Ultra-fast dry repair varnish for automobiles and preparation method thereof

A varnish, automotive technology, applied in the coating and other directions, can solve the problems of insufficiency, sticking dust, prolonging the customer's pick-up time, etc., to save energy, reduce baking time, and improve coating efficiency.

Inactive Publication Date: 2010-08-25

商丘市博大化工有限公司

View PDF3 Cites 31 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

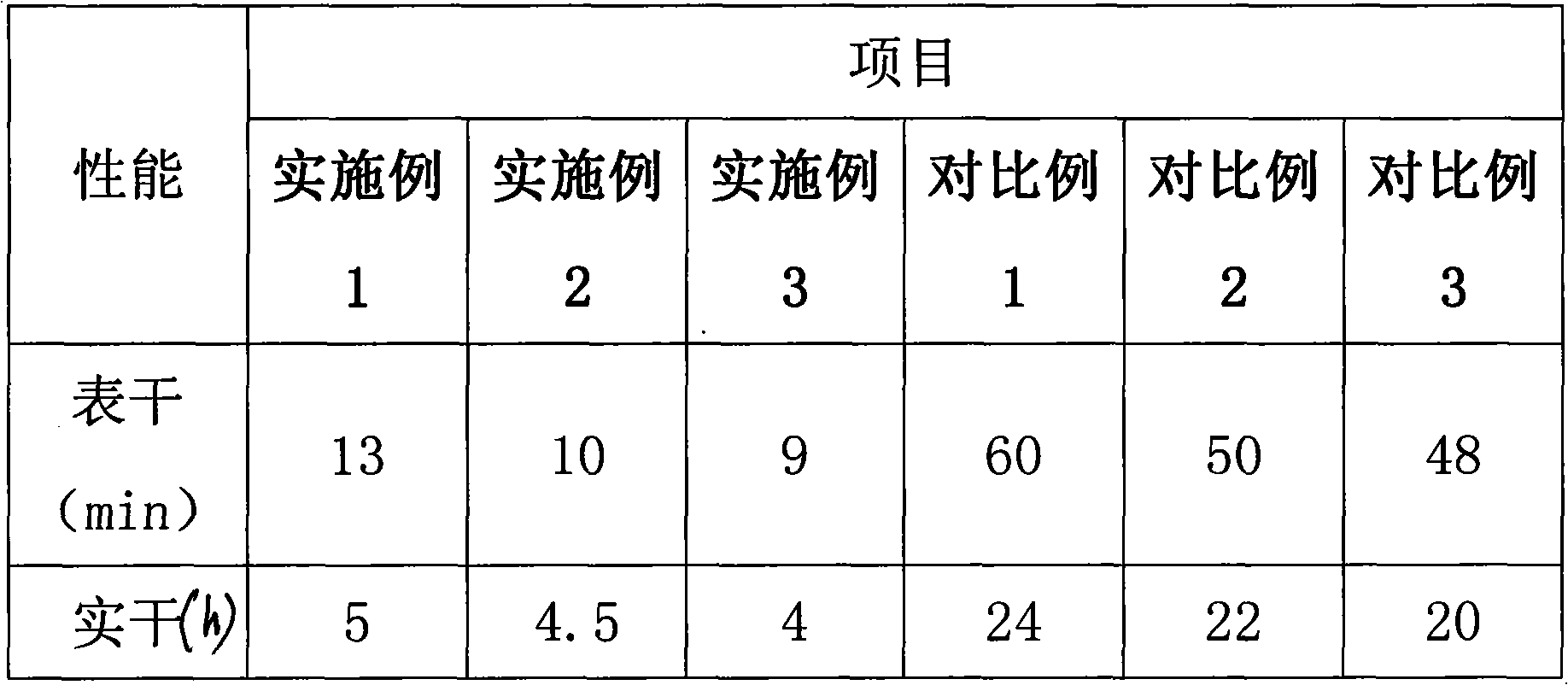

At present, the surface dry time of the known car repair varnish after spraying is 60 minutes at a temperature of 25°C. After drying overnight, it is waxed and polished. If the surface dry time is too long, it will easily cause paint film defects such as sticky dust, which greatly affects post-treatment. The process and performance objectively prolong the time for customers to pick up the car, which cannot meet the needs of picking up the car within 1-2 hours

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an ultra-fast dry repair varnish for automobiles and a preparation method thereof. The composition of the varnish comprises the following components in certain percentage by weight: solvent, modified additive, varnish film forming matrix, flatting agent 1, flatting agent 2, drier, light stabilizer 1, light stabilizer 2 and curing agent. After the repair varnish of the invention is used, at the temperature of below 25 DEG C, the repair varnish is surface dry in 10 minutes, can not stick dust, and can be waxed and polished after 1 hour. Compared with the prior art, the baking time is reduced, the energy source is saved and the spraying efficiency is improved.

Description

technical field The invention relates to a chemical coating and a preparation method thereof, in particular to an ultra-fast-drying repair varnish for automobiles and a preparation method thereof. Background technique The car body is coated with a layer of paint film for protection and decoration, but the paint film is often damaged during use. At this time, the car owner needs to put it in the repair shop for re-spraying. The characteristics of car refinish paint are self-drying, quick repair, and easy toning; as an indispensable part of car maintenance, car refinish paint has gradually developed into an independent industry. Car refinish paint is different from the original car paint that people are familiar with. It needs to match the various colors of the car. It can be dried and baked during the construction process. , gloss, durability and other aspects must be consistent, to repair without leaving traces. At present, the surface dry time of the known car repair varn...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D133/00C09D5/00

Inventor 田华宋海珠韩文礼

Owner 商丘市博大化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com