Ceramic catalyst carrier

A ceramic catalyst and ceramic technology, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problems of low efficiency, reduced efficiency, uneven mixing of ammonia gas/nitrogen oxide, etc., and reduce the use of cost, life extension, and safety risk reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

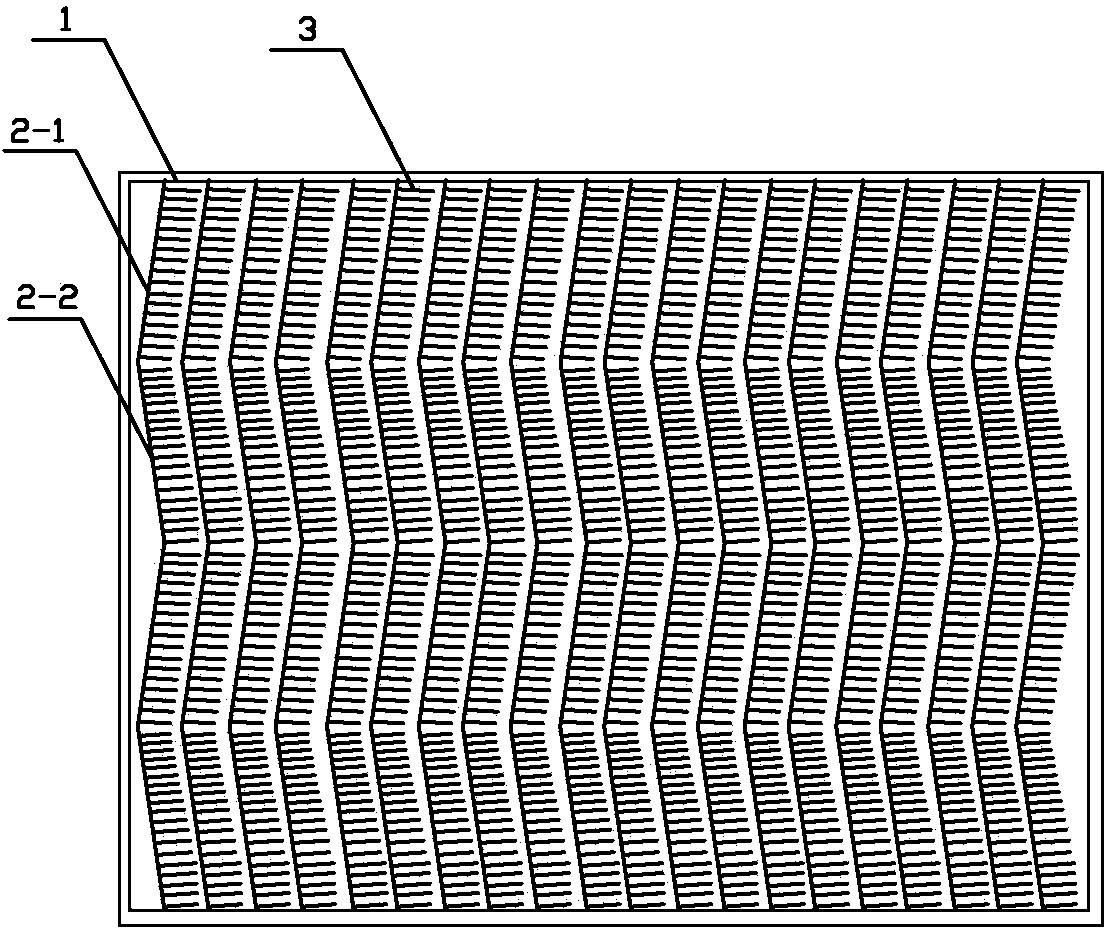

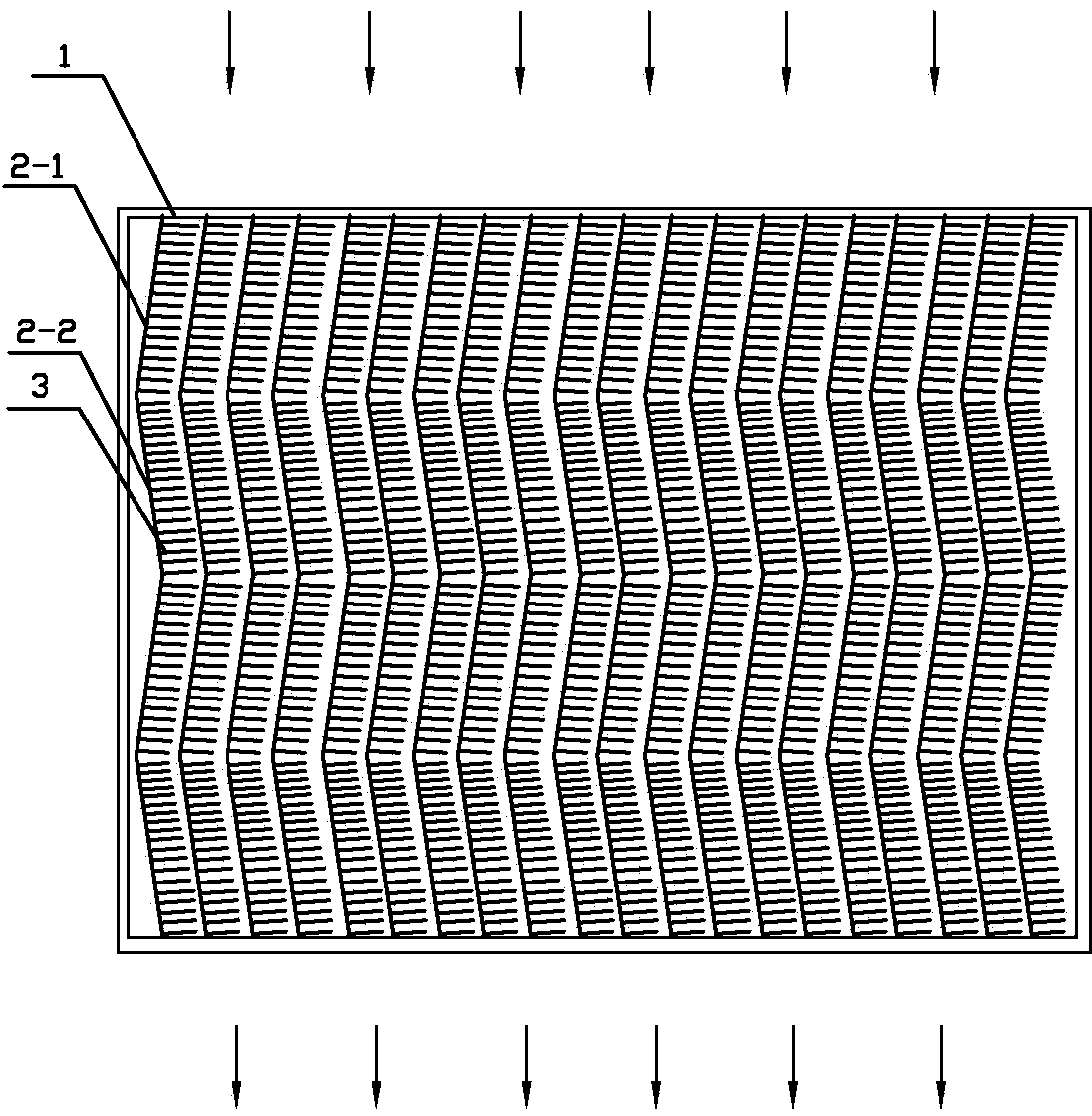

[0027] Such as figure 1 The ceramic catalyst carrier shown includes a support frame 1, and a herringbone ceramic wave plate is arranged side by side inside the support frame 1, and the herringbone ceramic wave plate is divided into a first ceramic wave plate 2-1 and a second ceramic wave plate 2-2; Hair-shaped ceramic rods 3 are set on a ceramic wave plate 2-1, and each hair-shaped ceramic rod 3 is perpendicular to the first ceramic wave plate 2-1; hair-shaped ceramic rods 3 are set on the second ceramic wave plate 2-2, and each hair-shaped ceramic rod 3 is perpendicular to the first ceramic wave plate 2-1; The hair-like ceramic rod 3 is perpendicular to the second ceramic wave plate 2-2.

[0028] The angle between the first ceramic wave plate 2-1 and the second ceramic wave plate 2-2 is 130-160°.

[0029] The herringbone ceramic wave plate and the hair-shaped ceramic rod 3 are collectively referred to as the hair-shaped herringbone ceramic group carrier.

[0030] 2-5 hair-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com