Flexible continuously cast water gap and manufacturing method thereof

A continuous casting nozzle and manufacturing method technology, applied in the direction of manufacturing tools, casting equipment, casting melt containers, etc., can solve the problems that affect the safe production of the continuous casting process, the manufacturing process is complicated, and cracks are easy to form, so as to reduce the baking temperature and time, simple manufacturing method, and the effect of preventing crack formation and brittle fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

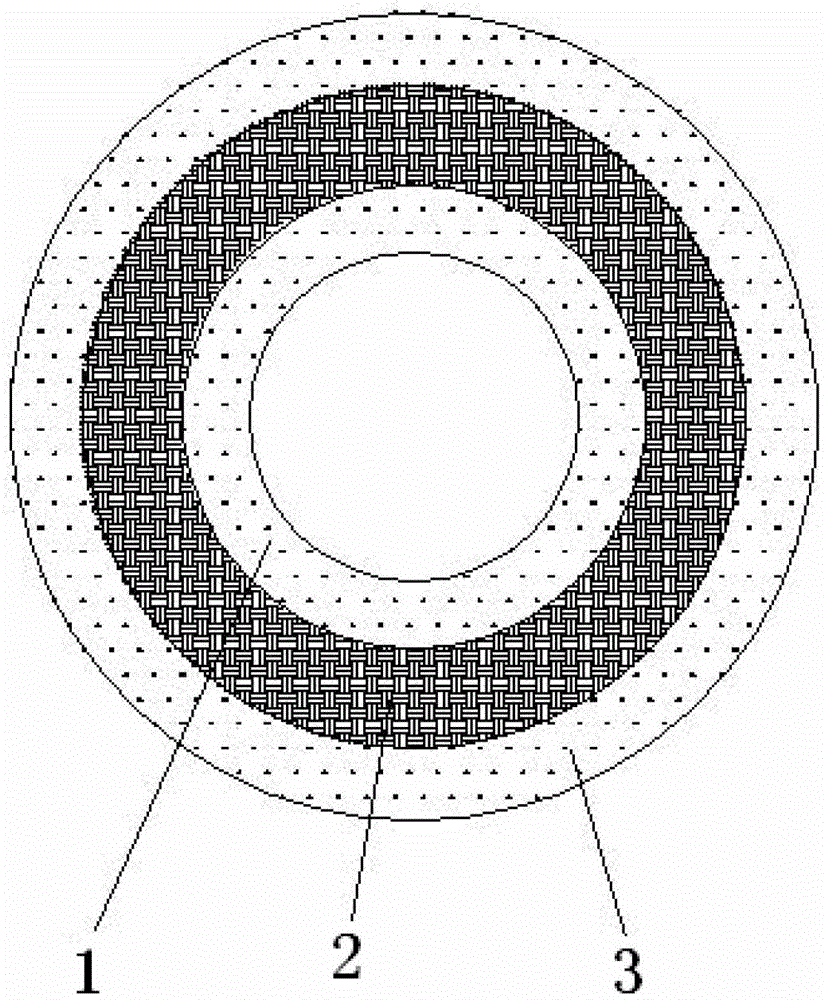

[0046] Embodiment 1: submerged nozzle and its manufacturing method

[0047] The volume of the inner layer and the outer layer of the submerged nozzle produced in this embodiment are equal, the materials of the upper section of the nozzle, the slag line section, and the lower section are the same, the refractory materials of the inner and outer layers of the nozzle are the same, and the middle layer is graphite fiber cloth. The ratio of raw materials used in the nozzle is shown in Table 1.

[0048] Table 1 Raw materials and proportions used in submerged nozzles

[0049] material

The proportion of each material to the total volume of raw materials (%)

3~5mm corundum

20

1~3mm corundum

15

0.1~1mm corundum

15

<0.1mm corundum

15

5

15

Graphite fiber cloth

5

Phenolic Resin

6

Sintering aid MgO

4

[0050] The method of manufacturi...

Embodiment 2

[0056] Embodiment 2: ladle shroud and manufacturing method thereof

[0057] The volume of the inner layer and the outer layer of the submerged nozzle are equal, the material of the upper section of the nozzle, the slag line section and the lower section are the same, the refractory material of the inner and outer layers of the nozzle is the same, and the middle layer is graphite fiber cloth. The ratio of raw materials used in the nozzle is shown in Table 2.

[0058] Table 2 Raw materials and proportions used in long nozzles of large bales

[0059] material

The proportion of each material to the total volume of raw materials (%)

3~5mm corundum

15

1~3mm corundum

10

0.1~1mm corundum

10

1~3mm fused silica

10

20

15

5

Graphite fiber cloth

5

Phenolic Resin

6

Sintering aid MgO

4

[0060] The meth...

Embodiment 3

[0066] Embodiment 3 Ladle shroud and its manufacturing method

[0067] The volume of the inner layer of the submerged nozzle is equal to that of the outer layer. The material of the upper section of the nozzle, the slag line section and the lower section are the same. The mixture of graphite fine fibers and refractory raw materials used in the inner and outer layers is 1:1 by volume. The proportion of raw materials used in the nozzle is shown in Table 3.

[0068] Table 3 Raw materials and proportions used in long nozzles of bales

[0069] material

The proportion of each material to the total volume of raw materials (%)

3~5mm corundum

15

1~3mm corundum

10

0.1~1mm corundum

10

1~3mm fused silica

10

20

15

5

graphite fine fiber

5

Phenolic Resin

6

Sintering aid MgO

4

[0070] The method of man...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com