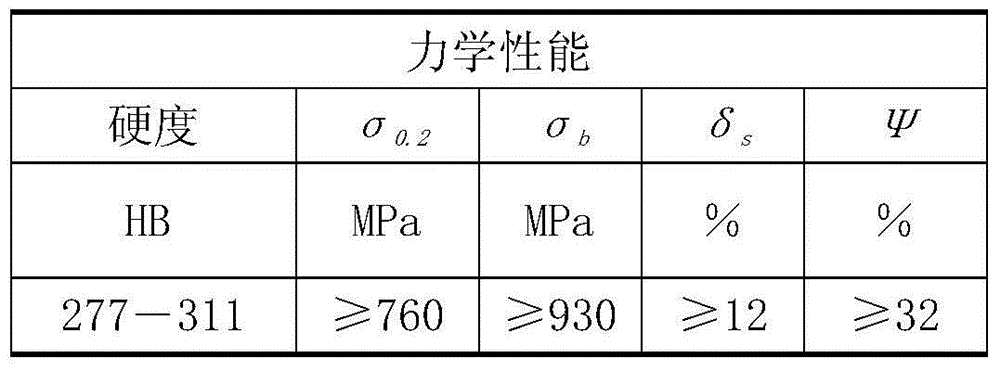

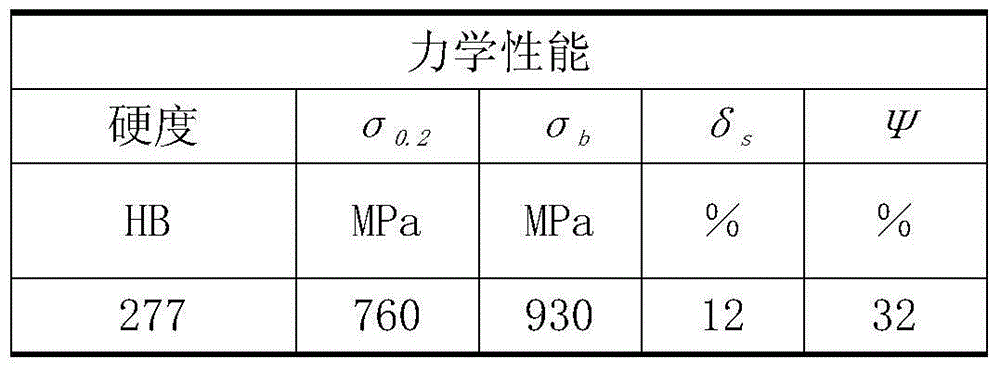

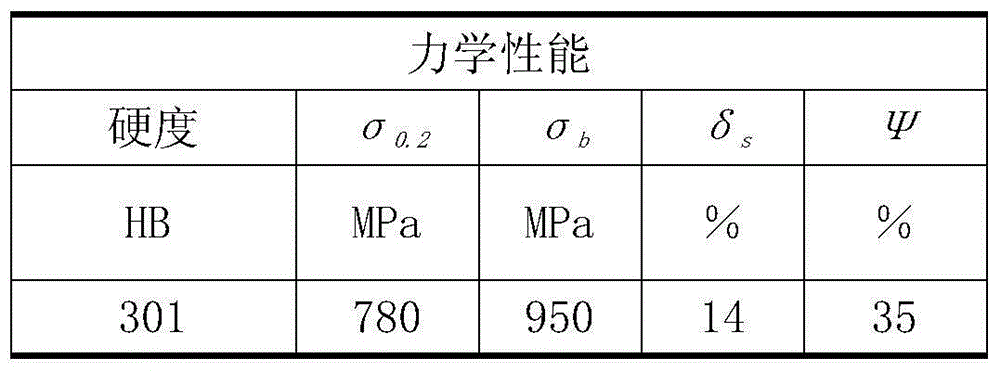

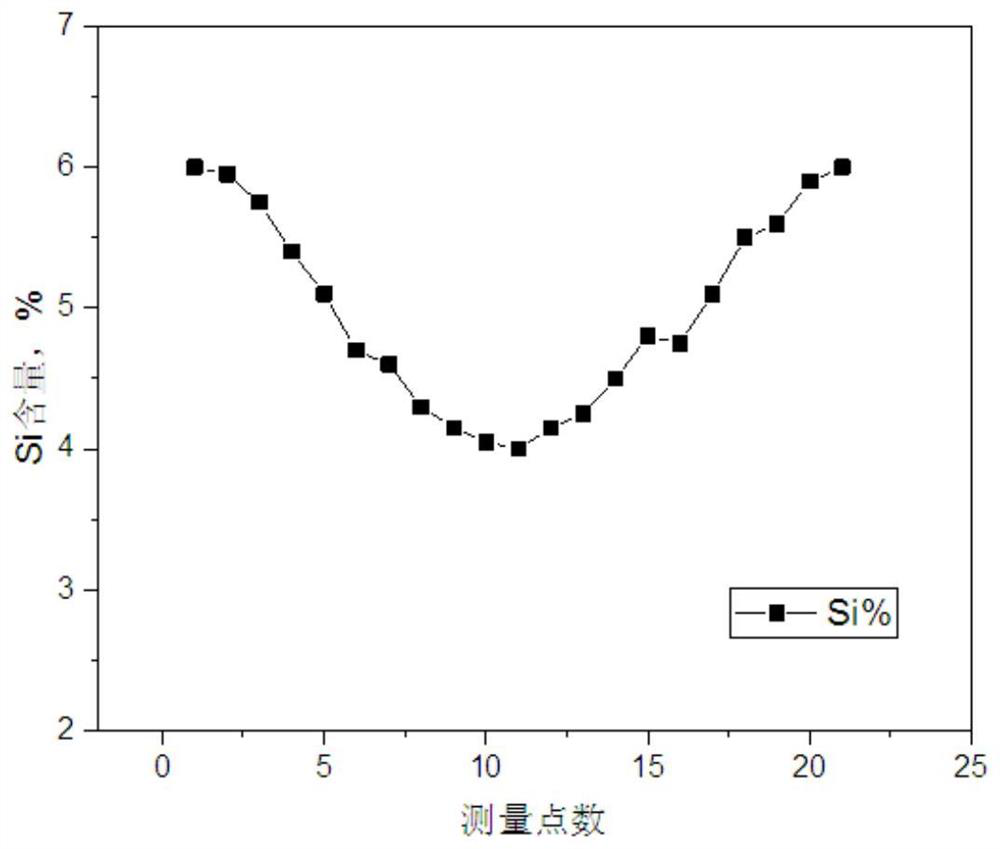

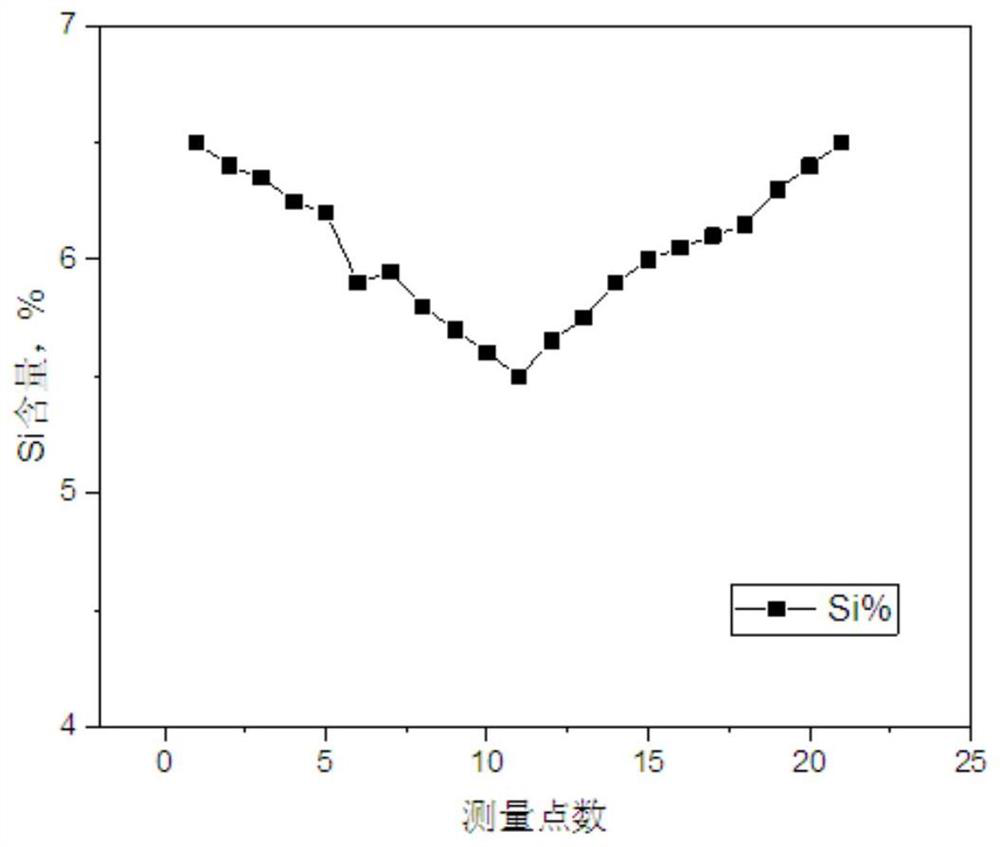

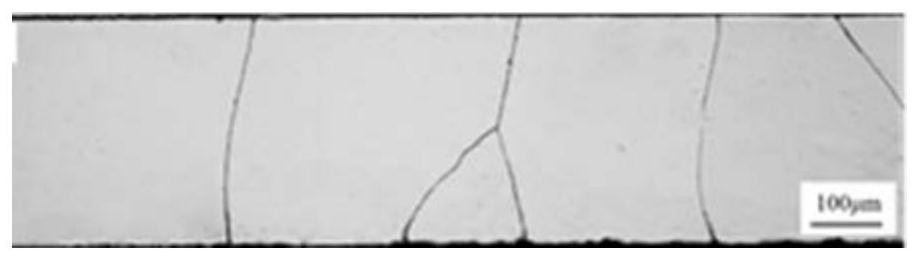

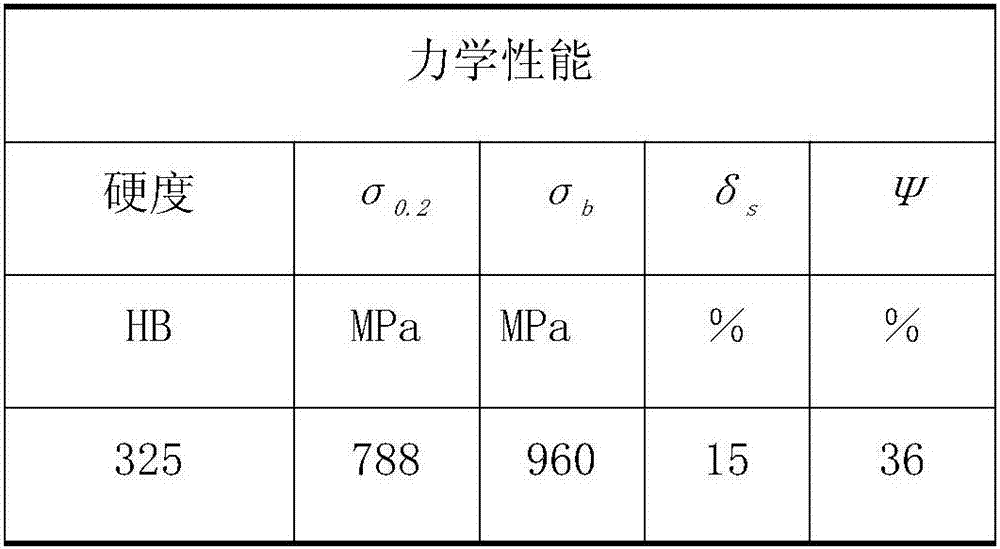

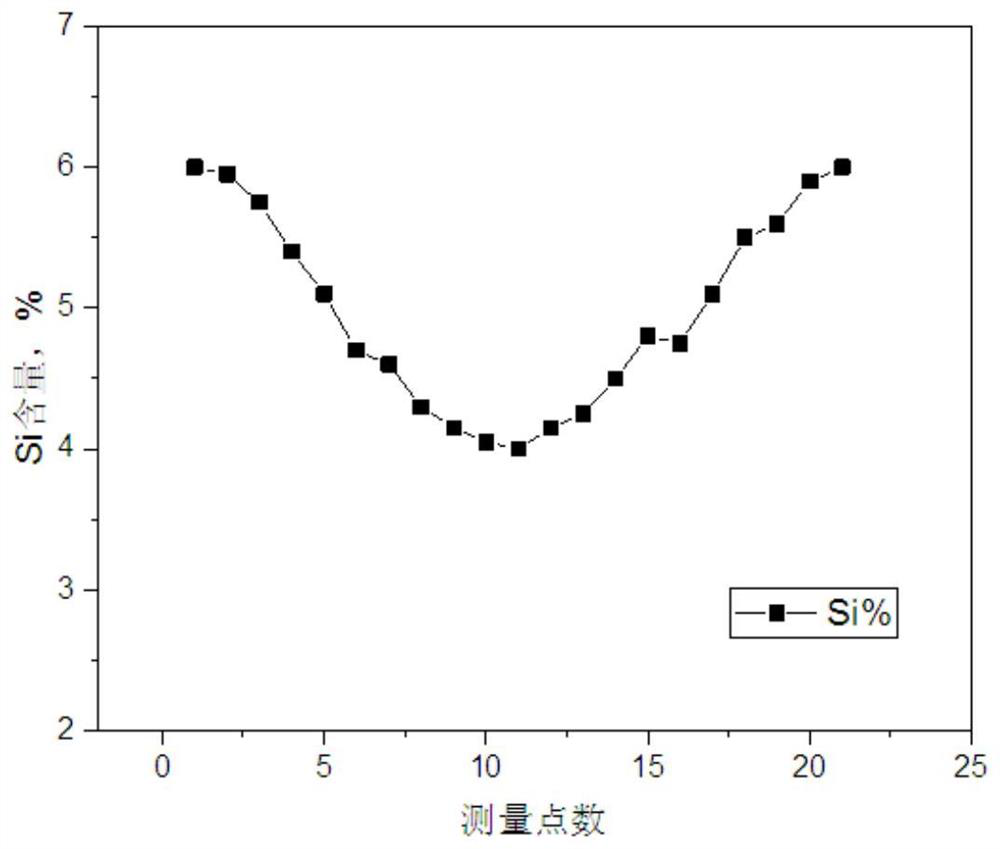

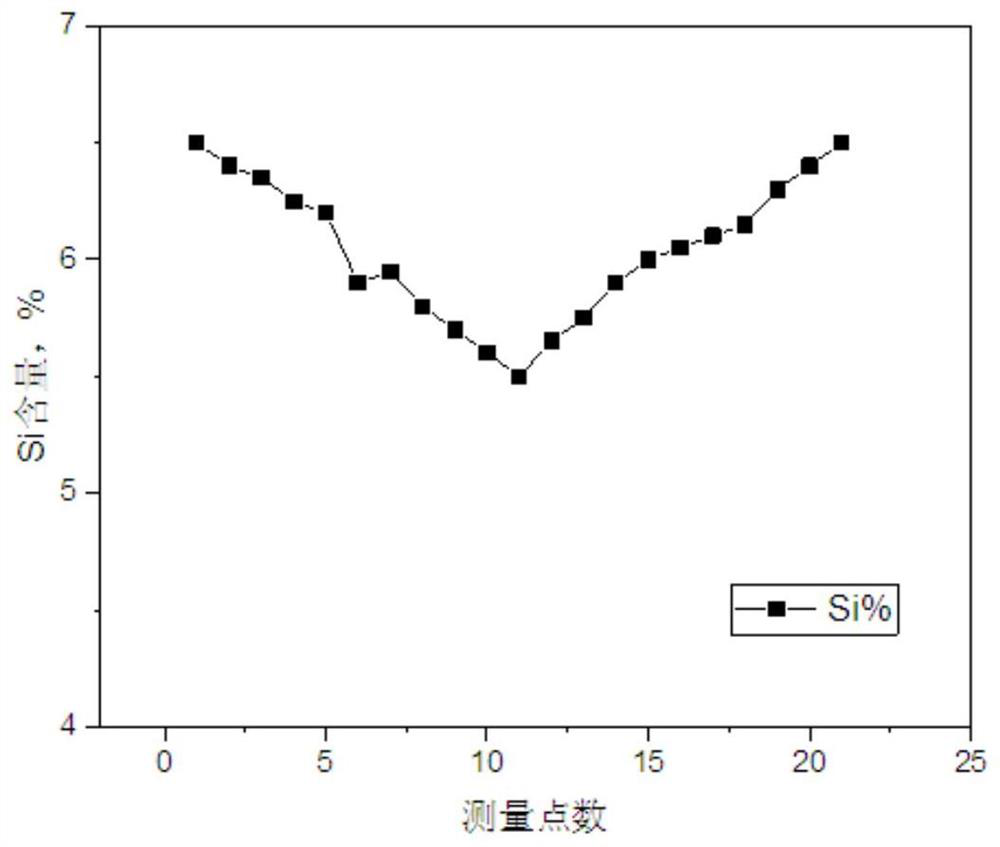

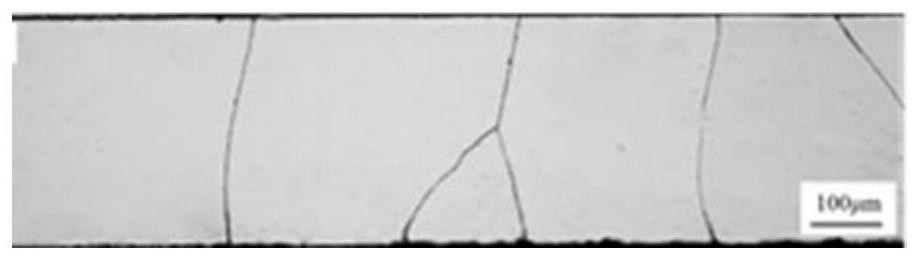

High-silicon gradient silicon steel thin strip and preparation method thereof

ActiveCN112410672AAvoid brittle crackingSolve quality problemsSolid state diffusion coatingUltimate tensile strengthSilicon

The invention discloses a high-silicon gradient silicon steel thin strip and a preparation method thereof. The steel thin strip comprises the following components in percentage by mass of 0.001 to 0.08% of C, 4.5 to 6.5% of Si and the balance of Fe and inevitable impurities, and has the thickness of 0.1 to 0.35mm, the width of less than or equal to 1000mm, the magnetic induction intensity (B8) / T of 1.25-1.56, the iron loss P10 / 400 of 5.1-12 W / kg, the strength of 470-720MPa and the ductility of 2.5-10%. During preparation, a silicon steel thin strip raw material is taken and subjected to surface treatment, and is sequentially subjected to preheating and reduction operation at a specific temperature, first-stage siliconizing treatment is conducted, second-stage siliconizing and annealing treatment is conducted after annealing, cooling is conducted to the room temperature at a specific cooling speed, and the high-silicon-gradient silicon steel thin strip is prepared. According to the process, an ultra-thin low-silicon steel thin strip is used as an initial raw material, brittle cracking in the high-silicon steel rolling process is avoided, a high-silicon concentration gradient thin strip product with the consistent Si content or the gradually-reduced Si content on the surface and the core can be prepared, and the prepared silicon steel thin strip has excellent overall performance.

Owner:NORTHEASTERN UNIV

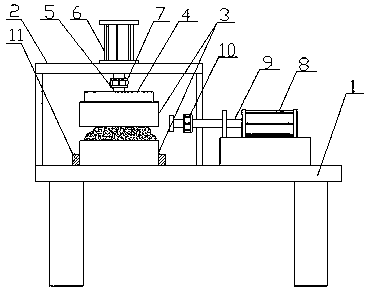

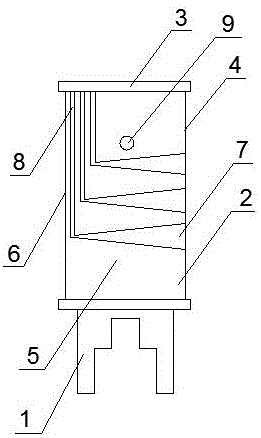

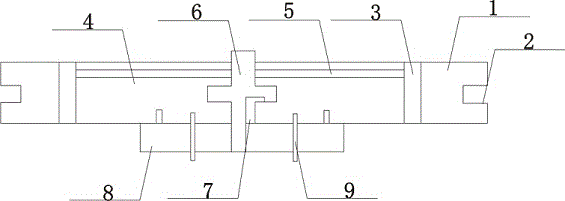

Rock shear strength tester

PendingCN110907268AAvoid brittle crackingHigh precisionMaterial strength using steady shearing forcesClassical mechanicsTester device

The invention discloses a rock shear strength tester which comprises a longitudinal pressure device and a horizontal pressure device. Two vertically symmetrical rock fixing boxes are arranged below the longitudinal pressure device, the horizontal pressure device corresponds to the side surface of the upper rock fixing box, and the rock fixing box is a square box with openings at the opposite innersides. A limiting plate is arranged in the middle in each rock fixing box, a plurality of square supporting columns longitudinally penetrate through the limiting plate and are arranged on the limiting plate in a matrix mode, longitudinal threaded holes are formed in the square supporting columns and are in threaded connection with the threaded columns at one end, and one end of each threaded column extends out of the bottom of the rock fixing box and then is rotationally connected with the bottom of the rock fixing box. The rock shear strength tester has the characteristics that the structureis simple, the cost is low, the rock is firmly fixed, an experiment is not easy to fail, and the experimental results are more accurate.

Owner:GUIZHOU INST OF TECH

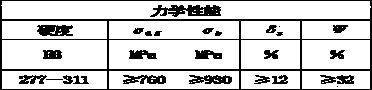

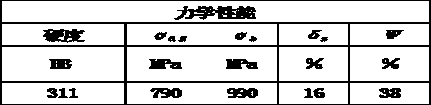

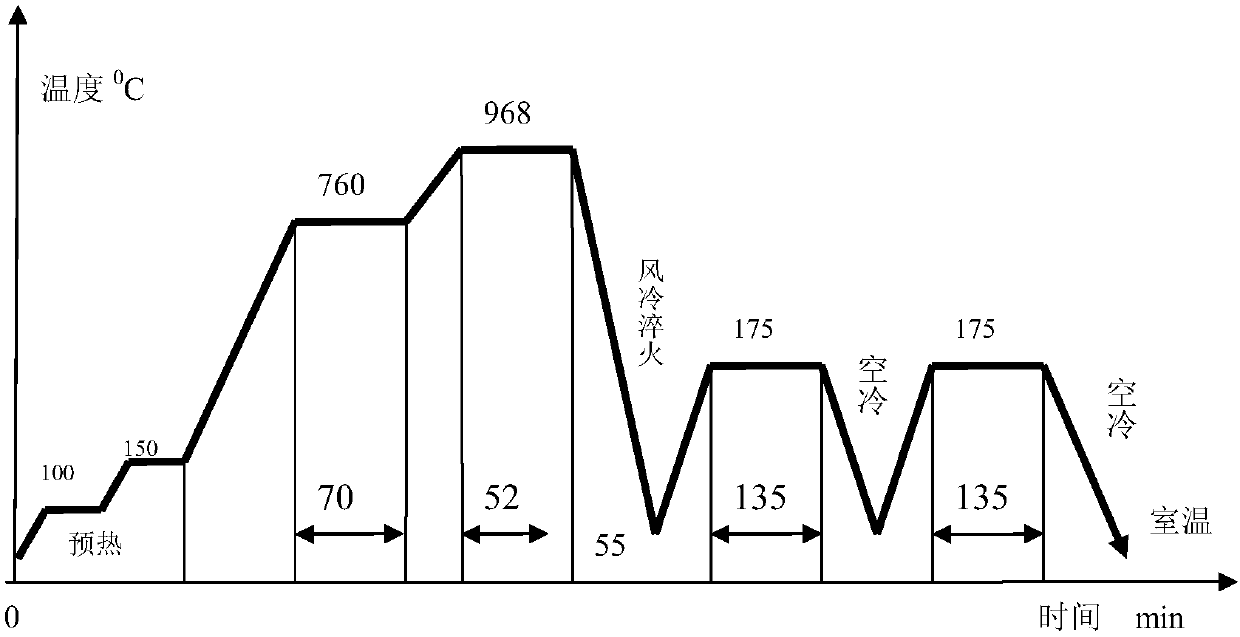

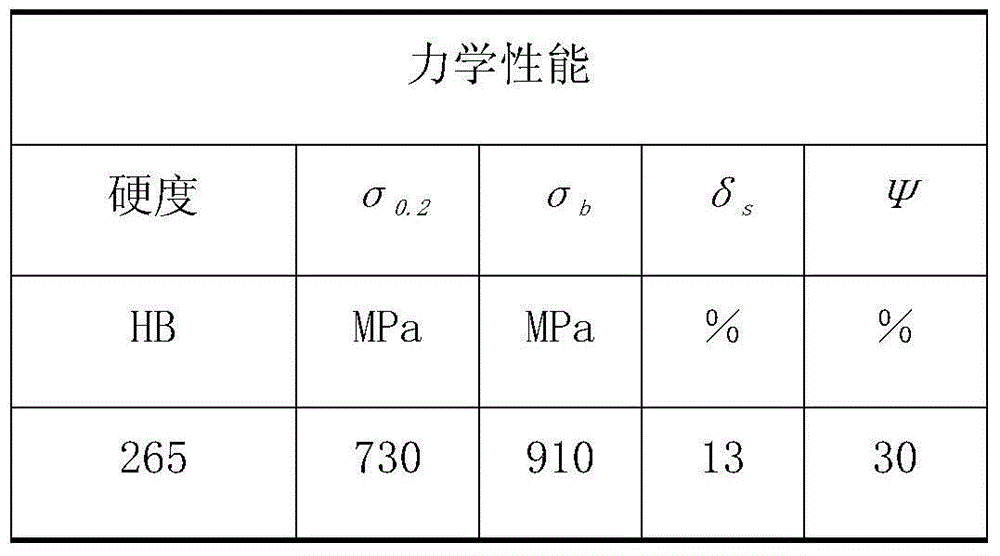

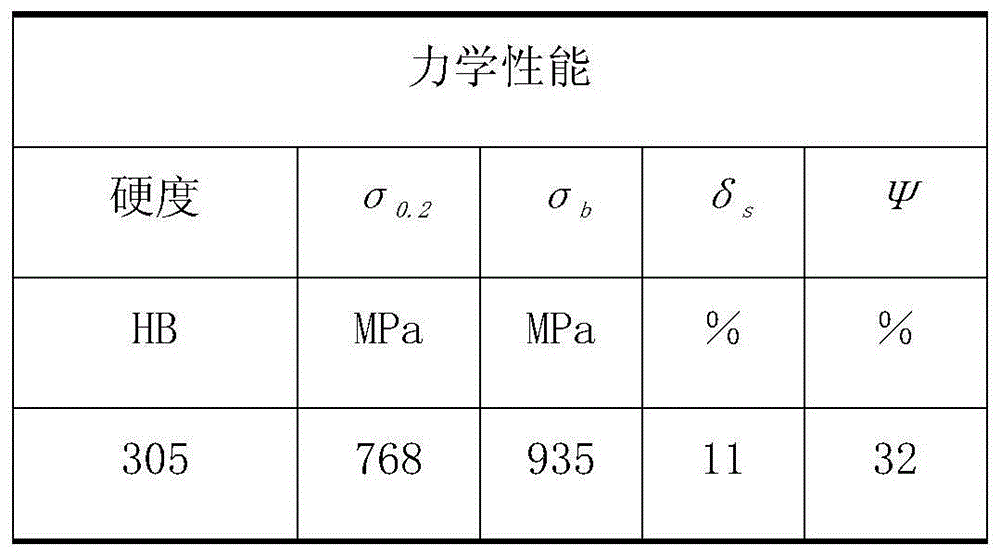

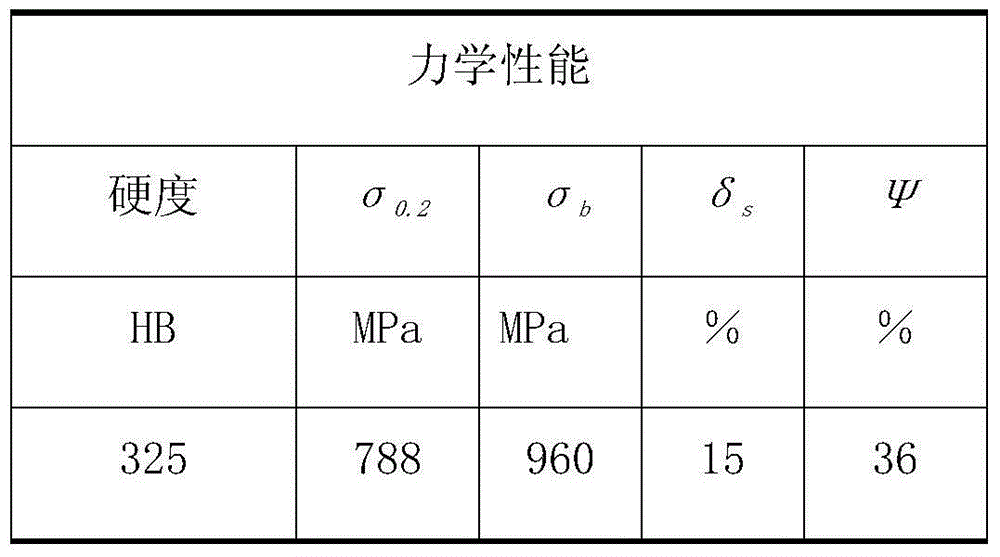

Heat treatment quenching technology for chrome-molybdenum hubbing steel precision part

The invention discloses a heat treatment quenching technology for a chrome-molybdenum hubbing steel precision part. The technology comprises the steps that 1, a workpiece is placed into a quenching furnace to be preheated two times to 150 DEG C; 2, the workpiece is heated in the quenching furnace in two levels to the quenching temperature of 968 DEG C and kept warm; 3, te workpiece is discharged from the furnace, air cooled and quenched to 55 DEG C; and 4, the workpiece is placed into a tempering furnace two times to 175 DEG C, kept warm, tempered, discharged out of the furnace and air cooled.The workpiece is heated in the quenching furnace in two levels to the quenching temperature and kept warm, and the workpiece is preheated, continues to be heated to 760 DEG C and is kept warm for 70min, heated to the quenching temperature of 968 DEG C and kept warm for 52 min. The service life and mechanical property of two knife edge parts (comprising a male die and a female die) are remarkablyimproved, die work parts have high hardness, high impact toughness and wear resistance, and excessive abrasion, deformation, fragile cracking and other early failure are prevented.

Owner:HUBEI ENG INST

Formula of alloy glass die steel

InactiveCN105401092AAvoid brittle crackingReduce production and use costsTitaniumChemical composition

The invention discloses a formula of alloy glass die steel. According to the chemical components, the steel material comprises, by weight, 1-5% of titanium, 6-8% of chrome, 15% or less of silicon, 0.5-0.95% of vanadium, 5-9% of phosphorus, 10-12% of zinc, and 3-8% of copper. The formula has the beneficial effects that the alloy glass die steel is composed of main alloy components including iron, silicon, zinc and copper, die cracking and fracturing are reduced or avoided, the production and using cost is reduced, the service life of a die is prolonged, and the performance is improved.

Owner:TAICANG WANGMEI MOLD CO LTD

High-pressure-resistant turbine blade and production process thereof

ActiveCN105239021AReduce segregationReduced impact toughnessFurnace typesHeat treatment furnacesTurbine bladeRare earth

The invention relates to a high-pressure-resistant turbine blade. The chemical components of the high-pressure-resistant turbine blade include 0.019-0.021% of C, 0.09-0.11% of Si, 0.83-0.85% of Mn, 0.55-0.57% of Ni, 1.7-1.9% of Cr, 0.11-0.13% of Mo, 3.9-4.1% Co, 4.26-4.28% of V, 0.01-0.03% of Nb, 0.03-0.05% of Cu, 6.21-6.23% of Al, 0.007-0.009% of N, 0.23-0.25% of Ti, 0.08-0.10% of rare earth metal and the balance Fe. The invention further provides a production process for the high-pressure-resistant turbine blade. The impact toughness of the blade is greatly improved, the anti-water-erosion capacity and the corrosion resistance of the blade are improved, and the service life of the blade is prolonged.

Owner:南京赛达科技有限公司

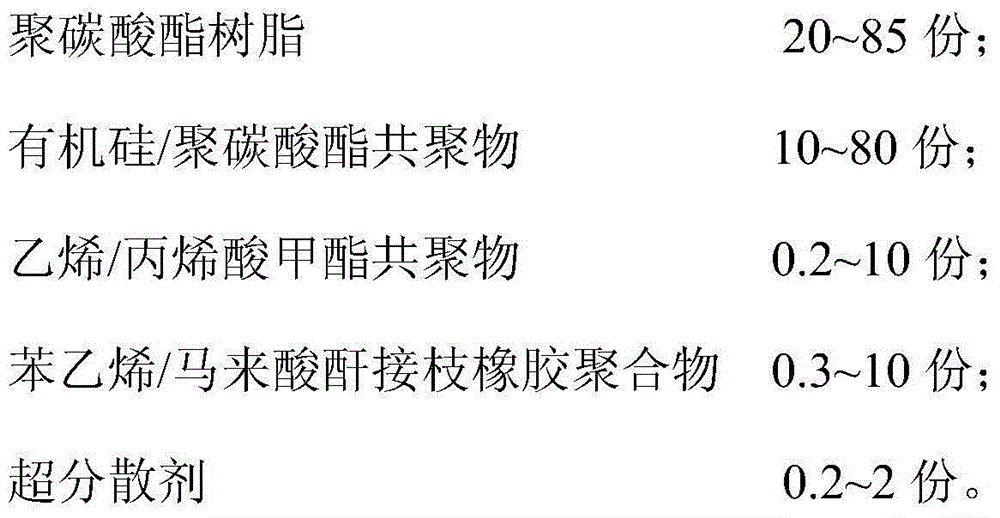

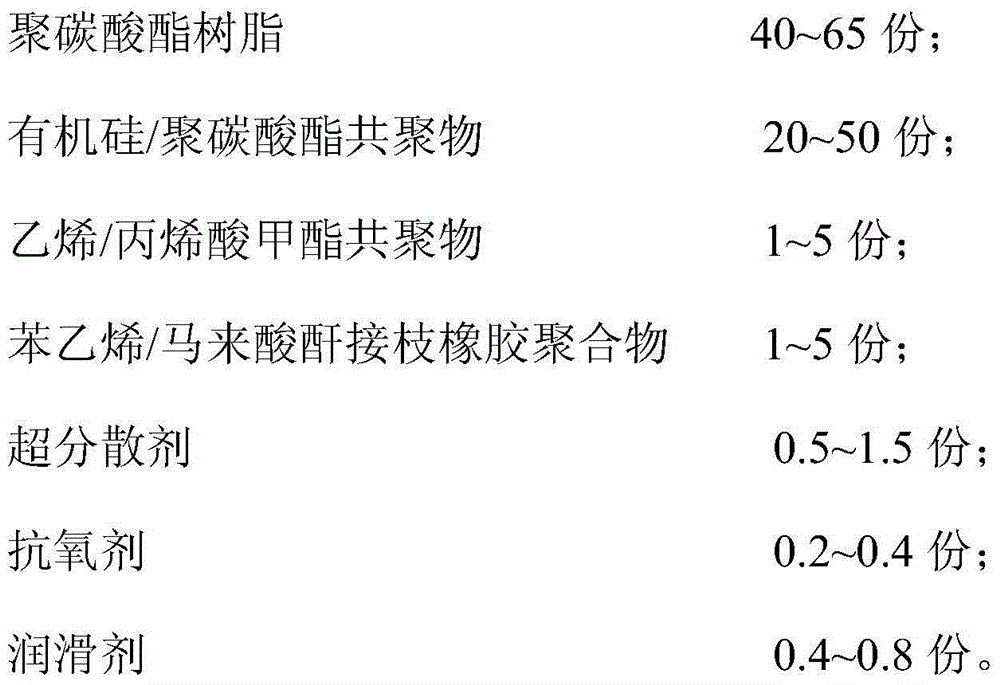

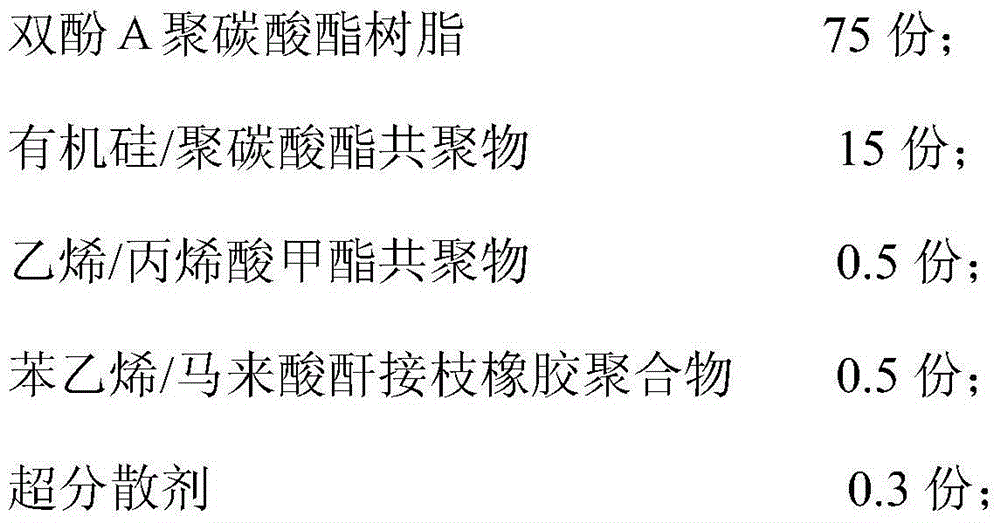

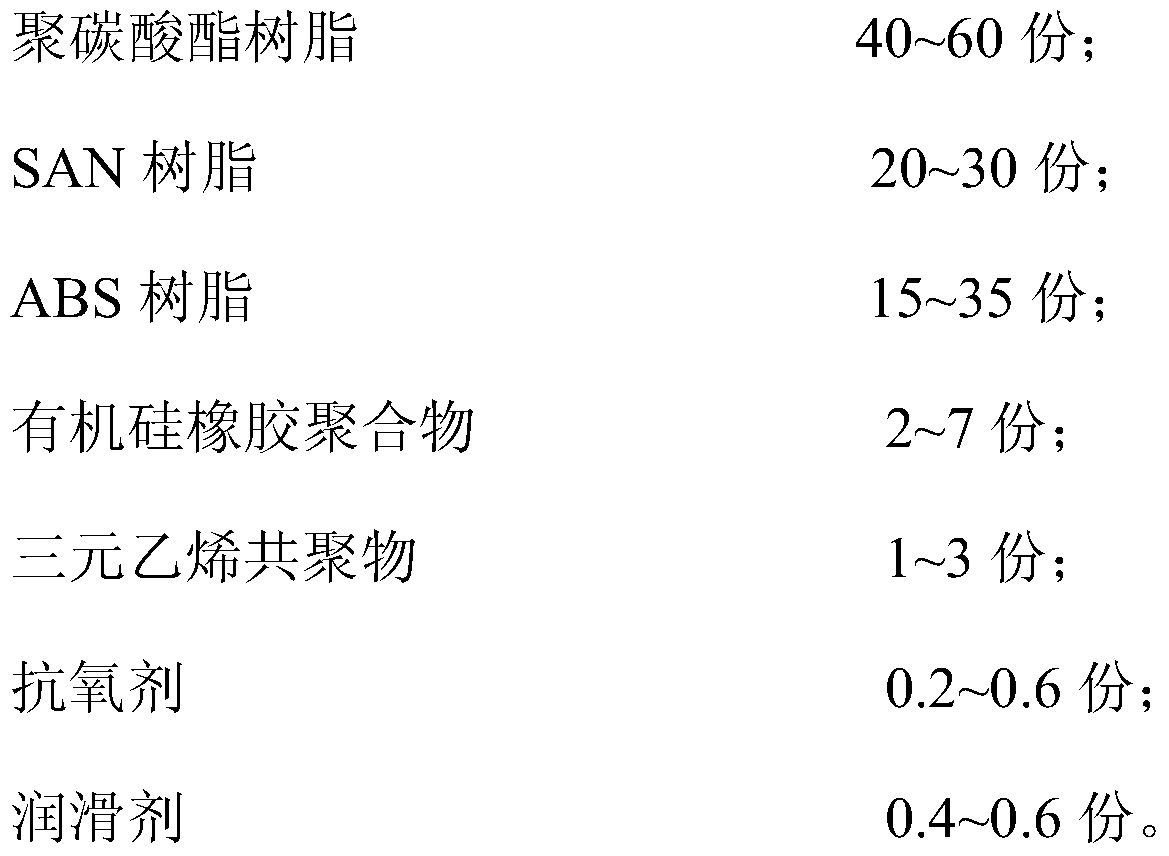

Electroplatable polycarbonate composition and preparation method thereof

InactiveCN104910602AImprove cold resistanceEnhanced resistance to strong oxidizing acidsCrack resistancePolycarbonate

The invention provides an electroplatable polycarbonate composition and a preparation method thereof. The polycarbonate composition is mainly prepared from the following raw materials in parts by mass: 20-85 parts of polycarbonate resin, 10-80 parts of organosilicone / polycarbonate copolymer, 0.2-10 parts of ethylene / methyl acrylate copolymer, 0.3-10 parts of styrene / maleic anhydride-grafted rubber polymer and 0.2-2 parts of a hyperdispersant. The polycarbonate composition provided by the invention is good in ultralow-temperature cracking resistance, electroplating corrosion cracking resistance and embedded steel sheet stress cracking resistance; an electroplated layer is high in binding force; plated pieces are good in quality.

Owner:SHENZHEN HALCYON NEW MATERIALS

Water-erosion-preventing turbine blade

InactiveCN107524474AAvoid erosionImprove dehumidification effectBlade accessoriesFurnace typesAqueous dropletSteam turbine blade

The invention discloses an anti-corrosion steam turbine blade, which includes a blade root, a blade shape and a blade crown, and the blade root, the blade shape, and the blade crown are connected in sequence, and the blade shape includes an air inlet edge, an inner arc, an air outlet edge and an outer edge. The air guide groove and the dehumidification groove are arranged on the airfoil, one end of the air guide groove is located on the air inlet side, and the air guide groove is from the air inlet side to the air outlet side, and one end of the dehumidification groove is located between the blade shape and the air outlet side. At the joint of the leaf crown, the dehumidification tank is close to the air outlet edge, the dehumidification tank is from the leaf crown to the blade root, the remote end of the air guide groove communicates with the end of the dehumidification tank, and the dehumidification tank on the leaf crown corresponds to A through hole is opened at the end of the groove. In the anti-corrosion steam turbine blade provided by the invention, the water droplets produced by the liquefaction of high-temperature steam are thrown out from the through hole on the blade crown along the dehumidification tank, so as to prevent the water droplets from being located on the blade shape for a long time to cause the blades to be eroded by the water droplets.

Owner:南京赛达科技有限公司

A steam turbine blade capable of improving impact toughness and its production process

ActiveCN104060191BReduced impact toughnessImprove impact toughnessFurnace typesHeat treatment furnacesMischmetalChemical composition

The invention is a steam turbine blade which can improve the impact toughness. The mass percentage of its chemical composition is: C: 0.13-0.15%, Si: 0.8-0.9%, Mn: 0.5-0.8%, Cr: 14-16%, Ni: 0.1-0.3%, Cu: 1.3-1.5%, Mo: 0.6-1.1%, W: 0.1-0.15%, V: 0.36-0.45%, Nb: 0.5-0.8%, Al: 0.28-0.30%, Ti : 0.16-0.18%, B: 0.08-0.10%, Na: 0.45-0.48%, S≤0.02%, P≤0.03%, rare earth metal: 0.3-0.6%, the balance is Fe; the invention also provides The production process of the steam turbine blade with high toughness, the invention can greatly improve the impact toughness of the blade and improve the service life of the blade.

Owner:南京赛达科技有限公司

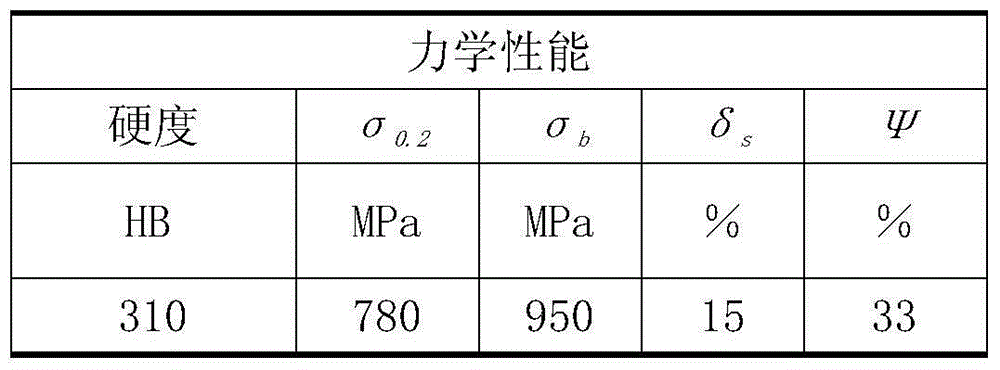

A steam turbine blade capable of improving water erosion resistance and its production process

ActiveCN104060192BReduced impact toughnessImprove impact toughnessFurnace typesHeat treatment furnacesChemical compositionSteam turbine blade

The invention provides a turbine blade capable of enhancing water corrosion resistance, which comprises the following chemical components: 0.26-0.28% of C, 0.13-0.15% of Si, 0.75-0.77% of Mn, 0.63-0.65% of Ni, 10.5-10.7% of Cr, 0.65-0.67% of Mo, 0.16-0.18% of V, 0.82-0.84% of Sr, 0.15-0.17% of Nb, 0.05-0.07% of Cu, 0.24-0.26% of Al, 0.13-0.15% of Ti, 0.06-0.08% of B, at most 0.03% of S, at most 0.03% of P, 0.12-0.15% of rare-earth metal and the balance of Fe. The production technique can greatly enhance the impact toughness of the blade, enhance the water corrosion resistance and corrosion resistance of the blade and prolong the service life of the blade.

Owner:南京赛达科技有限公司

A diamond saw blade for rail sawing machine and its production process

ActiveCN108098062BNot easy to damageHigh hardnessMetal sawing tool makingMetal sawing toolsRare-earth elementIron powder

Owner:苏州卫优知识产权运营有限公司

A kind of electroplating pc/abs alloy material and preparation method thereof

The invention provides an electroplated PC (Poly Carbonate) / ABS (Acrylonitrile Butadiene StyreneAcrylonitrile Butadiene Styrene) alloy material and a preparation method thereof. The electroplated PC / ABS alloy material is prepared from the following raw materials in parts by mass: 30 to 70 parts of panlite, 15 to 35 parts of SAN resin, 10 to 40 parts of ABS resin and 1 to 10 parts of organic silicon rubber polymer. The organic silicon rubber polymer is added in the electroplated PC / ABS alloy material provided by the invention, the synergistic effect among the raw materials is fully utilized, and the optimizing process on the content of the raw materials is performed, so that the solution resistance and the toughness of the PC / ABS alloy material are improved, and hardening, embrittlement and cracking after coarsening electroplating are prevented.

Owner:SHENZHEN HALCYON NEW MATERIALS

A kind of medium carbon non-quenched and tempered steel and preparation method thereof

ActiveCN113621882BImprove toughnessReduce internal stressTemperature control deviceMetal rolling arrangementsCarbideToughness

The application relates to a medium carbon non-quenched and tempered steel and a preparation process thereof, belonging to the technical field of iron and steel production. In this application, by limiting the content of Al, Nb and Ti, accurately controlling the content of V and N, and controlling the ratio of Σ(Al+Nb+V+Ti) / N to be between 6-9, a suitable content and dispersed precipitation are formed in the steel. The carbides and nitrides of Al, Nb, V, Ti, etc. can be refined, so that the brittle cracking of the steel can be reduced and the surface quality can be improved while ensuring the strength and toughness of the steel. The present application can reduce the internal stress of the medium carbon non-quenched and tempered steel and reduce the crack susceptibility through the precise control of the multi-process node process in the preparation process.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

A high temperature resistant steam turbine blade and its production process

ActiveCN104099516BImprove performanceImprove impact toughnessBlade accessoriesSolid state diffusion coatingChemical compositionHeat resistance

Owner:南京赛达科技有限公司

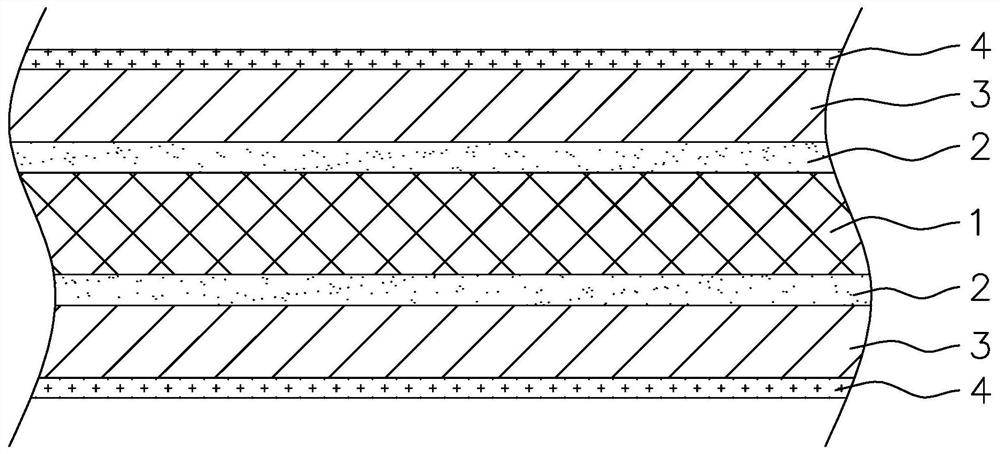

Graphene-based antibacterial fabric and production process thereof

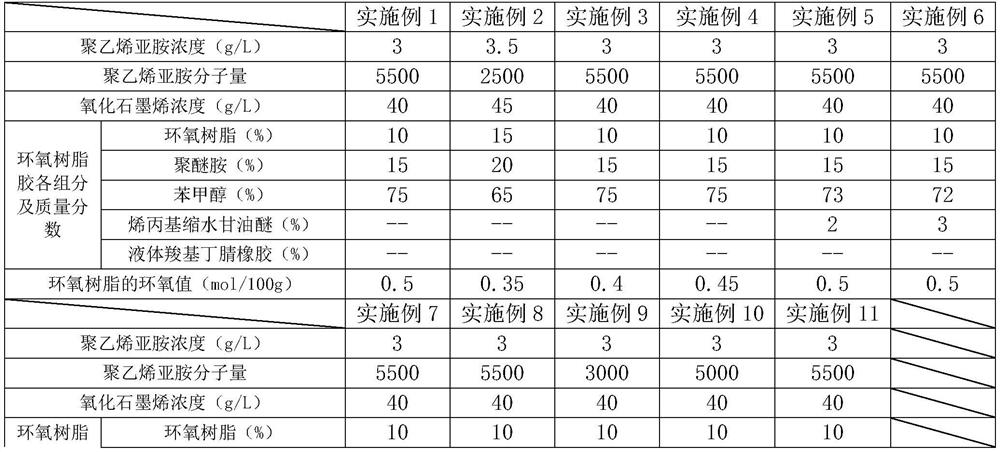

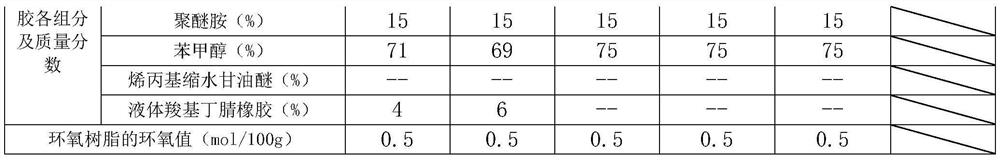

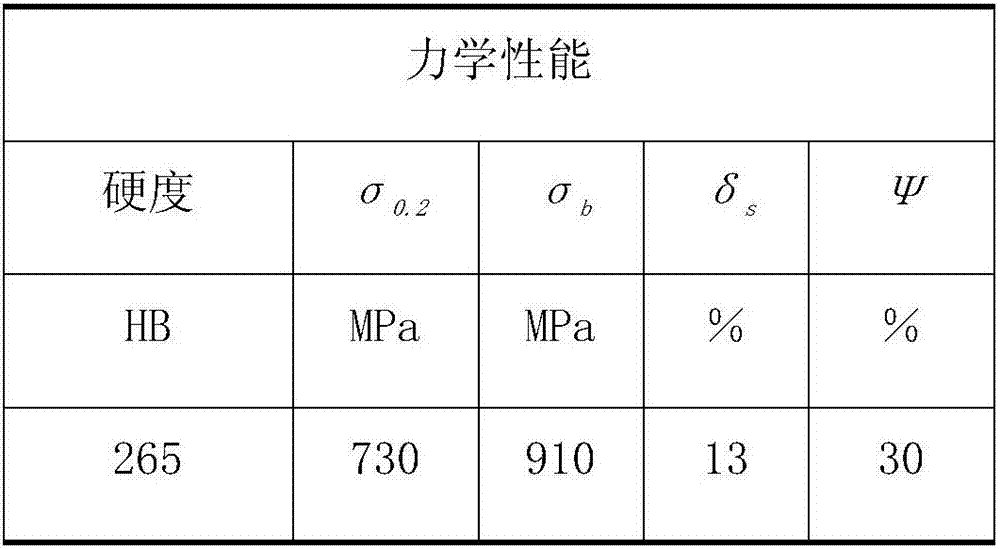

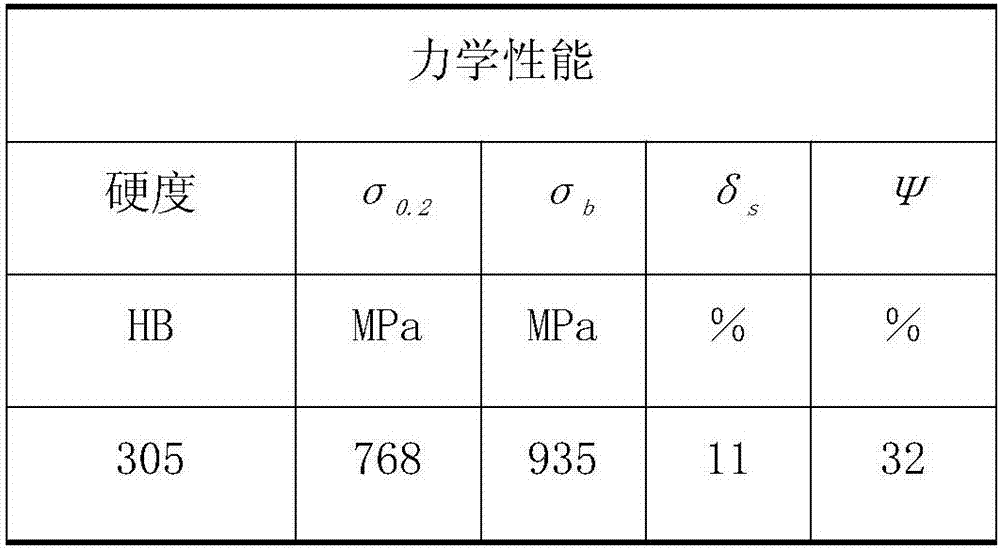

The invention relates to the field of fabrics, and particularly discloses a graphene-based antibacterial fabric and a production process thereof. The fabric sequentially comprises a fabric layer, a bonding layer, a graphene layer and a protective layer from inside to outside; the fabric layer is formed by tatting cotton fibers; the bonding layer is a structural layer which is formed after the surface of the fabric layer is finished by polyethyleneimine and plays a role in bonding transition; the graphene layer is a structural layer which is formed by hot-press finishing of graphene oxide on the surface of the bonding layer and plays a main antibacterial role; the protective layer is a structural layer which is formed by crosslinking epoxy resin glue on the surface of the bonding layer and mainly has a protective effect; and the epoxy resin glue is mainly formed by mixing epoxy resin, polyether amine and benzyl alcohol. The graphene antibacterial fabric prepared by the process has good wear resistance on the surface and can be used for a long time, and the graphene layer is not easy to wear or not prone to falling off, so that the graphene antibacterial fabric has more durable antibacterial performance.

Owner:HANGZHOU KELIDA HOME TEXTILE CO LTD

A high-pressure resistant steam turbine blade and its production process

ActiveCN105239021BReduce segregationReduced impact toughnessFurnace typesHeat treatment furnacesTurbine bladeMetallurgy

The invention relates to a high-pressure-resistant turbine blade. The chemical components of the high-pressure-resistant turbine blade include 0.019-0.021% of C, 0.09-0.11% of Si, 0.83-0.85% of Mn, 0.55-0.57% of Ni, 1.7-1.9% of Cr, 0.11-0.13% of Mo, 3.9-4.1% Co, 4.26-4.28% of V, 0.01-0.03% of Nb, 0.03-0.05% of Cu, 6.21-6.23% of Al, 0.007-0.009% of N, 0.23-0.25% of Ti, 0.08-0.10% of rare earth metal and the balance Fe. The invention further provides a production process for the high-pressure-resistant turbine blade. The impact toughness of the blade is greatly improved, the anti-water-erosion capacity and the corrosion resistance of the blade are improved, and the service life of the blade is prolonged.

Owner:南京赛达科技有限公司

A kind of high-silicon gradient silicon steel strip and its preparation method

ActiveCN112410672BAvoid brittle crackingSolve quality problemsSolid state diffusion coatingPhysical chemistryUltimate tensile strength

A high-silicon gradient silicon steel thin strip and its preparation method according to the present invention, the thin strip includes components and mass percentages of C 0.001-0.08%, Si 4.5-6.5%, the balance is Fe and unavoidable impurities, and the thickness is 0.1~0.35mm, width≤1000mm, magnetic induction (B8) / T 1.25‑1.56, iron loss P10 / 400 5.1‑12W / kg, strength 470‑720MPa, elongation 2.5‑10%. During preparation, the silicon steel thin strip raw material is surface treated, preheated at a specific temperature in turn, after the reduction operation, the first stage of siliconizing treatment is performed, and after annealing, the second stage of siliconizing and annealing treatment is performed, and cooled at a specific cooling rate to room temperature to prepare high silicon gradient silicon steel thin strips. This process uses ultra-thin low-silicon steel strip as the initial raw material, which avoids brittle cracking in the rolling process of high-silicon steel, and can produce high-silicon-concentration-gradient thin strip products with the same Si content on the surface and the core or gradually reduced Si content. Silicon steel thin strip has excellent overall properties.

Owner:NORTHEASTERN UNIV LIAONING

Granite decorative panels

ActiveCN104153532BReduce weightEasy to carryCovering/liningsFire proofingSurface mountingCement board

The invention discloses a granite decorative board, which comprises a decorative board body, connecting grooves are arranged on both sides of the decorative board body, a vermiculite board is arranged near the connecting groove on the decorative board body, the vermiculite board is vertically installed on the decorative board body, and the vermiculite There are two stone slabs, a coating layer is connected between the two vermiculite slabs, and an insulation board is installed on the lower surface of the coating layer. The thickness of the insulation board is greater than the thickness of the coating layer. There is a foamed cement slab, and the foamed cement slab is flexibly connected to the main body of the decorative board, and a steel connecting column is installed between the foamed cement slab and the decorative board body, there are two steel connecting columns, and the top of the steel connecting column Extends within the insulation board. The granite decorative board is light in weight, easy to carry, has good fireproof performance, can avoid brittle cracking at the same time, and can effectively prevent the plate from arching and deformation, ensuring that the shrinkage joint gap of the plate is small, the overall is more reasonable, and the decorative effect is more obvious .

Owner:广东满大装饰工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com