Patents

Literature

37results about How to "Prevent brittle fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

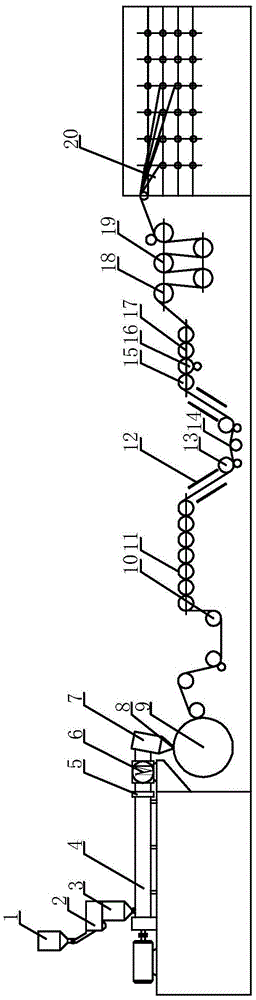

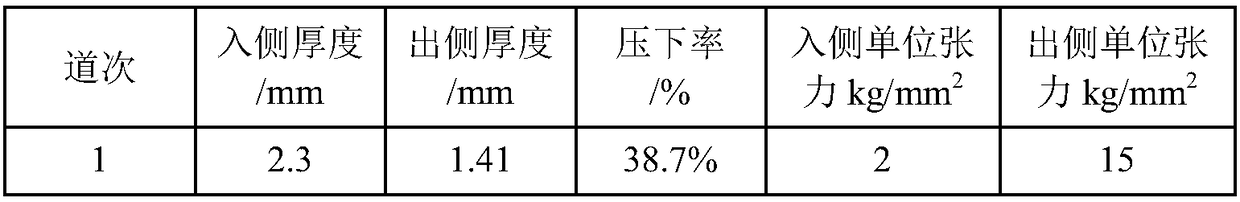

Cold rolling method for high-magnetic-induction grain-oriented silicon steel in extremely thin specification

ActiveCN106583448ARealize aging rollingPrevent brittle fractureMetal rolling arrangementsReduction rateRough surface

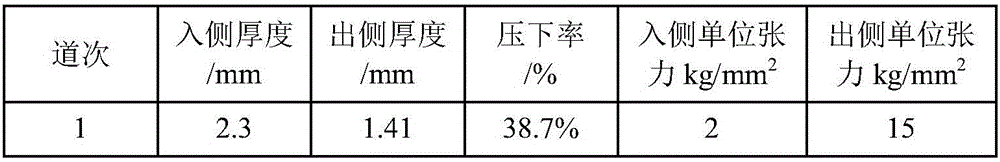

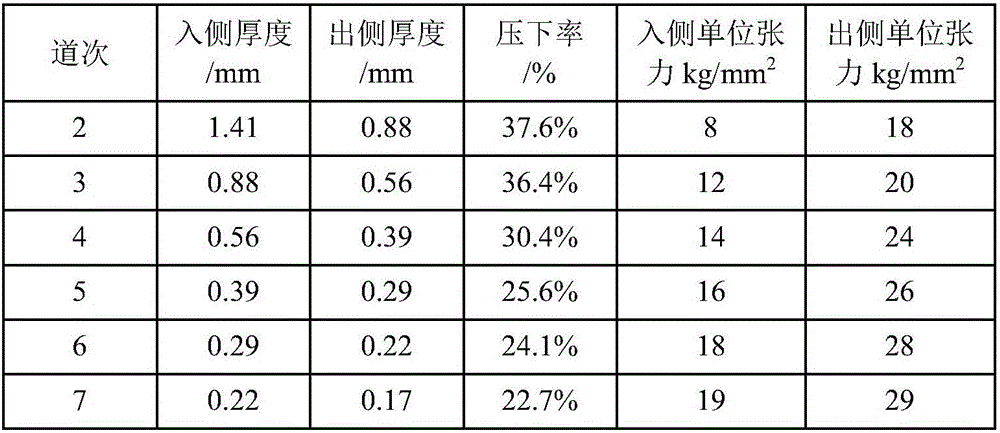

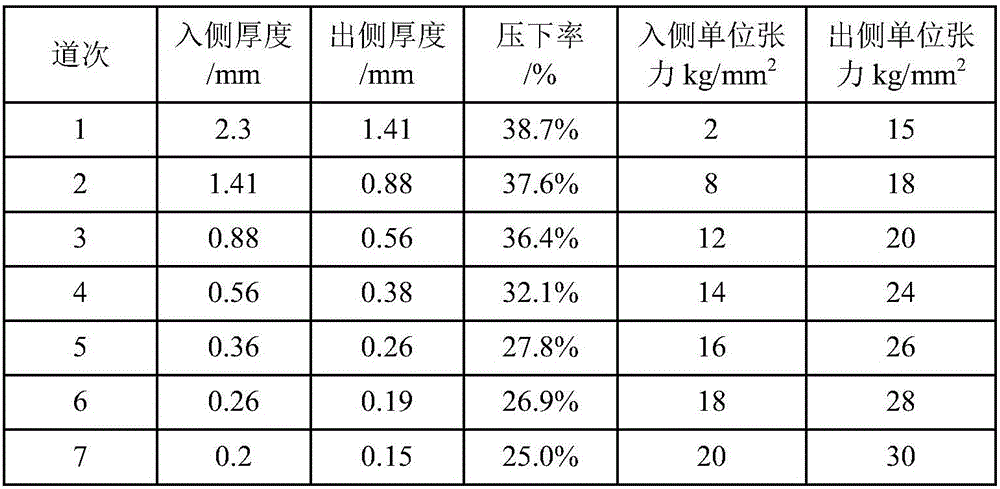

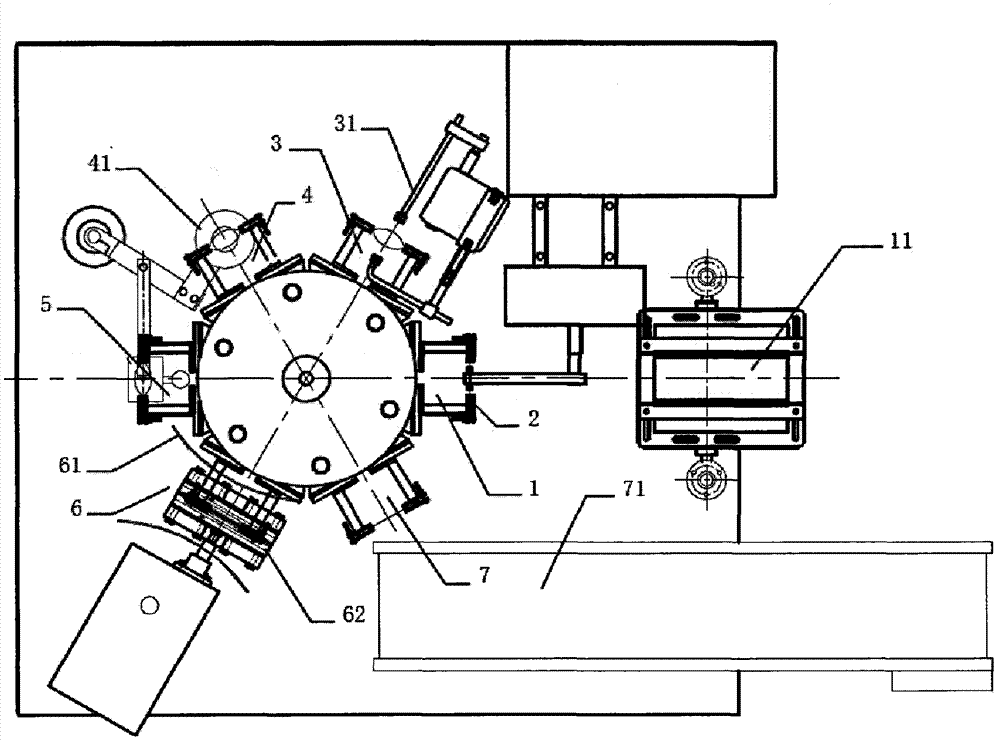

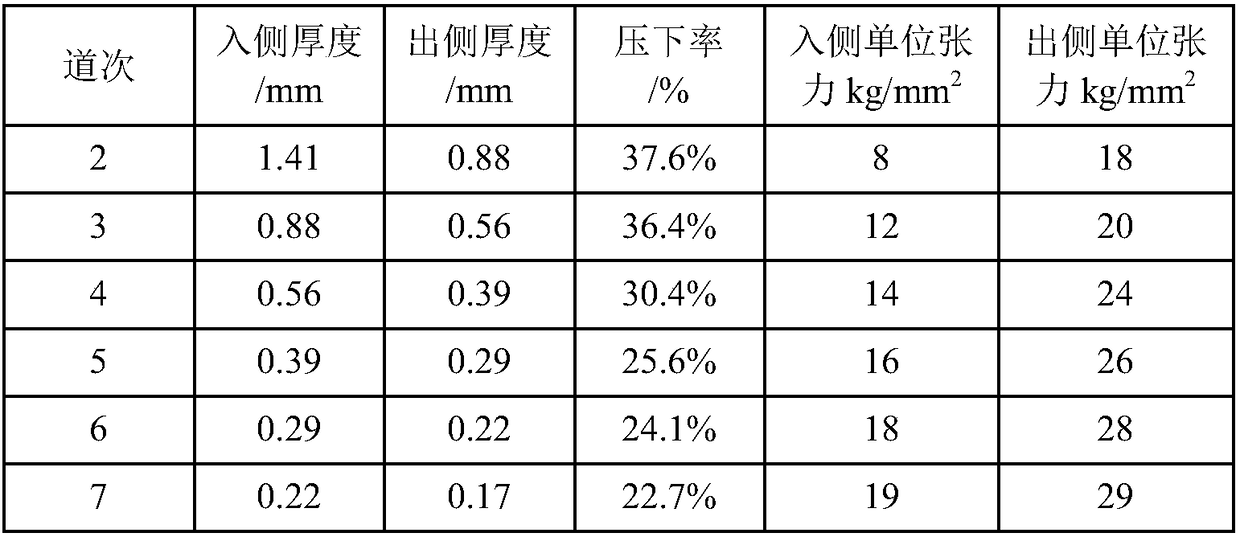

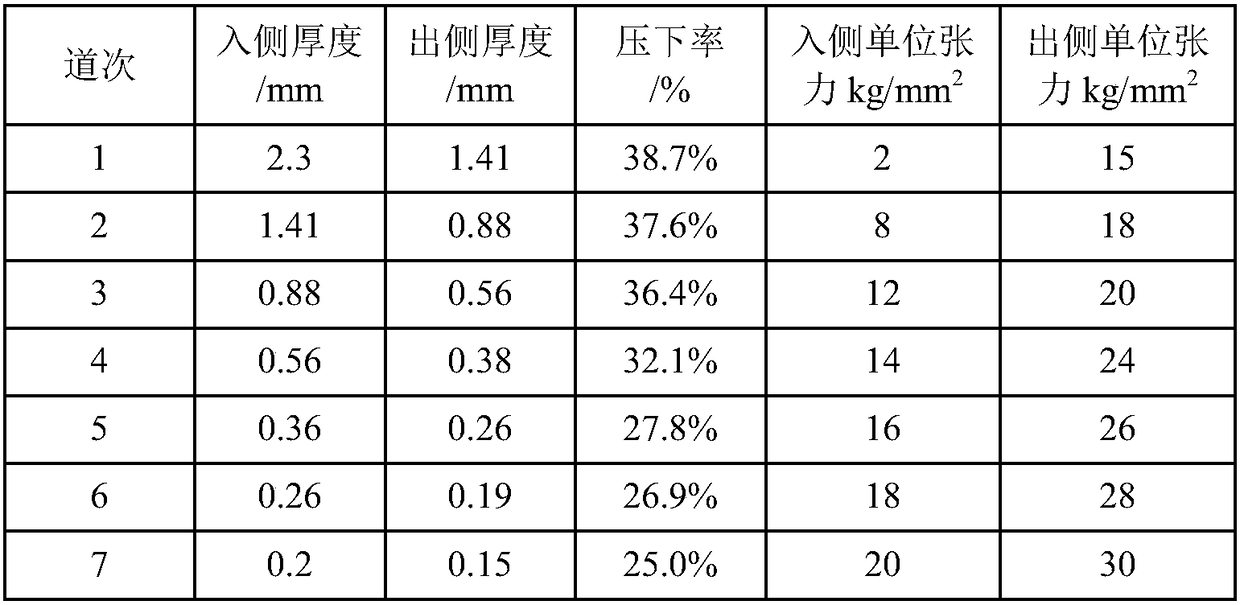

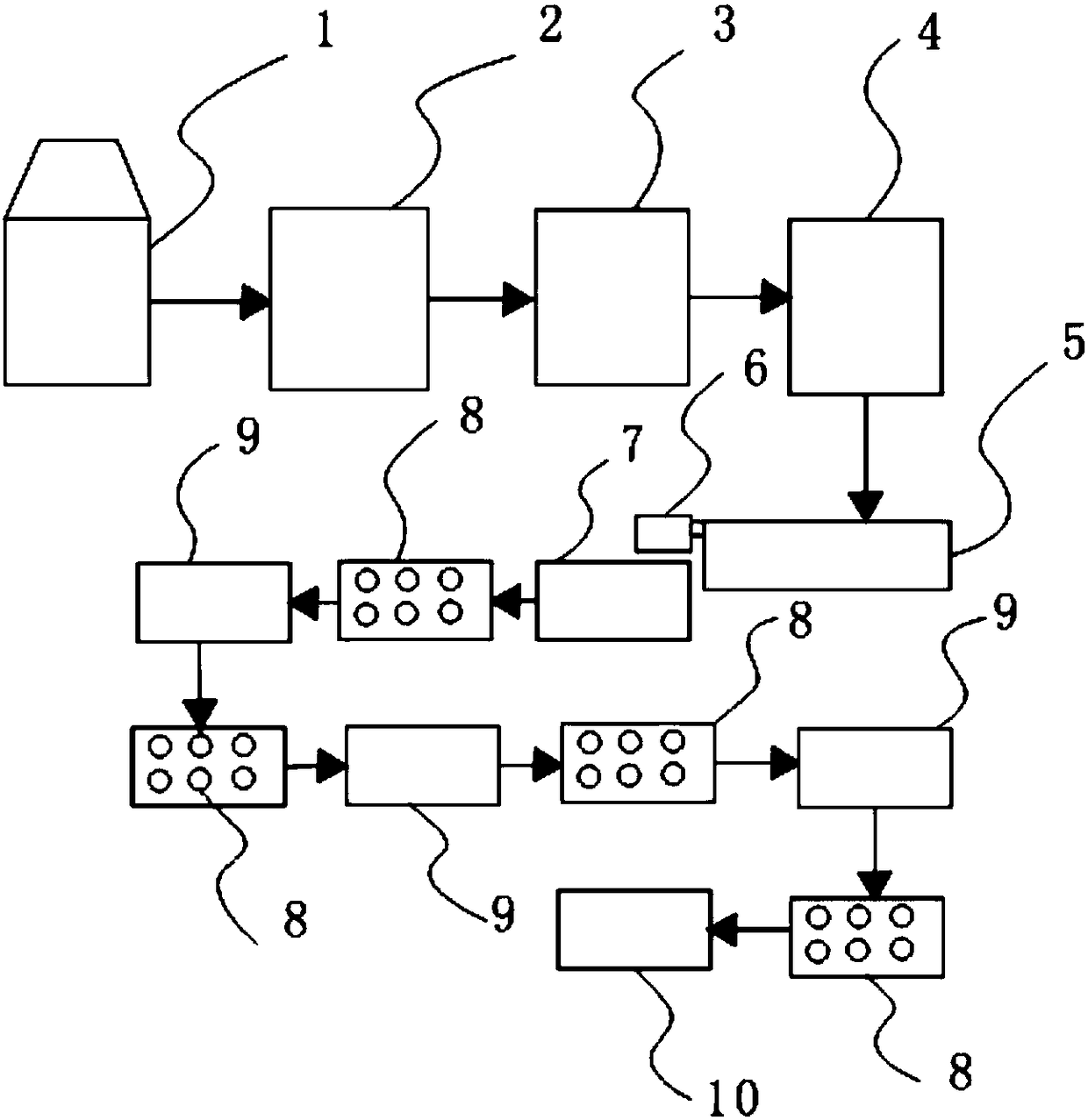

The invention discloses a cold rolling method for high-magnetic-induction grain-oriented silicon steel in the extremely thin specification. The method comprises steps as follows: (1) the thickness before rolling ranges from 2.0 mm to 2.5 mm, and normalization pickling is performed; (2) the primary cold rolling method is adopted, and continuous reversible seven-pass cold rolling is performed: (2.1) rough-surface working rolls are adopted for the first five passes, and fine-surface working rolls are adopted for the last two passes; (2.2) the reduction rate of each pass is controlled, the reduction rate of the first pass ranges from 30% to 45%, the reduction rate of the last pass ranges from 18% to 31%, and the reduction rates of the rest passes range from 24% to 42%; (2.3) technological lubrication and cooling are performed through emulsion spraying; the plate temperature in the first three passes is controlled to gradually increased to 200-230 DEG C; the temperature is reduced for rolling in the fourth pass; the plate temperature in the subsequent passes is controlled to be 60-80 DEG C; (2.4) automatic plate shape control is performed; (2.5) the rolling force in each pass is controlled to range from 250 T to 520 T; the unit tension on the entrance side of each pass is controlled to range from 2 kg / mm<2> to 20 kg / mm<2>, and the unit tension on the exit side of the pass is controlled to range from 15 kg / mm<2> to 30 kg / mm<2>; (2.6) the product thickness after rolling ranges from 0.15 mm to 0.2 mm; (3) subsequent procedures are conducted conventionally. With the method, the production efficiency of the high-end silicon steel in the extremely thin specification is substantially increased, and products are free of plate shape quality defects and are high in surface quality.

Owner:武汉钢铁有限公司

Full-automatic ribbon packaging process

InactiveCN104494929AImprove packaging efficiencyPrevent brittle fractureWrapper twisting/gatheringSolid materialEngineeringDehydration

The invention relates to a full-automatic ribbon packaging process. The full-automatic ribbon packaging process comprises the following steps: loading bags, opening bags, feeding, injecting water, sealing and blanking. The full-automatic ribbon packaging process has the beneficial effects that a full-automatic packaging machine matched with the process is customized through the packaging process, so that the packaging workers (only one worker is needed for bundling, weighing and feeding) are greatly reduced and the labor cost is effectively lowered in the ribbon producing and packaging process; secondly, the packaging working efficiency of a ribbon can be obviously improved, and the production cost of the ribbon is lowered to the greatest extent; moreover, in the packaging process, the water injecting process is increased, so that the ribbon is prevented from being embrittled and cracked due to dehydration during transportation or storage, and thus, the storage time and the service life of the ribbon are greatly prolonged.

Owner:合益(温州)智能装备有限公司

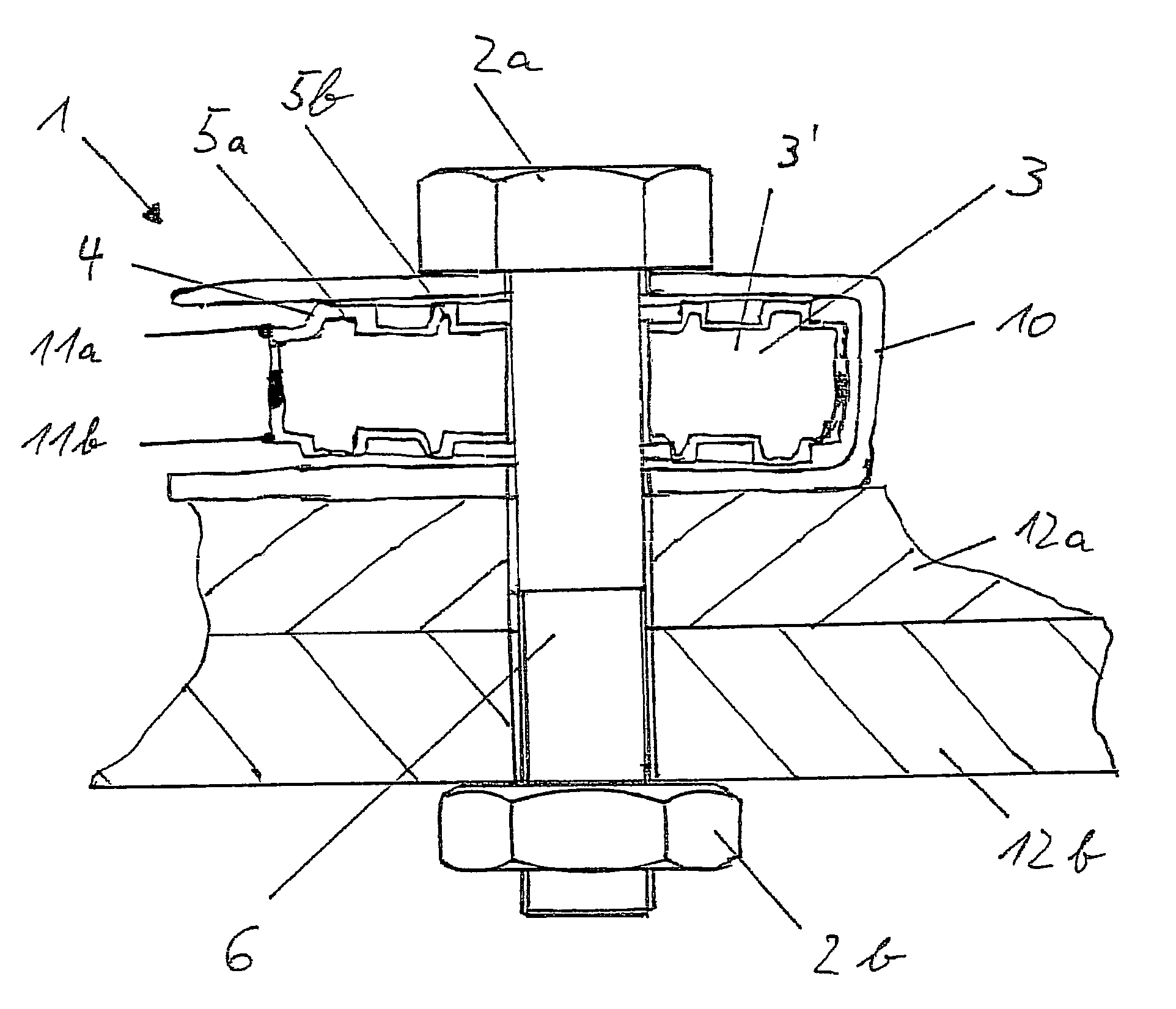

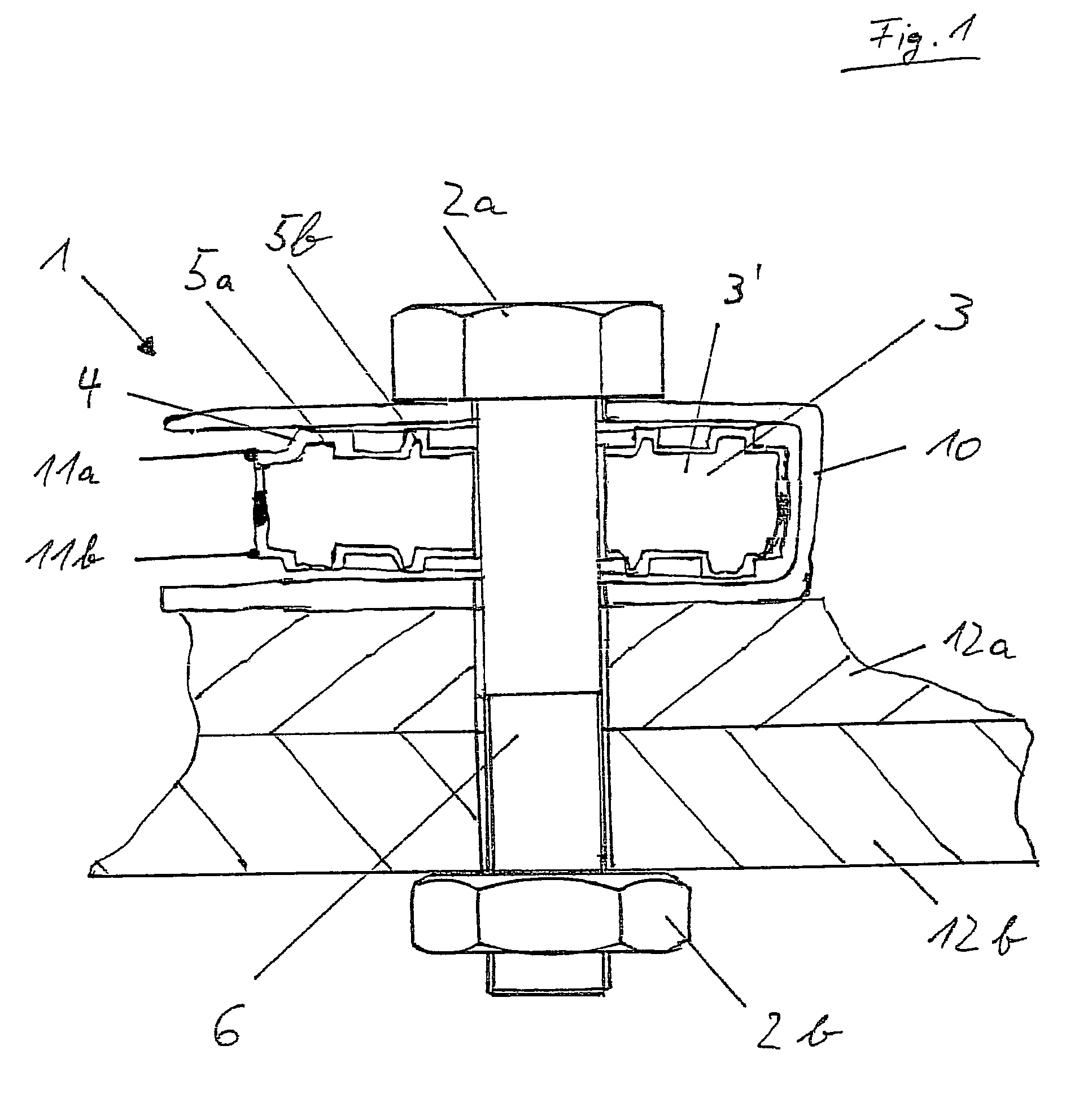

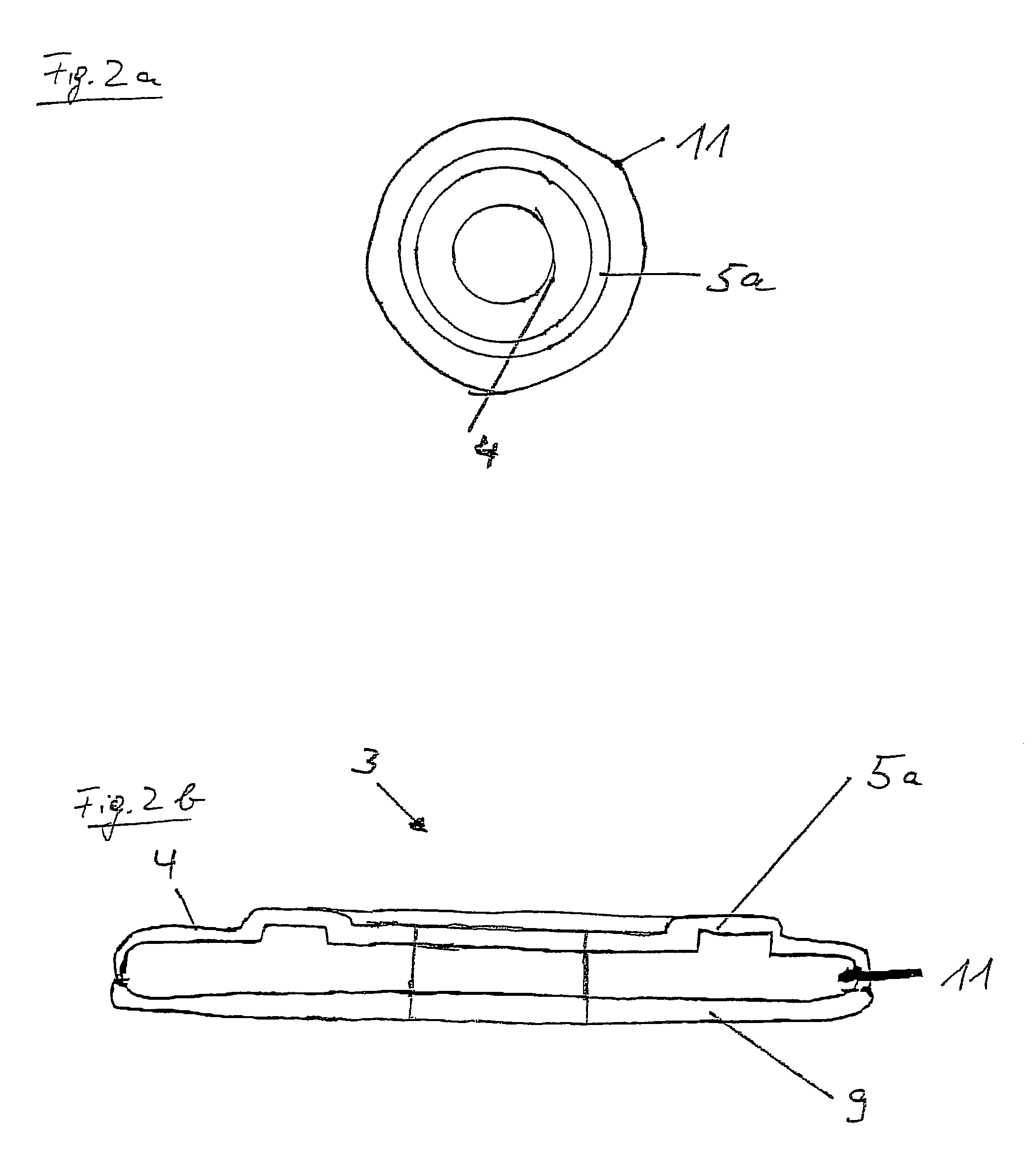

Control device for non-positive connections

InactiveUS7350419B2Prevent brittle fractureEasy to transformMeasurement of torque/twisting force while tighteningLoad modified fastenersEngineeringMechanical engineering

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

High-pressure twisting-electric field assistant thermal treatment fine grain method for ZrTiAlV alloy

The invention discloses a high-pressure twisting-electric field assistant thermal treatment fine grain method for a ZrTiAlV alloy. The high-pressure twisting-electric field assistant thermal treatment fine grain method mainly comprises the following steps: performing vacuum electric field assistant solution treatment on 47Zr-45Ti-5Al-3V alloy plates on spark plasma sintering equipment at the temperature of 600 DEG C, 700 DEGC or 800 DEGC, keeping the temperature for 20 minutes, and subsequently turning off the power to naturally cool and reduce the temperature; performing high-pressure twisting on the plate after solution treatment under the pressure of 4GPa or 5GPa in a twisting angle of 360 degrees; performing vacuum electric field assistant recrystallization annealing treatment on the 47Zr-45Ti-5Al-3V alloy plates subjected to different solution treatment and high-pressure twisting processes at the temperature of 800 DEGC, and keeping the temperature for 20 minutes, wherein the vacuum degree is 10-3Pa. The crystal size of the finally prepared 47Zr-45Ti-5Al-3V alloy plate is within 20-120mu m, the yield strength is within 1173-1307MPa, the tensile strength is 1325-1484MPa, and the ductility is within 11.2-15.7%.

Owner:YANSHAN UNIV

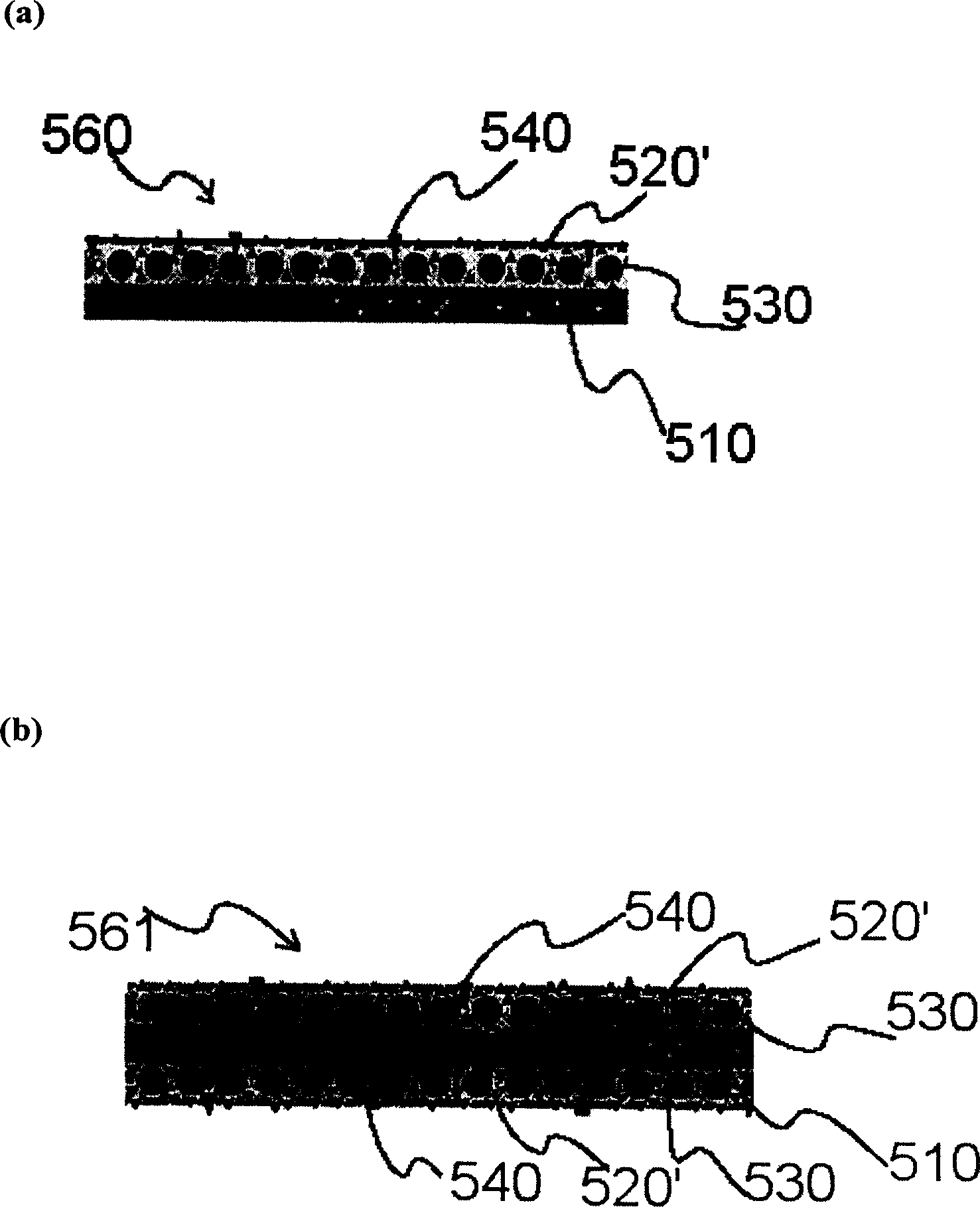

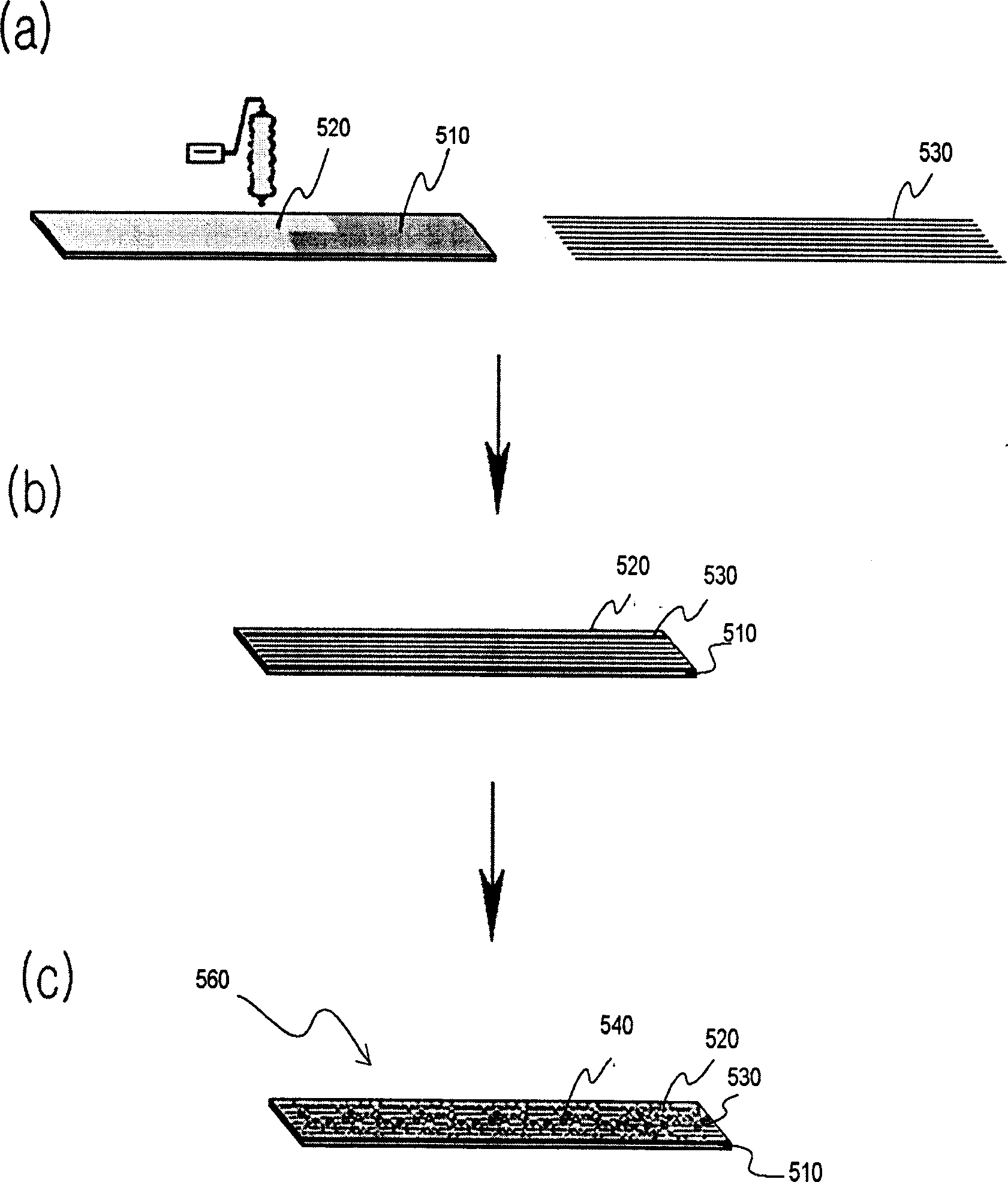

Composite panel for repairing reinforcing con'c body and method of using the same

InactiveCN1503871AEnsure safetyImprove heat resistanceConstruction materialIn situ pavingsHigh strength concreteWater leakage

Disclosed are a panel for repairing and reinforcing a concrete body, a multi-purpose anchor, an anchor for level adjustment and injection a method for repairing and reinforcing the concrete body using the same, which can connect adhesives and anchors at weak parts of the concrete body, which is neutralized, aged, deteriorated, cracked due to water leakage, or segregated, or at parts requiring the repair and reinforcement due to a change in use environment. The composite reinforced panel includes lightweight concrete, high strength concrete or a steel plate and reinforcing means, thereby being effectively prevented from bad environments causing a drop of reinforcing capacity, providing good heatproof and fireproof properties, and maximizing merits of materials used as the reinforcing means. The multi-purpose anchor has a bolt and an injection pipe, fixes the panel to the concrete body effectively, serves as a spacer maintaining a prescribed interval between the panel and the concrete body, and serves to inject filler and discharge the inside air to the outside, thereby improving construction efficiency. The anchor for level adjustment and injection has a male screw and a female screw at an end and an injection pipe of a straw type, thereby improving the construction efficiency when the concrete panel is installed.

Owner:MAINTENANCE PROFESSIONAL +1

High-toughness abrasion-resistant alloy steel for excavator bucket and production process thereof

ActiveCN103014515AControl quantityReduce sizeSoil-shifting machines/dredgersExcavatorWear resistance

The invention discloses a high-toughness abrasion-resistant alloy steel for an excavator bucket, which comprises the following chemical components in percentage by weight: 0.24-0.28% of C, 0.6-1.0% of Si, 1.2-1.5% of Mn, 0.6-1.1% of Cr, 0.3-0.5% of Mo, 0.05-0.10% of V, 0.004-0.006% of B, 0.08-0.12% of Ti, 0.01-0.025% of Ce, 0.02-0.03% of La, P less than or equal to 0.03%, S less than or equal to 0.03% and the balance of iron and impurities. Compared with the traditional high-manganese steel, the high-toughness abrasion-resistant alloy steel disclosed by the invention has the advantages of higher abrasion resistance, toughness and impact resistance; and the high-toughness abrasion-resistant alloy steel can be used for ensuring that the normal working of an excavator, preventing and controlling the early brittle failure, reduces the shut-down and maintenance times, increases the labor productivity and the equipment utilization ratio and reduces the production cost.

Owner:滁州恒昌机械装备制造有限公司

Low-carbon multi-component alloy steel for excavator bucket tooth, and its production technology

The invention discloses a low-carbon multi-component alloy steel for an excavator bucket tooth. The alloy steel comprises 0.20-0.26wt% of C, 0.4-0.6wt% of Si, 0.6-1.2wt% of Mn, 0.5-0.8wt% of Cr, 0.4-0.6wt% of Mo, 0.2-0.3wt% of Cu, 0.8-1.5wt% of Ni, 0.08-0.12wt% of Ti, 0.04-0.06wt% of Y, 0.02-0.04wt% of Ce, 0.02wt% or less of P, 0.02wt% or less of S, and the balance Fe and impurities. The micro-alloying treatment of trace elements comprising Mo, Cu, Ti, Ni, Y, Ce and the like increases nucleation and further refines crystal grains, so the number, the size and the form distribution of carbides are effectively controlled, included slag is deteriorated, the metallurgical quality and the comprehensive wear resistance are improved, and the comprehensive performances and the service life of the alloy steel are maximally improved. The adoption of a reasonable heat treatment technology, appropriate annealing treatment and appropriate quenching tempering substantially improves the hardness and the impact resistance of the alloy steel.

Owner:滁州恒昌机械装备制造有限公司

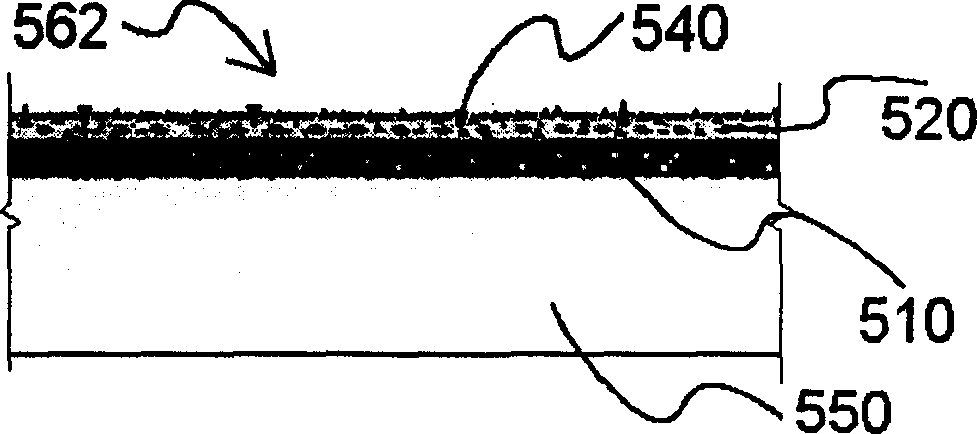

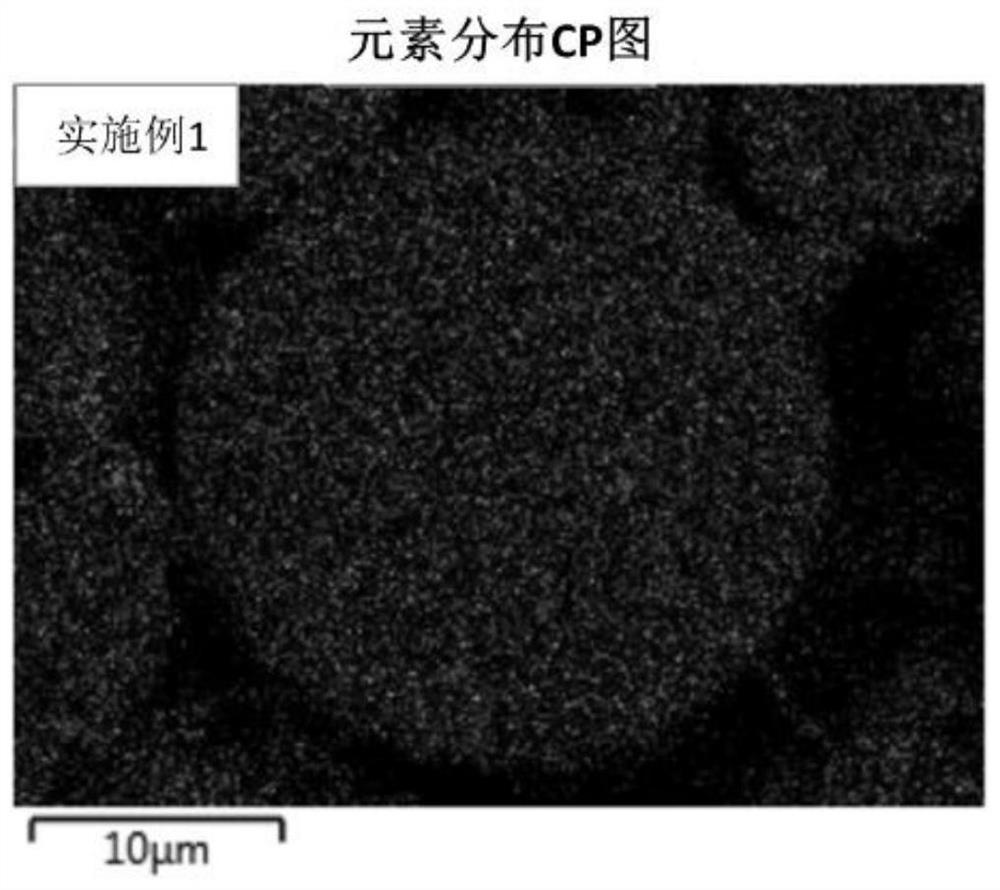

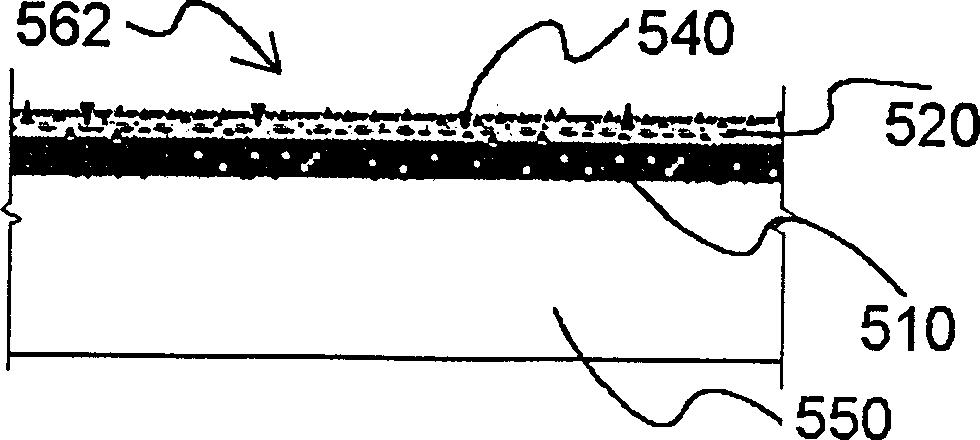

Positive electrode active material, positive electrode plate and lithium ion secondary battery

ActiveCN112447939AIncrease energy densityImprove structural stabilitySecondary cellsPositive electrodesChemical physicsHigh energy

The invention discloses a positive electrode active material, a positive electrode plate and a lithium ion secondary battery. The positive electrode active material comprises secondary particles formed by aggregation of primary particles, the primary particles are lithium transition metal oxides, and transition metal sites of the lithium transition metal oxides comprise nickel and doping elements;and the Young's modulus E of the primary particles satisfies 175 GPa < = E < = 220 GPa. By adopting the positive electrode active material provided by the invention, the lithium ion secondary batterycan have relatively high energy density and high-temperature cycle performance at the same time.

Owner:CONTEMPORARY AMPEREX TECH CO

Metal pipe protection reinforcing system

InactiveCN101994892AExcellent steam and heat resistanceTight and effective bondingCorrosion preventionPipe protection against corrosion/incrustationFiberMetal

The invention discloses a metal pipe protection reinforcing system which covers the surfaces of both a metal pipeline tubular product and a connecting part and contains a fiber assembly with excellent steaming resistance and a resin assembly. The fiber assembly with excellent steaming resistance is preferably selected from a polyphenylene sulfide fibre assembly. The metal pipe protection reinforcing system has the characteristics of acid and alkali corrosion resistance, good steaming resistance, and the like, is convenient for construction, prolongs the service life of the metal pipe, and has better repair function on a corroded protective layer.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

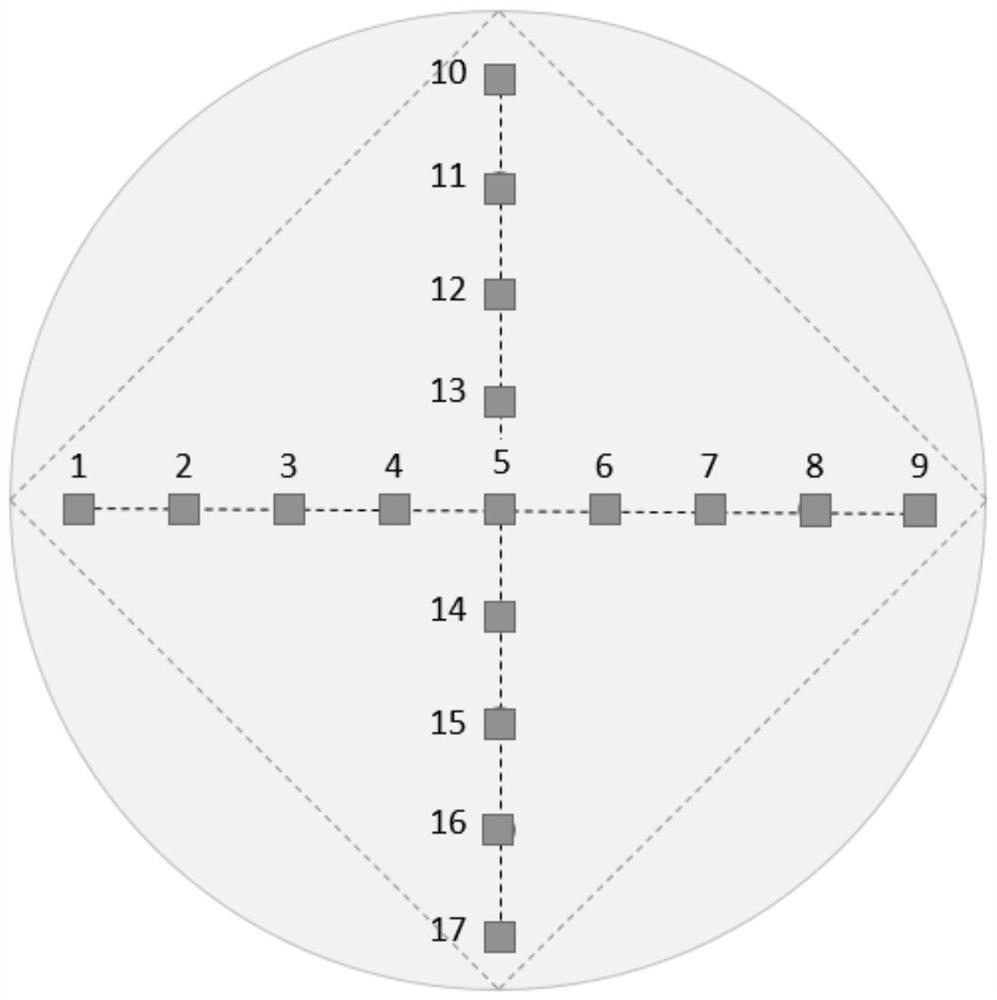

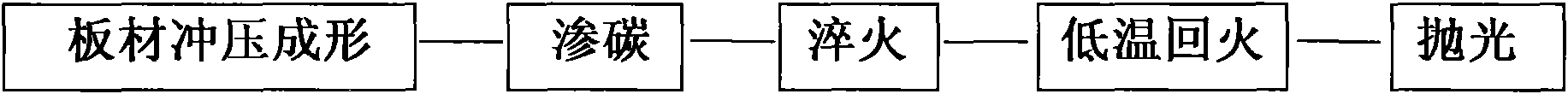

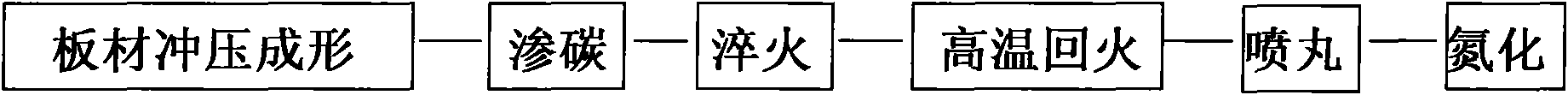

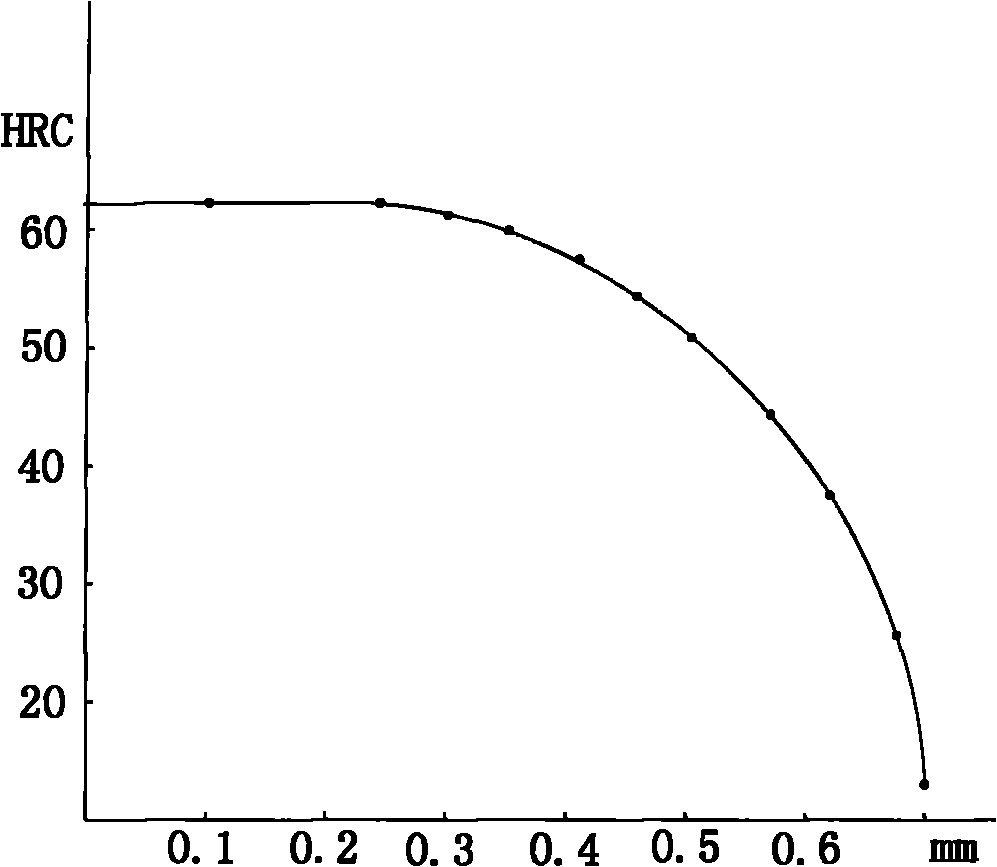

Heat treatment process of rocker

InactiveCN101994119APrevent brittle fractureEasily brokenSolid state diffusion coatingPass rateBrittle fracture

The invention discloses a heat treatment process of a rocker, belonging to the workpiece heat treatment processes for general machinery. The heat treatment process for the rocker workpiece can guarantee stable quality and prevent workpiece from brittle fracture, and has reduced requirement on carburization equipment and the product pass rate reaching 100%. The heat treatment process comprises the processes of impact molding, carburization, quenching, high-temperature tempering, preheating and malcomising for the rockers.

Owner:徐鹤铭

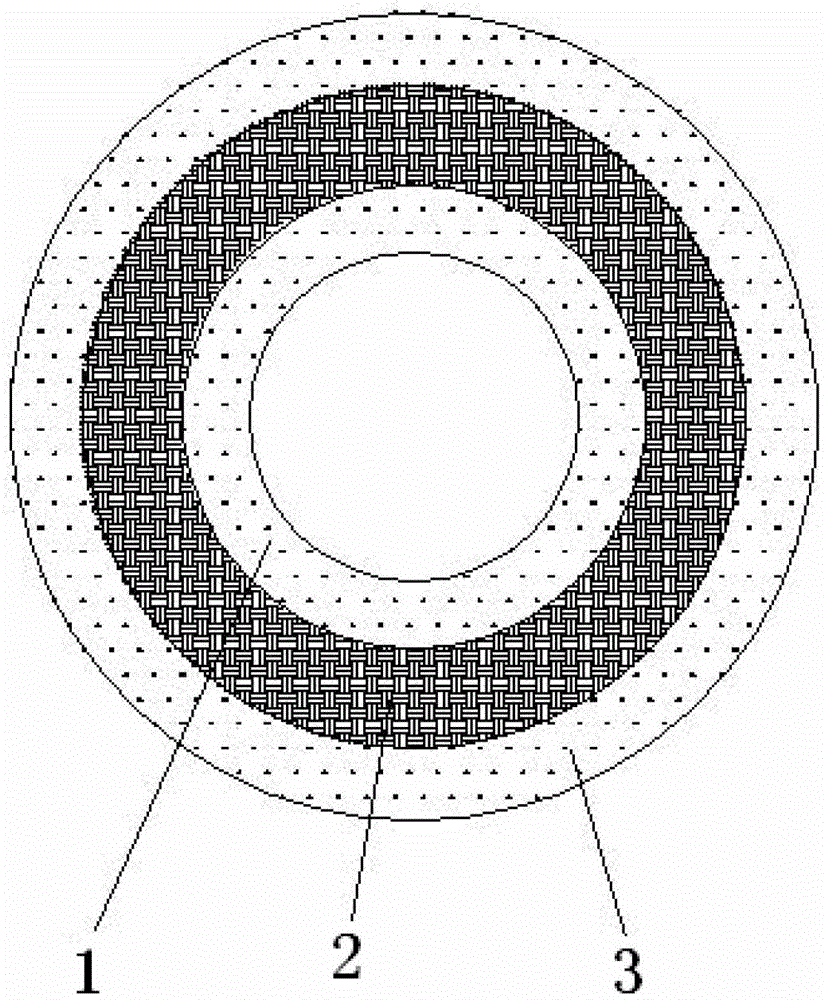

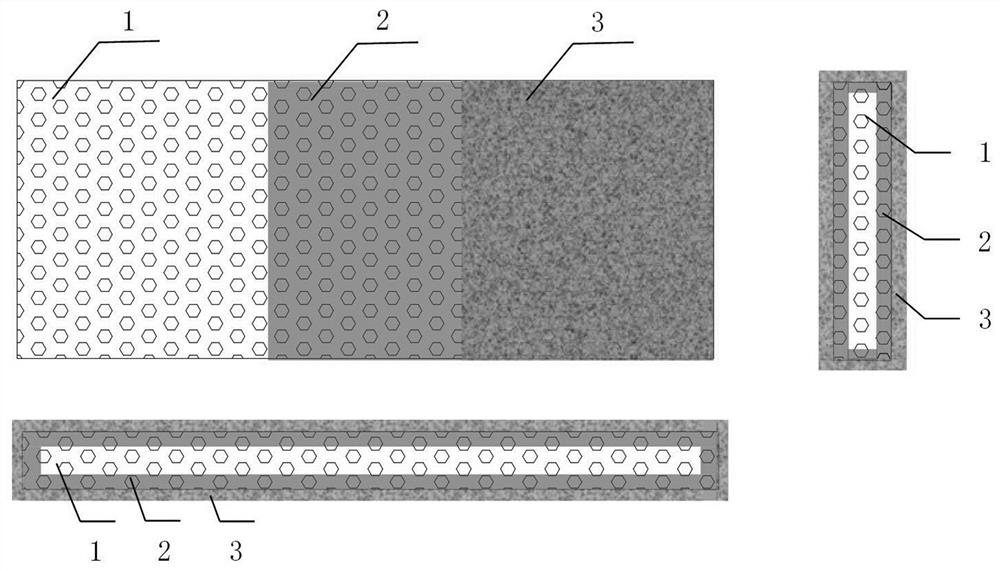

Flexible continuously cast water gap and manufacturing method thereof

The invention provides a flexible continuously cast water gap and a manufacturing method thereof, and belongs to the technical field of metallurgy. The water gap comprises an inner layer, an outer layer and an intermediate layer, wherein the inner layer is made of a fireproof material; the outer layer is made of a fireproof material; and the intermediate layer is arranged between the inner layer and the outer layer and is made of a fiber-shaped material or a fireproof material mixed with the fiber-shaped material. Since the fiber material intermediate layer is formed in the water gap, the water gap has certain flexibility, can resist mechanical outer force of impact, vibration and the like, prevents crack formation and brittle failure, and can lower the baking temperature and time to certain extent, thereby prolonging the using times and the service life; additionally, the manufacturing method is simple, and a water gap of a specific shape can be manufactured.

Owner:LAIWU IRON & STEEL GRP

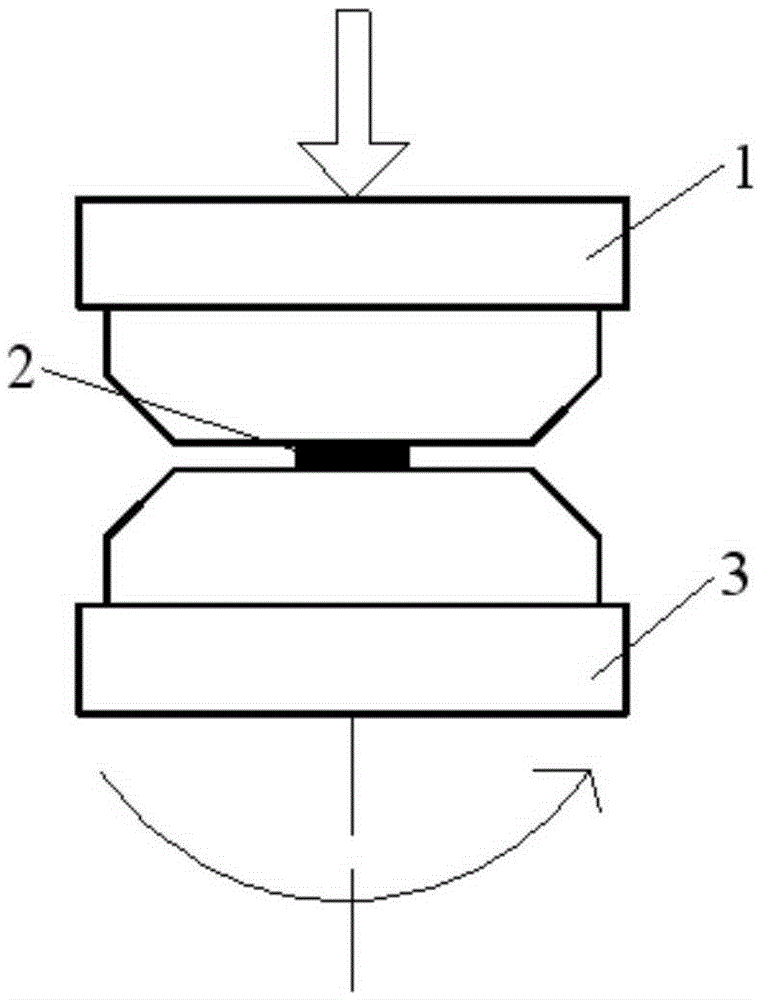

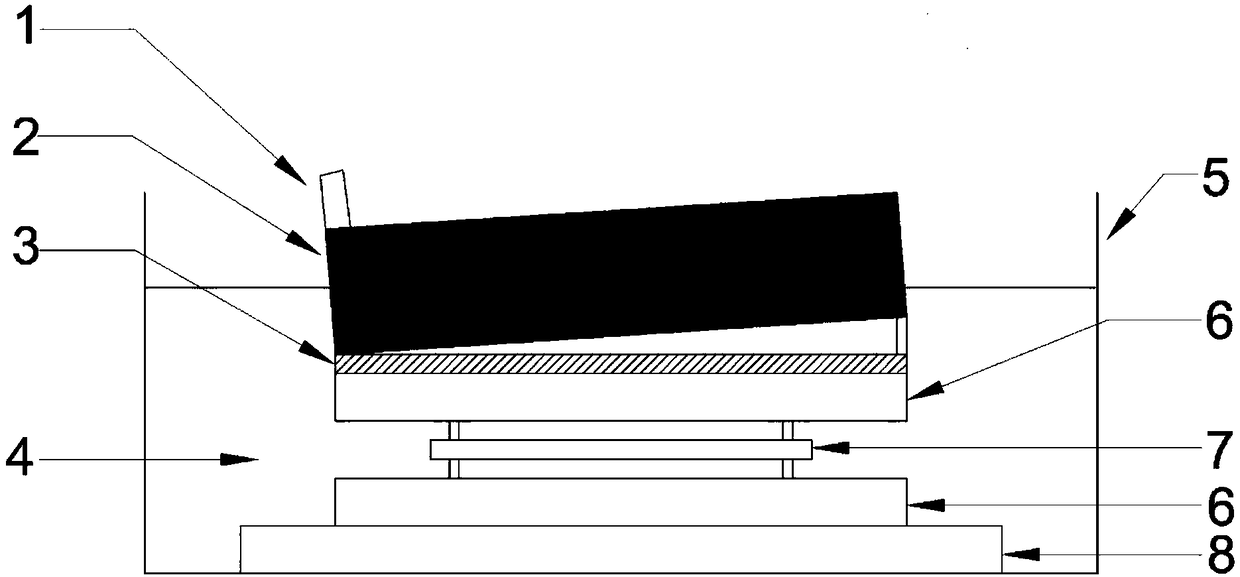

Explosive welding method for zirconium-based metal glass plate and light metal plate

ActiveCN108406079AGuaranteed cleanlinessGood for explosive weldingWelding/soldering/cutting articlesNon-electric welding apparatusDetonatorDetonation

The invention discloses an explosive welding method for a zirconium-based metal glass plate and a light metal plate. The explosive welding method adopts a special explosive water tank, a special emulsion explosive, a detonator, a zirconium-based metal glass plate, a light metal plate, a cutting board and a priming apparatus, wherein the special explosive water tank is used for storing water; and the explosive welding method specifically comprises a welding material processing step and a testing apparatus installation step. The explosive welding method disclosed by the invention belongs to thetechnical field of welding and specifically belongs to underwater explosive welding; the zirconium-based metal glass plate and the light metal plate are placed on the cutting board arranged in the special explosive water tank after being horizontally and fixedly sealed; and the special emulsion explosive and the detonator are placed on a flying plate. Detonation wave is transmitted via water so asto realize welding of the zirconium-based metal glass plate and the light metal plate. The explosive welding method disclosed by the invention has the advantages that the detonation wave generated byexplosion is transmitted by using water as a medium so that the overall zirconium-based metal glass plate is kept intact and is unchanged in unbalance property, and the zirconium-based metal glass plate and the light metal plate are welded together.

Owner:CHINA UNIV OF MINING & TECH

A method of using pet to produce flat yarn

ActiveCN103789869BImprove melt strengthImprove toughnessMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterYarn

Owner:ZHEJIANG WANKAI NEW MATERIAL

Cold rolling method of ultra-thin gauge high magnetic induction grain-oriented silicon steel

ActiveCN106583448BRealize aging rollingPrevent brittle fractureMetal rolling arrangementsEmulsionLubrication

The invention discloses a cold rolling method for high-magnetic-induction grain-oriented silicon steel in the extremely thin specification. The method comprises steps as follows: (1) the thickness before rolling ranges from 2.0 mm to 2.5 mm, and normalization pickling is performed; (2) the primary cold rolling method is adopted, and continuous reversible seven-pass cold rolling is performed: (2.1) rough-surface working rolls are adopted for the first five passes, and fine-surface working rolls are adopted for the last two passes; (2.2) the reduction rate of each pass is controlled, the reduction rate of the first pass ranges from 30% to 45%, the reduction rate of the last pass ranges from 18% to 31%, and the reduction rates of the rest passes range from 24% to 42%; (2.3) technological lubrication and cooling are performed through emulsion spraying; the plate temperature in the first three passes is controlled to gradually increased to 200-230 DEG C; the temperature is reduced for rolling in the fourth pass; the plate temperature in the subsequent passes is controlled to be 60-80 DEG C; (2.4) automatic plate shape control is performed; (2.5) the rolling force in each pass is controlled to range from 250 T to 520 T; the unit tension on the entrance side of each pass is controlled to range from 2 kg / mm<2> to 20 kg / mm<2>, and the unit tension on the exit side of the pass is controlled to range from 15 kg / mm<2> to 30 kg / mm<2>; (2.6) the product thickness after rolling ranges from 0.15 mm to 0.2 mm; (3) subsequent procedures are conducted conventionally. With the method, the production efficiency of the high-end silicon steel in the extremely thin specification is substantially increased, and products are free of plate shape quality defects and are high in surface quality.

Owner:武汉钢铁有限公司

Method for producing flat filaments from polyester chips

InactiveCN108166082APrevent brittle fractureEvenly heatedArtificial filament heat treatmentMelt spinning methodsPolyesterTraction system

The invention relates to the field of high-polymer material processing, in particular to a method for producing flat filaments from polyester chips. The method comprises the following steps that 1, the polyester chips, an anti-aging agent and color master batch are mixed, stirred, crystallized, dried and processed to be uniform, and then the mixture enters a screw extruder; 2, the chips are melted, blended and then extruded in the screw extruder; 3, the chips enter a spinneret die head device and are sprayed by a spinneret plate to obtain initial flat filaments; 4, after being cooled, the initial flat filaments enter an initial traction system to be stretched; 5, the initial flat filaments enter an oven and are heated and kept warm; 6, the initial flat filaments are subjected to traction and stretching again; 7, step 4, step 5 and step 6 are repeated 2-4 times, and flat filament finished products are obtained; 8, the flat filament finished products are wound and packed. The flat filaments produced through the method are high in anti-aging performance and high in tensile strength.

Owner:常州至能土工材料有限公司

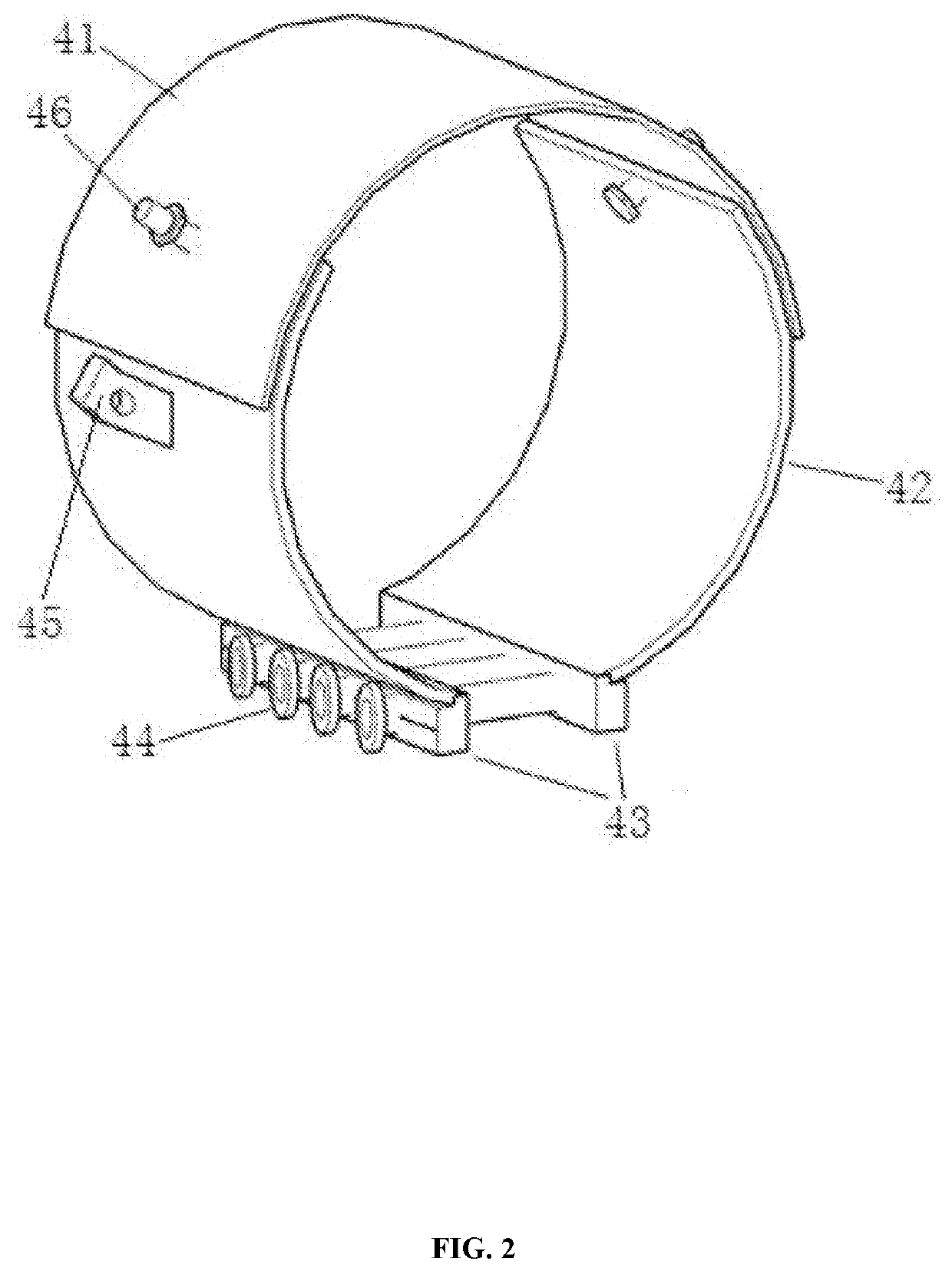

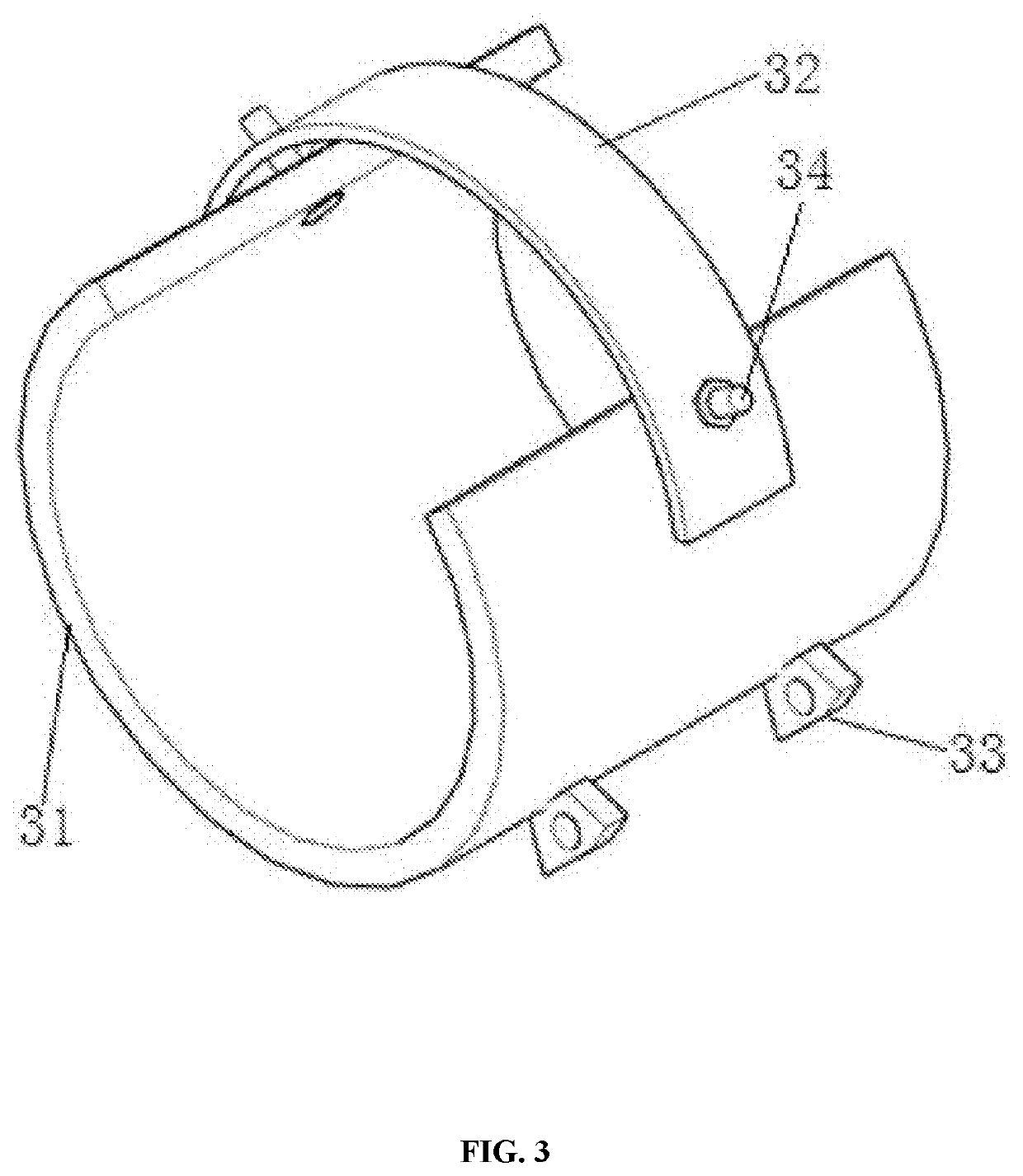

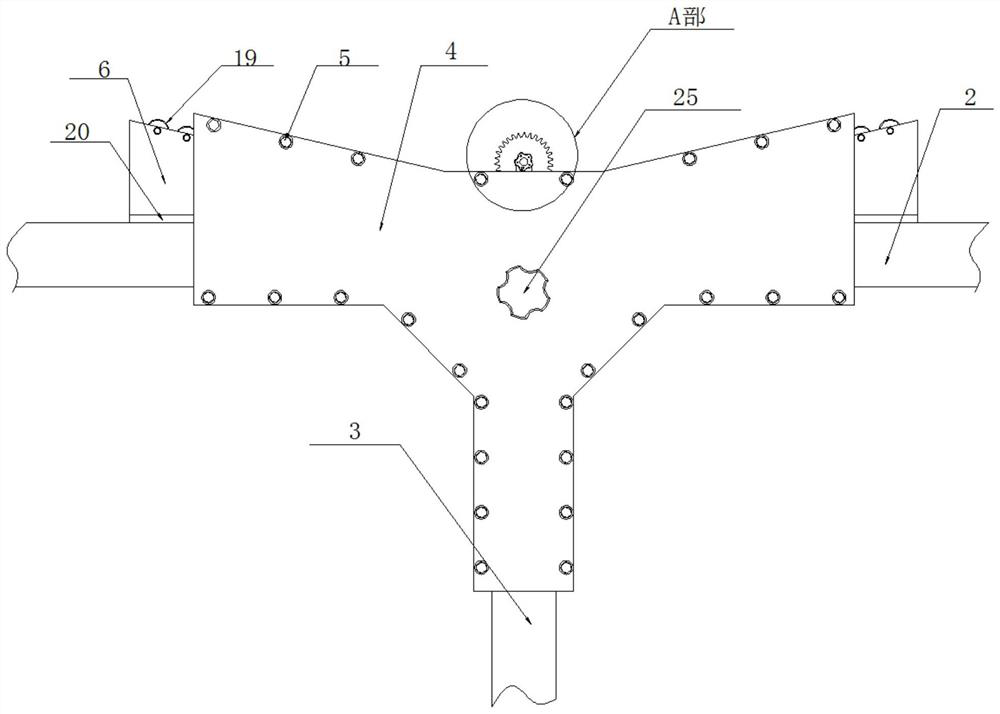

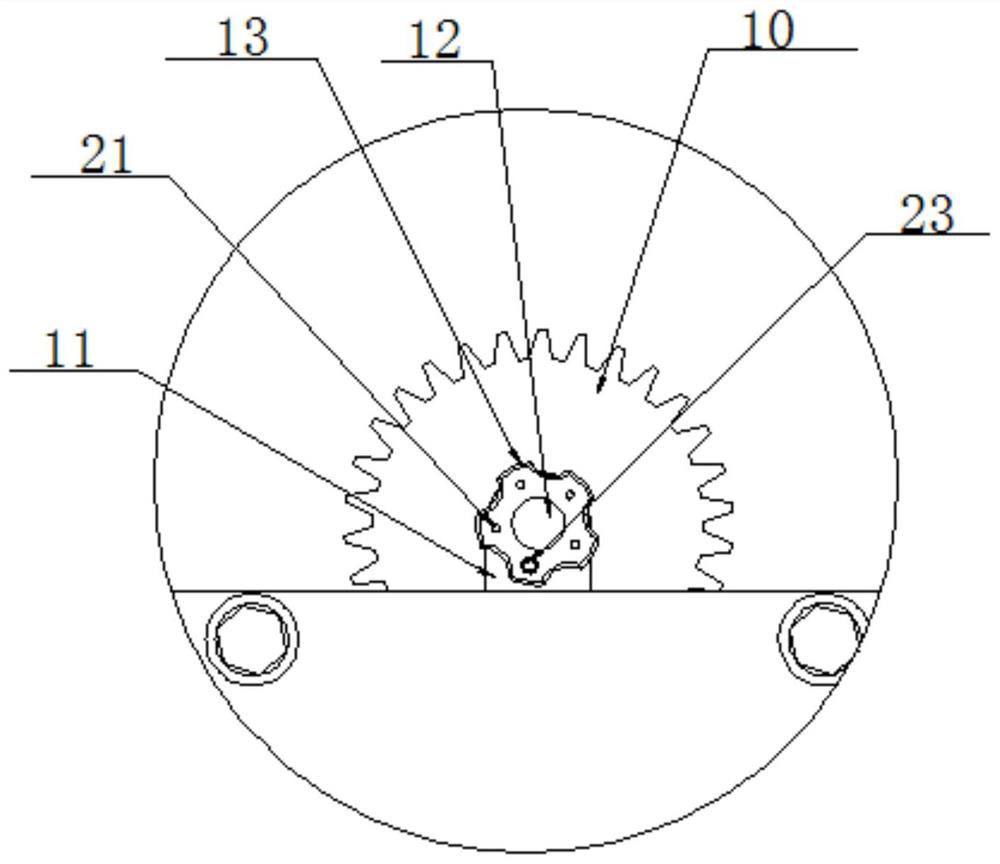

Device and method for reinforcing round section wood beam by combination of prestressed FRP sheet and high strength steel wire rope

ActiveUS20220178158A1Convenient reinforcement constructionLittle disturbanceBuilding repairsBuilding material handlingFiberClassical mechanics

The present disclosure relates to a device and a method for reinforcing a round section wood beam by the combination of a prestressed Fiber Reinforce Plastic (FRP) sheet and a high strength steel wire rope. The device includes an FRP sheet adhered to a bottom surface of a log beam in the length direction. A middle supporting piece is mounted in the middle of the log beam. An end part reinforcing anchoring piece is mounted at each of two ends of the log beam. FRP hoops are adhered to the log beam and are located between the middle supporting piece and each of the end part reinforcing anchoring pieces at intervals in the length direction. High strength steel wire ropes with both ends connected to the corresponding end part reinforcing anchoring pieces are respectively arranged on the two sides of the middle supporting piece.

Owner:FUZHOU UNIV

High-toughness abrasion-resistant alloy steel for excavator bucket and production process thereof

ActiveCN103014515BControl quantityReduce sizeSoil-shifting machines/dredgersWear resistanceToughness

The invention discloses a high-toughness abrasion-resistant alloy steel for an excavator bucket, which comprises the following chemical components in percentage by weight: 0.24-0.28% of C, 0.6-1.0% of Si, 1.2-1.5% of Mn, 0.6-1.1% of Cr, 0.3-0.5% of Mo, 0.05-0.10% of V, 0.004-0.006% of B, 0.08-0.12% of Ti, 0.01-0.025% of Ce, 0.02-0.03% of La, P less than or equal to 0.03%, S less than or equal to 0.03% and the balance of iron and impurities. Compared with the traditional high-manganese steel, the high-toughness abrasion-resistant alloy steel disclosed by the invention has the advantages of higher abrasion resistance, toughness and impact resistance; and the high-toughness abrasion-resistant alloy steel can be used for ensuring that the normal working of an excavator, preventing and controlling the early brittle failure, reduces the shut-down and maintenance times, increases the labor productivity and the equipment utilization ratio and reduces the production cost.

Owner:滁州恒昌机械装备制造有限公司

Composite panel for reinforcing concrete body

InactiveCN1265069CEnsure safetyImprove heat resistanceConstruction materialIn situ pavingsHigh strength concreteFiber

Disclosed are a panel for repairing and reinforcing a concrete body, a multi-purpose anchor, an anchor for level adjustment and injection a method for repairing and reinforcing the concrete body using the same, which can connect adhesives and anchors at weak parts of the concrete body, which is neutralized, aged, deteriorated, cracked due to water leakage, or segregated, or at parts requiring the repair and reinforcement due to a change in use environment. The composite reinforced panel includes lightweight concrete, high strength concrete or a steel plate and reinforcing means, thereby being effectively prevented from bad environments causing a drop of reinforcing capacity, providing good heatproof and fireproof properties, and maximizing merits of materials used as the reinforcing means. The multi-purpose anchor has a bolt and an injection pipe, fixes the panel to the concrete body effectively, serves as a spacer maintaining a prescribed interval between the panel and the concrete body, and serves to inject filler and discharge the inside air to the outside, thereby improving construction efficiency. The anchor for level adjustment and injection has a male screw and a female screw at an end and an injection pipe of a straw type, thereby improving the construction efficiency when the concrete panel is installed.

Owner:MAINTENANCE PROFESSIONAL +1

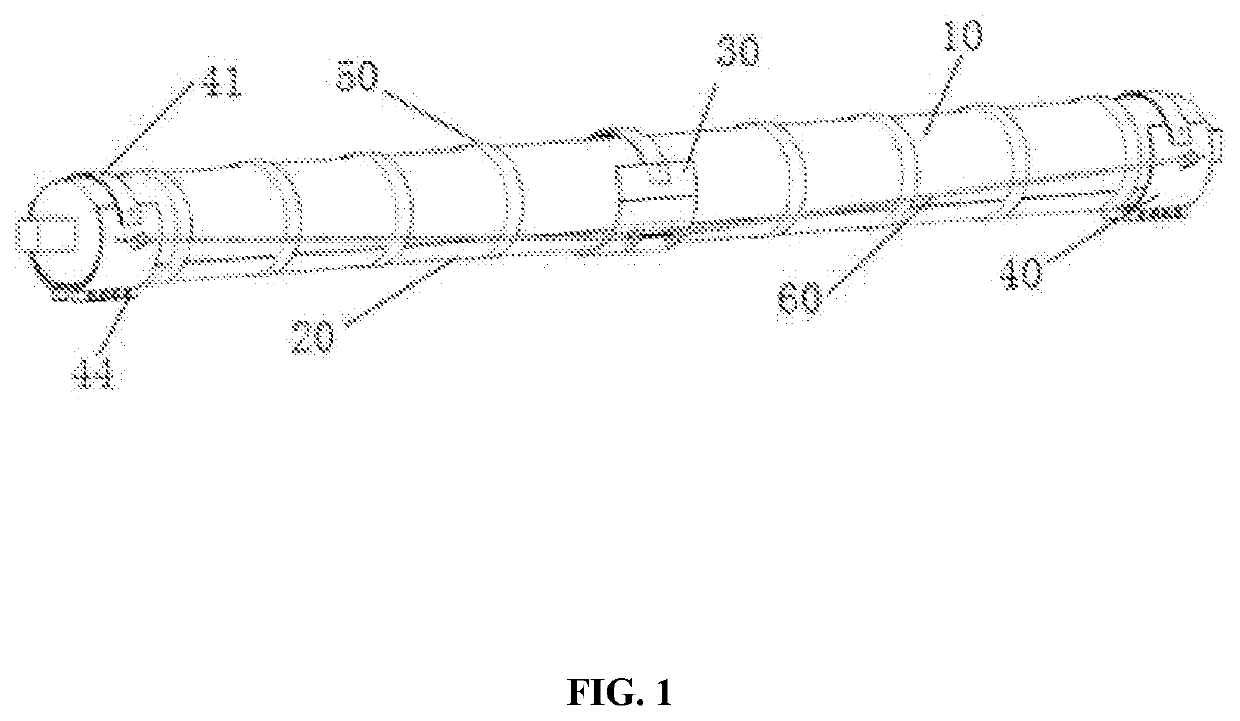

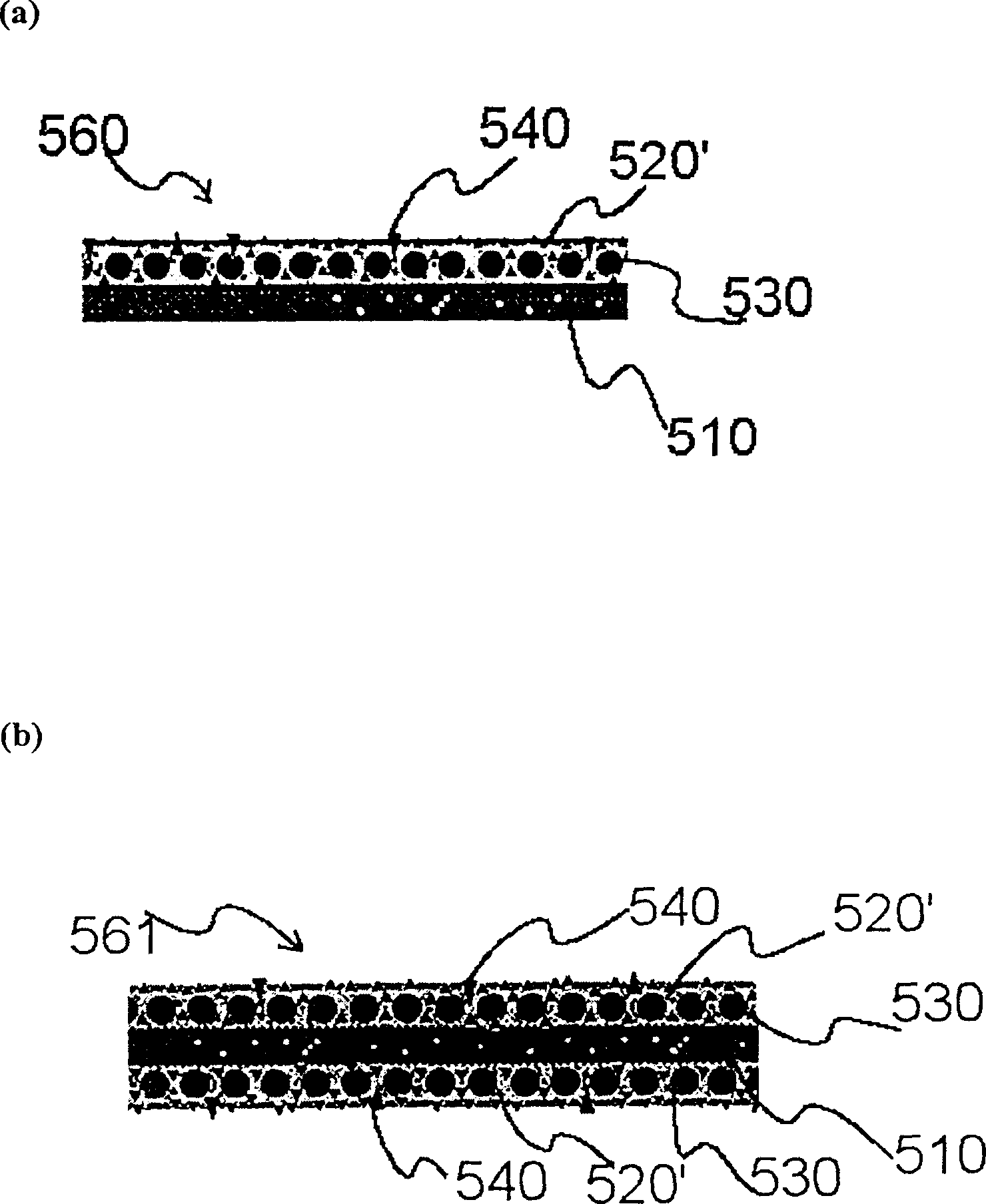

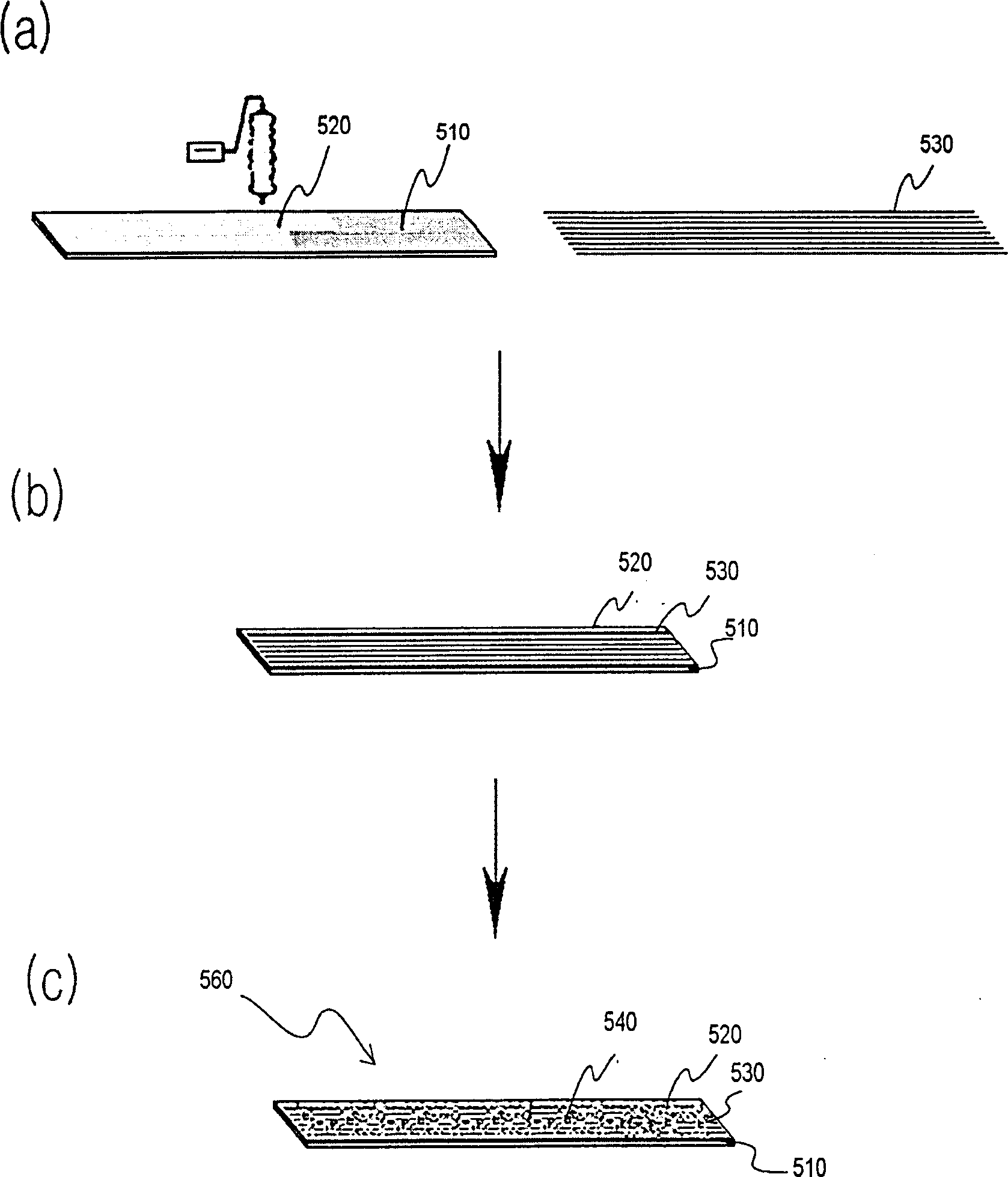

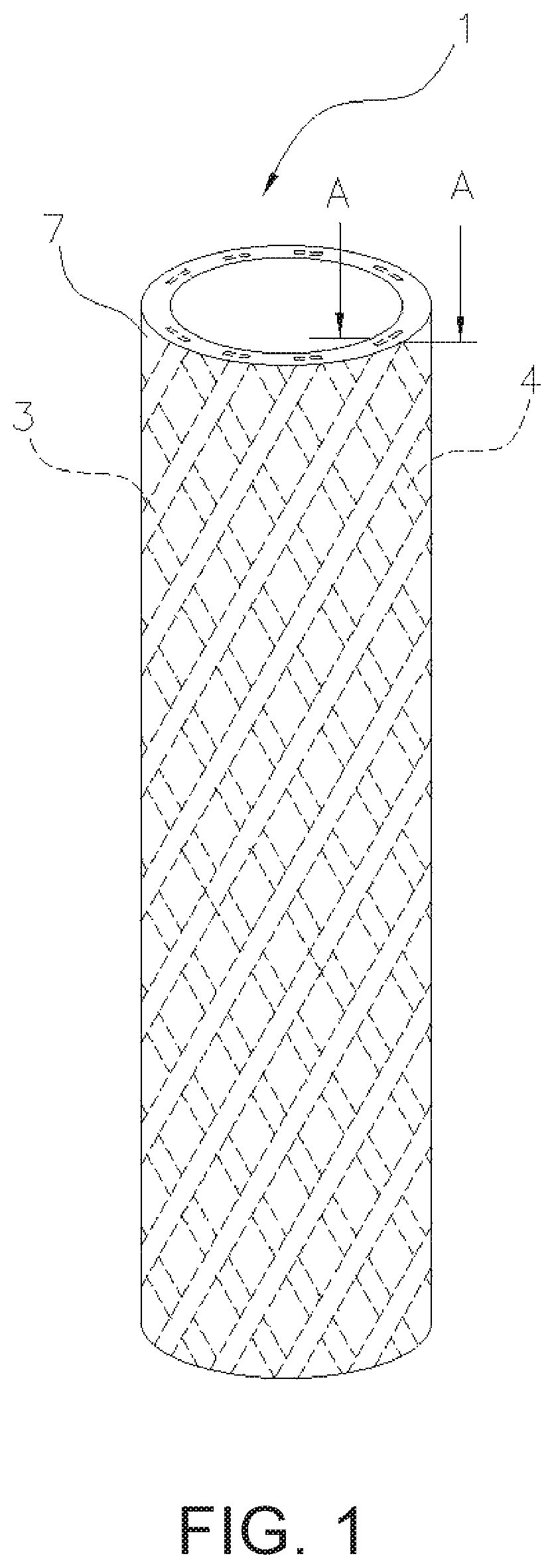

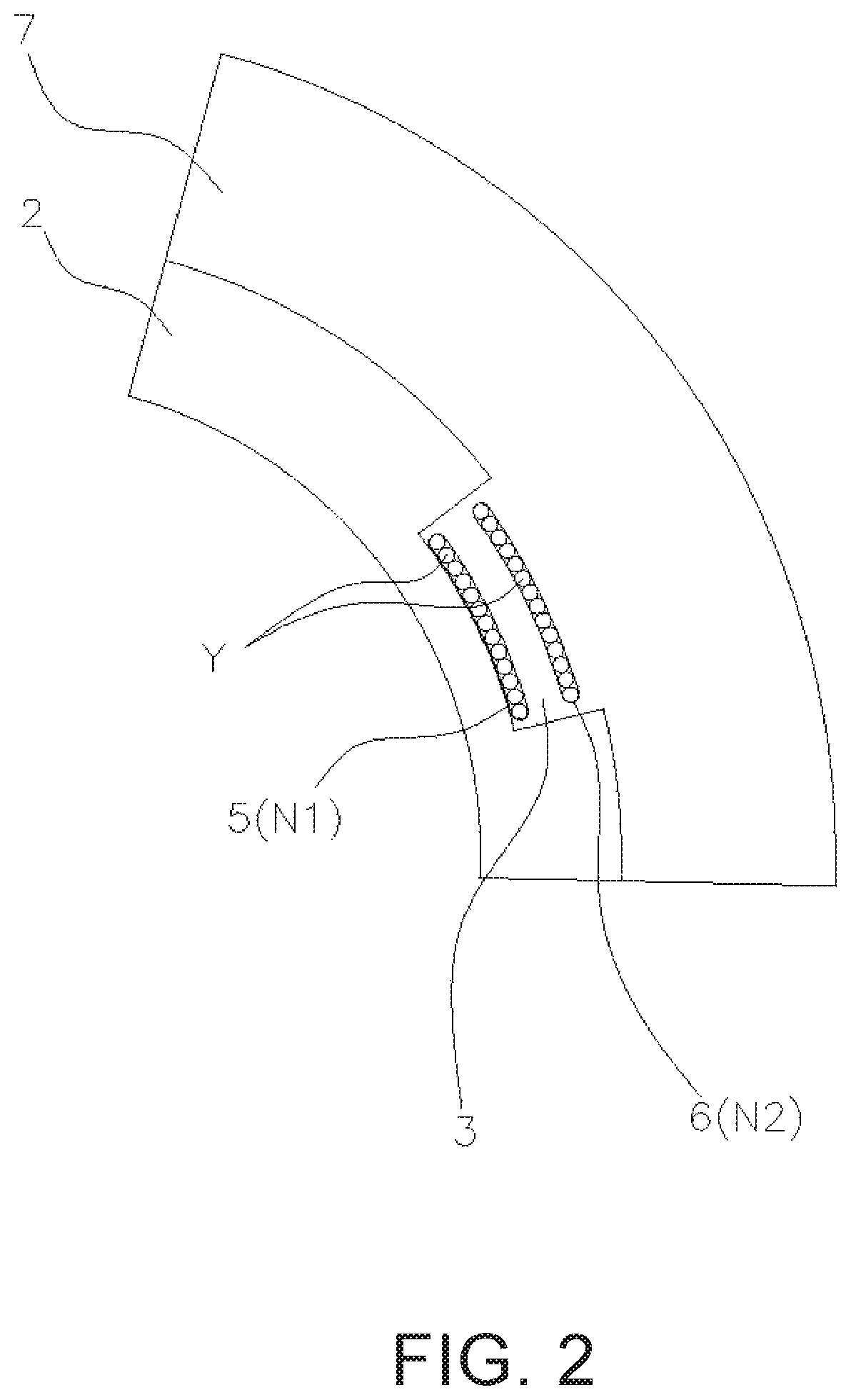

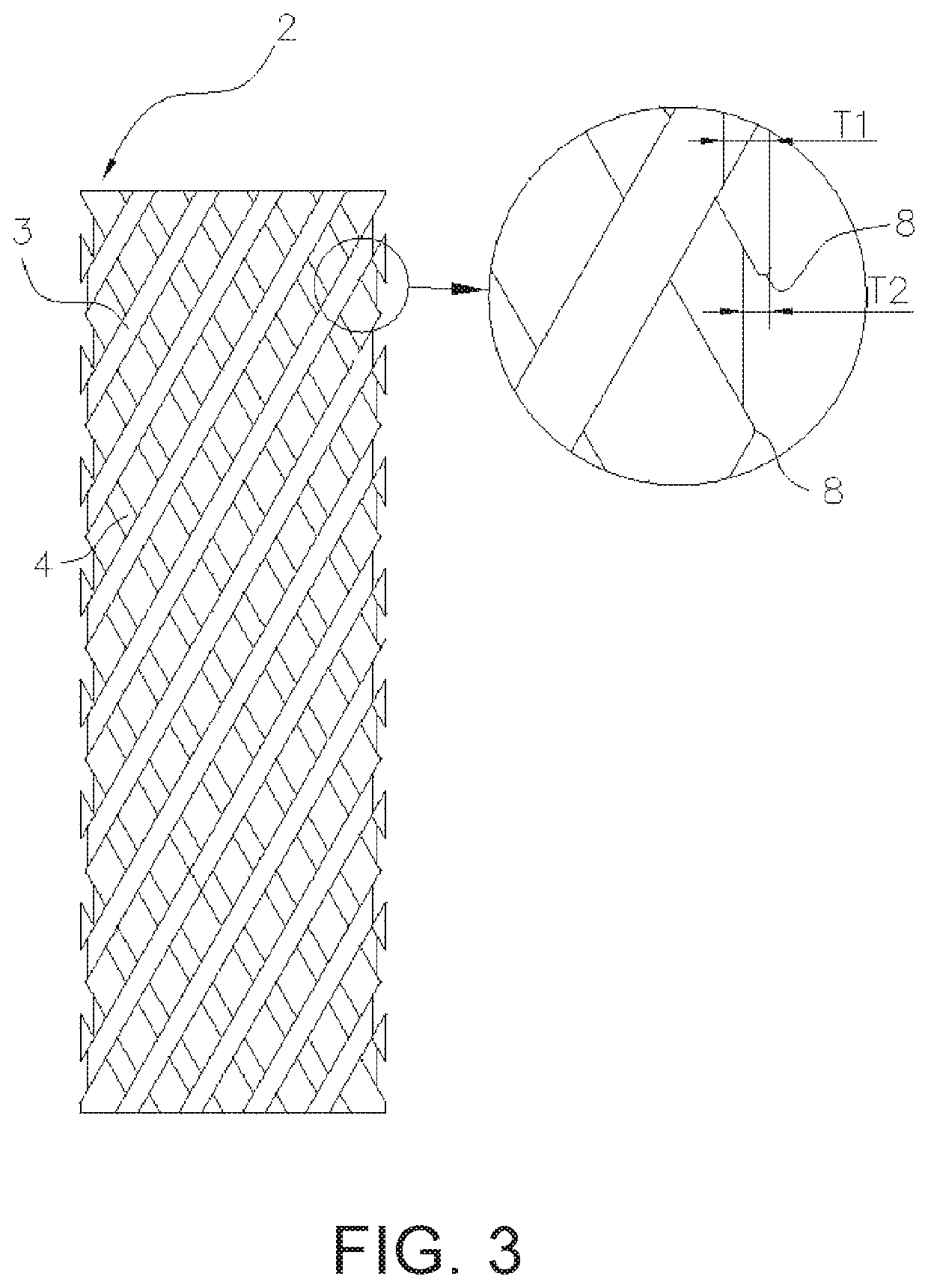

Tubular body containing SiC fiber and method for producing the same

ActiveUS11380445B2Improve thermal conductivityPrevent brittle fractureOptical rangefindersFuel elementsSic fiberFibrous layer

A first SiC layer formed into a tubular shape and made of a SiC material, a first groove which spirals in one direction along the outer periphery of the first SiC layer, a first SiC fiber layer made of a plurality of SiC fibers wound along the first groove, a second SiC fiber layer made of a plurality of SiC fibers wound outside of the first SiC fiber layer in a direction different from the one direction, and a second SiC layer which is made of a SiC material and which covers the first SiC layer, the first SiC fiber layer, and the second SiC fiber layer are provided. The first SiC fiber layer and the second SiC fiber layer are separated from each other at intersections of the first SiC fiber layer and the second SiC fiber layer.

Owner:ADMAP

Excavator silicon-manganese alloy steel bucket tooth casting and its processing technology

ActiveCN103014519BEasy to shapeImprove distributionFurnace typesHeat treatment furnacesRare-earth elementManganese

Owner:滁州恒昌机械装备制造有限公司

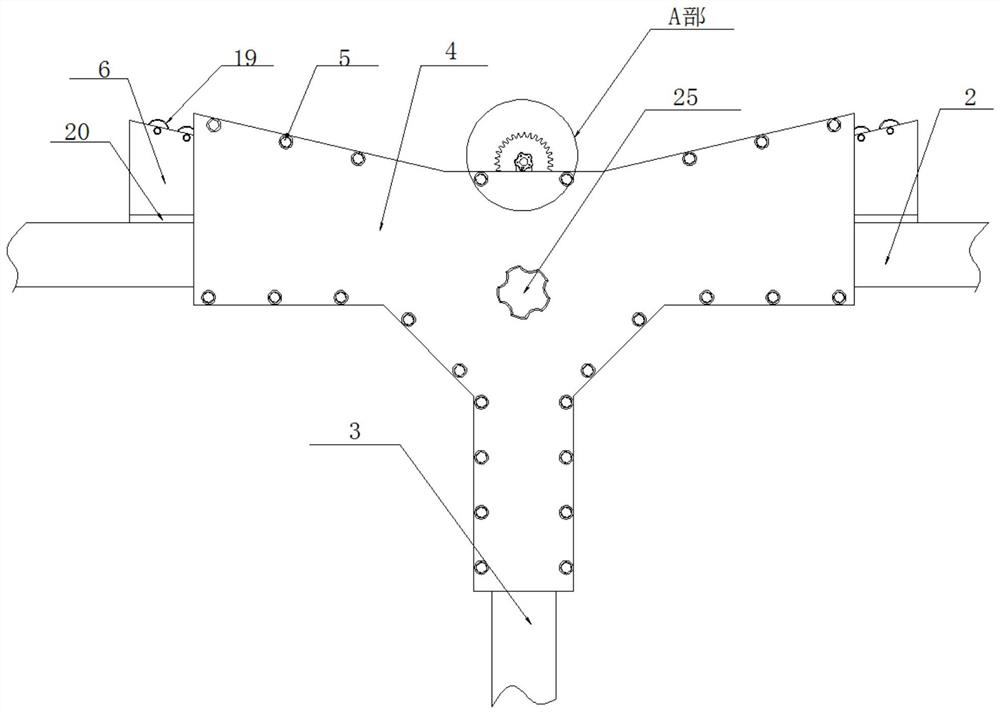

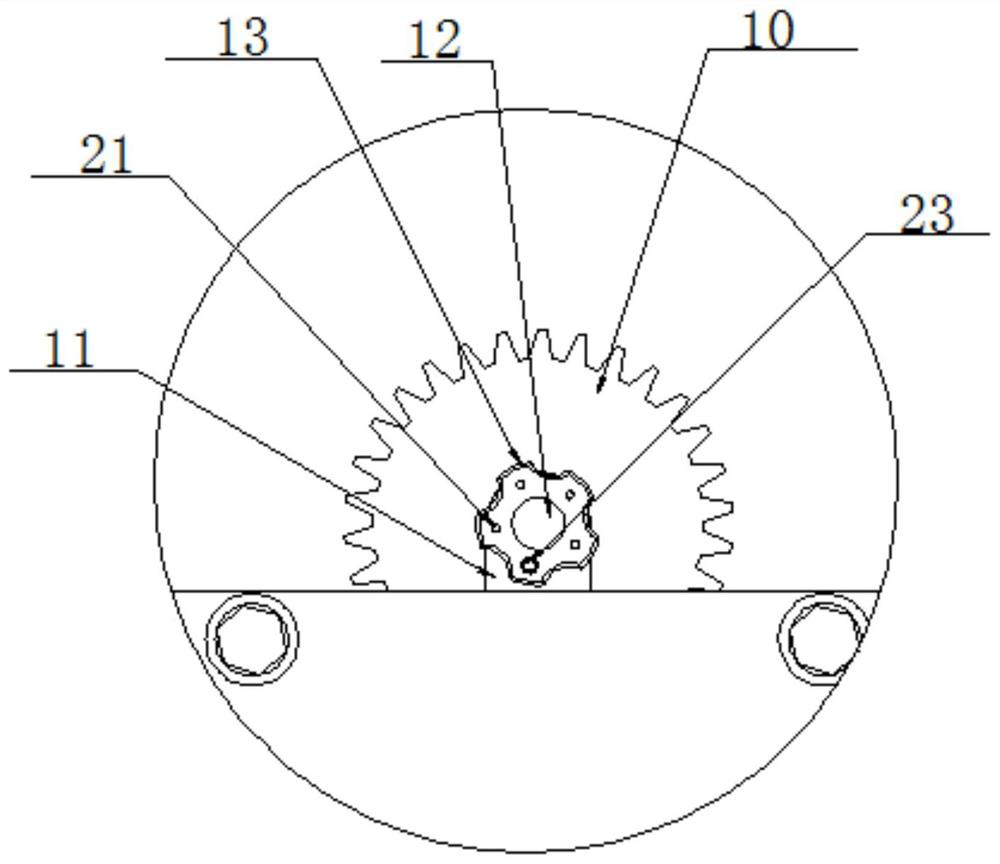

Installation, connection and reinforcement device for building steel structure

ActiveCN112081252BPrevent brittle fractureImprove stress resistanceProtective buildings/sheltersShock proofingEarthquake resistanceThreaded pipe

An installation, connection and reinforcement device for a building steel structure, the invention relates to the technical field of steel structures, the shell is arranged on the connecting part of the beam body and the column body through the open end cover on the front side; the left and right sides of the shell on the upper side of the beam body Slanted wedges are inserted symmetrically; screw rods are vertically fixed on the opposite surfaces of the slanted wedges, and the ends of the screw rods on the left and right sides are respectively inserted into the left and right ends of the internally threaded pipe through screw thread rotation, and the middle part of the internally threaded pipe is fixed A worm is provided, and the upper side of the worm is meshed with a worm wheel. After the upper side of the worm wheel moves through the upper side of the housing, it is arranged in the middle of the shaft seat through the rotation of the rotating shaft. The front end of the rotating shaft passes through the front side of the shaft seat. , the fixed connection has a No. 1 hand screw; the connection between the beam and the column is reinforced to effectively prevent the brittle fracture of the welded part of the beam and column when the steel structure beam is under too much force, which will cause the column to deform or even collapse. At the same time, increase Compressive and seismic performance of beam and column joints.

Owner:SHAN DONG JUXIN GRP STEEL STRUCTURE CO LTD

Marine impact-resistant foamed aluminum-based composite board and preparation method thereof

ActiveCN114686089AHigh compressive strengthImprove structural strengthPretreated surfacesPolyurea/polyurethane coatingsCompressive resistanceComposite plate

The invention discloses a marine shock-resistant foamed aluminum-based composite board which comprises a foamed aluminum base material, a polyurethane infiltration layer is arranged on the surface of the foamed aluminum base material, pores in the surface of the foamed aluminum base material are completely filled with the polyurethane infiltration layer, and a wear-resistant layer is arranged on the surface of the polyurethane infiltration layer. The polyurethane infiltration layer is sprayed on the surface of the foamed aluminum base material, pores in the surface of the foamed aluminum are filled, the stress condition of pore walls of the foamed aluminum is improved, when the foamed aluminum is subjected to impact load and local concentrated stress, the filling layer can provide effective support for the pore walls, brittle fracture of the pore walls is prevented, and the service life of the foamed aluminum is prolonged. The surface of the foamed aluminum material is effectively protected, the overall compressive strength of the foamed aluminum material is improved, and the problem that pore walls on the surface of the foamed aluminum are fragile and broken is solved; and the wear-resistant layer is sprayed on the surface of the polyurethane infiltration layer, so that the wear resistance of the foamed aluminum-based composite board is improved, and the foamed aluminum-based composite board has the characteristics of simple processing technology, low cost and applicability to foamed aluminum base materials in different shapes.

Owner:713 RES INST OF CHINA SHIPBUILDING IND CORP

Aluminum alloy aluminum rod and manufacturing method for making aluminum lamps from the aluminum alloy aluminum rod

The invention discloses an aluminum alloy aluminum bar. The aluminum alloy aluminum bar comprises, by weight, 0.45%-0.55% of Mg, 0.2%-0.4% of Si, less than 0.1% of Fe, less than 0.1% of Cu, less than 0.1% of Mn, less than 0.1% of Zn, and the balance Al. When the aluminum alloy aluminum bar is used for manufacturing an aluminum lamp, a mold is made of H13 steel and comprises a bottom mold body, a middle mold body and a face mold body; the bottom mold body conducts primary feeding, flow guiding is carried out through five holes, the middle mold body conducts secondary feeding, and flow guiding is carried out through eight holes; aluminum materials are distributed into a welding chamber after being fused and are extruded out through an extrusion working belt, the mold is heated through a decreasing heating method and is heated to 510 DEG C at first, and heat is preserved for 0.5-1.5 h; and then, the temperature is lowered to 450 DEG C, heat is preserved for 1.5-2.5 h, an aluminum bar product is obtained, after being machined, the aluminum bar product is manufactured into a lampholder and a lamp barrel, and thus the aluminum lamp is obtained. By means of the aluminum alloy aluminum bar, the service life of the mold can be prolonged, and the yield of the aluminum lamp is increased.

Owner:RUIAN JINYU ALUMINUM

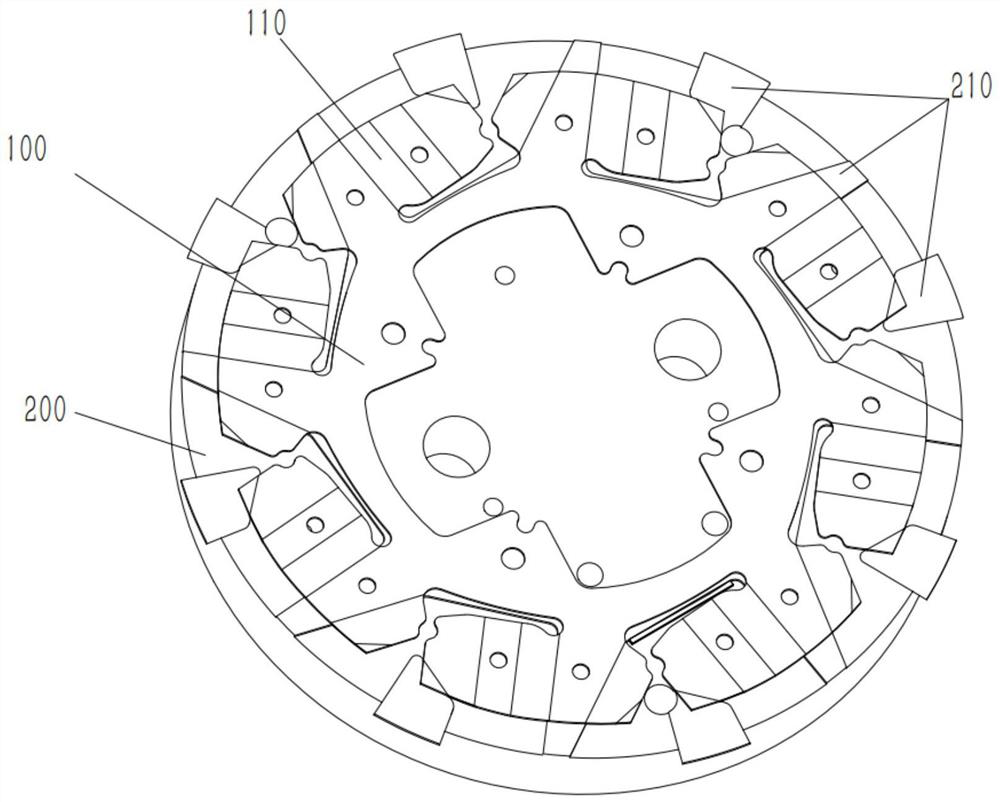

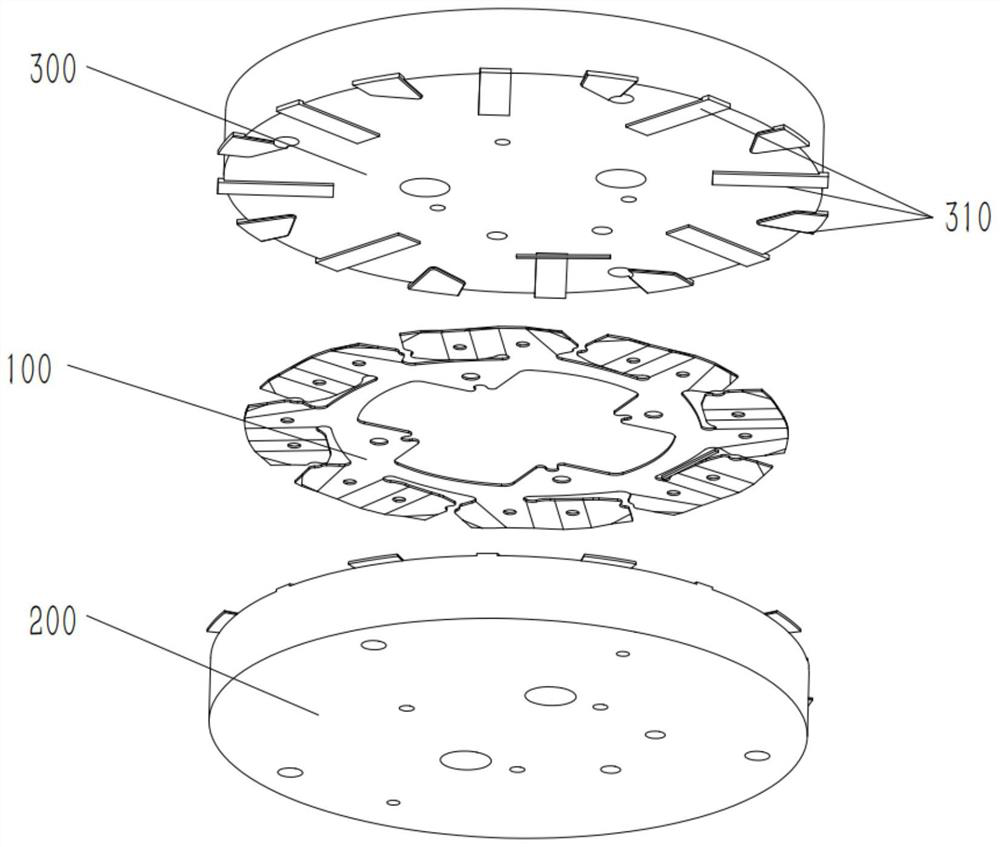

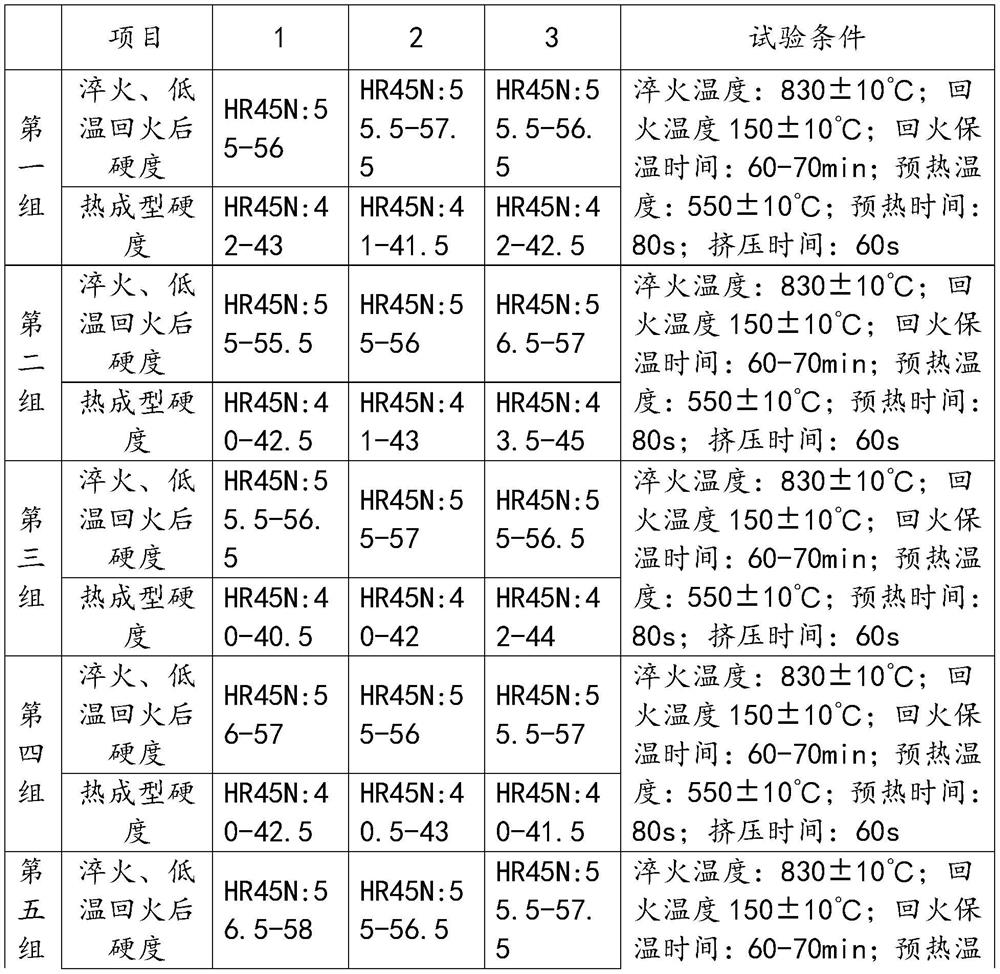

Forming process of corrugated shrapnel and corrugated shrapnel

The invention provides a forming process of a corrugated elastic piece and a corrugated elastic piece, and relates to the field of clutch elastic pieces. The forming process of the corrugated elasticpiece comprises the following steps: making a soft 65-Mn blank into an elastic piece blank; carrying out quenching treatment on the elastic piece blank; carrying out low-temperature tempering treatment on the quenched elastic piece blank; putting the elastic piece blank subjected to low-temperature tempering into a mould, heating the elastic piece blank, and extruding the elastic piece blank to form corrugation by using the mould; and carrying out punching treatment on the corrugated elastic piece blank. By means of the process, the soft 65-Mn blank can be thermally formed into the corrugatedelastic piece, and the corrugated elastic piece is used for relieving the problems that a corrugated elastic piece has small corrugation bending angle, large stress, and high occurrence rate of the corrugation height attenuation in the forming process in the prior art. The corrugated elastic piece is manufactured and formed by adopting the forming process of the corrugated elastic piece.

Owner:CHONGQING CHANGAN CLUTCH MFG

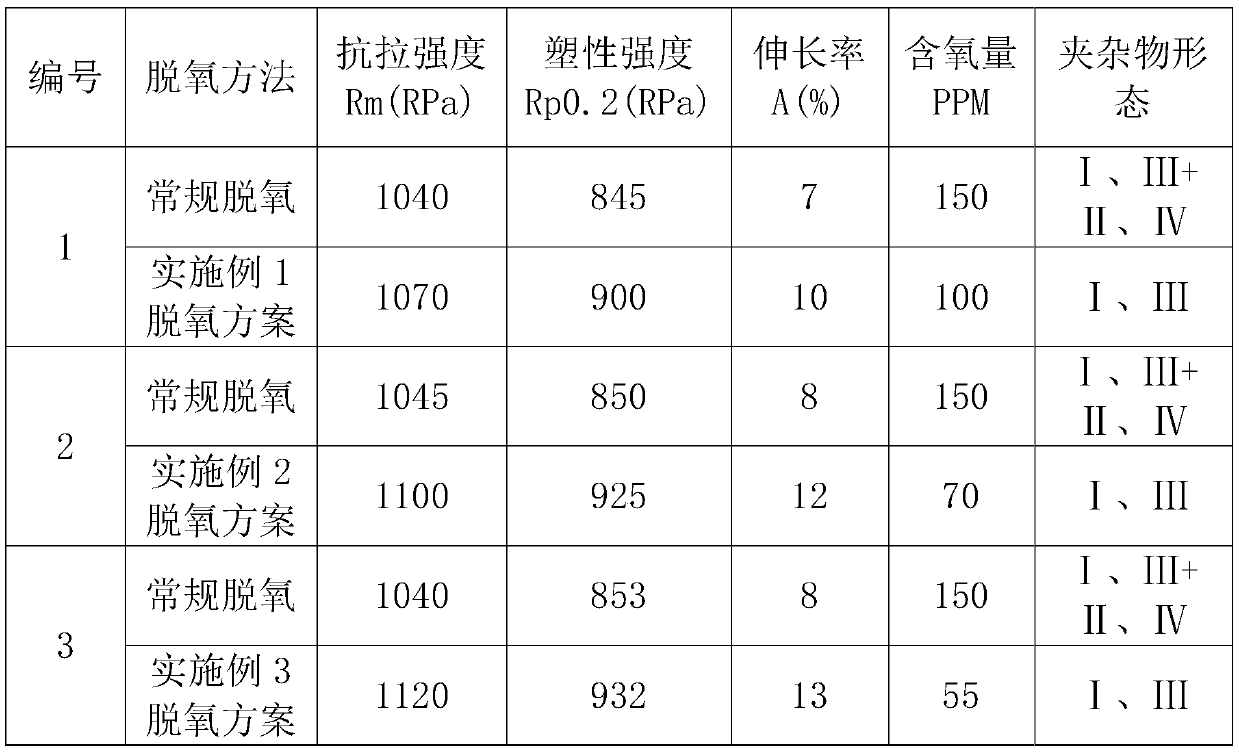

A kind of cast steel deoxidation alloy and its processing method and using method

The invention discloses a cast steel deoxidized alloy and a processing method and a use method of the cast steel deoxidized alloy, and belongs to the field of cast steel molten steel smelting. The deoxidized alloy comprises, by mass percent, 15-25% of Re, 8-20% of Ca, 5-15% of Ba, 5-20% of Ti, 5-20% of Zr, 5-20% of Si, 0.5-3% of Mg and the balance Fe. The deoxidized alloy is prepared by adopting afusion casting method, the fusion casting method is suitable for casting ordinary carbon steel, alloy steel, stainless steel and other cast steel, the content of oxygen in the cast steel can be effectively reduced, the harmful effects of oxygen on the content of the cast steel are reduced, and the cast steel product quality is improved.

Owner:MAANSHAN RUIHUI ENTERPRISE

Low-carbon multi-component alloy steel for excavator bucket tooth, and its production technology

The invention discloses a low-carbon multi-component alloy steel for an excavator bucket tooth. The alloy steel comprises 0.20-0.26wt% of C, 0.4-0.6wt% of Si, 0.6-1.2wt% of Mn, 0.5-0.8wt% of Cr, 0.4-0.6wt% of Mo, 0.2-0.3wt% of Cu, 0.8-1.5wt% of Ni, 0.08-0.12wt% of Ti, 0.04-0.06wt% of Y, 0.02-0.04wt% of Ce, 0.02wt% or less of P, 0.02wt% or less of S, and the balance Fe and impurities. The micro-alloying treatment of trace elements comprising Mo, Cu, Ti, Ni, Y, Ce and the like increases nucleation and further refines crystal grains, so the number, the size and the form distribution of carbides are effectively controlled, included slag is deteriorated, the metallurgical quality and the comprehensive wear resistance are improved, and the comprehensive performances and the service life of the alloy steel are maximally improved. The adoption of a reasonable heat treatment technology, appropriate annealing treatment and appropriate quenching tempering substantially improves the hardness and the impact resistance of the alloy steel.

Owner:滁州恒昌机械装备制造有限公司

Building steel structure mounting, connecting and reinforcing device

ActiveCN112081252APrevent brittle fractureImprove stress resistanceProtective buildings/sheltersShock proofingThreaded pipeEarthquake resistant

The invention relates to the technical field of steel structures, in particular to a building steel structure mounting, connecting and reinforcing device. The device is characterized in that a shell covers a connecting part of a beam body and a column body through an opening end on the front side, inclined wedge blocks are symmetrically inserted into the left side and the right side in the shell on the upper side of the beam body, screw rods are vertically and fixedly arranged on the opposite faces of the inclined wedge blocks, the ends of the screw rods on the left side and the right side arerotationally inserted into the left end and the right end of an inner threaded pipe through threads, a worm is fixedly arranged in the middle of the inner threaded pipe, a worm gear is arranged on the upper side of the worm in a meshed mode, after the upper side of the worm gear movably penetrates through the upper side, the worm gear is rotationally arranged in the middle of a shaft seat througha rotating shaft, and the front end of the rotating shaft penetrates through the shaft seat located on the front side and then is fixedly connected with a first hand screw. According to the device, the connecting part of the beam and the column is reinforced, so that the column is effectively prevented from deforming and even collapsing due to brittle rupture of the welding part of the beam and the column when the steel structure beam is stressed excessively, and meanwhile, the compression resistance and the shock resistance of the connecting part of the beam and the column are improved.

Owner:SHAN DONG JUXIN GRP STEEL STRUCTURE CO LTD

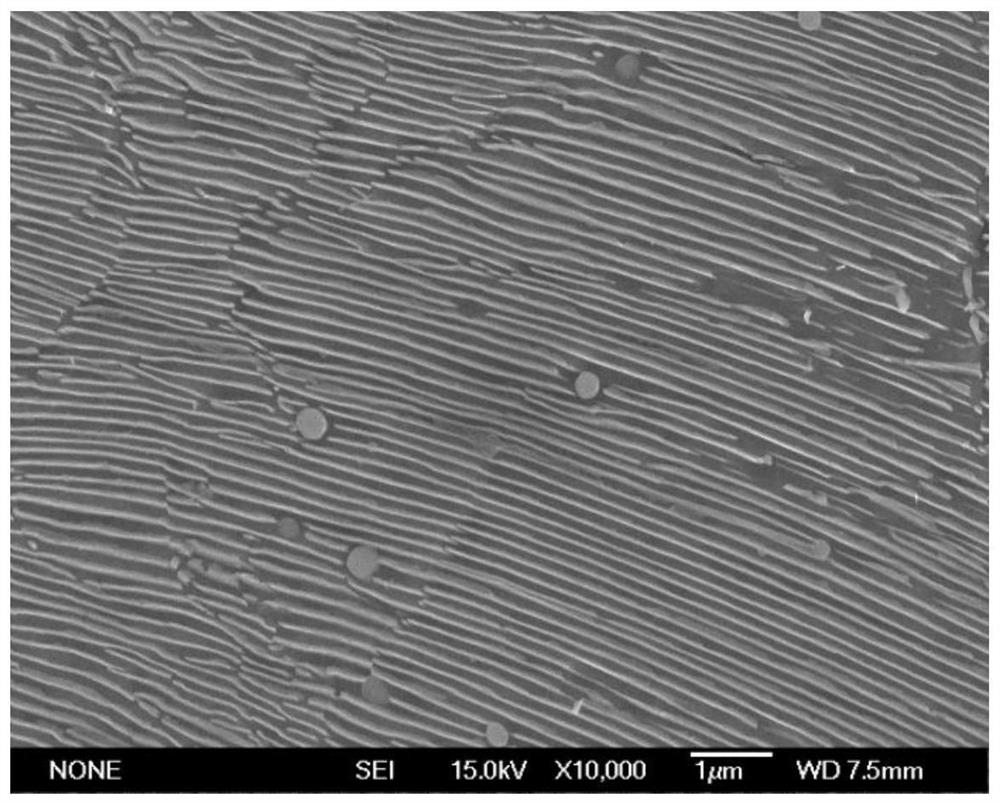

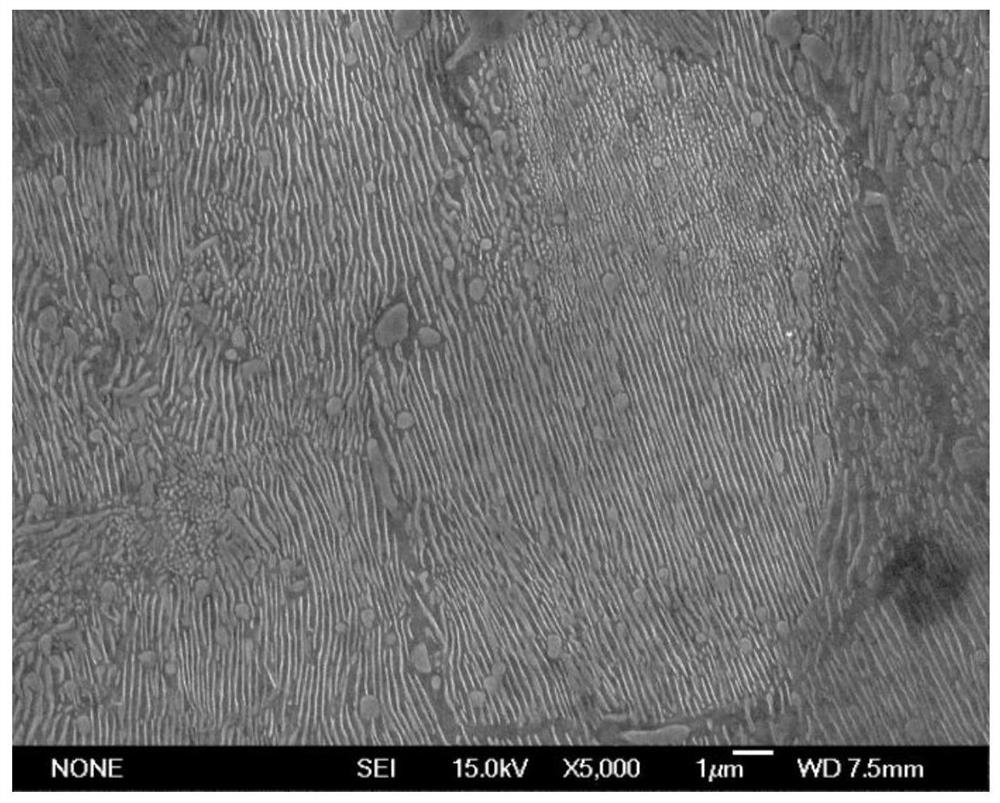

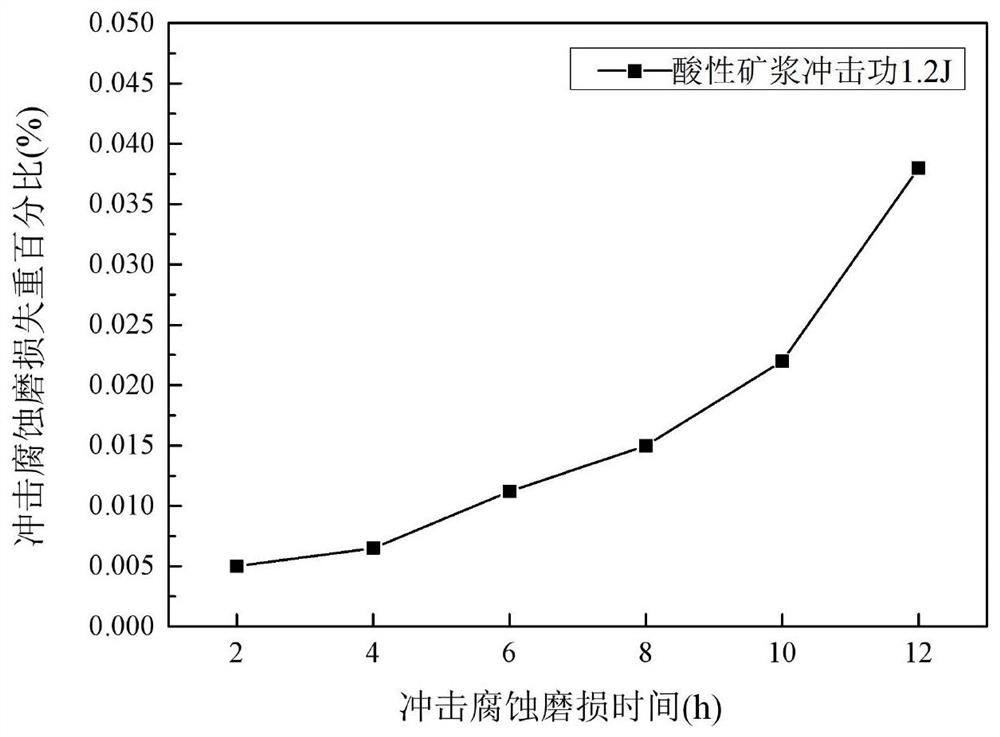

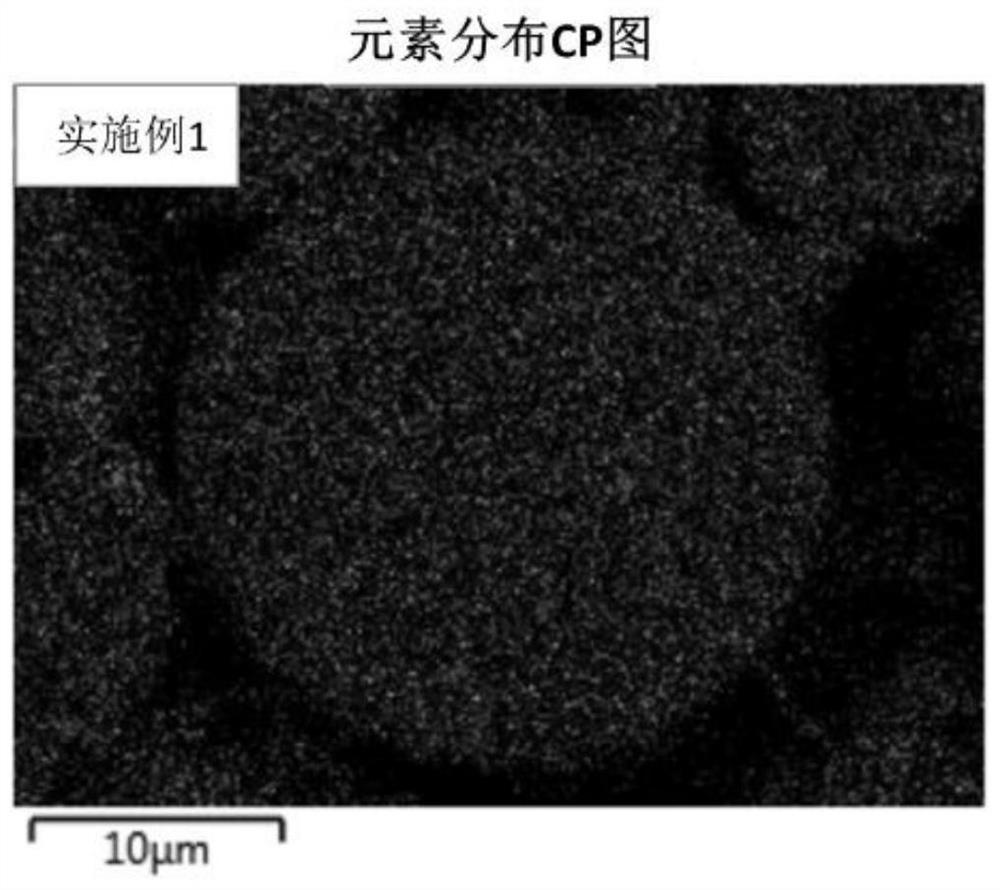

High-carbon corrosion-wear-resistant cast semi-automatic ball mill lining plate steel and preparation method and application thereof

ActiveCN112746225AGuaranteed toughnessImprove toughnessFurnace typesGrain treatmentsCarbon corrosionMo element

The invention provides high-carbon corrosion-wear-resistant cast semi-automatic ball mill lining plate steel and a preparation method and application thereof, and belongs to the technical field of semi-automatic ball mill lining plates. According to the steel, Cu, Cr and Ni elements with good corrosion resistance are taken as main elements, and the alloy elements are enriched in a rust layer, so that formation of an amorphous rust layer is promoted, the structure of the rust layer is improved, the density and the cohesiveness to the steel surface are improved, and the isolation effect with the atmosphere is enhanced, thereby slowing down the corrosion rate and effectively improving the corrosion resistance of the steel; and meanwhile, Ti and Nb elements are added, the content of a Mo element is increased, the corrosion-resistance of the cast steel can be effectively improved, and the wear resistance of the cast steel is improved while the toughness is guaranteed. Results of the embodiment show that the high-carbon corrosion-wear-resistant semi-automatic ball mill lining plate not only has better wear resistance, but also is high in hardness and excellent in toughness, and has impact-corrosion resistance and high impact-corrosion-wear resistance at the same time.

Owner:SHANGHAI UNIV

Positive electrode active material, positive electrode sheet and lithium ion secondary battery

ActiveCN112447939BIncrease energy densityImprove structural stabilitySecondary cellsPositive electrodesChemical physicsHigh energy

The invention discloses a positive electrode active material, a positive electrode sheet and a lithium ion secondary battery. The positive electrode active material includes secondary particles formed by gathering primary particles, the primary particles are lithium transition metal oxides, and the lithium transition metal oxides The transition metal sites include nickel and doping elements; and the Young's modulus E of the primary particles is 175GPa≤E≤220GPa. By adopting the cathode active material provided by the invention, the lithium-ion secondary battery can simultaneously take into account higher energy density and high-temperature cycle performance.

Owner:CONTEMPORARY AMPEREX TECH CO

Aluminum alloy aluminum bar and method for manufacturing aluminum lamp through aluminum alloy aluminum bar

The invention discloses an aluminum alloy aluminum bar. The aluminum alloy aluminum bar comprises, by weight, 0.45%-0.55% of Mg, 0.2%-0.4% of Si, less than 0.1% of Fe, less than 0.1% of Cu, less than 0.1% of Mn, less than 0.1% of Zn, and the balance Al. When the aluminum alloy aluminum bar is used for manufacturing an aluminum lamp, a mold is made of H13 steel and comprises a bottom mold body, a middle mold body and a face mold body; the bottom mold body conducts primary feeding, flow guiding is carried out through five holes, the middle mold body conducts secondary feeding, and flow guiding is carried out through eight holes; aluminum materials are distributed into a welding chamber after being fused and are extruded out through an extrusion working belt, the mold is heated through a decreasing heating method and is heated to 510 DEG C at first, and heat is preserved for 0.5-1.5 h; and then, the temperature is lowered to 450 DEG C, heat is preserved for 1.5-2.5 h, an aluminum bar product is obtained, after being machined, the aluminum bar product is manufactured into a lampholder and a lamp barrel, and thus the aluminum lamp is obtained. By means of the aluminum alloy aluminum bar, the service life of the mold can be prolonged, and the yield of the aluminum lamp is increased.

Owner:RUIAN JINYU ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com