Patents

Literature

52results about How to "Reduce the risk of belt breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

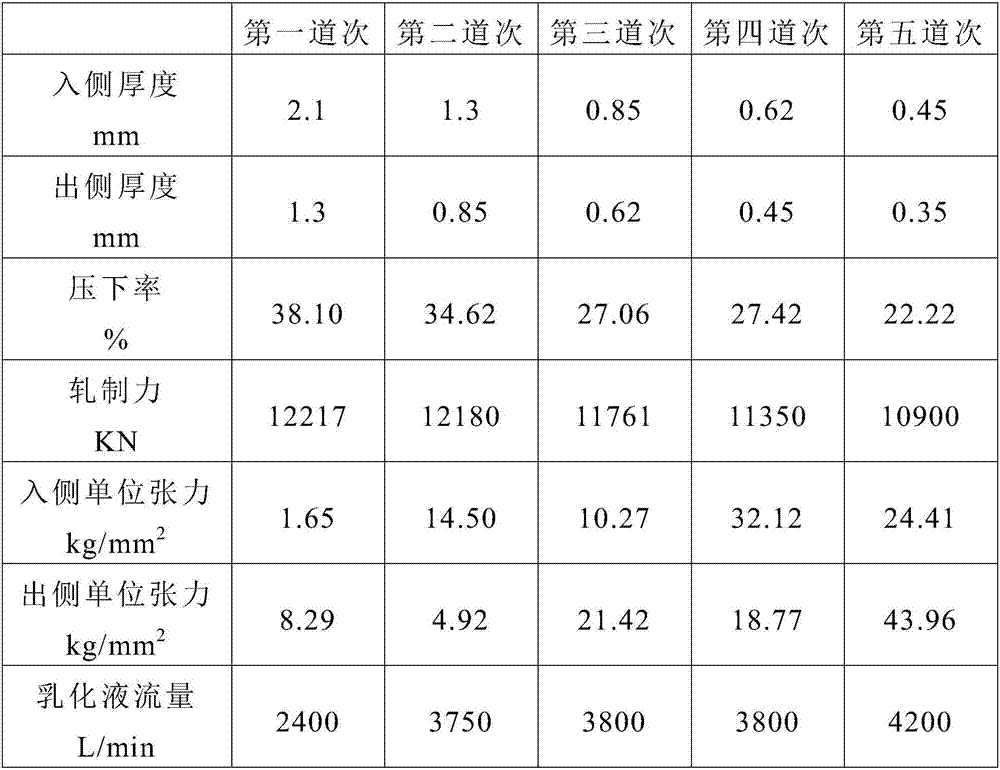

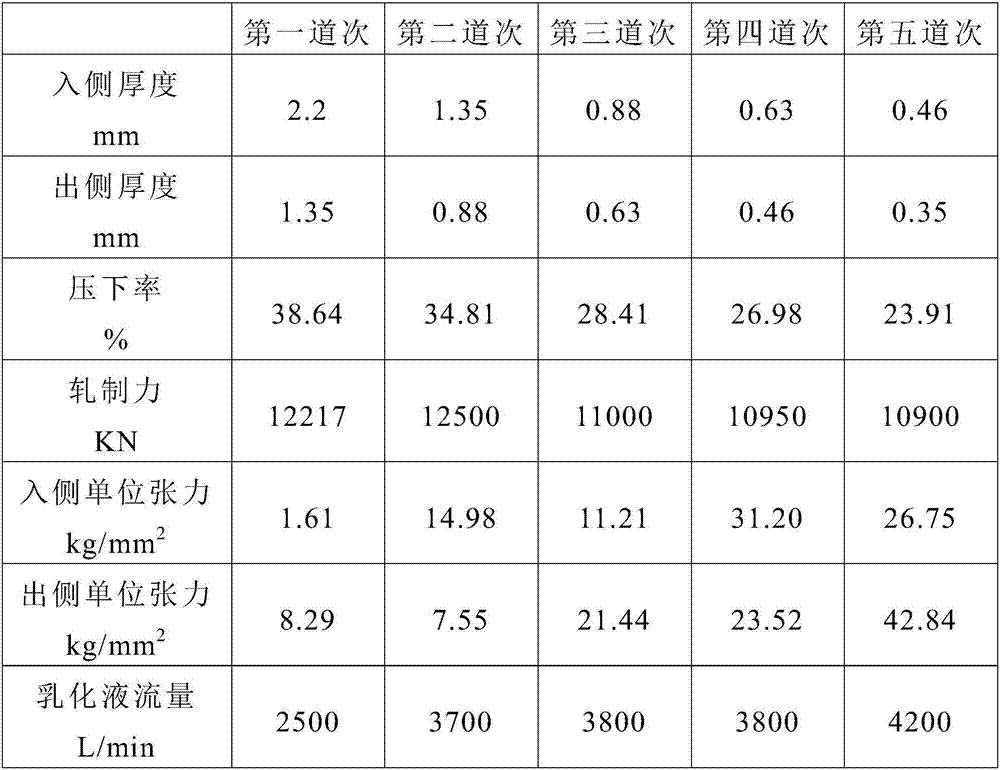

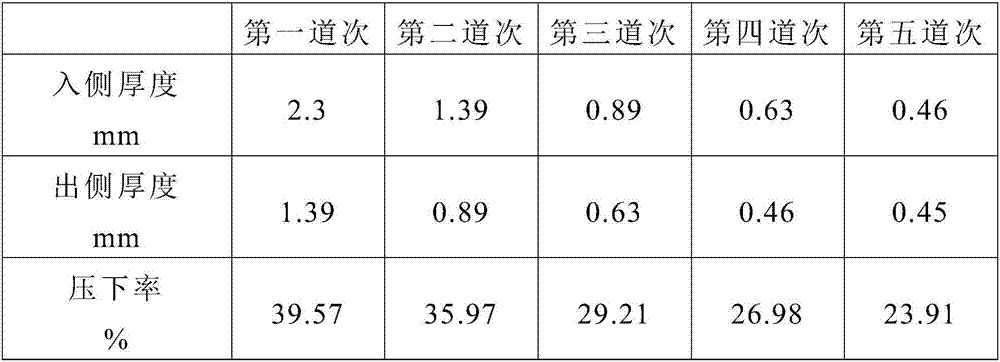

Cold rolling method for high grade non-oriented silicon steel through hot rolling, acid pickling and non-edge-cutting

ActiveCN107962075ALow costReduce resistanceRoll force/gap control deviceTemperature control deviceReduction rateThermal expansion

The invention relates to the field of silicon steel cold rolling, and discloses a cold rolling method for high grade non-oriented silicon steel through hot rolling, acid pickling and non-edge-cutting.The cold rolling method comprises the following steps that a steel coil is obtained, non-edge-cutting normalizing acid pickling is carried out, then a one-time cold rolling method is adopted for continuous reversible type five-pass cold rolling, the reduction rate, rolling force, entry side unit tension and exit side unit tension of each pass are controlled, emulsified liquid spraying is adoptedin rolling for process lubricating and cooling, thermal expansion adjustment steel coil plate shape of a working roll is controlled in a partitioned cooling mode, a rolled product is obtained, and then subsequent procedures are conducted conventionally. The cold rolling method for high grade non-oriented silicon steel through hot rolling solves the problems of poor rolling efficiency and poor finished product rate of high silicon content varieties.

Owner:武汉钢铁有限公司

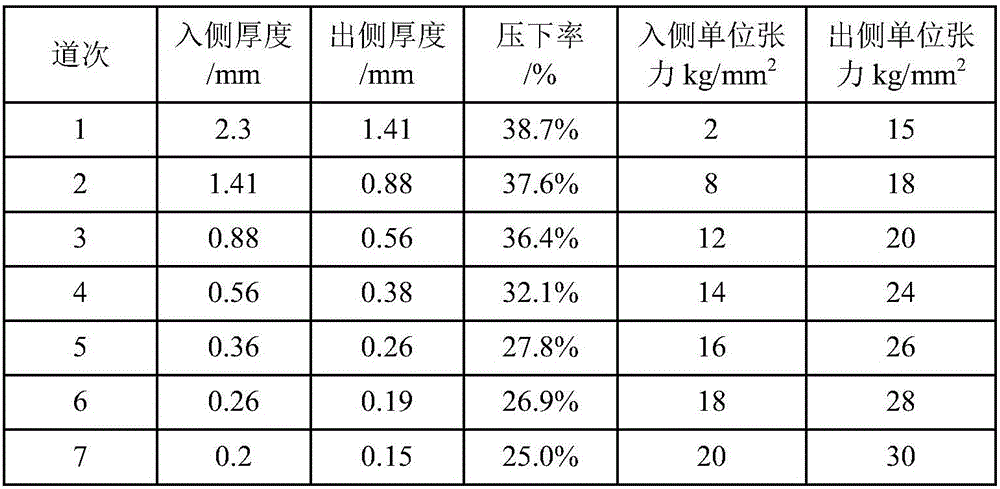

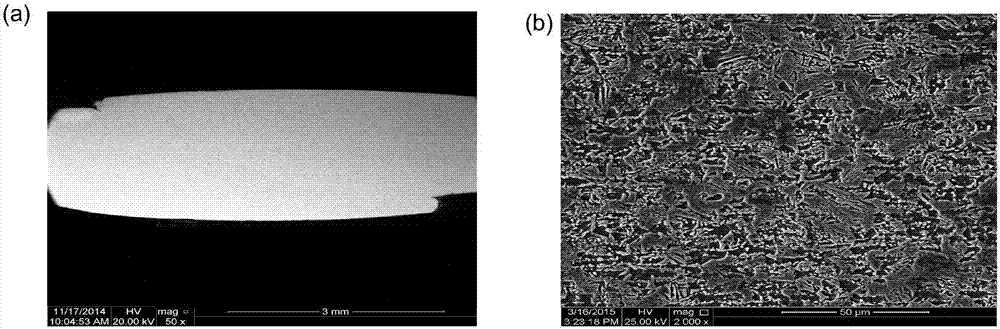

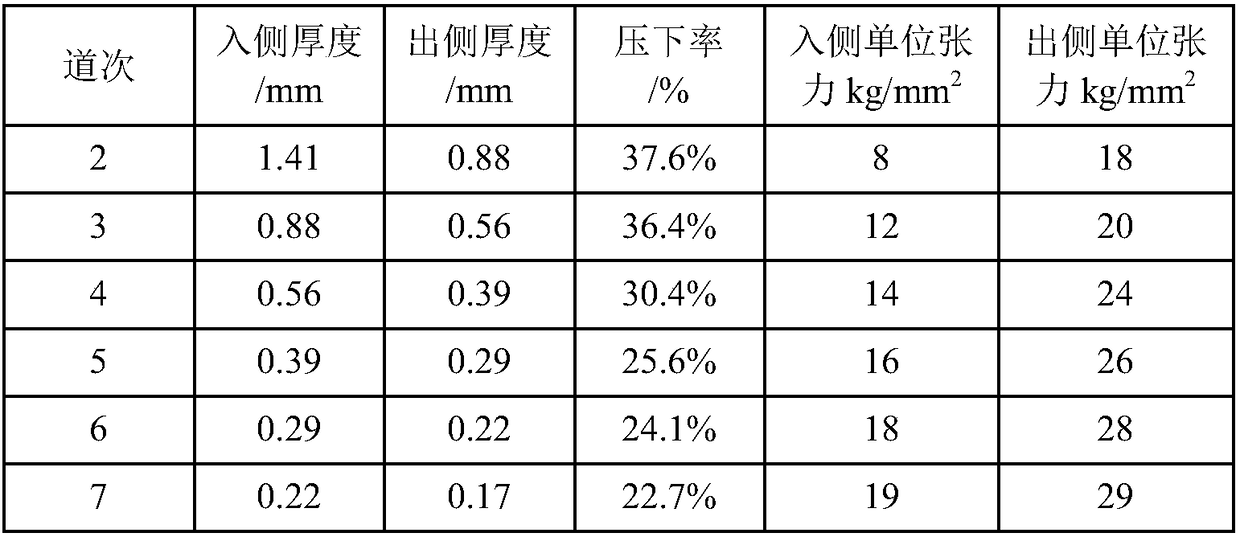

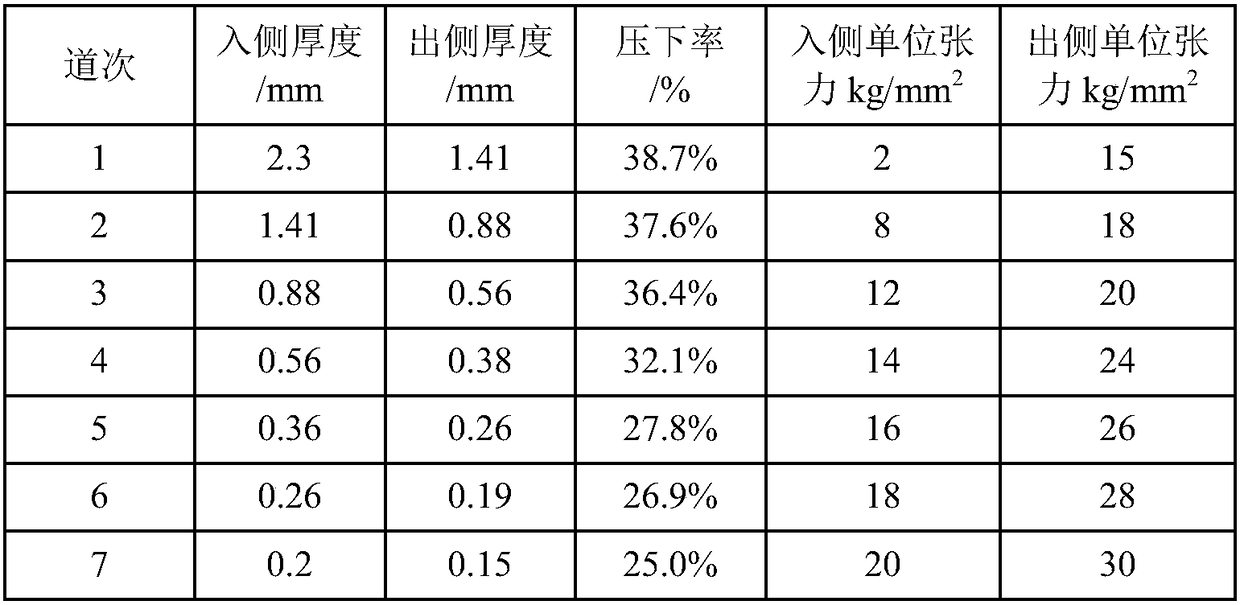

Cold rolling method for high-magnetic-induction grain-oriented silicon steel in extremely thin specification

ActiveCN106583448ARealize aging rollingPrevent brittle fractureMetal rolling arrangementsReduction rateRough surface

The invention discloses a cold rolling method for high-magnetic-induction grain-oriented silicon steel in the extremely thin specification. The method comprises steps as follows: (1) the thickness before rolling ranges from 2.0 mm to 2.5 mm, and normalization pickling is performed; (2) the primary cold rolling method is adopted, and continuous reversible seven-pass cold rolling is performed: (2.1) rough-surface working rolls are adopted for the first five passes, and fine-surface working rolls are adopted for the last two passes; (2.2) the reduction rate of each pass is controlled, the reduction rate of the first pass ranges from 30% to 45%, the reduction rate of the last pass ranges from 18% to 31%, and the reduction rates of the rest passes range from 24% to 42%; (2.3) technological lubrication and cooling are performed through emulsion spraying; the plate temperature in the first three passes is controlled to gradually increased to 200-230 DEG C; the temperature is reduced for rolling in the fourth pass; the plate temperature in the subsequent passes is controlled to be 60-80 DEG C; (2.4) automatic plate shape control is performed; (2.5) the rolling force in each pass is controlled to range from 250 T to 520 T; the unit tension on the entrance side of each pass is controlled to range from 2 kg / mm<2> to 20 kg / mm<2>, and the unit tension on the exit side of the pass is controlled to range from 15 kg / mm<2> to 30 kg / mm<2>; (2.6) the product thickness after rolling ranges from 0.15 mm to 0.2 mm; (3) subsequent procedures are conducted conventionally. With the method, the production efficiency of the high-end silicon steel in the extremely thin specification is substantially increased, and products are free of plate shape quality defects and are high in surface quality.

Owner:武汉钢铁有限公司

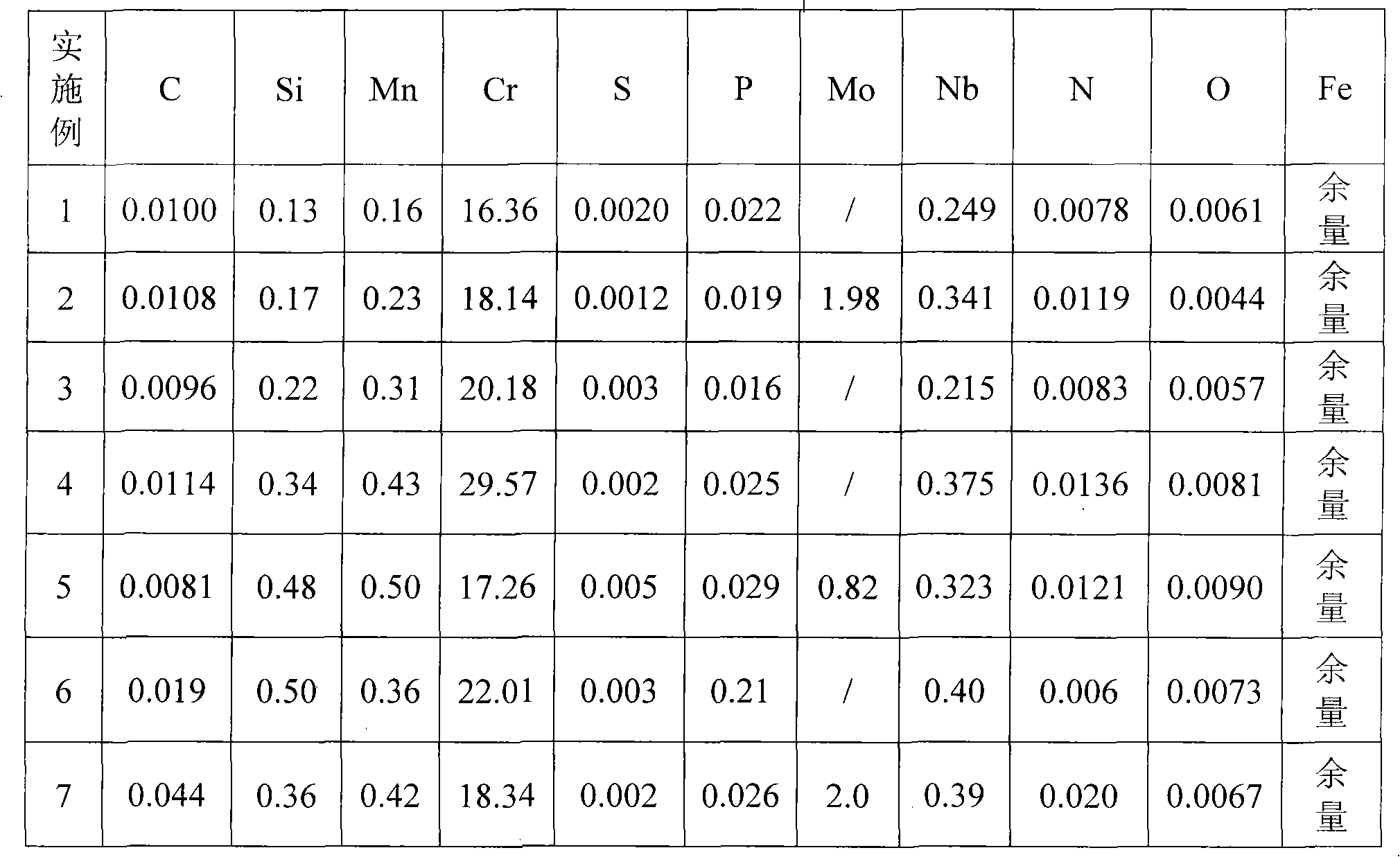

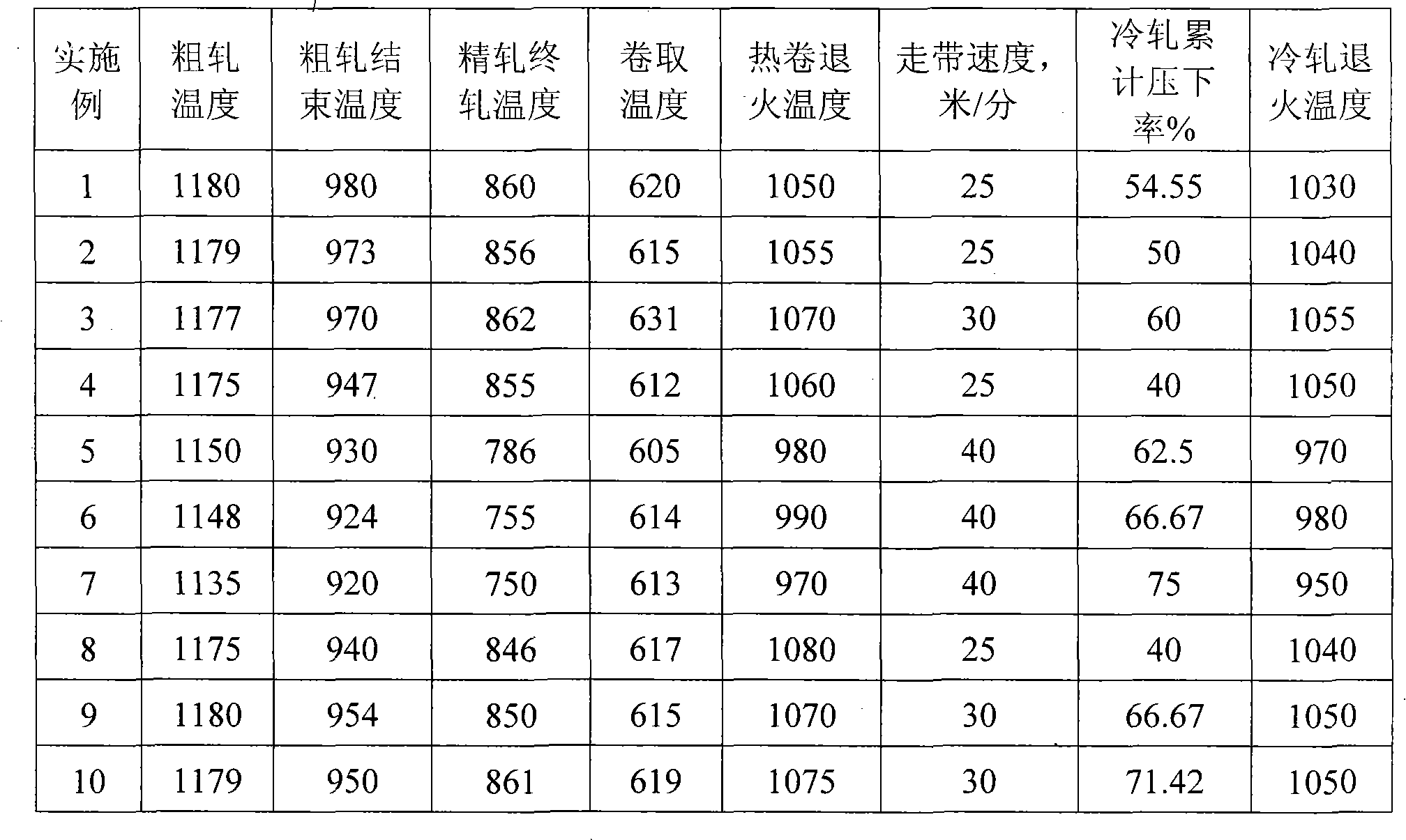

Ferritic stainless steel with good wrinkle resistance and production method thereof

InactiveCN101845595AGood wrinkle effectProduction process is feasibleWrinkle skinTransition temperature

The invention relates to ferritic stainless steel with good wrinkle resistance and a production method thereof. The ferritic stainless steel comprises the following components by weight percentage: less than or equal to 0.02 percent of C, less than or equal to 0.02 percent of N, 0.10-0.50 percent of Si, 0.10-0.50 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.01 percent of S, 16-30 percent of Cr, less than or equal to 1.00 percent of Ni, 0.15-0.40 percent of Nb, less than or equal to 16 percent of Nb / (C+N), less than or equal to 0.010 percent of O, less than or equal to 1.00 percent of Cu and the rest being Fe and inevitable impurity elements. Since the stabilization element Ti which can damage the surface quality of continuous casting and increase the brittle transition temperature is not added, and only the stabilization element Nb is added, the invention can reduce the quantity of casting blank repair and the strip breakage risk, improve the surface quality and overall performance, eliminate the wrinkle of the surface of the ferriticstainless steel cold-rolled plate with a medium and high Cr content, reduce the wear and repair loss during the production process, and decrease the production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

High-efficiency non-oriented silicon steel and preparation method thereof

InactiveCN110042310AReduce iron lossReduce the risk of belt breakageIncreasing energy efficiencySteelmakingChemical composition

The invention discloses high-efficiency non-oriented silicon steel and a preparation method thereof. The high-efficiency non-oriented silicon steel comprises the chemical components in percentage by mass of at most 0.005% of C, 1.0-2.0% of Si, 0.2-0.8% of Als, 0.25-0.8% of Mn, 0.01-0.05% of Sn, at most 0.02% of P, at most 0.0040% of S, at most 0.0020% of N, at most 0.0020% of Nb, at most 0.0020% of V, at most 0.0020% of Ti and the rest of Fe and unavoidable impurities. The high-efficiency non-oriented silicon steel and the preparation method have the advantages that by the strict component control in steelmaking, the impurity elements meeting the target requirement is ensured; by hot skin rolling, high temperature normalizing, induction heating before cold rolling, annealing and rapid warming and a low temperature long-time insulation process, the high-efficiency non-oriented silicon steel is obtained; and the iron loss of a finished product is P1.5 / 50<=3.2W / kg, and magnetic inductionis B50>=1.73T.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +2

Aging-resistant tinplated substrate and manufacturing method thereof

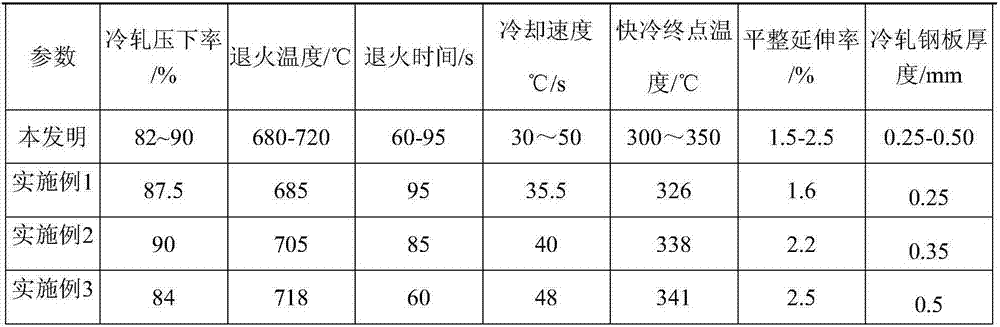

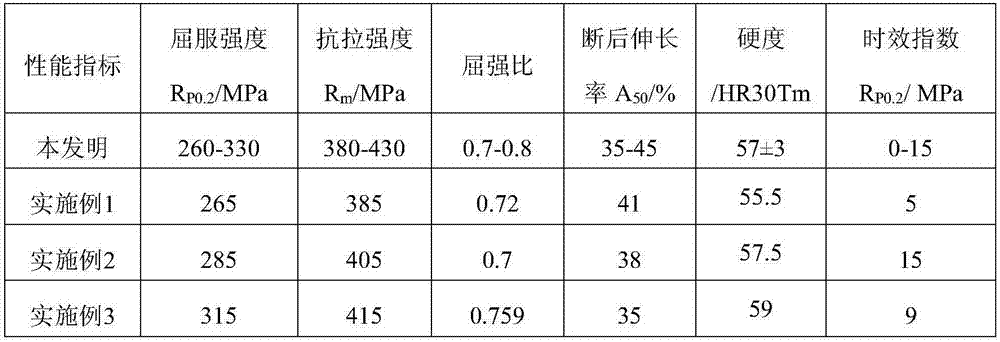

The invention relates to an aging-resistant tinplated substrate and a manufacturing method thereof. The technical problems that in the prior art, tinplated substrates with the hardness value being 57+ / -3HR30Tm are low in aging resistance and poor in plate shape and surface quality are solved. The aging-resistant tinplated substrate contains 0-0.005% of C, 0-0.04% of Si, 0.3%-0.5% of Mn, 0.05%-0.08% of P, 0-0.02% of S, 0.01%-0.06% of Alt, 0-0.005% of N, 0.04%-0.08% of Ti, and the balance iron and unavoidable impurities. The yield strength R<p0.2> of the tinplated substrate is 260-330 MPa, the yield ratio of the tinplated substrate is 0.7-0.8, the after-fracture percentage elongation A<50> of the tinplated substrate is 35%-45%, and the aging index AI value of the tinplated substrate is 0-15MPa. The aging-resistant tinplated substrate and the manufacturing method thereof are mainly used for substrates of cans and covers with the aging requirement or complicated deformation.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Lap resistance welding method of high-strength strip steel with carbon equivalent being greater than 0.5

ActiveCN107138837ANo reserved spaceAdd induction heating and other annealing hot standby difficult situationWelding/soldering/cutting articlesResistance welding apparatusElectrical resistance and conductanceChemical composition

The invention discloses a lap resistance welding method of high-strength strip steel with the carbon equivalent being greater than 0.5. The lap resistance welding method comprises the following steps that a high-strength steel plate is welded on a narrow lap resistance welding machine; and after the welding is completed, a postweld heat treatment technology is carried out. The high-strength strip steel mainly comprises the following chemical components, by weight percentage, less than or equal to 0.30% of C, less than or equal to 0.80% of Si, less than or equal to 1.50% of Mn, less than or equal to 0.035% of P, 0.030% of S and the balance Fe and other microelements. The tensile strength Rm of a rolled hard coil of the high-strength strip steel is greater than or equal to 800MPa. By adopting an automatic resistance welding technology for connecting the strip steel and by matching with postweld heat treatment, the welding residual stress is eliminated, a welding joint structure is improved, and continuous stable production of high-strength steel plate products is ensured.

Owner:MAANSHAN IRON & STEEL CO LTD

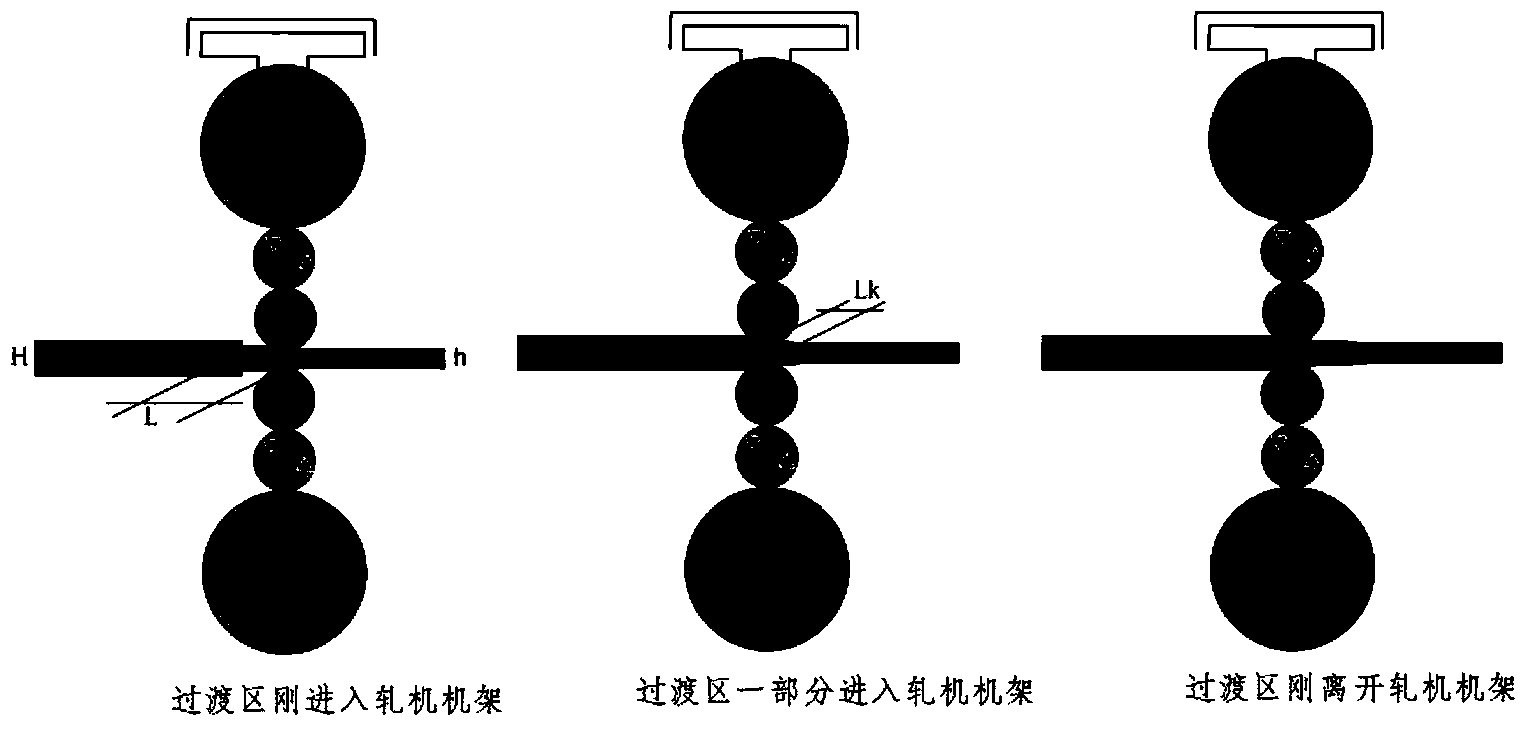

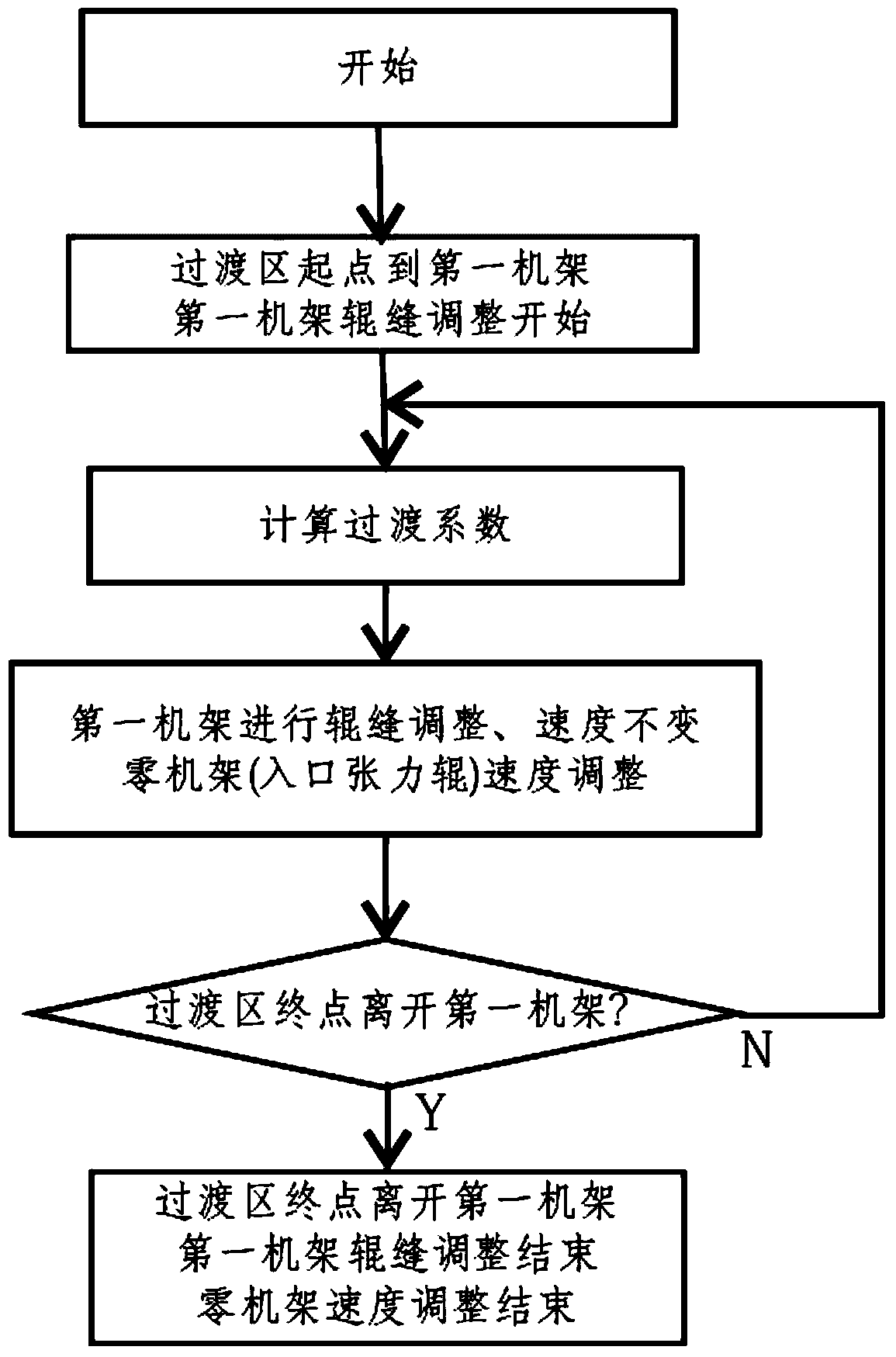

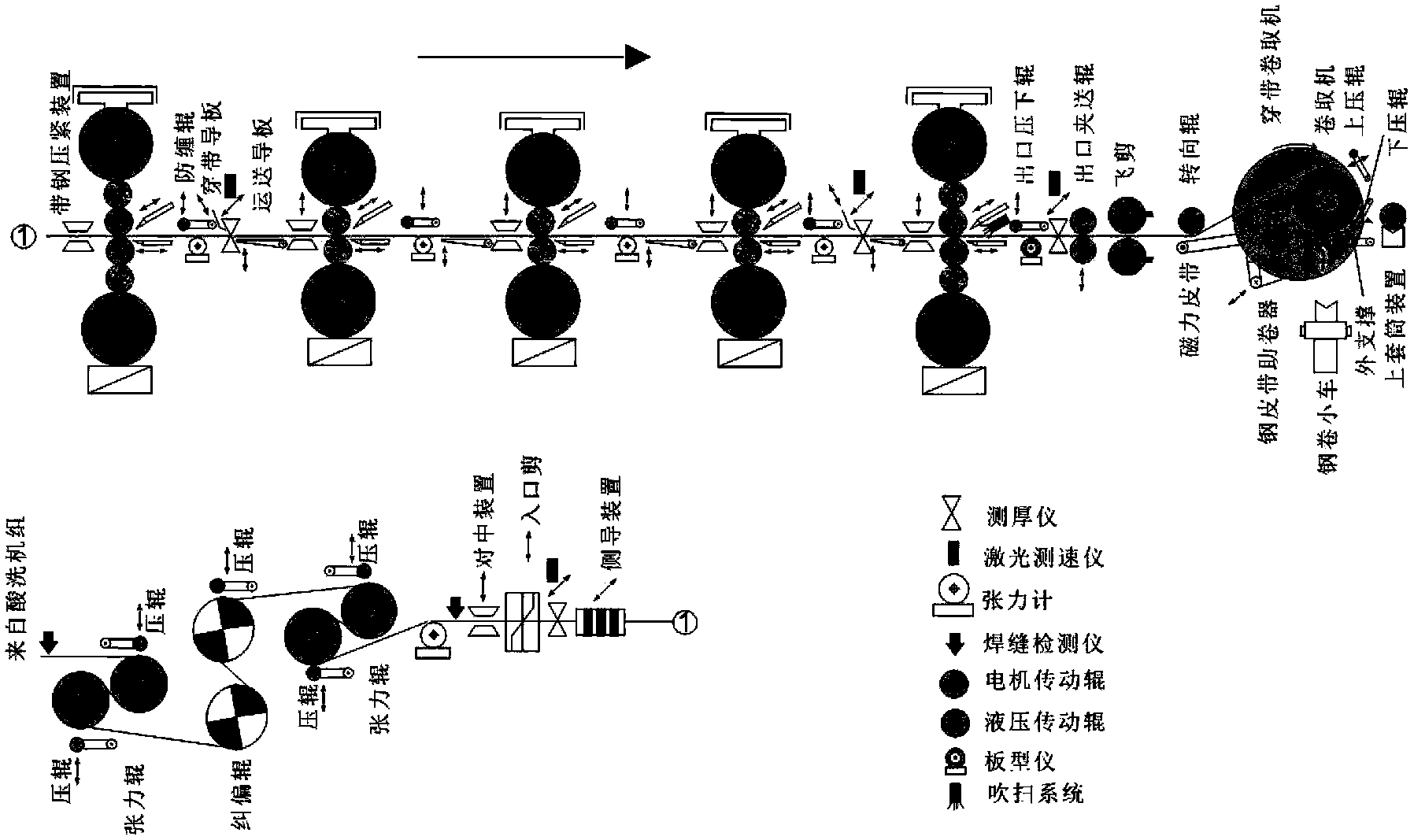

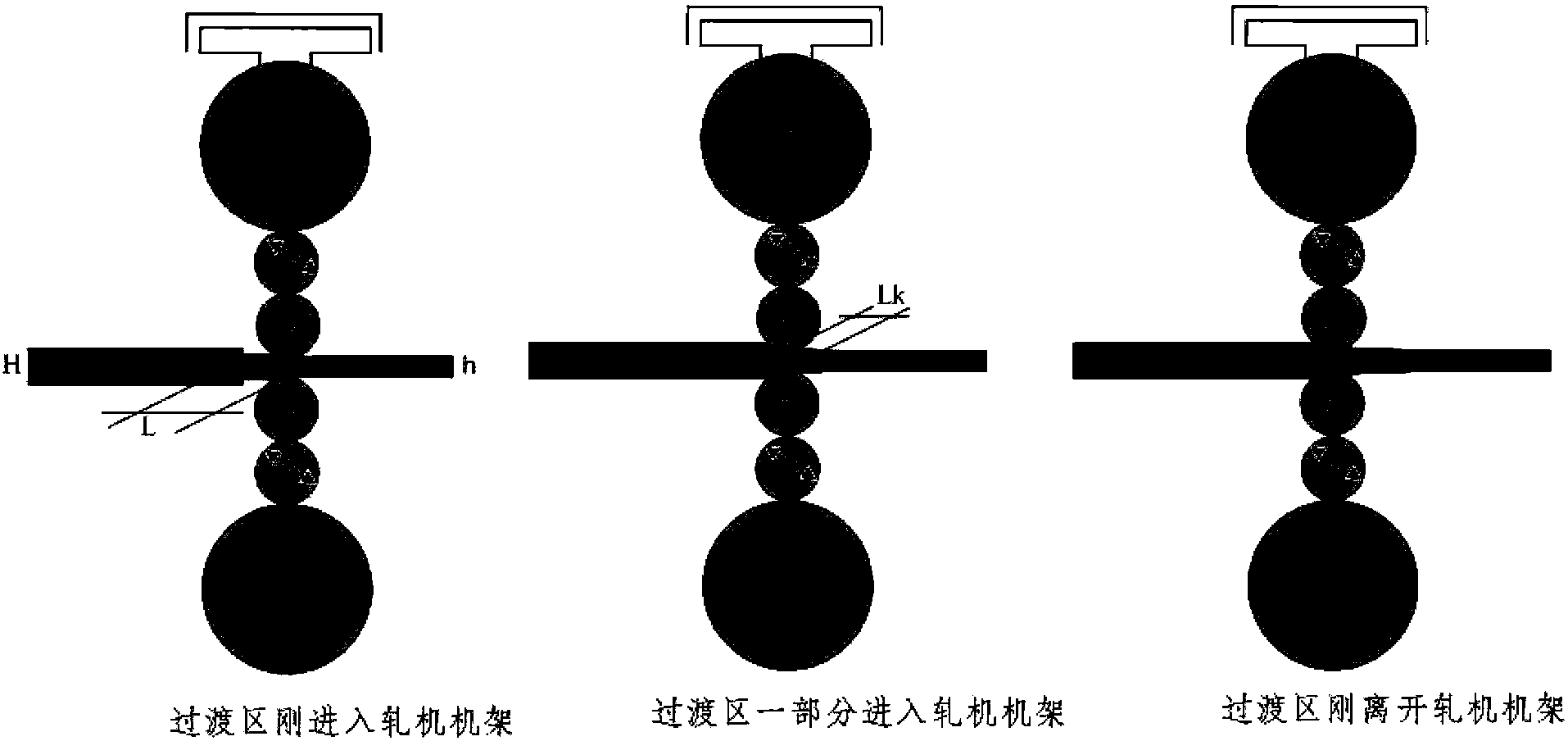

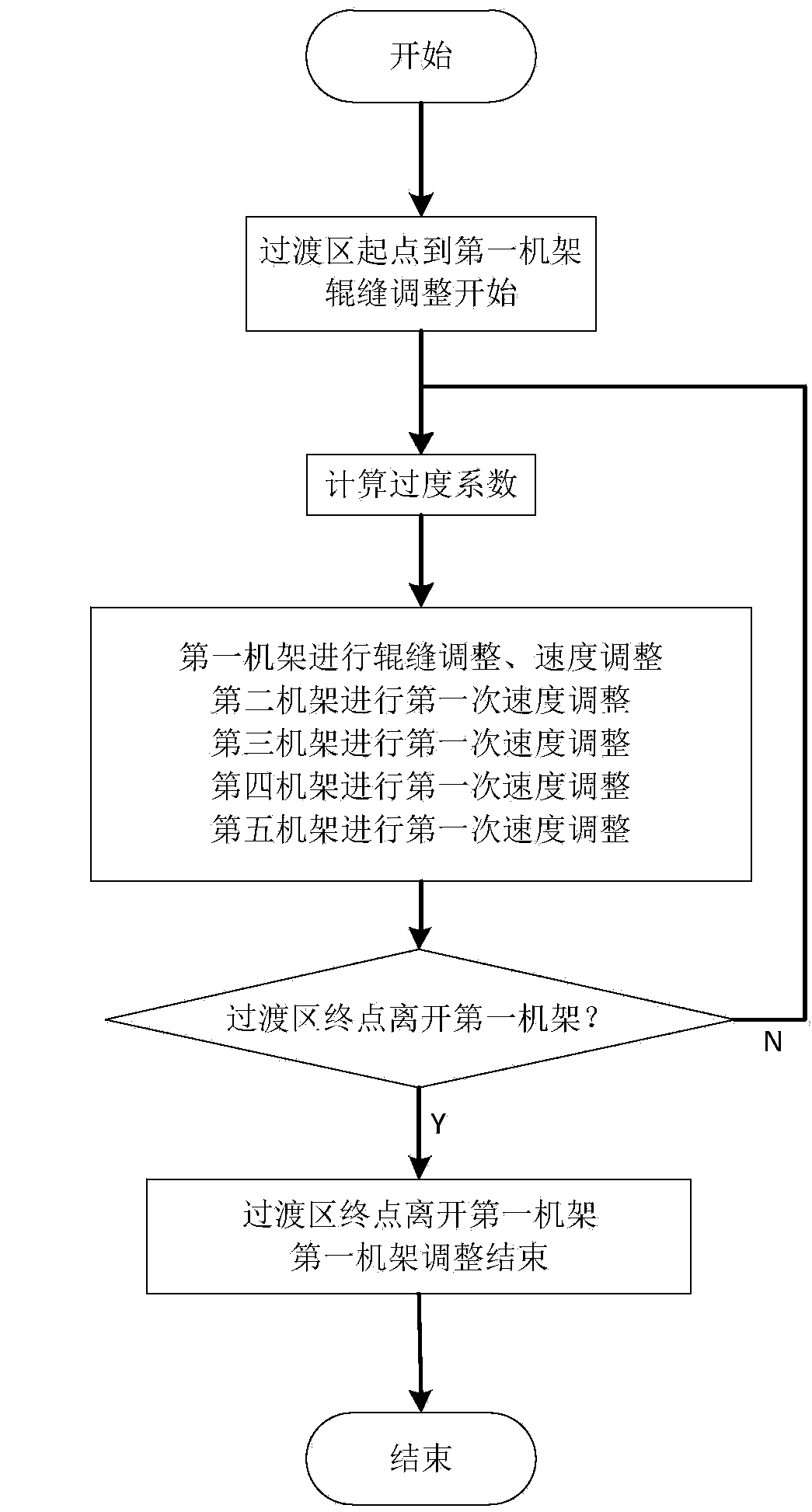

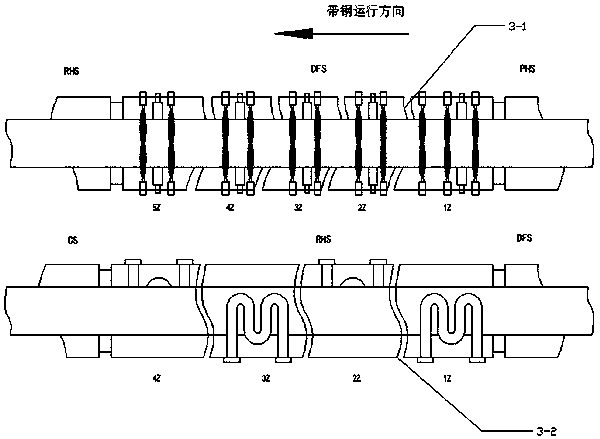

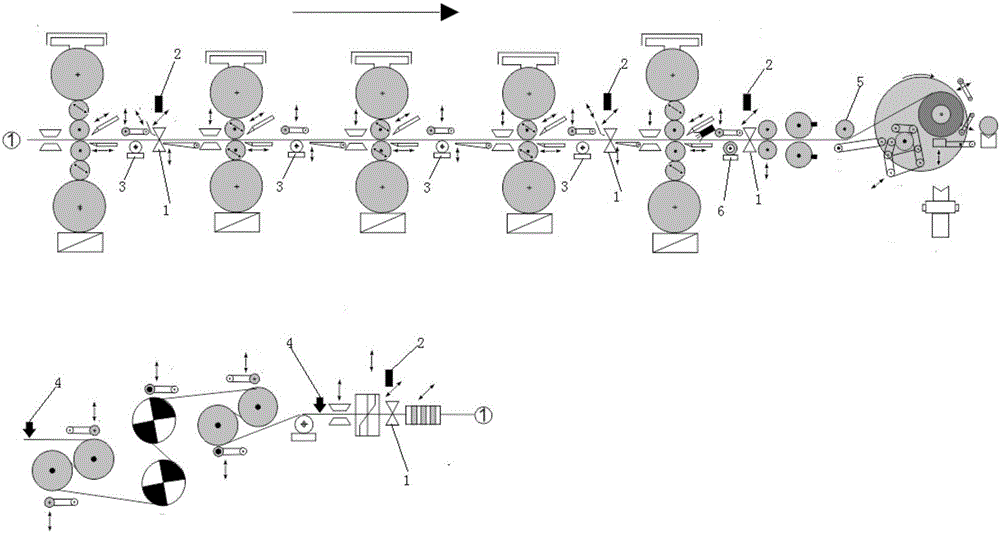

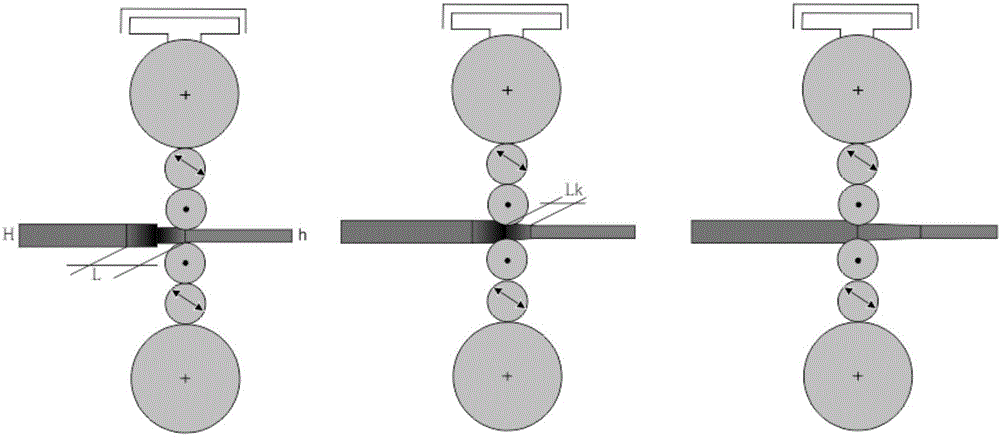

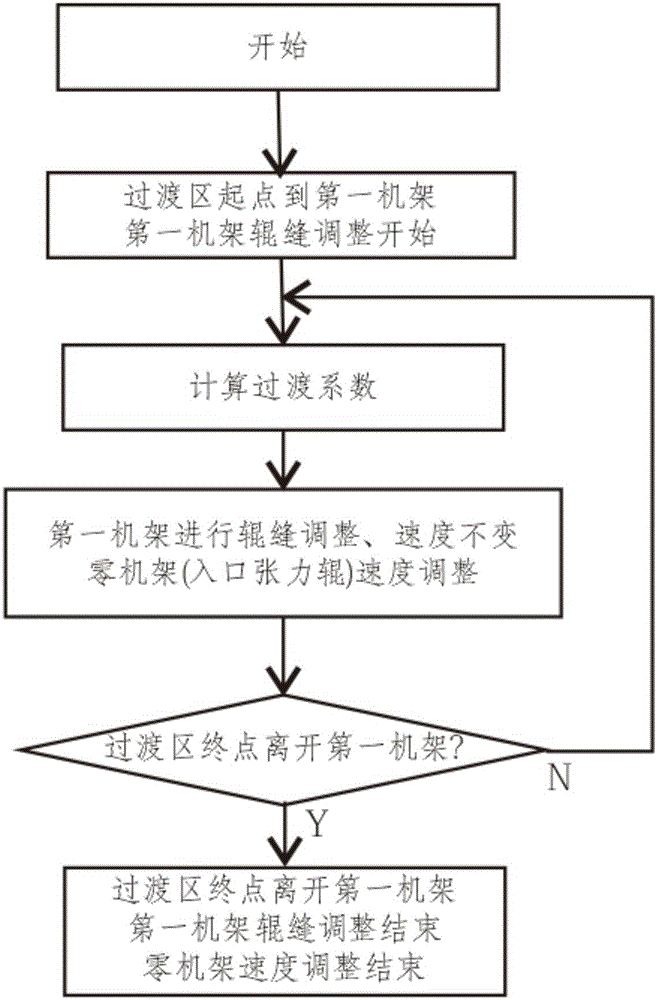

Flying gauge change control method of tandem cold mill

ActiveCN103551389AReduce tension fluctuationsQuality improvementRoll mill control devicesMetal rolling arrangementsEngineeringChange control

The invention discloses a flying gauge change method for a five-rack tandem cold mill. The method comprises the following steps of determining a transition region of flying gauge change; calculating a transition coefficient according to the length of the transition region, the original thickness of band steel before rolling of each rack and the set thickness of the band steel after rolling of each rack; in a transition process, calculating a dynamically adjusted roll gap set value of each rack according to the transition coefficient, and regulating the band steel outlet speed of each rack according to reverse flow. By the adoption of the flying gauge change method, a flying gauge change process of the five-rack tandem cold mill can be optimized, the stability of the flying gauge change is improved, equipment impact is reduced, the out-of-tolerance of the band steel is reduced, the speed of the flying gauge change is increased, and the time of the flying gauge change is shortened.

Owner:WISDRI WUHAN AUTOMATION

Flying gauge change control method of tandem cold mill

ActiveCN104338753AReduce tension fluctuationsQuality improvementRoll mill control devicesMetal rolling arrangementsChange controlStrip steel

The invention discloses a flying gauge change control method of a tandem cold mill. The method comprises the following steps: determining a transition region of flying gauge change, computing transition coefficients according to the length of the transition region, the original thickness of strip steel before the strip steel is rolled by a frame and the set thickness of the strip steel after the strip steel is rolled by the frame, computing a roll gap set value for dynamic adjustment of each frame according to the transition coefficients when a transition process is performed, and adjusting the strip steel discharge speed of each frame according to fair current. By adopting the method, the flying gauge change process of the tandem cold mill can be optimized, the smoothness of flying gauge change is improved, equipment impact is reduced, out-of-tolerance of strip steel is reduced, the speed of flying gauge change is increased, and the time of flying gauge change is shortened.

Owner:WISDRI WUHAN AUTOMATION

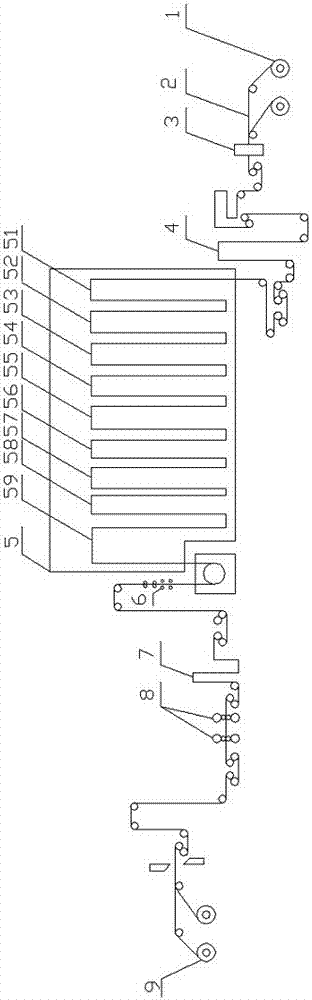

Rapid start method for vertical continuous annealing furnace

ActiveCN108070707AExtension of timeIncrease unit capacityFurnace typesHeat treatment furnacesStart timeHydrogen

The invention relates to a rapid start method for a vertical continuous annealing furnace. By adoption of the rapid start method for the vertical continuous annealing furnace, the problem that in theprior art, after a vertical continuous annealing furnace is stopped to be maintained, the furnace start time is long, and consequentially, the production rhythm and productivity are affected is solved. The rapid start method for the vertical continuous annealing furnace comprises the steps that after the vertical continuous annealing furnace is maintained, start conditions of the vertical continuous annealing furnace are confirmed; pure-nitrogen purging is conducted on the inside atmosphere of the vertical continuous annealing furnace; the vertical continuous annealing furnace is heated; hydrogen-containing purging is conducted on the inside atmosphere of the vertical continuous annealing furnace; and strip steel of the vertical continuous annealing furnace is controlled to start to operate. The rapid start method for the vertical continuous annealing furnace is simple and easy to operate, and the production efficiency and productivity of the vertical continuous annealing furnace are effectively improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

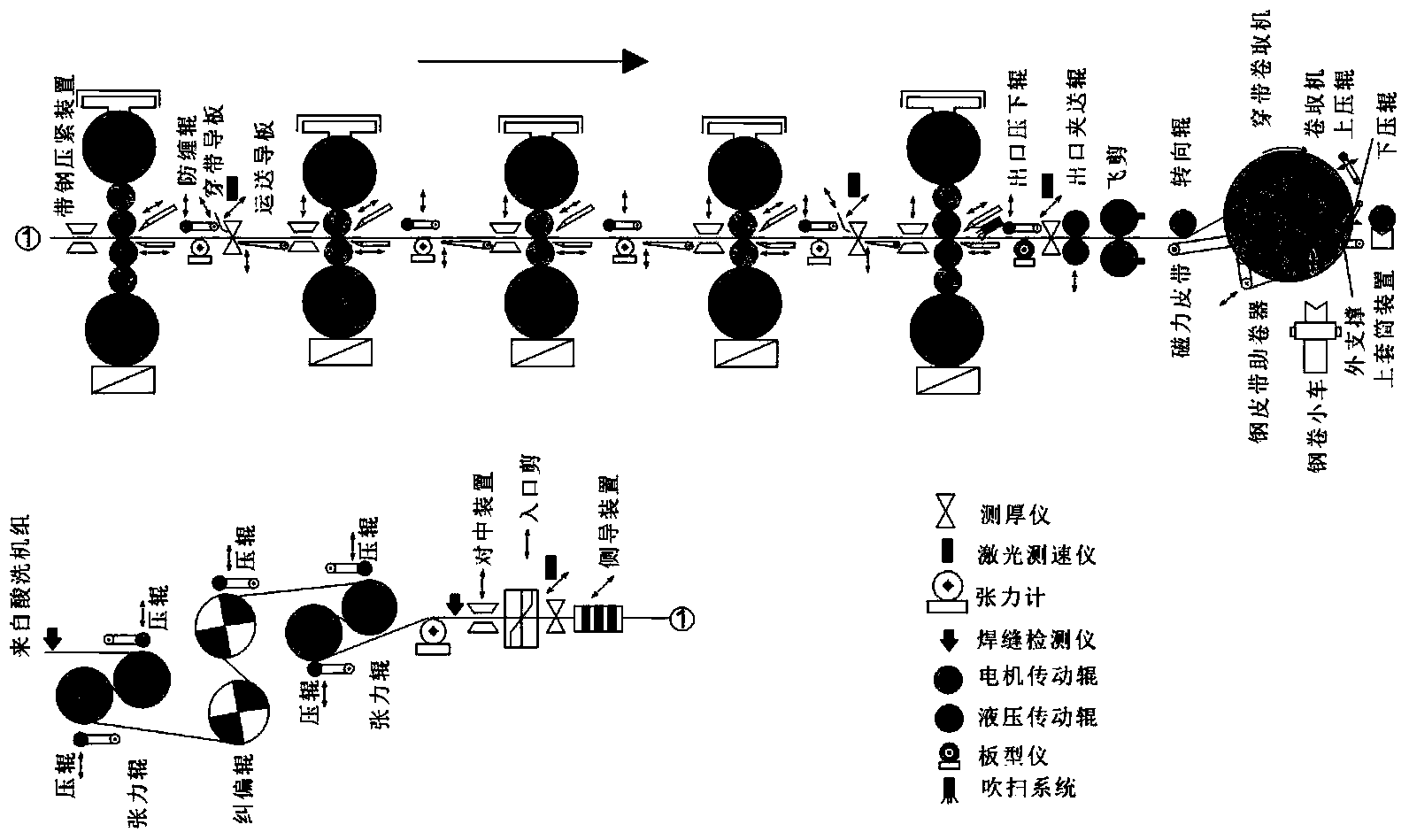

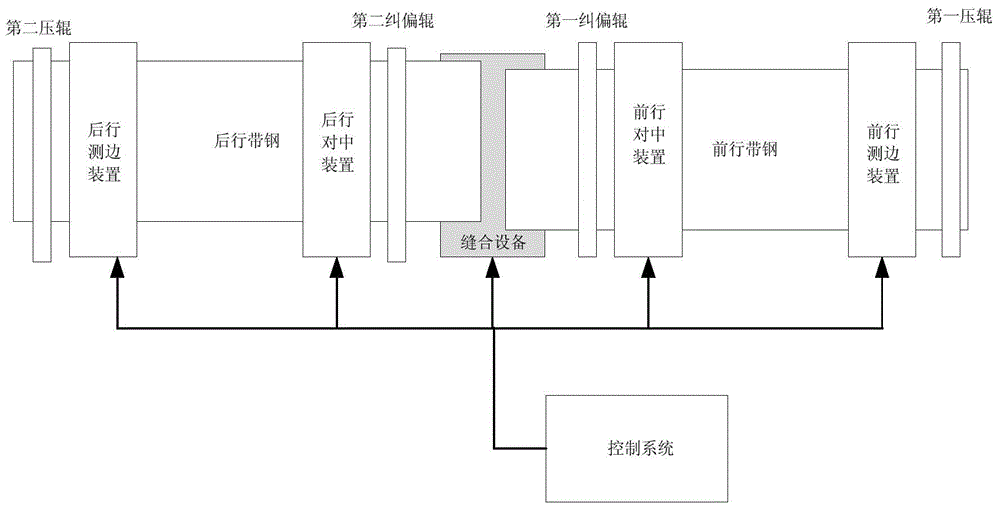

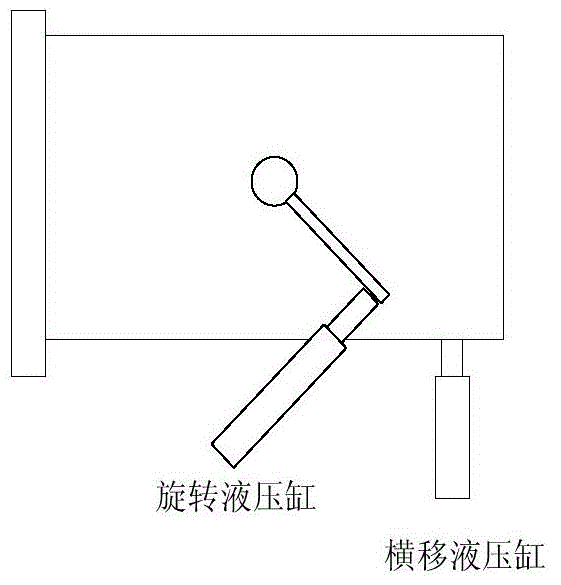

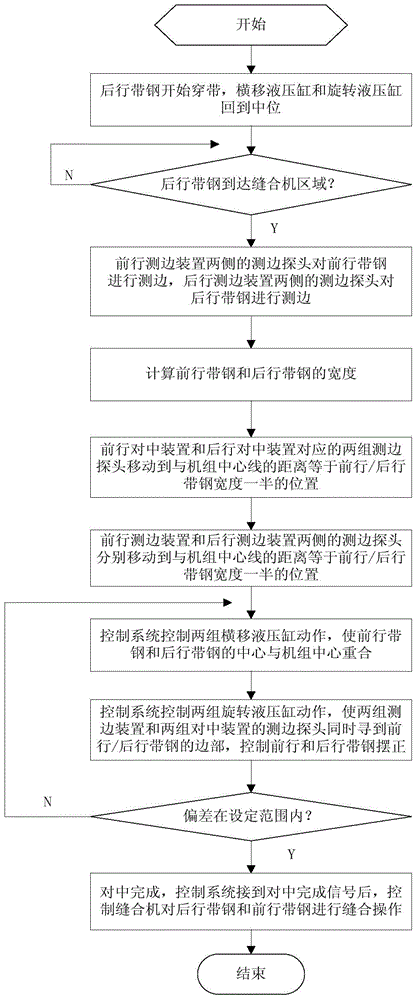

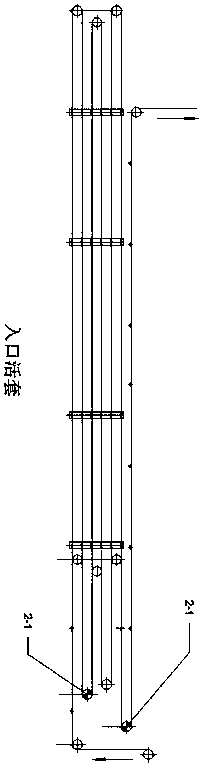

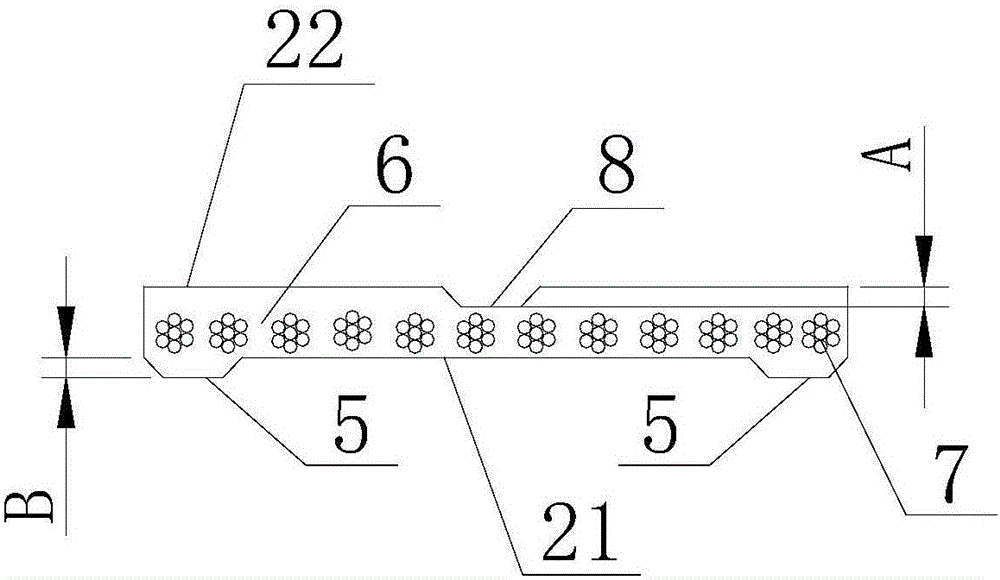

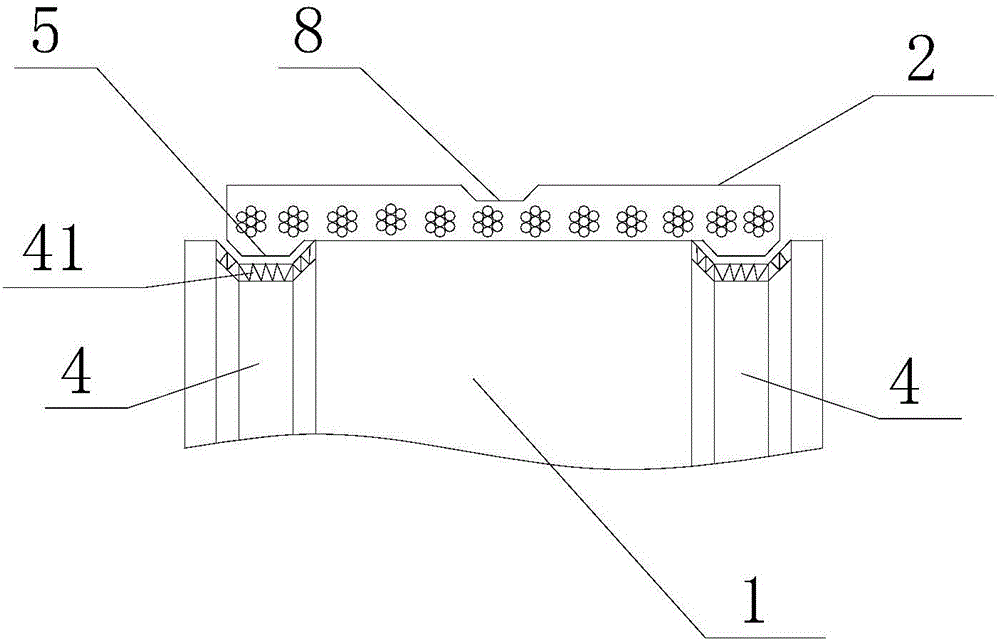

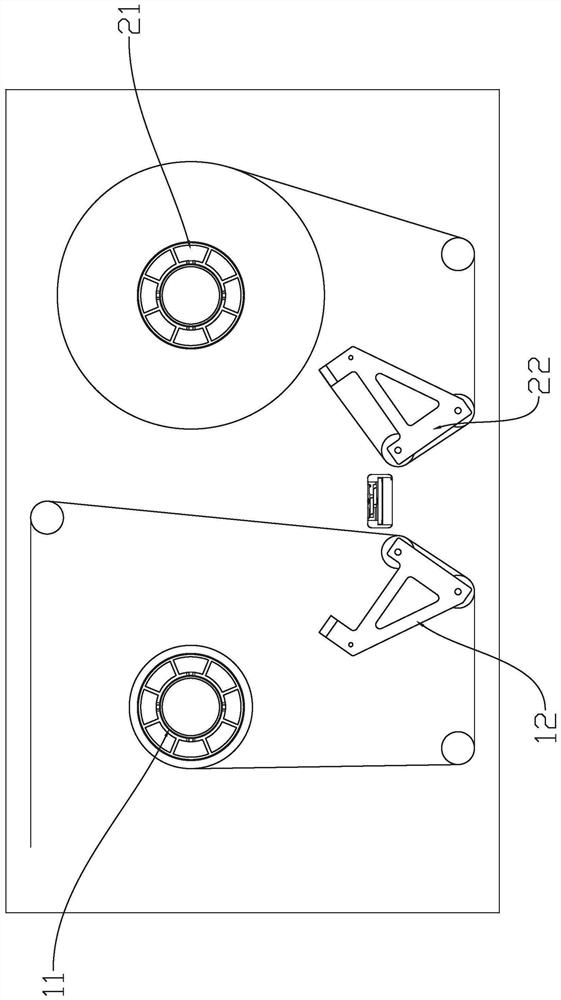

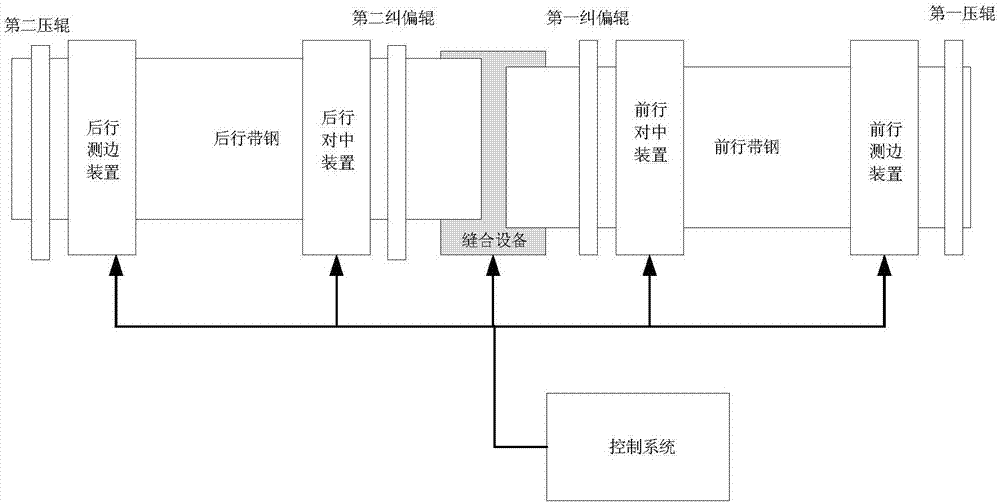

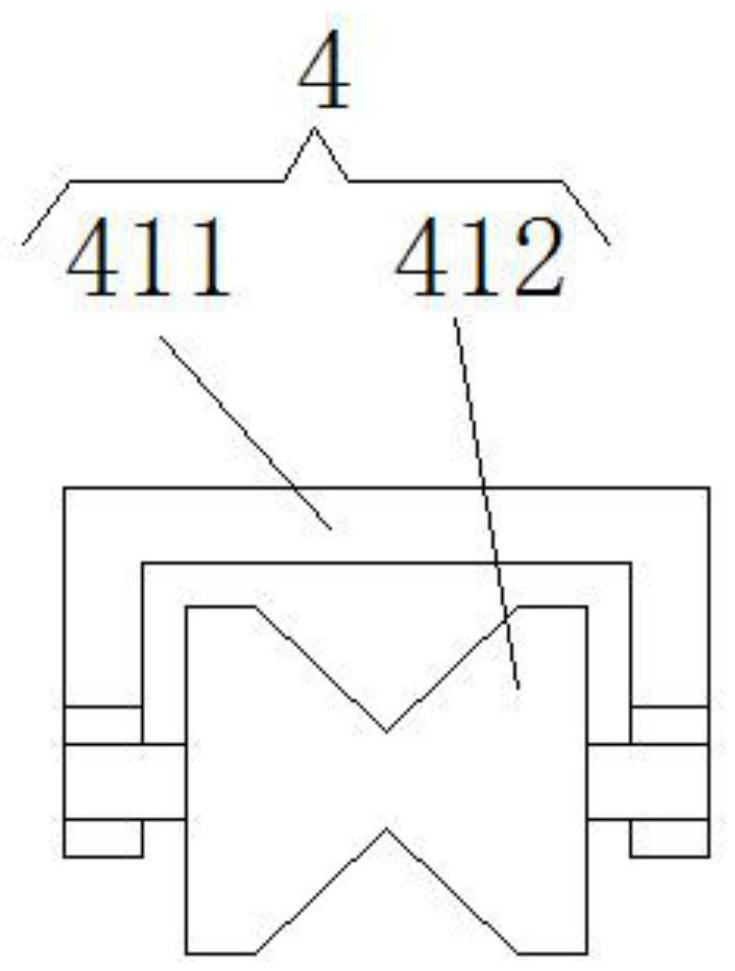

Control method and equipment for suturing and centering thin strip steel for continuous annealing furnace

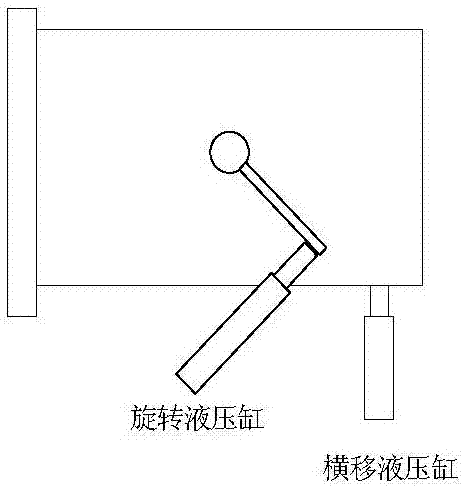

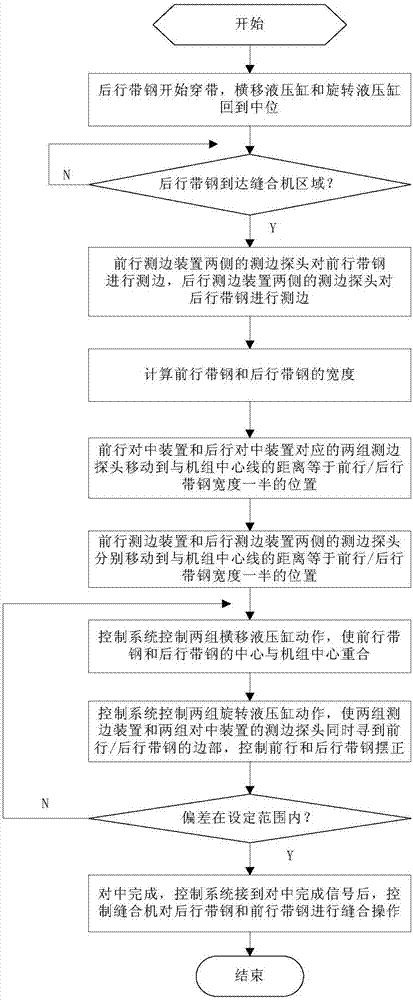

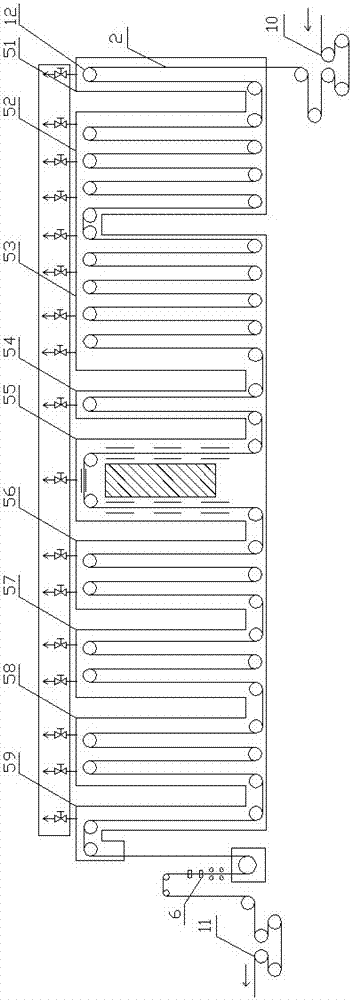

ActiveCN105618596AReduce the risk of belt breakageImprove sewing precisionMetal-working feeding devicesMetal working apparatusHydraulic cylinderStructural engineering

The invention relates to the technical field of strip steel rolling, in particular to a control method and equipment for suturing and centering thin strip steel for a continuous annealing furnace. According to the control method and equipment, centering devices and side measuring devices are respectively adopted in the front and the back of suturing equipment, the centering devices are mainly used for detecting whether the center position of the strip steel moving forwards and the center position of the strip steel moving backwards are located in the center position of a unit, and the side measuring devices are mainly used for detecting whether the strip steel moving forwards and the strip steel moving backwards are placed right, namely whether the center line of the strip steel is parallel with the center line of the unit; a horizontal-moving hydraulic cylinder and a rotating hydraulic cylinder are respectively installed in front and back of the suturing equipment, the strip steel in front of the suturing equipment and the strip steel in back of the suturing equipment can be placed right and centered through cooperation between a first correction roller and a second correction roller, the suturing accuracy can be improved greatly, the strip breakage risk of the unit is lowered, and production is more smooth. According to the control method and equipment, the technical problems that existing control methods are poor in suturing accuracy and the strip breakage risk exists especially when the strip steel in front and the strip steel in back are different in width are solved.

Owner:BAOSHAN IRON & STEEL CO LTD

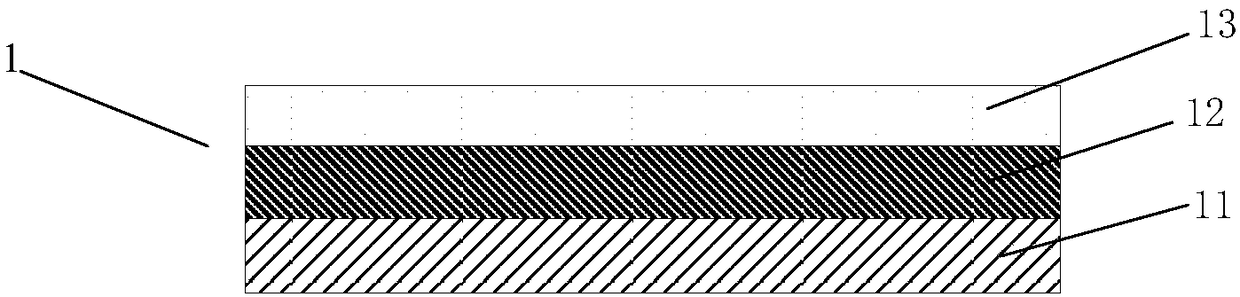

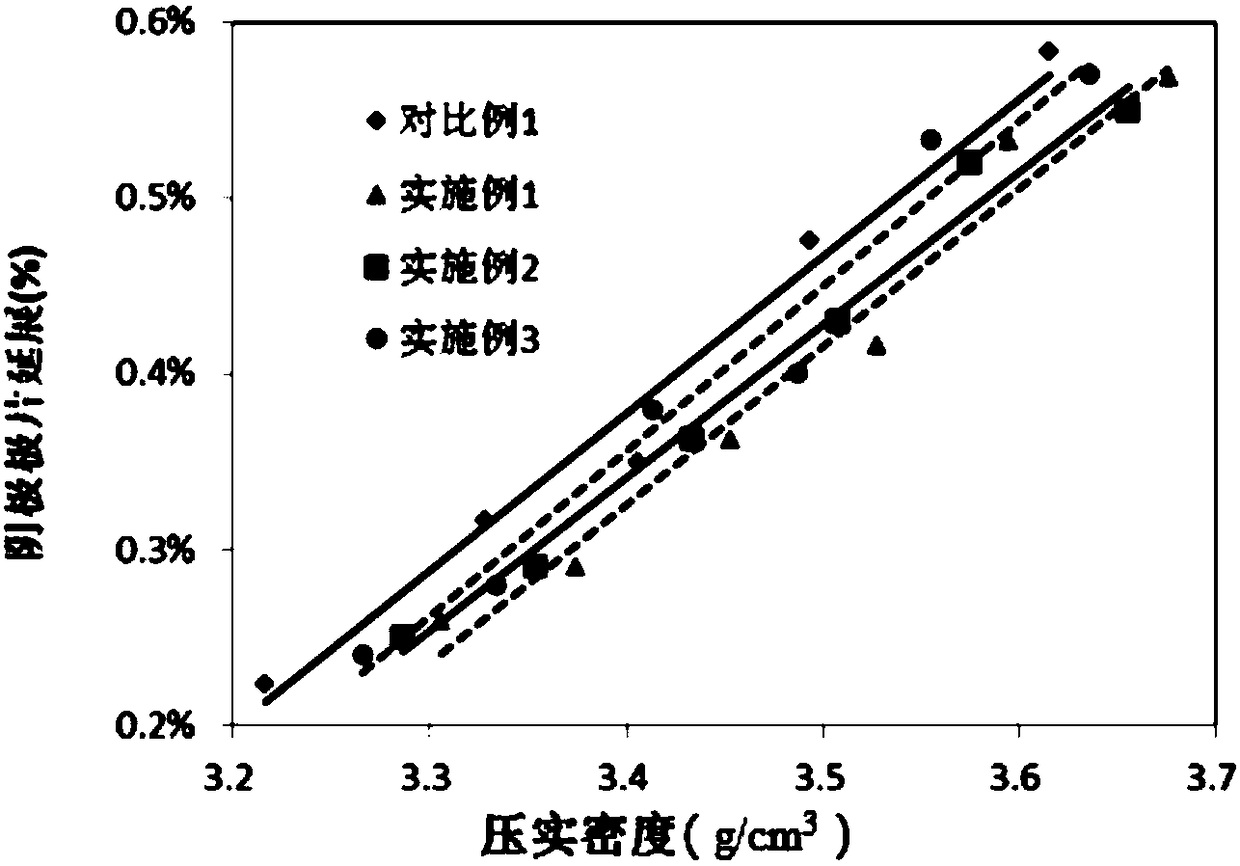

Anode plate, secondary battery thereof and preparation method

ActiveCN109326767AReduce stretchGood flexibilityElectrode rolling/calenderingSecondary cellsSilicone oilMaterials science

The invention relates to the technical field of secondary batteries, in particular to an anode plate, a secondary battery thereof and a preparation method. The anode plate comprises an anode current collector, an anode active material layer and a lubricating coating layer, wherein the anode active material layer is positioned on the anode current collector; the lubricating coating layer is positioned on the anode active material layer; the lubricating coating layer comprises modified silicone oil. The anode plate has the advantages that the cold-press ductility is decreased; by arranging the lubricating coating layer on the anode plate, the flexibility of the anode plate is improved, the cold-press pressure of cold-press equipment and the ductility of the anode plate are reduced, the high-quality rate in a cold-press procedure is improved, the loss of the cold-press equipment is reduced, the belt breaking risk in the cold-press process of the anode plate is decreased, and the manufacturing cost of the cold-press procedure is reduced.

Owner:CONTEMPORARY AMPEREX TECH CO

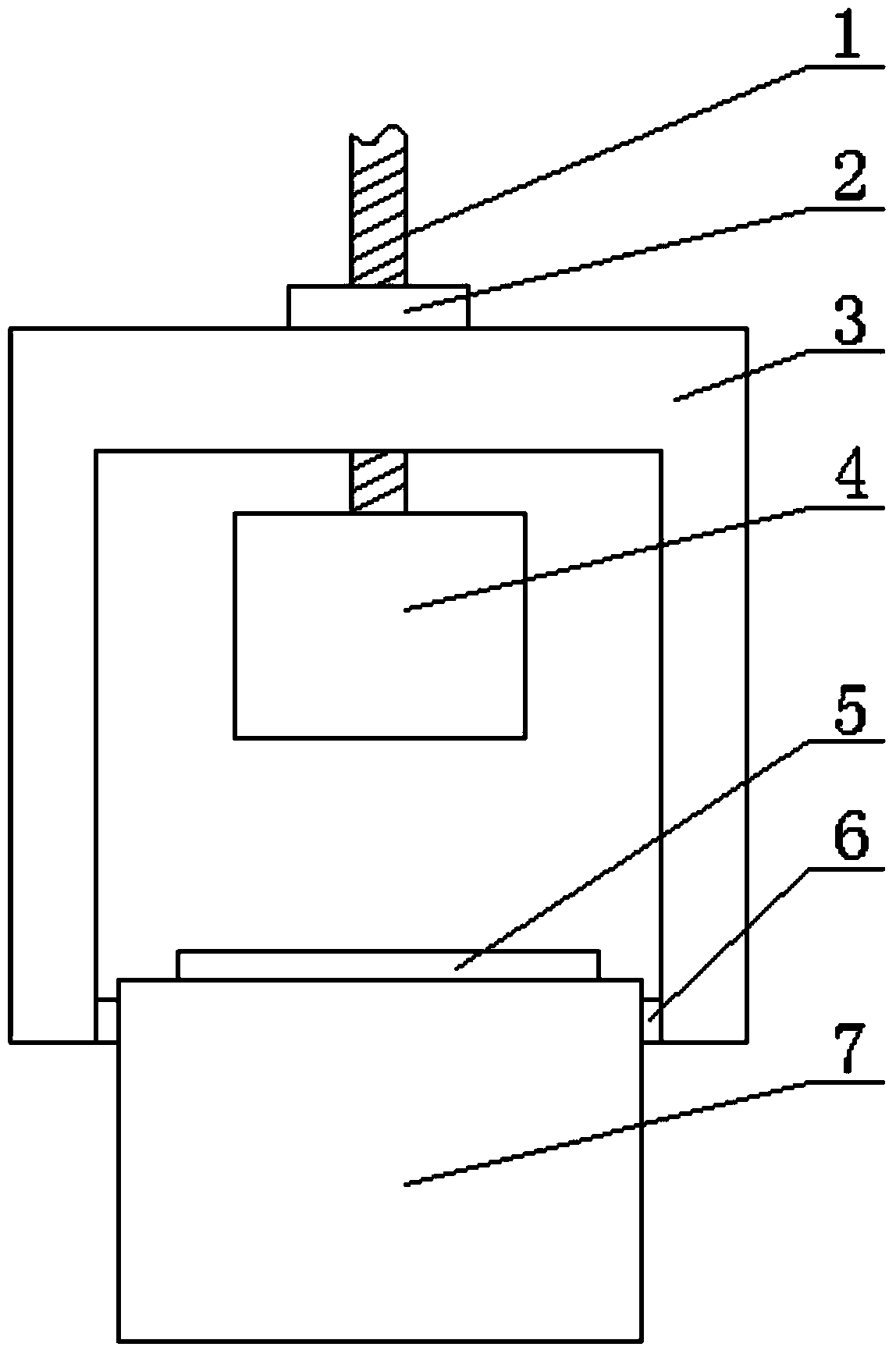

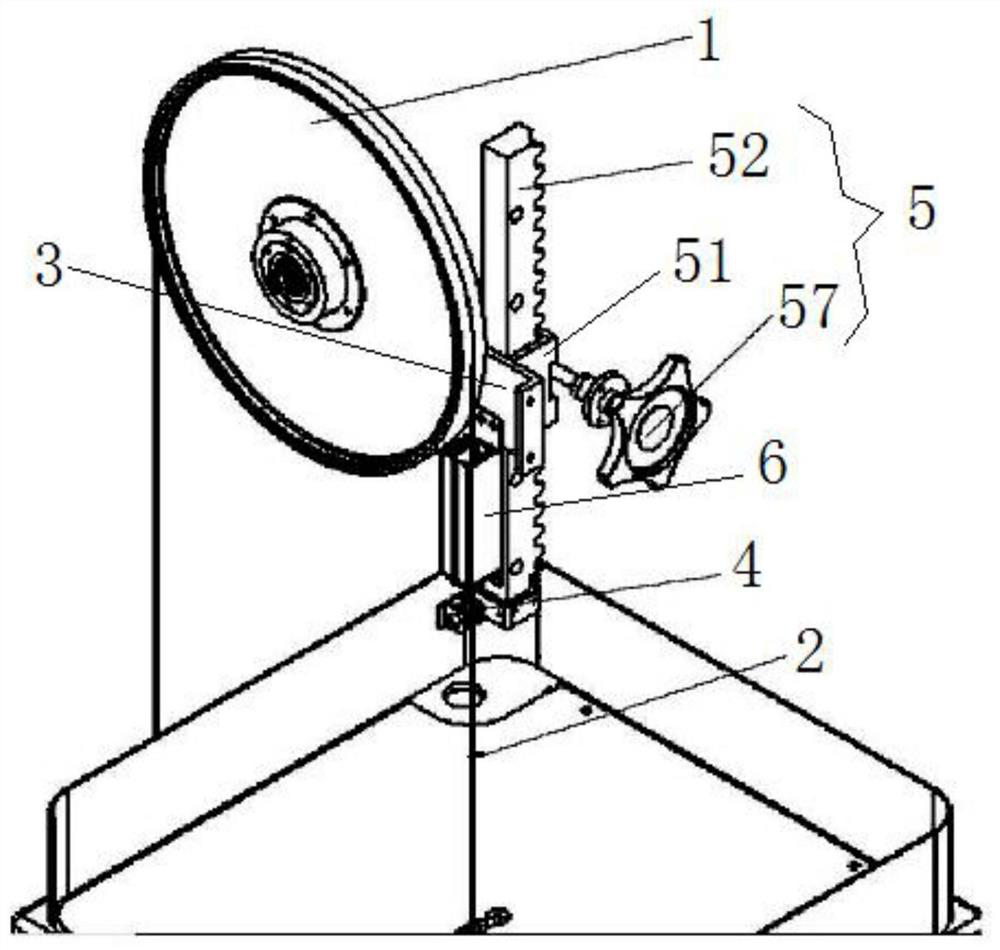

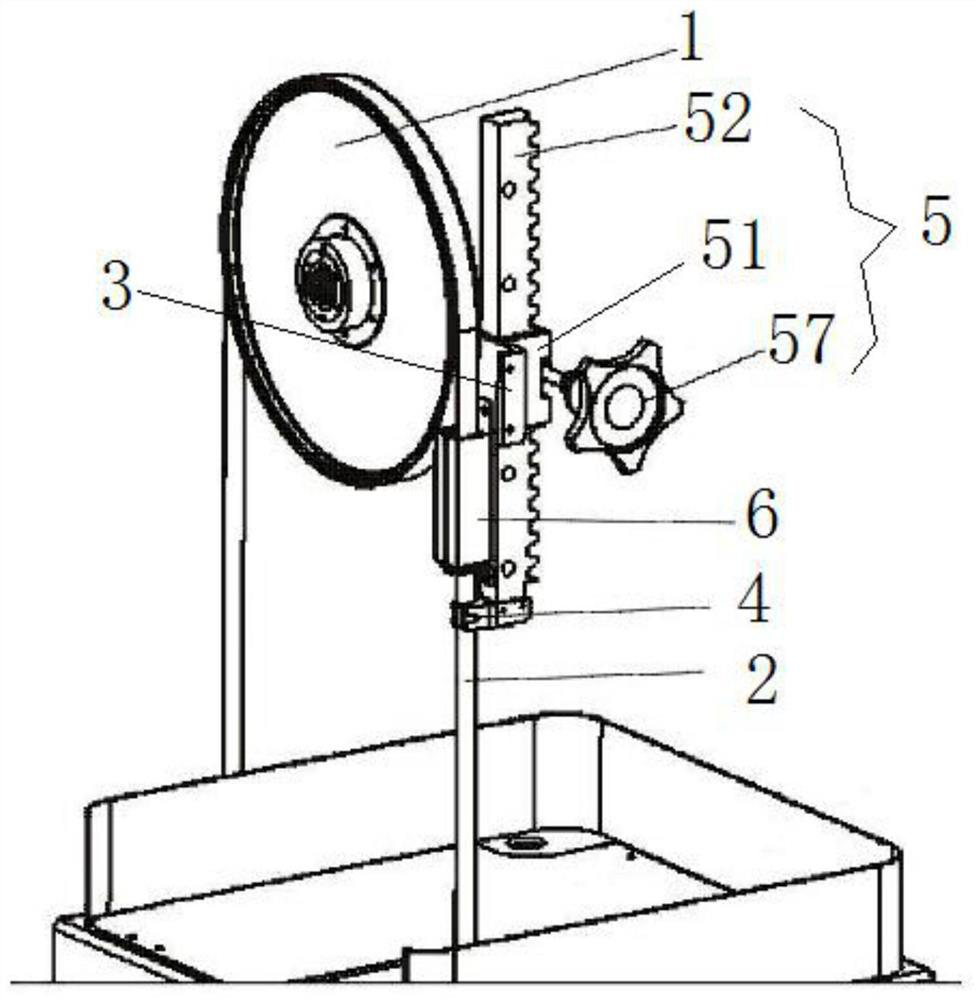

Welding line stretching and bending experimental instrument

ActiveCN104266898AImprove reliabilityReduce the risk of belt breakageStrength propertiesProduction lineWeld line

The invention discloses a welding line stretching and bending experimental instrument. The welding line stretching and bending experimental instrument comprises an upper clamp, a lower clamp, a swing arm and an adjustment assembly, the upper clamp and the lower clamp are used for clamping a welding line test piece, the adjustment assembly is used for adjusting a vertical position of the upper clamp, the lower clamp is movably connected to the swing arm, the swing arm is located above the lower clamp and can turn over relatively to the lower clamp, the upper clamp is arranged on the swing arm by the adjustment assembly, and the upper clamp can vertically move relatively to the swing arm by adjustment of the adjustment assembly. The experimental instrument can simulate cold rolling production line-produced loads on a welding line, improve welding line detection reliability and provide quantification basis for welding line quality evaluation.

Owner:BEIJING SHOUGANG CO LTD

Method for preventing weld seam strip breakage of thin material strip steel

ActiveCN109014646AEffective controlReduce tensionWelding/cutting auxillary devicesAuxillary welding devicesWeld seamStrip steel

The invention relates to a method for preventing weld seam strip breakage of thin material strip steel. The method is characterized by comprising the following steps of (1) welding control; (2) entryloop control; (3) continuous annealing control; (4) air knife control; and (5) leveling and withdrawing-straightening control. The method effectively avoids the technical problem of the weld seam strip breakage of the strip steel through the coordinated control of multiple steps.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

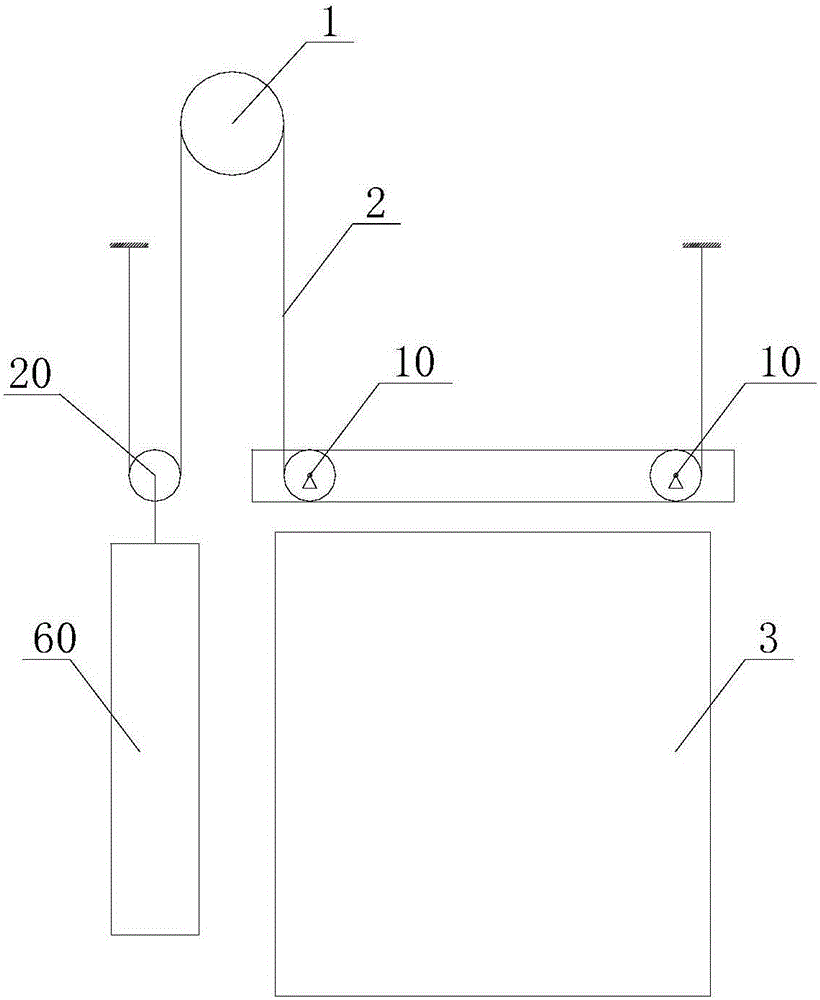

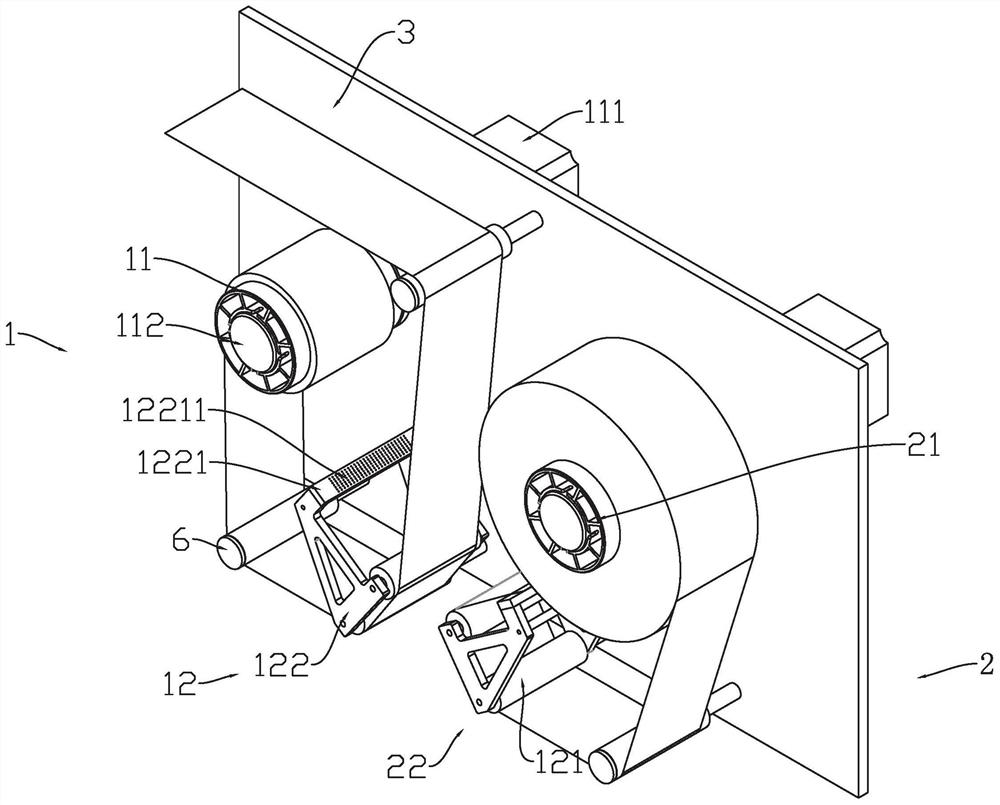

Elevator

The invention discloses an elevator. The elevator comprises an elevator car and a dragging and bearing mechanism; the dragging and bearing mechanism comprises a dragging and bearing unit and rotating wheels, the dragging and bearing unit is of a flat strip shape and is provided with a first working face and a second working face, one of the first working face and the second working face is provided with a guide belt groove, and the other of the first working face and the second working face is provided with protruding guide bodies; the guide belt groove and the protruding guide bodies extend in the length direction of the dragging and bearing unit and are arranged in a staggered mode in the width direction of the dragging and bearing unit; and rolling surfaces of the rotating wheels are provided with rotating wheel protrusion bodies matched with the guide belt groove or guide wheel grooves matched with the protruding guide bodies, the guide belt groove is in clearance fit with the rotating wheel protrusion bodies, protruding guide bodies is in clearance fit with the guide wheel grooves, and gaps are reserved between the outer surfaces of the protruding guide bodies and the inner surfaces of the guide wheel grooves. The elevator has the advantages of effectively avoiding belt breakage and being low in cost, safe and reliable.

Owner:SJEC CORP

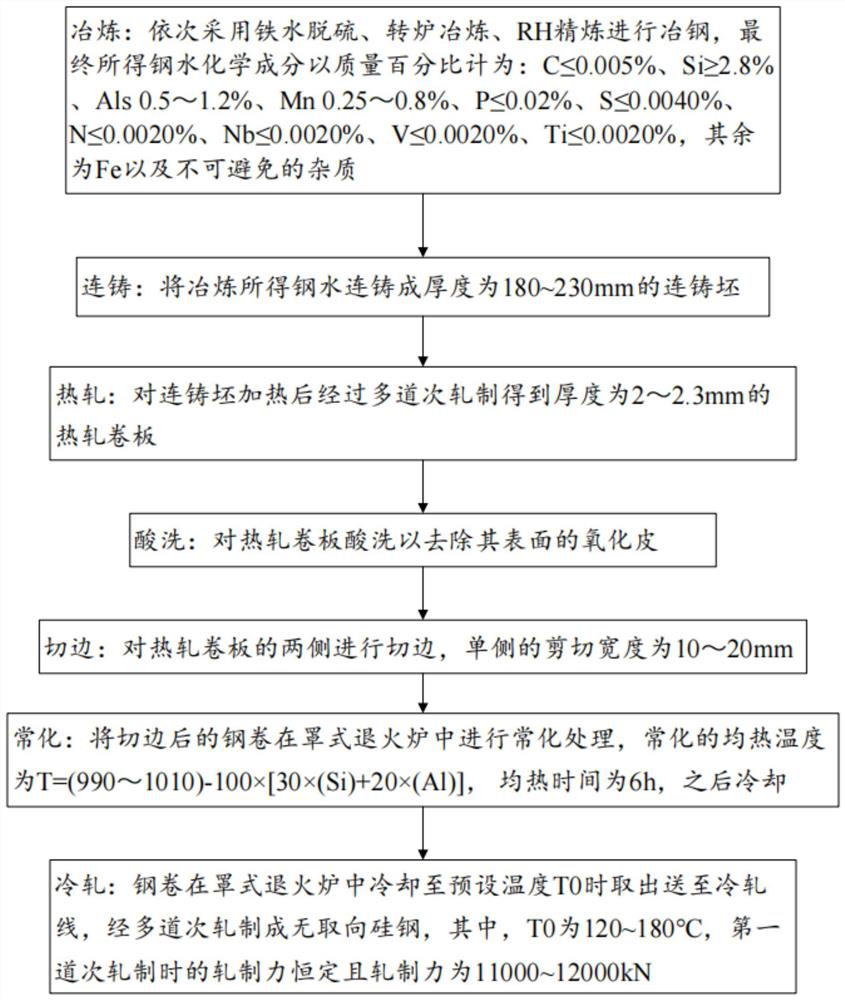

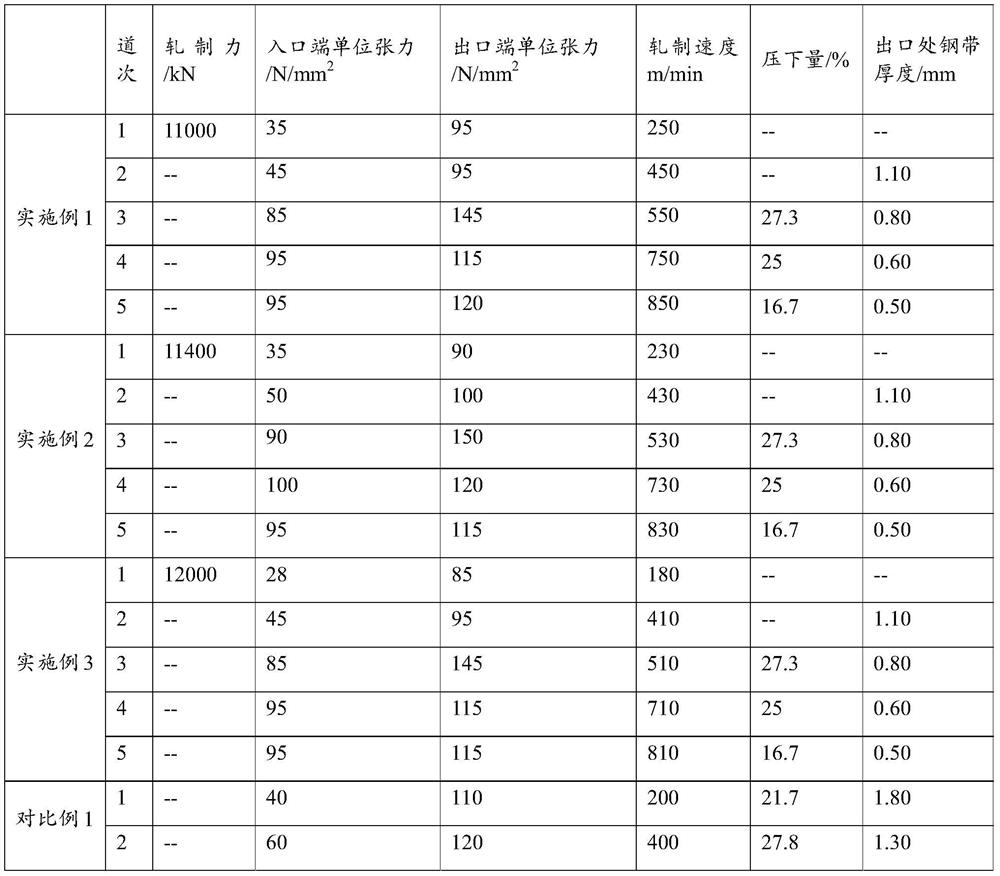

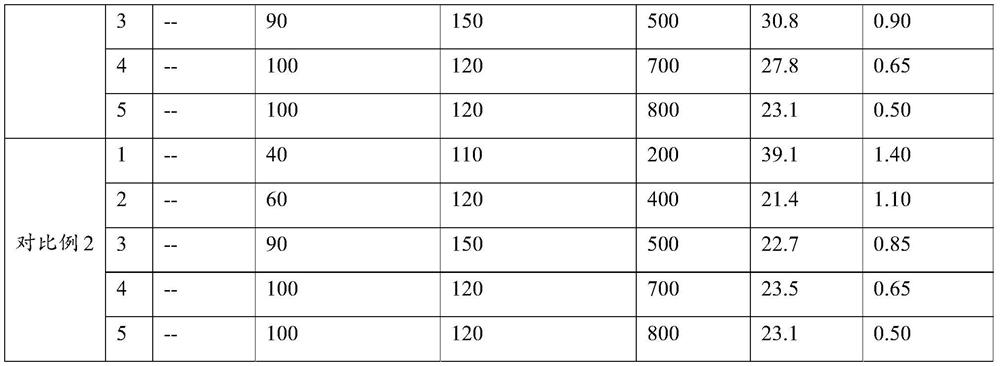

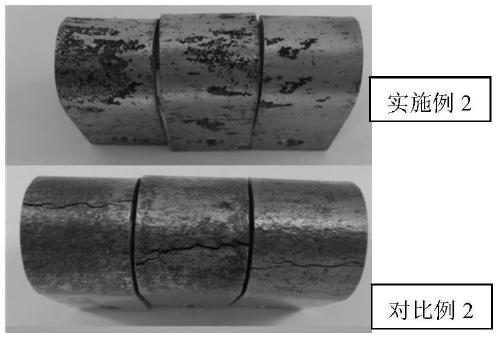

High-grade non-oriented silicon steel and production method thereof

ActiveCN114045434AReduce iron lossExcellent magnetic induction performanceFurnace typesHeat treatment furnacesMolten steelSilicon

The invention discloses high-grade non-oriented silicon steel and a production method thereof. The production method comprises the steps of smelting, continuous casting, hot rolling, acid pickling, trimming, normalizing and cold rolling. The molten steel finally obtained through smelting comprises the following chemical components in percentage by mass: less than or equal to 0.005% of C, more than or equal to 2.8% of Si, 0.5-1.2% of Als, 0.25-0.8% of Mn, less than or equal to 0.02% of P, less than or equal to 0.0040% of S, less than or equal to 0.0020% of N, less than or equal to 0.0020% of Nb, less than or equal to 0.0020% of V, less than or equal to 0.0020% of Ti and the balance of Fe and inevitable impurities. In the edge cutting procedure, the two sides of the hot-rolled coil plate are subjected to edge cutting, and the shearing width of the single side is 10-20 mm; normalizing is conducted in a cover type annealing furnace, the soaking temperature T is equal to (990-1010)-100 * [30 * (Si) + 20 * (Al)], the soaking time is 6 h, and then cooling is conducted; when the steel coil is cooled to a preset temperature T0 in the cover type annealing furnace, the steel coil is taken out and sent to a cold rolling line for cold rolling, the T0 is 120-180 DEG C, and the rolling force during first-pass rolling is constant and is 11000-12000 kN. According to the method, frequent strip breakage caused by high brittleness in the cold rolling process of the high-grade non-oriented silicon steel can be avoided.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +1

Soft tin-plate and making process thereof

ActiveCN100473741CExcellent plate passabilityStable mechanical propertiesRoll mill control devicesFurnace typesTin platingContinuous annealing

The soft tin-plate consists of C not more than 0.006 wt%, Mn 0.10-0.20 wt%, Al 0.025-0.075 wt%, Si not more than 0.03 wt%, Ti 0.03-0.08 wt%, P not more than 0.015 wt%, S not more than 0.015 wt%, N not more than 0.003 wt%, and O not more than 0.004 wt%, except Fe and inevitable impurities. Its production process includes the following steps: smelting steel, continuous casting and rolling, hot rolling, acid pickling and rolling, continuous annealing, flattening and tin plating.

Owner:BAOSHAN IRON & STEEL CO LTD

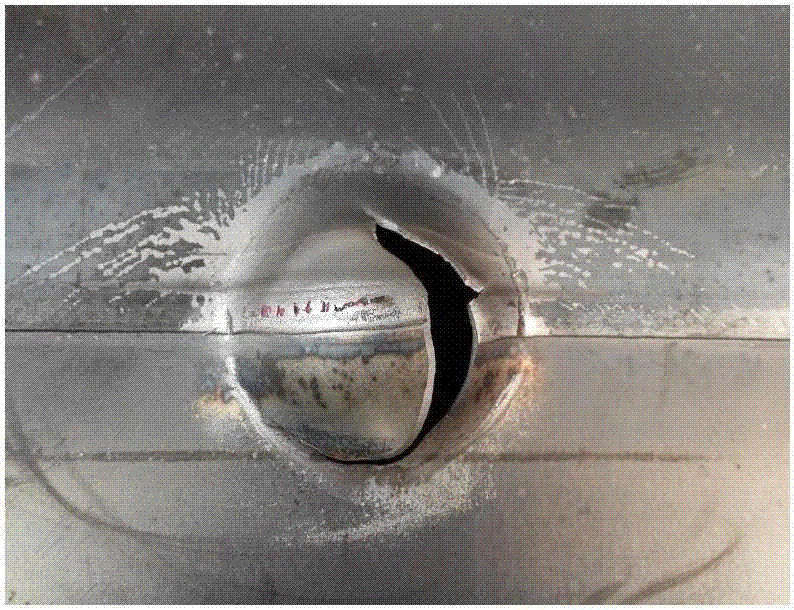

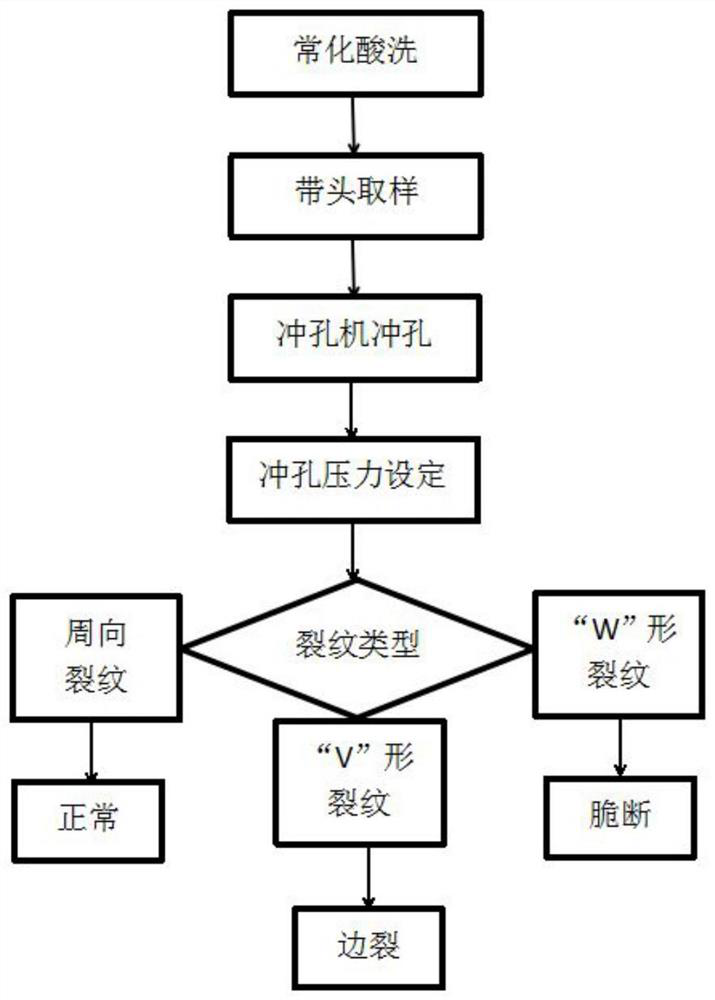

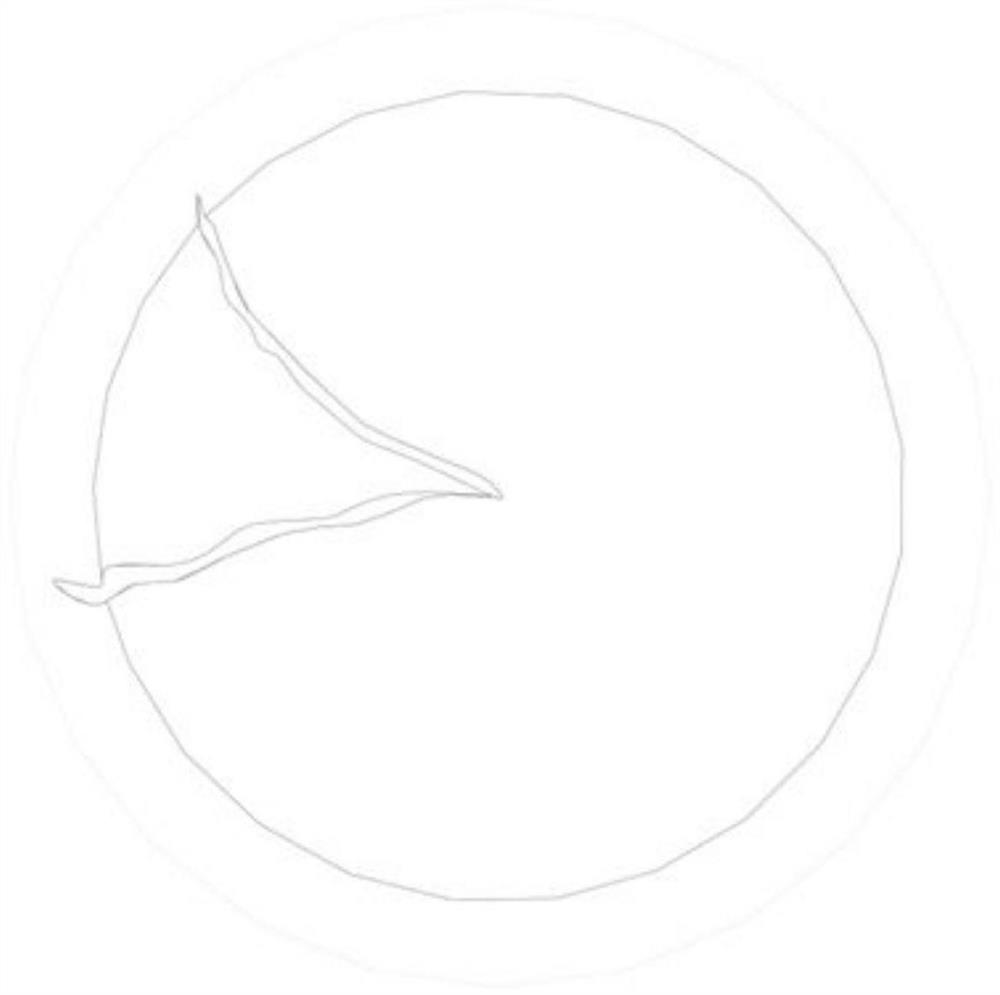

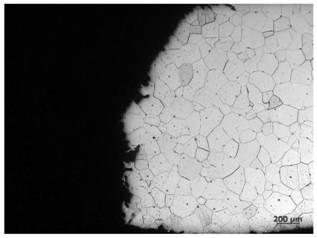

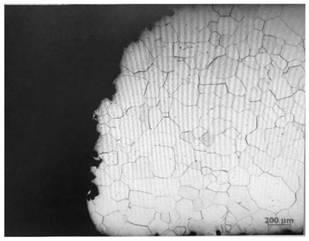

Method for pre-judging occurrence of oriented silicon steel cold rolling brittle failures

ActiveCN113020278AAvoid it happening againReduce the risk of belt breakageRolling safety devicesMetal rolling arrangementsPunchingStructural engineering

The invention provides a method for pre-judging occurrence of oriented silicon steel cold rolling brittle failures. The method comprises the following steps of shearing and sampling 20-30 cm of an acid pickling strip head, and marking a working side and a transmission side on an obtained sample plate; and sending the taken sample plate to a welding seam detection punching machine, punching the sample plate through the punching machine, setting different punching machine pressures according to different steel strip thicknesses, and pre-judging whether a normalized coil has the brittle failure in the cold rolling process by observing the crack morphology after punching of the sample plate. According to the method, corresponding countermeasures can be formulated before cold rolling of strip steel, so that the loss caused by cold rolling strip breakage is reduced.

Owner:武汉钢铁有限公司

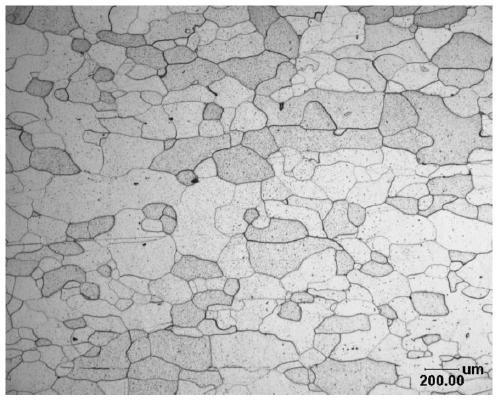

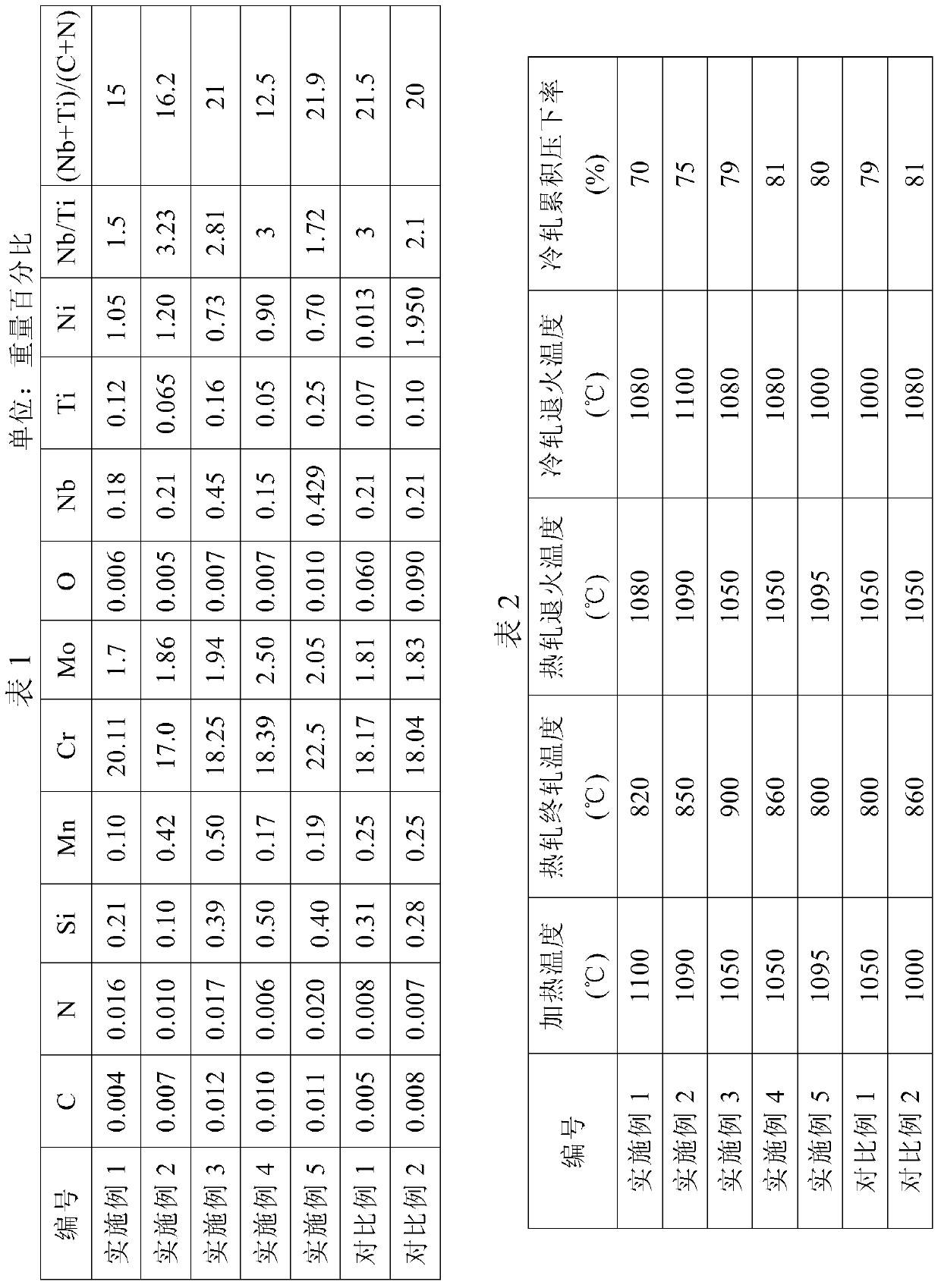

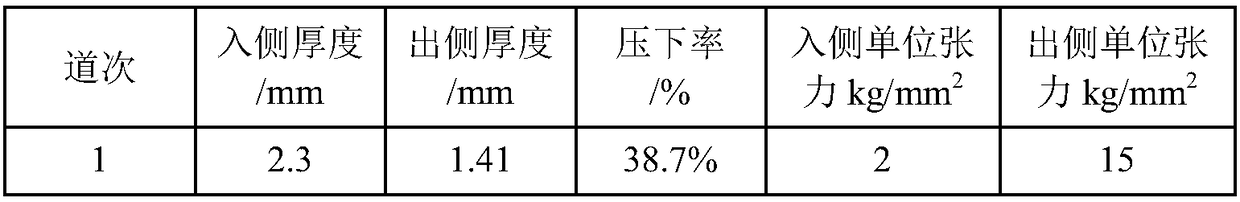

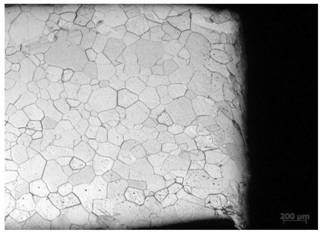

A kind of low-nickel type medium chromium ferritic stainless steel and its manufacturing method

The invention discloses low-nickel type medium-chromium ferrite stainless steel and a manufacturing method thereof. The low-nickel type medium-chromium ferrite stainless steel comprises, by weight, 0.7%-1.2% of Ni, 0.002%-0.012% of C, 0.002%-0.020% of N, 0.10%-0.50% of Si, 0.1%-0.50% of Mn, 17.00%-22.50% of Cr, 1.70%-2.50% of Mo, 0.15%-0.45% of Nb, 0.05%-0.25% of Ti, 0.005%-0.010% of O, and the balance Fe and inevitable impurities. The following relational expressions are met, wherein (C+N) is smaller than or equal than 0.030%, Nb / Ti is equal to 1.5-4, and (Nb+Ti) / (C+N) is equal to 12-22. The low-nickel type medium-chromium ferrite stainless steel obtained through the method has excellent low-temperature toughness and high strength; the ductile-brittle transition temperature is smaller than or equal to -40 DEG C, the yield strength is larger than or equal to 330MPa, and strength of extension is larger than or equal to 445MPa; and the metallographic structure is a pure ferrite equiaxed grain structure.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

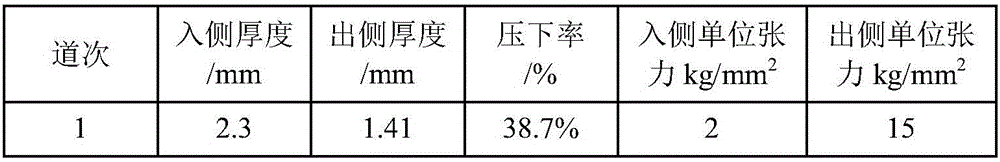

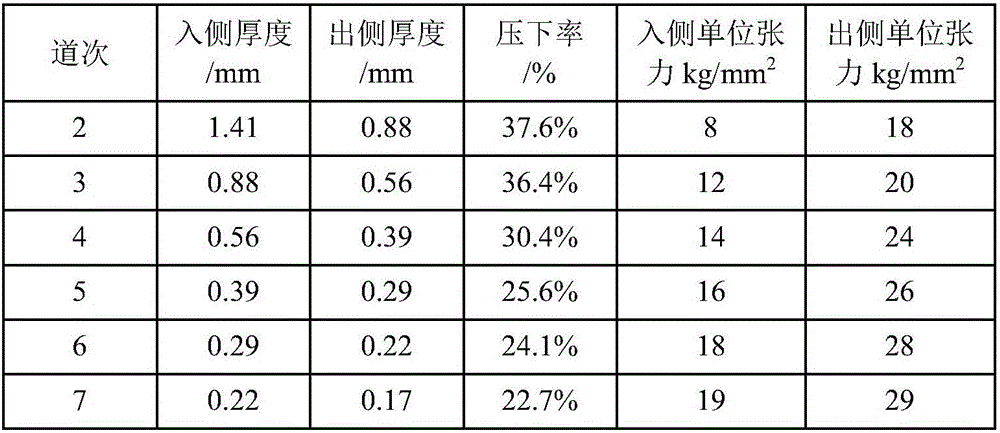

Cold rolling method of ultra-thin gauge high magnetic induction grain-oriented silicon steel

ActiveCN106583448BRealize aging rollingPrevent brittle fractureMetal rolling arrangementsEmulsionLubrication

The invention discloses a cold rolling method for high-magnetic-induction grain-oriented silicon steel in the extremely thin specification. The method comprises steps as follows: (1) the thickness before rolling ranges from 2.0 mm to 2.5 mm, and normalization pickling is performed; (2) the primary cold rolling method is adopted, and continuous reversible seven-pass cold rolling is performed: (2.1) rough-surface working rolls are adopted for the first five passes, and fine-surface working rolls are adopted for the last two passes; (2.2) the reduction rate of each pass is controlled, the reduction rate of the first pass ranges from 30% to 45%, the reduction rate of the last pass ranges from 18% to 31%, and the reduction rates of the rest passes range from 24% to 42%; (2.3) technological lubrication and cooling are performed through emulsion spraying; the plate temperature in the first three passes is controlled to gradually increased to 200-230 DEG C; the temperature is reduced for rolling in the fourth pass; the plate temperature in the subsequent passes is controlled to be 60-80 DEG C; (2.4) automatic plate shape control is performed; (2.5) the rolling force in each pass is controlled to range from 250 T to 520 T; the unit tension on the entrance side of each pass is controlled to range from 2 kg / mm<2> to 20 kg / mm<2>, and the unit tension on the exit side of the pass is controlled to range from 15 kg / mm<2> to 30 kg / mm<2>; (2.6) the product thickness after rolling ranges from 0.15 mm to 0.2 mm; (3) subsequent procedures are conducted conventionally. With the method, the production efficiency of the high-end silicon steel in the extremely thin specification is substantially increased, and products are free of plate shape quality defects and are high in surface quality.

Owner:武汉钢铁有限公司

Car-frame-free elevator driven by traction steel belt

InactiveCN110526083AAvoid taking up spaceIncrease widthElevatorsBuilding liftsAgricultural engineeringSteel belt

The invention discloses a car-frame-free elevator driven by a traction steel belt. The elevator comprises a bearing device, a driving device and a lift car, a bearing wheel is arranged at the top of the bearing device, the bearing wheel is sleeved with a traction steel belt, one end of the traction steel belt is connected with a first steel belt terminating device, and the other end of the traction steel belt sequentially penetrates through the driving device and the lift car and is connected with a second steel belt terminating device; a car roof beam is arranged at the top of the lift car, abase is arranged at the bottom of the lift car, the base is connected with the periphery of the car roof beam through vertical plates, the lower end of the base is connected with an installation frame, and car bottom wheels matched with the traction steel belt are arranged at the two ends of the installation frame. The first steel belt terminating device, the second steel belt terminating deviceand the driving device are arranged side by side in the horizontal length direction of the bearing wheel. The elevator has the characteristics of high space utilization rate, high safety and low maintenance cost.

Owner:SICHER ELEVATOR

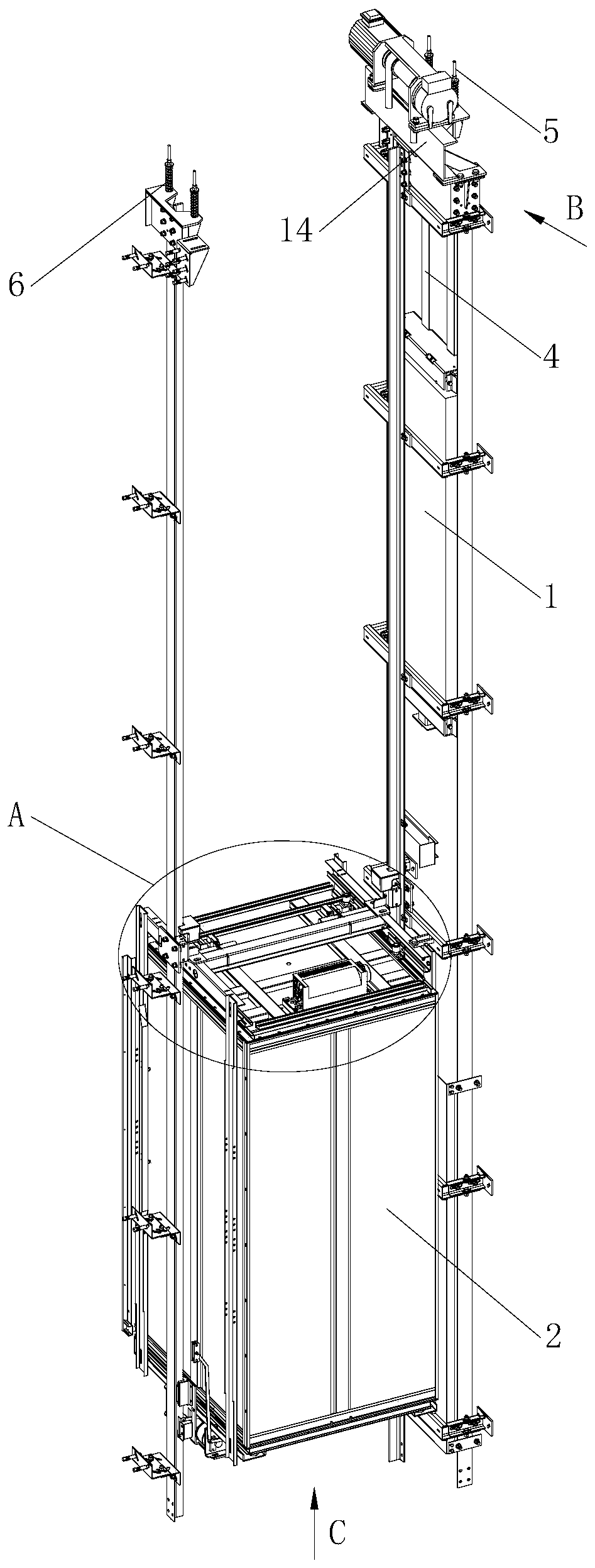

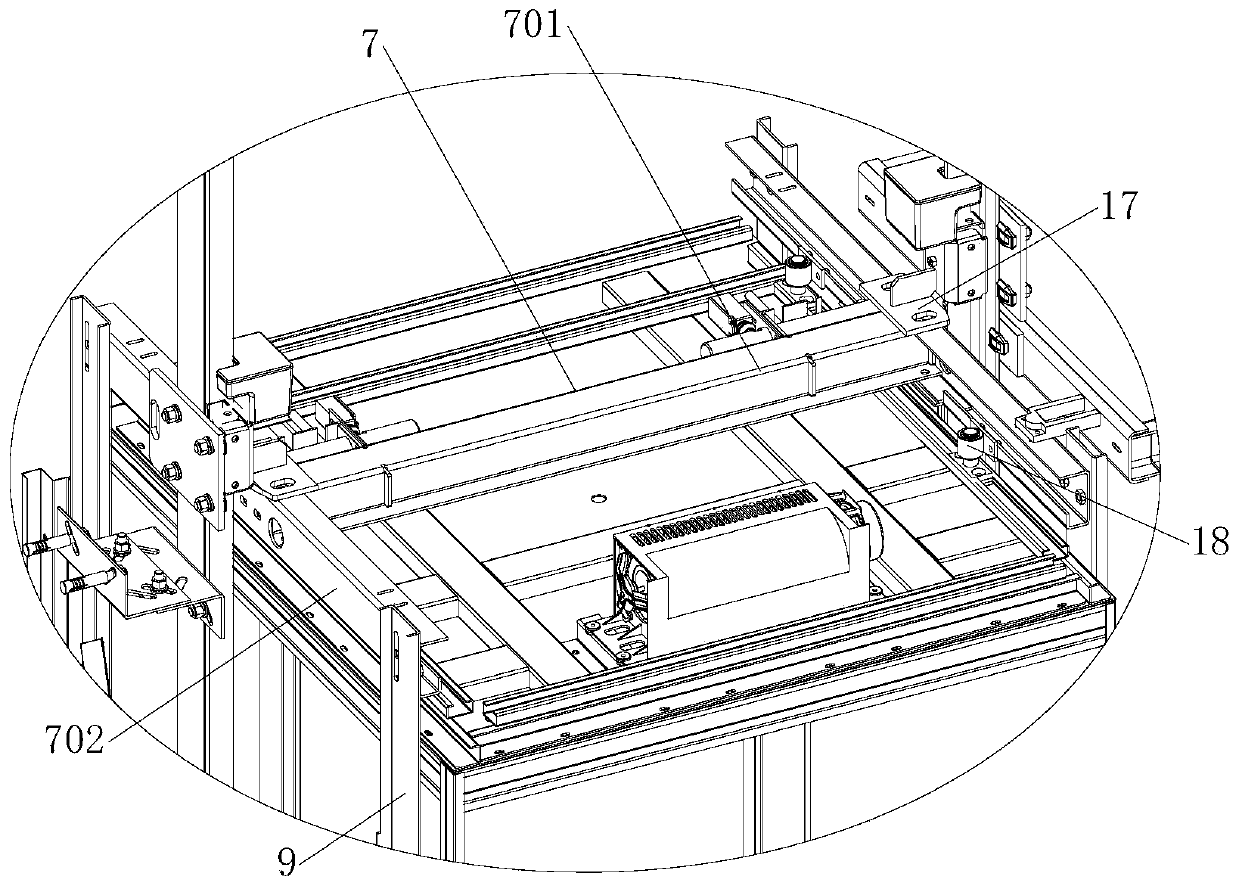

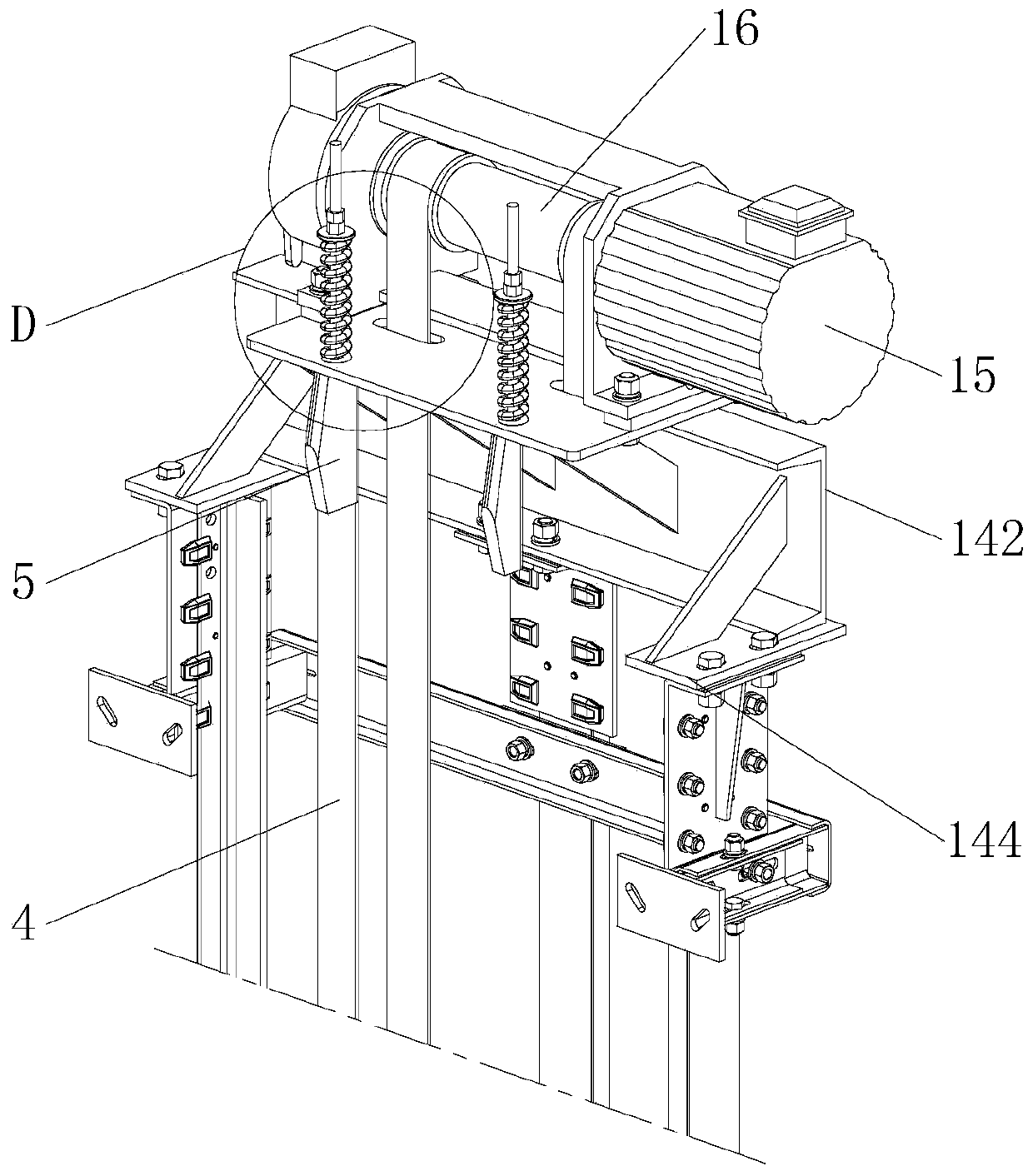

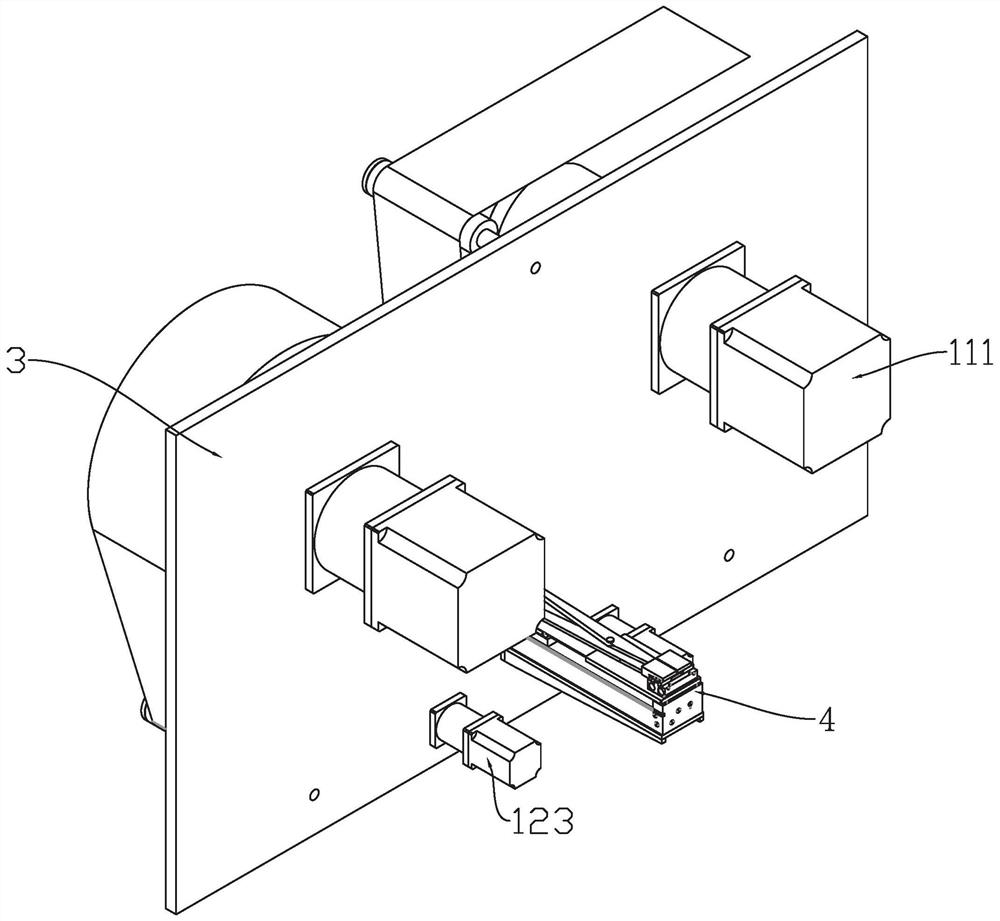

Automatic roll changing device

PendingCN113753638AReduce the risk of belt breakageImprove efficiencyWebs handlingStructural engineeringMechanical engineering

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD +1

Ultra-low iron loss non-oriented silicon steel and production method thereof

ActiveCN114045433AReduce iron lossGuaranteed MagneticFurnace typesHeat treatment furnacesMolten steelSilicon

The invention discloses an ultra-low iron loss non-oriented silicon steel and a production method thereof. The production method comprises the steps that adopting molten iron desulfurization, converter smelting and RH furnace refining sequentially for steel smelting, and finally obtaining molten steel which comprises, by mass percent, smaller than or equal to 0.003% of C, 2.8%-3.4% of Si, 0.1%-0.5% of Mn, 0.6%-1.3% of Al, smaller than or equal to 0.0015% of S, smaller than or equal to 0.0020% of N, smaller than or equal to 0.03% of P, smaller than or equal to 0.003% of Ti, smaller than or equal to 0.003% of V and smaller than or equal to 0.003% of Nb, the sum of Si and Al is larger than or equal to 3.80% and smaller than or equal to 4.15%, and the balance of Fe and inevitable impurities; continuously casting molten steel obtained by smelting into a continuous casting blank; heating the continuous casting blank, and performing multi-pass rolling to obtain a hot-rolled coil plate; shearing the two side parts of the hot-rolled coil plate; carrying out normalizing pickling, wherein the normalizing temperature ranges from 900 DEG C to 930 DEG C, and the normalizing time ranges from 30 s to 60 s; and obtaining the non-oriented silicon steel with the thickness of 0.35-0.5 mm through multi-pass cold rolling, wherein the reduction rate during first-pass cold rolling is larger than or equal to 37%, and the rolling speed ranges from 70 m / min to 180 m / min. The non-oriented silicon steel prepared by the method has ultralow iron loss and is not easy to break during cold rolling.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +2

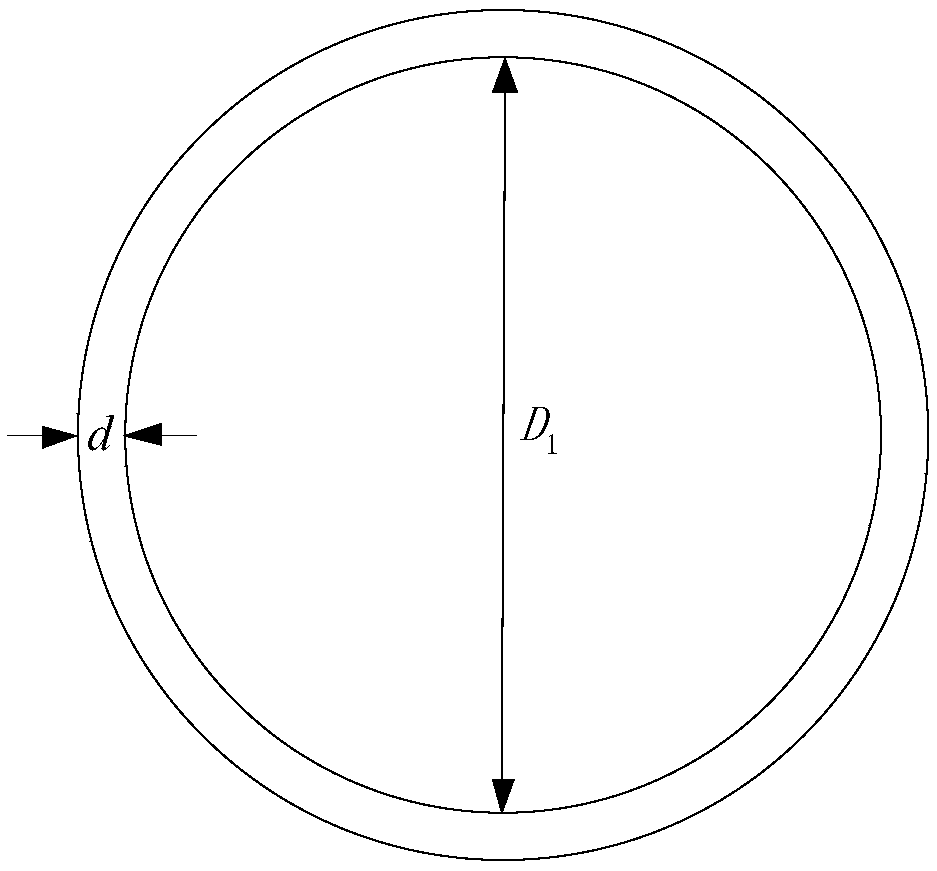

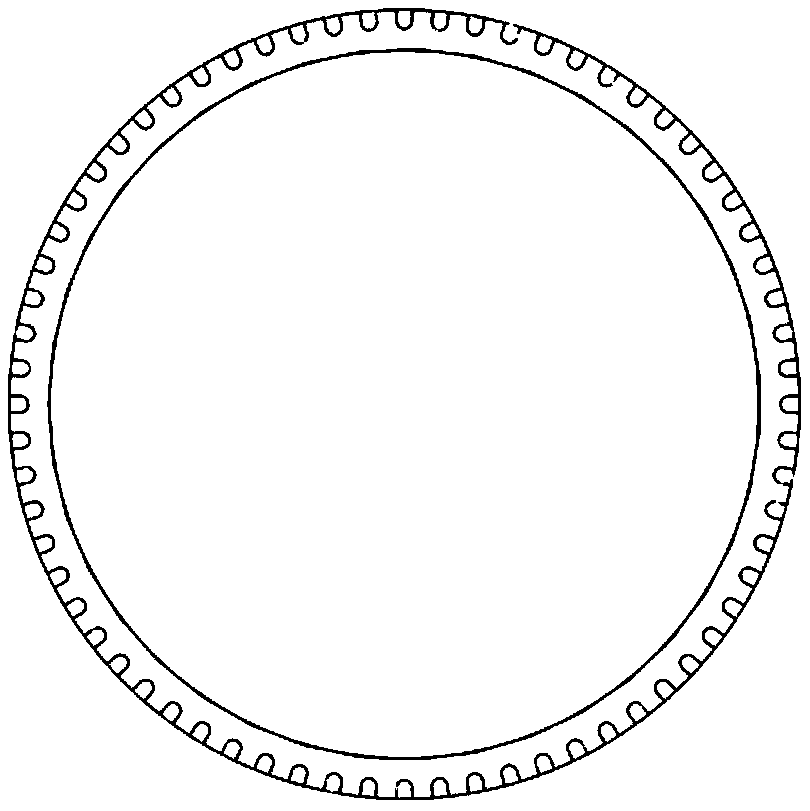

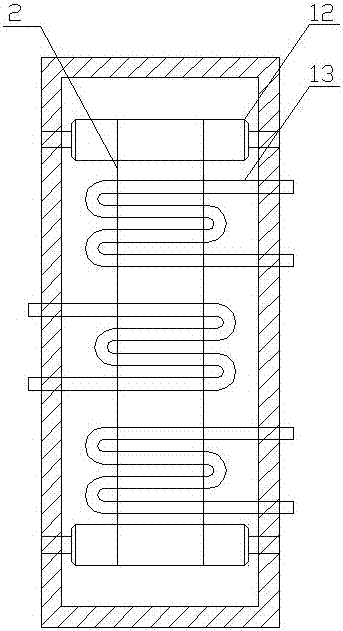

Oriented silicon steel annealing sleeve and oriented silicon steel annealing method

ActiveCN108796178AImprove uniformityImprove the uniformity of magnetic propertiesFurnace typesHeat treatment process controlSilicon

The invention discloses an oriented silicon steel annealing sleeve and an oriented silicon steel annealing method. The oriented silicon steel annealing sleeve comprises a tubular sleeve body and at least two grooves evenly formed in the outer wall of the sleeve body; the length direction of the grooves is parallel with the axial direction of the sleeve body; and one end face of each groove and theupper end face of the sleeve body are located in the same plane. The oriented silicon steel annealing method comprises the steps that the oriented silicon steel annealing sleeve serves as an inner core to wind oriented silicon steel so as to obtain a steel coil; the steel coil is put into a furnace to be subjected to high-temperature annealing, and the upper end face of the sleeve body faces upwards in the high-temperature annealing process; and after high-temperature annealing is finished, the steel coil is conveyed to a stretching leveling machine to be uncoiled, and then the oriented silicon steel annealing sleeve is taken down. The oriented silicon steel annealing sleeve and the oriented silicon steel annealing method can improve the uniformity of the temperature of the steel coil inthe high-temperature annealing process.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

A control method and equipment for seaming centering of thin strip steel in continuous annealing furnace

ActiveCN105618596BReduce the risk of belt breakageImprove sewing precisionMetal-working feeding devicesMetal working apparatusStrip steelEngineering

Owner:BAOSHAN IRON & STEEL CO LTD

A method for rapid start-up of a vertical continuous annealing furnace

ActiveCN108070707BStart fastReduce the risk of belt breakageFurnace typesHeat treatment furnacesHydrogenStart time

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Control method to reduce the risk of bending material operation in the annealing furnace

ActiveCN105316474BStable temperatureGood flexibilityFurnace typesHeat treatment process controlStrip steelProcess zone

The invention provides a control method of reducing buckled material operation risk in an annealing furnace. The control method includes the following steps: (1) shut down and temperature reduction: when strip steel in the annealing furnace is found buckled, switching the annealing furnace into a temperature reduction mode and meanwhile shutting down the machine set in a sectionalized temperature reducing manner, when the machine set is shut down, releasing tension of each part in the machine set, powering-off fans in a quick-cooling section and a final-cooling section, powering-on a stabilizing roller and an air bellow in the quick-cooling section and a squeeze-drying roller in the final-cooling section, and relieving pressure of a buffer roller at inlet of the annealing furnace timely to ensure the strip steel at the inlet to be in a loosen status; (2) tension set: according to a tension formula, calculating the total tension of the process zones to obtain a total tension set value of the process zones; (3) operation of the machine set; and (4) abnormal situation treatment. The control method is high-effective and safe, is easy to carry out, is low in cost, and can reduce breaking risk of a buckled material in an in-furnace operation process effectively.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

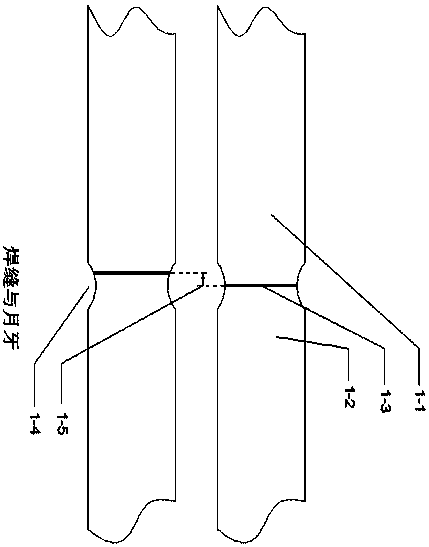

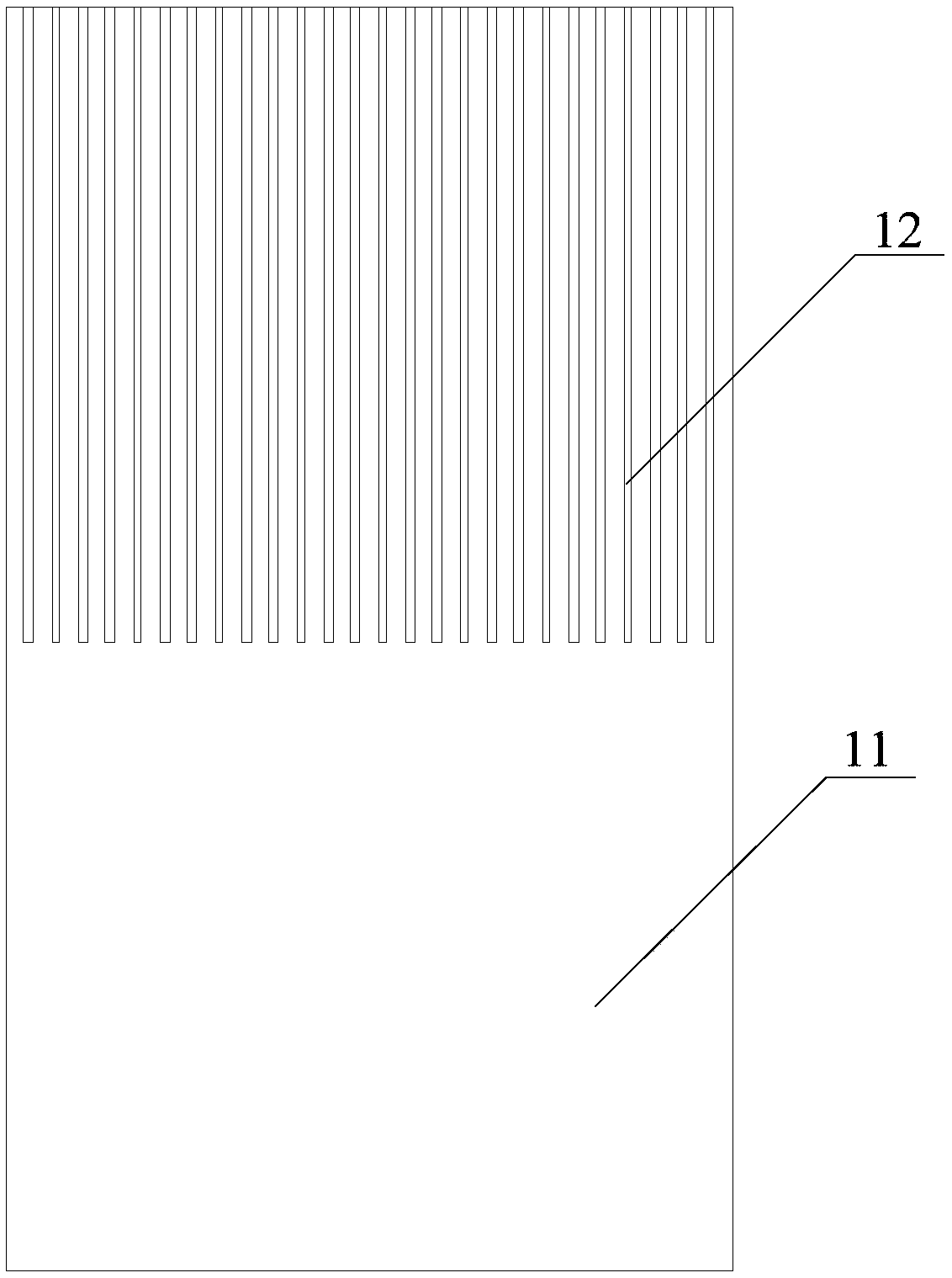

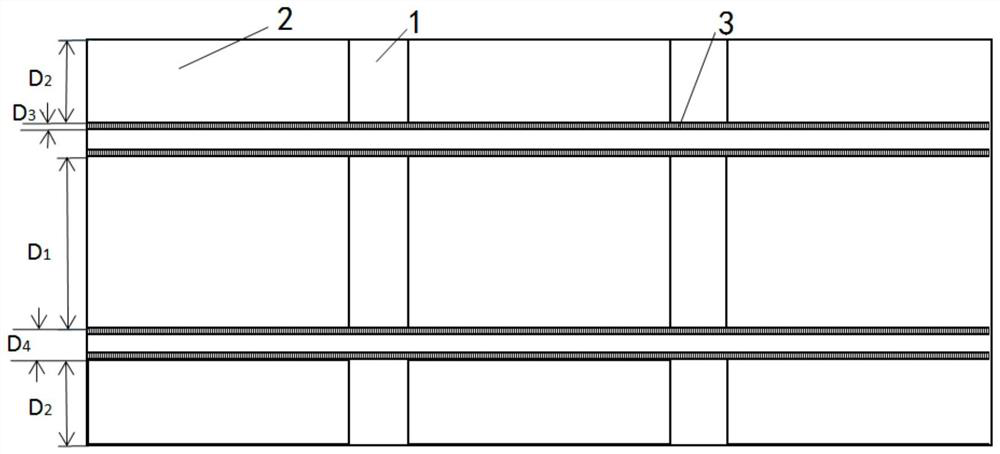

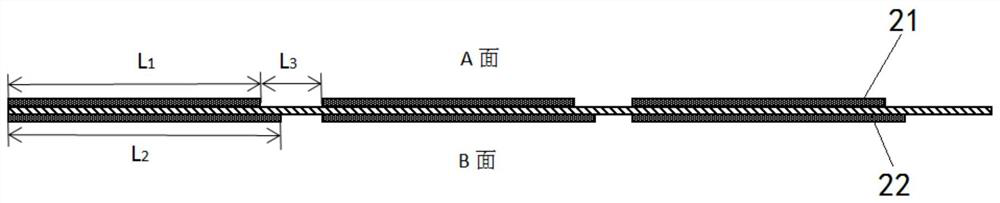

Lithium ion battery positive pole piece and gap coating method thereof

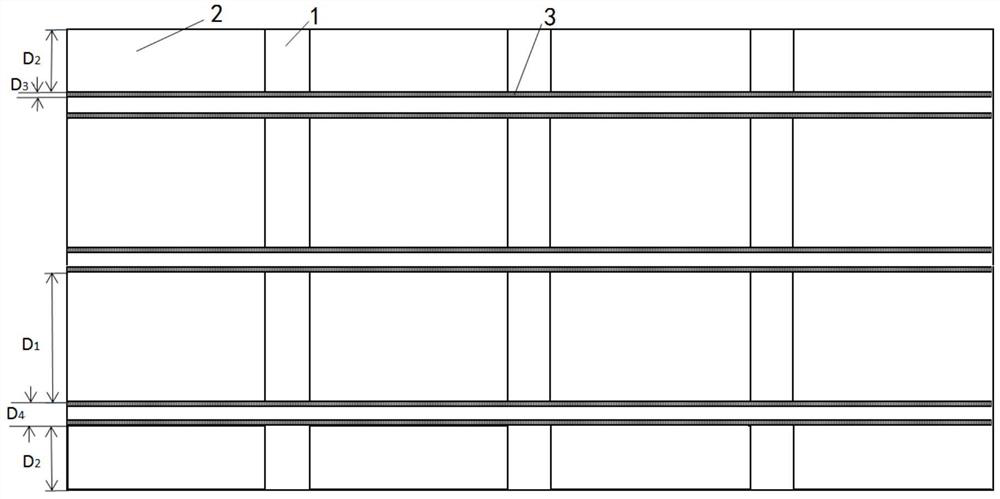

PendingCN114284464ASolve the phenomenon of broken beltAvoid short circuitElectrode manufacturing processesSecondary cellsMetallurgySlurry

The invention relates to a lithium ion battery positive pole piece and a gap coating method thereof.The positive pole piece comprises an aluminum foil (1), a positive slurry layer (2) and ceramic layers (3), the positive slurry layer (2) and the ceramic layers (3) are arranged on the aluminum foil (1), and the ceramic layers (3) are continuously distributed in the length direction of the pole piece and distributed at intervals in the width direction of the pole piece; the positive slurry layers (2) are distributed at intervals along the length direction and the width direction of the pole piece, and the ceramic layers (3) are connected with the positive slurry layers (2). Compared with the prior art, the problem of stress accumulation effect in the coating process can be effectively solved, and the problem of cold pressing strip breakage is improved.

Owner:BATTERO TECH CORP LTD

A dynamic specification variable control method for tandem cold rolling mill

ActiveCN103551389BReduce tension fluctuationsQuality improvementRoll mill control devicesMetal rolling arrangementsStrip steelControl theory

The invention discloses a dynamic gauge change control method of a cold tandem rolling mill, comprising the following steps: determining the transition area of the dynamic gauge change; The rolling thickness of this stand is set to calculate the transition coefficient; when the transition process occurs, calculate the dynamically adjusted roll gap setting value of each stand according to the transition coefficient, and adjust the strip outlet of each stand according to the countercurrent speed. The method of the invention can optimize the dynamic specification change process of the five-stand cold tandem rolling mill, improve the smoothness of the dynamic specification change, reduce equipment impact, reduce strip out-of-tolerance, increase the dynamic specification change speed, and reduce the dynamic specification change time.

Owner:WISDRI WUHAN AUTOMATION

A lap resistance welding method for high-strength strip steel with carbon equivalent greater than 0.5

ActiveCN107138837BGuarantee normal productionImprove toughnessWelding/soldering/cutting articlesResistance welding apparatusElectrical resistance and conductanceWelding residual stress

Owner:MAANSHAN IRON & STEEL CO LTD

Guiding mechanism

InactiveCN112475458AReduce vibration frequencyReduce vibrationMetal sawing devicesBelt grinding machinesEngineeringMachine

The invention discloses a guide mechanism which is mounted on a sawing machine. A pair of rotating wheels are arranged on the sawing machine; a tool belt is tightened on the pair of rotating wheels; the guide mechanism comprises a mounting plate with one end fixed to a rack; the mounting plate is parallel to the rotating wheels, and the other end of the mounting plate extends to one side of the tool belt driven by the rotating wheels; a telescopic mechanism in the vertical direction is mounted on the mounting plate; the bottom end of the telescopic mechanism in the vertical direction is a movable end; and the bottom end of the telescopic mechanism in the vertical direction is fixedly connected with a guide unit matched with the tool belt. According to the guide mechanism, the vibration frequency and amplitude of the part, not making contact with the rotating wheels, of the tool belt can be reduced through the guide unit, and therefore the belt breaking risk is reduced.

Owner:马鞍山海森控电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com