Ferritic stainless steel with good wrinkle resistance and production method thereof

A production method and ferrite technology, which is applied in the field of stainless steel product manufacturing, can solve the problems of increasing the grinding amount of casting billets, affecting the production rhythm, increasing process costs, etc., so as to improve surface quality and comprehensive performance, and reduce casting billet grinding Feasible effect of quantity and production process

Inactive Publication Date: 2010-09-29

BAOSHAN IRON & STEEL CO LTD

View PDF2 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The problem with the above two methods is that the first method cannot completely eliminate the wrinkling problem of the cold-rolled sheet, but also affects the surface quality of the continuous casting slab, increases the grinding amount of the slab, and increases the brittle transition temperature of the steel

The second method wastes energy, increases process costs and affects production rhythm

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0032] Below in conjunction with embodiment the present invention is described further.

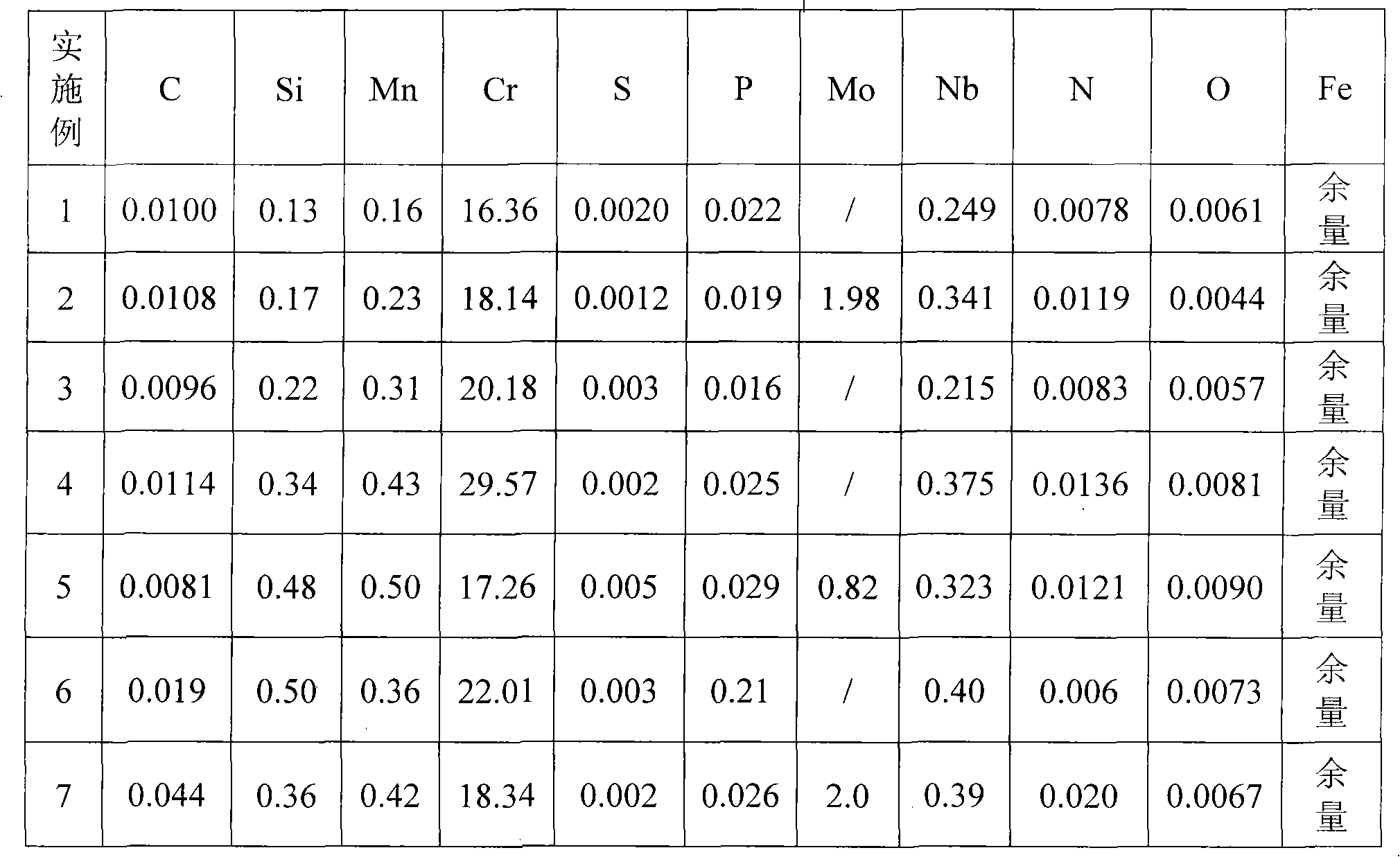

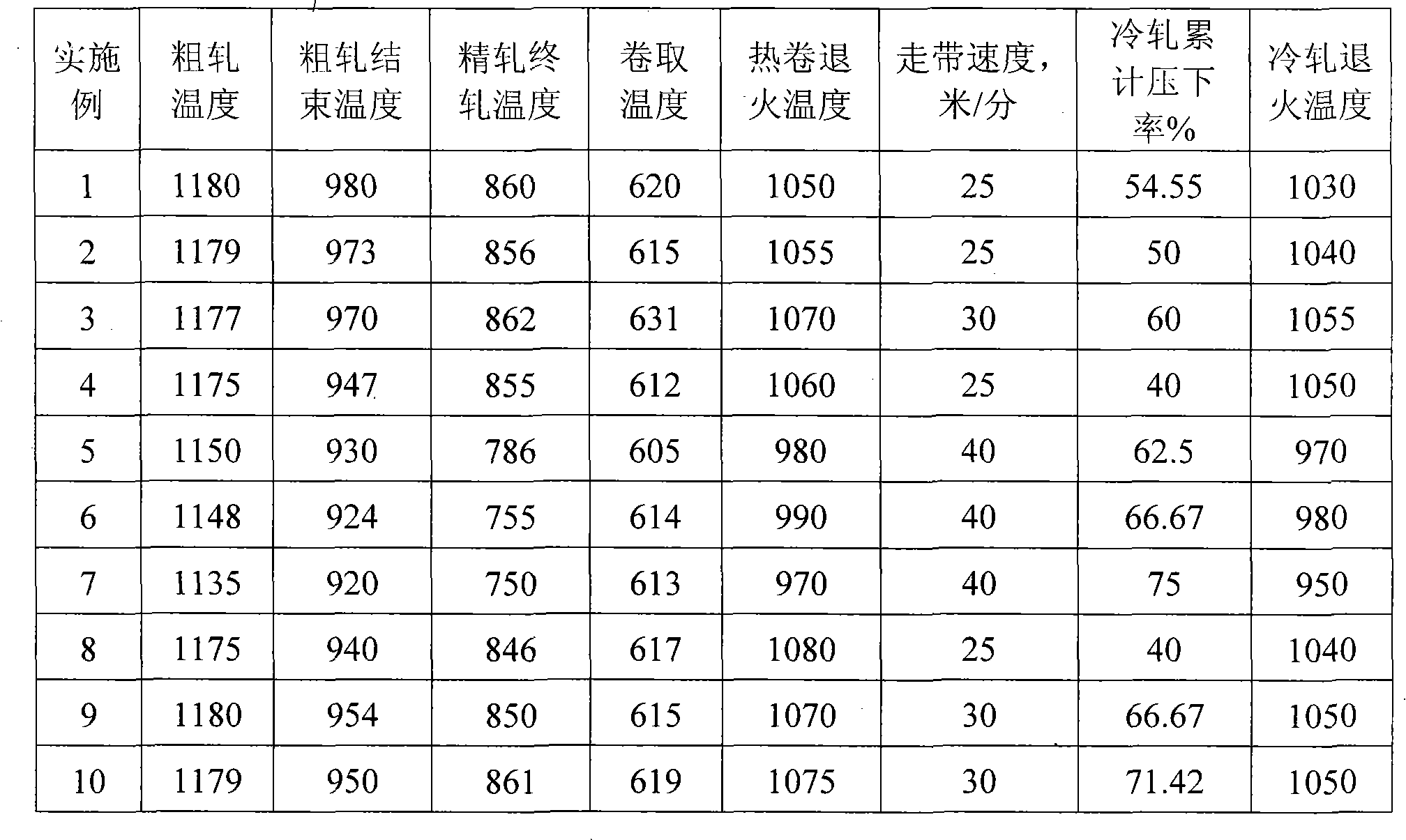

[0033] Table 1 shows examples of ferritic stainless steel with single stable chemical composition of Nb; Table 2 shows examples produced by different hot rolling processes and heat treatment and annealing process systems.

[0034] Table 1

[0035]

[0036] Table 2

[0037]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to ferritic stainless steel with good wrinkle resistance and a production method thereof. The ferritic stainless steel comprises the following components by weight percentage: less than or equal to 0.02 percent of C, less than or equal to 0.02 percent of N, 0.10-0.50 percent of Si, 0.10-0.50 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.01 percent of S, 16-30 percent of Cr, less than or equal to 1.00 percent of Ni, 0.15-0.40 percent of Nb, less than or equal to 16 percent of Nb / (C+N), less than or equal to 0.010 percent of O, less than or equal to 1.00 percent of Cu and the rest being Fe and inevitable impurity elements. Since the stabilization element Ti which can damage the surface quality of continuous casting and increase the brittle transition temperature is not added, and only the stabilization element Nb is added, the invention can reduce the quantity of casting blank repair and the strip breakage risk, improve the surface quality and overall performance, eliminate the wrinkle of the surface of the ferriticstainless steel cold-rolled plate with a medium and high Cr content, reduce the wear and repair loss during the production process, and decrease the production cost.

Description

technical field [0001] The invention belongs to the field of stainless steel product manufacturing, and mainly relates to the use of monostable element Nb to form precipitates with C and N in ferritic stainless steel, improve the comprehensive performance of ferritic stainless steel, and combine the manufacturing process to improve pure ferrite Surface wrinkling of stainless steel after cold rolling. Background technique [0002] Ferritic stainless steel, especially medium and high Cr ultra-pure ferritic stainless steel with low C and N content is more and more popular. This is because compared with the traditional ferritic stainless steel with high C and N content, its corrosion resistance and processing performance are greatly improved, and its comprehensive performance is better than nickel-containing austenitic stainless steel in many applications. Body stainless steel. However, when the medium and high Cr ferritic stainless steel is used to produce cold-rolled thicker...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/26C22C38/48C21D8/02

Inventor 徐军崔培耀沈春飞

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com