Intensive barn curing process of safflower mammoth gold tobacco leaves

A curing process, intensive technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of unsatisfactory effect of Honghua Dajinyuan tobacco leaves, reduced aroma of tobacco leaves, long curing time, etc., and reduce the rate of blue veins , the effect of reducing the ash rate and increasing the amount of aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

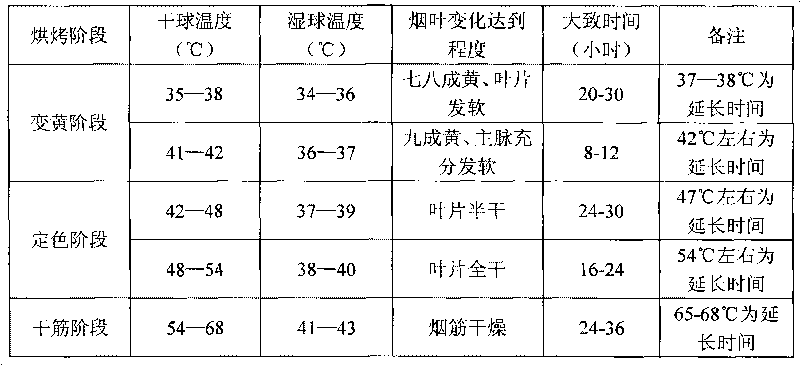

[0016] Now process of the present invention will be further described:

[0017] There are six stages in the baking process of the middle and lower tobacco leaves of Honghua Dajinyuan: the first stage, the dry bulb temperature is 37-38°C, the wet bulb temperature is 37-38°C, and the baking time is 20-24 hours, until the leaf tip Turn yellow 4-7 cm. In the second stage, the dry bulb temperature is 38-39°C, the wet bulb temperature is 36-41°C, and the baking time is 30-36 hours, until the veined reeds and leaves collapse under heat. In the third stage, the dry bulb temperature is 42-43°C, the wet bulb temperature is 37-38°C, and the baking time is 18-20°C, until the mesophyll is completely yellow and 3 pairs of leaf strips are not yellow in the branch veins and the main veins are soft. In the fourth stage, the dry bulb temperature is 45-48°C, the wet bulb temperature is 37-38°C, and the baking time is 20-24 hours, until the main veins turn yellow and the tips curl. In the fifth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com