Precipitation strengthening heat treatment process of austenitic heat-resistant steel containing Nb

A technology of austenitic heat-resistant steel and precipitation strengthening, which is applied in the direction of improving process efficiency, etc., can solve the problems affecting the high-temperature performance of heat-resistant steel, the number of precipitation, and the substructure, so as to meet the performance requirements and avoid brittle cracking , the effect of promoting nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

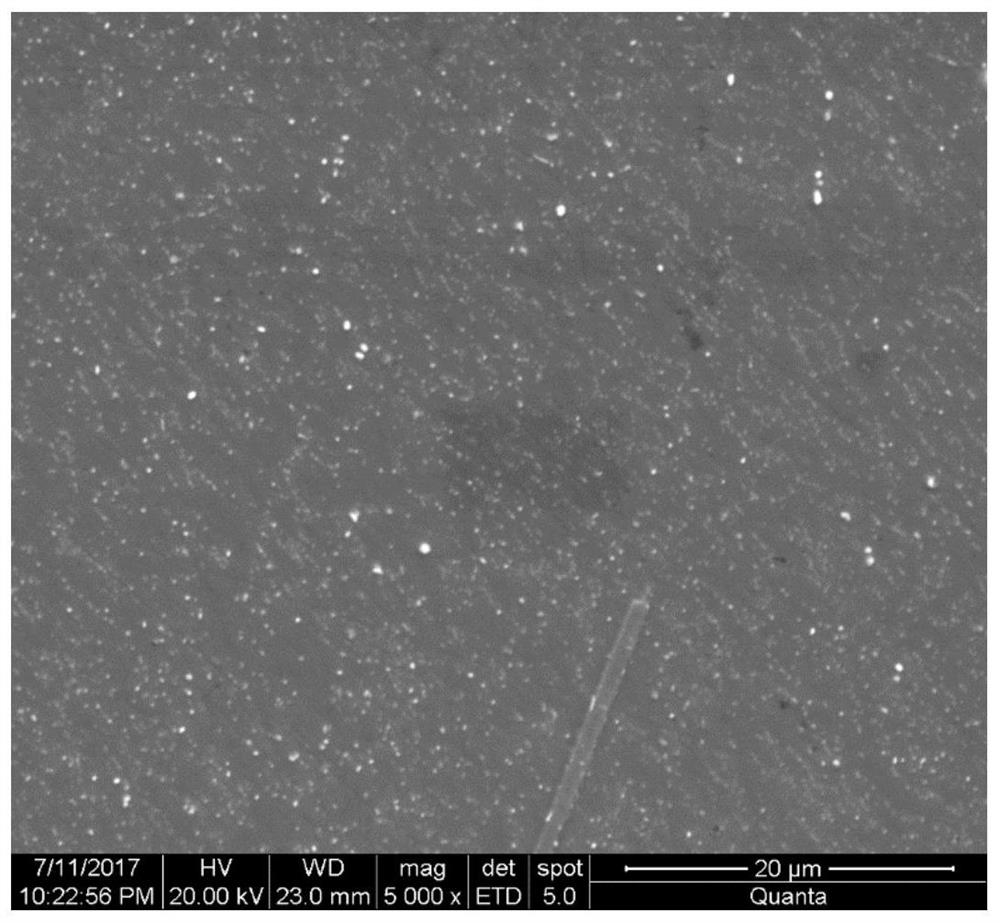

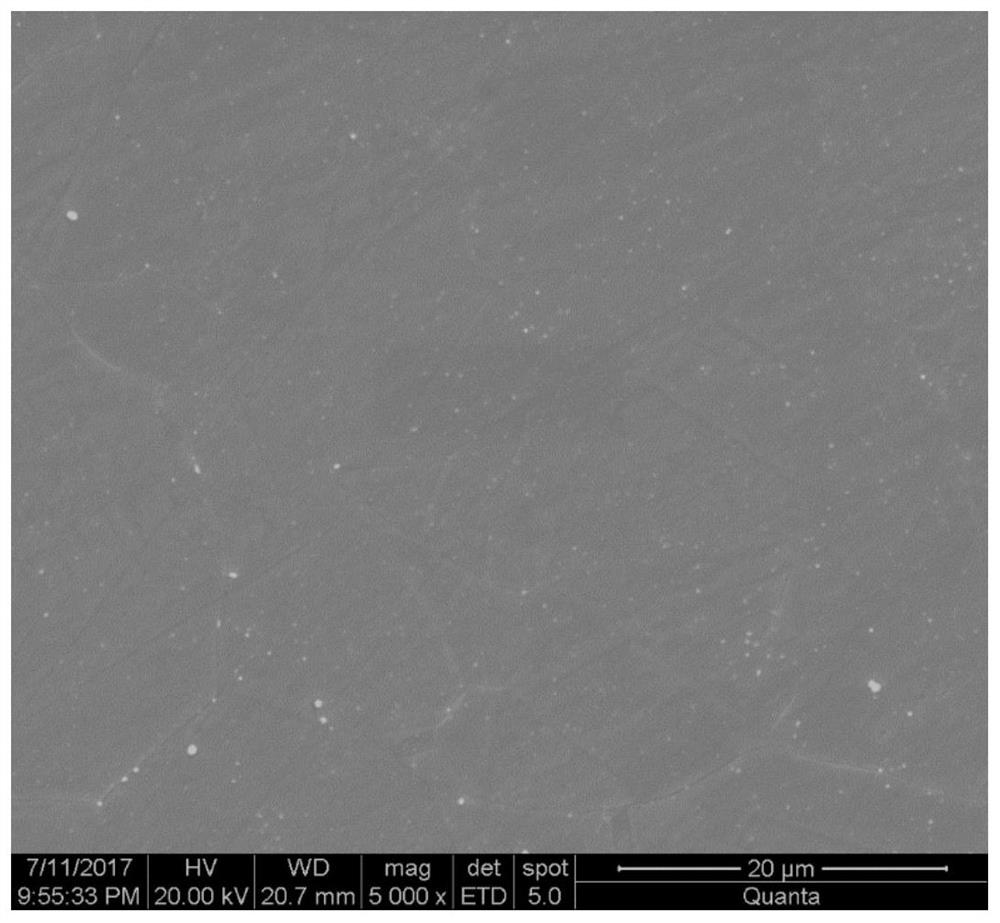

Image

Examples

Embodiment 1

[0030] A kind of Nb-containing austenitic heat-resistant steel, composed of the following components in terms of mass percentage:

[0031] C 0.06%, Cr 25.5%, Ni 21.3%, Si 0.9%, Mn 1.4%, N 0.19%, Nb 0.5%, Al 0.002%, Ti 0.001%, Fe balance.

[0032] The Nb-containing austenitic heat-resistant steel of this embodiment is processed through the following processes:

[0033] (1) According to the composition of the Nb-containing austenitic heat-resistant steel in this embodiment, it is smelted into an ingot that meets the requirements by means of vacuum induction melting;

[0034] (2) Heat the ingot at 1300°C for 2 hours for high-temperature solid solution to ensure complete dissolution of primary carbides in the structure and eliminate dendrite segregation in the steel ingot;

[0035] (3) In order to ensure the compactness and uniformity of the structure, the steel ingot obtained in step (2) was furnace-cooled to 1200°C and forged. The initial forging temperature was 1200°C and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com