Patents

Literature

484results about How to "Reduce baking time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

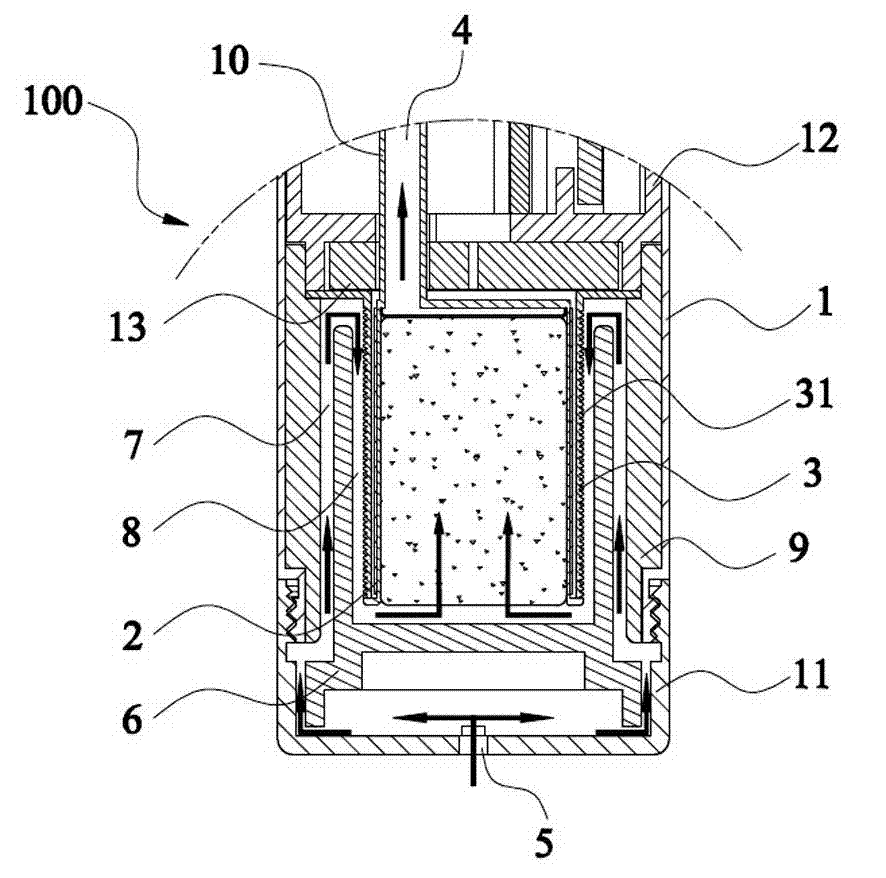

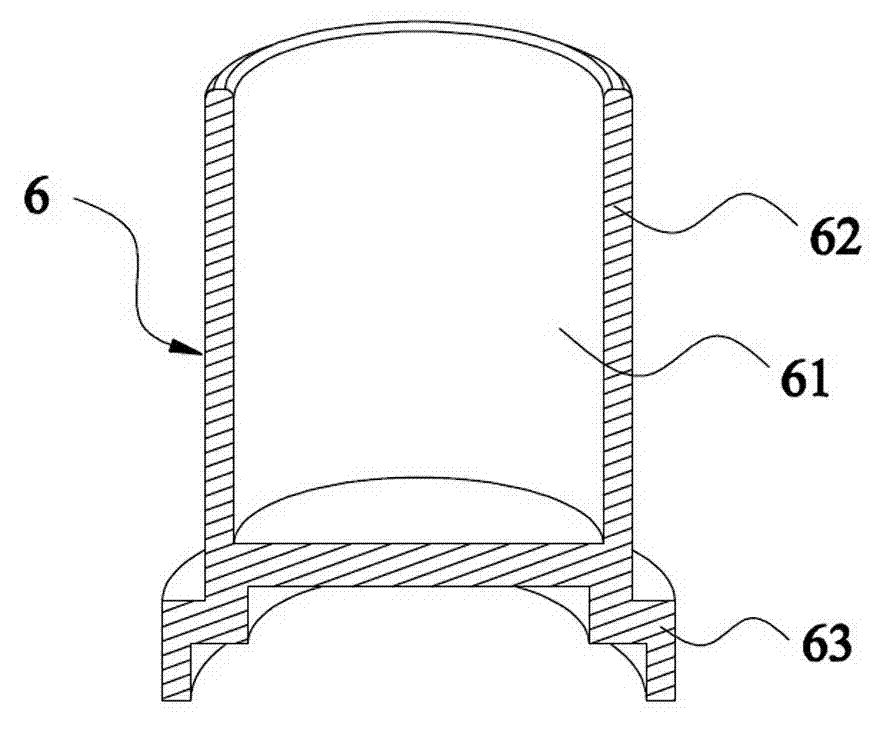

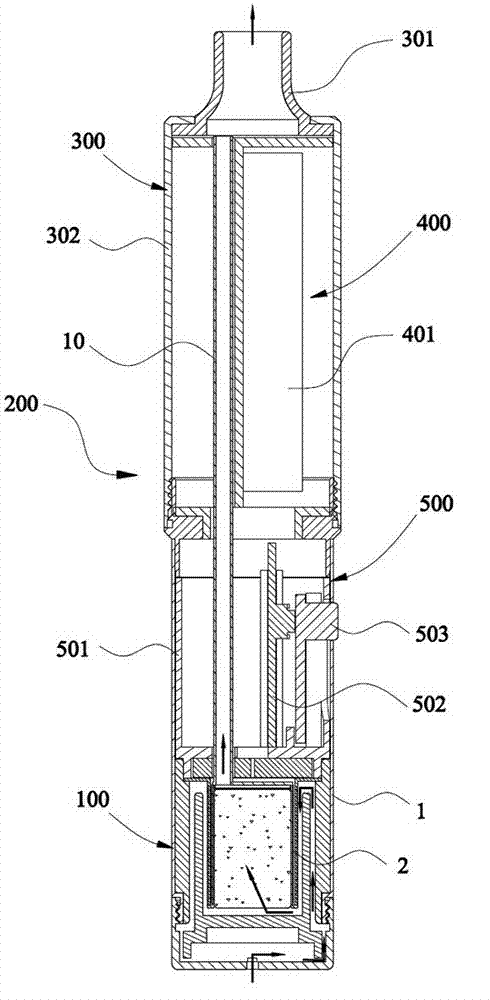

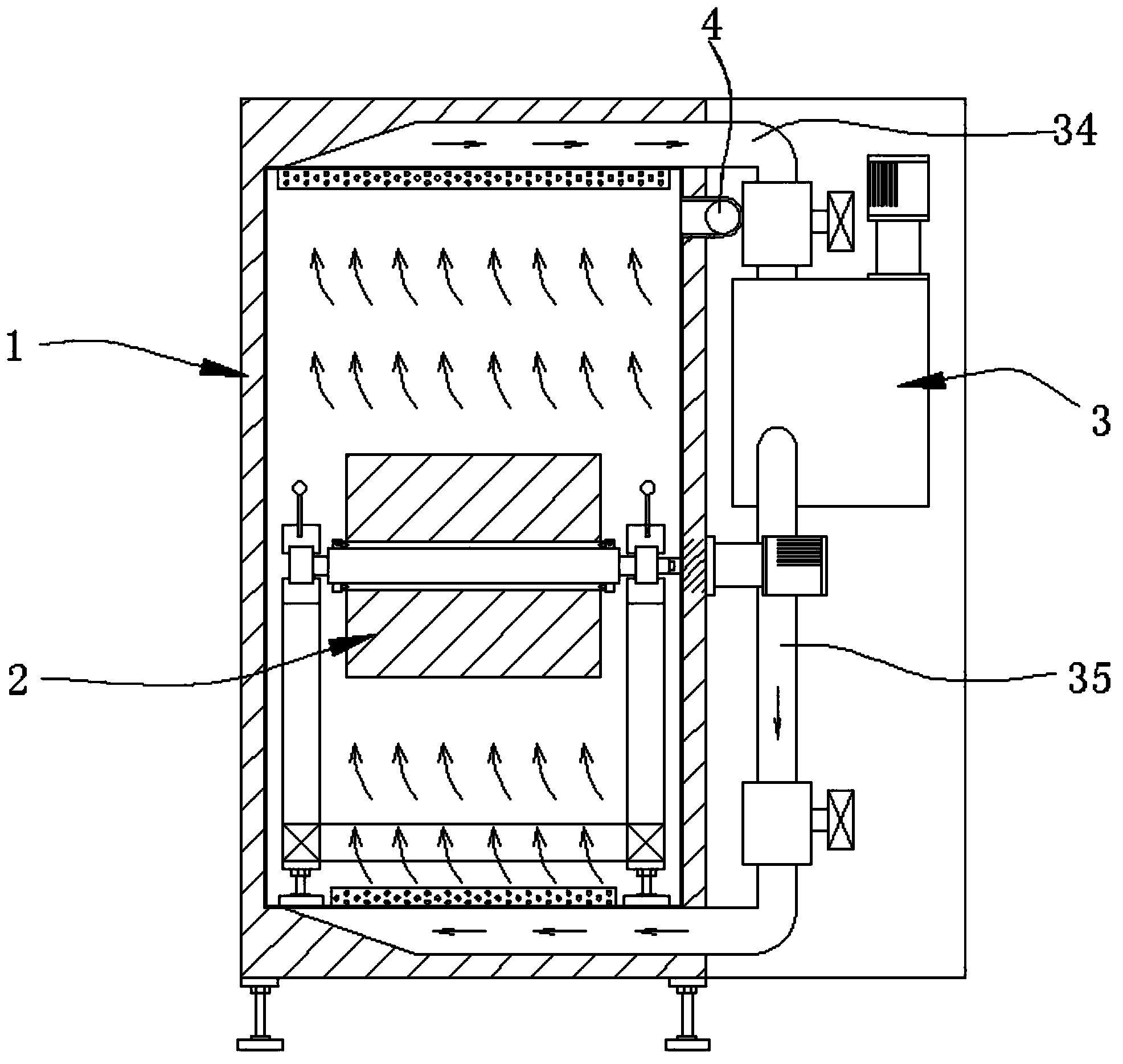

Baking type atomization device and aerosol inhalation device

The invention discloses a baking type atomization device which comprises a shell, a baking chamber arranged in the shell, a heating unit, an air inlet and an air outlet. The baking chamber is sleeved with the heating unit. The baking type atomization device further comprises an air guide ring, the air guide ring is provided with a cavity suitable for containing the baking chamber, a first gap communicated with the air inlet is arranged between the outer wall of the air guide ring and the inner wall of the shell, and a second gap for being communicating the first gap and the baking chamber is arranged between the heating unit and the inner wall of the air guide ring. According to the baking type atomization device and an aerosol inhalation device, the double-heating mode of circumferential type heating and thermal current heating is used for heating the baking chamber and preheating air in the second gap, so that the temperature in the baking chamber rises rapidly, the baking time is shortened greatly, therefore, rapid heating is achieved, electric energy is saved effectively, and the heating efficiency is improved. The invention further provides the aerosol inhalation device with the baking type atomization device.

Owner:SHENZHEN FIRST UNION TECH CO LTD

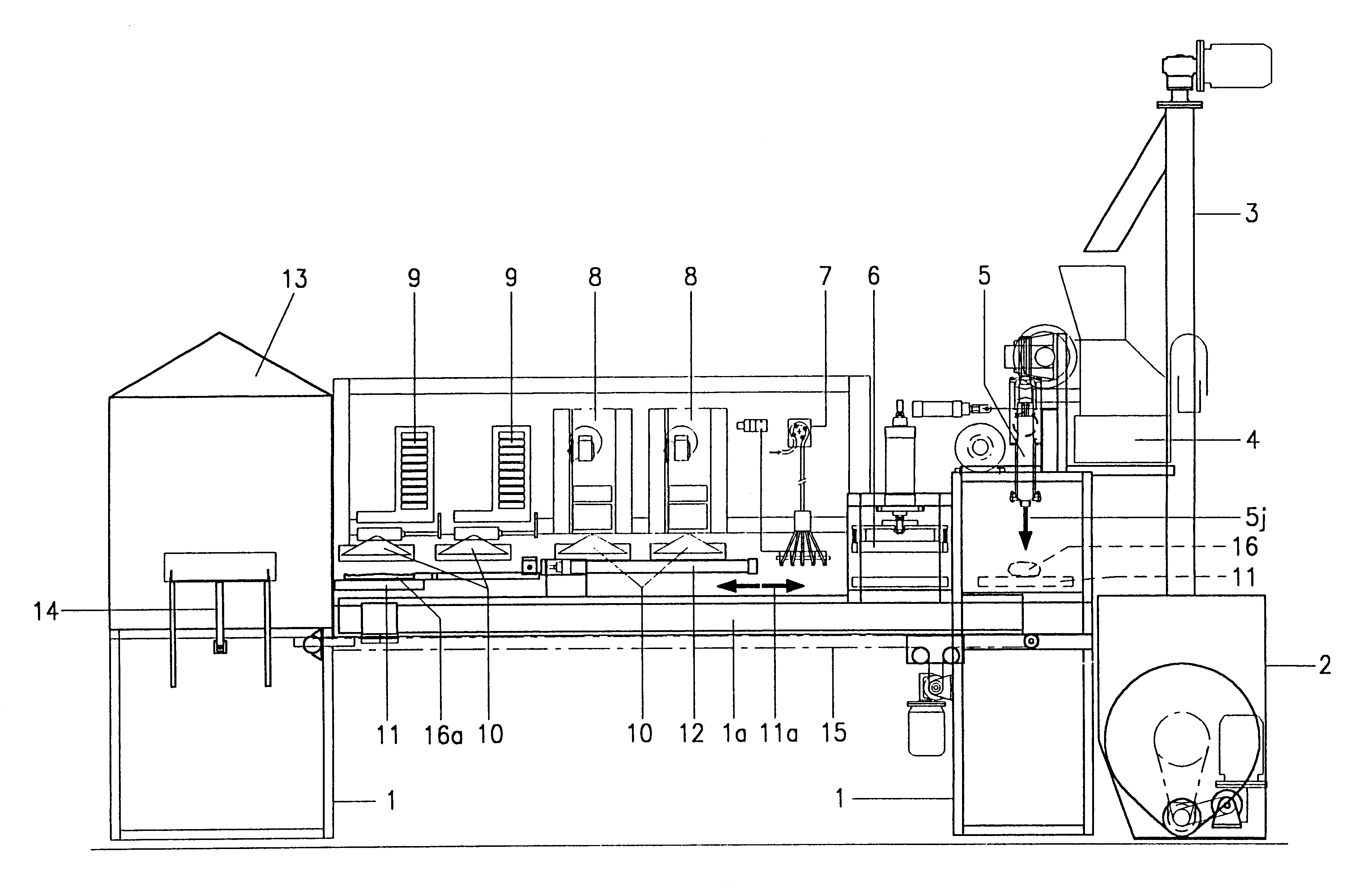

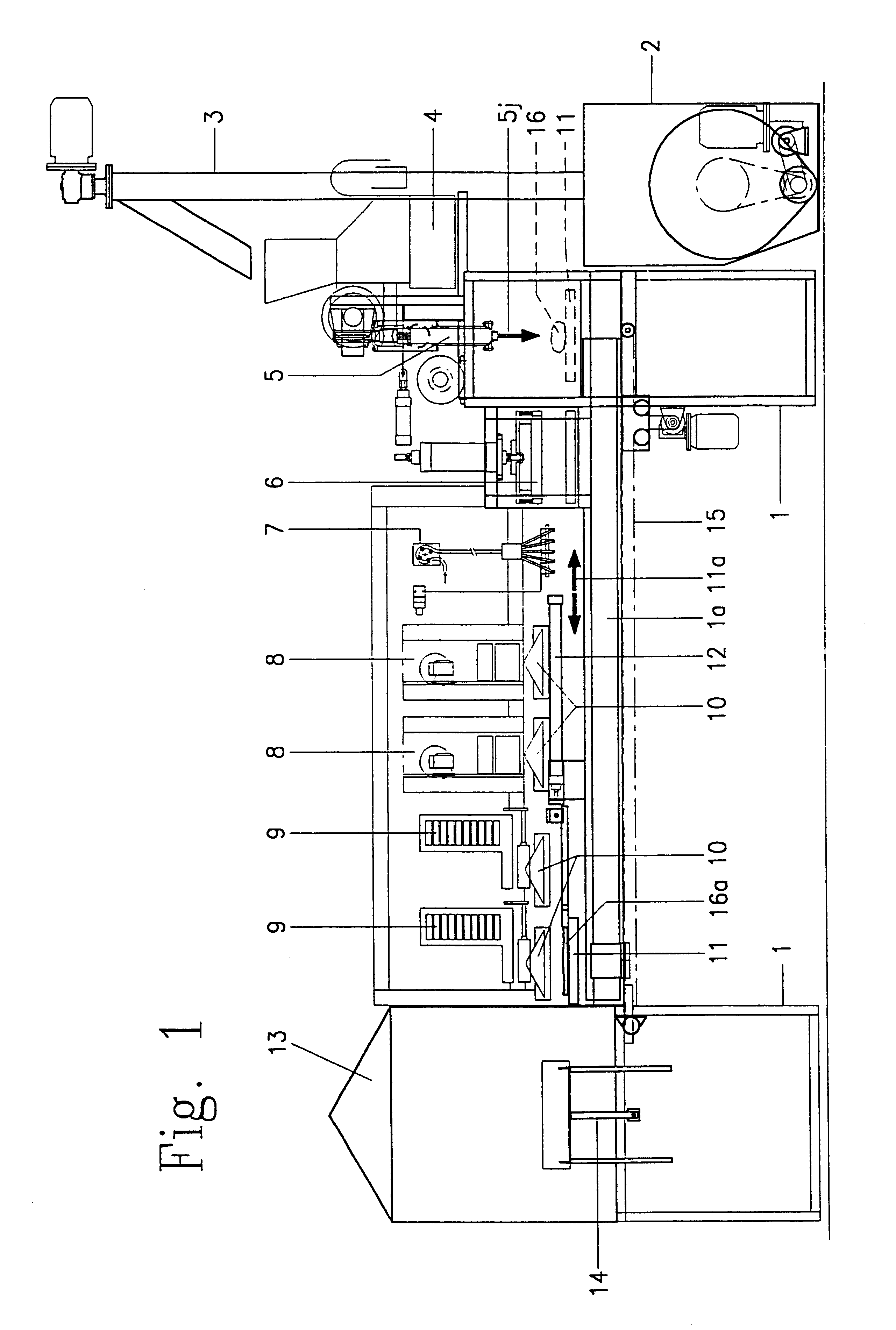

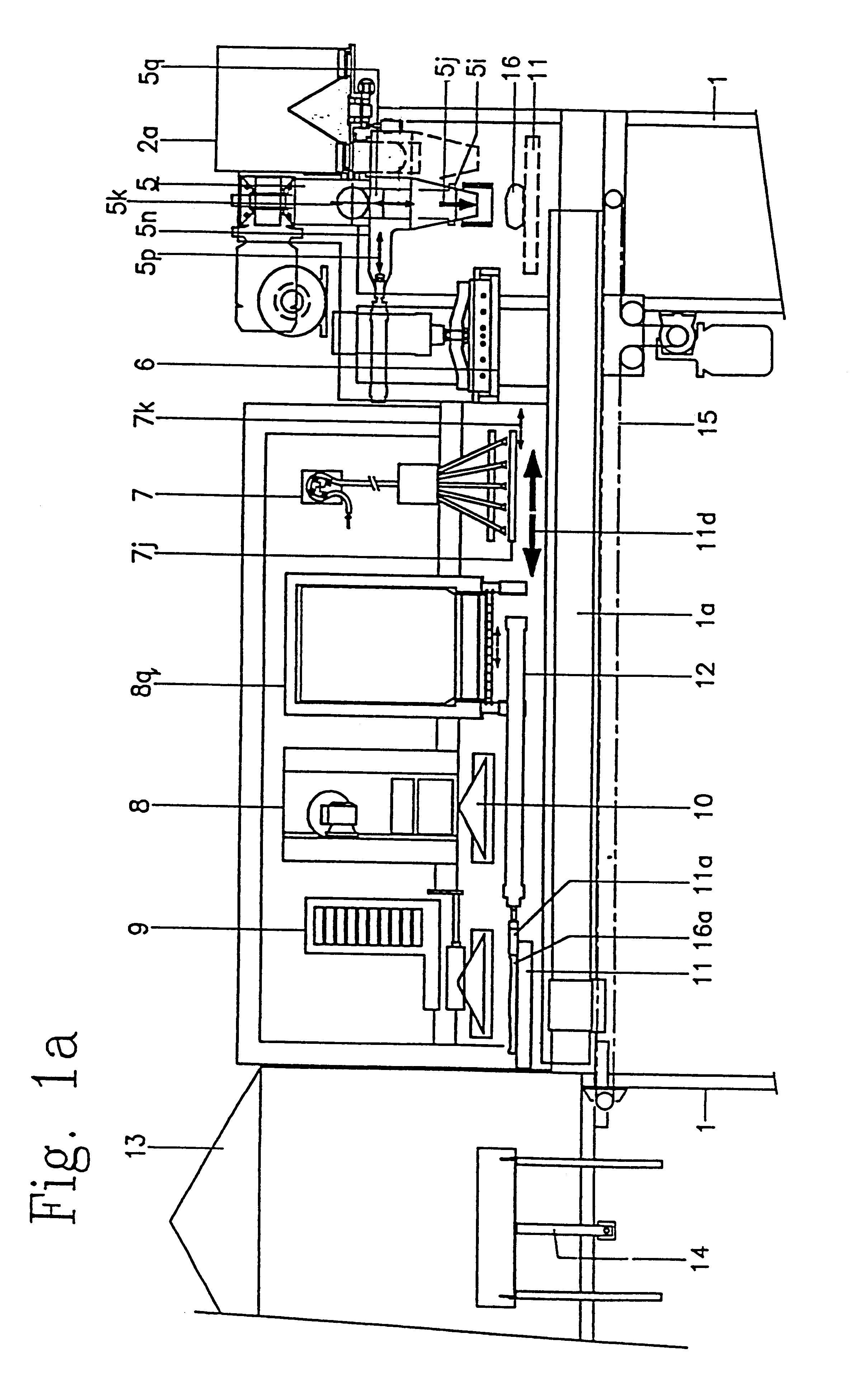

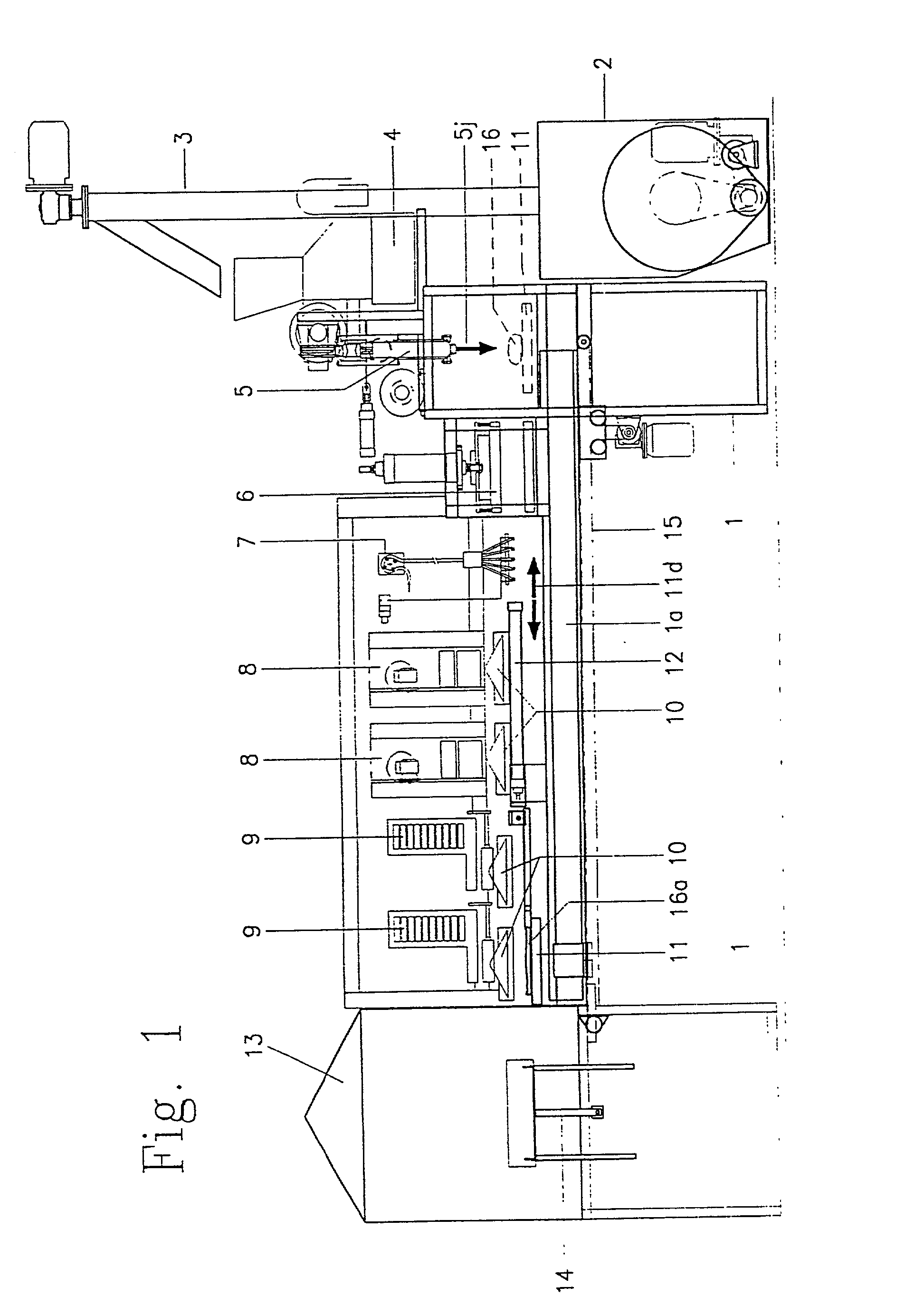

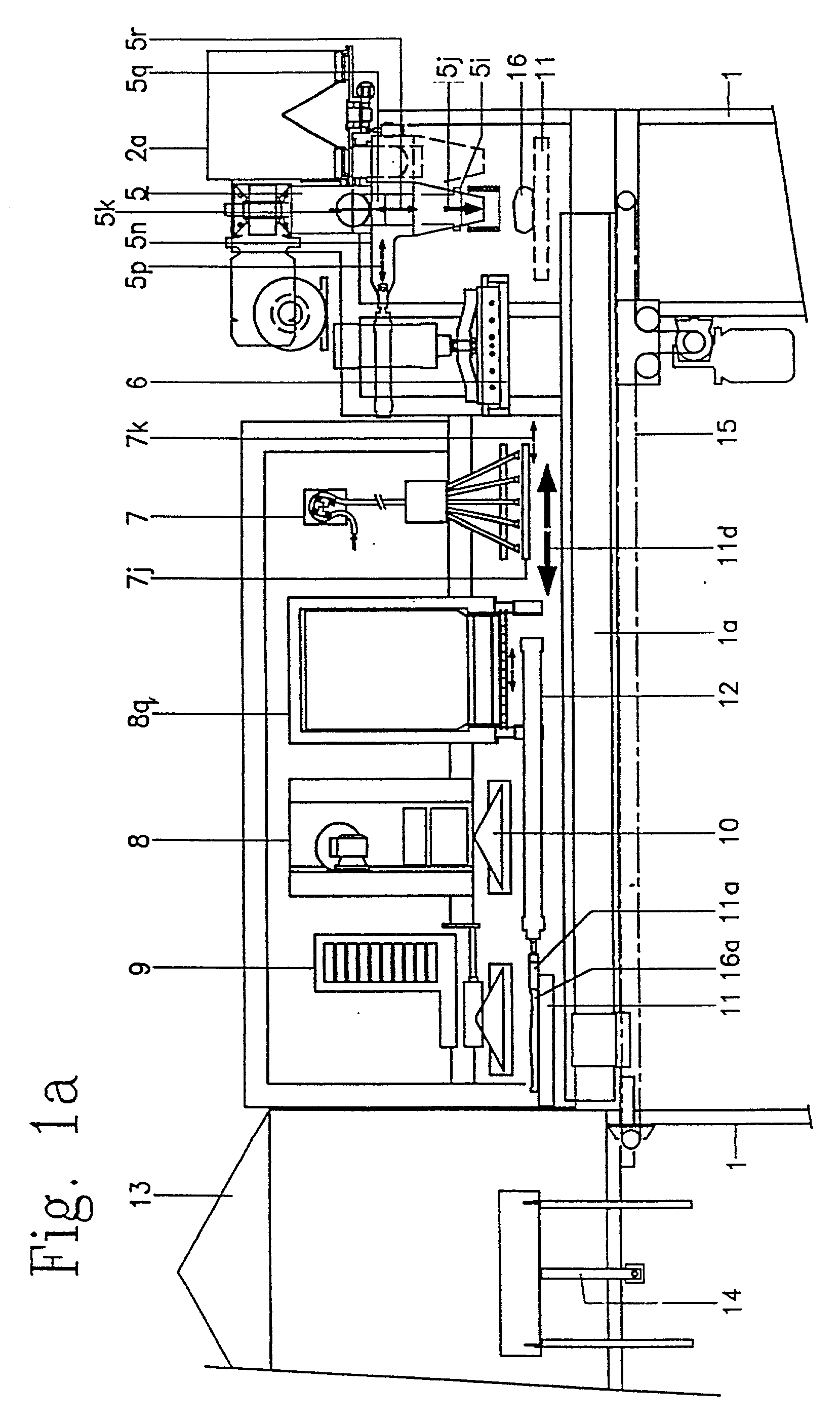

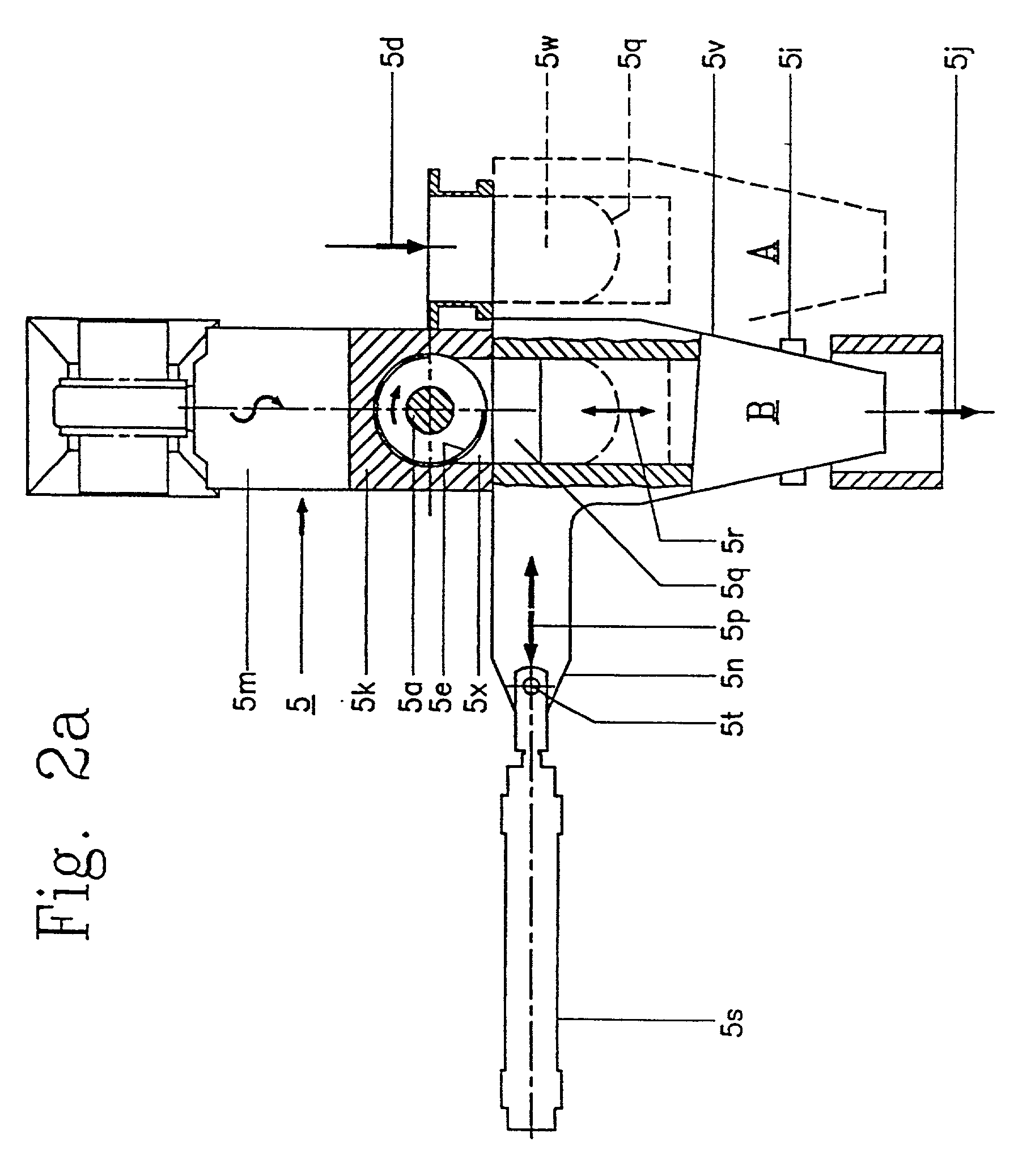

Method for producing pizza

InactiveUS6245370B1Precise portioningMaintain hygienic conditionDough treatmentConfectioneryEngineeringAdditive ingredient

A method for mechanically and automatically producing flat, round, dough and / or pizza bases without the use of baking tins for the dough bases and without using pre-prepared bases. Toppings and / or sauce are applied to the dough bases through at least one topping station. The dough bases are prepared from dough ingredients in a kneading and extrusion device, and then passed through a series of processing stations such as a shaping press, a metering and distribution station for tomato puree or sauce, or several metering stations for the topping, and the baking station, on a preheated transport plate. Each dough base is prepared and provided with a topping according to individual orders from a list.

Owner:SITOS

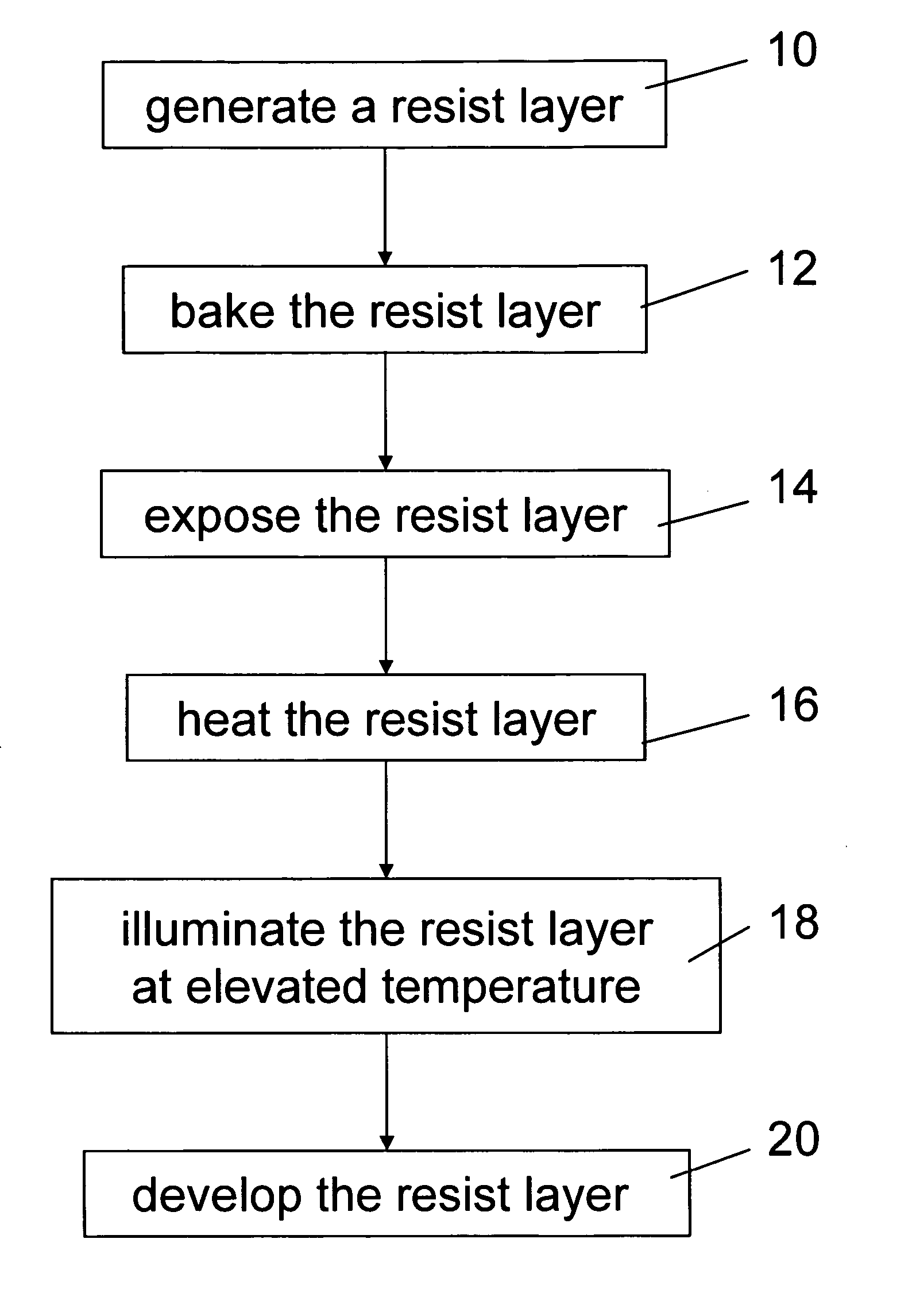

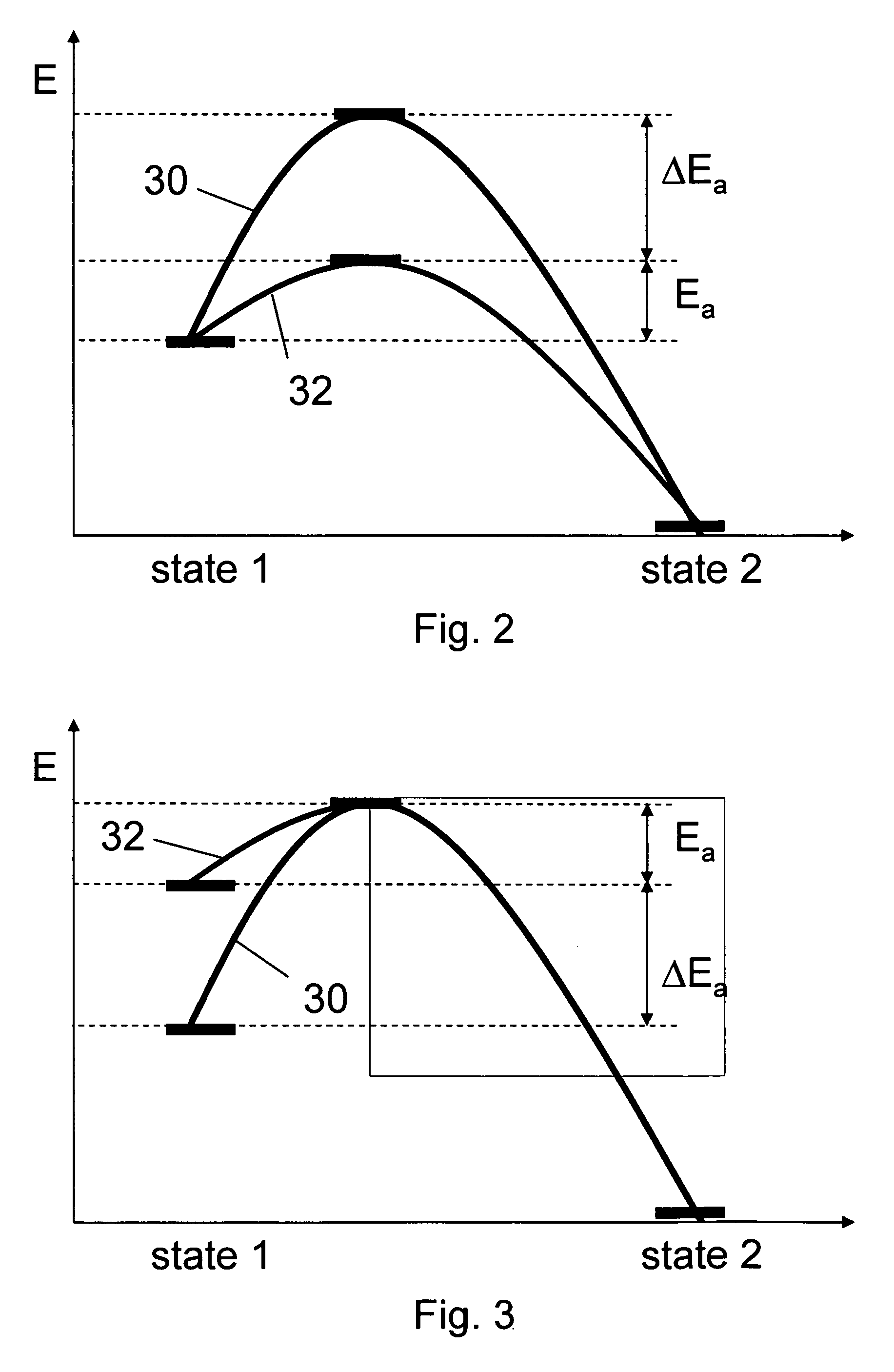

Method and apparatus for a post exposure bake of a resist

InactiveUS20060269879A1Reduce blurReduce diffusePhotomechanical exposure apparatusPhotosensitive material processingResistSolubility

Method and Apparatus for A Post Exposure Bake Of A Resist In a Method for patterning a chemically amplified resist layer, the resist layer is provided on a substrate, the resist layer comprising resist molecules in a first state with a first solubility. Predetermined regions of the resist layer are exposed to a first radiation to generate a catalytic species in the exposed predetermined regions of the resist layer. The resist layer is exposed to a second radiation and resist molecules in the predetermined regions of the resist layer are converted from the first state into a second state with a second solubility, the conversion of a resist molecule being catalyzed by the catalytic species, and the activation energy of the catalyzed conversion of the resist molecule being lowered by the absorption of the second radiation in the resist molecule. The resist layer is developed with a predetermined developer.

Owner:INFINEON TECH AG

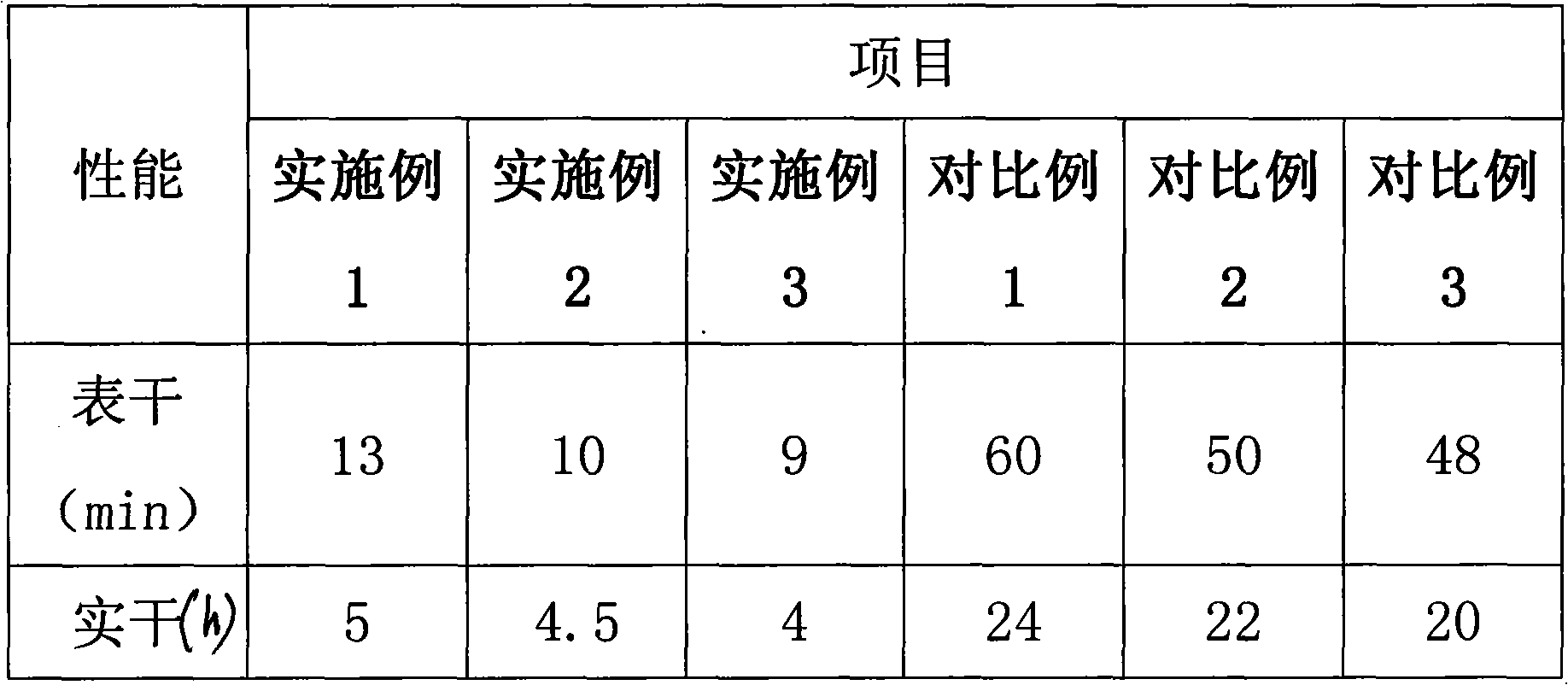

Ultra-fast dry repair varnish for automobiles and preparation method thereof

The invention discloses an ultra-fast dry repair varnish for automobiles and a preparation method thereof. The composition of the varnish comprises the following components in certain percentage by weight: solvent, modified additive, varnish film forming matrix, flatting agent 1, flatting agent 2, drier, light stabilizer 1, light stabilizer 2 and curing agent. After the repair varnish of the invention is used, at the temperature of below 25 DEG C, the repair varnish is surface dry in 10 minutes, can not stick dust, and can be waxed and polished after 1 hour. Compared with the prior art, the baking time is reduced, the energy source is saved and the spraying efficiency is improved.

Owner:商丘市博大化工有限公司

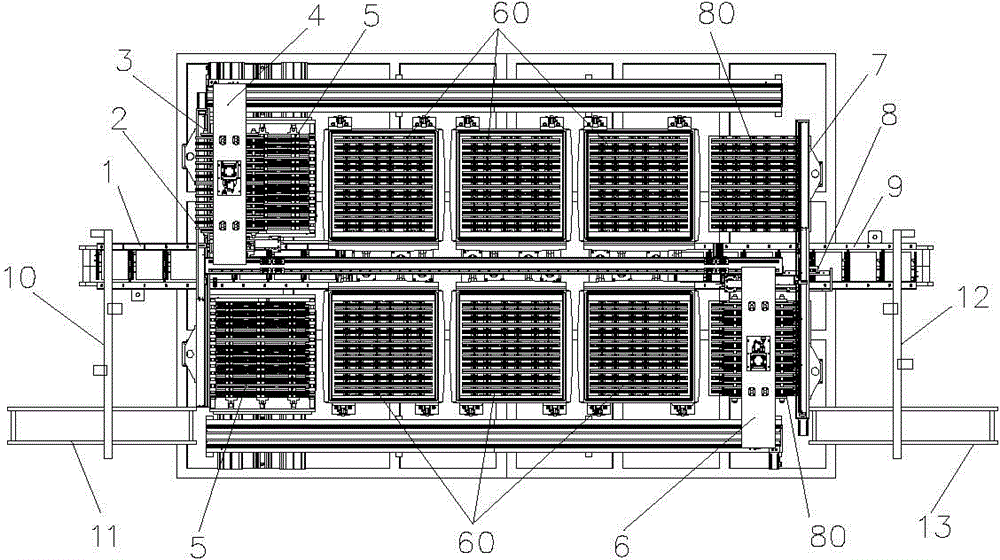

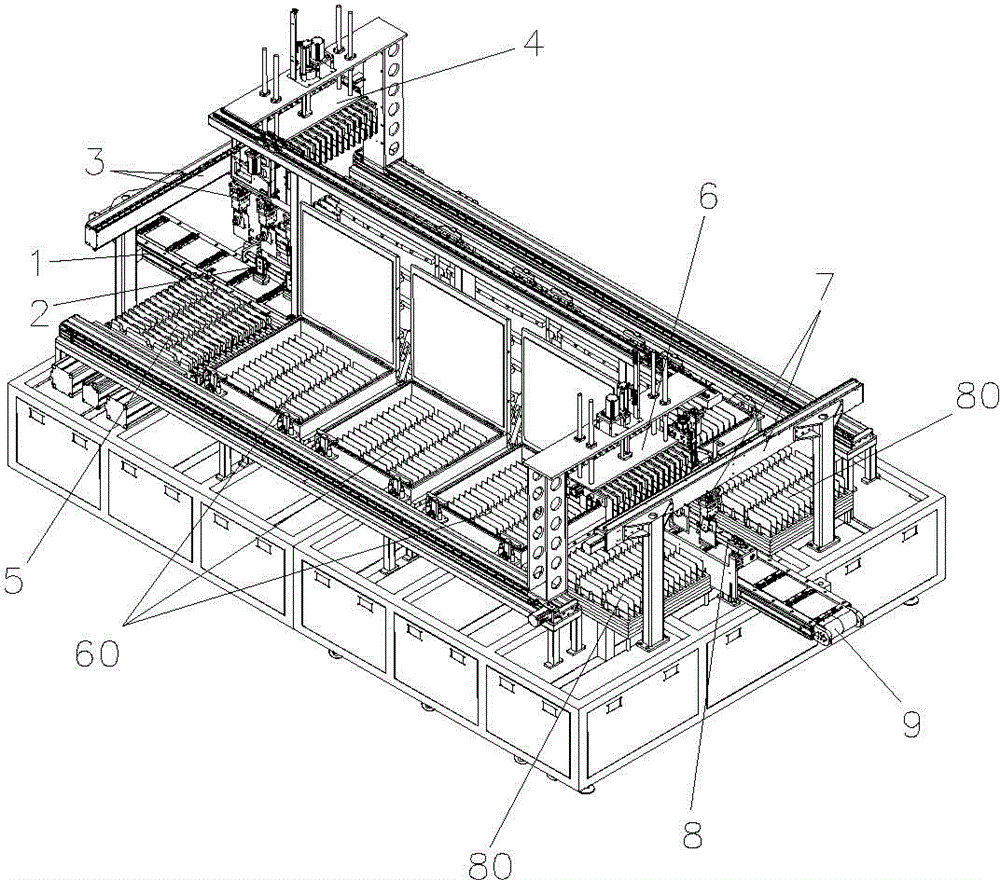

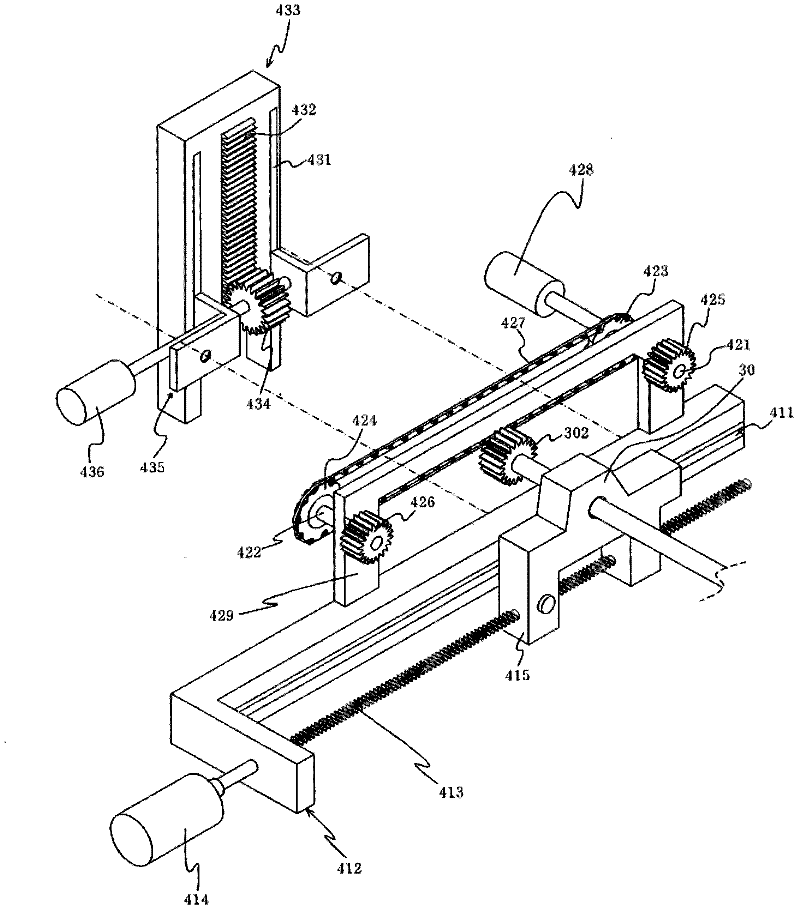

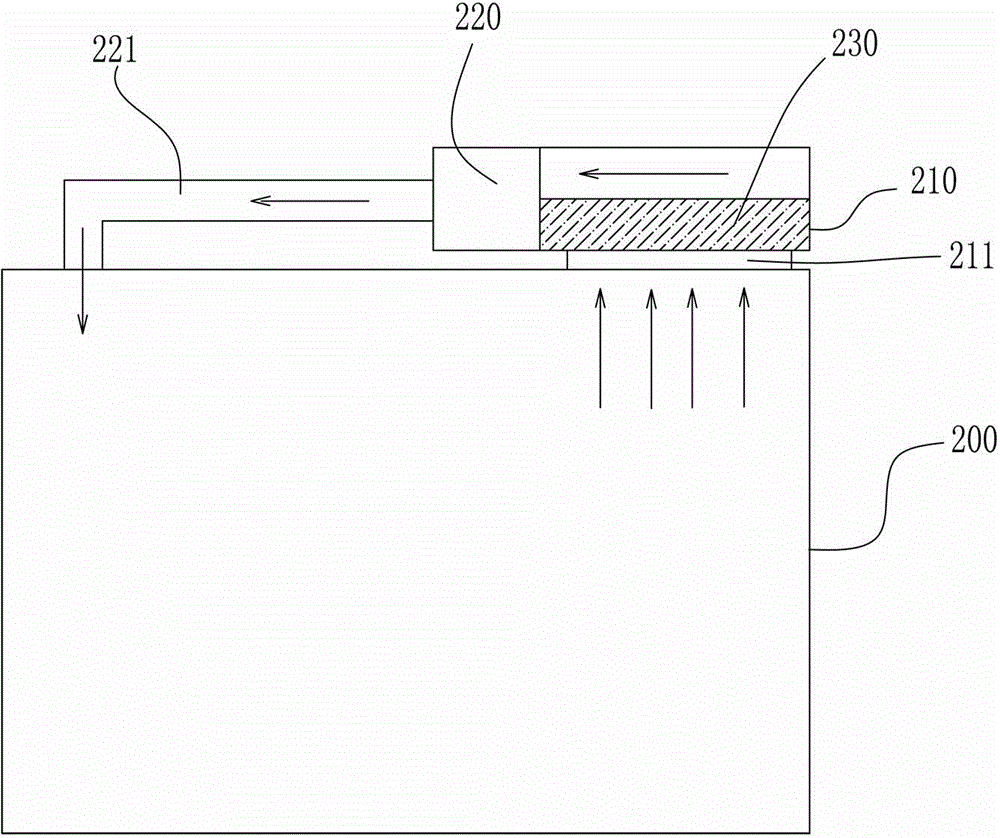

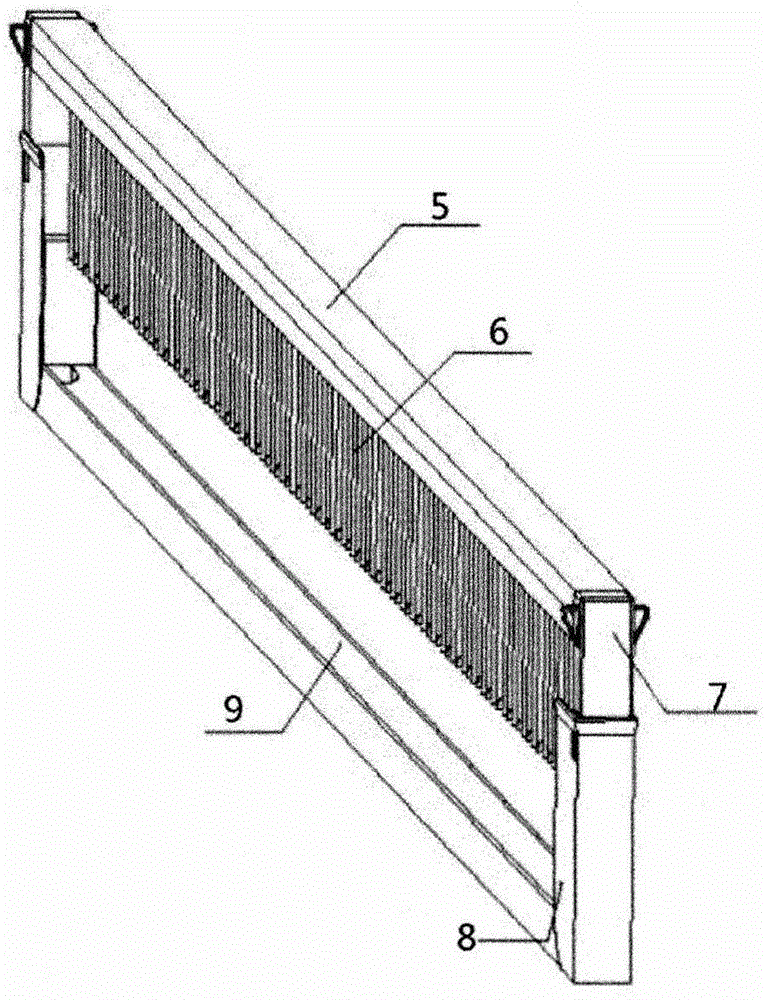

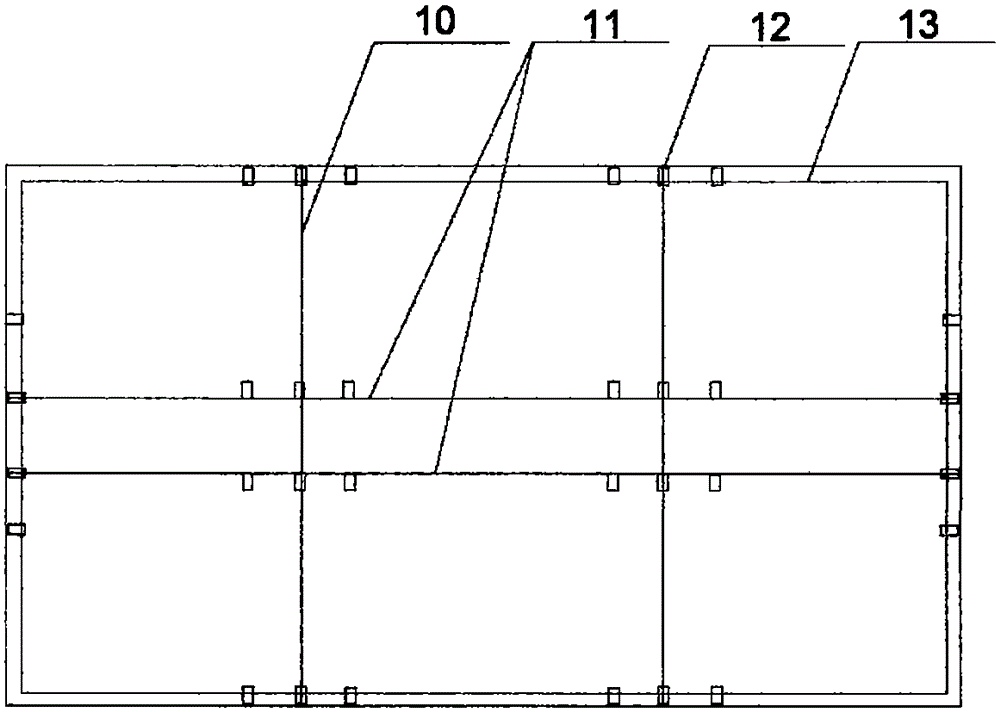

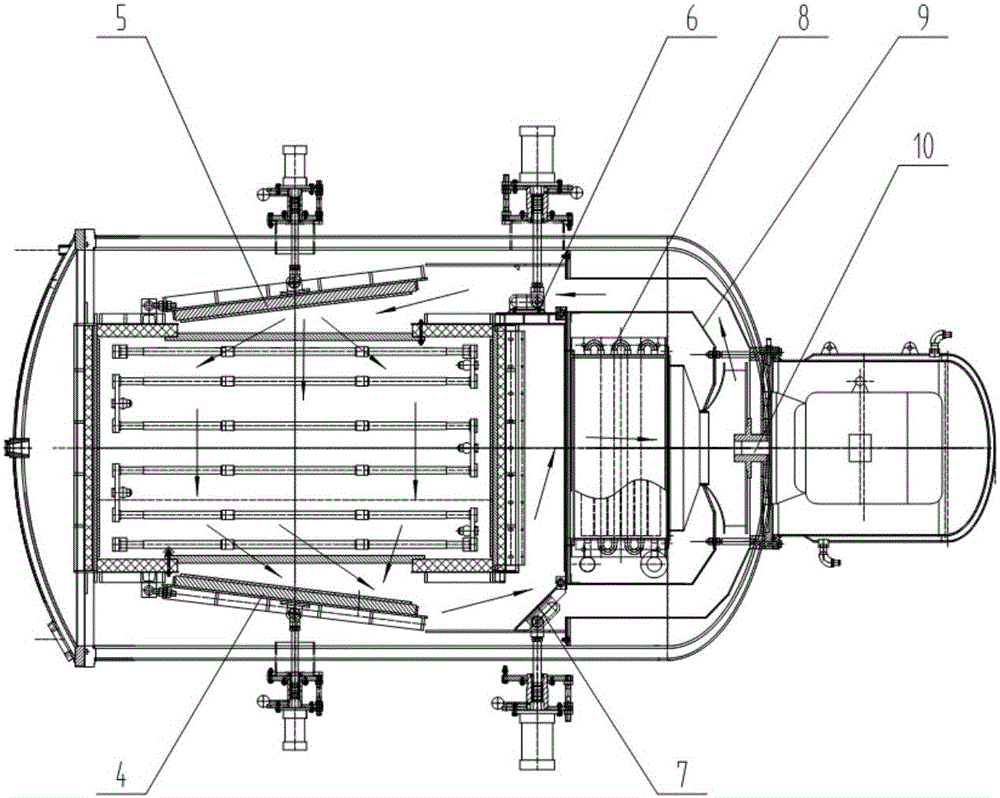

Polymer lithium battery vacuum baking tunnel furnace and production technology

InactiveCN104567310AFast evaporationReduce baking timeFinal product manufactureSecondary cells manufactureProcess engineeringPolymer

The invention relates to the technical field of lithium battery production equipment, in particular to a polymer lithium battery vacuum baking tunnel furnace and a production technology. The polymer lithium battery vacuum baking tunnel furnace comprises a vacuum baking tunnel furnace device, wherein the vacuum baking tunnel furnace device comprises a left contact type heating mechanism, a right contact type heating mechanism, a left material discharging buffer fixture and a right material discharging buffer fixture, three vacuum baking furnaces are sequentially arranged between the left contact type heating mechanism and the left material discharging buffer fixture, and three vacuum baking furnaces are sequentially arranged between the right contact type heating mechanism and the right material discharging buffer fixture. The polymer lithium battery vacuum baking tunnel furnace has the advantages that the cost is greatly reduced, and the production efficiency is improved.

Owner:DONGGUAN ALI AUTOMATION CO LTD

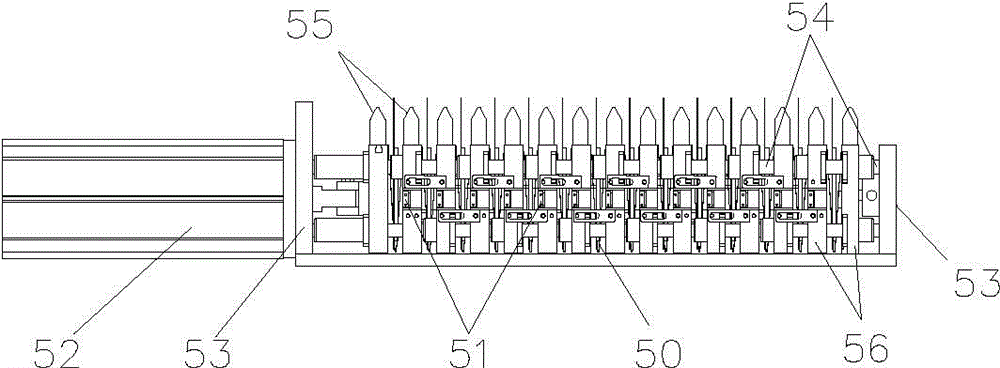

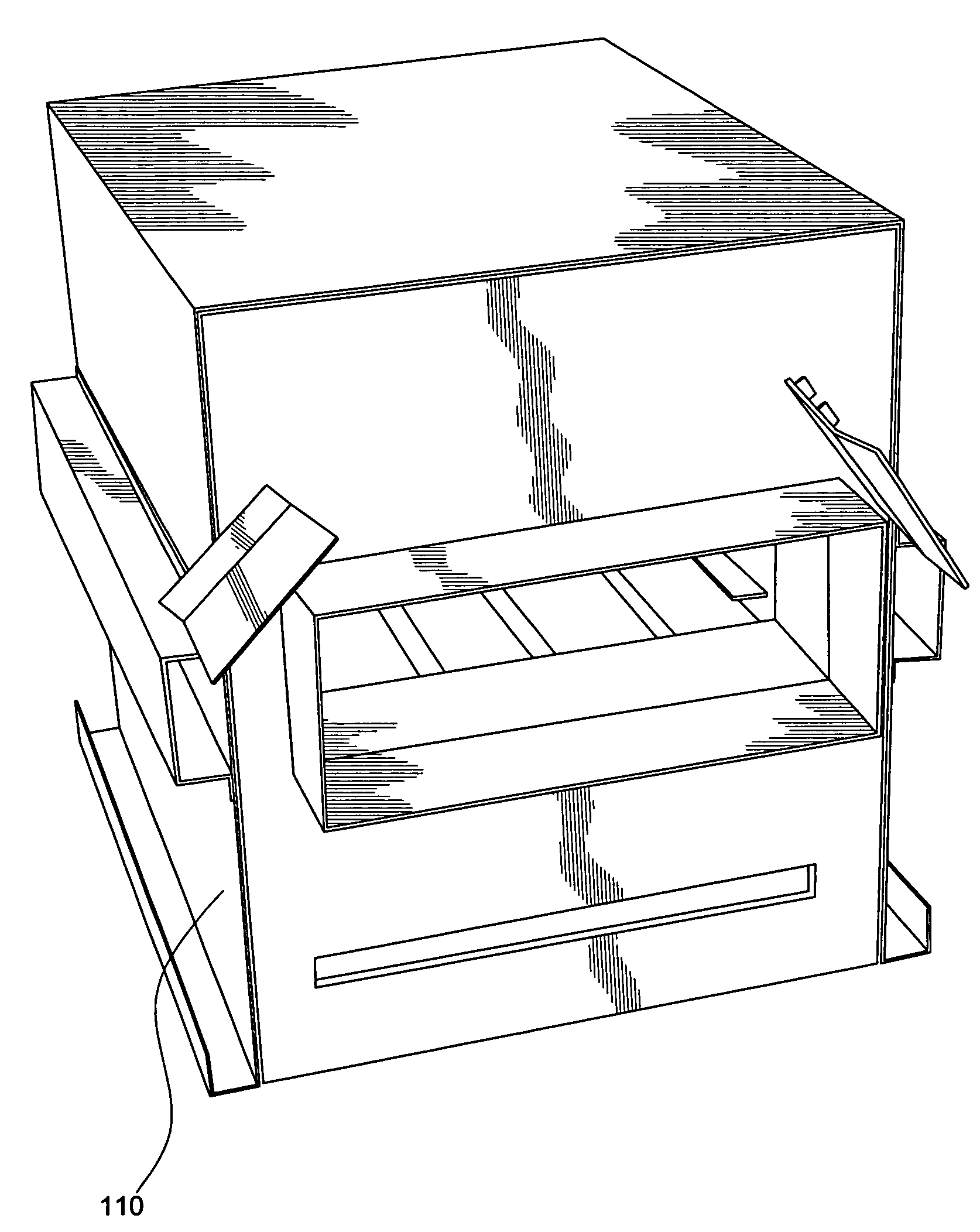

Method and device for producing pizza

InactiveUS20010024671A1Short timeReduce baking timeBaking mixturesConfectioneryAdditive ingredientEngineering

The invention is an apparatus for producing pizza by a mechanical, automated system without using baking tins for the dough bases and without using pre-prepared or pre-shaped bases. Dough bases are individually prepared from fresh pre-proportioned dough ingredients by a kneading and extrusion device. The dough base is then passed through a series of processing stations, such as a shaping press, a metering and distribution device for tomato purees or sauces, at least one metering and distribution station for garnishing (topping) ingredients and a baking station. The dough bases pass through the series of stations on a preheated or continuously heated transportation sheet. No pre-produced or pre-cooked, semi-finished products are used in the method. Each dough base is prepared and provided with toppings according to individual orders selected from a list.

Owner:SITOS

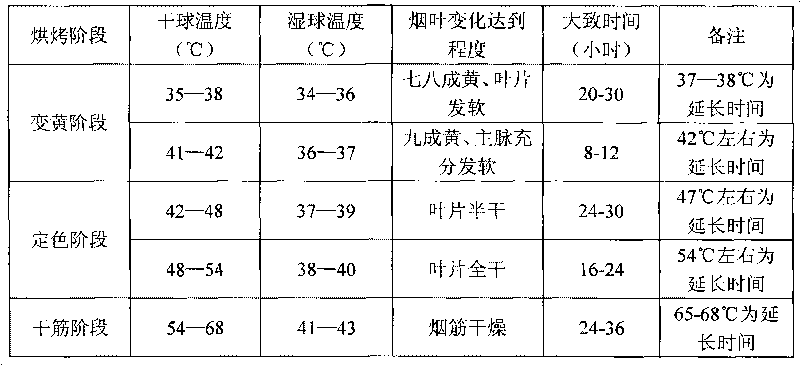

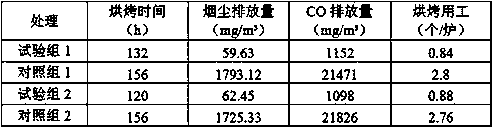

Intensive barn curing process of safflower mammoth gold tobacco leaves

InactiveCN101692929AReduced rate of blue veinsReduce dust hanging rateTobacco preparationEconomic benefitsEngineering

The invention relates to an intensive barn curing process of safflower mammoth gold tobacco leaves. The intensive barn curing process is characterized in that tobacco leaves of a middle lower part and tobacco leaves of an upper part are separately cured, wherein the curing of the tobacco leaves of the middle lower part has six stages, and the curing of the tobacco leaves of the upper part has eight stages. The intensive barn curing process achieves a better effect through controlling corresponding technical conditions in an intensive barn. After curing, the blue vein rate of the tobacco leaves is reduced, the dust rate of the tobacco leaves is reduced, the volume of aroma of the tobacco leaves is obviously increased, the curing time is shortened, and each furnace saves coal by 11 percent. The invention reduces over-cured tobacco leaves and increases the economic benefits.

Owner:云南省烟草公司大理州公司

Thin-film getter with high gas absorption performance and preparation method thereof

ActiveCN103182297AImprove adhesionInhibition of poisoningOther chemical processesDispersed particle separationAbsorption capacityRadio frequency magnetron sputtering

The invention provides a thin-film getter with high gas absorption performance and a preparation method thereof. The thin-film getter is formed by depositing a gas absorbing layer on a metal, silicon, ceramic or glass substrate or on the inner wall of a sealed device or is a film with two-layer structure composed by the gas absorbing layer and an adjusting layer, wherein the gas absorbing layer is multi-component alloy formed by Zr, Co and at least one material selected from the group consisting of Y, La, Ce, Pr and Nd, and the adjusting layer is one or alloy of more selected from the group consisting of Ti, Zr, Y, Hf, Mn, Cu, Cr, Al, Fe, Pt and Ru. The preparation method employs radio frequency magnetron sputtering for deposition of films of the gas absorbing layer and the adjusting layer. The thin-film getter provided by the invention is activated at a temperature in a range of 250 to 350 DEG C, has a high gas absorption rate and high gas absorption capacity, overcomes the problems of poor adhesion, low preparation efficiency and easy poisoning during activation of conventional thin-film getters and can meet design requirements for a vacuum working environment needed for realizing high reliability and a long service life of micro-electromechanical systems (MEMS), flat-panel displays (OLED / FED / LCD), solar heat-insulating boards and hydrogen-sensitive microelectronic devices.

Owner:GRIMAT ENG INST CO LTD

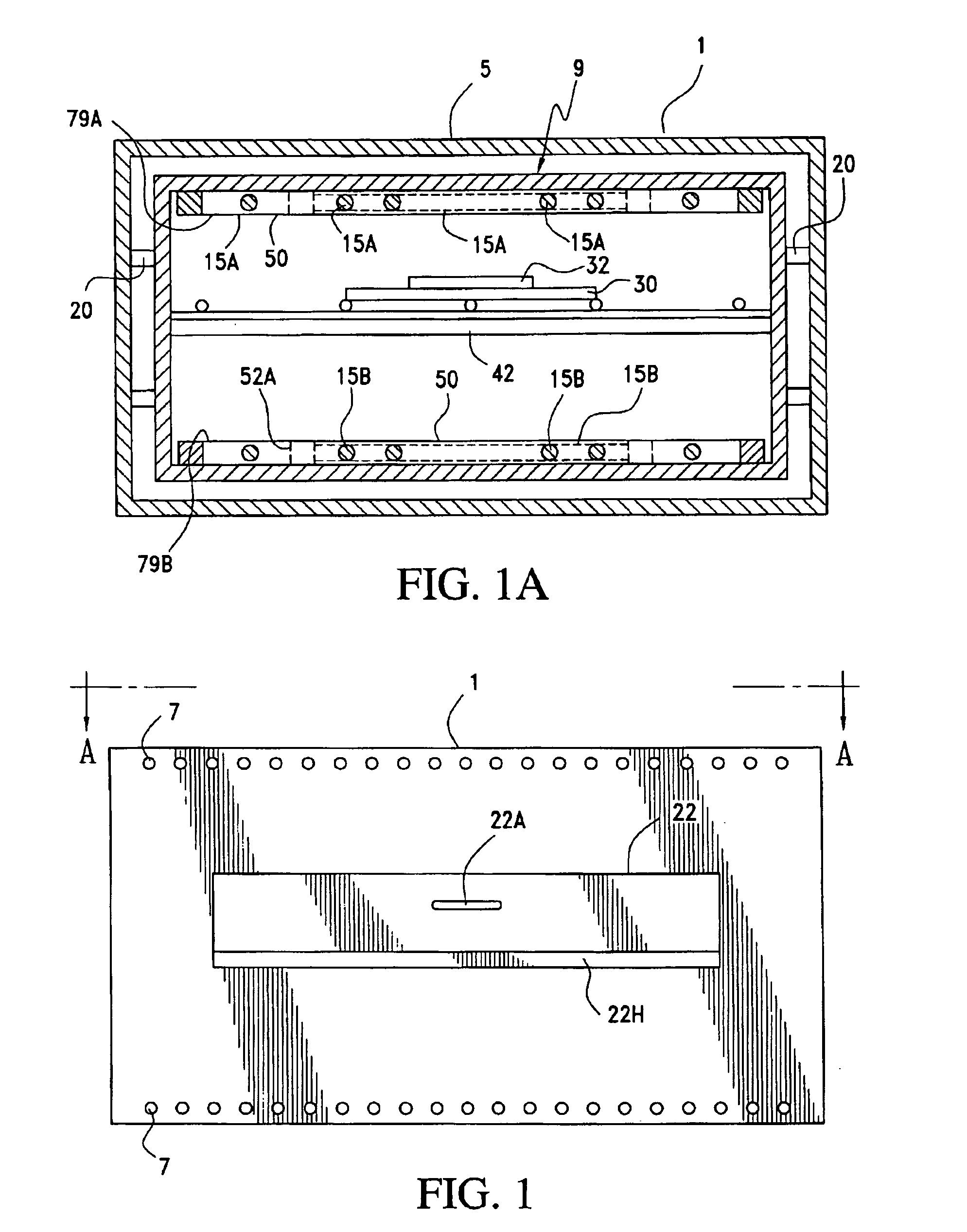

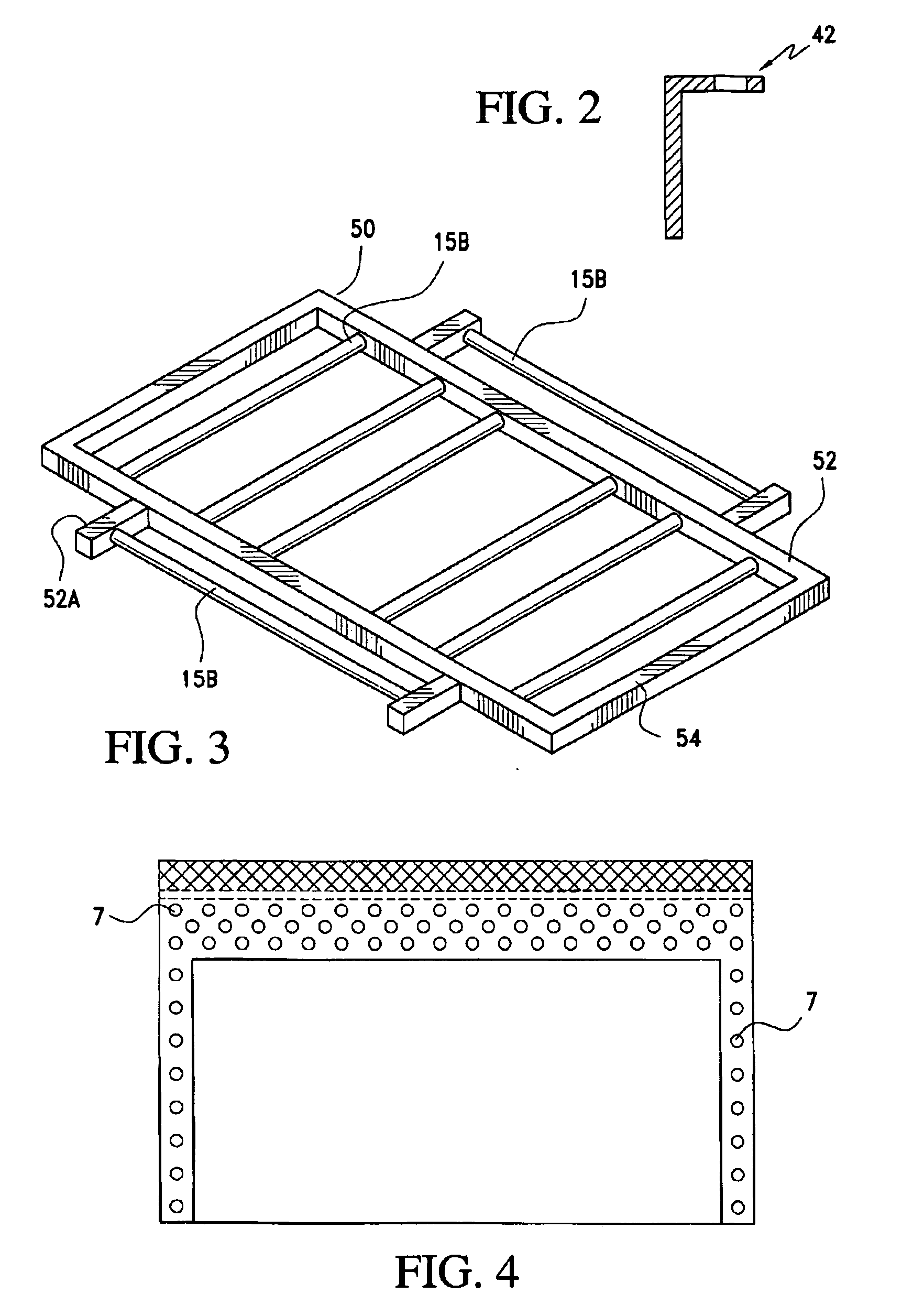

Infrared oven

The disclosed invention relates to an oven for cooking foodstuffs such as pizza by infrared radiation. The oven includes heating elements formed of Fe—Cr—Al alloy wire in a sealed quartz tube heating elements. The heating elements may receive power continuously or in pulses to generate infrared radiation over selected time periods to cook a foodstuff.

Owner:REDI KWICK CORP

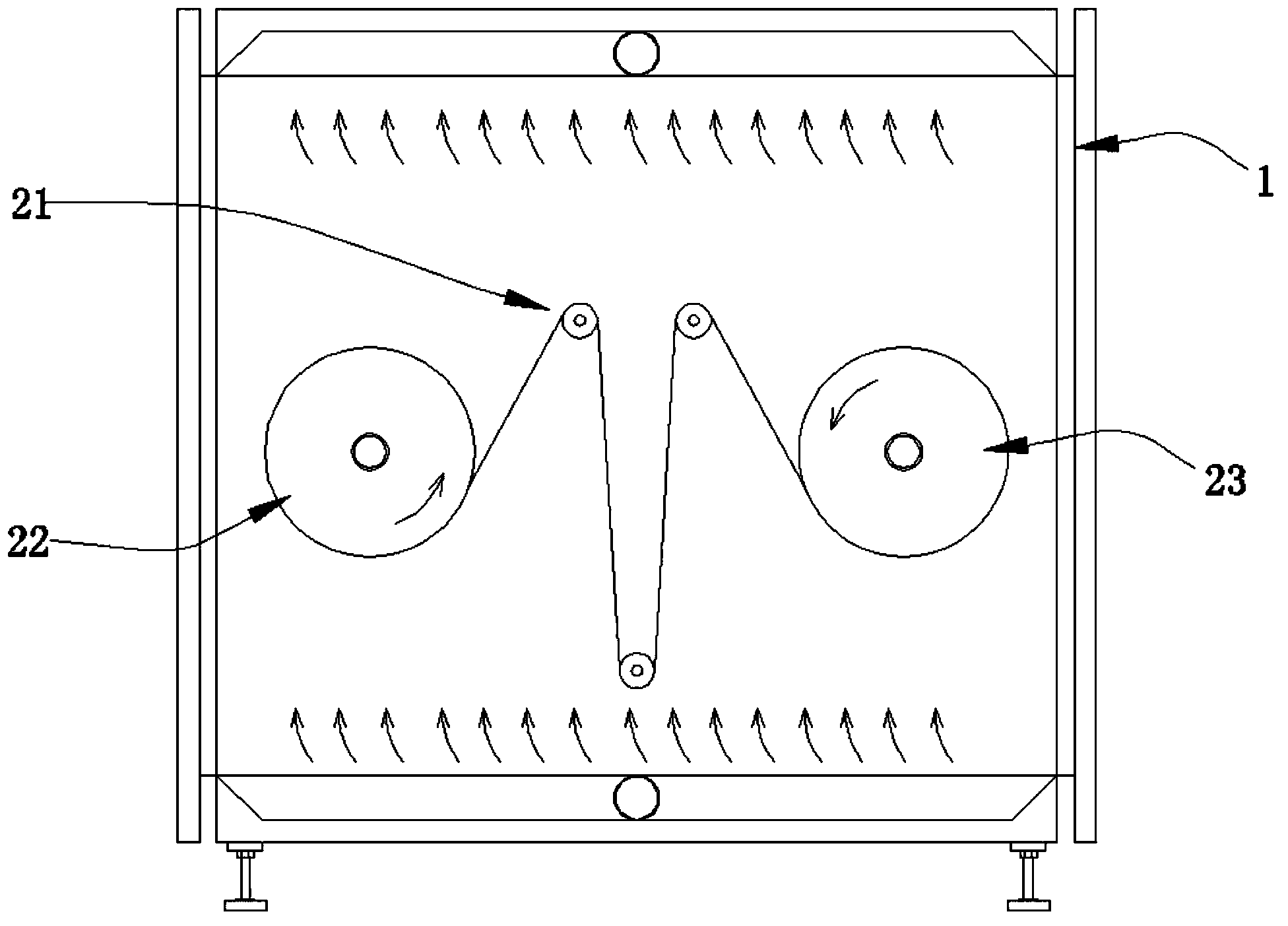

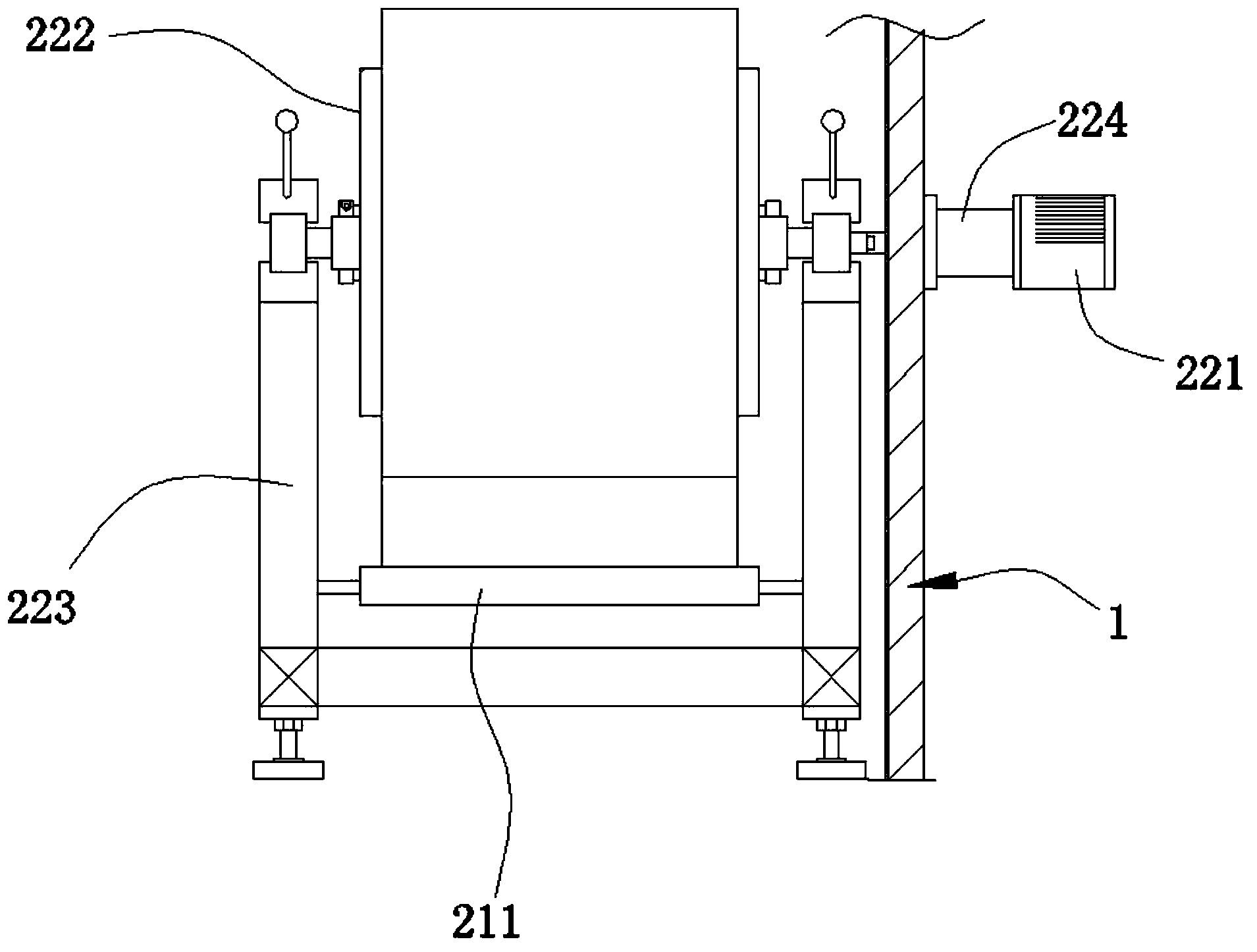

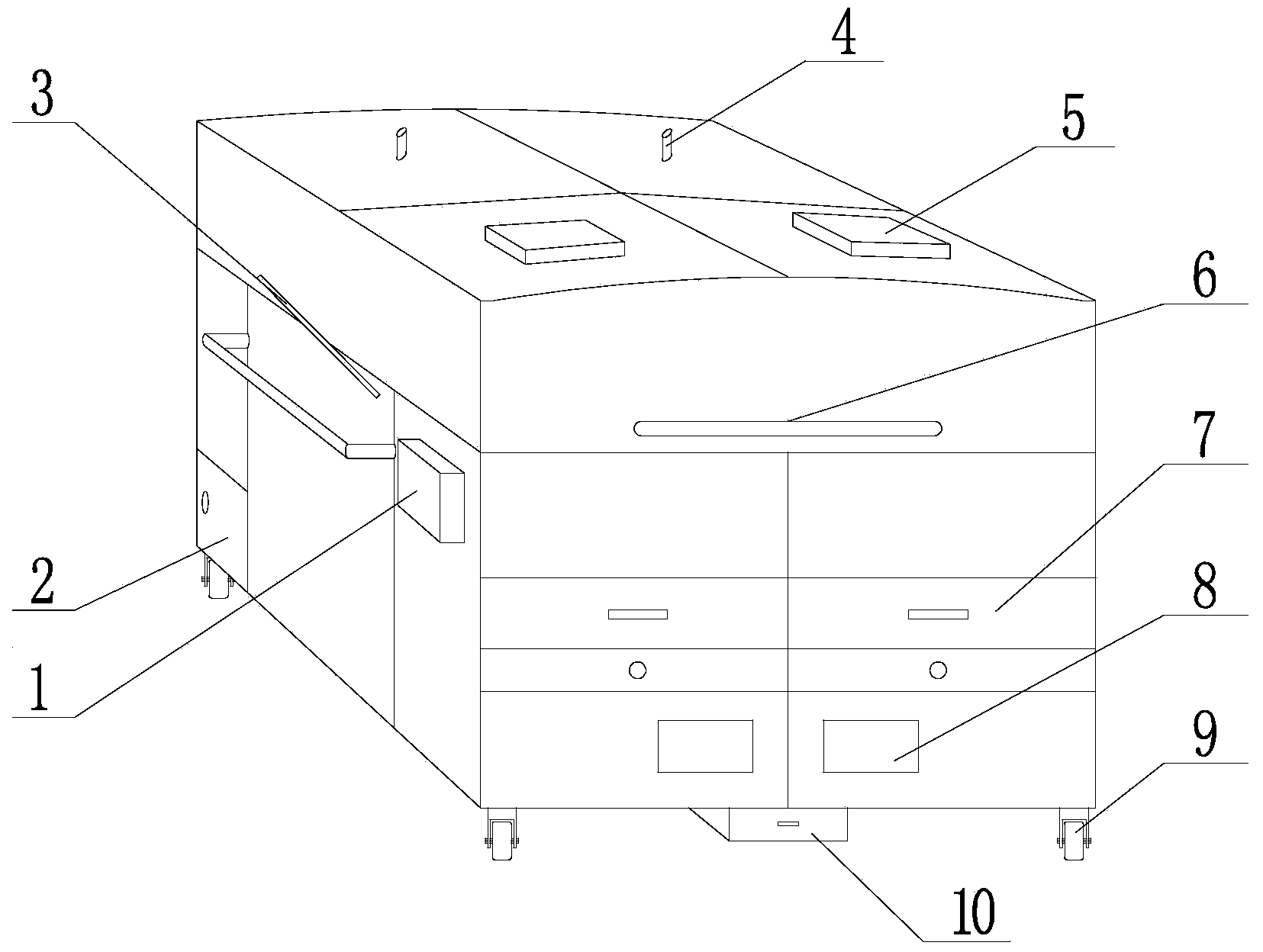

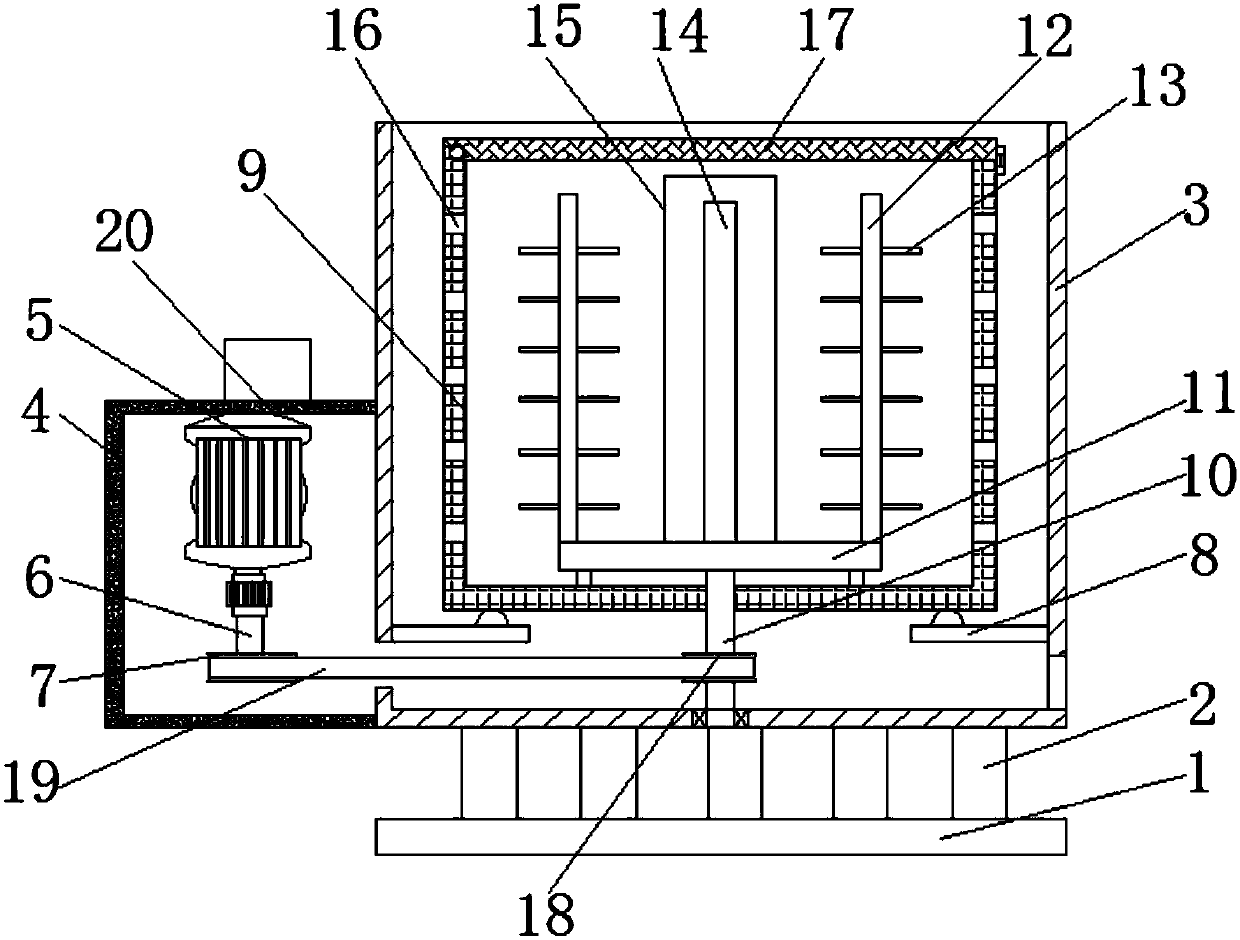

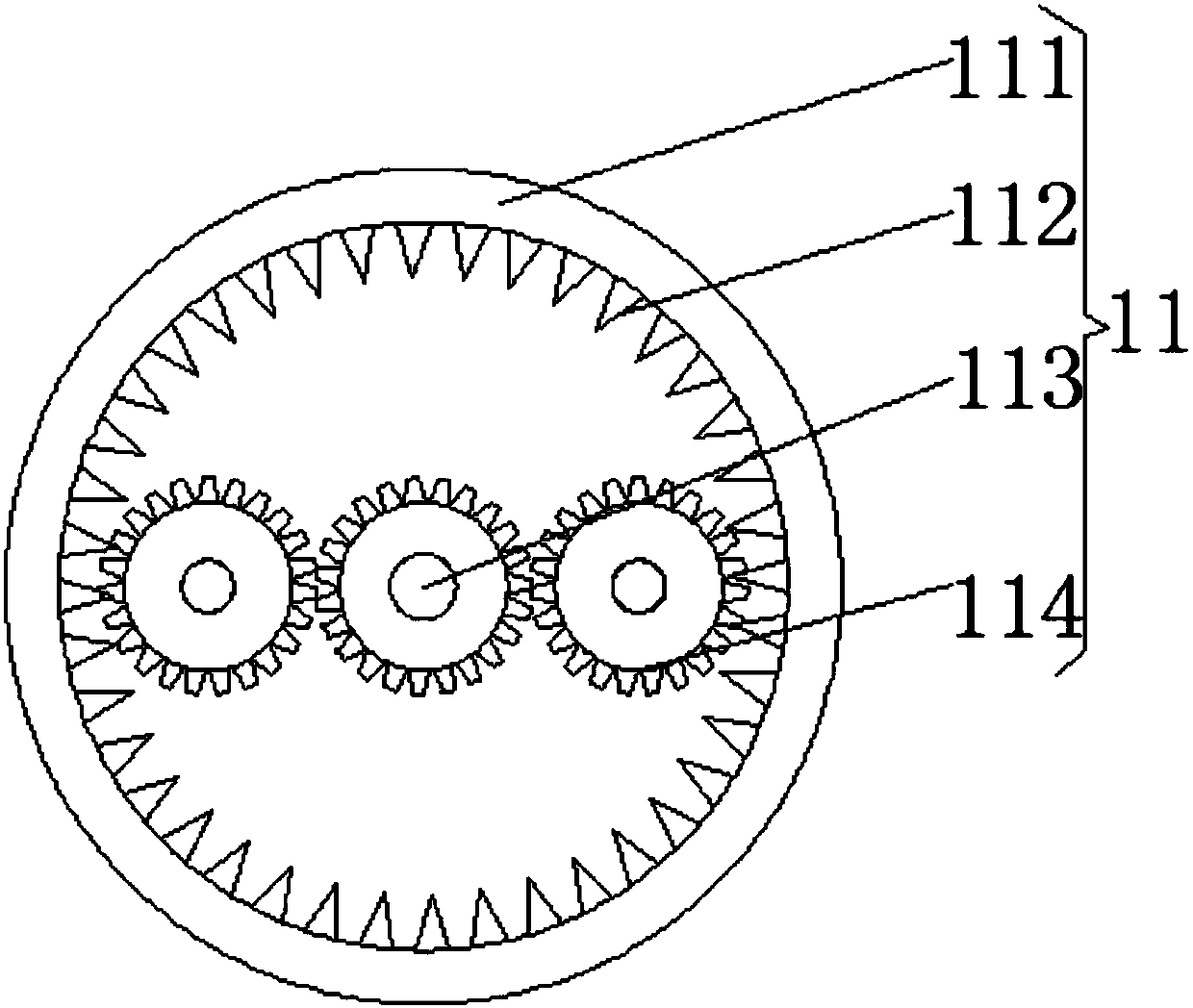

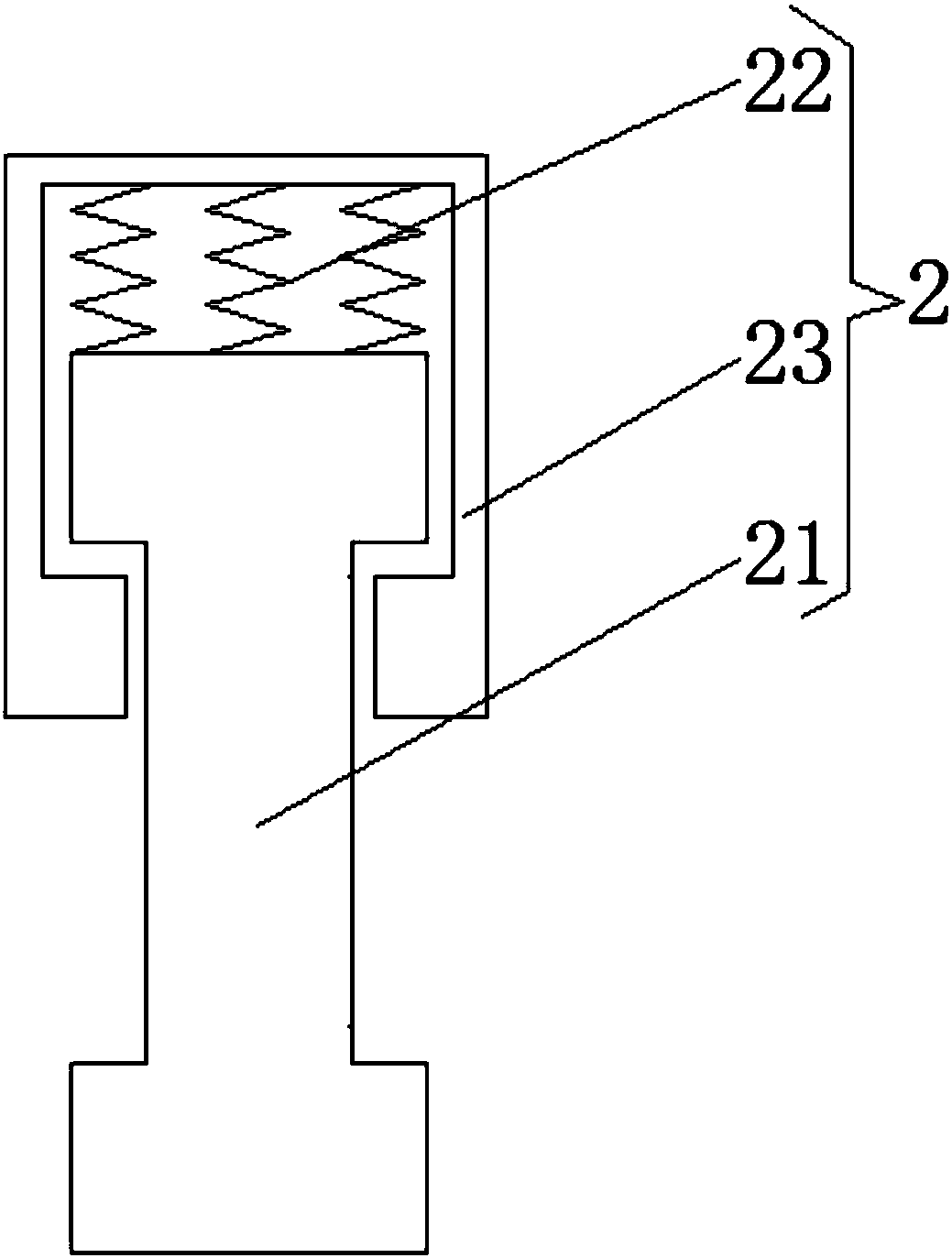

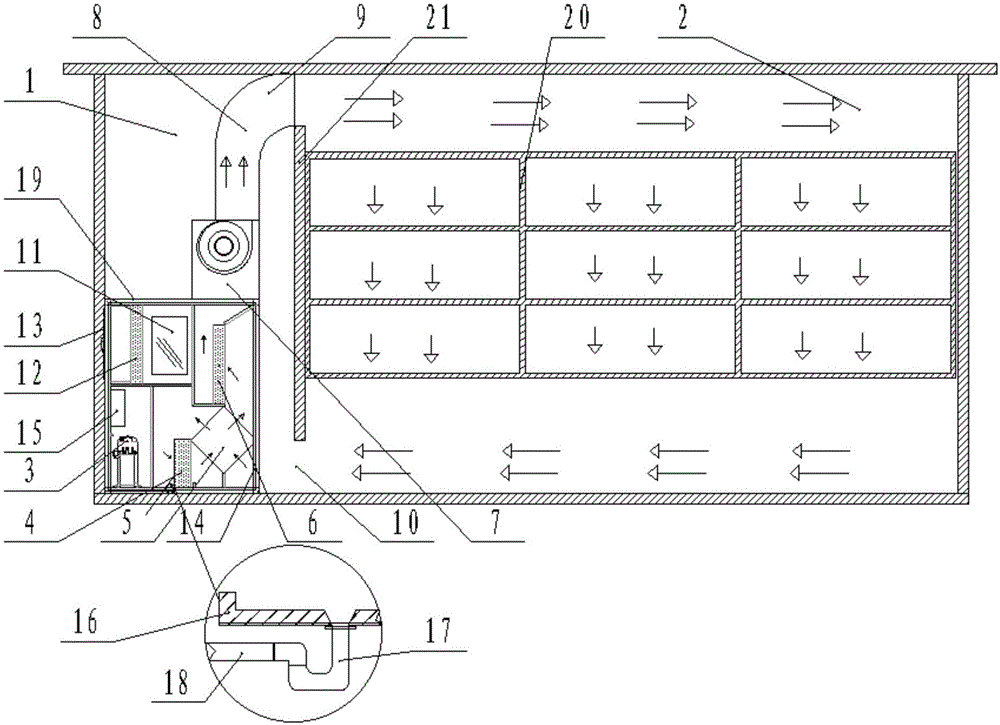

Vacuum drying oven

InactiveCN103836886AReduce heating rateFast heatingDrying using combination processesDrying machines with local agitationPower batteryNitrogen

The invention discloses a vacuum drying oven. The vacuum drying oven comprises a vacuum oven body. The interior of the vacuum oven body is at least provided with a roll material winding and unwinding mechanism. The outer sidewall of the vacuum oven body is at least provided with a wind-powered light emitting device. The vacuum drying oven is simple in structure and reasonable in design; roll materials in the vacuum oven body can be unwound for baking through the roll material winding and unwinding mechanism, so that baking time is effectively shortened, and baking quality is improved. Meanwhile, hot air is delivered to an inner cavity of the vacuum oven body through the wind-powered light emitting device to form a dynamic loop for circulation heating, the heat cycle is fast, the temperature rise rate of the vacuum drying oven can be increased, good temperature uniformity can also be acquired, so that a drying effect is further improved, and product quality is guaranteed. Moreover, nitrogen which has a drying effect can further be led in through a nitrogen pipe, water is pumped out through a vacuum tube, and therefore a breath type drying effect is formed. In this way, drying time is substantially shortened, production efficiency is enhanced, and the vacuum drying oven can be widely popularized and especially applicable to the power battery industry.

Owner:陈伟陵

Dry material using waste magnesia carbon brick as main raw material and preparation method of dry material

The invention discloses a dry material using a waste magnesia carbon brick as a main raw material and a preparation method of the dry material. The dry material comprises the following components of, by mass, 95-97 wt. %, 2.3-3.9 wt. % of modified resins, 0.1-0.3 wt. % of urotropin, and 0.5-0.9 wt. % of sodium borate. The dry material uses the waste magnesia carbon brick as the raw material for preparing the dry material so that resource consumption is reduced, and costs are reduced due to the fact that the waste magnesia carbon brick is less than 400.00 yuan / ton while traditional magnesite or forsterite is 1950.00 yuan / ton on average, and costs of the raw material can be saved by over 79%. The waste magnesia carbon brick is treated at high temperatures, tundish baking time is saved by 3 hours, energy consumption is saved, and baking costs are reduced by over 50%. The modified resins are used as binding agents so that nose choking smoke and poisonous harmful gases can not be produced. The dry material has the advantages of being energy-saving, emission-reducing, environment-friendly and low in cost, and according to the dry material, problems of poor intensity at normal temperatures and poor slag resistance at high temperatures of the dry material are solved.

Owner:浙江攀盛冶金材料有限公司

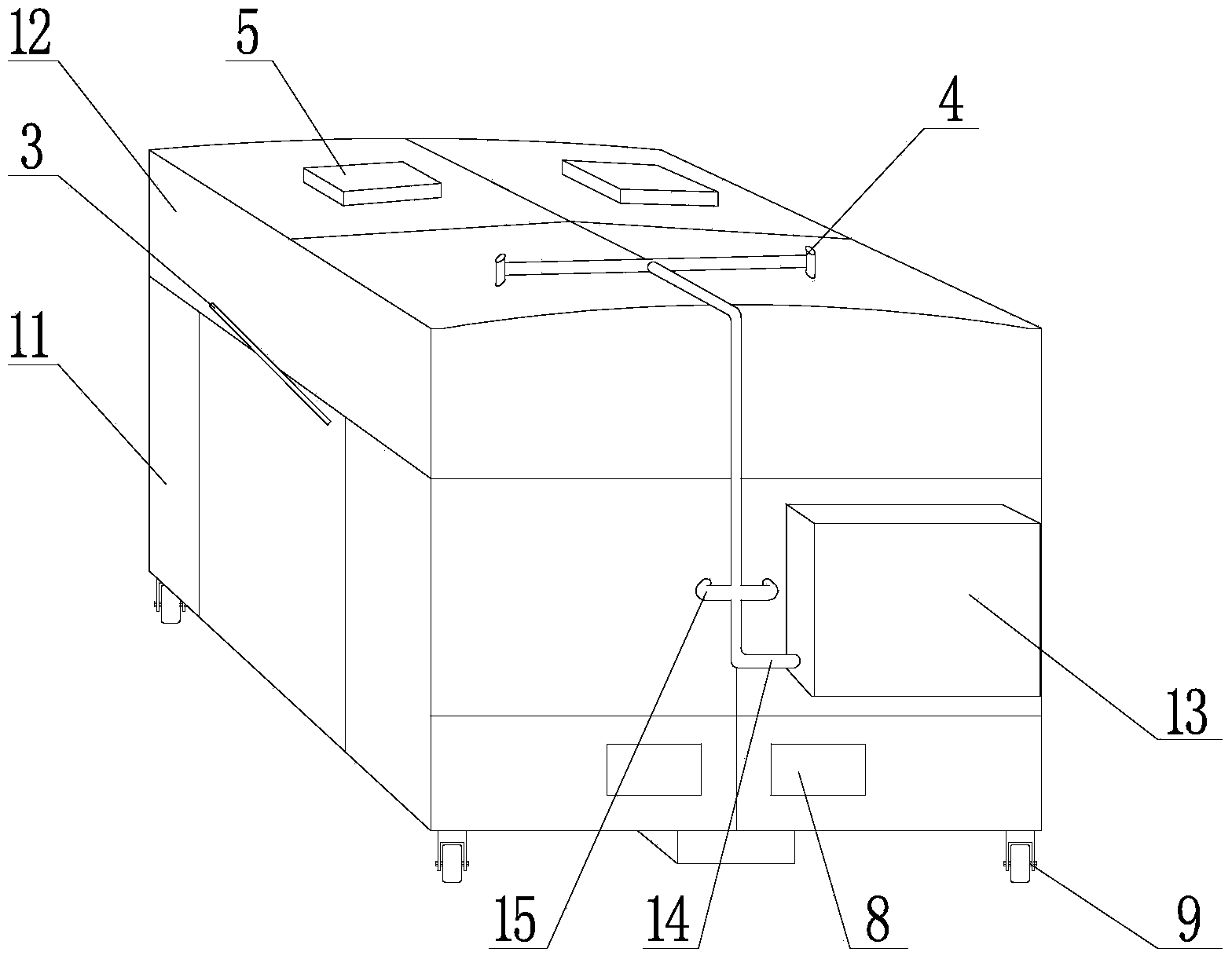

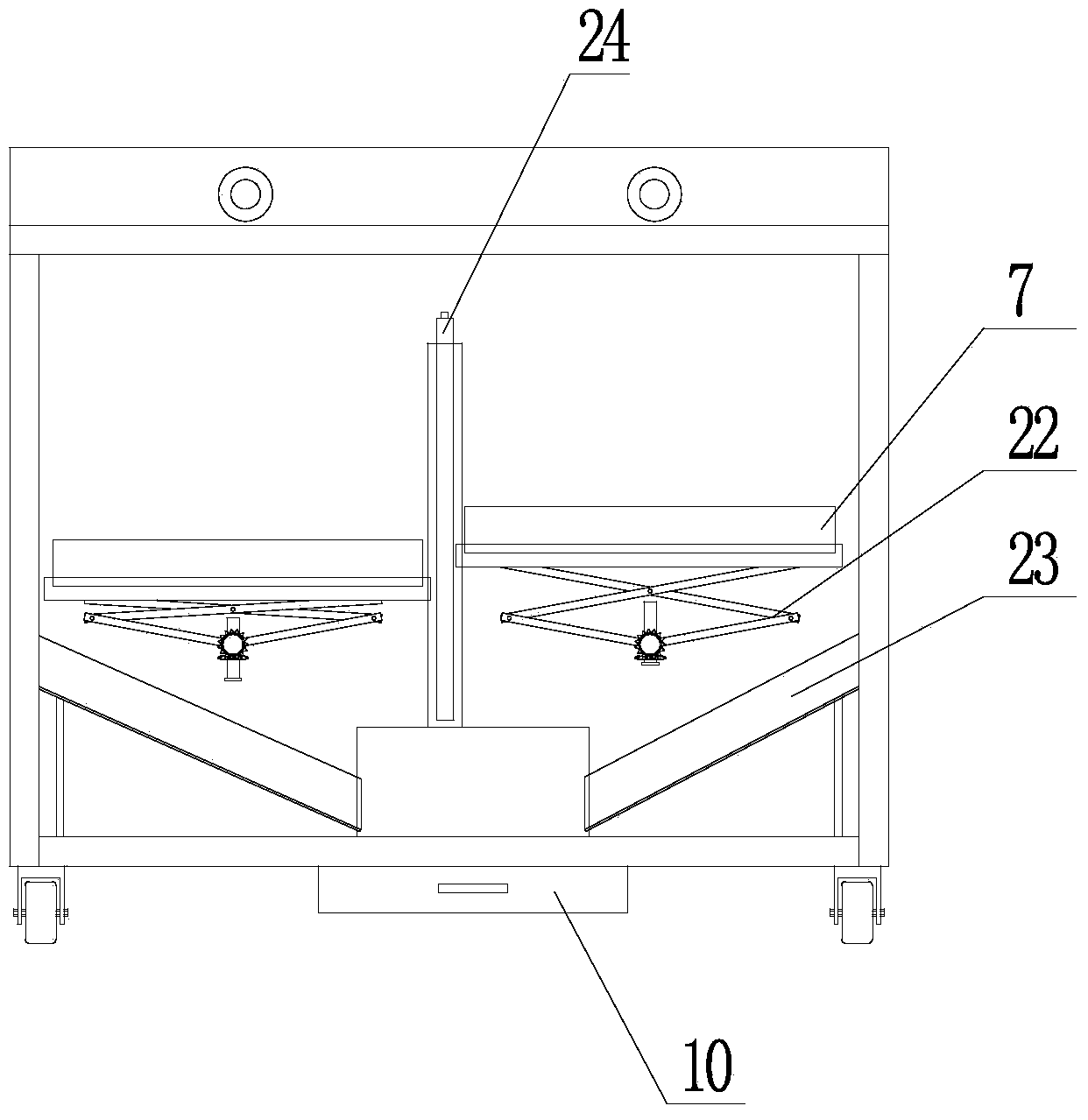

Mobile meat roaster

ActiveCN102378591AImprove work convenienceFree from inhalationRoasting apparatusEngineeringGrilled food

Owner:崔光镐

Method for processing organic dried bamboo shoots

ActiveCN102240013AImprove crispnessImprove toughnessClimate change adaptationFood preparationCooking & bakingFlavor

The invention discloses a method for processing organic dried bamboo shoots, and the method comprises the following steps: (1) husking fresh bamboo shoots in a whole; (2) cleaning the husked fresh bamboo shoots; (3) placing the husked and cleaned fresh bamboo shoots into a steamer and steaming for 40-90 minutes; (4) rinsing the steamed fresh bamboo shoots with running water, and cooling to room temperature; (5) immediately placing the fresh bamboo shoots into a dehydrator and dehydrating until the water content is 30-40%; (6) sealing the bamboo shoots dehydrated in the step 5 by utilizing a film bag for fermentation and color protection; (7) roasting for 7-8 hours at the temperature of 60-90 DEG C in a baking room or an oven, and airing until the water content is 5-10%; and (8) sealing and packaging. The method provided by the invention has the advantages of simple equipment and high production efficiency. The dried bamboo shoots produced by utilizing the method provided by the invention are exquisite in tissue structure, are in faint yellow, have crisp and tender mouthfeel, are convenient to eat, and preserve the unique strong flavor of the bamboo shoots.

Owner:HUNAN ACAD OF FORESTRY

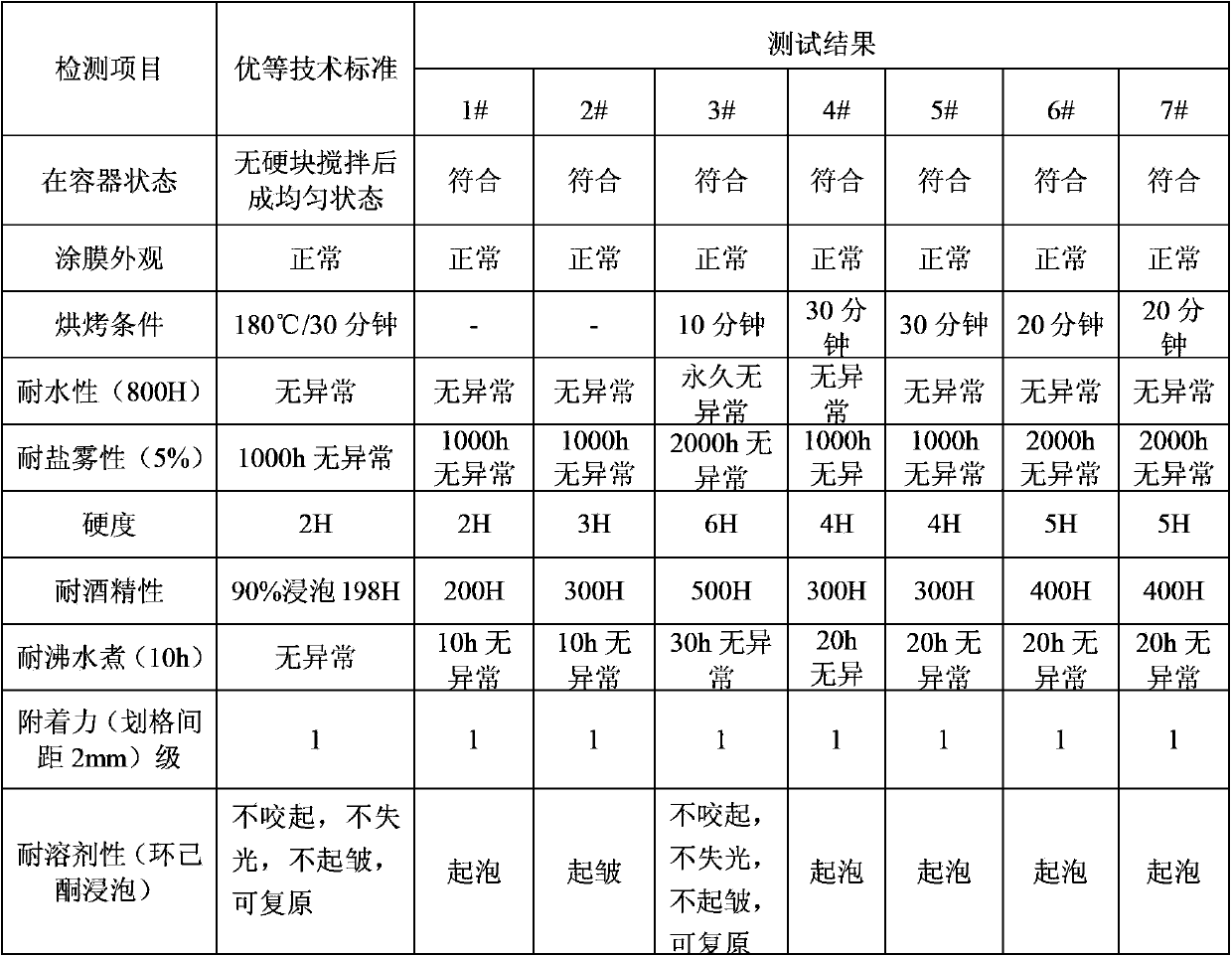

Water-based glass coating

ActiveCN103965715AReduce baking timeIncrease productivityPolyurea/polyurethane coatingsWater basedAlcohol

The invention relates to a water-based glass coating, and belongs to the technical field of coating. The invention provides a water-based glass coating, which comprises the following components by mass percentage: 30%-40% of acrylic resin, 25%-35% of epoxy polyurethane synthetic resin, 1%-3% of a coupling agent, 10%-20% of amino resin, 0.1%-0.3% of a wetting agent, 1%-2% of a leveling agent, 0.5%-2% of a thickening agent, 0.2%-0.8% of a defoaming agent, 8%-12% of a curing agent and the balance of deionized water. The water-based glass coating of the invention shortens the baking time, improves production efficiency, highlights super abrasion resistance and high hardness on the promise of high adhesion, water resistance and alcohol resistance, and fills the gaps of the domestic water glass coating in special fields.

Owner:惠州市华昱美实业有限公司

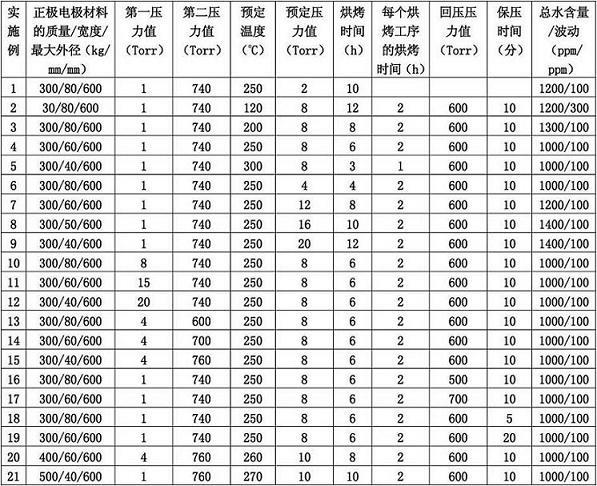

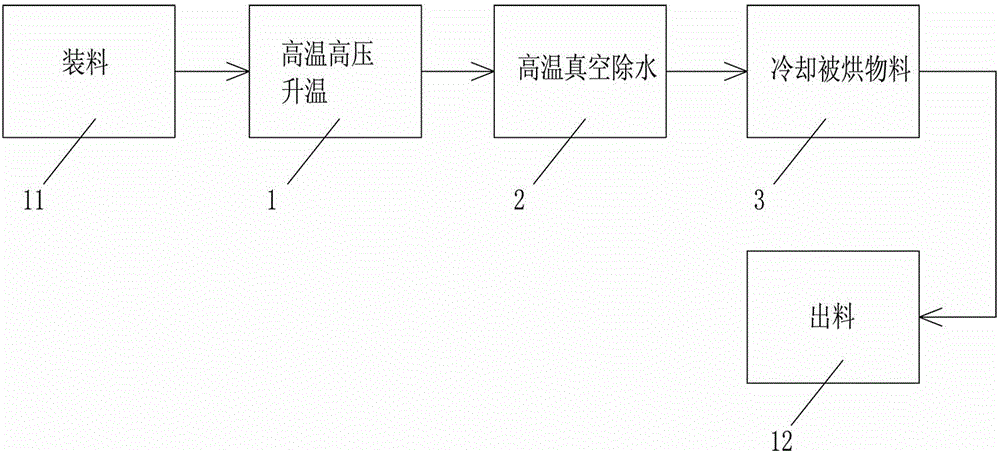

Drying method for positive electrode material of lithium ion battery

ActiveCN102110803AReduce moisture contentGuaranteed stabilityDrying using combination processesElectrode manufacturing processesShielding gasEngineering

The invention provides a drying method for a positive electrode material of a lithium ion battery. The method comprises the following steps: a) placing a positive electrode material in a drying chamber with an internal circulation fan; b) vacuumizing the drying chamber; c) introducing a protection gas into the drying chamber; d) heating and vacuumizing the drying chamber, rising the temperature of the drying chamber to a predetermined temperature, and reducing the pressure value of the drying chamber to a predetermined pressure value, wherein the predetermined temperature is 120 to 300 DEG C, and the predetermined pressure value is not more than 20 Torr; e) roasting the positive electrode material under the predetermined pressure value and the predetermined temperature, wherein the internal circulation fan is rotated in the roasting process; and f) cooling and taking out the positive electrode material. According to the drying method provided by the invention, the moisture content of the positive electrode material can be effectively reduced, the total positive electrode material of the positive electrode materials is less than 1400 ppm, and even less than 1000 ppm, the stability for the drying degree of the positive electrode materials can be ensured, and the security and service life of the battery are improved.

Owner:FUJIAN NANPING NANFU BATTERY

Intensive curing barn baking process for airflow alternate-operation flue-cured tobacco

ActiveCN102068028AReduce the plane temperature differenceReduce vertical temperature differenceTobacco preparationTobacco treatmentEcological environmentOperation mode

The invention relates to an intensive curing barn baking process for airflow alternate-operation flue-cured tobacco, belonging to the technical field of flue-cured tobacco preparation process. The intensive curing barn baking process for airflow alternate-operation flue-cured tobacco is the improvement on the existing intensive curing barn baking process. The improvement point is characterized inthat interval time for the alternate operation of airflow rise and airflow descending is as follows: in the low-temperature humidifying and yellowing stage: two airflow operation modes are provided, the time interval is 0.50 hour, and alternation is carried out once; in the stable-temperature dehumidifying and withering stage: two airflow operation modes are provided, the time interval is 0.50 hour, and alternation is carried out once; in the ventilating, dewatering and leaf-drying stage: two airflow operation modes are provided, the time interval is 0.75 hour, and alternation is carried out once; and in the temperature and moisture controlling and tendon drying stage: two airflow operation modes are provided, the time interval is 1.00 hour, and alternation is carried out once. Other baking operation technologies of the process are same with the conventional baking process. The intensive curing barn baking process can obviously improve the baking property of the tobacco loading chamber of the intensive curing barn, improve tobacco leaf baking quality, and improve the safety for baking the tobacco leaf. The intensive curing barn baking process is suitable for intensive baking underdifferent ecological environment conditions in the tobacco area in China.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Automatic charcoal-fire sheep roasting machine

InactiveCN103651646AGuaranteed tasteKeep fresh tasteSpecial goods bakingAutomatic controlComputer module

The invention provides an automatic charcoal-fire sheep roasting machine. The automatic charcoal-fire sheep roasting machine comprises an oven, a grill, charcoal fire chambers and a control unit; the oven comprises a box body, and coaxial shaft sleeves are arranged at the upper end of the box body in pairs; a rotary shaft is arranged on the grill, the shaft head at one end of the rotary shaft is fixedly connected with a transmission device which is connected with a driving device, and the driving device is connected with the control unit; air holes are formed in the bottoms of the charcoal fire chambers which are arranged inside the box body and below the grill, and ventilation openings are formed in the positions, below the charcoal fire chambers, of the box body; the control unit comprises a rotary-shaft forward and reverse rotation motion control module, a forward and reverse rotation number control module and a master switch. The automatic charcoal-fire sheep roasting machine achieves uniform roasting heating, saves manpower, is capable of automatically controlling roasting time and short in roasting time, achieves good mouthfeel, is capable of being used for roasting multiple sheep, achieves batch roasting, saves energy, is beneficial to environmental protection, improves efficiency, reduces the number of carcinogenic substances adhering to the surfaces of the roasted sheep, guarantees cleanliness of waste gas, and has the advantages of being simple in structure, convenient to operate and low in cost.

Owner:刘文山

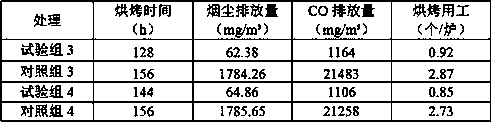

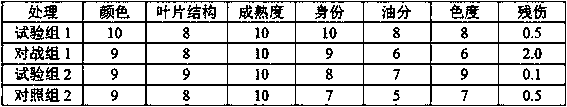

High-efficiency baking method for improving appearance quality of K326 variety of tobacco leaves

InactiveCN110638081ASolve the problem that it is easy to turn yellow and difficult to fix the colorImprove appearance qualityTobacco preparationAgricultural engineeringWet-bulb temperature

The invention discloses a high-efficiency baking method for improving appearance quality of K326 variety of tobacco leaves. The method is characterized by baking by using biomass fuel, harvesting properly mature K326 variety of tobacco leaves; arranging rods into a baking room to be baked, wherein the yellowing period control comprises initial yellowing period control, middle yellowing period control and later yellowing control, the color fixing period control comprises the initial color fixing stage and the later color fixing stage, and the initial color fixing stage control comprises temperature rise in the rate of 1 DEG C / 1-2h after the yellowing period control is finished; and the stem drying stage control comprises rising the temperature of a dry bulb to 66-67 DEG C, and adjusting thetemperature of a wet bulb to 40-42 DEG C. Through the slow temperature rise at the early color fixing stage, the problems that the grey smoke hanging and process execution are inaccurate, the bakingtime is long, the combustion efficiency is low, the pollution is large, and the feeding is frequent since the yellowing is easy and the color fixing is difficult, the tobacco leaves after baking are stiff, the fragrance is not enough, the temperature rise is slow, and the stable temperature is unstable in the traditional K326 tobacco leaf baking process are solved by combining the high temperatureand low humidity at the stage of drying the stems, and the proportion of the tobacco in middle and high quality and the quality of the baked tobacco leaves are obviously improved.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Amino stoving varnish capable of being cured quickly at low temperature

ActiveCN103087603ALow baking temperatureReduce baking timeEpoxy resin coatingsPolyester coatingsComposite materialAntifoam agent

The invention relates to amino stoving varnish, and in particular to amino stoving varnish capable of capable of being cured quickly at a low temperature. The amino stoving varnish comprises the following components in parts by weight: 50-60 parts of hydroxy acrylic resin or alkyd resin, 10-20 parts of amino resin, 1-5 parts of functional auxiliary, 0.1-0.5 part of flatting agent, 0.1-0.5 part of antifoaming agent and 10-20 parts of diluent. A preparation method of the amino stoving varnish provided by the invention is simple, and the prepared product has strong applicability and good quality.

Owner:浙江德尚化工科技有限公司

Method for drying lithium ion battery or battery pole piece

ActiveCN104061761AIncrease capacityReduce baking timeDrying using combination processesThermodynamicsEngineering

Owner:SHENZHEN XINYUREN TECH

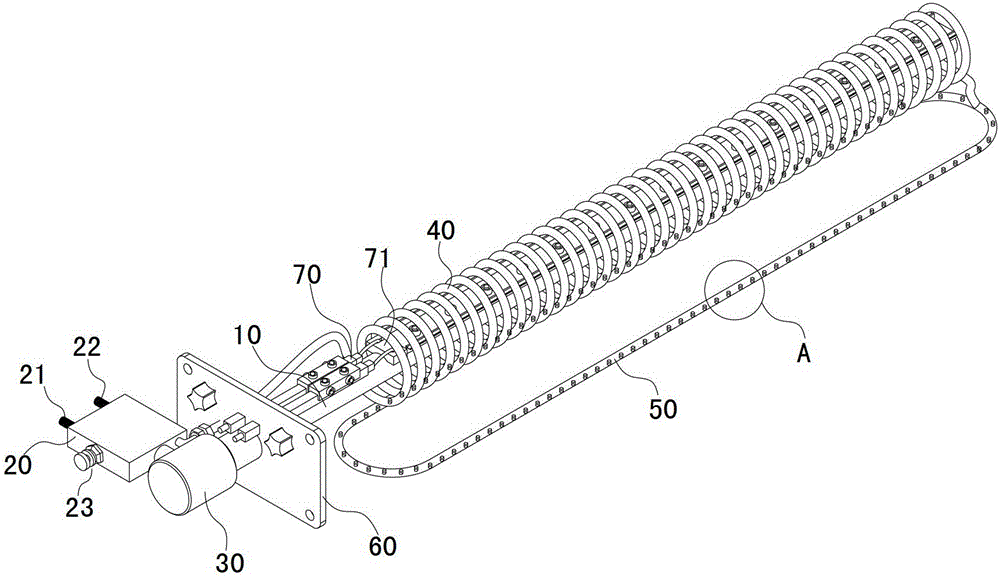

A food baking device

The invention relates to a food baking device which comprises a fire tube, a steam tube, a baking tube and an ignition mechanism, wherein one end of the fire tube is opened while the other end is a blind end, wherein the opened end of the fire tube is used for inputting natural gas and air to a tube cavity of the fire tube; a combustion chamber for accommodating the mixed gas composed of the natural gas and air is formed in the fire tube; a plurality of fire ejecting holes are formed in a tube wall of the fire tube; the steam tube is in a spiral form and is wound on the periphery of the fire tube; the inlet end of the steam tube is used for inputting steam to the tube cavity of the steam tube; the tube cavity of the baking tube is communicated with the outlet end of the steam tube; a plurality of gas outlets are arranged on the baking tube: the ignition mechanism is used for igniting the mixed gas in the fire tube. The food baking device utilizes the superheated steam to bake food, so that the water content in food can be kept, the mouth feeling of food is promoted, and under the same temperature, the superheated steam is used for baking food so as to reduce the baking time, increase the baking efficiency and save energy source.

Owner:广州浩胜食品机械有限公司

Peeling and baking process of fresh fructus momordicae

InactiveCN102696996AReduce lossesReduce baking timeFood processingFood preparationCooking & bakingPuccinia xanthii

The invention discloses a peeling and baking process of fresh fructus momordicae. The peeling and baking process comprises the following steps of: naturally saccharifying the picked fresh fructus momordicae; peeling off the saccharified fructus momordicae, taking seed and flesh out, dividing the seed and flesh into a plurality of segments and flatly placing on a baking screen; placing the baking screen in a baking room or an electrical baking box for baking; baking at the temperature of 60-70 DEG C for 6-7 hours to dry the surface skin layer; ripening at the temperature of 70-80 DEG C for 5-6 hours; and baking at the temperature of 55-60 DEG C for 10-12 hours. The peeling and baking process has the advantages that the fruit flesh baked by the process is tawny, the baking time is shortened by 60 percent compared with that of the conventional drying process, the structure is compact, an extremely attractive appearance is achieved, the time and the energy are saved, the nutrient content loss is low, and the original fruit flavor is kept.

Owner:龙胜各族自治县和平罗汉果农民专业合作社

Water-absorbing master batch for moulding regenerated plastic and preparation method for same

The invention relates to a water-absorbing master batch for moulding regenerated plastic and a preparation method for the same. The water-absorbing master batch is composed of 15-35 parts of carrier resin, 65-85 parts of kieselguhr, 2-8 parts of a lubricating agent, 1-3 parts of a coupling agent, and 0-3 parts of a dispersing agent. The water-absorbing master batch disclosed by the invention is added and used during moulding processing for regenerated plastic, and capable of removing water and unknown low-molecular-weight volatile matters contained in the plastic, so that the plastic products have no water spray and air bubbles, and a drying process can be simplified, and machining time and machining expense can be saved while the quality of the products is improved; additionally, the water-absorbing master batch is capable of reducing the pungent smell generated by the plastic due to degradation and the like, and is widely used in various plastic moulding processes of plastic pipes, injection moulding, hollow blow-moulding and the like.

Owner:HEFEI GENIUS NEW MATERIALS

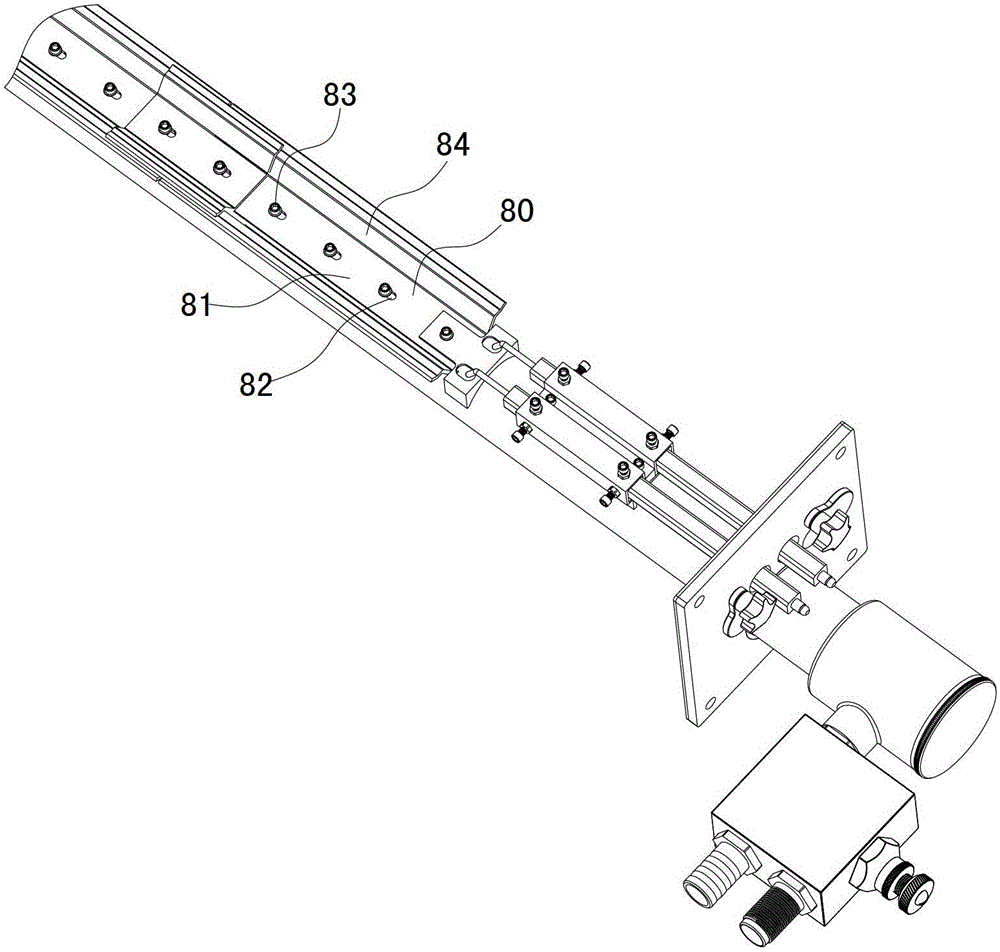

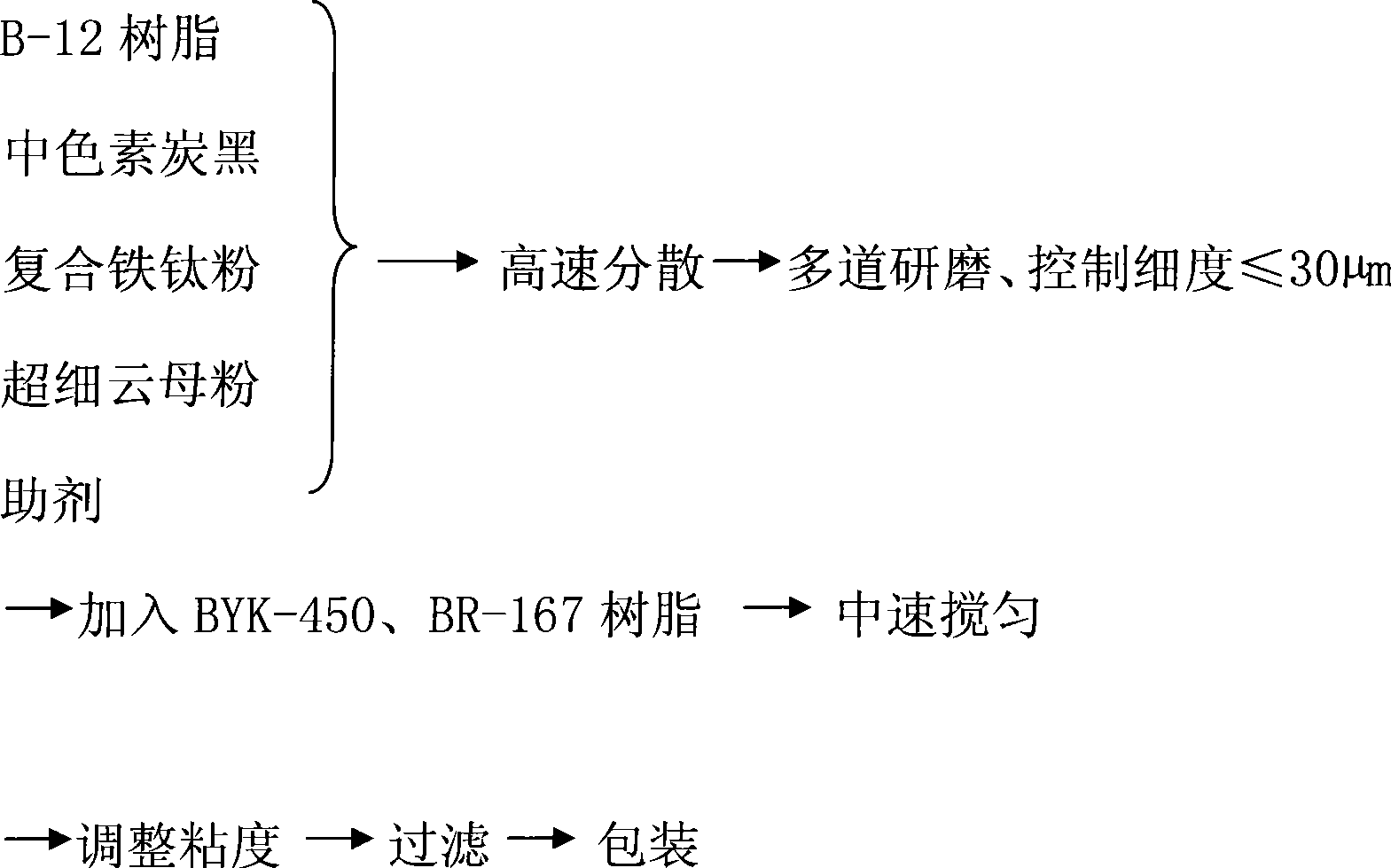

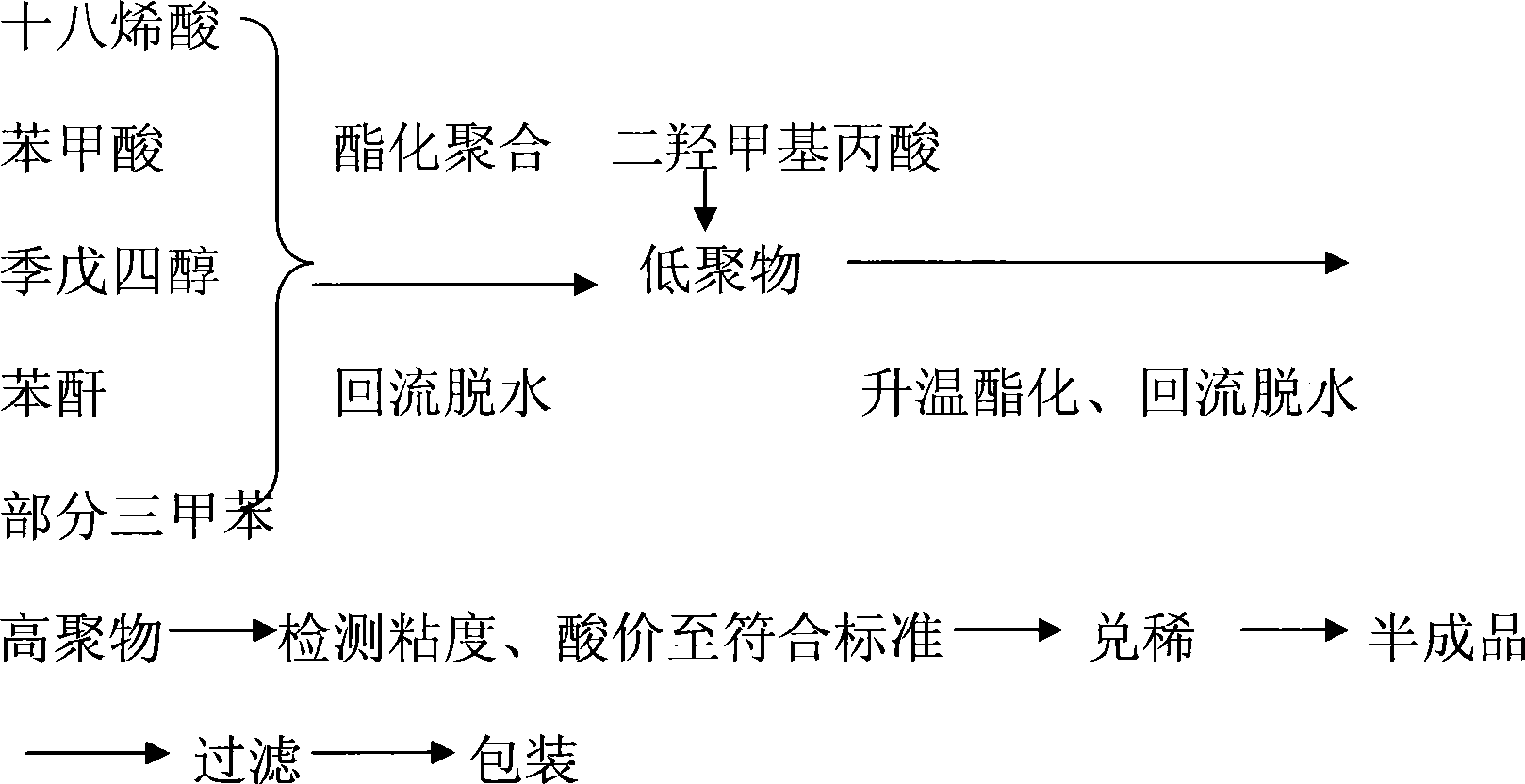

Low temperature quick-drying amino paint for automobile chassis and production method thereof

ActiveCN101434809AImprove efficiencyImprove coating efficiencyPolyester coatingsBenzoic acidPropanoic acid

The invention provides a low-temperature fast-dry amino automobile chassis paint and a production method thereof, wherein, the paint consists of B-12 resin, medium pigment carbon black, compound ferrotitanium powder, ultra-fine mica powder, an auxiliary agent, sealed paratoluenesulfonic acid BYK-450 and BR-167 amino resin; B-12 resin is prepared by octadecenoic acid, benzoic acid, pentaerythritol, phthalic anhydride, dimethylol propionic acid, and trimethyl benzene. The automobile chassis paint adopts special B-12 resin synthetic route to lead the polymer chain to have more active functional groups simultaneously to be matched with the blocked paratoluenesulfonic acid, reduces the baking temperature of the existing amino paint from 130 DEG C to 90 DEG C and reduces the curing film-forming time from 1 hour to half an hour. As the paint film has high crosslinking density, compound ferrotitanium powder and squamous anti-rust pigment are matched for use, and the polyaniline is used for improving the anticorrosive potentials, thus leading the salt spray resistance of the paint to achieve 150 hours and improving the protection performance and the coating efficiency.

Owner:ANQING LINGHU PAINT

Agricultural byproduct dewatering drying machine

InactiveCN107621142AEvenly heatedSpeed up dryingDrying solid materialsDrying machines with non-progressive movementsAgricultural engineeringEngineering

The invention discloses an agricultural byproduct dewatering drying machine which comprises a base. A damper is fixedly connected to the top of the base. The damper comprises a damping plate. A damping spring is fixedly connected to the top of an inner cavity of the damping plate. The end, away from the top of the inner cavity, of the damping spring is fixedly connected with a damping rod. The bottom end of the damping rod penetrates the bottom of the damping plate and extends to the outer portion of the damping plate. A box body is fixedly connected to the top of the damping plate. The left side of the box body is fixedly connected with a motor box, and a motor is fixedly connected to the top of an inner cavity of the motor box. By means of the agricultural byproduct dewatering drying machine, due to use of a roller, water on the surfaces of humid agricultural byproducts can be rapidly removed, and the baking time is shortened; and due to use of a stirring rod, the phenomenon that thesurface layer is dry and the inner layer is humid is avoided, the drying quality is ensured, the service life of the machine is prolonged, the production cost is reduced, and the production efficiency is improved.

Owner:重庆市六方格农业综合开发有限公司

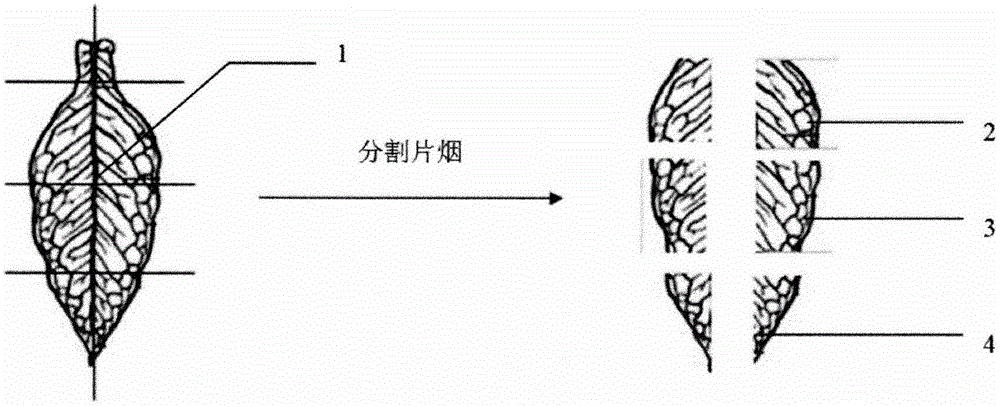

Tobacco leaf segmented strip roasting method

ActiveCN105167148AIncrease the effective amount of smokeReduce baking timeTobacco preparationTobacco processorBiology

The invention discloses a tobacco leaf segmented strip roasting method. The method comprises the specific steps that main veins of mature harvested fresh tobacco leaves are removed according to the tobacco leaf growing parts, and segmented main vein auxiliary materials can be used for independently roasted or used in other ways; the tobacco leaves are segmented from leaf bases, leaf middles and leaf tips into small tobacco strips, a specific clamping device is used for managing and fixing the tobacco strips, and the tobacco strips are placed into a roasting room; the tobacco strips are gradually yellowed and dried, and tobacco leaf roasted yellowing, roasted fragrance and fragrance preservation are achieved; de-enzyming and impurity removal are carried out on the toasted tobacco strips according to threshing and reroasting standards, and packaged alcoholization is carried out. The requirement of the cigarette industry for high-quality raw material tobacco strips is met, the time spent for conventional main vein toasting and main vein drying for the whole tobacco leaves at high temperature is omitted, the effective tobacco packaging amount is improved, time and energy consumption are saved, meanwhile, tobacco leaf reroasting link is simplified, and the tobacco leaf processing factorization is achieved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

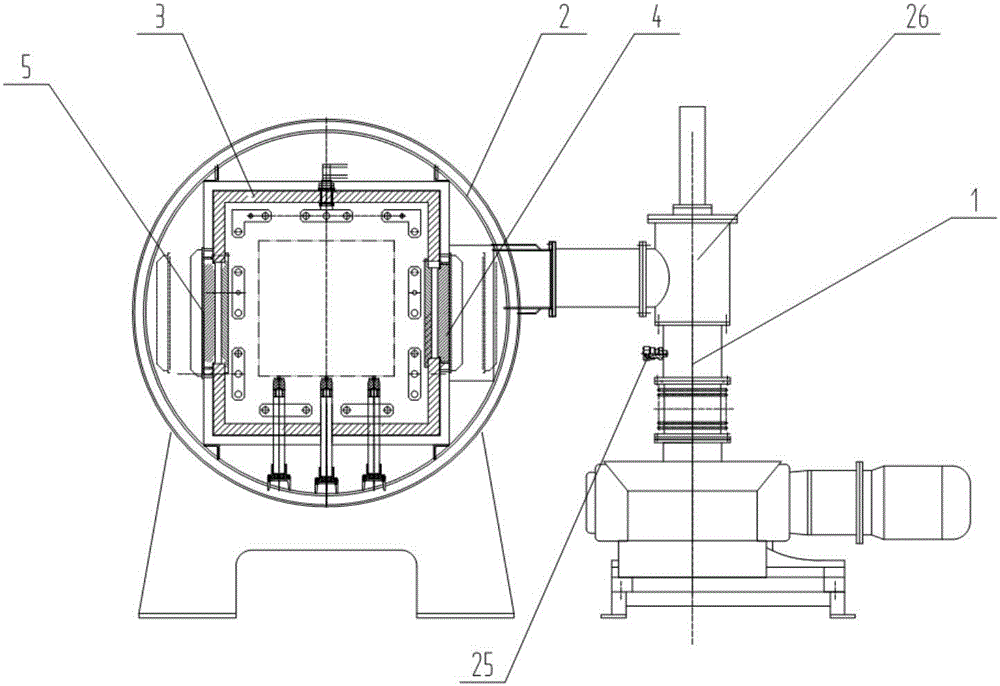

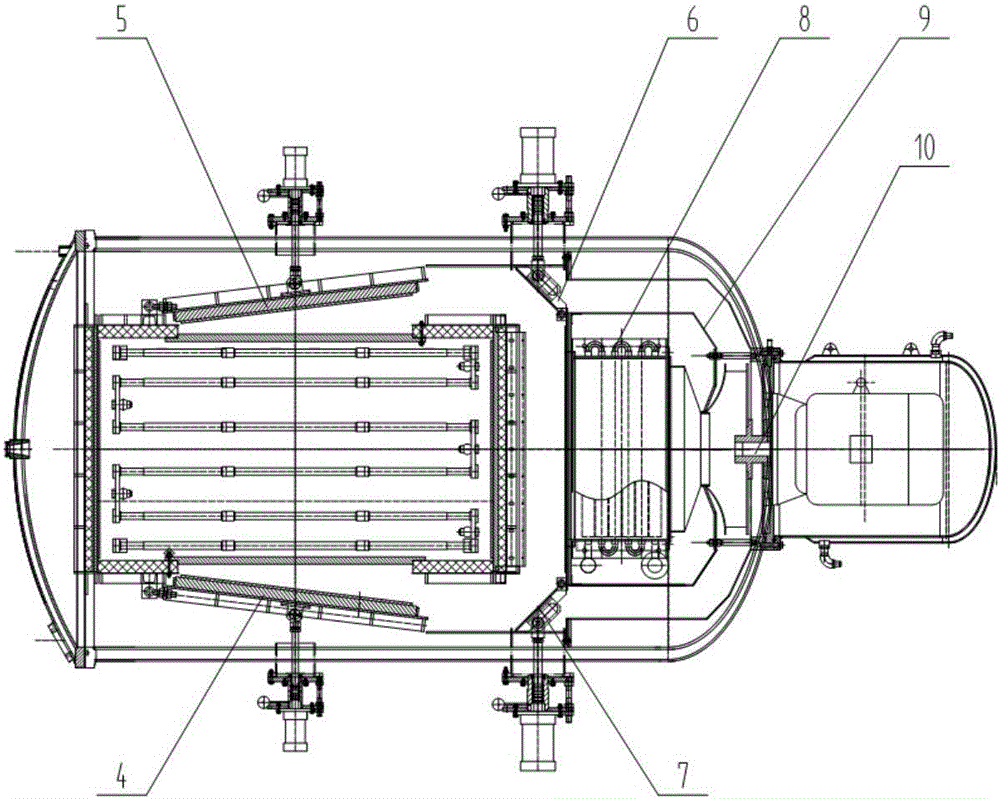

Multifunctional vacuum furnace

InactiveCN106500503AAvoid energy lossHeating evenlyMuffle furnacesRetort furnacesVacuum furnaceReverse mode

Disclosed is a multifunctional vacuum furnace. The multifunctional vacuum furnace is characterized in that the front portion of the body of a heating chamber is provided with a movable front left air door and a movable front right air door, a rear left reversing air door and a rear right reversing air door are symmetrically installed at the air flue end outside the heating chamber, air door air cylinders are installed outside a furnace shell, and air cylinder piston rods penetrate through the furnace shell to be connected with air door pin shafts through sealing structures. The multifunctional vacuum furnace has the advantages that in the heating process, the front left air door and the front right air door are closed, no air through hole is formed, energy loss in the heating process is avoided, energy is saved, and it is ensured that heating is more uniform; and in the cooling process, the opening degree of the front left air door and that of the front right air door are large, meanwhile, the rear left air door and the rear right air door can achieve reversing, in other words, airflow alternately flows in a reversing mode inside the heating chamber, outside the heating chamber, on the left of the heating chamber and on the right of the heating chamber, reversing time can be set, accordingly, workpieces are uniformly cooled, the cooling speed is increased, and the furnace discharge time is shortened. The problem that production efficiency is affected is solved, energy consumption is lowered to minimum, product performance is higher, and production efficiency is improved.

Owner:SHENYANG HENGJIN VACUUM TECH

Method for baking tobacco leaves of honghua dajinyuan (Chinese character) variety by use of closed tobacco curing barn

ActiveCN105146705AReduce baking timeAvoid it happening againTobacco preparationChinese charactersEngineering

The invention relates to a method for baking tobacco leaves of a honghua dajinyuan (Chinese character) variety by use of a closed tobacco curing barn, and belongs to the technical field of tobacco leaf processing. The method comprises the following steps: a yellowing stage, a leaf-drying stage and a stem-drying stage; at the yellowing stage, putting the tobacco leaves into the closed tobacco curing barn, baking the tobacco leaves with a dehumidifying heat pump, and heating the tobacco leaves at the temperature rise rate of 1-2 DEG C / h until the dry bulb temperature is 33-36 DEG C and the wet bulb temperature is 30-35 DEG C, and keeping for 20-25 hours until over 40% of tobacco leaves at a top table turn yellow; heating the tobacco leaves at the temperature rise rate of 0.5-1.5 DEG C / h until the dry bulb temperature is 37-39 DEG C and the wet bulb temperature is 32-36 DEG C and keeping for 20-30 hours; and heating the tobacco leaves at the temperature rise rate of 0.5-1 DEG C / h until the dry bulb temperature is 42-43 DEG C and the wet bulb temperature is 33-36 DEG C and keeping for 16-20 hours until the tobacco leaves turn yellow. The method has the beneficial effects that the baking time of the honghua dajinyuan can be effectively shortened; the baked green tobacco is avoided; the ratio of variegated tobacco and withered tobacco of the honghua dajinyuan is effectively reduced; the mould phenomenon of the tobacco leaves can be avoided.

Owner:云南省烟草公司大理州公司 +1

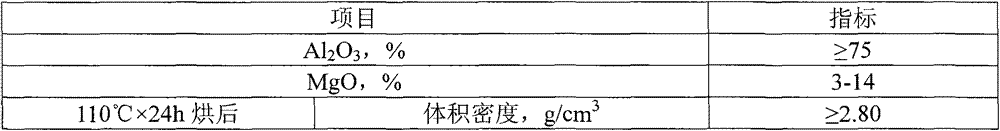

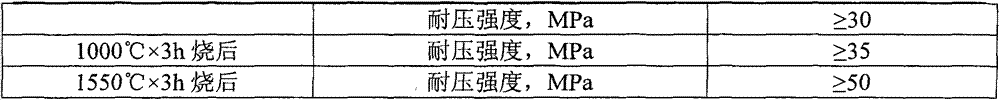

Explosion proofing castable for steel ladle working layer

The invention belongs to the technical field of a refractory material technology for steel ladles in the ferrous metallurgy industry, and discloses an explosion proofing castable for a steel ladle working layer. The explosion proofing castable is characterized in that a composite explosion-proof agent and a composite water reducing agent are introduced in the castable, and the composition and the mixing ratio of the castable are adjusted, so that the inner structure of a material is improved, the air permeability and the strength at an intermediate temperature of the material are improved, the problem that the castable is peeled, separated and then cracked during being baked can be effectively avoided, the resulting loss of a user can be avoided, and simultaneously, the baking time is reduced, the energy is saved, and the pollution is reduced.

Owner:北京利尔高温材料股份有限公司

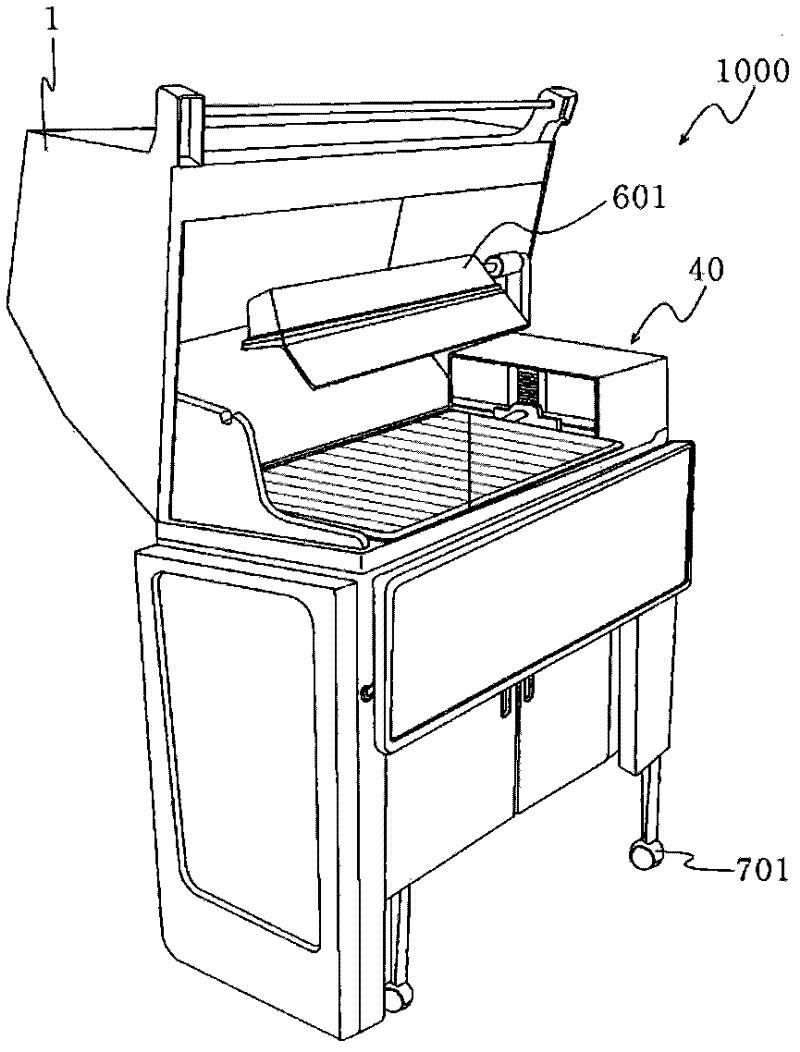

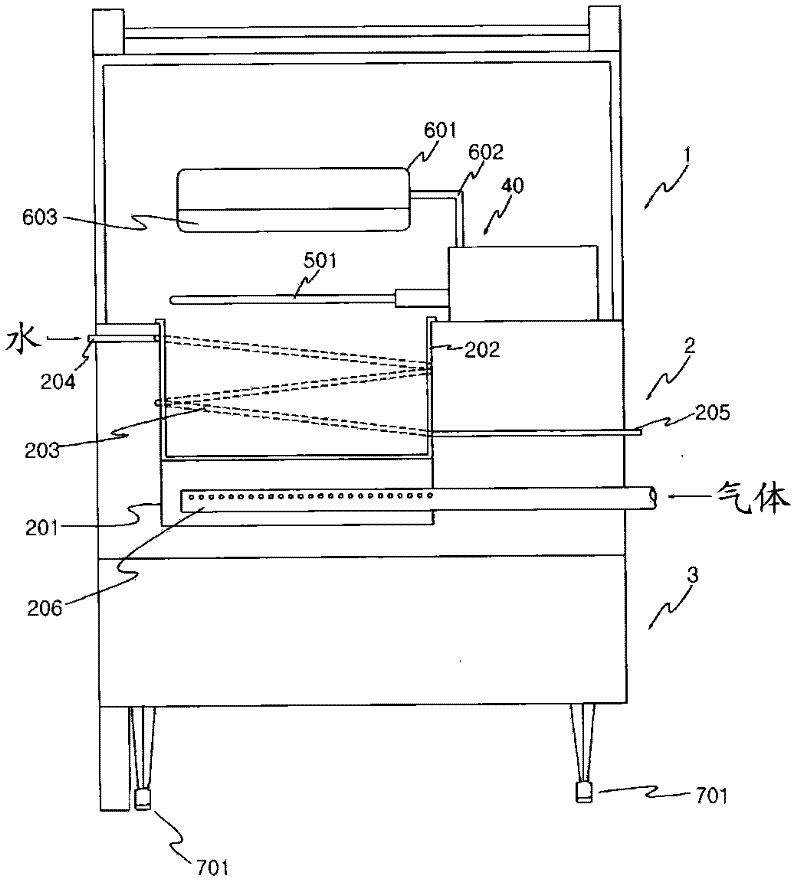

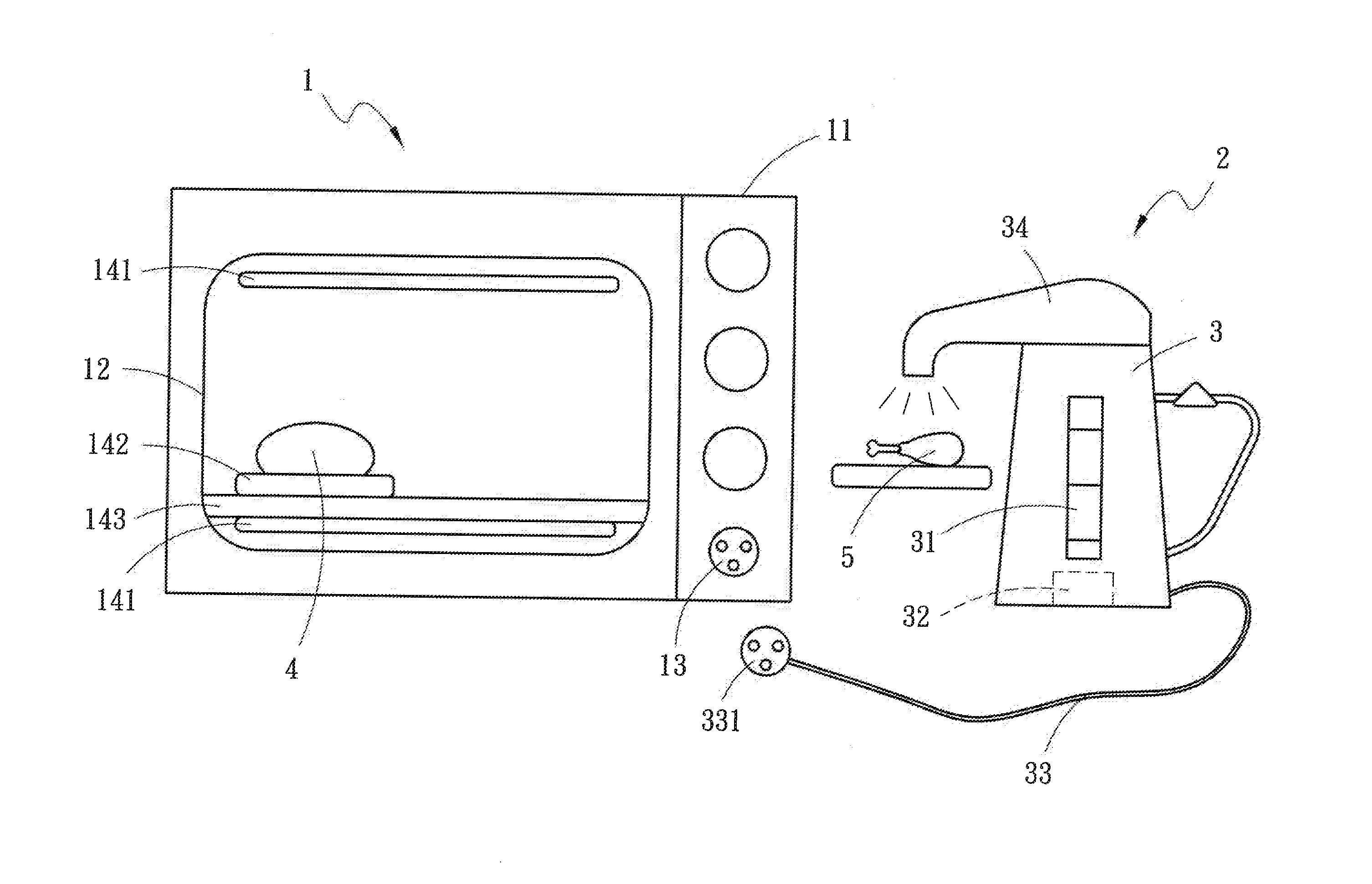

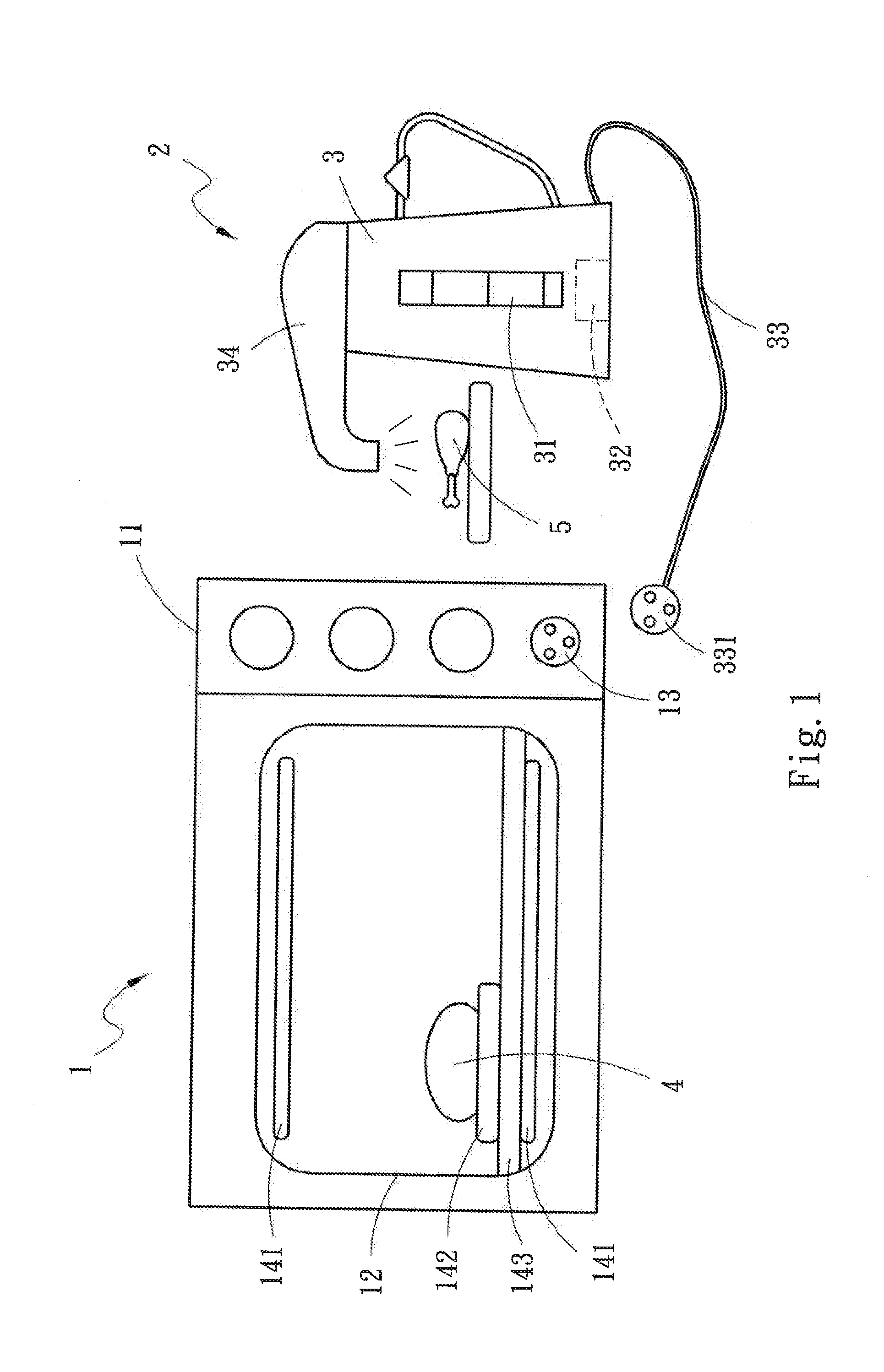

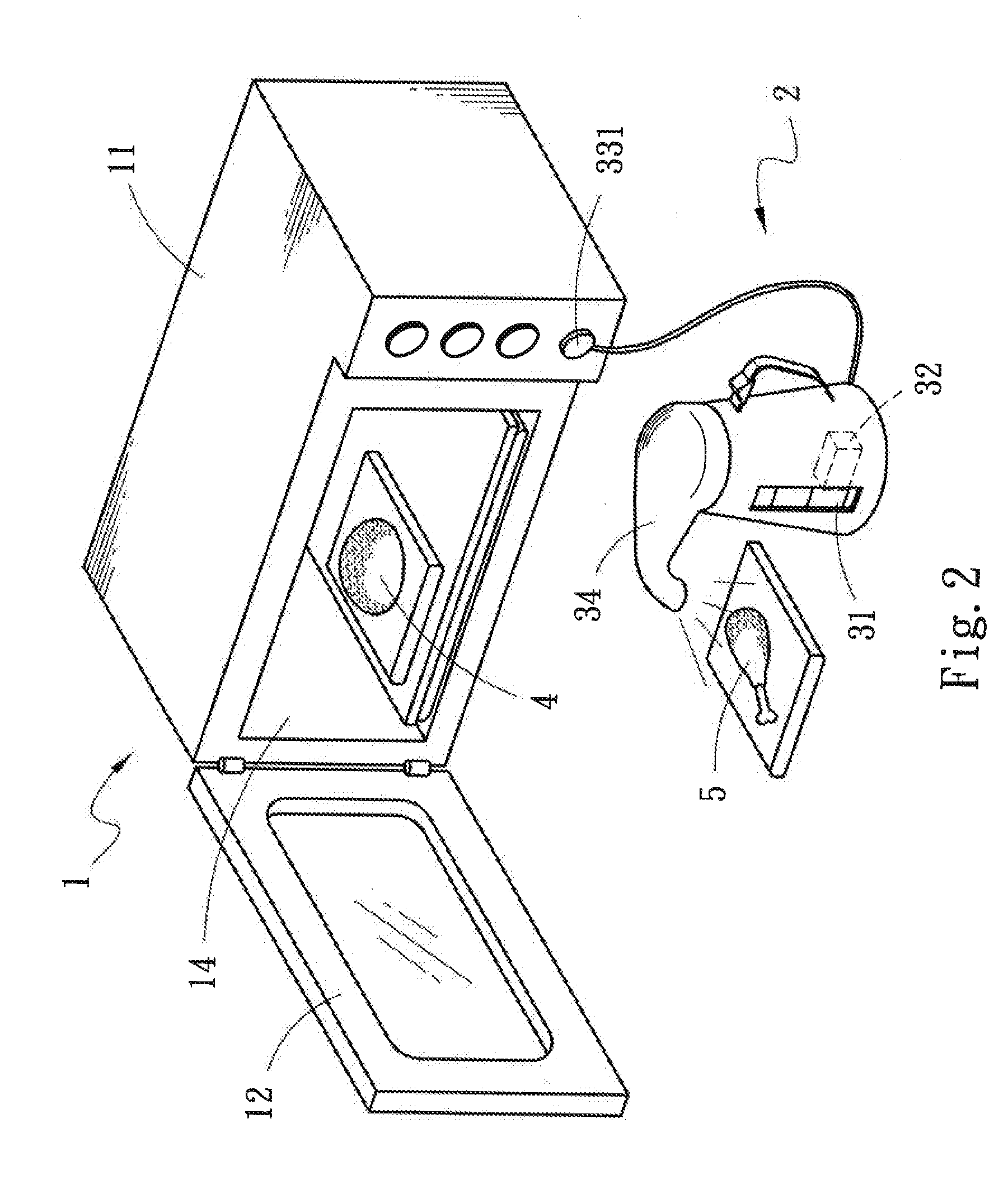

Oven equipped with a detachable steam device and baking method thereof

InactiveUS20130344214A1Reduce baking timeImprove baking usabilityOven air-treatment devicesMeat/fish preservation by heatingElectricityEngineering

An oven equipped with a detachable steam device includes an electric connecting portion. The steam device includes a body which has a water reservoir, a heater, a power cord and a steam ejection head. The water reservoir is connected to the heater. The power cord is electrically connected to the electric connecting portion. The steam ejection head is connected to and communicates with the water reservoir. Hence high temperature steam can be sprayed timely at a desired amount onto the surface of foodstuffs located outside or inside the oven through the steam ejection head, and the foodstuffs with varying sizes or characteristics can be baked at the same time to improve baking convenience and practicality and also make the baked foodstuffs more tasty.

Owner:ENDAHRIC SB INT COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com