Drying method for positive electrode material of lithium ion battery

An electrode material and positive electrode technology, which is applied in the drying field of positive electrode materials, can solve the problems of large fluctuations in the total water content of the electrode, high total water content, and affecting the uniformity and service life of lithium-iron battery product quality. Effects of shortening baking time, reducing moisture content, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Put the positive electrode material with a mass of about 300kg into the drying chamber through the material receiving trolley. The positive electrode material is placed in a roll, and the width of the positive electrode material is 80mm, and the outer diameter is at most 600mm. Next, vacuumize the drying chamber so that the vacuum degree in the drying chamber reaches 1 Torr. Then, nitrogen with a purity of 99.999% was injected to raise the pressure in the drying chamber to 740 Torr. Then, increase the temperature in the drying chamber to make it reach 250 o After C, vacuum again to 2Torr. Then, at constant temperature (250 o C) Under constant pressure (2Torr), keep baking for 10 hours. During the baking process, the internal circulation fan in the drying room is in a state of high-speed rotation. After the baking is finished, nitrogen gas is injected to restore the pressure value in the drying chamber to 760 Torr, and then, it is cooled to normal temperature. So far...

Embodiment 2

[0042] Put the positive electrode material with a mass of about 30kg into the drying chamber through the material receiving trolley. The positive electrode material is placed in a roll, and the width of the positive electrode material is 80mm, and the maximum outer diameter is 600mm. Next, vacuumize the drying chamber so that the vacuum degree in the drying chamber reaches 1 Torr. Then, nitrogen with a purity of 99.999% was injected to raise the pressure in the drying chamber to 740 Torr. Then, increase the temperature in the drying chamber so that its temperature reaches 120 o After C, vacuum again to 8 Torr. Then, at constant temperature (120 o C) Under constant pressure (8Torr), keep baking for 2 hours. Next, perform a back pressure process, that is, inject nitrogen gas to back pressure to 600 Torr and keep it for 10 minutes. Then, reduce the pressure in the drying chamber to 8 Torr, and bake for 2 hours. This is repeated 6 times, that is, the baking time is 12 hours. ...

Embodiment 3-21

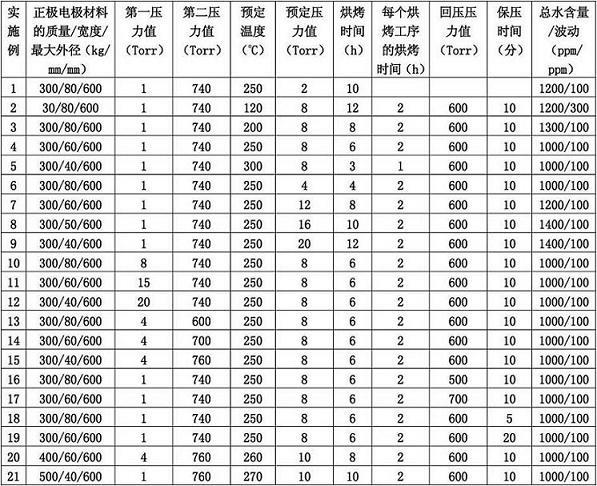

[0045] Examples 3-21 adopt the same process steps as Example 2, and the process parameters and experimental results involved are shown in Table 1.

[0046] Table 1

[0047]

[0048] It can be seen from Table 1 that the total water content of the positive electrode materials obtained by the drying method according to the present invention is not higher than 1400ppm, and the total water content of the positive electrode materials obtained in most embodiments is not higher than 1000ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com